Fused Filament Fabrication of PEEK: A Review of Process-Structure-Property Relationships

Abstract

1. Introduction

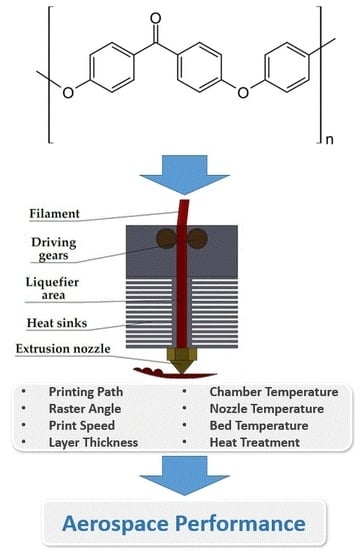

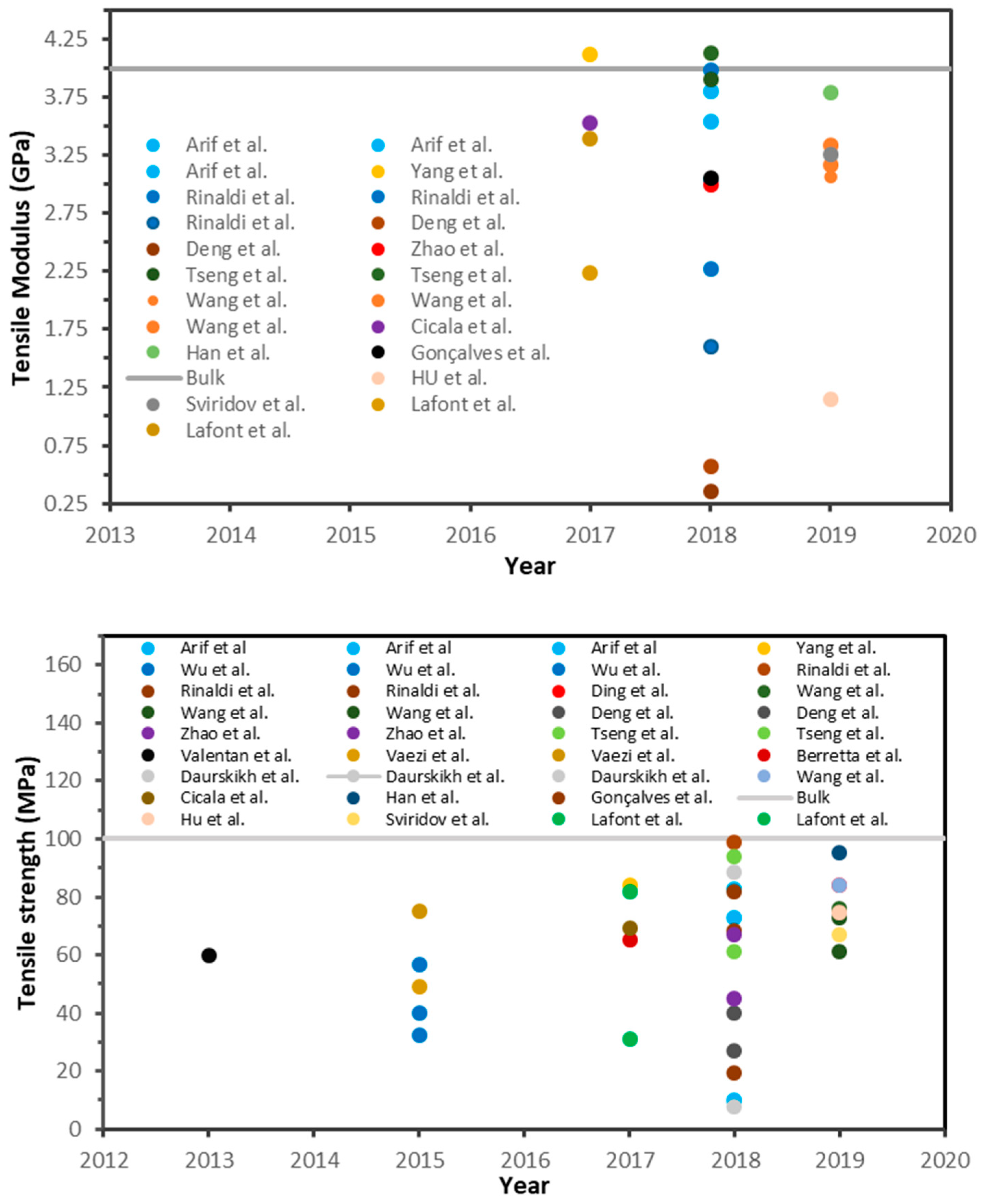

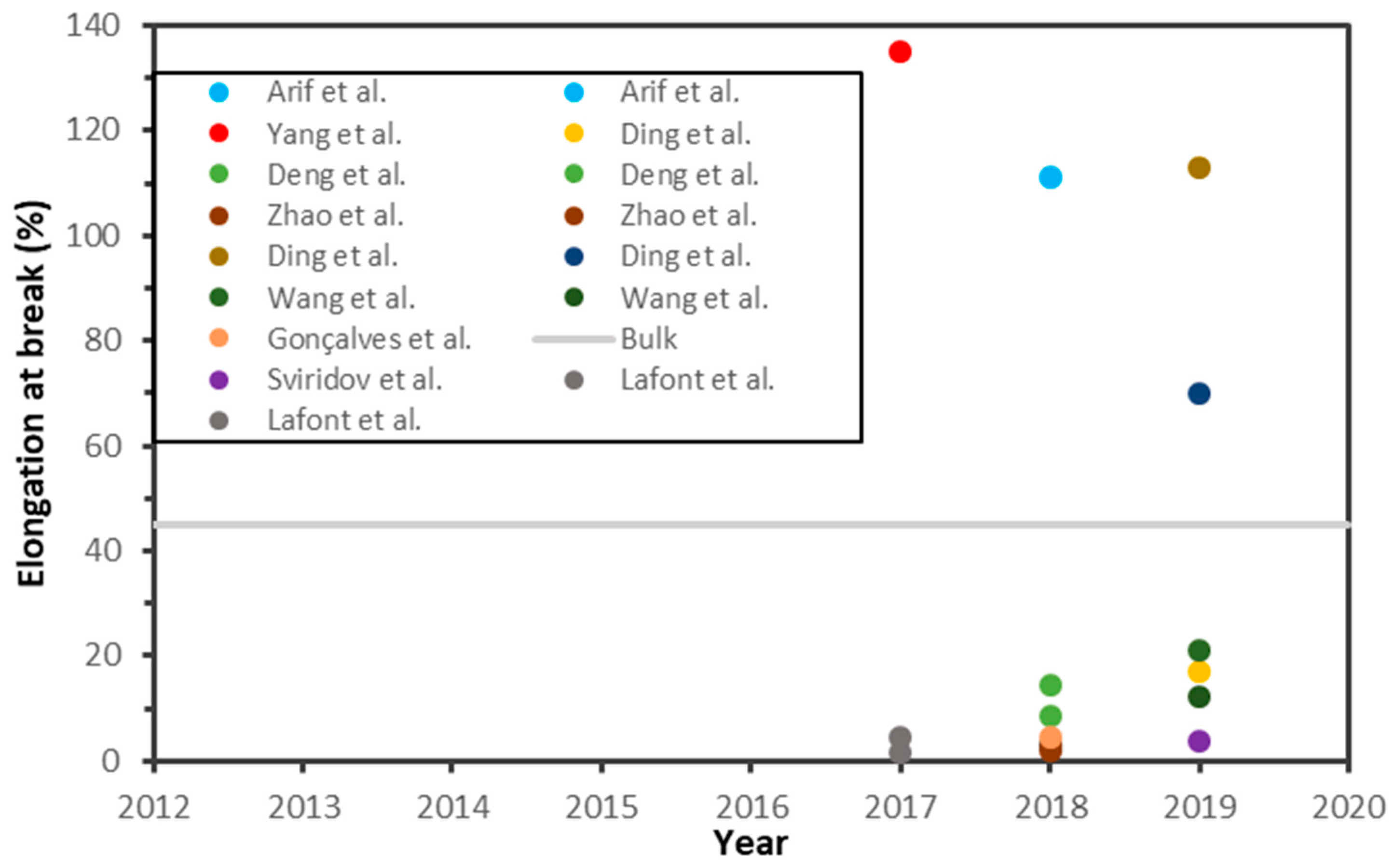

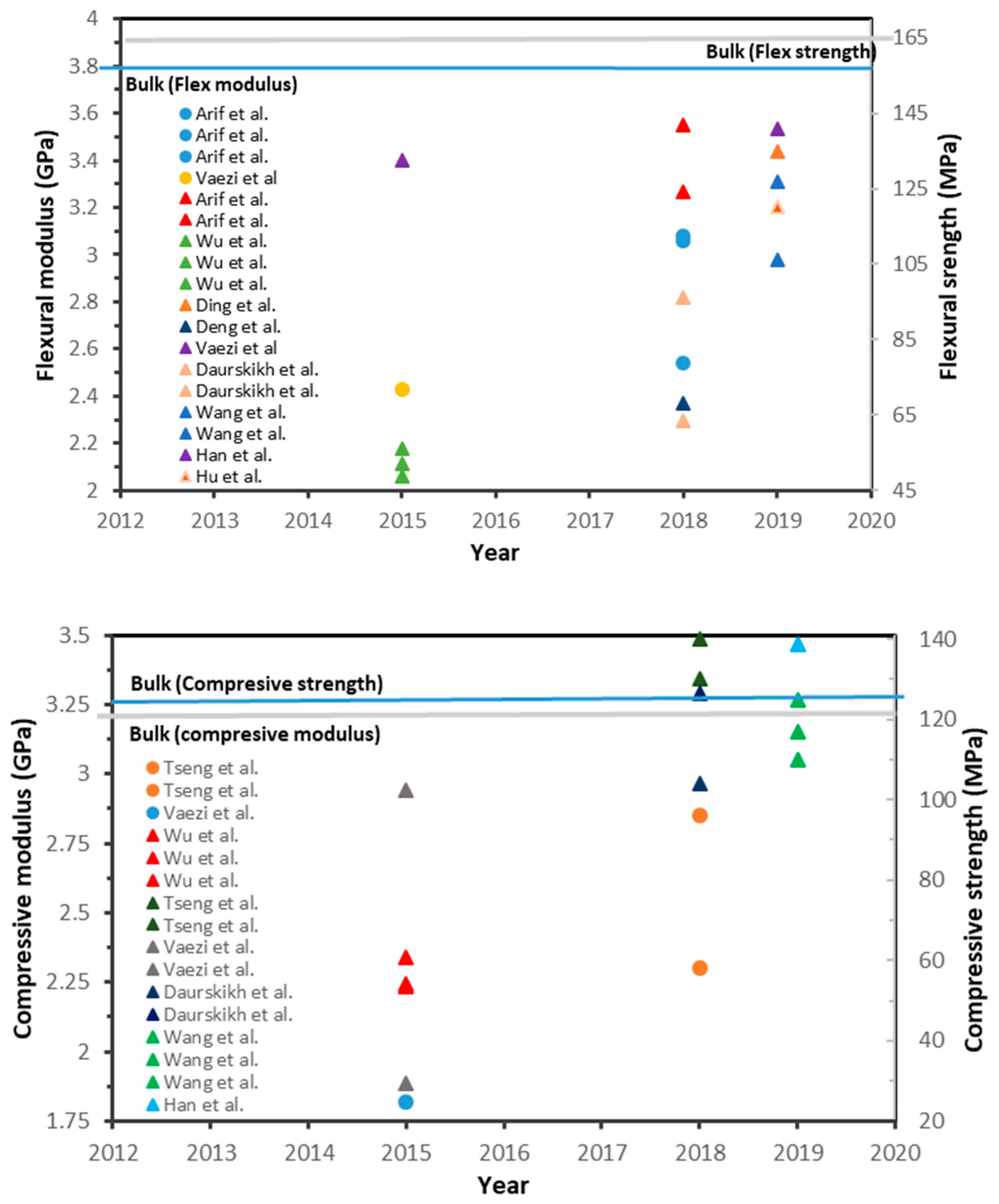

2. Challenges of 3D printing of PEEK

3. Process-Structure-Property Relationships

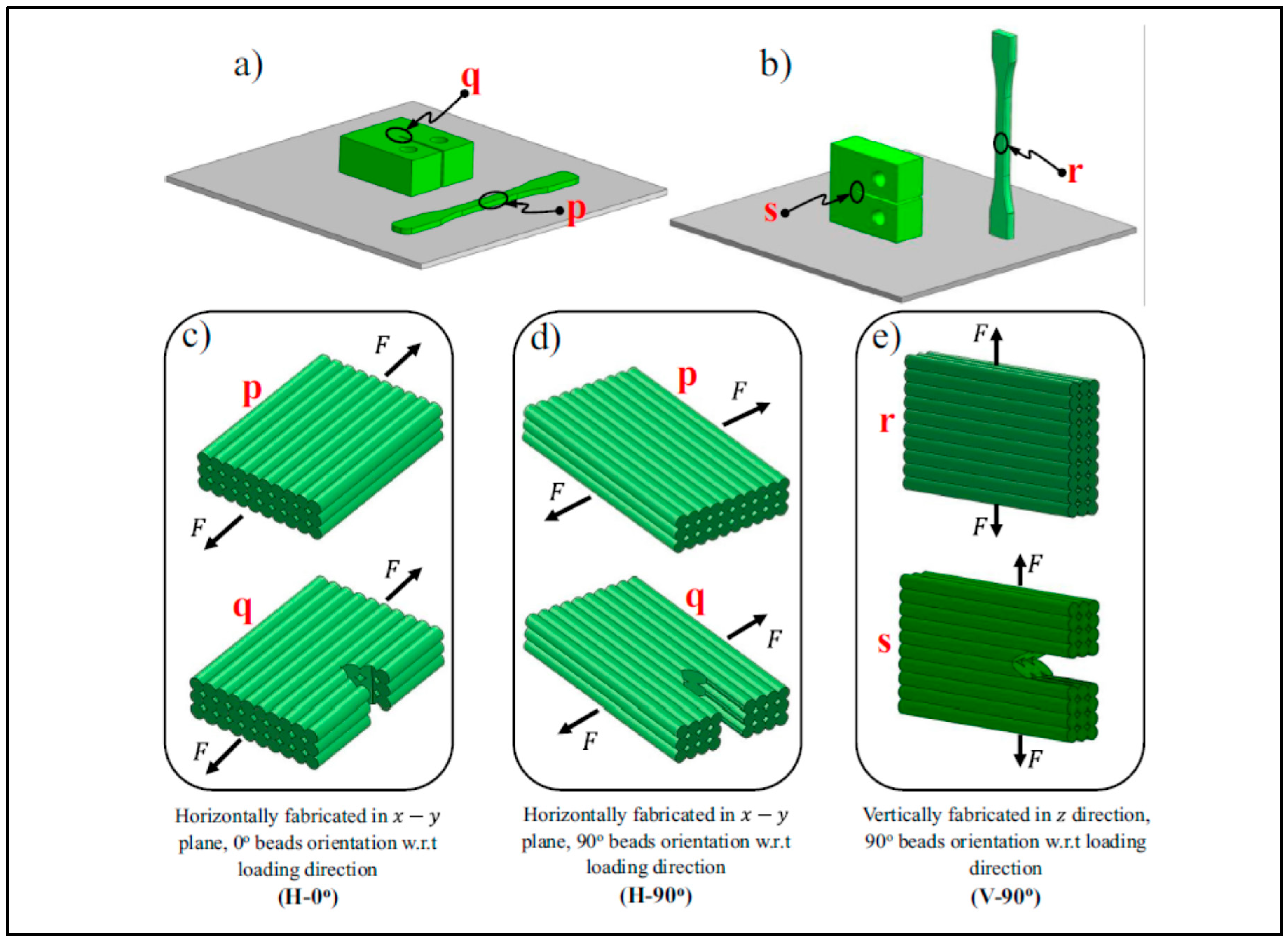

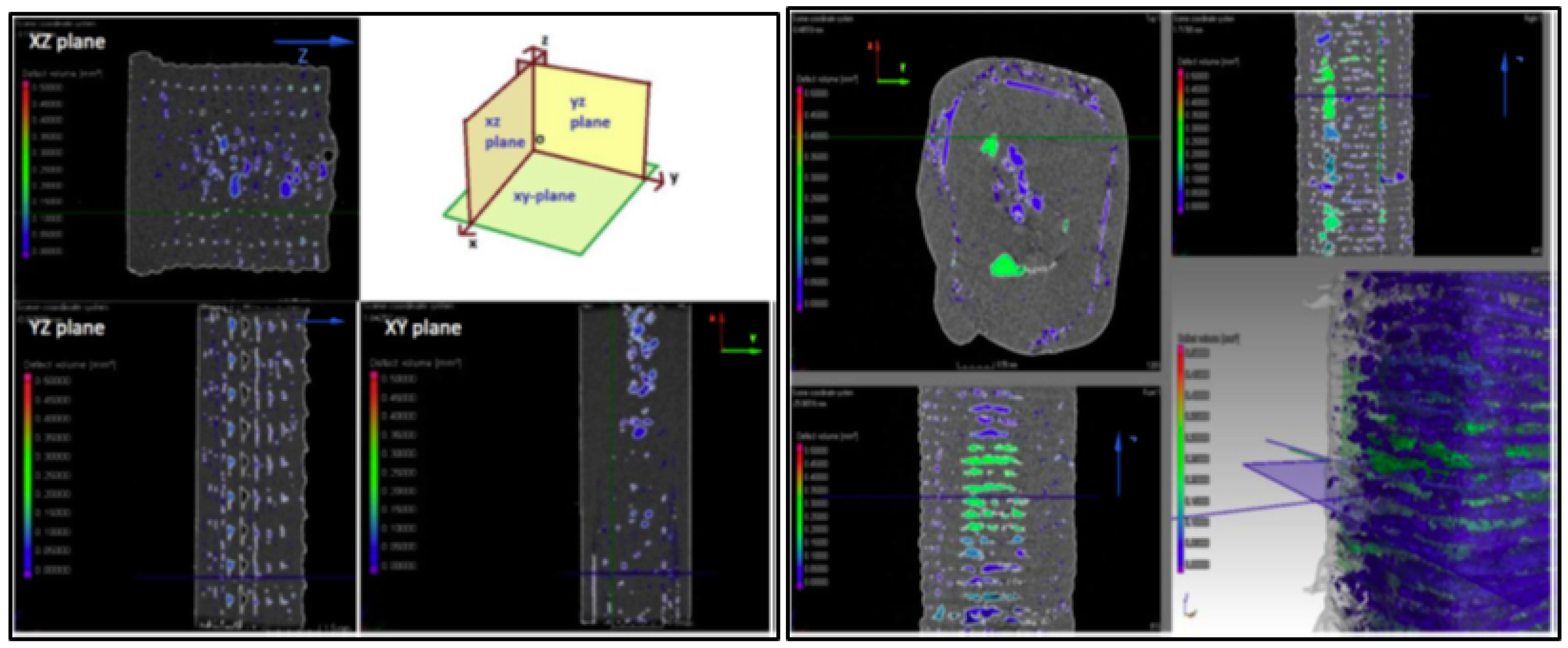

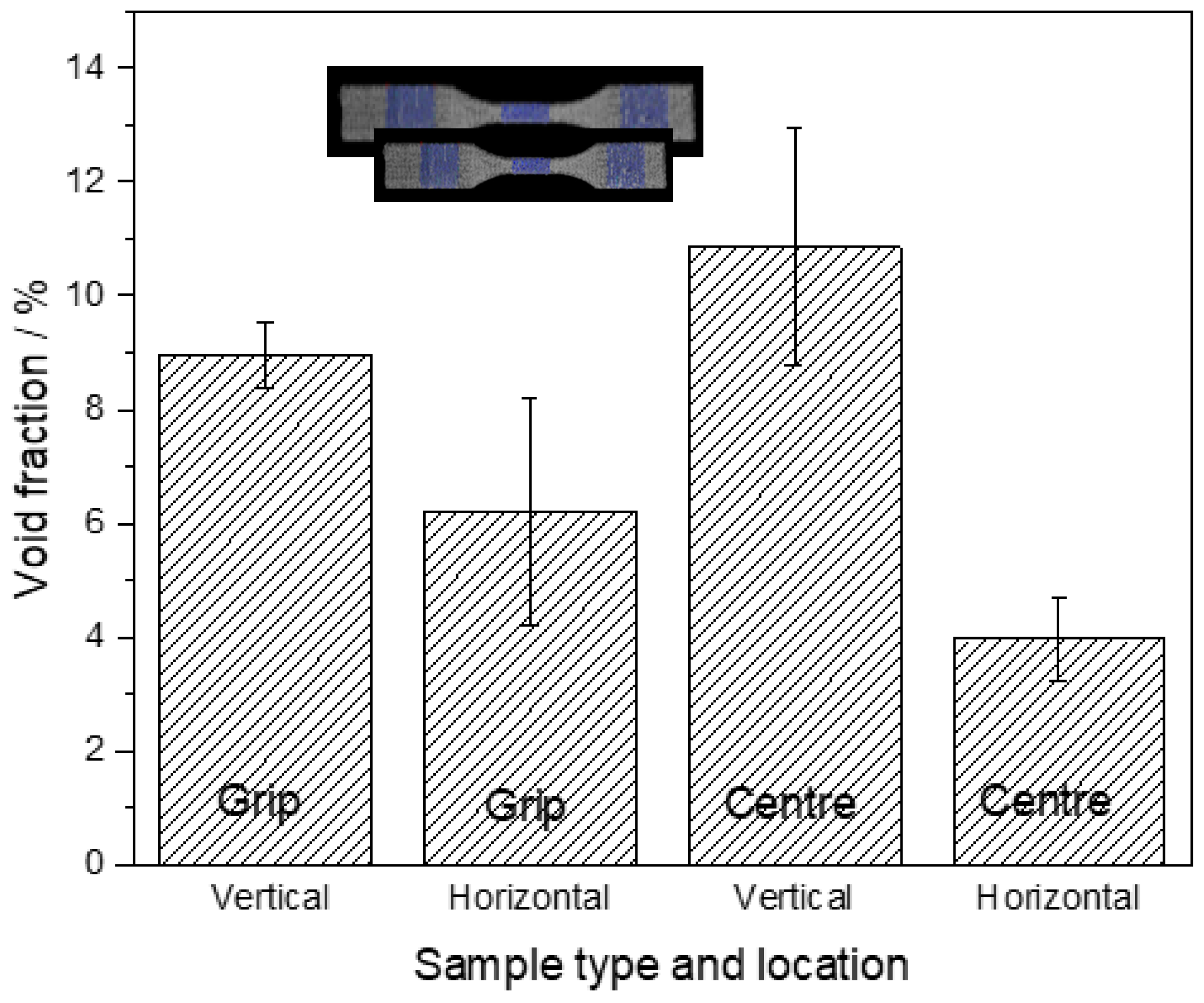

3.1. Printing Path Parameters

3.2. Printing Layer Thickness

3.3. Processing Conditions

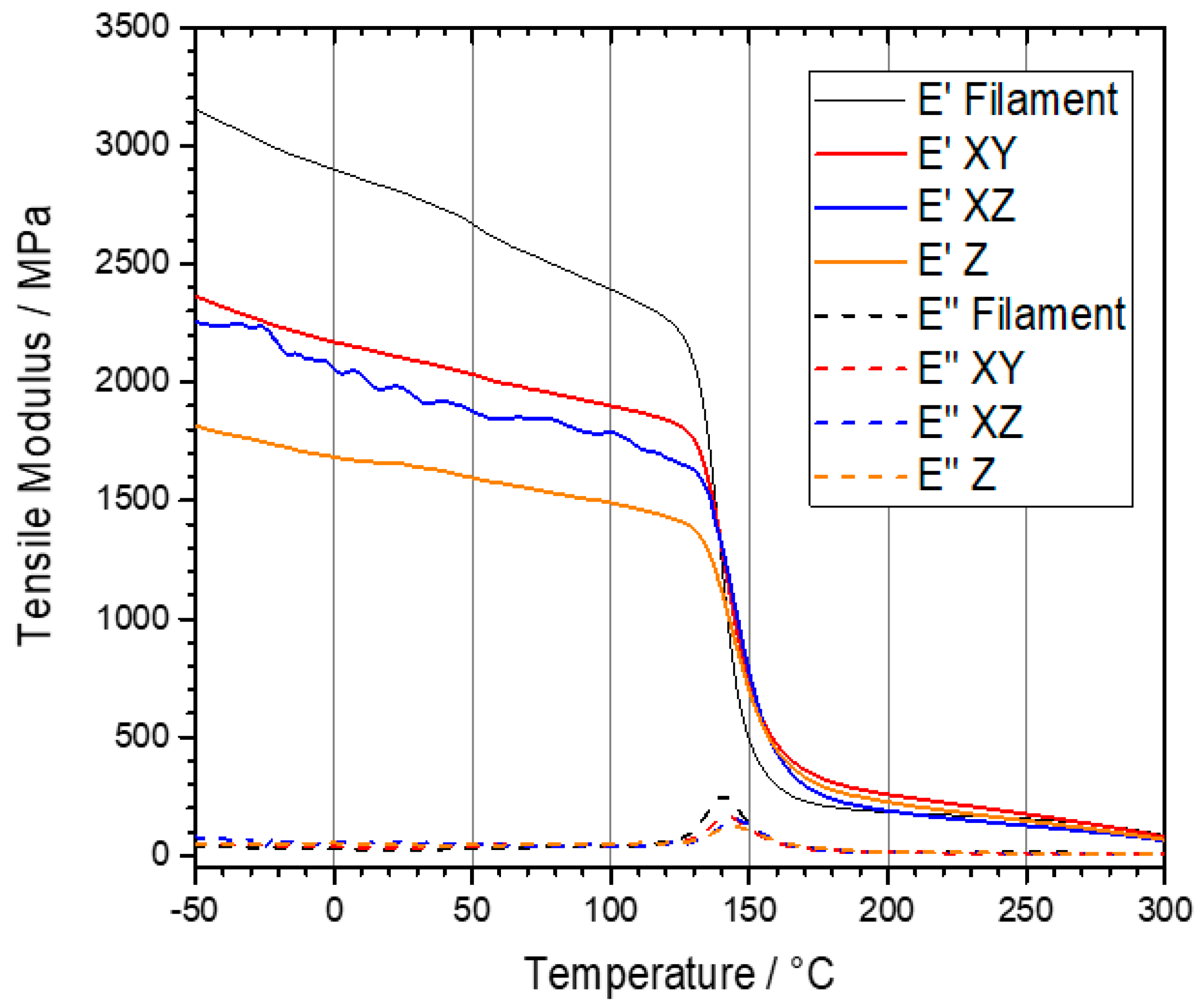

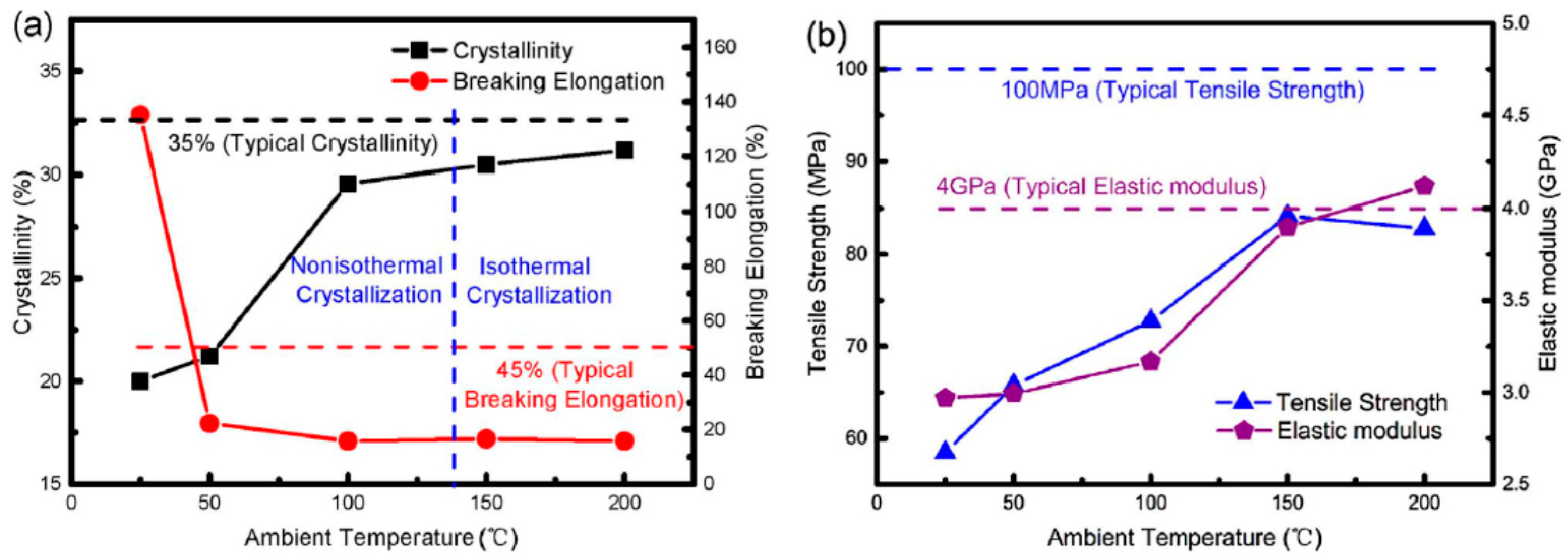

