A Review on the Kenaf/Glass Hybrid Composites with Limitations on Mechanical and Low Velocity Impact Properties

Abstract

1. Introduction

2. Kenaf Plant

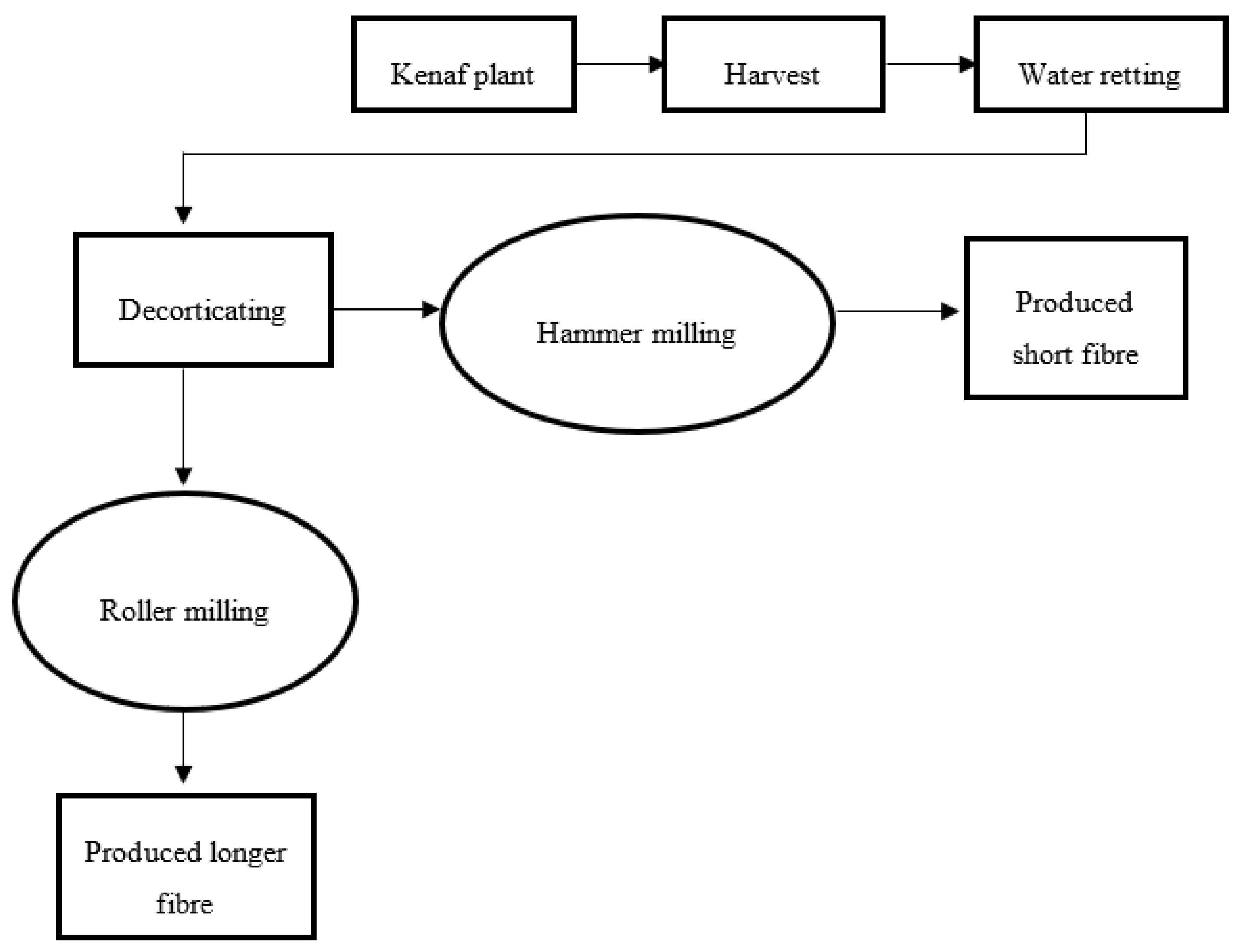

3. Extraction of Kenaf Fibres

4. Glass Fibre

5. Mechanical Properties of Kenaf/Glass Hybrid Composites

6. Low Velocity Impact Properties of Kenaf Composites

7. Low Velocity Impact of Glass Composites

8. Low Velocity Impact of Kenaf/Glass Hybrid Composites

9. Conclusions

Acknowledgments

Conflicts of Interest

References

- Zakikhani, P.; Zahari, R.; Sultan, M.T.; Majid, D.L. Thermal degradation of four bamboo species. BioResources 2016, 11, 414–425. [Google Scholar] [CrossRef]

