Influence of Polymer Composites and Memory Foam on Energy Absorption in Vehicle Application

Abstract

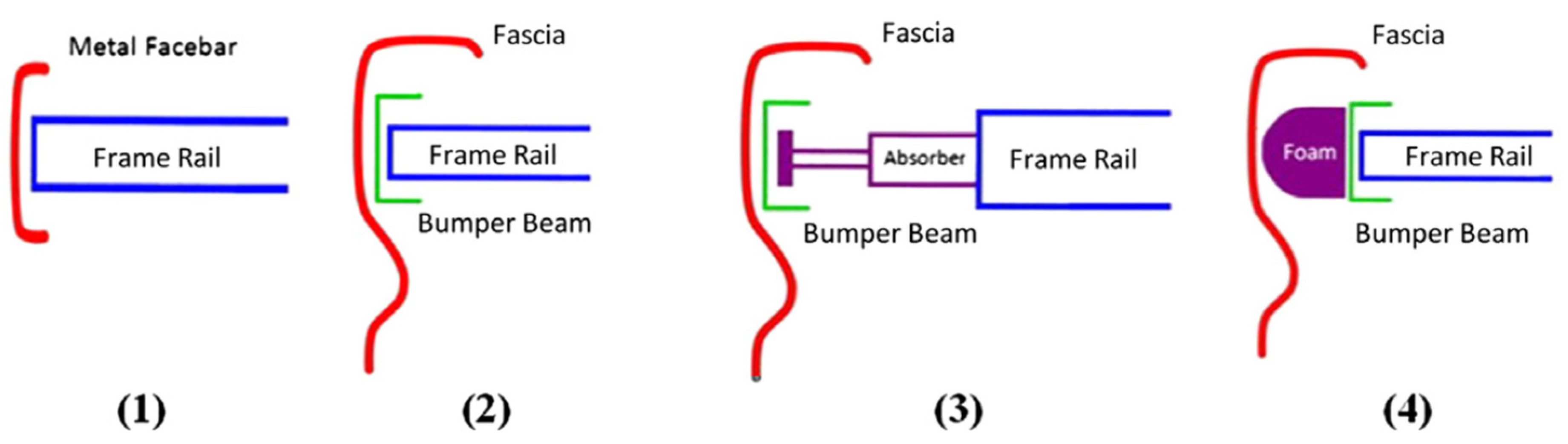

1. Introduction

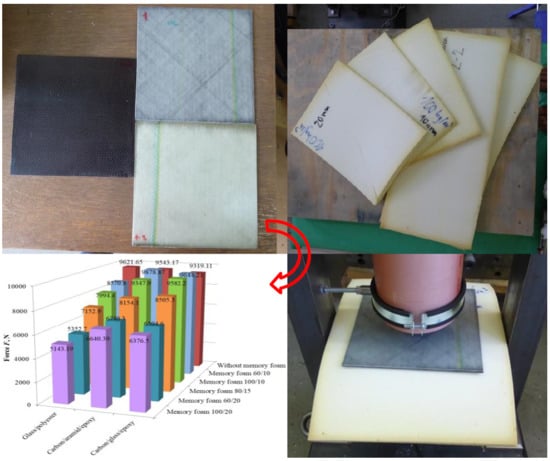

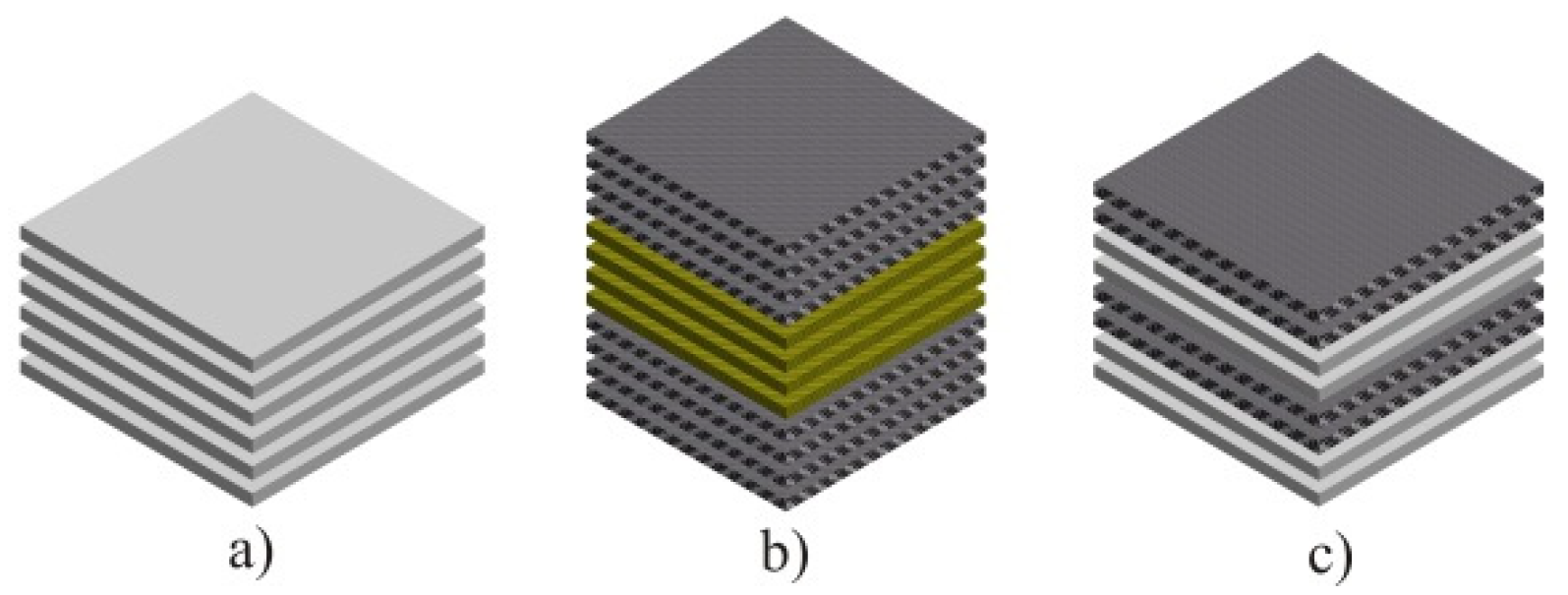

