Influence of Graphene Platelet Aspect Ratio on the Mechanical Properties of HDPE Nanocomposites: Microscopic Observation and Micromechanical Modeling

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

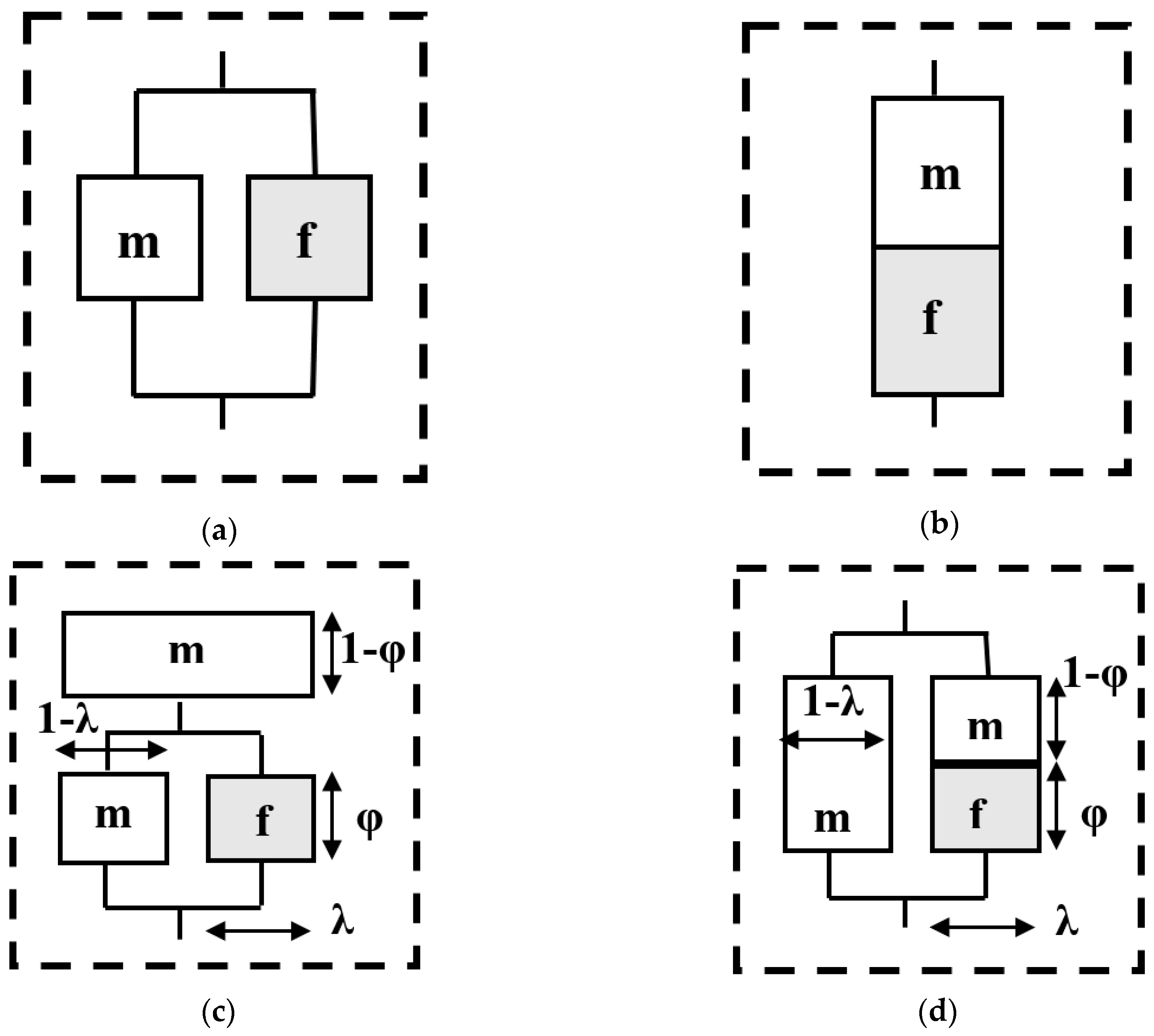

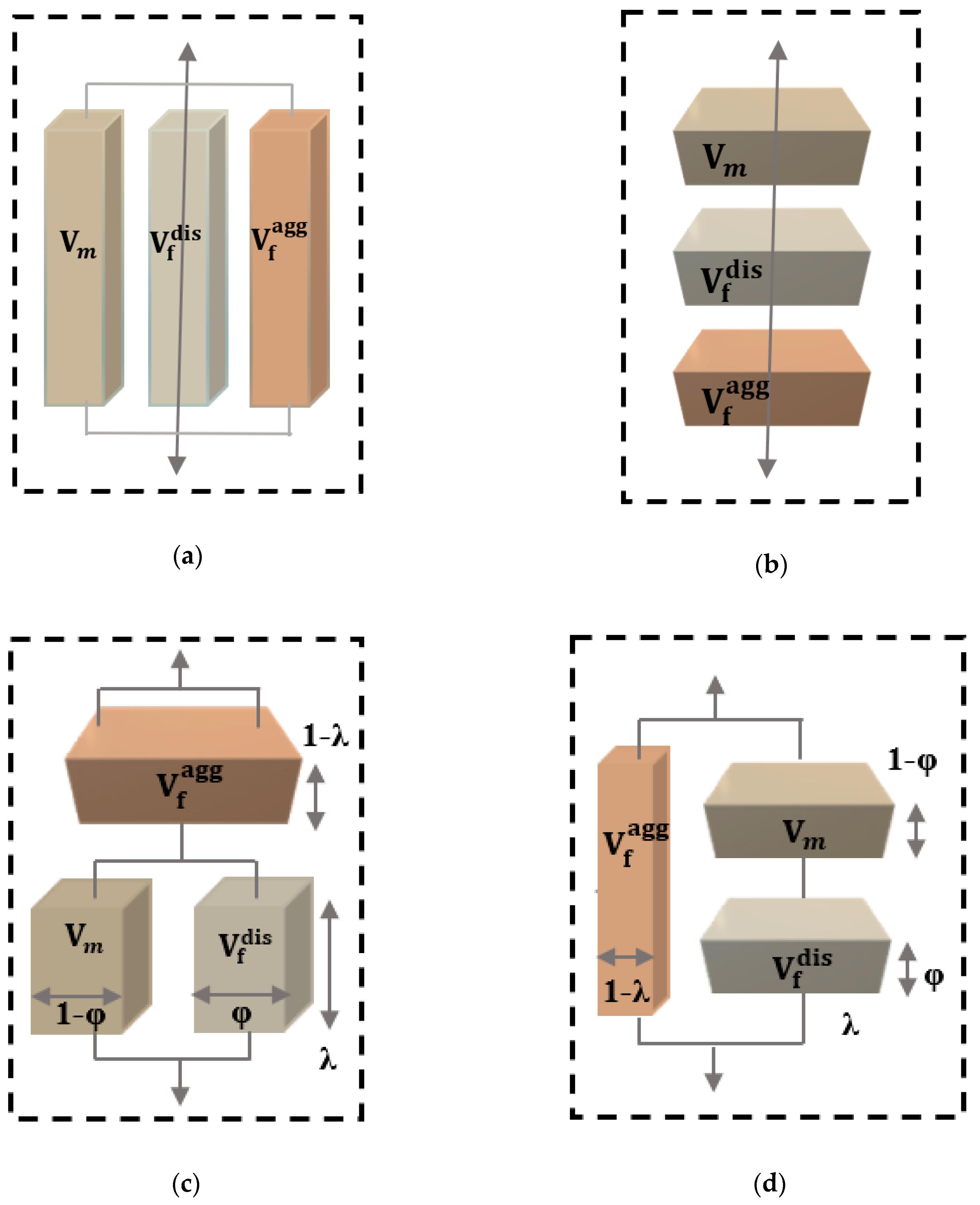

3.1. Theoretical Background

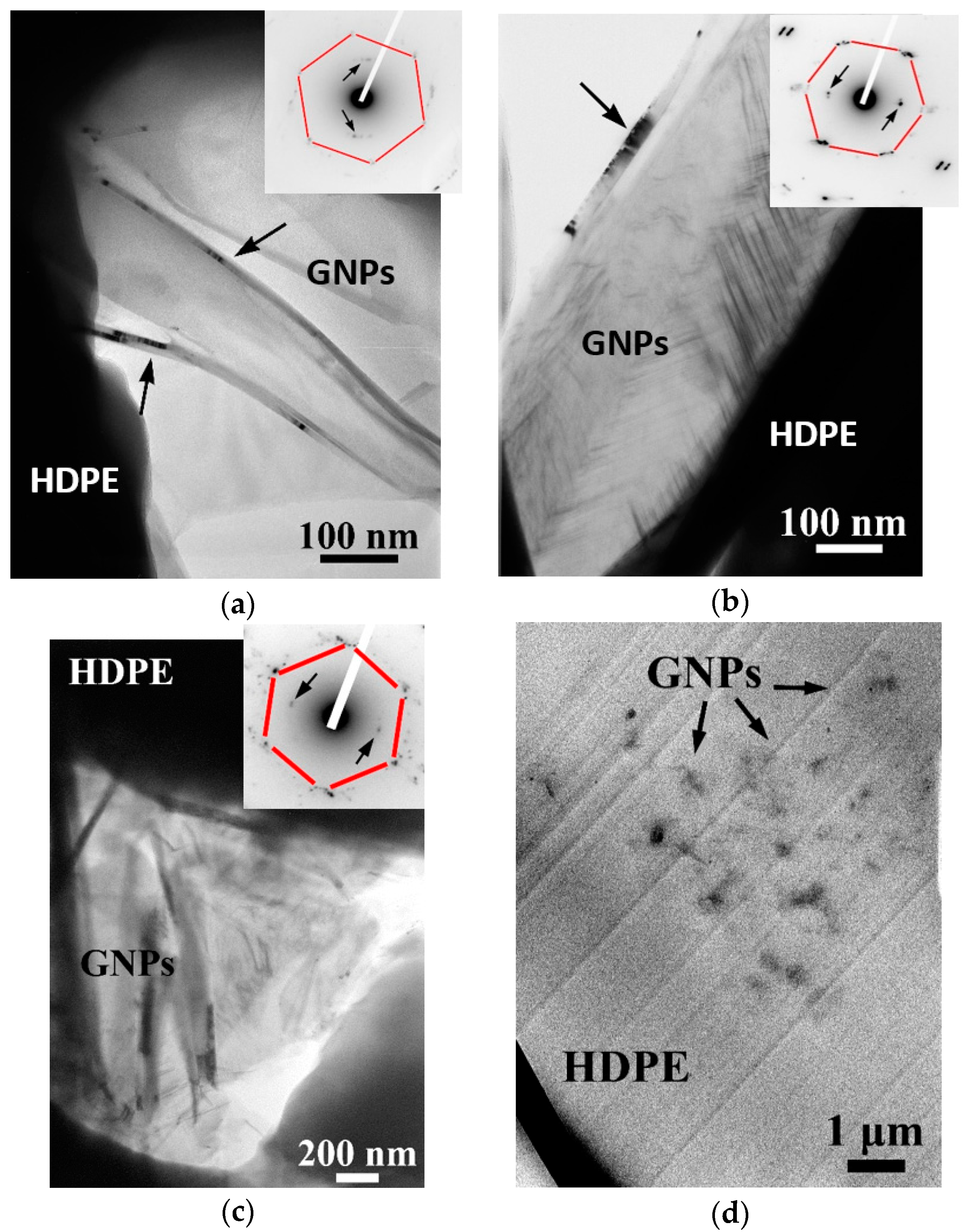

3.2. Structural and Morphological Properties of HDPE/GNP Nanocomposites

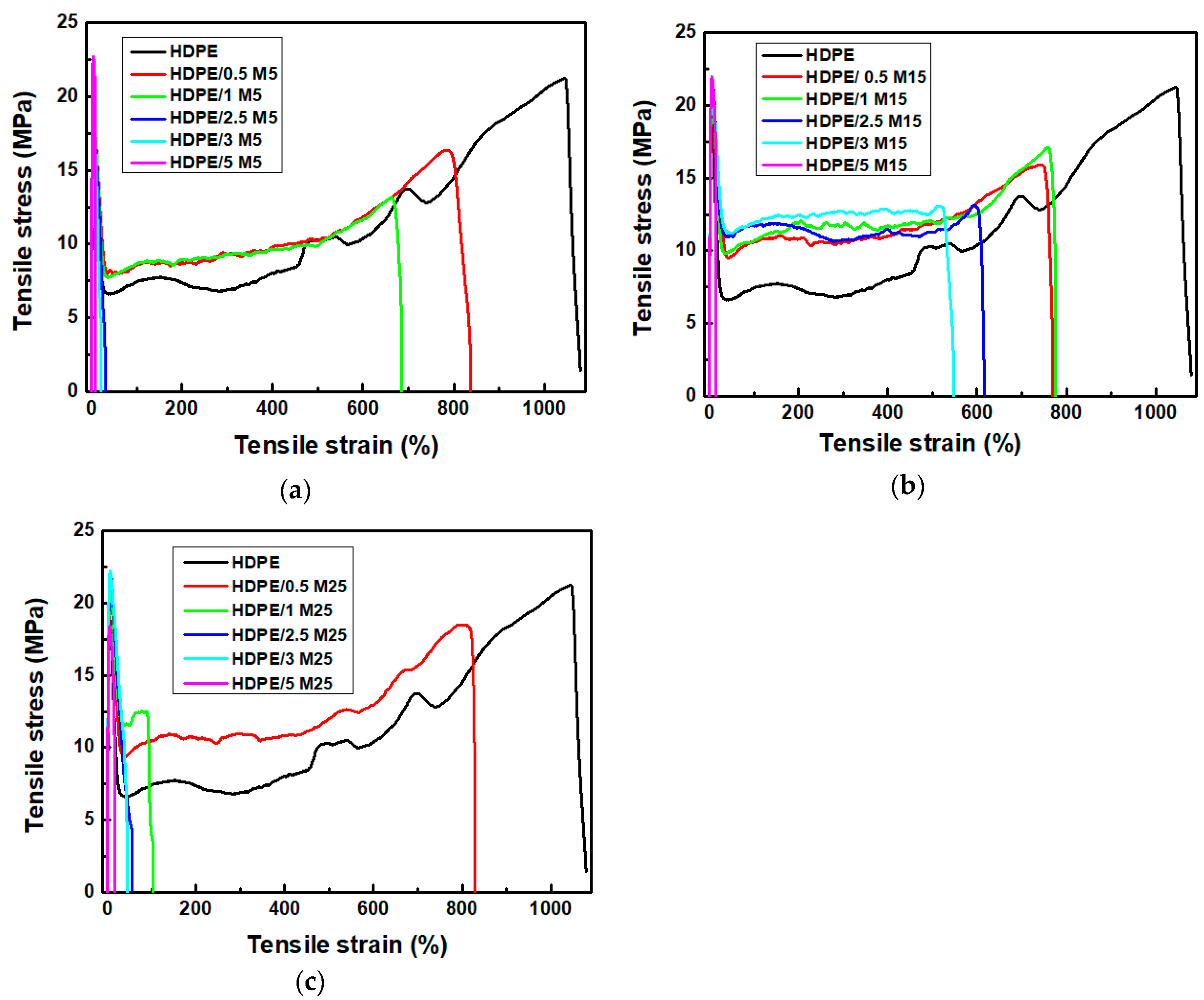

3.3. Mechanical and Thermomechanical Properties of HDPE/GNPs Nanocomposites

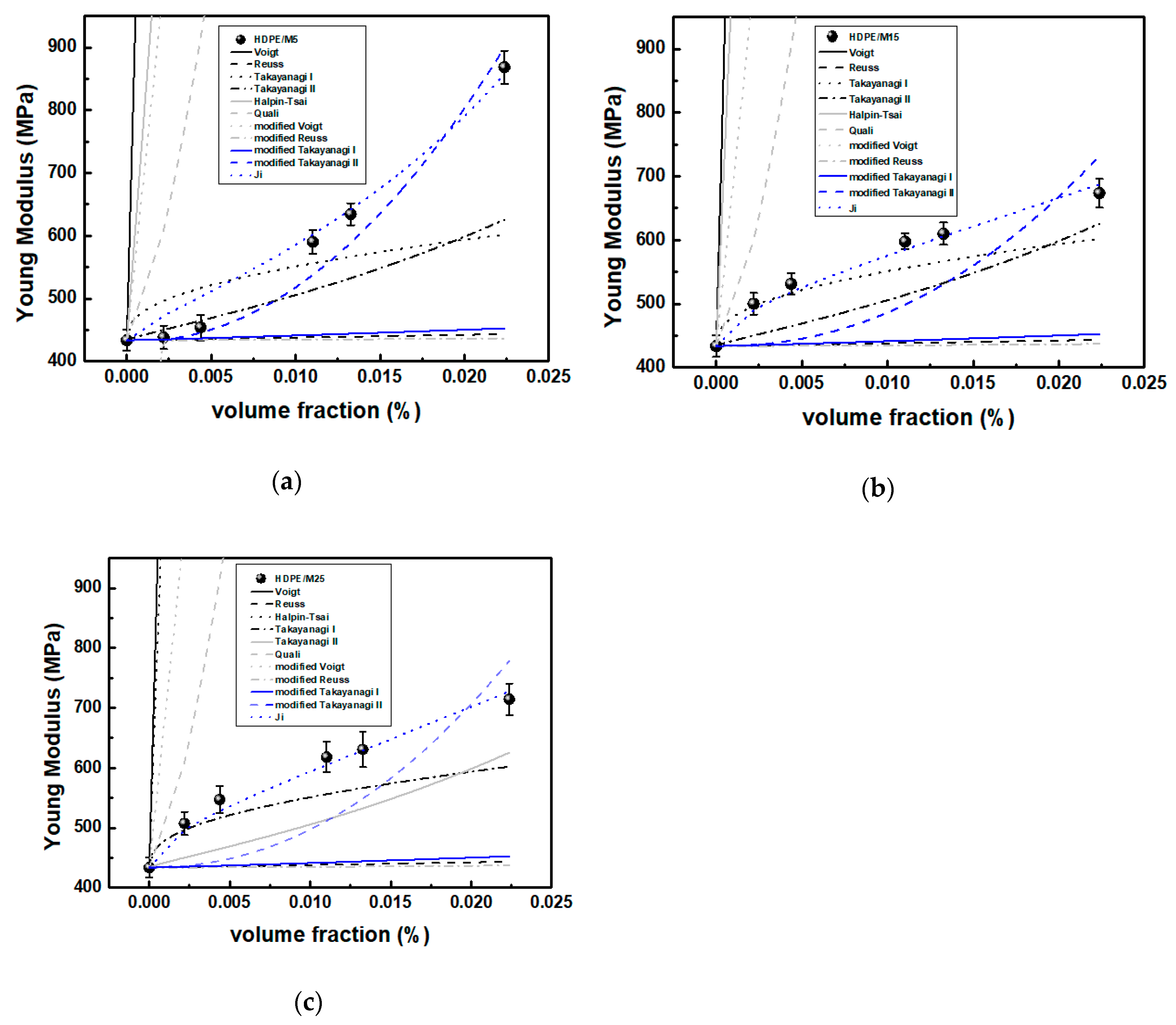

3.4. Micromechanical Modeling of HDPE/GNP Nanocomposites

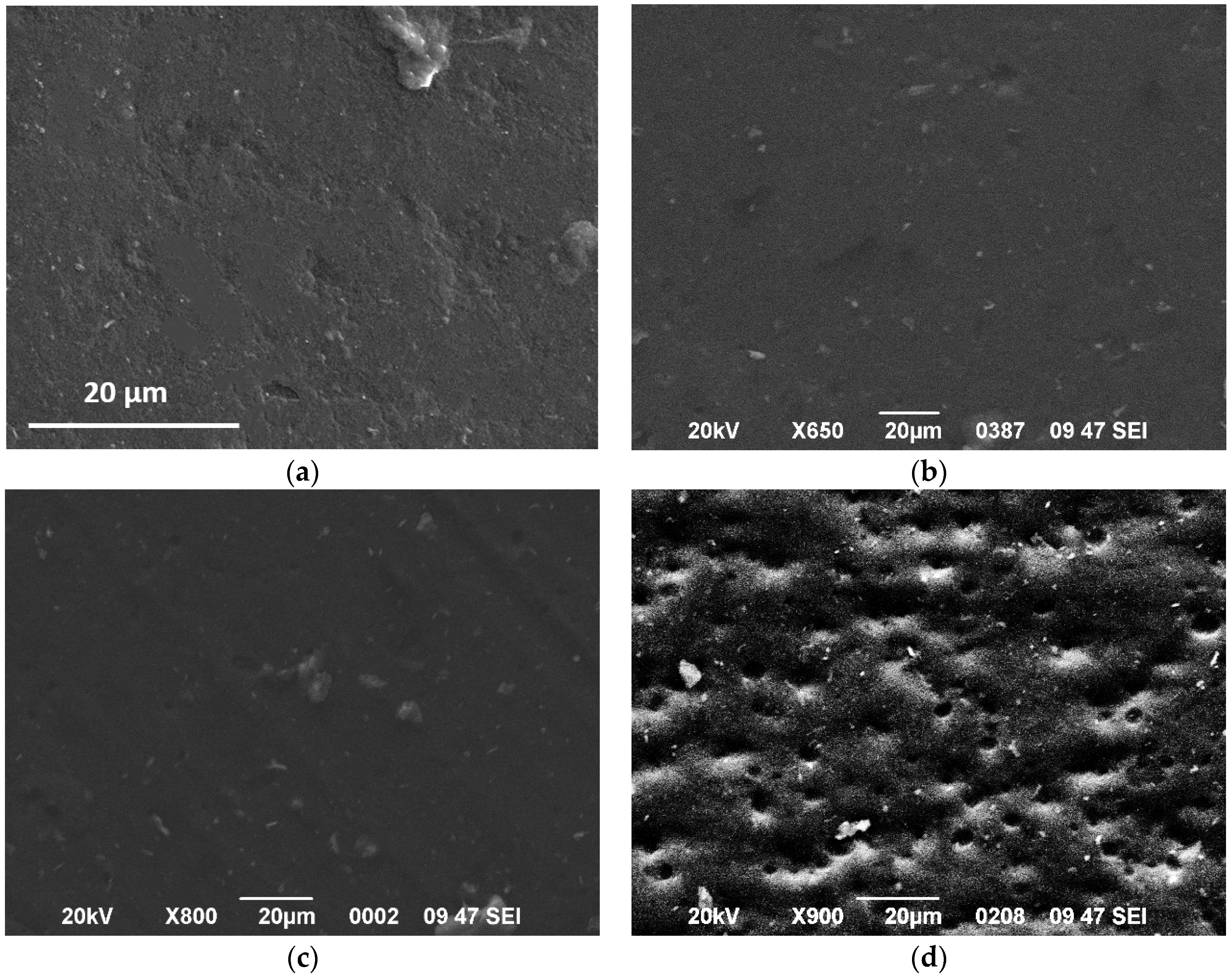

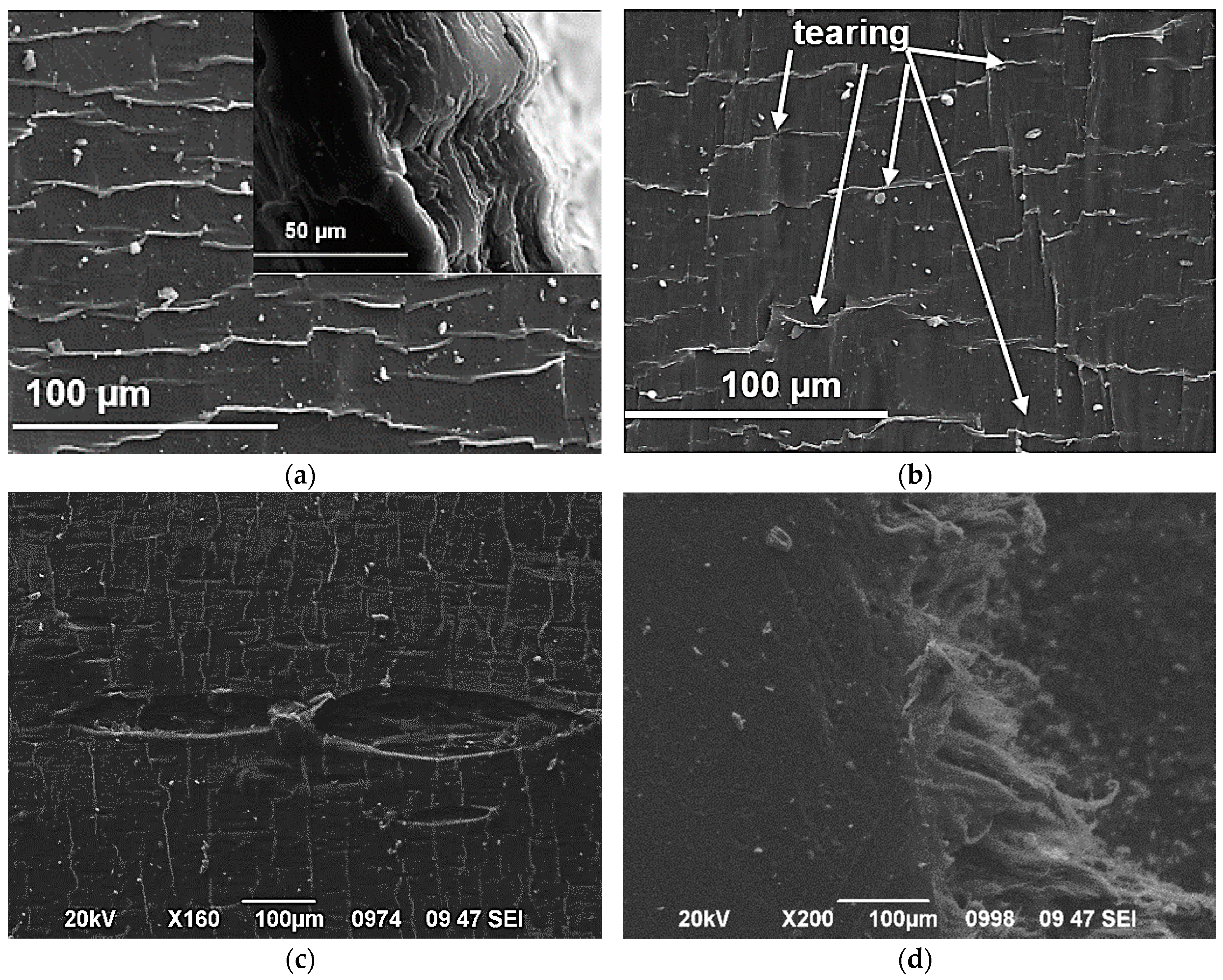

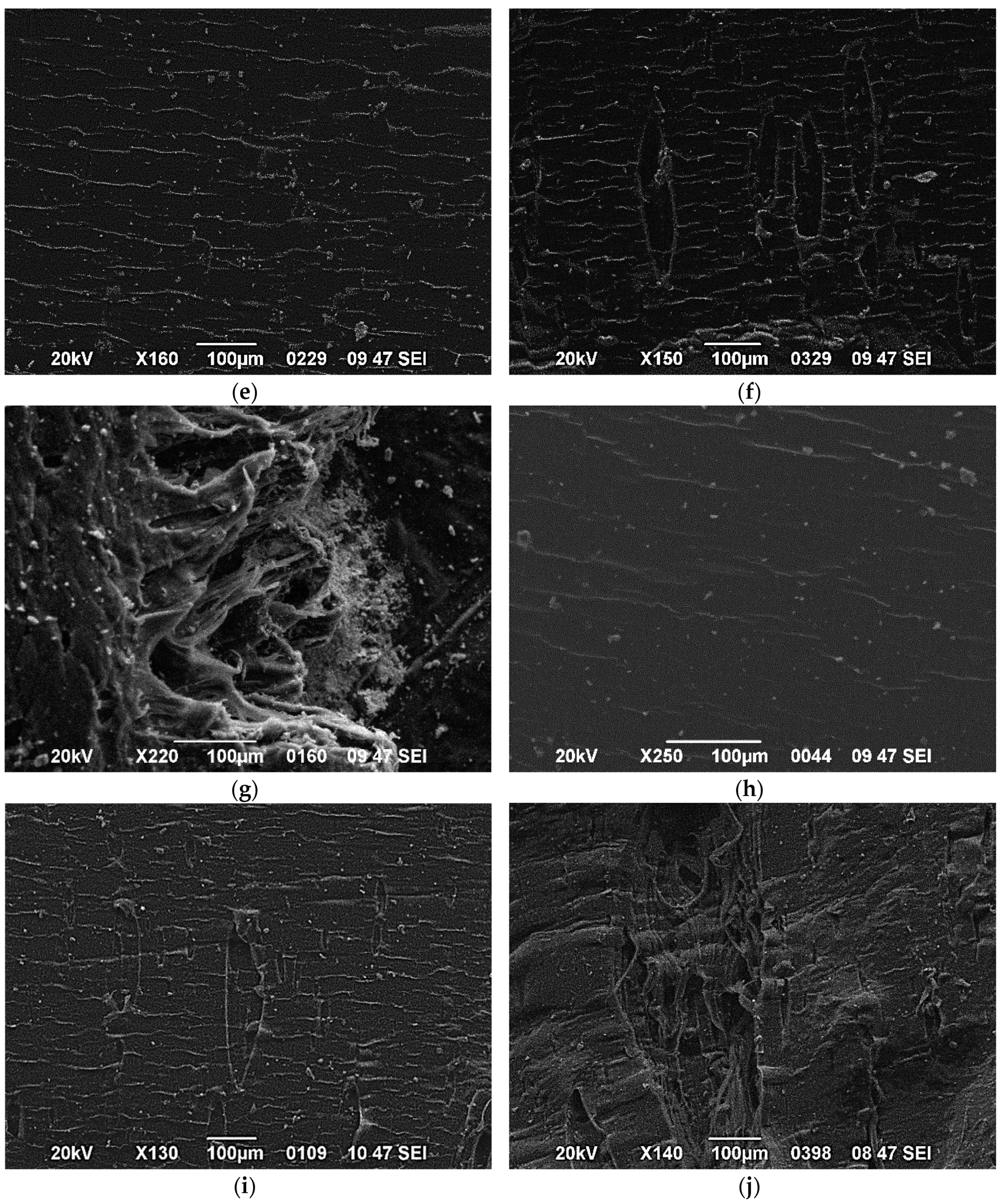

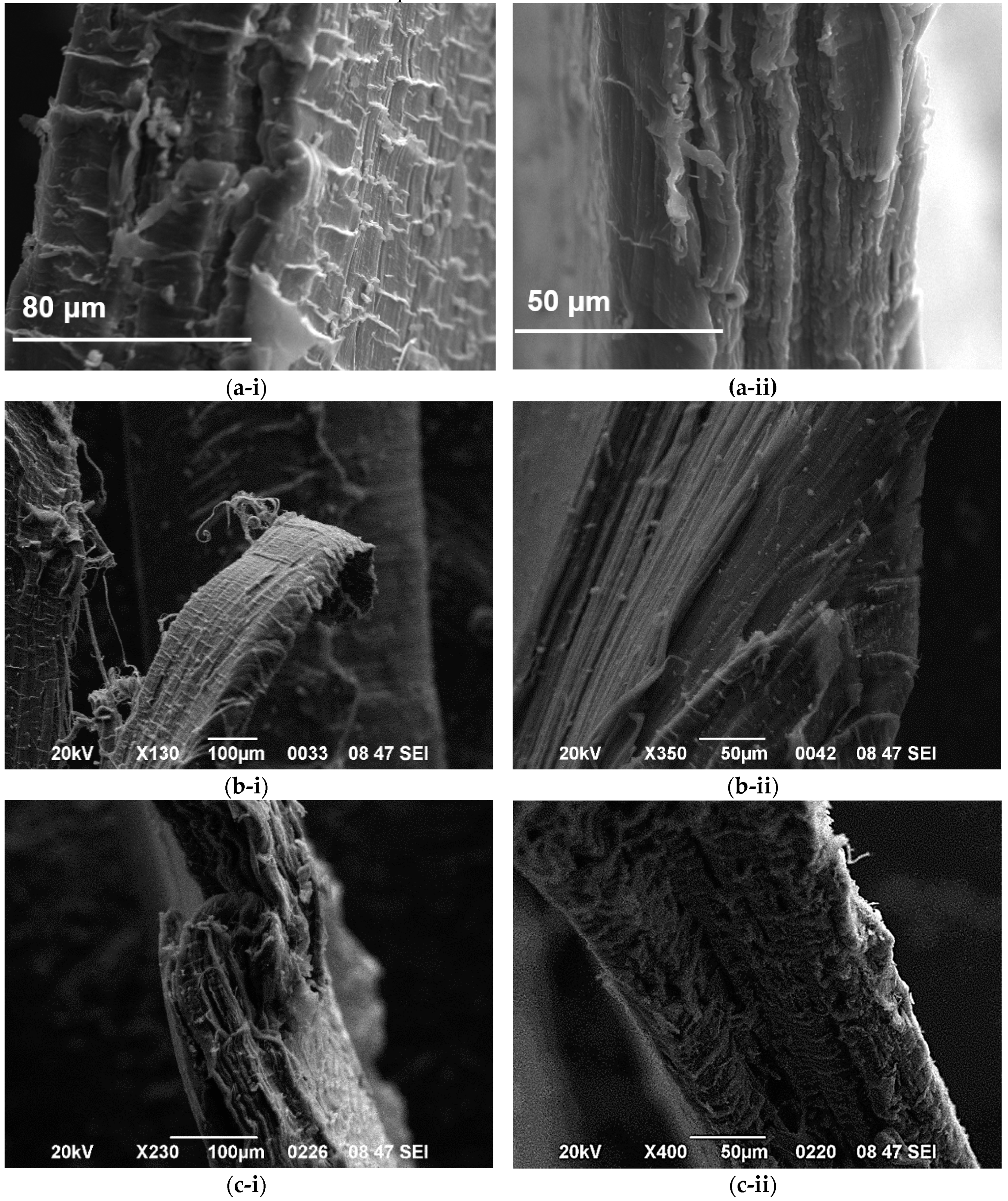

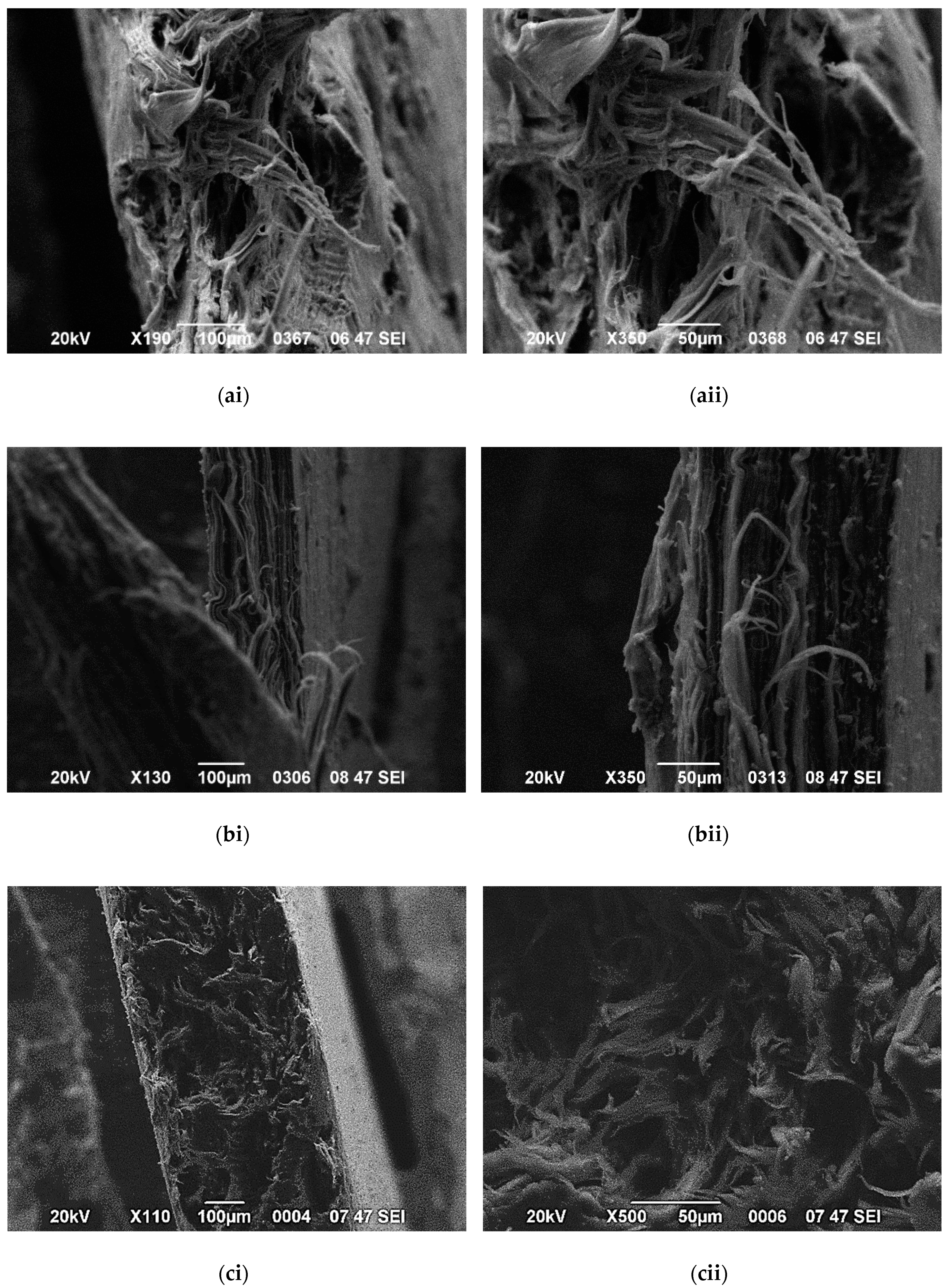

3.5. Fractography of HDPE/GNPs Nanocomposites