- Mohammed, L.; Ansari, M.N.; Pua, G.; Jawaid, M.; Islam, M.S. A review on natural fiber reinforced polymer composite and its applications. Int. J. Polym. Sci. 2015, 2015, 243947. [Google Scholar] [CrossRef]

- Peças, P.; Carvalho, H.; Salman, H.; Leite, M. Natural fibre composites and their applications: A review. J. Compos. Sci. 2018, 2, 66. [Google Scholar] [CrossRef]

- Khan, T.; Hameed Sultan, M.T.; Ariffin, A.H. The challenges of natural fiber in manufacturing, material selection, and technology application: A review. J. Reinf. Plast. Compos. 2018, 37, 770–779. [Google Scholar] [CrossRef]

- Chee, S.S.; Jawaid, M.; Sultan, M.T.; Alothman, O.Y.; Abdullah, L.C. Thermomechanical and dynamic mechanical properties of bamboo/woven kenaf mat reinforced epoxy hybrid composites. Compos. Part B: Eng. 2019, 163, 165–174. [Google Scholar] [CrossRef]

- Venkateshwaran, N.; Elayaperumal, A.; Sathiya, G.K. Prediction of tensile properties of hybrid-natural fiber composites. Compos. Part B: Eng. 2012, 43, 793–796. [Google Scholar] [CrossRef]

- Sood, M.; Dwivedi, G. Effect of fiber treatment on flexural properties of natural fiber reinforced composites: A review. Egypt. J. Pet. 2018, 27, 775–783. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Yogesha, B. Studies on hybridization effect of jute/kenaf/E-glass woven fabric epoxy composites for potential applications: Effect of laminate stacking sequences. J. Ind. Text. 2018, 47, 1830–1848. [Google Scholar] [CrossRef]

- Gangil, B.; Kumar, S. Comparative evaluation on mechanical properties of jute/bamboo-glass hybrid reinforced polyester composites. Asian J. Sci. Technol. 2017, 8, 5190–5194. [Google Scholar]

- Panthapulakkal, S.; Sain, M. Injection-molded short hemp fiber/glass fiber-reinforced polypropylene hybrid composites—Mechanical, water absorption and thermal properties. J. Appl. Polym. Sci. 2007, 103, 2432–2441. [Google Scholar] [CrossRef]

- Zuhudi, N.Z.; Lin, R.J.; Jayaraman, K. Flammability, thermal and dynamic mechanical properties of bamboo–glass hybrid composites. J. Thermoplast. Compos. Mater. 2016, 29, 1210–1228. [Google Scholar] [CrossRef]

- Safri, S.N.; Sultan, M.T.; Jawaid, M.; Majid, M.A. Analysis of dynamic mechanical, low-velocity impact and compression after impact behaviour of benzoyl treated sugar palm/glass/epoxy composites. Compos. Struct. 2019, 226, 111308. [Google Scholar] [CrossRef]

- Satya, P.; Karan, M.; Kar, C.S.; Mahapatra, A.K.; Mahapatra, B.S. Assessment of molecular diversity and evolutionary relationship of kenaf (Hibiscus cannabinus L.), roselle (H. sabdariffa L.) and their wild relatives. Plant Syst. Evol. 2013, 299, 619–629. [Google Scholar] [CrossRef]

- Devadas, A.; Nirmal, U.; Hossen, J. Investigation into mechanical & tribological performance of kenaf fibre particle reinforced composite. Cogent Eng. 2018, 5, 1479210. [Google Scholar]