2. Materials and Production of Hybrid Composites

2.1. Materials for Composite Plates

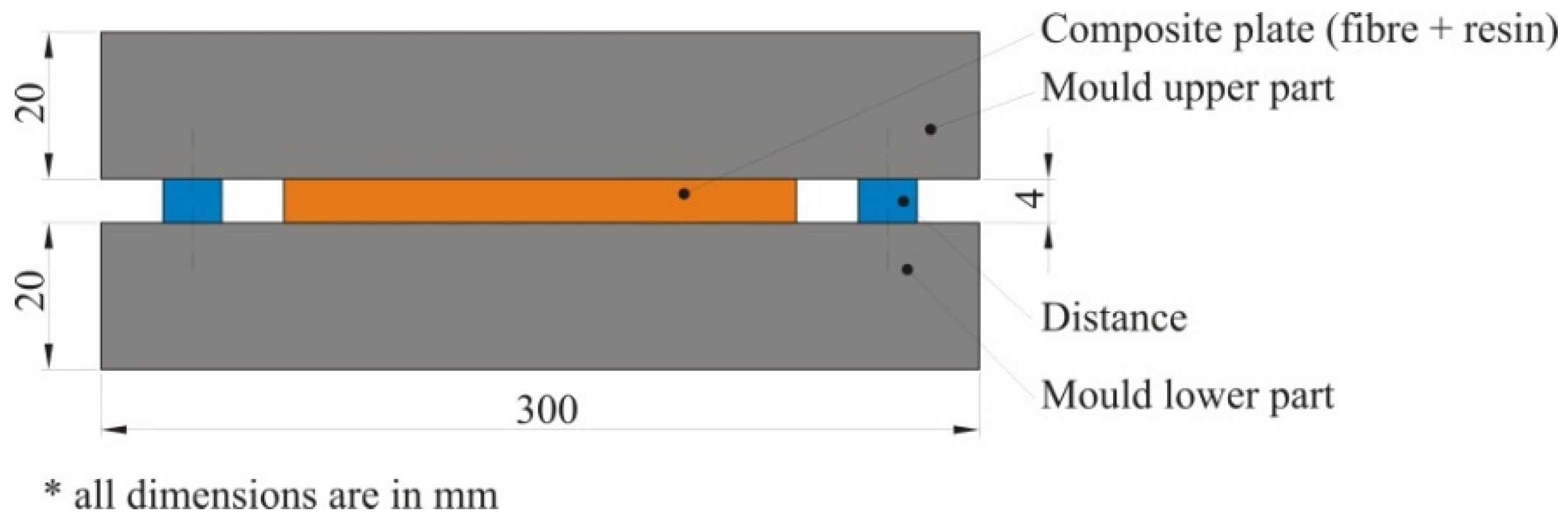