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Shi, Y.; Peng, L.; Ding, Y.; Zhao, Y.; Yu, G. Nanostructured conductive polymers for advanced energy storage. Chem. Soc. Rev. 2015, 44, 6684–6696. [Google Scholar] [CrossRef] [PubMed]

- Ren, P.G.; Di, Y.Y.; Zhang, Q.; Li, L.; Pang, H.; Li, Z.M. Composites of ultrahigh-molecular-weight polyethylene with graphene sheets and/or MWCNTs with segregated network structure: Preparation and properties. Macromol. Mater. Eng. 2012, 297, 437–443. [Google Scholar] [CrossRef]

- Peeters, M.; Goderis, B.; Vonk, C.; Reynaers, H.; Mathot, V. Morphology of homogeneous copolymers of ethene and 1-octene. I. Influence of thermal history on morphology. J. Polym. Sci. Part B Polym. Phys. 1997, 35, 2689–2713. [Google Scholar] [CrossRef]

- Yang, Z.; Peng, H.; Wang, W.; Liu, T. Crystallization behavior of poly(ε-caprolactone)/layered double hydroxide nanocomposites. J. Appl. Polym. Sci. 2010, 116, 2658–2667. [Google Scholar] [CrossRef]

- Biswas, S.; Drzal, L.T. A novel approach to create a highly ordered monolayer film of graphene nanosheets at the liquid-liquid interface. Nano Lett. 2009, 9, 167–172. [Google Scholar] [CrossRef]

- Tarani, E.; Papageorgiou, G.Z.; Bikiaris, D.N.; Chrissafis, K. Kinetics of crystallization and thermal degradation of an isotactic polypropylene matrix reinforced with graphene/glass-fiber filler. Molecules 2019, 24, 1984. [Google Scholar] [CrossRef]

- Qin, Z.; Safaei, B.; Pang, X.; Chu, F. Traveling wave analysis of rotating functionally graded graphene platelet reinforced nanocomposite cylindrical shells with general boundary conditions. Results Phys. 2019, 15, 102752. [Google Scholar] [CrossRef]