- Mohd, H.; Arifin, A.; Nasima, J.; Hazandy, A.H.; Khalil, A. Journey of kenaf in Malaysia: A review. Sci. Res. Essays 2014, 9, 458–470. [Google Scholar] [CrossRef]

- Ayadi, R.; Hanana, M.; Mzid, R.; Hamrouni, L.; Khouja, M.L.; Salhi Hanachi, A. Hibiscus cannabinus L.–Kenaf: A review paper. J. Nat. Fibers 2017, 14, 466–484. [Google Scholar]

- Akil, H.; Omar, M.F.; Mazuki, A.A.; Safiee, S.Z.; Ishak, Z.M.; Bakar, A.A. Kenaf fiber reinforced composites: A review. Mater. Des. 2011, 32, 4107–4121. [Google Scholar] [CrossRef]

- Kumar, R.; Hashmi, S.A.; Nimanpure, S.; Naik, A. Enhanced dynamic mechanical properties of kenaf epoxy composites. Adv. Mater. Proceeding 2017, 749–757. [Google Scholar] [CrossRef]

- Jeyanthi, S.; Rani, J.J. Improving mechanical properties by kenaf natural long fiber reinforced composite for automotive structures. J. Appl. Sci. Eng. 2012, 15, 275–280. [Google Scholar]

- Saba, N.; Paridah, M.T.; Jawaid, M. Mechanical properties of kenaf fibre reinforced polymer composite: A review. Constr. Build. Mater. 2015, 76, 87–96. [Google Scholar] [CrossRef]

- Adole, A.M.; Yatim, J.M.; Ramli, S.A.; Othman, A.; Mizal, N.A. Kenaf Fibre and Its Bio-Based Composites: A Conspectus. Pertanika J. Sci. Technol. 2019, 27, 297–329. [Google Scholar]

- Juliana, A.H.; Paridah, M.T.; Rahim, S.; Nor Azowa, I.; Anwar, U.M. Effect of adhesion and properties of kenaf (Hibiscus cannabinus L.) stem in particleboard performance. J. Adhes. Sci. Technol. 2014, 28, 546–560. [Google Scholar] [CrossRef]

- Kian, L.K.; Saba, N.; Jawaid, M.; Sultan, M.T. A review on processing techniques of bast fibers nanocellulose and its polylactic acid (PLA) nanocomposites. Int. J. Biol. Macromol. 2019, 121, 1314–1328. [Google Scholar] [CrossRef] [PubMed]

- Paridah, M.T.; Basher, A.B.; SaifulAzry, S.; Ahmed, Z. Retting process of some bast plant fibres and its effect on fibre quality: A review. BioResources 2011, 6, 5260–5281. [Google Scholar]

- Sisti, L.; Totaro, G.; Vannini, M.; Celli, A. Retting process as a pretreatment of natural fibers for the development of polymer composites. In Lignocellulosic Composite Materials; Springer International Publishing: Cham, Switzerland, 2018; pp. 97–135. [Google Scholar]

- Bacci, L.; Di Lonardo, S.; Albanese, L.; Mastromei, G.; Perito, B. Effect of different extraction methods on fiber quality of nettle (Urtica dioica L.). Text. Res. J. 2011, 81, 827–837. [Google Scholar] [CrossRef]

- Vetter, R.E.; Ribeiro, R.A.; Ribeiro, M.G.; Miranda, I.P. Studies on drying of imperial bamboo. Eur. J. Wood Wood Prod. 2015, 73, 411–414. [Google Scholar] [CrossRef]

- Fan, M.; Weclawski, B. Long natural fibre composites. In Advanced High Strength Natural Fibre Composites in Construction; Woodhead Publishing: Cambriadge, UK, 2017; pp. 141–177. [Google Scholar]

- Ayorinde, A.T.; Makanjuola, G.A.; Aluko, O.B.; Owolarafe, O.K.; Sanni, L.A. Performance evaluation of a kenaf decorticator. Agric. Eng. Int. CIGR J. 2019, 21, 192–202. [Google Scholar]