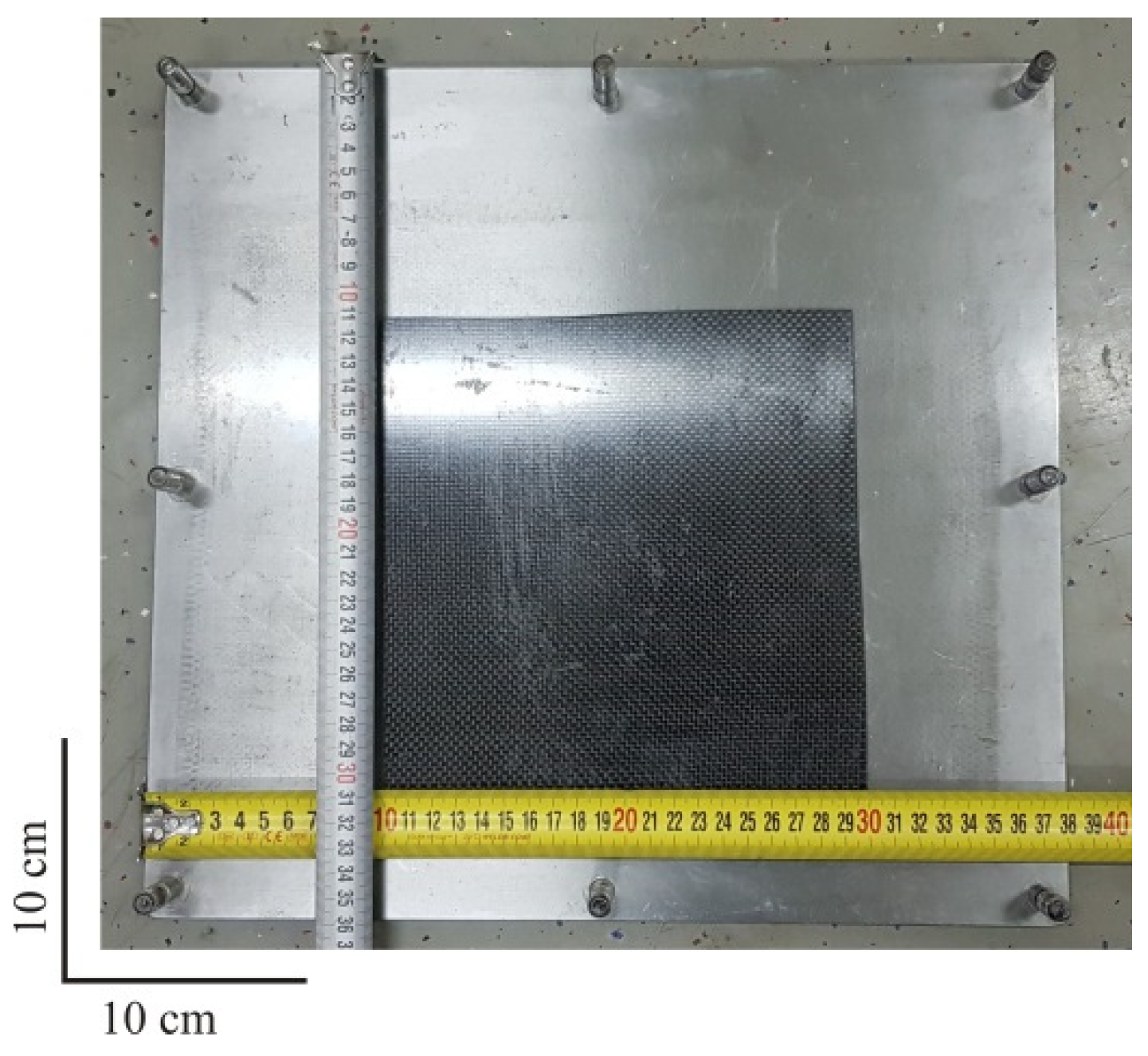

2.2. Production of Composites Plates

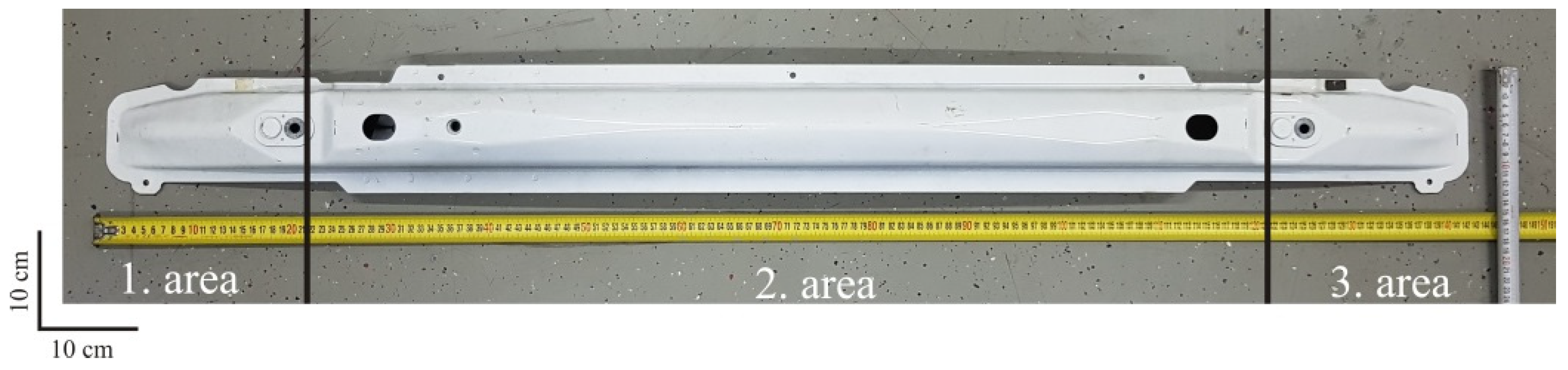