- Qin, Z.; Zhao, S.; Pang, X.; Safaei, B.; Chu, F. A unified solution for vibration analysis of laminated functionally graded shallow shells reinforced by graphene with general boundary conditions. Int. J. Mech. Sci. 2020, 170, 105341. [Google Scholar] [CrossRef]

- Gao, W.; Qin, Z.; Chu, F. Wave propagation in functionally graded porous plates reinforced with graphene platelets. Aerosp. Sci. Technol. 2020, 102, 105860. [Google Scholar] [CrossRef]

- El Achaby, M.; Qaiss, A. Processing and properties of polyethylene reinforced by graphene nanosheets and carbon nanotubes. Mater. Des. 2013, 44, 81–89. [Google Scholar] [CrossRef]

- Tripathi, S.N.; Rao, G.S.S.; Mathur, A.B.; Jasra, R. Polyolefin/graphene nanocomposites: A review. RSC Adv. 2017, 7, 23615–23632. [Google Scholar] [CrossRef]

- Castela, M.; Mart, G.; Marco, C.; Ellis, G.; Salavagione, H.J. Effect of Click-Chemistry Approaches for Graphene Modi fi cation on the Electrical, Thermal, and Mechanical Properties of Polyethylene/Graphene Nanocomposites. Macromolecules 2013, 46, 8980–8987. [Google Scholar] [CrossRef]