- Gao, S.; Han, G.; Jiang, W.; Zhang, Y.; Zhang, X. Steam explosion and alkali-oxygen combined effect for degumming of kenaf fiber. BioResources 2015, 10, 5476–5488. [Google Scholar] [CrossRef]

- Wong, L.Y.; Saad, W.Z.; Mohamad, R.; Tahir, P.M. Efficacy of Aspergillus fumigatus R6 Pectinase in Enzymatic Retting of Kenaf. BioResources 2016, 11, 10030–10041. [Google Scholar] [CrossRef][Green Version]

- Mohd Nurazzi, N.; Khalina, A.; Sapuan, S.M.; Dayang Laila, A.H.; Rahmah, M.; Hanafee, Z. A Review: Fibres, Polymer Matrices and Composites. Pertanika J. Sci. Technol. 2017, 25, 1085–1102. [Google Scholar]

- Sharba, M.J.; Leman, Z.; Sultan, M.T.; Ishak, M.R.; Hanim, M.A. Partial replacement of glass fiber by woven kenaf in hybrid composites and its effect on monotonic and fatigue properties. BioResources 2016, 11, 2665–2683. [Google Scholar] [CrossRef]

- Prince Engineering. 2018. Available online: https://www.build-on-prince.com/ (accessed on 12 July 2019).

- Shah, A.U.; Sultan, M.T.; Jawaid, M.; Cardona, F.; Talib, A.R. A review on the tensile properties of bamboo fiber reinforced polymer composites. BioResources 2016, 11, 10654–10676. [Google Scholar]

- Landesmann, A.; Seruti, C.A.; Batista, E.D. Mechanical properties of glass fiber reinforced polymers members for structural applications. Mater. Res. 2015, 18, 1372–1383. [Google Scholar] [CrossRef]

- Gibhardt, D.; Doblies, A.; Meyer, L.; Fiedler, B. Effects of hygrothermal ageing on the interphase, fatigue, and mechanical properties of glass fibre reinforced epoxy. Fibers 2019, 7, 55. [Google Scholar] [CrossRef]

- Ramesh, M.; Nijanthan, S. Mechanical property analysis of kenaf–glass fibre reinforced polymer composites using finite element analysis. Bull. Mater. Sci. 2016, 39, 147–157. [Google Scholar] [CrossRef]

- Sapiai, N.; Jumahat, A.; Mahmud, J. Flexural and tensile properties of kenaf/glass fibres hybrid composites filled with carbon nanotubes. J. Teknol. 2015, 76, 115–120. [Google Scholar] [CrossRef][Green Version]

- Salleh, Z.; Berhan, M.N.; Hyie, K.M.; Isaac, D.H. Cold-pressed kenaf and fibreglass hybrid composites laminates: Effect of fibre types. World Acad. Sci. Eng. Technol. Int. Sci. Index 2012, 71, 11. [Google Scholar]

- Amel, B.A.; Paridah, M.T.; Sudin, R.; Anwar, U.M.; Hussein, A.S. Effect of fiber extraction methods on some properties of kenaf bast fiber. Ind. Crop. Prod. 2013, 46, 117–123. [Google Scholar] [CrossRef]

- Yuhazri, M.Y.; Phongsakorn, P.T.; Haeryip Sihombing, I.P.; Jeefferie, A.R.; Puvanasvaran, A.P.; Kamarul, A.M.; Kannan, R. Mechanical properties of kenaf/polyester composites. Int. J. Eng. Technol. 2011, 11, 127–131. [Google Scholar]

- Bakar, N.H.; Hyie, K.M.; Jumahat, A.; Latip, E.N.; Kalam, A.N.; Salleh, Z. Influence of Different Matrices on The Tensile and Impact Properties of Treated Kenaf Composites. Adv. Mater. Res. 2016, 1133, 136–140. [Google Scholar] [CrossRef]

- Bakar, N.H.; Hyie, K.M.; Mohamed, A.F.; Salleh, Z.; Kalam, A. Kenaf fibre composites using thermoset epoxy and polyester polymer resins: Energy absorbed versus tensile properties. Mater. Res. Innov. 2014, 18, 505–509. [Google Scholar] [CrossRef]