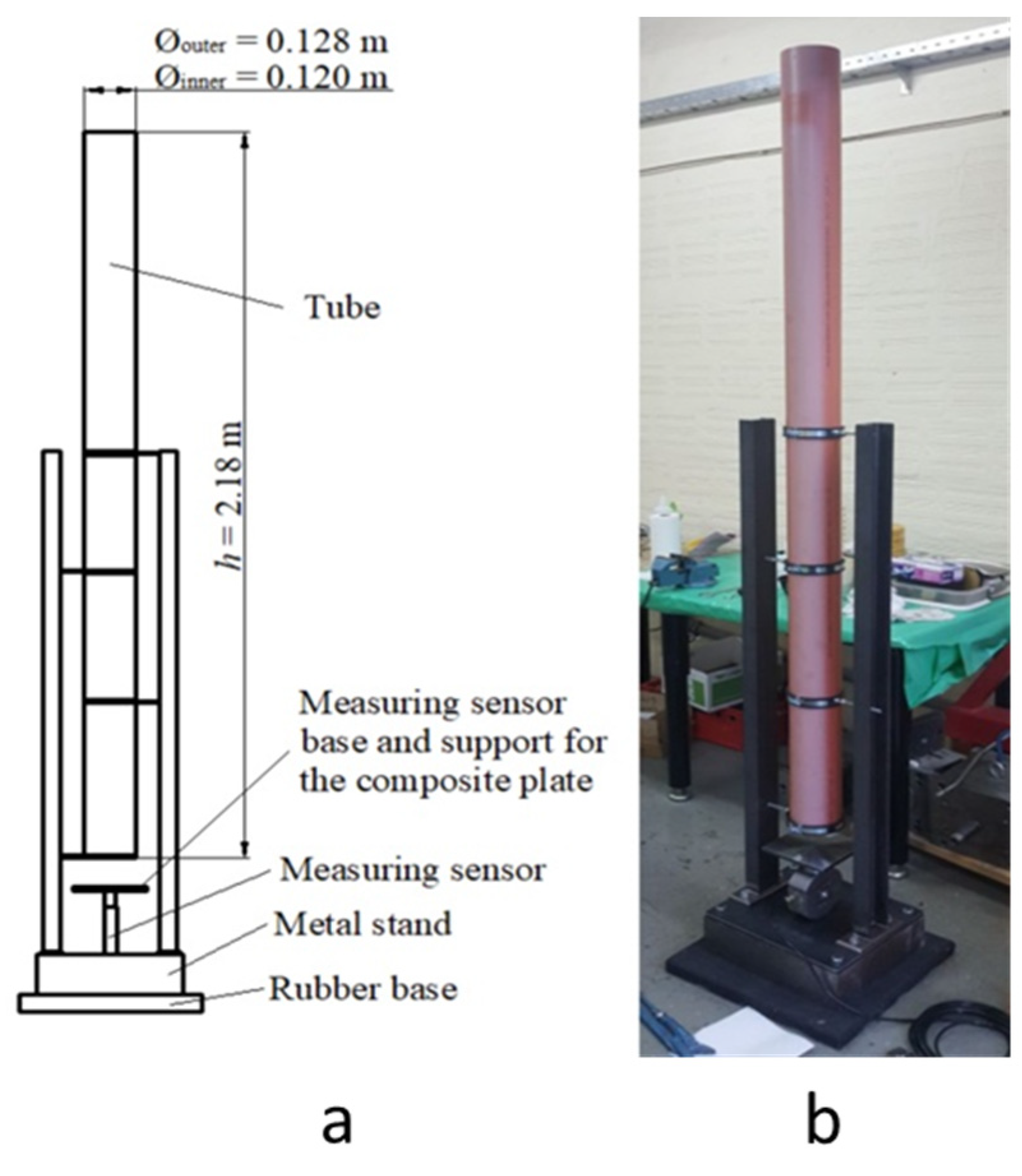

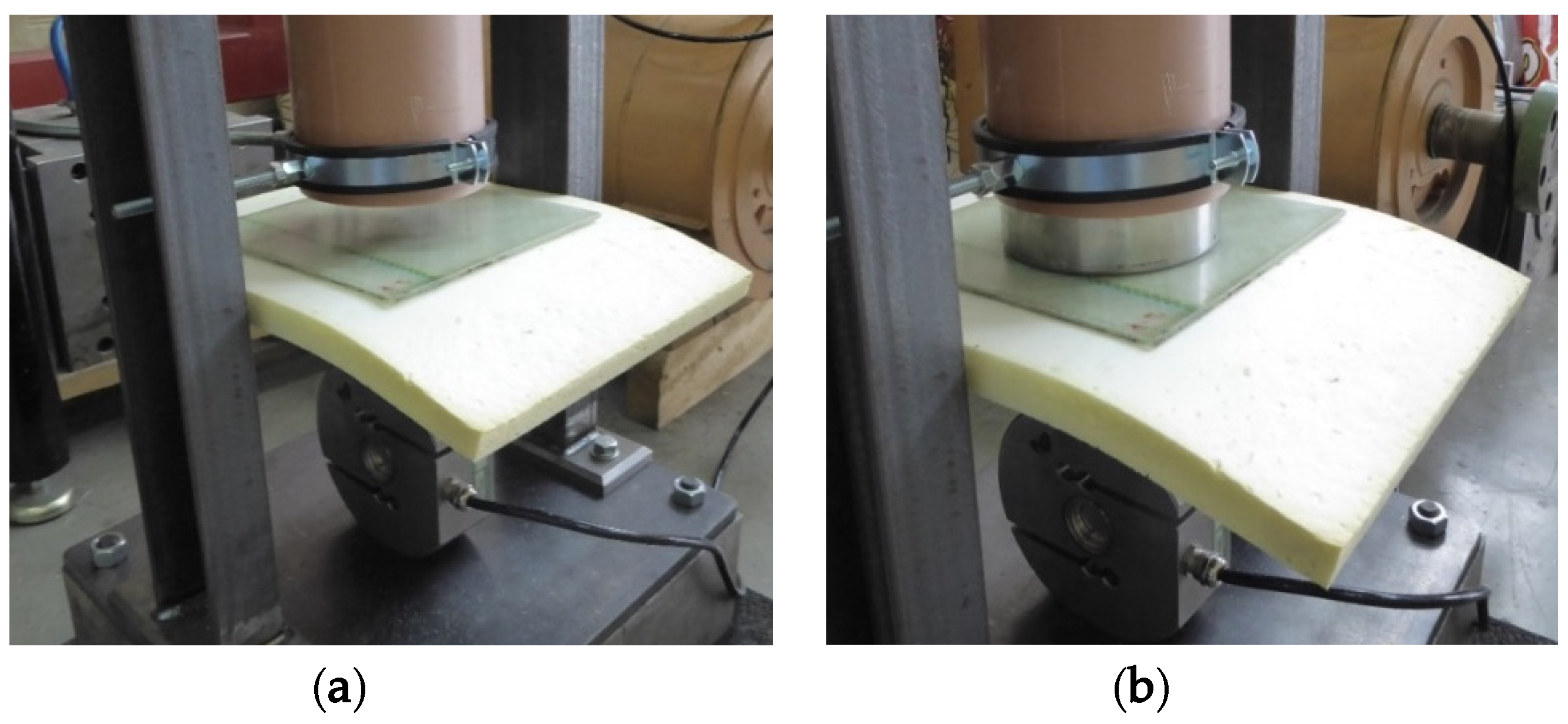

3. Description of an Absorption Test

