Influence Mechanism and Optimization Analysis of Technological Parameters for the Composite Prepreg Tape Winding Process

Abstract

:1. Introduction

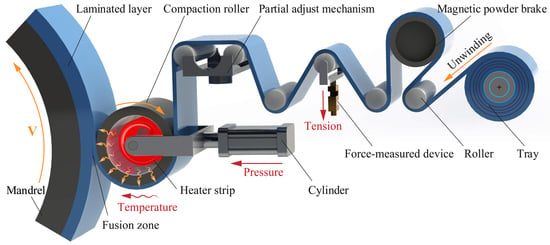

2. Composite Prepreg Tape Winding Process

3. Experimental Design and Procedure

3.1. Experimental Design

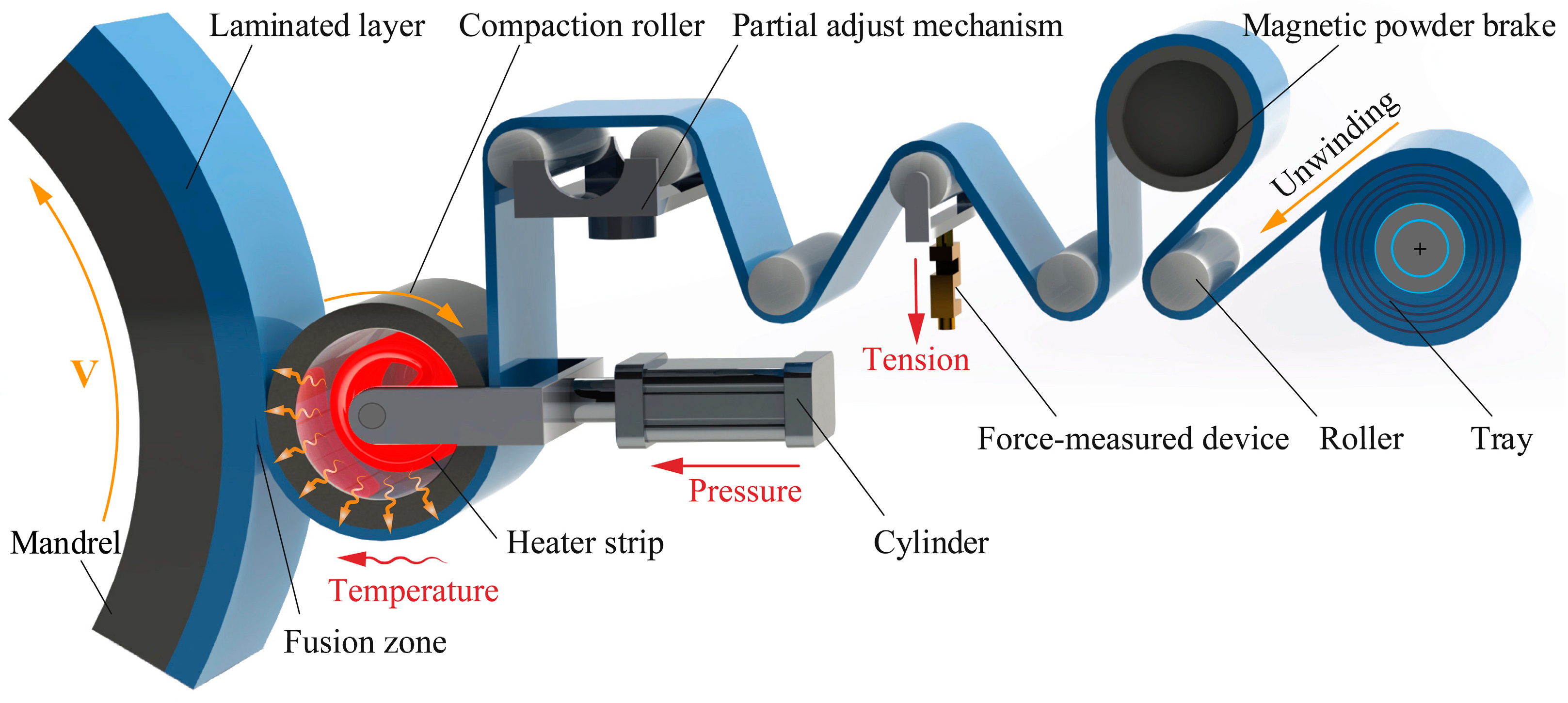

3.2. Sample Preparation and Measurement

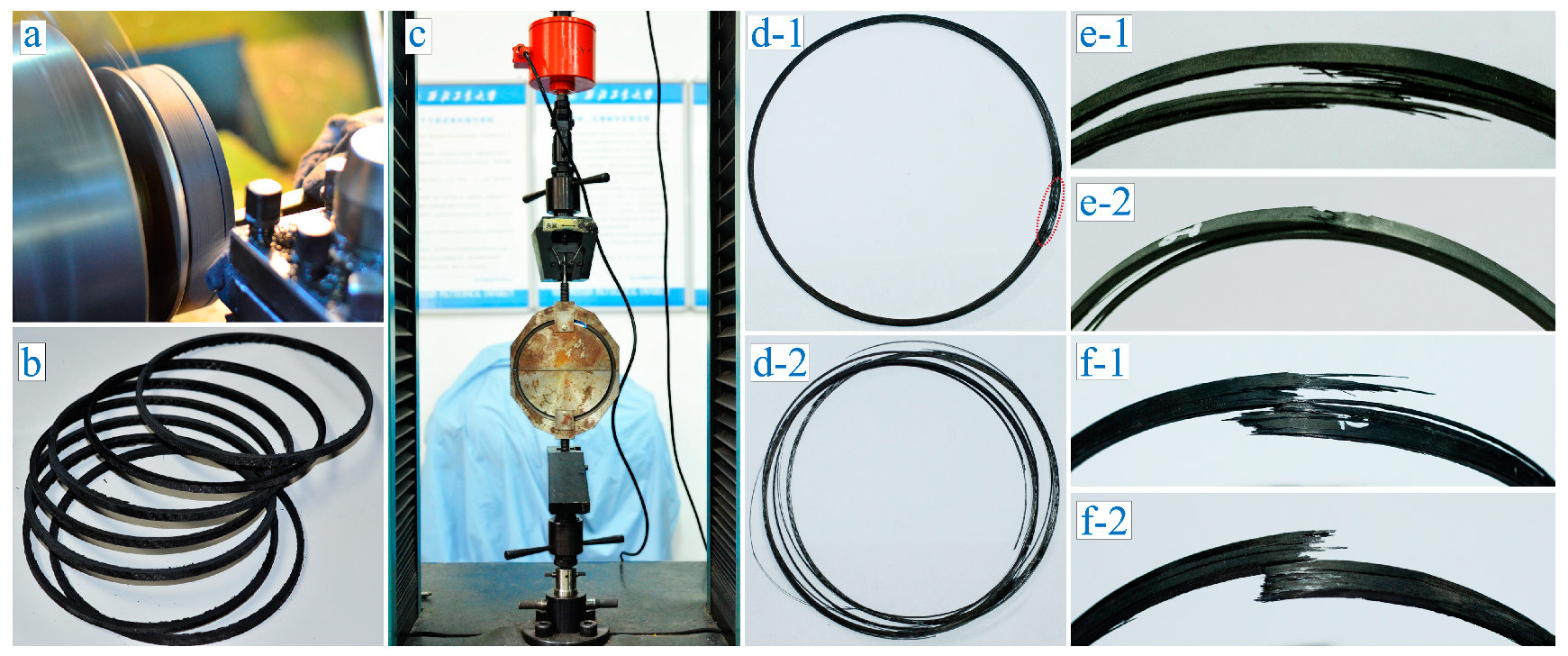

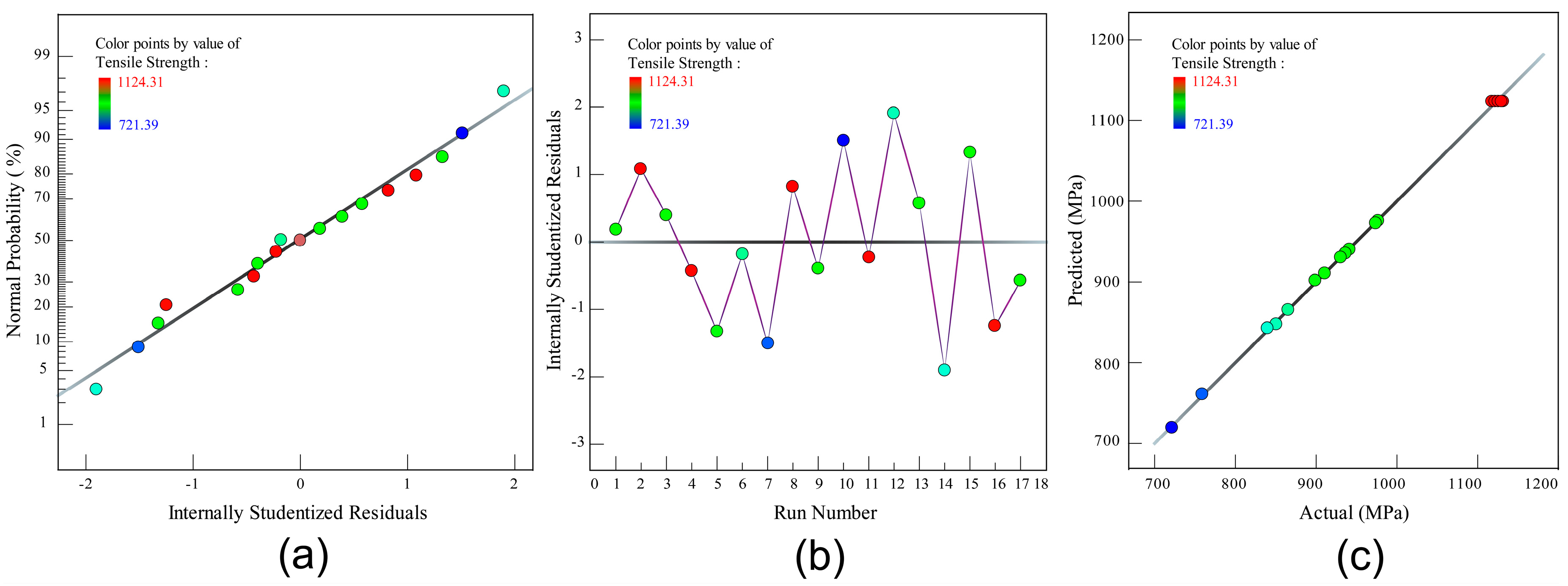

3.3. Experimental Results and Analysis

4. Influence Mechanism and Optimization of Parameters

4.1. Sensitivity Analysis for Single Parameter

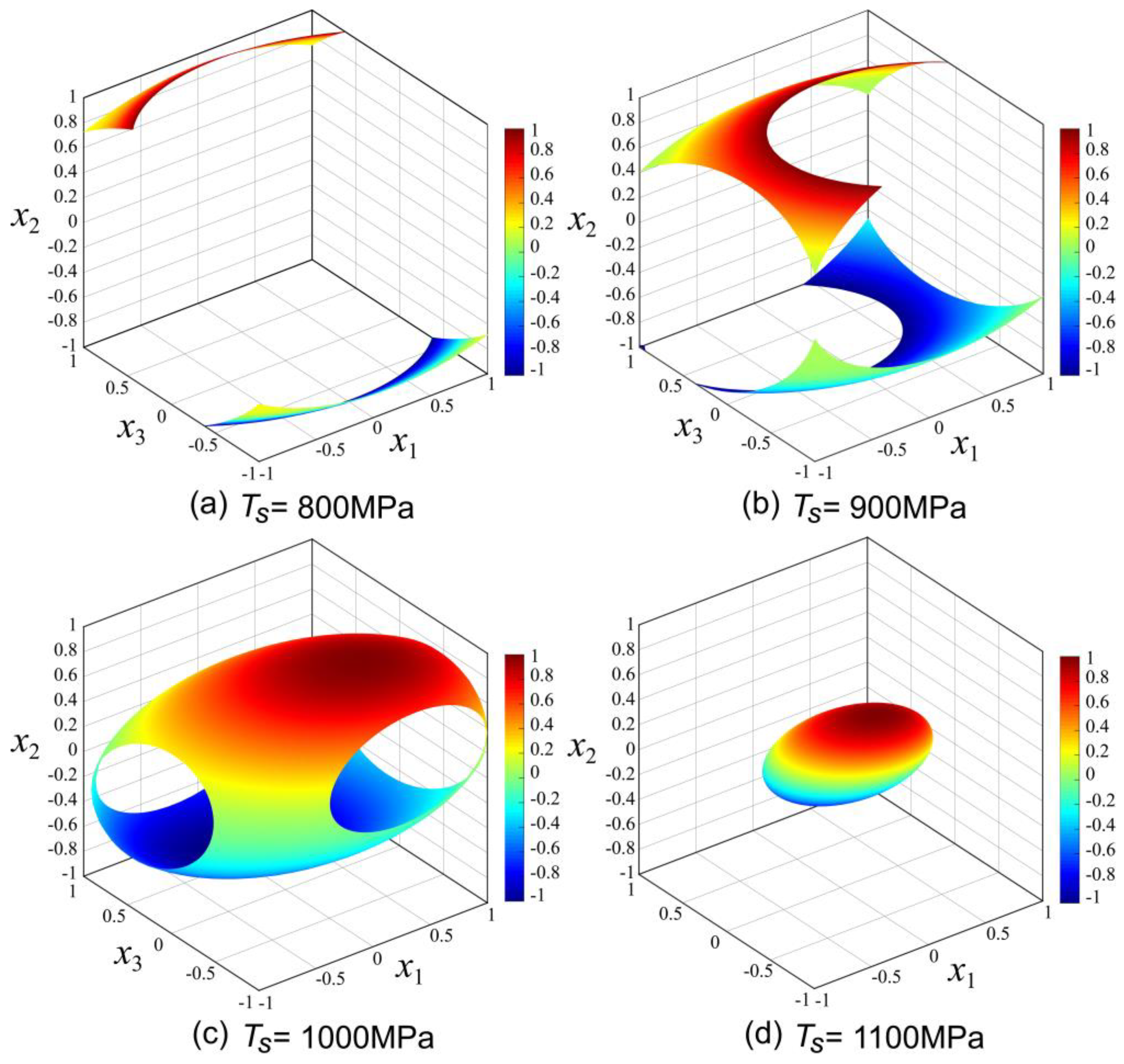

4.2. Iso-Surfaces Analysis for Parameter Range