3.3.1. Ambient/Printing Chamber Temperature

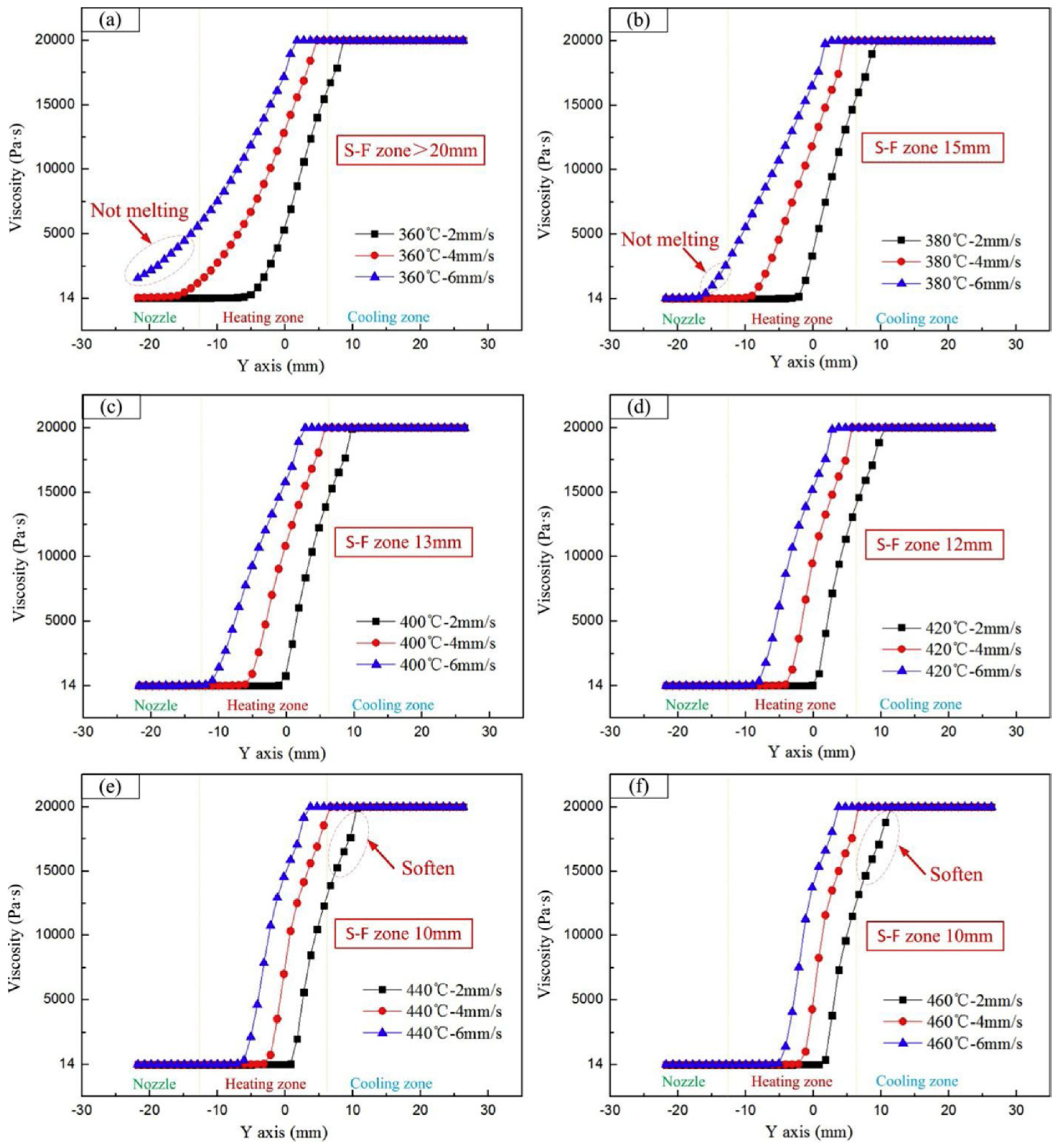

3.3.2. Nozzle Temperature

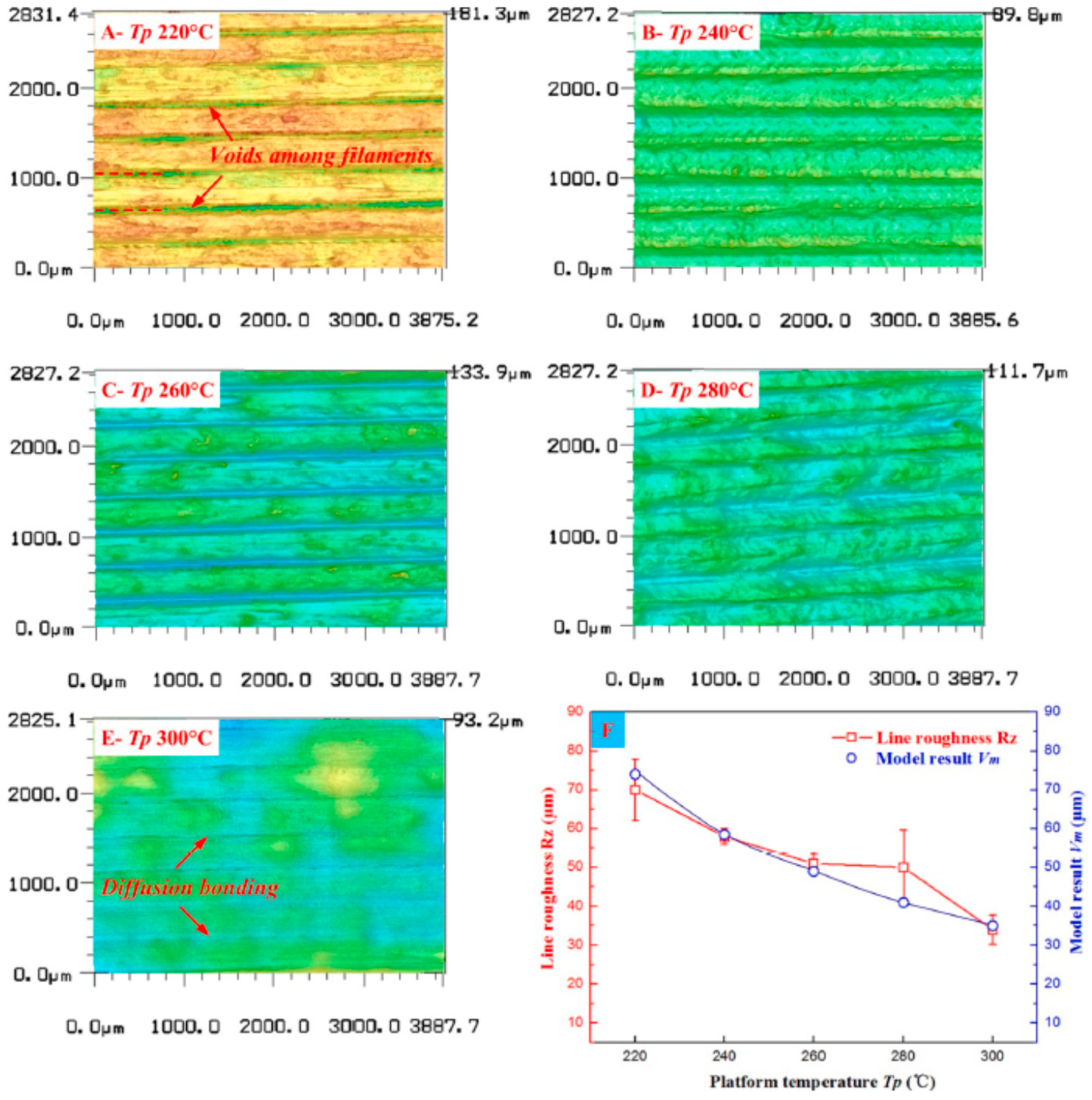

3.3.3. Bed Temperature

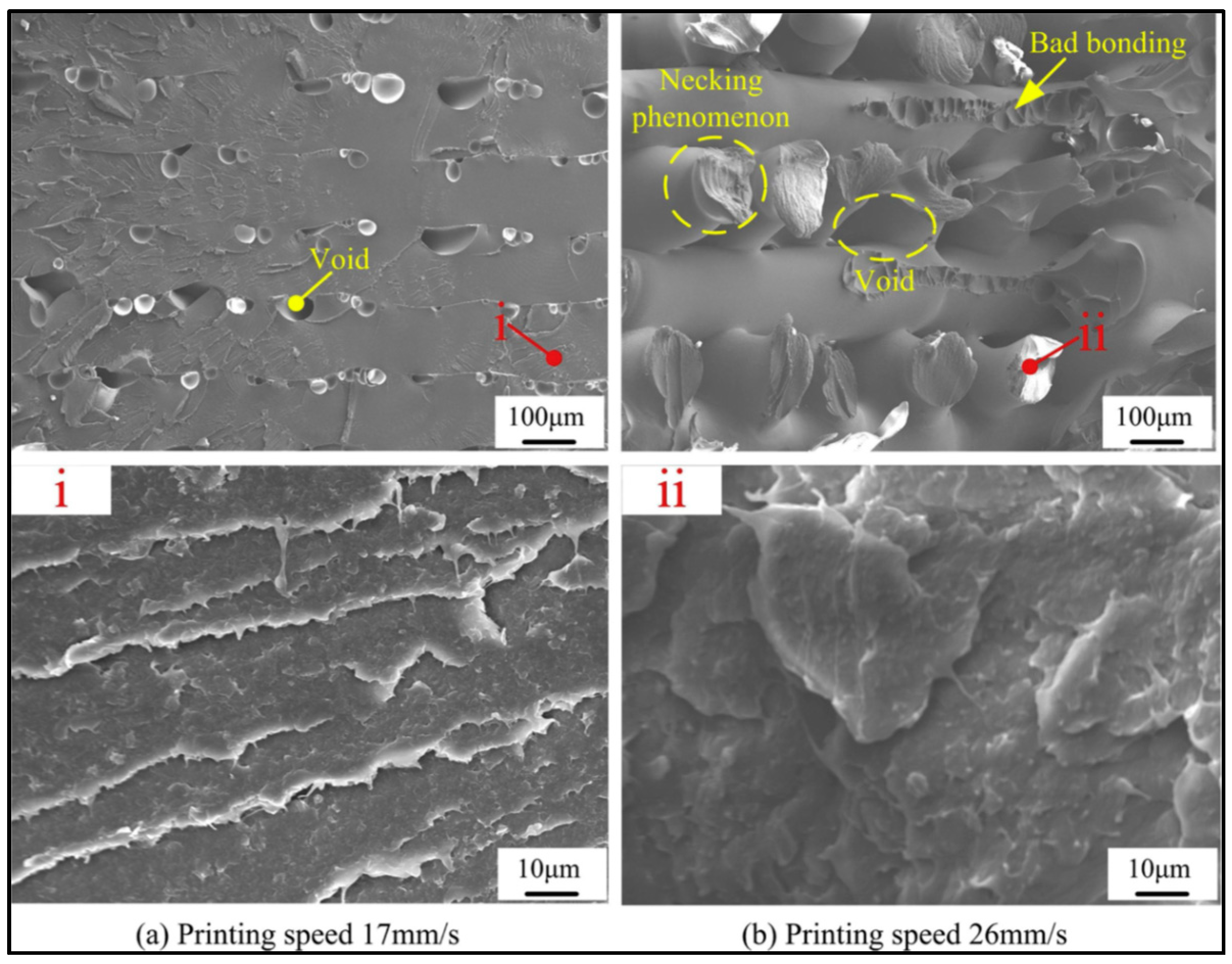

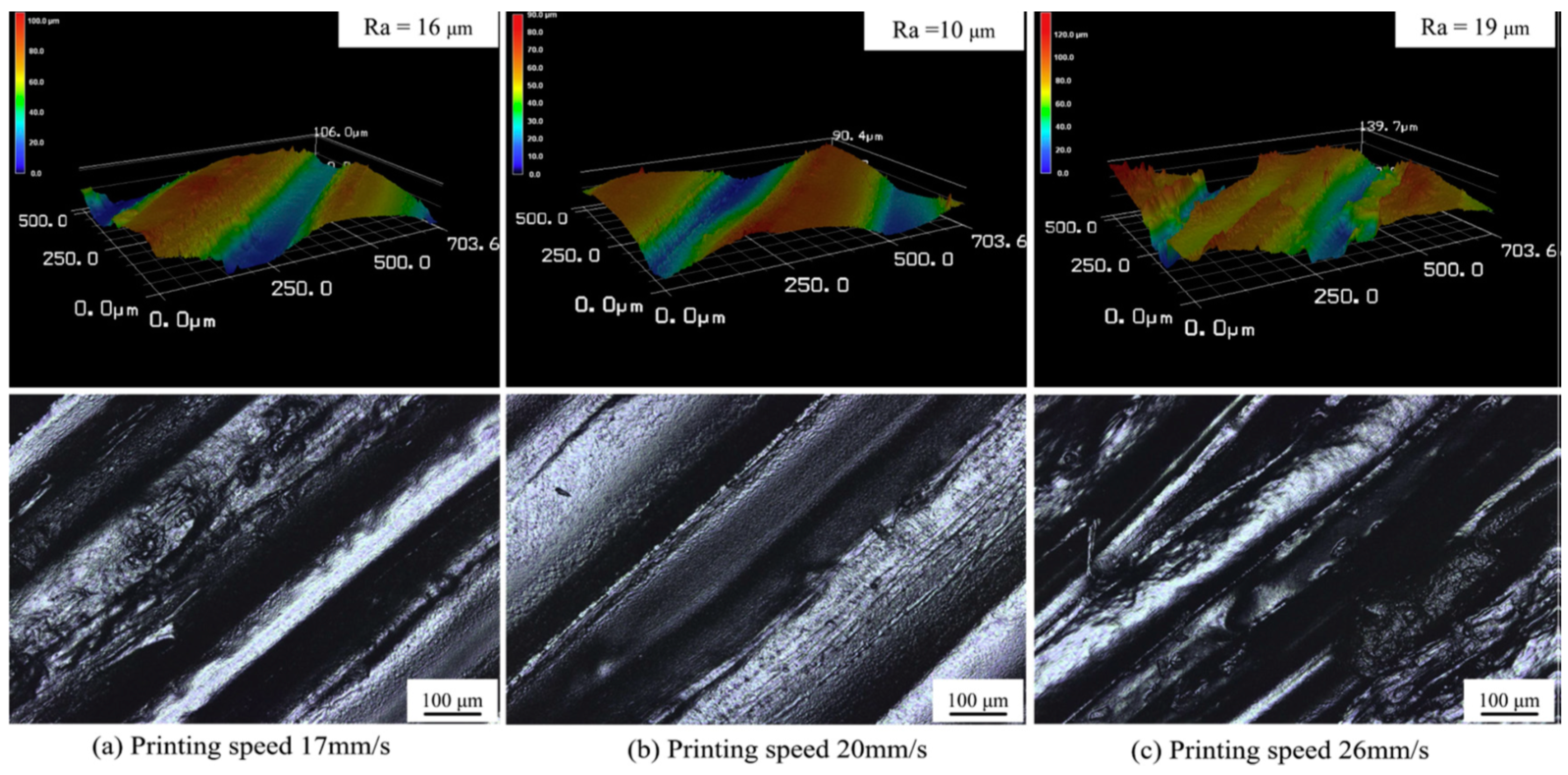

3.3.4. Printing Speed

3.3.5. Heat Treatment Methods

4. Thermal and Irradiation Degradation

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Herzberger, J.; Sirrine, J.M.; Williams, C.B.; Long, T.E. Polymer Design for 3D Printing Elastomers: Recent Advances in Structure, Properties, and Printing. Prog. Polym. Sci. 2019, 97, 101144. [Google Scholar] [CrossRef]