4. Results of Absorption Test

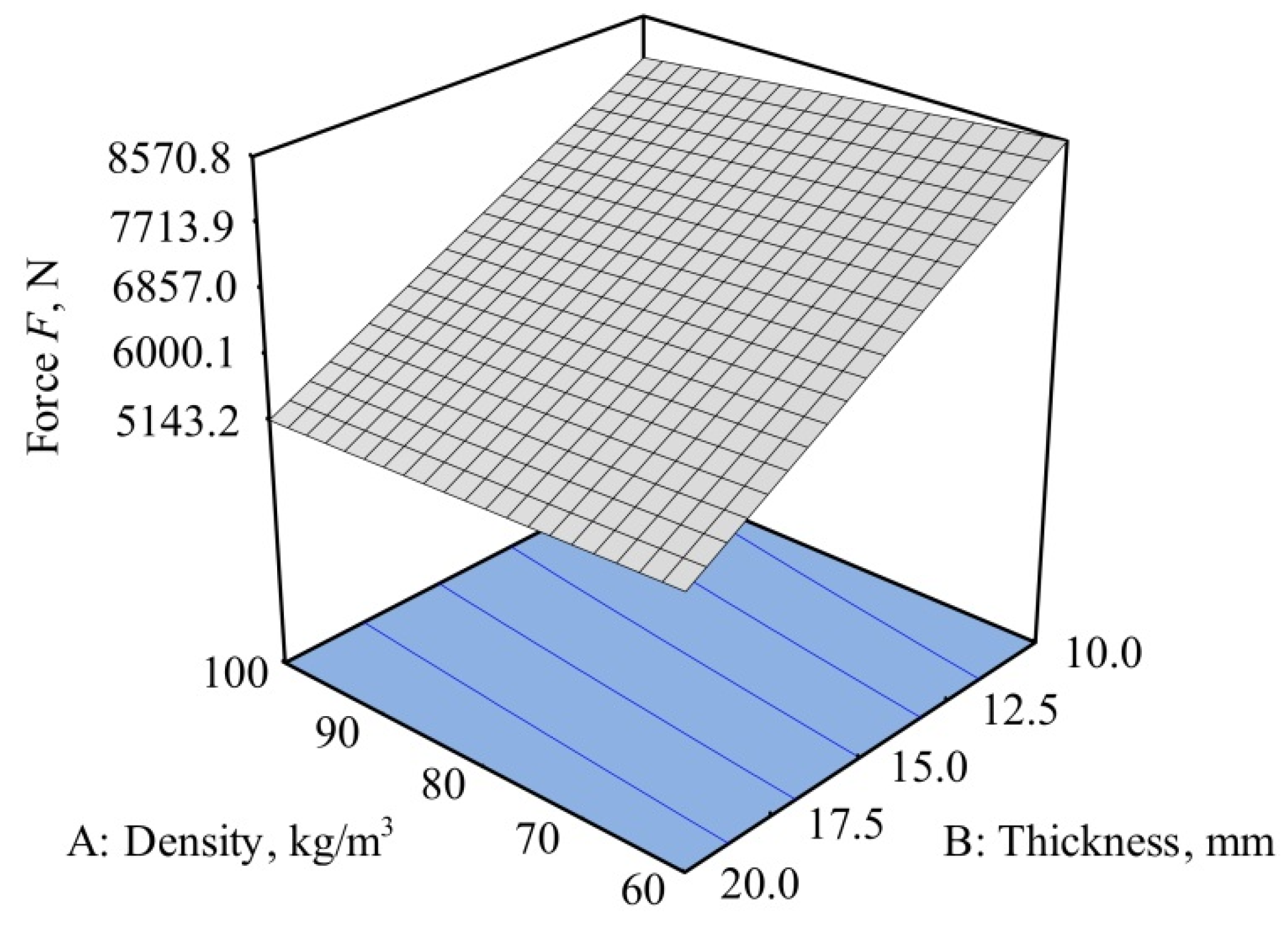

4.1. Results for Glass Fiber/Polyester Composite