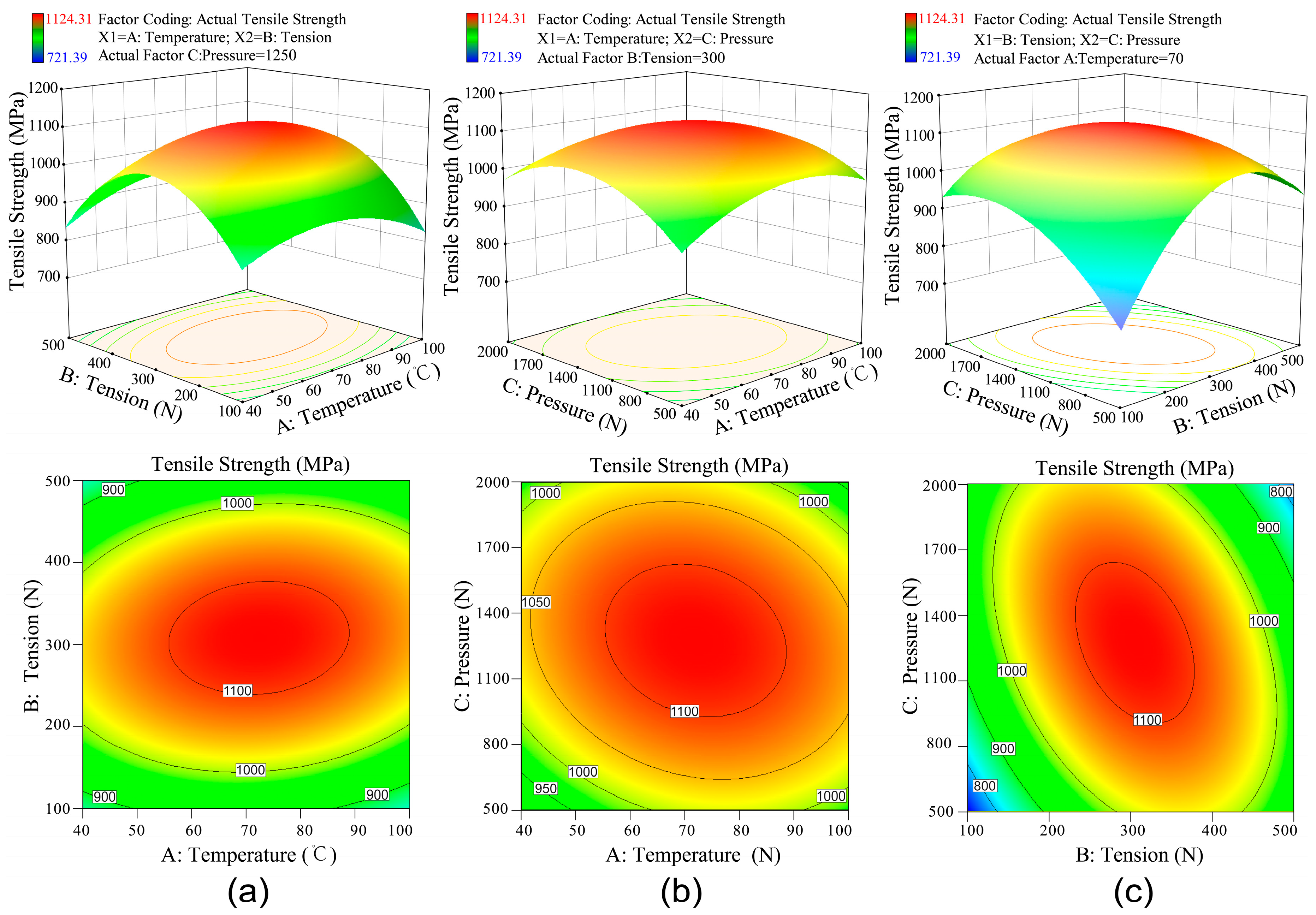

4.3. Coupling Analysis for Process Parameters

4.4. Optimization and Validation

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lukaszewicz, D.H.J.A.; Ward, C.; Potter, K.D. The engineering aspects of automated prepreg layup: History, present and future. Compos. Part B Eng. 2012, 43, 997–1009. [Google Scholar] [CrossRef]

- Oromiehie, E.; Prusty, B.G.; Compston, P.; Rajan, G. Automated fibre placement based composite structures: Review on the defects, impacts and inspections techniques. Compos. Struct. 2019, 224, 110987. [Google Scholar] [CrossRef]

- Rafiee, R. On the mechanical performance of glass-fibre-reinforced thermosetting-resin pipes: A review. Compos. Struct. 2016, 143, 151–164. [Google Scholar] [CrossRef]