- Salman, S.D.; Leman, Z.; Sultan, M.T.; Ishak, M.R.; Cardona, F. The effects of orientation on the mechanical and morphological properties of woven kenaf-reinforced poly vinyl butyral film. BioResources 2016, 11, 1176–1188. [Google Scholar] [CrossRef]

- Salman, S.D.; Leman, Z.; Sultan, M.T.; Ishak, M.R.; Cardona, F. Influence of fiber content on mechanical and morphological properties of woven kenaf reinforced PVB film produced using a hot press technique. Int. J. Polym. Sci. 2016. [Google Scholar] [CrossRef]

- Mohd Radzuan, N.A.; Ismail, N.F.; Radzi, F.M.; Khairul, M.; Razak, Z.B.; Tharizi, I.B.; Sulong, A.B.; Che Haron, C.H.; Muhamad, N. Kenaf Composites for Automotive Components: Enhancement in Machinability and Moldability. Polymers 2019, 11, 1707. [Google Scholar] [CrossRef] [PubMed]

- Pandian, A.; Sultan, M.T.H.; Marimuthu, U.; Shah, A.U.M. Low Velocity Impact Studies on Fibre-Reinforced Polymer Composites and Their Hybrids–Review In Encyclopedia of Renewable and Sustainable Materials; Elsevier: Oxford, UK, 2019; pp. 1–12. [Google Scholar]

- Ismail, M.F.; Sultan, M.T.; Hamdan, A.; Shah, A.U.; Jawaid, M. Low velocity impact behaviour and post-impact characteristics of kenaf/glass hybrid composites with various weight ratios. J. Mater. Res. Technol. 2019, 8, 2662–2673. [Google Scholar] [CrossRef]

- Razali, N.; Sultan, M.T.; Mustapha, F.; Yidris, N.; Ishak, M.R. Impact damage on composite structures—A review. Int. J. Eng. Sci. 2014, 3, 8–20. [Google Scholar]

- Maimi, P.; Rodríguez, H.; Blanco, N.; Mayugo, J.A. Numerical modeling of matrix cracking and intralaminar failure in advanced composite materials. In Numerical Modelling of Failure in Advanced Composite Materials; Woodhead Publishing: Cambriadge, UK, 2015; pp. 175–192. [Google Scholar]

- Boria, S.; Scattina, A.; Belingardi, G. Impact behavior of a fully thermoplastic composite. Compos. Struct. 2017, 167, 63–75. [Google Scholar] [CrossRef]

- Tan, R.; Xu, J.; Sun, W.; Liu, Z.; Guan, Z.; Guo, X. Relationship Between Matrix Cracking and Delamination in CFRP Cross-Ply Laminates Subjected to Low Velocity Impact. Materials 2019, 12, 3990. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillò, J.; D’Altilia, S.; Valente, T.; Santulli, C.; Touchard, F.; Chocinski-Arnault, L.; Mellier, D.; Lampani, L.; Gaudenzi, P. Damage tolerance of carbon/flax hybrid composites subjected to low velocity impact. Compos. Part B: Eng. 2016, 91, 144–153. [Google Scholar] [CrossRef]

- Sultan, M.T.; Worden, K.; Staszewski, W.J.; Pierce, S.G.; Dulieu-Barton, J.M.; Hodzic, A. Impact damage detection and quantification in CFRP laminates; a precursor to machine learning. In Proceedings of the 7th International Workshop on Structural Health Monitoring (IWSHM 2009), Stanford, CA, USA, 9–11 September 2009; pp. 1528–1537. [Google Scholar]

- Wan Busu, W.N.; Anuar, H.; Ahmad, S.H.; Rasid, R.; Jamal, N.A. The mechanical and physical properties of thermoplastic natural rubber hybrid composites reinforced with Hibiscus cannabinus, L and short glass fiber. Polym. Plast. Technol. Eng. 2010, 49, 1315–1322. [Google Scholar] [CrossRef]