- Alghamdi, A.S.; Materials, A. Synthesis and Mechanical Characterization of High Density Polyethylene/Graphene Nanocomposites. Eng. Technol. Appl. Sci. Res. 2018, 8, 2814–2817. [Google Scholar]

- Batista, N.L.; Helal, E.; Kurusu, R.S.; Moghimian, N.; David, E.; Demarquette, N.R.; Hubert, P. Mass-produced graphene—HDPE nanocomposites: Thermal, rheological, electrical, and mechanical properties. Polym. Eng. Sci. 2019, 59, 675–682. [Google Scholar] [CrossRef]

- Seo, H.M.; Park, J.H.; Dao, T.D.; Jeong, H.M. Compatibility of functionalized graphene with polyethylene and its copolymers. J. Nanomater. 2013, 2013, 9–11. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, T.; Wang, J.; Guo, W.; Qian, Z.; Wei, T. Preparation of antistatic high-density polyethylene composites based on synergistic effect of graphene nanoplatelets and multi-walled carbon nanotubes. Polym. Adv. Technol. 2018, 29, 407–416. [Google Scholar] [CrossRef]

- Seibers, Z.; Orr, M.; Collier, G.S.; Henriquez, A.; Gabel, M.; Shofner, M.L.; La Saponara, V.; Reynolds, J. Chemically Functionalized Reduced Graphene Oxide as Additives in Polyethylene Composites for Space Applications. Polym. Eng. Sci. 2020, 60, 86–94. [Google Scholar] [CrossRef]

- Abuibaid, A.Z.A.; Iqbal, M.Z. Thermally reduced graphene/polyethylene nanocomposites: Effects of graphene on isothermal and nonisothermal crystallization of polyethylene. Heliyon 2020, 6, e03589. [Google Scholar] [CrossRef]

- Chavan, S.; Gumtapure, V.; Perumal D, A. Numerical and experimental analysis on thermal energy storage of polyethylene/functionalized graphene composite phase change materials. J. Energy Storage 2020, 27, 101045. [Google Scholar] [CrossRef]