- Pollack, S.; Venkatesh, C.; Neff, M.; Healy, A.V.; Hu, G.; Fuenmayor, E.A.; Lyons, J.G.; Major, I.; Devine, D.M. Polymer-Based Additive Manufacturing: Historical Developments, Process Types and Material Considerations. In Polymer-Based Additive Manufacturing; Springer: Berlin/Heidelberg, Germany, 2019; pp. 1–22. [Google Scholar]

- Chia, H.N.; Wu, B.M. Recent advances in 3D printing of biomaterials. J. Biol. Eng. 2015, 9, 4. [Google Scholar] [CrossRef]

- Melchels, F.P.W.; Feijen, J.; Grijpma, D.W. A review on stereolithography and its applications in biomedical engineering. Biomaterials 2010, 31, 6121–6130. [Google Scholar] [CrossRef] [PubMed]

- Gibson, I.; Shi, D. Material properties and fabrication parameters in selective laser sintering process. Rapid Prototyp. J. 1997, 3, 129–136. [Google Scholar] [CrossRef]

- Stansbury, J.W.; Idacavage, M.J. 3D printing with polymers: Challenges among expanding options and opportunities. Dent. Mater. 2016, 32, 54–64. [Google Scholar] [CrossRef] [PubMed]

- Kruth, J.-P.; Wang, X.; Laoui, T.; Froyen, L. Lasers and materials in selective laser sintering. Assem. Autom. 2003, 23, 357–371. [Google Scholar] [CrossRef]

- Turner, B.N.; Gold, S.A. A review of melt extrusion additive manufacturing processes: II. Materials, dimensional accuracy, and surface roughness. Rapid Prototyp. J. 2015, 21, 250–261. [Google Scholar] [CrossRef]