- Salman, S.D.; Sharba, M.J.; Leman, Z.; Sultan, M.T.; Ishak, M.R.; Cardona, F. Physical, mechanical, and morphological properties of woven kenaf/polymer composites produced using a vacuum infusion technique. Int. J. Polym. Sci. 2015, 2015, 894565. [Google Scholar] [CrossRef] [PubMed]

- Taufiq, M.J.; Mansor, M.R.; Mustafa, Z. Characterisation of wood plastic composite manufactured from kenaf fibre reinforced recycled-unused plastic blend. Compos. Struct. 2018, 189, 510–515. [Google Scholar] [CrossRef]

- Ismail, A.S.; Jawaid, M.; Sultan, M.T.; Hassan, A. Physical and Mechanical Properties of Woven Kenaf/Bamboo Fiber Mat Reinforced Epoxy Hybrid Composites. BioResources 2019, 14, 1390–1404. [Google Scholar]

- Yong, C.K.; Ching, Y.C.; Chuah, C.H.; Liou, N.S. Effect of fiber orientation on mechanical properties of kenaf-reinforced polymer composite. BioResources 2015, 10, 2597–2608. [Google Scholar] [CrossRef]

- El-Shekeil, Y.A.; Salit, M.S.; Abdan, K.; Zainudin, E.S. Development of a new kenaf bast fiber-reinforced thermoplastic polyurethane composite. BioResources 2011, 6, 4662–4672. [Google Scholar]

- Khalil, H.A.; Suraya, N.L.; Atiqah, N.; Jawaid, M.; Hassan, A. Mechanical and thermal properties of chemical treated kenaf fibres reinforced polyester composites. J. Compos. Mater. 2013, 47, 3343–3350. [Google Scholar] [CrossRef]

- Hamidon, M.H.; Sultan, M.T.; Ariffin, A.H.; Shah, A.U. Effects of fibre treatment on mechanical properties of kenaf fibre reinforced composites: A review. J. Mater. Res. Technol. 2019, 8, 3327–3337. [Google Scholar] [CrossRef]

- Noor Azammi, A.M.; Sapuan, S.M.; Ishak, M.R.; Sultan, M.T. Mechanical properties of kenaf fiber thermoplastic polyurethane-natural rubber composites. Polimery 2018, 63, 524–530. [Google Scholar] [CrossRef]

- Alavudeen, A.; Rajini, N.; Karthikeyan, S.; Thiruchitrambalam, M.; Venkateshwaren, N. Mechanical properties of banana/kenaf fiber-reinforced hybrid polyester composites: Effect of woven fabric and random orientation. Mater. Des. 2015, 66, 246–257. [Google Scholar] [CrossRef]

- Islam, M.R.; Beg, M.D.; Gupta, A. Characterization of laccase-treated kenaf fibre reinforced recycled polypropylene composites. BioResources 2013, 8, 3753–3770. [Google Scholar] [CrossRef][Green Version]

- Salman, S.D.; Leman, Z.; Sultan, M.T.; Ishak, M.R.; Cardona, F. Kenaf/synthetic and Kevlar®/cellulosic fiber-reinforced hybrid composites: A review. BioResources 2015, 10, 8580–8603. [Google Scholar] [CrossRef]

- Yahaya, R.; Sapuan, S.M.; Jawaid, M.; Leman, Z.; Zainudin, E.S. Effect of layering sequence and chemical treatment on the mechanical properties of woven kenaf–aramid hybrid laminated composites. Mater. Des. 2015, 67, 173–179. [Google Scholar] [CrossRef]

- Mostafa, N.H.; Ismarrubie, Z.N.; Sapuan, S.M.; Sultan, M.T. Effect of equi-biaxially fabric prestressing on the tensile performance of woven E-glass/polyester reinforced composites. J. Reinf. Plast. Compos. 2016, 35, 1093–1103. [Google Scholar] [CrossRef]

- Heckadka, S.S.; Nayak, S.Y.; Narang, K.; Vardhan Pant, K. Chopped strand/plain weave E-glass as reinforcement in vacuum bagged epoxy composites. J. Mater. 2015, 2015, 957043. [Google Scholar] [CrossRef][Green Version]