- Cruz-Aguilar, A.; Navarro-Rodríguez, D.; Pérez-Camacho, O.; Fernández-Tavizón, S.; Gallardo-Vega, C.A.; García-Zamora, M.; Barriga-Castro, E.D. High-density polyethylene/graphene oxide nanocomposites prepared via in situ polymerization: Morphology, thermal, and electrical properties. Mater. Today Commun. 2018, 16, 232–241. [Google Scholar] [CrossRef]

- Vasileiou, A.A.; Kontopoulou, M.; Docoslis, A. A noncovalent compatibilization approach to improve the filler dispersion and properties of polyethylene/graphene composites. ACS Appl. Mater. Interfaces 2014, 6, 1916–1925. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.; Drzal, L.T. Improving electrical conductivity and mechanical properties of high density polyethylene through incorporation of paraffin wax coated exfoliated graphene nanoplatelets and multi-wall carbon nano-tubes. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1840–1849. [Google Scholar] [CrossRef]

- Mohan, V.B.; Bhattacharyya, D. Mechanical, electrical and thermal performance of hybrid polyethylene-graphene nanoplatelets-polypyrrole composites: A comparative analysis of 3D printed and compression molded samples. Polym. Technol. Mater. 2020, 59, 780–796. [Google Scholar] [CrossRef]

- Evgin, T.; Turgut, A.; Hamaoui, G.; Spitalsky, Z.; Horny, N.; Micusik, M.; Chirtoc, M.; Sarikanat, M.; Omastova, M. Size effects of graphene nanoplatelets on the properties of high-density polyethylene nanocomposites: Morphological, thermal, electrical, and mechanical characterization. Beilstein J. Nanotechnol. 2020, 11, 167–179. [Google Scholar] [CrossRef] [PubMed]

- Lin, S.; Anwer, M.A.S.; Zhou, Y.; Sinha, A.; Carson, L. Evaluation of the thermal, mechanical and dynamic mechanical characteristics of modified graphite nanoplatelets and graphene oxide high-density polyethylene composites. Compos. Part B Eng. 2017, 132, 61–68. [Google Scholar] [CrossRef]

- Gaska, K.; Xu, X.; Gubanski, S.; Kádár, R. Electrical, mechanical, and thermal properties of LDPE graphene nanoplatelets composites produced by means of melt extrusion process. Polymers 2017, 9, 11. [Google Scholar] [CrossRef] [PubMed]

- Honaker, K.; Vautard, F.; Drzal, L.T. Investigating the mechanical and barrier properties to oxygen and fuel of high density polyethylene–graphene nanoplatelet composites. Mater. Sci. Eng. B Solid State Mater. Adv. Technol. 2017, 216, 23–30. [Google Scholar] [CrossRef]

- Ulutan, S.; Gilbert, M. Mechanical properties of HDPE/magnesium hydroxide composites. J. Mater. Sci. 2000, 35, 2115–2120. [Google Scholar] [CrossRef]

- Liu, Z.; Peng, W.; Zare, Y.; Hui, D.; Rhee, K.Y. Predicting the electrical conductivity in polymer carbon nanotube nanocomposites based on the volume fractions and resistances of the nanoparticle, interphase, and tunneling regions in conductive networks. RSC Adv. 2018, 8, 19001–19010. [Google Scholar] [CrossRef]

- Amraei, J.; Jam, J.E.; Arab, B.; Firouz-Abadi, R.D. Modeling the interphase region in carbon nanotube-reinforced polymer nanocomposites. Polym. Compos. 2019, 40, E1219–E1234. [Google Scholar] [CrossRef]

- Li, H.X.; Zare, Y.; Rhee, K.Y. The percolation threshold for tensile strength of polymer/CNT nanocomposites assuming filler network and interphase regions. Mater. Chem. Phys. 2018, 207, 76–83. [Google Scholar] [CrossRef]

- Zare, Y.; Rhee, K.Y. Prediction of tensile modulus in polymer nanocomposites containing carbon nanotubes (CNT) above percolation threshold by modification of conventional model. Curr. Appl. Phys. 2017, 17, 873–879. [Google Scholar] [CrossRef]

- Tarani, E.; Terzopoulou, Z.; Bikiaris, D.N.; Kyratsi, T.; Chrissafis, K.; Vourlias, G. Thermal conductivity and degradation behavior of HDPE/graphene nanocomposites. J. Therm. Anal. Calorim. 2017, 129, 1715–1726. [Google Scholar] [CrossRef]

- Tarani, E.; Wurm, A.; Schick, C.; Bikiaris, D.N.; Chrissafis, K.; Vourlias, G. Effect of graphene nanoplatelets diameter on non-isothermal crystallization kinetics and melting behavior of high density polyethylene nanocomposites. Thermochim. Acta 2016, 643, 94–103. [Google Scholar] [CrossRef]

- Tarani, E.; Papageorgiou, D.G.; Valles, C.; Wurm, A.; Terzopoulou, Z.; Bikiaris, D.N.; Schick, C.; Chrissafis, K.; Vourlias, G. Insights into crystallization and melting of high density polyethylene/graphene nanocomposites studied by fast scanning calorimetry. Polym. Test. 2018, 67, 349–358. [Google Scholar] [CrossRef]

- Roumeli, E.; Pavlidou, E.; Bikiaris, D.; Chrissafis, K. Microscopic observation and micromechanical modeling to predict the enhanced mechanical properties of multi-walled carbon nanotubes reinforced crosslinked high density polyethylene. Carbon N. Y. 2014, 67, 475–487. [Google Scholar] [CrossRef]

- Takayanagi, M.; Imada, K.; Kajiyama, T. Mechanical properties and fine structure of drawn polymers. J. Polym. Sci. Part C Polym. Symp. 2007, 15, 263–281. [Google Scholar] [CrossRef]

- Uemura, S.; Takayanagi, M. Application of the theory of elasticity and viscosity of two-phase systems to polymer blends. J. Appl. Polym. Sci. 1966, 10, 113–125. [Google Scholar] [CrossRef]

- Takayanagi, M.; Uemura, S.; Minami, S. Application of equivalent model method to dynamic rheo-optical properties of crystalline polymer. J. Polym. Sci. Part C Polym. Symp. 2007, 5, 113–122. [Google Scholar] [CrossRef]

- Zare, Y.; Garmabi, H. Predictions of Takayanagi model for tensile modulus of polymer/CNT nanocomposites by properties of nanoparticles and filler network. Colloid Polym. Sci. 2017, 295, 1039–1047. [Google Scholar] [CrossRef]

- Zare, Y. Modeling of tensile modulus in polymer/carbon nanotubes (CNT) nanocomposites. Synth. Met. 2015, 202, 68–72. [Google Scholar] [CrossRef]

- Hui, C.Y.; Shia, D. Simple formulae for the effective moduli of unidirectional aligned composites. Polym. Eng. Sci. 1998, 38, 774–782. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, Q.; Chen, D.; Lu, P. Enhanced mechanical properties of graphene-based polyvinyl alcohol composites. Macromolecules 2010, 43, 2357–2363. [Google Scholar] [CrossRef]

- Quali, N.; Cavalille, J.Y.; Perez, J. Elastic, viscoelastic and plastic behavior of multiphase polymer blends. Plast. Rubber Compos. Process. Appl. 1991, 16, 55–60. [Google Scholar]

- Shin, H.; Yang, S.; Choi, J.; Chang, S.; Cho, M. Effect of interphase percolation on mechanical behavior of nanoparticle-reinforced polymer nanocomposite with filler agglomeration: A multiscale approach. Chem. Phys. Lett. 2015, 635, 80–85. [Google Scholar] [CrossRef]