- Zu, L.; Xu, H.; Zhang, B.; Li, D.; Zi, B.; Zhang, B. Design and production of filament-wound composite square tubes. Compos. Struct. 2018, 191, 202–208. [Google Scholar] [CrossRef]

- Saenz-Castillo, D.; Martin, M.I.; Calvo, S.; Rodriguez-Lence, F.; Guemes, A. Effect of processing parameters and void content on mechanical properties and ndi of thermoplastic composites. Compos. Part A Appl. Sci. Manuf. 2019, 121, 308–320. [Google Scholar] [CrossRef]

- Leon, A.; Perez, M.; Barasinski, A.; Abisset-Chavanne, E.; Defoort, B.; Chinesta, F. Multi-scale modeling and simulation of thermoplastic automated tape placement: Effects of metallic particles reinforcement on part consolidation. Nanomaterials 2019, 9, 695. [Google Scholar] [CrossRef] [Green Version]

- Henriquez, R.G.; Mertiny, P. 3.21 Filament winding applications. In Comprehensive Composite Materials II; Elsevier: Amsterdam, Holland, 2018; Volume 3, pp. 556–577. [Google Scholar]

- Han, Z.Y.; Sun, S.Z.; Li, W.Q.; Zhao, Y.X.; Shao, Z.X. Experimental study of the effect of internal defects on stress waves during automated fiber placement. Polymers 2018, 10, 413. [Google Scholar] [CrossRef] [Green Version]

- Sun, S.; Han, Z.; Fu, H.; Jin, H.; Dhupia, J.S.; Wang, Y. Defect characteristics and online detection techniques during manufacturing of frps using automated fiber placement: A review. Polymers 2020, 12, 1337. [Google Scholar] [CrossRef]

- Dalibor, I.H.; Lisboa, T.V.; Marczak, R.J.; Amico, S.C. Optimum slippage dependent, non-geodesic fiber path determination for a filament wound composite nozzle. Eur. J. Mech. A Solids 2020, 82, 103994. [Google Scholar] [CrossRef]

- Stokes-Griffin, C.M.; Compston, P.; Matuszyk, T.I.; Cardew-Hall, M.J. Thermal modelling of the laser-assisted thermoplastic tape placement process. J. Thermoplast. Compos. Mater. 2015, 28, 1445–1462. [Google Scholar] [CrossRef]

- Mazumdar, S.K.; Hoa, S. Determination of manufacturing conditions for hot-gas-aided thermoplastic tape winding. J. Thermoplast. Compos. Mater. 1996, 9, 35–53. [Google Scholar] [CrossRef]