- Guo, N.; Leu, M.C. Additive manufacturing: Technology, applications and research needs. Front. Mech. Eng. 2013, 8, 215–243. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Schmidt, M.; Pohle, D.; Rechtenwald, T. Selective laser sintering of PEEK. CIRP Ann. 2007, 56, 205–208. [Google Scholar] [CrossRef]

- Siddiq, A.R.; Kennedy, A.R. Porous poly-ether ether ketone (PEEK) manufactured by a novel powder route using near-spherical salt bead porogens: Characterisation and mechanical properties. Mater. Sci. Eng. C 2015, 47, 180–188. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.; Sharma, V.S.; Sachdeva, A. Progress in selective laser sintering using metallic powders: A review. Mater. Sci. Technol. 2016, 32, 760–772. [Google Scholar] [CrossRef]

- Low, Z.-X.; Chua, Y.T.; Ray, B.M.; Mattia, D.; Metcalfe, I.S.; Patterson, D.A. Perspective on 3D printing of separation membranes and comparison to related unconventional fabrication techniques. J. Memb. Sci. 2017, 523, 596–613. [Google Scholar] [CrossRef]

- Korpela, J.; Kokkari, A.; Korhonen, H.; Malin, M.; Närhi, T.; Seppälä, J. Biodegradable and bioactive porous scaffold structures prepared using fused deposition modeling. J. Biomed. Mater. Res. Part B Appl. Biomater. 2013, 101, 610–619. [Google Scholar] [CrossRef] [PubMed]

- Bernard, A.; Fischer, A. New trends in rapid product development. CIRP Ann. 2002, 51, 635–652. [Google Scholar] [CrossRef]

- Healy, A.; Waldron, C.; Geever, L.; Devine, D.; Lyons, J. Degradable nanocomposites for fused filament fabrication applications. J. Manuf. Mater. Process. 2018, 2, 29. [Google Scholar] [CrossRef]

- Dawoud, M.; Taha, I.; Ebeid, S.J. Mechanical behaviour of ABS: An experimental study using FDM and injection moulding techniques. J. Manuf. Process. 2016, 21, 39–45. [Google Scholar] [CrossRef]

- Faes, M.; Ferraris, E.; Moens, D. Influence of inter-layer cooling time on the quasi-static properties of ABS components produced via fused deposition modelling. Procedia CIRP 2016, 42, 748–753. [Google Scholar] [CrossRef]

- McLouth, T.D.; Severino, J.V.; Adams, P.M.; Patel, D.N.; Zaldivar, R.J. The impact of print orientation and raster pattern on fracture toughness in additively manufactured ABS. Addit. Manuf. 2017, 18, 103–109. [Google Scholar] [CrossRef]

- Afrose, M.F.; Masood, S.H.; Iovenitti, P.; Nikzad, M.; Sbarski, I. Effects of part build orientations on fatigue behaviour of FDM-processed PLA material. Prog. Addit. Manuf. 2016, 1, 21–28. [Google Scholar] [CrossRef]

- Song, Y.; Li, Y.; Song, W.; Yee, K.; Lee, K.-Y.; Tagarielli, V.L. Measurements of the mechanical response of unidirectional 3D-printed PLA. Mater. Des. 2017, 123, 154–164. [Google Scholar] [CrossRef]

- Cuiffo, M.A.; Snyder, J.; Elliott, A.M.; Romero, N.; Kannan, S.; Halada, G.P. Impact of the fused deposition (FDM) printing process on polylactic acid (PLA) chemistry and structure. Appl. Sci. 2017, 7, 579. [Google Scholar] [CrossRef]

- Cicala, G.; Ognibene, G.; Portuesi, S.; Blanco, I.; Rapisarda, M.; Pergolizzi, E.; Recca, G. Comparison of Ultem 9085 used in fused deposition modelling (FDM) with polytherimide blends. Materials 2018, 11, 285. [Google Scholar] [CrossRef]

- Fischer, M.; Schöppner, V. Fatigue behavior of FDM parts manufactured with Ultem 9085. Jom 2017, 69, 563–568. [Google Scholar] [CrossRef]

- Zaldivar, R.J.; Witkin, D.B.; McLouth, T.; Patel, D.N.; Schmitt, K.; Nokes, J.P. Influence of processing and orientation print effects on the mechanical and thermal behavior of 3D-Printed ULTEM® 9085 Material. Addit. Manuf. 2017, 13, 71–80. [Google Scholar] [CrossRef]

- Puigoriol-Forcada, J.M.; Alsina, A.; Salazar-Martín, A.G.; Gomez-Gras, G.; Pérez, M.A. Flexural fatigue properties of polycarbonate fused-deposition modelling specimens. Mater. Des. 2018, 155, 414–421. [Google Scholar] [CrossRef]

- Salazar-Martin, A.G.; Perez, M.A.; García-Granada, A.-A.; Reyes, G.; Puigoriol-Forcada, J.M. A study of creep in polycarbonate fused deposition modelling parts. Mater. Des. 2018, 141, 414–425. [Google Scholar] [CrossRef]

- Domingo-Espin, M.; Puigoriol-Forcada, J.M.; Garcia-Granada, A.-A.; Llumà, J.; Borros, S.; Reyes, G. Mechanical property characterization and simulation of fused deposition modeling Polycarbonate parts. Mater. Des. 2015, 83, 670–677. [Google Scholar] [CrossRef]

- Viskadourakis, Z.; Sevastaki, M.; Kenanakis, G. 3D structured nanocomposites by FDM process: A novel approach for large-scale photocatalytic applications. Appl. Phys. A 2018, 124, 585. [Google Scholar] [CrossRef]

- Rymansaib, Z.; Iravani, P.; Emslie, E.; Medvidović-Kosanović, M.; Sak-Bosnar, M.; Verdejo, R.; Marken, F. All-Polystyrene 3D-Printed Electrochemical Device with Embedded Carbon Nanofiber-Graphite-Polystyrene Composite Conductor. Electroanalysis 2016, 28, 1517–1523. [Google Scholar] [CrossRef]

- Basavaraj, C.K.; Vishwas, M. Studies on effect of fused deposition modelling process parameters on ultimate tensile strength and dimensional accuracy of nylon. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2016; Volume 149, p. 12035. [Google Scholar]

- Mostafa, K.G.; Montemagno, C.; Qureshi, A.J. Strength to cost ratio analysis of FDM Nylon 12 3D Printed Parts. Procedia Manuf. 2018, 26, 753–762. [Google Scholar] [CrossRef]

- Kamoona, S.N.; Masood, S.H.; Mohamed, O.A. Experimental investigation on flexural properties of FDM processed Nylon 12 parts using RSM. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 377, p. 12137. [Google Scholar]

- Wang, L.; Gardner, D.J. Effect of fused layer modeling (FLM) processing parameters on impact strength of cellular polypropylene. Polymer 2017, 113, 74–80. [Google Scholar] [CrossRef]

- Stoof, D.; Pickering, K. Sustainable composite fused deposition modelling filament using recycled pre-consumer polypropylene. Compos. Part B Eng. 2018, 135, 110–118. [Google Scholar] [CrossRef]

- Shahmirzadi, S.R.; Yousefi, A.A.; Naderpour, N. Morphology and rheological properties of copper–polypropylene composite as a candidate for fusion deposition modeling (FDM) filament. In Proceedings of the 12th International Seminar on Polymer Science and Technology, Tehran, Iran, 2–5 November 2016. [Google Scholar]

- Wu, J.; Chen, N.; Bai, F.; Wang, Q. Preparation of poly (vinyl alcohol)/poly (lactic acid)/hydroxyapatite bioactive nanocomposites for fused deposition modeling. Polym. Compos. 2018, 39, E508–E518. [Google Scholar] [CrossRef]

- Wu, J.; Chen, N.; Wang, Q. Preparation of novel thermoplastic poly (vinyl alcohol) with improved processability for fused deposition modeling. Polym. Adv. Technol. 2018, 29, 1447–1455. [Google Scholar] [CrossRef]

- Saviano, M.; Aquino, R.P.; Del Gaudio, P.; Sansone, F.; Russo, P. Poly (vinyl alcohol) 3D printed tablets: The effect of polymer particle size on drug loading and process efficiency. Int. J. Pharm. 2019, 561, 1–8. [Google Scholar] [CrossRef]

- Chen, G.; Chen, N.; Wang, Q. Fabrication and properties of poly (vinyl alcohol)/β-tricalcium phosphate composite scaffolds via fused deposition modeling for bone tissue engineering. Compos. Sci. Technol. 2019, 172, 17–28. [Google Scholar] [CrossRef]

- Bedi, P.; Singh, R.; Ahuja, I.P.S. Multifactor optimization of FDM process parameters for development of rapid tooling using SiC/Al2O3-reinforced LDPE filament. J. Thermoplast. Compos. Mater. 2020, 33, 581–598. [Google Scholar] [CrossRef]

- Bedi, P.; Singh, R.; Ahuja, I.P.S. Investigations for tool life of 3D printed HDPE and LDPE composite based rapid tooling for thermoplastics machining applications. Eng. Res. Express 2019, 1, 15003. [Google Scholar] [CrossRef]

- De Santis, R.; Gloria, A.; Russo, T.; Ronca, A.; D’Amora, U.; Negri, G.; Ronca, D.; Ambrosio, L. Viscoelastic properties of rapid prototyped magnetic nanocomposite scaffolds for osteochondral tissue regeneration. Procedia CIRP 2016, 49, 76–82. [Google Scholar] [CrossRef]

- Mohseni, M.; Hutmacher, D.; Castro, N. Independent evaluation of medical-grade bioresorbable filaments for fused deposition modelling/fused filament fabrication of tissue engineered constructs. Polymers 2018, 10, 40. [Google Scholar] [CrossRef] [PubMed]

- Kishore, V.; Chen, X.; Ajinjeru, C.; Hassen, A.A.; Lindahl, J.M.; Failla, J.; Kunc, V.; Duty, C.E. Additive Manufacturing of High Performance Semicrystalline Thermoplastics and Their Composites; Oak Ridge National Lab. (ORNL): Oak Ridge, TN, USA, 2016. [Google Scholar]

- Fuenmayor, E.; Forde, M.; Healy, A.; Devine, D.; Lyons, J.; McConville, C.; Major, I. Material considerations for fused-filament fabrication of solid dosage forms. Pharmaceutics 2018, 10, 44. [Google Scholar] [CrossRef] [PubMed]