- Thirukumaran, M.; Kannan, L.V.; Sankar, I. Study on mechanical properties of glass wool/epoxy reinforced composite. Int. J. Comput. Aided Eng. Technol. 2018, 10, 15–25. [Google Scholar] [CrossRef]

- Salman, S.D.; Leman, Z.; Sultan, M.T.; Ishak, M.R.; Cardona, F. Effect of kenaf fibers on trauma penetration depth and ballistic impact resistance for laminated composites. Text. Res. J. 2017, 87, 2051–2065. [Google Scholar] [CrossRef]

- Davoodi, M.M.; Sapuan, S.M.; Ahmad, D.; Aidy, A.; Khalina, A.; Jonoobi, M. Effect of polybutylene terephthalate (PBT) on impact property improvement of hybrid kenaf/glass epoxy composite. Mater. Lett. 2012, 67, 5–7. [Google Scholar] [CrossRef]

- Mohammed, M.; Rozyanty, A.R.; Beta, B.O.; Adam, T.; Osman, A.F.; Salem, I.A.; Dahham, O.S.; Al-Samarrai, M.N.; Mohammed, A.M. Influence of weathering effect in natural environment on thermal properties hybrid kenaf blast/glass fibre and unsaturated polyester composite. J. Phys. Conf. Ser. 2017, 908, 012004. [Google Scholar] [CrossRef]

- Ramnath, B.V.; Rajesh, S.; Elanchezhian, C.; Shankar, A.S.; Pandian, S.P.; Vickneshwaran, S.; Rajan, R.S. Investigation on mechanical behaviour of twisted natural fiber hybrid composite fabricated by vacuum assisted compression molding technique. Fibers Polym. 2016, 17, 80–87. [Google Scholar] [CrossRef]

- Jamal, S.K.; Hassan, S.A.; Wong, K.J.; Yahya, M.Y. Flexural and interlaminar shear study of hybrid woven kenaf/recycled GFRP (rGFRP) composites subjected to bending load. Int. J. Adv. Appl. Sci. 2017, 4, 45–50. [Google Scholar] [CrossRef]

- Elanchezhian, C.; Ramnath, B.V.; Kaosik, R.; Nellaiappan, T.K.; Santhosh Kumar, K.; Kavirajan, P.; Sughan, M.U. Evaluation of Mechanical Properties of Kenaf Based Hybrid Composite for Automotive Components Replacement. ARPN J. Eng. Appl. Sci. 2006, 10, 5518–5523. [Google Scholar]

- Asumani, O.M.; Reid, R.G.; Paskaramoorthy, R. The effects of alkali–silane treatment on the tensile and flexural properties of short fibre non-woven kenaf reinforced polypropylene composites. Compos. Part A: Appl. Sci. Manuf. 2012, 43, 1431–1440. [Google Scholar] [CrossRef]

- Majid, D.L.; Jamal, Q.M.; Manan, N.H. Low-velocity impact performance of glass fiber, kenaf fiber, and hybrid glass/kenaf fiber reinforced epoxy composite laminates. BioResources 2018, 13, 8839–8852. [Google Scholar] [CrossRef]

| Kingdom | Plantae |

|---|---|

| Class | Magnoliopsida |

| Order | Malvales |

| Family | Malvaceae |

| Genus | Hibiscus |

| Species | Hibiscus cannabinus L. |

| C-Glass | D-Glass | E-Glass | S-Glass | Ref. | |

|---|---|---|---|---|---|

| Density (g/cm3) | 2.56 | 2.11 | 2.54 | 2.53 | [34] |

| Tensile strength (MPa) | 3300 | 2500 | 3400 | 4600 | |

| Young’s Modulus (MPa) | 69 | 55 | 72 | 89 | |

| Elongation (%) | 4.8 | 4.5 | 4.7 | 5.2 |

| Kenaf | Glass | |

|---|---|---|

| Density (g/m3) | 1.45 | 2.55 |

| Tensile strength (MPa) | 930 | 3400 |

| Elastic modulus (GPa) | 53 | 71 |

| Elongation at break (%) | 1.6 | 3.4 |

| References | [18,35] | [36,37] |

| Materials | Mechanical Properties | Ref. | |

|---|---|---|---|

| Tensile | Flexural | ||

| 90° fibre orientation of kenaf + chopped strand glass fibre reinforced epoxy | 69.86 MPa | 162.566 MPa | [38] |