- Mack, J.; Schledjewski, R. Filament winding process in thermoplastics. In Manufacturing Techniques for Polymer Matrix Composites (PMCS); Elsevier: Amsterdam, Holland, 2012; pp. 182–208. [Google Scholar]

- Nath, N.K. Optimization of tape winding process parameters to enhance the performance of solid rocket nozzle throat back up liners using taguchi’s robust design methodology. J. Inst. Eng. Ser. C 2017, 98, 479–484. [Google Scholar] [CrossRef]

- Dai, S.C.; Ye, L. Characteristics of cf/pei tape winding process with on-line consolidation. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1227–1238. [Google Scholar] [CrossRef]

- Zaami, A.; Schäkel, M.; Baran, I.; Bor, T.C.; Janssen, H.; Akkerman, R. Temperature variation during continuous laser-assisted adjacent hoop winding of type-iv pressure vessels: An experimental analysis. J. Compos. Mater. 2020, 54, 1717–1739. [Google Scholar] [CrossRef] [Green Version]

- Shi, Y.-Y.; Tang, H.; Yu, Q. Development of a NC tape winding machine. In Global Design to Gain a Competitive Edge; Springer: London, UK, 2008; pp. 753–762. [Google Scholar]

- Sorrentino, L.; Anamateros, E.; Bellini, C.; Carrino, L.; Corcione, G.; Leone, A.; Paris, G. Robotic filament winding: An innovative technology to manufacture complex shape structural parts. Compos. Struct. 2019, 220, 699–707. [Google Scholar] [CrossRef]

- Libonati, F.; Vellwock, A.E.; El Louizi, F.; Hoffmann, R.; Colombo, C.; Ziegmann, G.; Vergani, L. Squeeze-winding: A new manufacturing route for biomimetic fiber-reinforced structures. Compos. Part A Appl. Sci. Manuf. 2020, 132, 105839. [Google Scholar] [CrossRef]

- Wang, Q.; Li, T.; Wang, B.; Liu, C.; Huang, Q.; Ren, M. Prediction of void growth and fiber volume fraction based on filament winding process mechanics. Compos. Struct. 2020, 246, 112432. [Google Scholar] [CrossRef]

- Eggers, F.; Almeida, J.H.S.; Azevedo, C.B.; Amico, S.C. Mechanical response of filament wound composite rings under tension and compression. Polym. Test. 2019, 78, 105951. [Google Scholar] [CrossRef]

- Xu, X.-M.; Zhang, W.-X.; Ding, X.-L.; Zhang, M.; Wei, S.-H. Design and analysis of a novel tension control method for winding machine. Chin. J. Mech. Eng. 2018, 31, 101. [Google Scholar] [CrossRef] [Green Version]

- He, X.D.; Shi, Y.Y.; Kang, C.; Yu, T. Analysis and control of the compaction force in the composite prepreg tape winding process for rocket motor nozzles. Chin. J. Aeronaut. 2017, 30, 836–845. [Google Scholar] [CrossRef] [Green Version]

- Colombo, C.; Vergani, L. Optimization of filament winding parameters for the design of a composite pipe. Compos. Part B Eng. 2018, 148, 207–216. [Google Scholar] [CrossRef]

- Nikishova, A.; Comi, G.E.; Hoekstra, A.G. Sensitivity analysis based dimension reduction of multiscale models. Math. Comput. Simul. 2020, 170, 205–220. [Google Scholar] [CrossRef] [Green Version]

- Saltelli, A.; Aleksankina, K.; Becker, W.; Fennell, P.; Ferretti, F.; Holst, N.; Li, S.S.; Wu, Q.L. Why so many published sensitivity analyses are false: A systematic review of sensitivity analysis practices. Environ. Model. Softw. 2019, 114, 29–39. [Google Scholar] [CrossRef]

- Song, X.; Zhang, J.; Zhan, C.; Xuan, Y.; Ye, M.; Xu, C. Global sensitivity analysis in hydrological modeling: Review of concepts, methods, theoretical framework, and applications. J. Hydrol. 2015, 523, 739–757. [Google Scholar] [CrossRef] [Green Version]

- Yang, A.M.; Han, Y.; Pan, Y.H.; Xing, H.W.; Li, J.Z. Optimum surface roughness prediction for titanium alloy by adopting response surface methodology. Results Phys. 2017, 7, 1046–1050. [Google Scholar] [CrossRef]