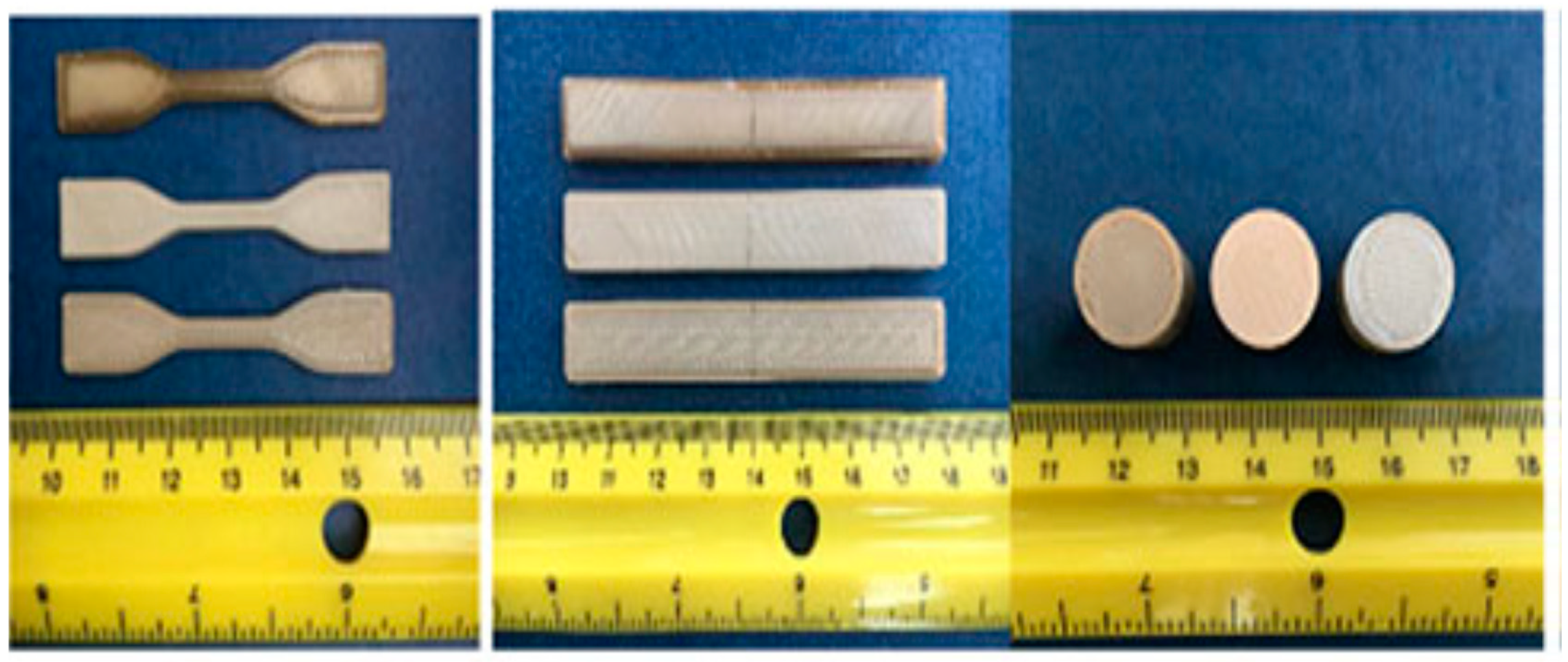

- Fuenmayor, E.; Forde, M.; Healy, A.V.; Devine, D.M.; Lyons, J.G.; McConville, C.; Major, I. Comparison of fused-filament fabrication to direct compression and injection molding in the manufacture of oral tablets. Int. J. Pharm. 2019, 558, 328–340. [Google Scholar] [CrossRef]

- Rocha, C.R.; Perez, A.R.T.; Roberson, D.A.; Shemelya, C.M.; MacDonald, E.; Wicker, R.B. Novel ABS-based binary and ternary polymer blends for material extrusion 3D printing. J. Mater. Res. 2014, 29, 1859–1866. [Google Scholar] [CrossRef]

- Torrado, A.R.; Shemelya, C.M.; English, J.D.; Lin, Y.; Wicker, R.B.; Roberson, D.A. Characterizing the effect of additives to ABS on the mechanical property anisotropy of specimens fabricated by material extrusion 3D printing. Addit. Manuf. 2015, 6, 16–29. [Google Scholar] [CrossRef]

- Toal, P.M., Jr.; Holmes, L.J.; Rodriguez, R.X.; Wetzel, E.D. Microstructured monofilament via thermal drawing of additively manufactured preforms. Addit. Manuf. 2017, 16, 12–23. [Google Scholar] [CrossRef]

- Rechtenwald, T.; Eßer, G.; Schmidt, M.; Pohle, D. Comparison between Laser Sintering of PEEK and PA using design of experiment methods. In Virtual Modelling and Rapid Manufacturing: Advanced Research in Virtual and Rapid Prototyping, Proceedings of the 2nd International Conference on Advanced Research in Virtual and Rapid Prototyping, Leiria, Portugal, 28 September–1 Octorber 2005; CRC Press: Boca Raton, FL, USA, 2005; p. 343. [Google Scholar]

- Fink, J.K. High Performance Polymers; William Andrew: Oxford, UK, 2014; ISBN 0323311431. [Google Scholar]

- Bishop, M.T.; Karasz, F.E.; Russo, P.S.; Langley, K.H. Solubility and properties of a poly (aryl ether ketone) in strong acids. Macromolecules 1985, 18, 86–93. [Google Scholar] [CrossRef]

- Kemmish, D.J. Practical Guide to High Performance Engineering Plastics; Smithers Rapra: Akron, OH, USA, 2011; ISBN 1847355781. [Google Scholar]

- Lee, C.-U.; Vandenbrande, J.; Goetz, A.E.; Ganter, M.A.; Storti, D.W.; Boydston, A.J. Room temperature extrusion 3D printing of polyether ether ketone using a stimuli-responsive binder. Addit. Manuf. 2019, 28, 430–438. [Google Scholar] [CrossRef]

- Bigg, D.M. Mechanical properties of particulate filled polymers. Polym. Compos. 1987, 8, 115–122. [Google Scholar] [CrossRef]

- Shekar, R.I.; Kotresh, T.M.; Rao, P.M.D.; Kumar, K. Properties of high modulus PEEK yarns for aerospace applications. J. Appl. Polym. Sci. 2009, 112, 2497–2510. [Google Scholar] [CrossRef]

- Zalaznik, M.; Kalin, M.; Novak, S. Influence of the processing temperature on the tribological and mechanical properties of poly-ether-ether-ketone (PEEK) polymer. Tribol. Int. 2016, 94, 92–97. [Google Scholar] [CrossRef]

- Kurtz, S.M.; Devine, J.N. PEEK biomaterials in trauma, orthopedic, and spinal implants. Biomaterials 2007, 28, 4845–4869. [Google Scholar] [CrossRef]

- Devine, D.M.; Hahn, J.; Richards, R.G.; Gruner, H.; Wieling, R.; Pearce, S.G. Coating of carbon fiber-reinforced polyetheretherketone implants with titanium to improve bone apposition. J. Biomed. Mater. Res. Part B Appl. Biomater. 2013, 101, 591–598. [Google Scholar] [CrossRef] [PubMed]

- Roskies, M.; Jordan, J.O.; Fang, D.; Abdallah, M.-N.; Hier, M.P.; Mlynarek, A.; Tamimi, F.; Tran, S.D. Improving PEEK bioactivity for craniofacial reconstruction using a 3D printed scaffold embedded with mesenchymal stem cells. J. Biomater. Appl. 2016, 31, 132–139. [Google Scholar] [CrossRef] [PubMed]

- Thieringer, F.M.; Sharma, N.; Mootien, A.; Schumacher, R.; Honigmann, P. Patient specific implants from a 3D printer–an innovative manufacturing process for custom PEEK implants in cranio-maxillofacial surgery. In Industrializing Additive Manufacturing—Proceedings of Additive Manufacturing in Products and Applications—AMPA2017, Proceedings of the International Conference on Additive Manufacturing in Products and Applications, Zurich, Switzerland, 13–15 September 2017; Springer: Berlin, Germany, 2017; pp. 308–315. [Google Scholar]

- Najeeb, S.; Zafar, M.S.; Khurshid, Z.; Siddiqui, F. Applications of polyetheretherketone (PEEK) in oral implantology and prosthodontics. J. Prosthodont. Res. 2016, 60, 12–19. [Google Scholar] [CrossRef] [PubMed]

- Evans, N.T.; Torstrick, F.B.; Lee, C.S.D.; Dupont, K.M.; Safranski, D.L.; Chang, W.A.; Macedo, A.E.; Lin, A.S.P.; Boothby, J.M.; Whittingslow, D.C. High-strength, surface-porous polyether-ether-ketone for load-bearing orthopedic implants. Acta Biomater. 2015, 13, 159–167. [Google Scholar] [CrossRef]

- Mihalko, W.M. Additive Manufacturing of Arthroplasty Implants. In 3D Printing in Orthopaedic Surgery; Elsevier: Amsterdam, The Netherlands, 2019; pp. 49–53. [Google Scholar]

- Deng, L.; Deng, Y.; Xie, K. AgNPs-decorated 3D printed PEEK implant for infection control and bone repair. Colloids Surf. B Biointerfaces 2017, 160, 483–492. [Google Scholar] [CrossRef]

- Chen, Y.; Neff, M.; McEvoy, B.; Cao, Z.; Pezzoli, R.; Murphy, A.; Gately, N.; Jnr, M.H.; Rowan, N.J.; Devine, D.M. 3D printed polymers are less stable than injection moulded counterparts when exposed to terminal sterilization processes using novel vaporized hydrogen peroxide and electron beam processes. Polymer 2019, 183, 121870. [Google Scholar] [CrossRef]

- Zhao, F.; Li, D.; Jin, Z. Preliminary investigation of poly-ether-ether-ketone based on fused deposition modeling for medical applications. Materials 2018, 11, 288. [Google Scholar] [CrossRef]

- Wahab, Z.; Marsh, Z.M.; Tessema, A.; Kidane, A.; Stefik, M.; Anneaux, B.L.; Ploehn, H.J. Effect of nanodiamond (ND) surface functionalization on the properties of ND/PEEK composites. IEEE Trans. Compon. Packag. Manuf. Technol. 2017, 7, 165–177. [Google Scholar] [CrossRef]

- Rinaldi, M.; Puglia, D.; Dominici, F.; Cherubini, V.; Torre, L.; Nanni, F. Melt processing and mechanical property characterization of high-performance poly (ether ether ketone)–carbon nanotube composite. Polym. Int. 2017, 66, 1731–1736. [Google Scholar] [CrossRef]

- Yang, Q.; Zhang, G.; Ma, Z.; Li, J.; Fan, X. Effects of processing parameters and thermal history on microcellular foaming behaviors of PEEK using supercritical CO2. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Clancy, G.; Peeters, D.; Oliveri, V.; Jones, D.; O’Higgins, R.M.; Weaver, P.M. A study of the influence of processing parameters on steering of carbon Fibre/PEEK tapes using laser-assisted tape placement. Compos. Part B Eng. 2019, 163, 243–251. [Google Scholar] [CrossRef]

- Berretta, S.; Evans, K.E.; Ghita, O. Processability of PEEK, a new polymer for high temperature laser sintering (HT-LS). Eur. Polym. J. 2015, 68, 243–266. [Google Scholar] [CrossRef]

- Weigel, T.; Schinkel, G.; Lendlein, A. Design and preparation of polymeric scaffolds for tissue engineering. Expert Rev. Med. Devices 2006, 3, 835–851. [Google Scholar] [CrossRef] [PubMed]

- Uhthoff, H.K.; Poitras, P.; Backman, D.S. Internal plate fixation of fractures: Short history and recent developments. J. Orthop. Sci. 2006, 11, 118–126. [Google Scholar] [CrossRef]

- Singh, S.; Prakash, C.; Ramakrishna, S. 3D printing of polyether-ether-ketone for biomedical applications. Eur. Polym. J. 2019, 114, 234–248. [Google Scholar] [CrossRef]

- Kantaros, A.; Karalekas, D. Fiber Bragg grating based investigation of residual strains in ABS parts fabricated by fused deposition modeling process. Mater. Des. 2013, 50, 44–50. [Google Scholar] [CrossRef]

- Kousiatza, C.; Karalekas, D. In-situ monitoring of strain and temperature distributions during fused deposition modeling process. Mater. Des. 2016, 97, 400–406. [Google Scholar] [CrossRef]

- Spoerk, M.; Sapkota, J.; Weingrill, G.; Fischinger, T.; Arbeiter, F.; Holzer, C. Shrinkage and Warpage Optimization of Expanded-Perlite-Filled Polypropylene Composites in Extrusion-Based Additive Manufacturing. Macromol. Mater. Eng. 2017, 302, 1700143. [Google Scholar] [CrossRef]

- Garcia-Gonzalez, D.; Rusinek, A.; Jankowiak, T.; Arias, A. Mechanical impact behavior of polyether-ether-ketone (PEEK). Compos. Struct. 2015, 124, 88–99. [Google Scholar] [CrossRef]

- Conrad, T.L.; Jaekel, D.J.; Kurtz, S.M.; Roeder, R.K. Effects of the mold temperature on the mechanical properties and crystallinity of hydroxyapatite whisker-reinforced polyetheretherketone scaffolds. J. Biomed. Mater. Res. Part B Appl. Biomater. 2013, 101, 576–583. [Google Scholar] [CrossRef] [PubMed]