| kenaf fibre yarn + woven glass fibre reinforced epoxy | 65.29 MPa | 115.71 MPa | [39] |

| Woven kenaf fibre + glass fibre mat reinforced unsaturated polyester | 85.49 MPa | 124.07 MPa | [40] |

| Composites | Parameters | Impact Strength | Ref. | |

|---|---|---|---|---|

| Kenaf + polyester | Chemical treatment | Untreated | 2.61 kJ/m2 | [42] |

| Treated with 6% NaOH | 15.77 kJ/m2 | |||

| Treated with 9% NaOH | 6.92 kJ/m2 | |||

| Kenaf + polyester | Untreated | 5.4 kJ/m2 | [62] | |

| Propionic anhydride | 7.7 kJ/m2 | |||

| Succinic anhydride | 7.3 kJ/m2 | |||

| Kenaf/banana + unsaturated polyester | Untreated | 23 kJ/m2 | [65] | |

| Treated with alkali | 26 kJ/m2 | |||

| Treated with sodium lauryl sulfate | 28 kJ/m2 | |||

| Kenaf + recycled polypropylene | Enzymatic treatment | Untreated | 22.51 J/m2 | [66] |

| Treated with laccase enzyme | 26.13 J/m2 |

| Kenaf Fibre | Glass Fibre | Matrix | Fabrication Method | Ref. |

|---|---|---|---|---|

| Woven kenaf fiber | Woven E-glass fiber | Epoxy | Hand lay-up | [73] |

| Twisted long kenaf fiber | Glass fiber | Epoxy | Hand lay-up | [74] |

| Kenaf fiber (direction 0°, 90°) | Glass fiber direction (0°, 90°) | Epoxy | Hand lay-up | [38] |

| Twisted kenaf fiber | Woven glass fiber | Epoxy | Vacuum pump Compression moulding | [75] |

| Kenaf fibre | Woven fibre glass | Polyester | Hand lay-up Cold press | [76] |

| Kenaf mat (20 cm × 20 cm) | Glass fiber (20 cm × 20 cm) | Unsaturated polyester | Hand lay-up Compression | [77] |

| Kenaf fibre | Glass fibre | Unsaturated polyester | Cold pressure hand lay-up | [78] |

| Non- woven kenaf mat | E-glass fibre | Polypropylene | Compression moulding | [79] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad Nadzri, S.N.Z.; Hameed Sultan, M.T.; Md Shah, A.U.; Safri, S.N.A.; Basri, A.A. A Review on the Kenaf/Glass Hybrid Composites with Limitations on Mechanical and Low Velocity Impact Properties. Polymers 2020, 12, 1285. https://doi.org/10.3390/polym12061285

Ahmad Nadzri SNZ, Hameed Sultan MT, Md Shah AU, Safri SNA, Basri AA. A Review on the Kenaf/Glass Hybrid Composites with Limitations on Mechanical and Low Velocity Impact Properties. Polymers. 2020; 12(6):1285. https://doi.org/10.3390/polym12061285

Chicago/Turabian StyleAhmad Nadzri, Seri Nur Zumaimi, Mohamed Thariq Hameed Sultan, Ain Umaira Md Shah, Syafiqah Nur Azrie Safri, and Adi Azriff Basri. 2020. "A Review on the Kenaf/Glass Hybrid Composites with Limitations on Mechanical and Low Velocity Impact Properties" Polymers 12, no. 6: 1285. https://doi.org/10.3390/polym12061285

APA StyleAhmad Nadzri, S. N. Z., Hameed Sultan, M. T., Md Shah, A. U., Safri, S. N. A., & Basri, A. A. (2020). A Review on the Kenaf/Glass Hybrid Composites with Limitations on Mechanical and Low Velocity Impact Properties. Polymers, 12(6), 1285. https://doi.org/10.3390/polym12061285