- Nagaraj, S.; Natarajan, V. Relation-aware isosurface extraction in multifield data. IEEE Trans. Vis. Comput. Graph. 2010, 17, 182–191. [Google Scholar] [CrossRef]

- Hernandez-Vazquez, J.-M.; Garitaonandia, I.; Fernandes, M.H.; Muñoa, J.; Lacalle, L.N.L.d. A consistent procedure using response surface methodology to identify stiffness properties of connections in machine tools. Materials 2018, 11, 1220. [Google Scholar] [CrossRef] [Green Version]

- Dharma, S.; Masjuki, H.H.; Ong, H.C.; Sebayang, A.H.; Silitonga, A.S.; Kusumo, F.; Mahlia, T.M.I. Optimization of biodiesel production process for mixed jatropha curcas-ceiba pentandra biodiesel using response surface methodology. Energy Convers. Manag. 2016, 115, 178–190. [Google Scholar] [CrossRef]

- Danmaliki, G.I.; Saleh, T.A.; Shamsuddeen, A.A. Response surface methodology optimization of adsorptive desulfurization on nickel/activated carbon. Chem. Eng. J. 2017, 313, 993–1003. [Google Scholar] [CrossRef]

- Lee, D.H.; Jeong, I.J.; Kim, K.J. A desirability function method for optimizing mean and variability of multiple responses using a posterior preference articulation approach. Qual. Reliab. Eng. Int. 2018, 34, 360–376. [Google Scholar] [CrossRef]

- Cho, H.J.; Lee, D.W.; Marasini, N.; Poudel, B.K.; Kim, J.H.; Ramasamy, T.; Yoo, B.K.; Choi, H.G.; Yong, C.S.; Kim, J.O. Optimization of self-microemulsifying drug delivery system for telmisartan using box—Behnken design and desirability function. J. Pharm. Pharmacol. 2013, 65, 1440–1450. [Google Scholar] [CrossRef] [PubMed]

- Jenarthanan, M.; Jeyapaul, R. Optimisation of machining parameters on milling of GFRP composites by desirability function analysis using taguchi method. Int. J. Eng. Sci. Technol. 2013, 5, 22–36. [Google Scholar] [CrossRef] [Green Version]

- Deng, B.; Shi, Y. Modeling and optimizing the composite prepreg tape winding process based on grey relational analysis coupled with bp neural network and bat algorithm. Nanoscale Res. Lett. 2019, 14, 296. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Deng, B.; Shi, Y. Modeling and simulation of voids in composite tape winding process based on domain superposition technique. Appl. Compos. Mater. 2017, 25, 1219–1236. [Google Scholar] [CrossRef]

- Aslan, N.; Cebeci, Y. Application of box—Behnken design and response surface methodology for modeling of some turkish coals. Fuel 2007, 86, 90–97. [Google Scholar] [CrossRef]

- Ye, G.; Ma, L.; Li, L.; Liu, J.; Yuan, S.; Huang, G. Application of box—Behnken design and response surface methodology for modeling and optimization of batch flotation of coal. Int. J. Coal Prep. Util. 2020, 40, 131–145. [Google Scholar] [CrossRef]

- Standardization Administration of the People’s Republic of China. Test Method for Mechanical Properties of Ring of Filament-Winding Reinforced Plastics; Standardization Administration of the People’s Republic of China: Beijing, China, 2008; GT/B 1458-2008.

- Dezan, D.J.; Rocha, A.D.; Ferreira, W.G. Parametric sensitivity analysis and optimisation of a solar air heater with multiple rows of longitudinal vortex generators. Appl. Energy 2020, 263, 114556. [Google Scholar] [CrossRef]

- Derringer, G.; Suich, R. Simultaneous optimization of several response variables. J. Qual. Technol. 1980, 12, 214–219. [Google Scholar] [CrossRef]

| Levels | ||||||

|---|---|---|---|---|---|---|

| Experimental Parameters | Symbol | Code | Units | Level −1 | Level 0 | Level 1 |