- Jin, L.; Ball, J.; Bremner, T.; Sue, H.-J. Crystallization behavior and morphological characterization of poly (ether ether ketone). Polymer 2014, 55, 5255–5265. [Google Scholar] [CrossRef]

- Wang, P.; Zou, B.; Xiao, H.; Ding, S.; Huang, C. Effects of printing parameters of fused deposition modeling on mechanical properties, surface quality, and microstructure of PEEK. J. Mater. Process. Technol. 2019, 271, 62–74. [Google Scholar] [CrossRef]

- Rinaldi, M.; Ghidini, T.; Cecchini, F.; Brandao, A.; Nanni, F. Additive layer manufacturing of poly (ether ether ketone) via FDM. Compos. Part B: Eng. 2018, 145, 162–172. [Google Scholar]

- Tseng, J.-W.; Liu, C.-Y.; Yen, Y.-K.; Belkner, J.; Bremicker, T.; Liu, B.H.; Sun, T.-J.; Wang, A.-B. Screw extrusion-based additive manufacturing of PEEK. Mater. Des. 2018, 140, 209–221. [Google Scholar] [CrossRef]

- Han, X.; Yang, D.; Yang, C.; Spintzyk, S.; Scheideler, L.; Li, P.; Li, D.; Geis-Gerstorfer, J.; Rupp, F. Carbon Fiber Reinforced PEEK Composites Based on 3D-Printing Technology for Orthopedic and Dental Applications. J. Clin. Med. 2019, 8, 240. [Google Scholar] [CrossRef]

- Yang, C.; Tian, X.; Li, D.; Cao, Y.; Zhao, F.; Shi, C. Influence of thermal processing conditions in 3D printing on the crystallinity and mechanical properties of PEEK material. J. Mater. Process. Technol. 2017, 248, 1–7. [Google Scholar] [CrossRef]

- Daurskikh, A.; Sgambati, A.; Graça, D.; Berg, M.; Baptista, A.; Angelo, M.; Lafont, U. Influence of spatial orientation on properties of 3D printed PEEK parts and their design adaptation. In Proceedings of the 69th International Astronautical Congress, Bremen, Germany, 1–5 October 2018. [Google Scholar]

- Wang, R.; Cheng, K.; Advincula, R.C.; Chen, Q. On the thermal processing and mechanical properties of 3D-printed polyether ether ketone. MRS Commun. 2019, 9, 1046–1052. [Google Scholar] [CrossRef]

- Basgul, C.; Yu, T.; MacDonald, D.W.; Siskey, R.; Marcolongo, M.; Kurtz, S.M. Structure–property relationships for 3D-printed PEEK intervertebral lumbar cages produced using fused filament fabrication. J. Mater. Res. 2018, 33, 2040–2051. [Google Scholar] [CrossRef]

- Wu, W.; Geng, P.; Li, G.; Zhao, D.; Zhang, H.; Zhao, J. Influence of layer thickness and raster angle on the mechanical properties of 3D-printed PEEK and a comparative mechanical study between PEEK and ABS. Materials 2015, 8, 5834–5846. [Google Scholar] [CrossRef]

- Arif, M.F.; Kumar, S.; Varadarajan, K.M.; Cantwell, W.J. Performance of biocompatible PEEK processed by fused deposition additive manufacturing. Mater. Des. 2018, 146, 249–259. [Google Scholar] [CrossRef]

- Rahman, K.M.; Letcher, T.; Reese, R. Mechanical properties of additively manufactured peek components using fused filament fabrication. In Proceedings of the ASME 2015 International Mechanical Engineering Congress and Exposition, Houston, TX, USA, 13–19 November 2015; American Society of Mechanical Engineers: New York, NY, USA, 2015; p. V02AT02A009. [Google Scholar]

- Geng, P.; Zhao, J.; Wu, W.; Ye, W.; Wang, Y.; Wang, S.; Zhang, S. Effects of extrusion speed and printing speed on the 3D printing stability of extruded PEEK filament. J. Manuf. Process. 2019, 37, 266–273. [Google Scholar] [CrossRef]

- Ding, S.; Zou, B.; Wang, P.; Ding, H. Effects of nozzle temperature and building orientation on mechanical properties and microstructure of PEEK and PEI printed by 3D-FDM. Polym. Test. 2019, 78, 105948. [Google Scholar] [CrossRef]

- Deng, X.; Zeng, Z.; Peng, B.; Yan, S.; Ke, W. Mechanical properties optimization of poly-ether-ether-ketone via fused deposition modeling. Materials 2018, 11, 216. [Google Scholar] [CrossRef] [PubMed]

- Honigmann, P.; Sharma, N.; Okolo, B.; Popp, U.; Msallem, B.; Thieringer, F.M. Patient-specific surgical implants made of 3D printed PEEK: Material, technology, and scope of surgical application. Biomed Res. Int. 2018, 2018, 4520636. [Google Scholar] [CrossRef] [PubMed]

- Stepashkin, A.A.; Chukov, D.I.; Senatov, F.S.; Salimon, A.I.; Korsunsky, A.M.; Kaloshkin, S.D. 3D-printed PEEK-carbon fiber (CF) composites: Structure and thermal properties. Compos. Sci. Technol. 2018, 164, 319–326. [Google Scholar] [CrossRef]

- Berretta, S.; Davies, R.; Shyng, Y.T.; Wang, Y.; Ghita, O. Fused Deposition Modelling of high temperature polymers: Exploring CNT PEEK composites. Polym. Test. 2017, 63, 251–262. [Google Scholar] [CrossRef]

- Xiaoyong, S.; Liangcheng, C.; Honglin, M.; Peng, G.; Zhanwei, B.; Cheng, L. Experimental analysis of high temperature PEEK materials on 3D printing test. In Proceedings of the 2017 9th International Conference on Measuring Technology and Mechatronics Automation (ICMTMA), Changsha, China, 14–15 January 2017; pp. 13–16. [Google Scholar]

- Wu, W.Z.; Geng, P.; Zhao, J.; Zhang, Y.; Rosen, D.W.; Zhang, H.B. Manufacture and thermal deformation analysis of semicrystalline polymer polyether ether ketone by 3D printing. Mater. Res. Innov. 2014, 18, S5–S12. [Google Scholar] [CrossRef]

- Vaezi, M.; Yang, S. Extrusion-based additive manufacturing of PEEK for biomedical applications. Virtual Phys. Prototyp. 2015, 10, 123–135. [Google Scholar] [CrossRef]

- Cicala, G.; Latteri, A.; Del Curto, B.; Lo Russo, A.; Recca, G.; Farè, S. Engineering thermoplastics for additive manufacturing: A critical perspective with experimental evidence to support functional applications. J. Appl. Biomater. Funct. Mater. 2017, 15, 10–18. [Google Scholar] [CrossRef]

- Han, X.; Sharma, N.; Xu, Z.; Scheideler, L.; Geis-Gerstorfer, J.; Rupp, F.; Thieringer, F.M.; Spintzyk, S. An In Vitro Study of Osteoblast Response on Fused-Filament Fabrication 3D Printed PEEK for Dental and Cranio-Maxillofacial Implants. J. Clin. Med. 2019, 8, 771. [Google Scholar] [CrossRef] [PubMed]

- Lafont, U.; Siarov, S.; Egmond, D.A.; van Semprimoschnig, C. 3D printed PEEK processed by fused filament fabrication: Properties and process relation. In Proceedings of the EUROMAT, Thessaloniki, Greece, 17–22 September 2017. [Google Scholar]

- Li, Q.; Zhao, W.; Li, Y.; Yang, W.; Wang, G. Flexural Properties and Fracture Behavior of CF/PEEK in Orthogonal Building Orientation by FDM: Microstructure and Mechanism. Polymers 2019, 11, 656. [Google Scholar] [CrossRef]

- Hu, B.; Duan, X.; Xing, Z.; Xu, Z.; Du, C.; Zhou, H.; Chen, R.; Shan, B. Improved design of fused deposition modeling equipment for 3D printing of high-performance PEEK parts. Mech. Mater. 2019, 137, 103139. [Google Scholar] [CrossRef]

- Wang, P.; Zou, B.; Ding, S. Modeling of surface roughness based on heat transfer considering diffusion among deposition filaments for FDM 3D printing heat-resistant resin. Appl. Therm. Eng. 2019, 161, 114064. [Google Scholar] [CrossRef]

- Sviridov, A.; Lopatina, I.; Kurganova, I. 3D-printed polyether ether ketone samples mechanical properties estimation. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 589, p. 12021. [Google Scholar]

- Basgul, C.; Yu, T.; MacDonald, D.W.; Siskey, R.; Marcolongo, M.; Kurtz, S.M. Does annealing improve the interlayer adhesion and structural integrity of FFF 3D printed PEEK lumbar spinal cages? J. Mech. Behav. Biomed. Mater. 2019, 102, 103455. [Google Scholar] [CrossRef] [PubMed]

- Van Egmond, D.A. Properties of Poly(Ether Ether Ketone) as a High Performance Engineering Thermoplastic Processed by Fused Deposition Modelling, Internship Report; ESA-TECQEE-RP-004897; 2015. [Google Scholar]

- Siarov, S. Additive Manufacturing With Engineering Thermoplastics, Internship Report; ESA-TECQTE-RP-003620; European Space Agency: Noordwijk, The Netherlands, 2017. [Google Scholar]

- Zhao, Y.; Zhao, K.; Li, Y.; Chen, F. Mechanical characterization of biocompatible PEEK by FDM. J. Manuf. Process. 2020, 56, 28–42. [Google Scholar] [CrossRef]

- Wang, P.; Zou, B.; Ding, S.; Li, L.; Huang, C. Effects of FDM-3D printing parameters on mechanical properties and microstructure of CF/PEEK and GF/PEEK. Chin. J. Aeronaut. 2020. [Google Scholar] [CrossRef]

- Rodgers, L.M.B.; Jaker, V.L. Method for Printing Three-Dimensional Parts wtih Crystallization Kinetics Control. U.S. Patent No. 9,527,242, 27 December 2016. [Google Scholar]

- Patel, P.; Hull, T.R.; Lyon, R.E.; Stoliarov, S.I.; Walters, R.N.; Crowley, S.; Safronava, N. Investigation of the thermal decomposition and flammability of PEEK and its carbon and glass-fibre composites. Polym. Degrad. Stab. 2011, 96, 12–22. [Google Scholar] [CrossRef]

- Díez-Pascual, A.M.; Naffakh, M.; Gómez, M.A.; Marco, C.; Ellis, G.; Martínez, M.T.; Ansón, A.; González-Domínguez, J.M.; Martínez-Rubi, Y.; Simard, B. Development and characterization of PEEK/carbon nanotube composites. Carbon N. Y. 2009, 47, 3079–3090. [Google Scholar] [CrossRef]

- Patel, P.; Hull, T.R.; McCabe, R.W.; Flath, D.; Grasmeder, J.; Percy, M. Mechanism of thermal decomposition of poly (ether ether ketone)(PEEK) from a review of decomposition studies. Polym. Degrad. Stab. 2010, 95, 709–718. [Google Scholar] [CrossRef]

- Day, M.; Sally, D.; Wiles, D.M. Thermal degradation of poly (aryl-ether-ether-ketone): Experimental evaluation of crosslinking reactions. J. Appl. Polym. Sci. 1990, 40, 1615–1625. [Google Scholar] [CrossRef]

- Perng, L.H.; Tsai, C.J.; Ling, Y.C. Mechanism and kinetic modelling of PEEK pyrolysis by TG/MS. Polymer 1999, 40, 7321–7329. [Google Scholar] [CrossRef]

- Díez-Pascual, A.M.; Guan, J.; Simard, B.; Gómez-Fatou, M.A. Poly(phenylene sulphide) and poly(ether ether ketone) composites reinforced with single-walled carbon nanotube buckypaper: I-Structure, thermal stability and crystallization behaviour. Compos. Part A Appl. Sci. Manuf. 2012, 43, 997–1006. [Google Scholar] [CrossRef]