- Chatterjee, A.P. A model for the elastic moduli of three-dimensional fiber networks and nanocomposites. J. Appl. Phys. 2006, 100. [Google Scholar] [CrossRef]

- Paul, B. Prediction of Elastic Constants of Multi-Phase Materials. Trans. AIME. 1960, 218, 36–41. [Google Scholar]

- Loos, M.R.; Manas-Zloczower, I. Reinforcement efficiency of carbon nanotubes—Myth and reality. Macromol. Theory Simul. 2012, 21, 130–137. [Google Scholar] [CrossRef]

- Diani, J.; Gall, K. Finite strain 3D thermoviscoelastic constitutive model for shape memory polymers. Society 2006, 22. [Google Scholar] [CrossRef]

- Ji, X.L.; Jing, J.K.; Jiang, W.; Jiang, B.Z. Tensile modulus of polymer nanocomposites. Polym. Eng. Sci. 2002, 42, 983–993. [Google Scholar] [CrossRef]

- Wakabayashi, K.; Brunner, P.; Pierre, C.; Torkelson, J.M. Polymer-graphite nanocomposites: Effective dispersion and major property enhancement via solid-state shear pulverization. Tech. Pap. Reg. Tech. Conf. Soc. Plast. Eng. 2008, 4, 1975–1979. [Google Scholar] [CrossRef]

- Xu, Y.; Lin, Z.; Huang, X.; Wang, Y.; Huang, Y.; Duan, X. Functionalized Graphene Hydrogel-Based High-Performance Supercapacitors. Adv. Mater. 2013, 25, 5779–5784. [Google Scholar] [CrossRef] [PubMed]

- Yang, B.X.; Pramoda, K.P.; Xu, G.Q.; Goh, S.H. Mechanical reinforcement of polyethylene using polyethylene-grafted multiwalled carbon nanotubes. Adv. Funct. Mater. 2007, 17, 2062–2069. [Google Scholar] [CrossRef]

- Khonakdar, H.A.; Wagenknecht, U.; Jafari, S.H.; Hässler, R.; Eslami, H. Dynamic mechanical properties and morphology of polyethylene/ethylene vinyl acetate copolymer blends. Adv. Polym. Technol. 2004, 23, 307–315. [Google Scholar] [CrossRef]

- Stachurski, Z.H.; Ward, I.M. Mechanical Relaxations in Polyethylene. J. Macromol. Sci. Part B 1969, 3, 445–494. [Google Scholar] [CrossRef]

- Zheng, W.; Lu, X.; Wong, S.C. Electrical and mechanical properties of expanded graphite-reinforced high-density polyethylene. J. Appl. Polym. Sci. 2004, 91, 2781–2788. [Google Scholar] [CrossRef]

- Zhang, J.; Ru, J.; Chen, H.; Li, D.; Lu, J. Viscoelastic creep and relaxation of dielectric elastomers characterized by a Kelvin-Voigt-Maxwell model. Appl. Phys. Lett. 2017, 110, 044104. [Google Scholar] [CrossRef]

- Gong, L.; Kinloch, I.A.; Young, R.J.; Riaz, I.; Jalil, R.; Novoselov, K.S. Interfacial stress transfer in a graphene monolayer nanocomposite. Adv. Mater. 2010, 22, 2694–2697. [Google Scholar] [CrossRef]

- Chatterjee, S.; Nafezarefi, F.; Tai, N.H.; Schlagenhauf, L.; Nüesch, F.A.; Chu, B.T.T. Size and synergy effects of nanofiller hybrids including graphene nanoplatelets and carbon nanotubes in mechanical properties of epoxy composites. Carbon N. Y. 2012, 50, 5380–5386. [Google Scholar] [CrossRef]

- King, J.A.; Klimek, D.R.; Miskioglu, I.; Odegard, G.M. Mechanical properties of graphene nanoplatelet/epoxy composites. J. Compos. Mater. 2015, 49, 659–668. [Google Scholar] [CrossRef]

- Ljungberg, N.; Bonini, C.; Bortolussi, F.; Boisson, C.; Heux, L.; Cavaillé, J.Y. New nanocomposite materials reinforced with cellulose whiskers in atactic polypropylene: Effect of surface and dispersion characteristics. Biomacromolecules 2005, 6, 2732–2739. [Google Scholar] [CrossRef] [PubMed]

- Dasari, A.; Duncan, S.J.; Misra, R.D.K. Micro and nano-scale deformation processes during scratch damage in high density polyethylene. Mater. Sci. Technol. 2003, 19, 239–243. [Google Scholar] [CrossRef]

- Dasari, A.; Duncan, S.J.; Misra, R.D.K. Microstructural aspects of tensile deformation of high density polyethylene. Mater. Sci. Technol. 2003, 19, 244–252. [Google Scholar] [CrossRef]

- Fim, F.; Basso, N.R.S.; Graebin, A.P.; Azambuja, D.S.; Galland, G.B. Thermal, electrical, and mechanical properties of polyethylene-graphene nanocomposites obtained by in situ polymerization. J. Appl. Polym. Sci. 2013, 128, 2630–2637. [Google Scholar] [CrossRef]

| Mechanical Model | A/A | Sample | ||

|---|---|---|---|---|

| HDPE/M5 | HDPE/M15 | HDPE/M25 | ||

| Vc (vol.%) | 0.0018 | 0.0006 | 0.0004 | |

| Modified Takayanagi II Model | c | 0.60 | - | - |

| Ji Model | τ (nm) | 1686.9 | 20.3 | 25.8 |

| Ei(0) (GPa) | 0.47 | 6.42 | 1.37 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tarani, E.; Chrysafi, I.; Kállay-Menyhárd, A.; Pavlidou, E.; Kehagias, T.; Bikiaris, D.N.; Vourlias, G.; Chrissafis, K. Influence of Graphene Platelet Aspect Ratio on the Mechanical Properties of HDPE Nanocomposites: Microscopic Observation and Micromechanical Modeling. Polymers 2020, 12, 1719. https://doi.org/10.3390/polym12081719

Tarani E, Chrysafi I, Kállay-Menyhárd A, Pavlidou E, Kehagias T, Bikiaris DN, Vourlias G, Chrissafis K. Influence of Graphene Platelet Aspect Ratio on the Mechanical Properties of HDPE Nanocomposites: Microscopic Observation and Micromechanical Modeling. Polymers. 2020; 12(8):1719. https://doi.org/10.3390/polym12081719

Chicago/Turabian StyleTarani, Evangelia, Iouliana Chrysafi, Alfréd Kállay-Menyhárd, Eleni Pavlidou, Thomas Kehagias, Dimitrios N. Bikiaris, George Vourlias, and Konstantinos Chrissafis. 2020. "Influence of Graphene Platelet Aspect Ratio on the Mechanical Properties of HDPE Nanocomposites: Microscopic Observation and Micromechanical Modeling" Polymers 12, no. 8: 1719. https://doi.org/10.3390/polym12081719

APA StyleTarani, E., Chrysafi, I., Kállay-Menyhárd, A., Pavlidou, E., Kehagias, T., Bikiaris, D. N., Vourlias, G., & Chrissafis, K. (2020). Influence of Graphene Platelet Aspect Ratio on the Mechanical Properties of HDPE Nanocomposites: Microscopic Observation and Micromechanical Modeling. Polymers, 12(8), 1719. https://doi.org/10.3390/polym12081719