| Heating temperature | T | x1 | °C | 40 | 70 | 100 |

| Tape tension | F | x2 | N | 100 | 300 | 500 |

| Roller pressure | P | x3 | N | 500 | 1250 | 2000 |

| No. | T/(°C) | F/(N) | P/(N) | x1 | x2 | x3 | TS/(MPa) |

|---|---|---|---|---|---|---|---|

| 1 | 100 | 500 | 1250 | 1 | 1 | 0 | 911.33 |

| 2 | 70 | 300 | 1250 | 0 | 0 | 0 | 1124.31 |

| 3 | 100 | 300 | 500 | 1 | 0 | −1 | 976.92 |

| 4 | 70 | 300 | 1250 | 0 | 0 | 0 | 1119.68 |

| 5 | 40 | 300 | 500 | −1 | 0 | −1 | 899.4 |

| 6 | 40 | 100 | 1250 | −1 | −1 | 0 | 865.11 |

| 7 | 70 | 500 | 2000 | 0 | 1 | 1 | 758.72 |

| 8 | 70 | 300 | 1250 | 0 | 0 | 0 | 1123.53 |

| 9 | 40 | 300 | 2000 | −1 | 0 | 1 | 972.47 |

| 10 | 70 | 100 | 500 | 0 | −1 | −1 | 721.39 |

| 11 | 70 | 300 | 1250 | 0 | 0 | 0 | 1120.32 |

| 12 | 40 | 500 | 1250 | −1 | 1 | 0 | 850.54 |

| 13 | 70 | 100 | 2000 | 0 | −1 | 1 | 930.36 |

| 14 | 100 | 100 | 1250 | 1 | −1 | 0 | 839.68 |

| 15 | 100 | 300 | 2000 | 1 | 0 | 1 | 942.07 |

| 16 | 70 | 300 | 1250 | 0 | 0 | 0 | 1117.2 |

| 17 | 70 | 500 | 500 | 0 | 1 | −1 | 935.85 |

| Source | SS | DF | MS | F Value | Prob > F |

|---|---|---|---|---|---|

| Model | 2.7 × 105 | 9 | 30,002.31 | 2567.59 | <0.0001 |

| T | 850.37 | 1 | 850.37 | 72.77 | <0.0001 |

| F | 1247.5 | 1 | 1247.5 | 106.76 | <0.0001 |

| P | 613.55 | 1 | 613.55 | 52.51 | 0.0002 |

| TF | 1858.47 | 1 | 1858.47 | 159.05 | <0.0001 |

| TP | 2911.68 | 1 | 2911.68 | 249.18 | <0.0001 |

| FP | 37,268.3 | 1 | 37,268.3 | 3189.41 | <0.0001 |

| T2 | 21,587.93 | 1 | 21,587.93 | 1847.49 | <0.0001 |

| F2 | 1.406 × 105 | 1 | 1.41 × 105 | 12,032.87 | <0.0001 |

| P2 | 43,539.59 | 1 | 43,539.59 | 3726.1 | <0.0001 |

| Residual | 81.8 | 7 | 11.69 | ||

| Lack of Fit | 47.79 | 3 | 15.93 | 1.87 | 0.2749 |

| Pure Error | 34 | 4 | 8.5 | ||

| Cor Total | 2.701 × 105 | 16 | |||

| DF: Degrees of Freedom; SS: Sum of Squares; MS: Mean Square | |||||

| No. | T/(°C) | F/(N) | P/(N) | Tensile Strength/(MPa) | Relative Error | |

| Predicted | Experiment | |||||

| 1 | 72 | 307 | 1263 | 1121.68 | 1129.16 | 0.67% |

| 2 | 1133.83 | 1.08% | ||||

| 3 | 1130.79 | 0.81% | ||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, B.; Shi, Y.; Yu, T.; Zhao, P. Influence Mechanism and Optimization Analysis of Technological Parameters for the Composite Prepreg Tape Winding Process. Polymers 2020, 12, 1843. https://doi.org/10.3390/polym12081843

Deng B, Shi Y, Yu T, Zhao P. Influence Mechanism and Optimization Analysis of Technological Parameters for the Composite Prepreg Tape Winding Process. Polymers. 2020; 12(8):1843. https://doi.org/10.3390/polym12081843

Chicago/Turabian StyleDeng, Bo, Yaoyao Shi, Tao Yu, and Pan Zhao. 2020. "Influence Mechanism and Optimization Analysis of Technological Parameters for the Composite Prepreg Tape Winding Process" Polymers 12, no. 8: 1843. https://doi.org/10.3390/polym12081843

APA StyleDeng, B., Shi, Y., Yu, T., & Zhao, P. (2020). Influence Mechanism and Optimization Analysis of Technological Parameters for the Composite Prepreg Tape Winding Process. Polymers, 12(8), 1843. https://doi.org/10.3390/polym12081843