- Díez-Pascual, A.M.; Naffakh, M.; González-Domínguez, J.M.; Ansón, A.; Martínez-Rubi, Y.; Martínez, M.T.; Simard, B.; Gómez, M.A. High performance PEEK/carbon nanotube composites compatibilized with polysulfones-II. Mechanical and electrical properties. Carbon N. Y. 2010, 48, 3500–3511. [Google Scholar] [CrossRef]

- Li, F.; Hu, Y.; Hou, X.; Hu, X.; Jiang, D. Thermal, mechanical, and tribological properties of short carbon fibers/PEEK composites. High Perform. Polym. 2018, 30, 657–666. [Google Scholar] [CrossRef]

- Mylläri, V.; Ruoko, T.-P.; Järvelä, P. The effects of UV irradiation to polyetheretherketone fibres–Characterization by different techniques. Polym. Degrad. Stab. 2014, 109, 278–284. [Google Scholar] [CrossRef]

- Nakamura, H.; Nakamura, T.; Noguchi, T.; Imagawa, K. Photodegradation of PEEK sheets under tensile stress. Polym. Degrad. Stab. 2006, 91, 740–746. [Google Scholar] [CrossRef]

- McKeen, L.W. The Effect of UV Light and Weather on Plastics and Elastomers; William Andrew: Oxford, UK, 2019; ISBN 0128172711. [Google Scholar]

- Nakamura, T.; Fujita, O. Effects of LEO Environment on Mechanical Properties of PEEK Films under Tensile Stress. In Proceedings of the International Symposium on SM/MPAC&SEED Experiment Tsukuba; Japan Aerospace Exploration Agency (JAXA): Tokyo, Japan, 2008; Volume 73. [Google Scholar]

| Material Properties | Typical Value |

|---|---|

| Density | 1.3 g/cm3 |

| Melting temperature | 343 °C |

| Glass transition temperature | 143 °C |

| Coefficient of thermal expansion | Average below Tg: 55 ppm/k Average above Tg: 140 ppm/k |

| Heat deflection temperature | 152 °C |

| Thermal conductivity | 0.32 W/ m.k |

| Young’s modulus | 4 GPa |

| Tensile strength | 100 MPa |

| Elongation at break | 45% |

| Flexural modulus | 3.9 GPa |

| Flexural strength | 162 MPa |

| Compressive modulus | 3.2 GPa |

| Compressive strength | 125 MPa |

| Shore D hardness | 84.5 |

| Water absorption | 0.45% |

| Flammability | V-0 |

| Study | PEEK | Printing Machine | Nozzle Temperature (°C) | Nozzle Diameter (mm) | Printing Speed (mm/s) | Bed Temperature (°C) | Layer Thickness (mm) | Infill Density (%) |

|---|---|---|---|---|---|---|---|---|

| Basgul, 2018 [91] | PEEK OPTIMA™ LT1 | Indmatec HPP 155/Gen 2 | 390–410 | 0.4 | 1000–3000 mm/min | 100 | 1st layer height: 0.1 Top solid layers: 3 | 100 |

| Wu, 2015 [92] | PEEK Jilin University | custom-build printer | - | 0.4 | - | - | 0.2–0.4 | - |

| Yang, 2017 [88] | VictrexPEEK 450G | custom-build printer | 360–480 | 0.4 | 40 | - | 0.2 | - |

| Arif, 2018 [93] | Victrex PEEK 450G | Indmatec HPP 155 | 410 °C; 1st layer: 390 °C | 0.4 | 800 mm/min; 1st layer: 300 mm/min | 100 | 0.1; 1st layer: 0.18 | 100 |

| Rahman, 2015 [94] | Arevo Labs | Arevo Labs | 340 | 1.8 | 50 | 230 | 0.25 | 100 |

| Rinaldi, 2018 [85] | Victrex PEEK 450 PF | Indmatec | 400 | 0.4 | 20 | 100 | - | 20–100 |

| Geng, 2019 [95] | VICTREX 450 G | self-made printing system | 360 | 0.4–0.6 | extrusion speed: 0.1–120 mm/min | 110 | - | - |

| Ding, 2019 [96] | 450G, Junhua, China | custom-build printer | 360–420 | 0.4 | 20 | 270 | 0.2 | - |

| Wang, 2019 [84] | - | custom-build printer | 360–460 | 0.4–0.8 | 17–26 | 280 | 0.1–0.5 | - |

| Deng, 2018 [97] | PEEK-ZhongshanYousheng | custom-build printer | 350–370 | - | 20–60 | - | 0.2–0.3 | 20–60 |

| Zhao, 2018 [69] | Victrex PEEK450G | homemade printer | 355–375 | 0.4 | 30 | 230–270 | 0.2 | 100 |

| Tseng, 2018 [86] | Victrex (PEEK 90G and PEEK 450G) | a new screw extrusion-based 3D printing system | 370–390 | - | - | 280 | - | - |

| Honigmann, 2018 [98] | Apium PEEK 450 | Apium P220 | Up to 520 | 0.4 | - | Up to 160 | 0.1–0.3 | - |

| Stepashkin, 2018 [99] | CF-composite Victrex 150 CA30 | custom-build printer | 380 | 0.35 | 100 mm/min | 95 | 0.25 | 100 |

| Berretta, 2017 [100] | VICTREX® 450G/Plasticyl PEEK 101 | MendleMax v2.0 | 350–390 | - | 30 | 300 | - | - |

| Xiaoyon, 2017 [101] | - | - | - | 0.4 | 20 | 25–130 | 0.8 | 100 |

| Wu, 2014 [102] | PEEK Jilin University | custom-build printer | 340–360 | - | - | 150 | 0.3 | - |

| Daurskikh, 2018 [89] | Victrex PEEK 450G | - | - | - | - | - | - | 100 |

| Vaezi, 2015 [103] | Victrex PEEK 450G | - | 350–450 | - | - | Up to 130 | 0.2 | - |

| Wang, 2019 [90] | Apium PEEK 450 Natural | Hyrel Hydra 16AS, Indmatec HPP 155, Intamsys FUNMAT HT | 400 | 0.4 | 20 | 100 | 0.1–0.2 | 100 |

| Cicala, 2017 [104] | Luvocomm | Roboze one 400+ | 420 | - | 20 | 110 | 0.1 | 75 |

| Han, 2019 [87] | Victrex PEEK 450G | Jugao-AM Tech. Corp | 420 | 0.4 | 40 | - | 0.2 | - |

| Han, 2019 [105] | Evonik VESTAKEEP®i4 G | Apium P220 | 480 | 0.4 | - | 130 | 0.2 | - |

| Gonçalve, 2018 [106] | Victrex PEEK 450G | Indmatec HPP 155 | 400 | 0.4 | 20 | 100 | 0.1 | 100 |

| Li, 2019 [107] | ZYPEEK 550 G | FUNMAT HT | 400 | 0.4 | 15 | 160 | 0.1 | 100 |

| Hu, 2019 [108] | Sting3d Technology | Modified Speedy Maker | 385 | 0.4 | 25 | 135 | 0.1 | 100 |

| Wang, 2019 [109] | PEEK 450G, Junhua | - | 380–420 | 0.4 | 5–25 | 220–300 | 0.1–0.3 | 100 |

| Sviridov, 2019 [110] | Victrex PEEK 381G | TotalZAnyForm 950 PRO HOT+ | 450 | 0.7 | 40 | - | 0.75 | 100 |

| Basgul, 2019 [111] | PEEK OPTIMA™ LT1 | Indmatec HPP 155/Gen 2 | 390–410 | 0.4 | 1500/2000 mm/min | 100 | 0.1 | 100 |

| Lafont, 2017 [106] van Egmond [112] | Victrex 450G | Indmatec HPP 155 | 390 | 0.4 | 20 | 100 | 0.1 | 100 |

| Brand Name | Nozzle Temperature (°C) | Bed Temperature (°C) | Printing Speed (mm/s) | Chamber Temperature (°C) | Bed Preparation |

|---|---|---|---|---|---|

| ThermaX™ | 375–410 | 130–145 | 10–50 for 0.2 mm thickness | 70–140 | Ultem™ Tape |

| 3D4MAKERS | 360–400 | 120 | 15–30 | 70–150 | PEI sheet |

| Polyfluor | 335–390 | 120 | - | - | - |

| KetaSpire® | 390–420 | >200 | - | - | - |

| LUVOCOM | 370–420 | >120 | - | - | - |

| Building Orientation/Raster Angle | Young’s Modulus (GPa) | Tensile Strength (MPa) | FlexuralStrength (MPa) |

|---|---|---|---|

| Horizontal/0° [93] | 3.80 | 82.58 | 142.0 |

| Horizontal/90° [93] | 3.54 | 72.88 | 124.3 |

| Vertical/90° [93] | 3.03 | 9.99 | 16.40 |

| Horizontal/+45°/−45° [85] | 3.98 | 98.9 | - |

| Vertical/+45°/−45° [85] | 1.6 | 19.6 | - |

| Horizontal/0° [94] | 2.83 | 73.19 | 114.16 |

| Horizontal/90° [94] | 2.69 | 53.91 | 78.63 |

| Horizontal/0°/90° [94] | 2.73 | 67.75 | 95.22 |

| Horizontal/0° [110] | 3.29 | 89.4 | - |

| Horizontal/+45°/−45° [110] | 3.03 | 81.7 | - |

| Horizontal/0°/90° [112] | 3.38 | 78.1 | - |

| Vertical/+45°/−45° | 2.21 | 31.1 | - |

| Tensile Strength (MPa) | |||||||

|---|---|---|---|---|---|---|---|

| Study | 360 °C | 380 °C | 400 °C | 420 °C | 440 °C | 460 °C | 480 °C |

| Yang et al. [88] | 48.5 | 49.5 | 54 | 59 | 55 | 57 | 55 |

| Wang et al. [84] | - | 59 | 67.5 | 70 | 72.5 | - | - |

| Ding et al. [96] | 82 | 79 | 83 | 84 | - | - | - |

| Study | Tonset (°C) | T10% (°C) | TMax (°C) | Heating Rate (°C/min) |

|---|---|---|---|---|

| [122] | inert: 514 oxidative: 466 | inert: 541 oxidative: 512 | inert: 554 oxidative: Tmax-I: 517 Tmax-II: 575 | 10 |

| [118] | inert: 521 | inert: 544 | inert: 558 | 10 |

| [123] | inert: 520 oxidative: 478 | inert: 544 oxidative: 520 | inert: 558 oxidative: Tmax-I: 530 Tmax-II: 584 | 10 |

| [124] | - | inert: 588 (MFI: 15 g/10 min) 592 (MFI: 27 g/10 min) 599 (MFI: 85 g/10 min) | inert: 590–600 | 10 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zanjanijam, A.R.; Major, I.; Lyons, J.G.; Lafont, U.; Devine, D.M. Fused Filament Fabrication of PEEK: A Review of Process-Structure-Property Relationships. Polymers 2020, 12, 1665. https://doi.org/10.3390/polym12081665

Zanjanijam AR, Major I, Lyons JG, Lafont U, Devine DM. Fused Filament Fabrication of PEEK: A Review of Process-Structure-Property Relationships. Polymers. 2020; 12(8):1665. https://doi.org/10.3390/polym12081665

Chicago/Turabian StyleZanjanijam, Ali Reza, Ian Major, John G. Lyons, Ugo Lafont, and Declan M. Devine. 2020. "Fused Filament Fabrication of PEEK: A Review of Process-Structure-Property Relationships" Polymers 12, no. 8: 1665. https://doi.org/10.3390/polym12081665

APA StyleZanjanijam, A. R., Major, I., Lyons, J. G., Lafont, U., & Devine, D. M. (2020). Fused Filament Fabrication of PEEK: A Review of Process-Structure-Property Relationships. Polymers, 12(8), 1665. https://doi.org/10.3390/polym12081665