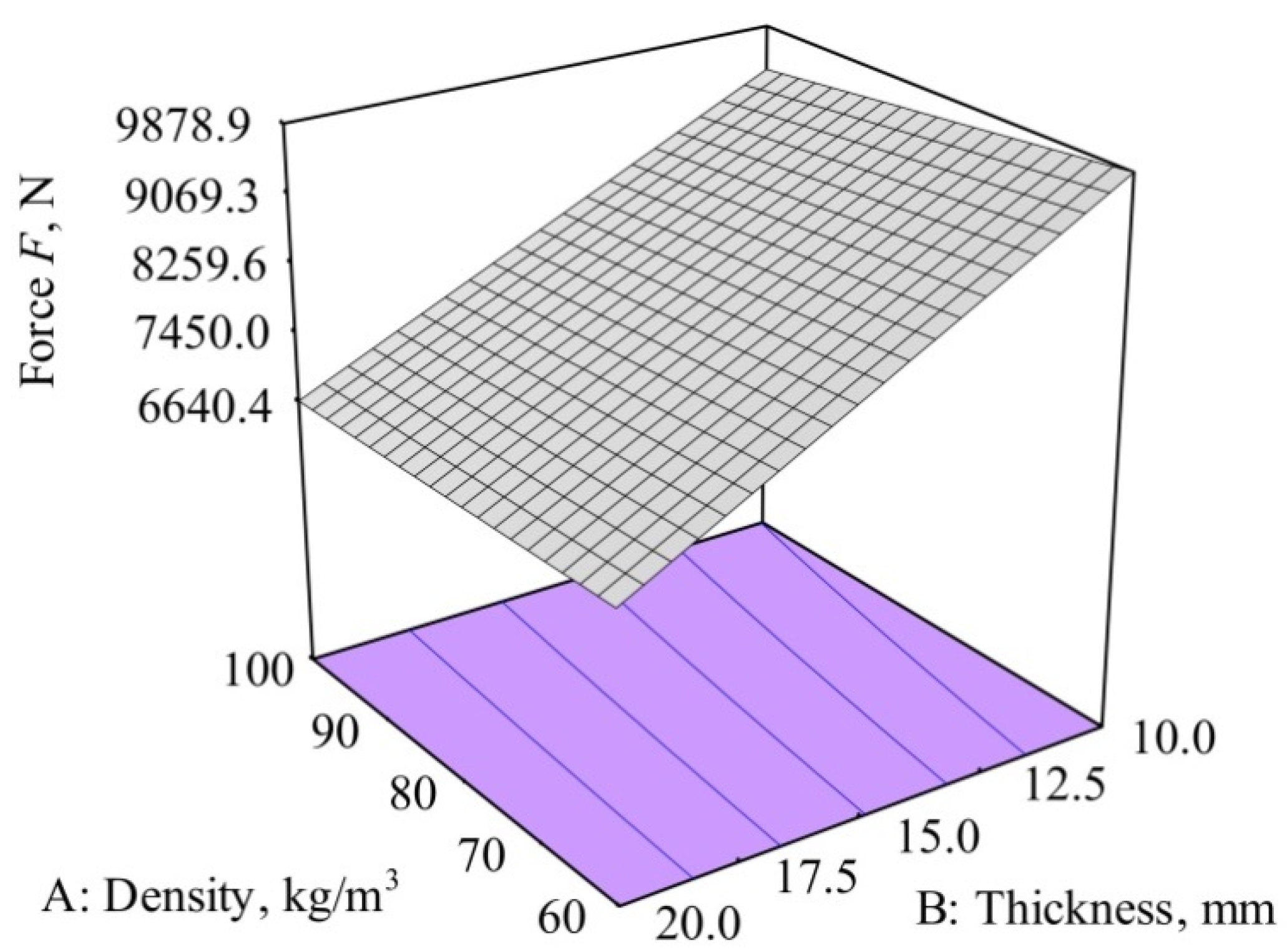

4.2. Results for Carbon/Aramid Fiber/Epoxy Hybrid Composite

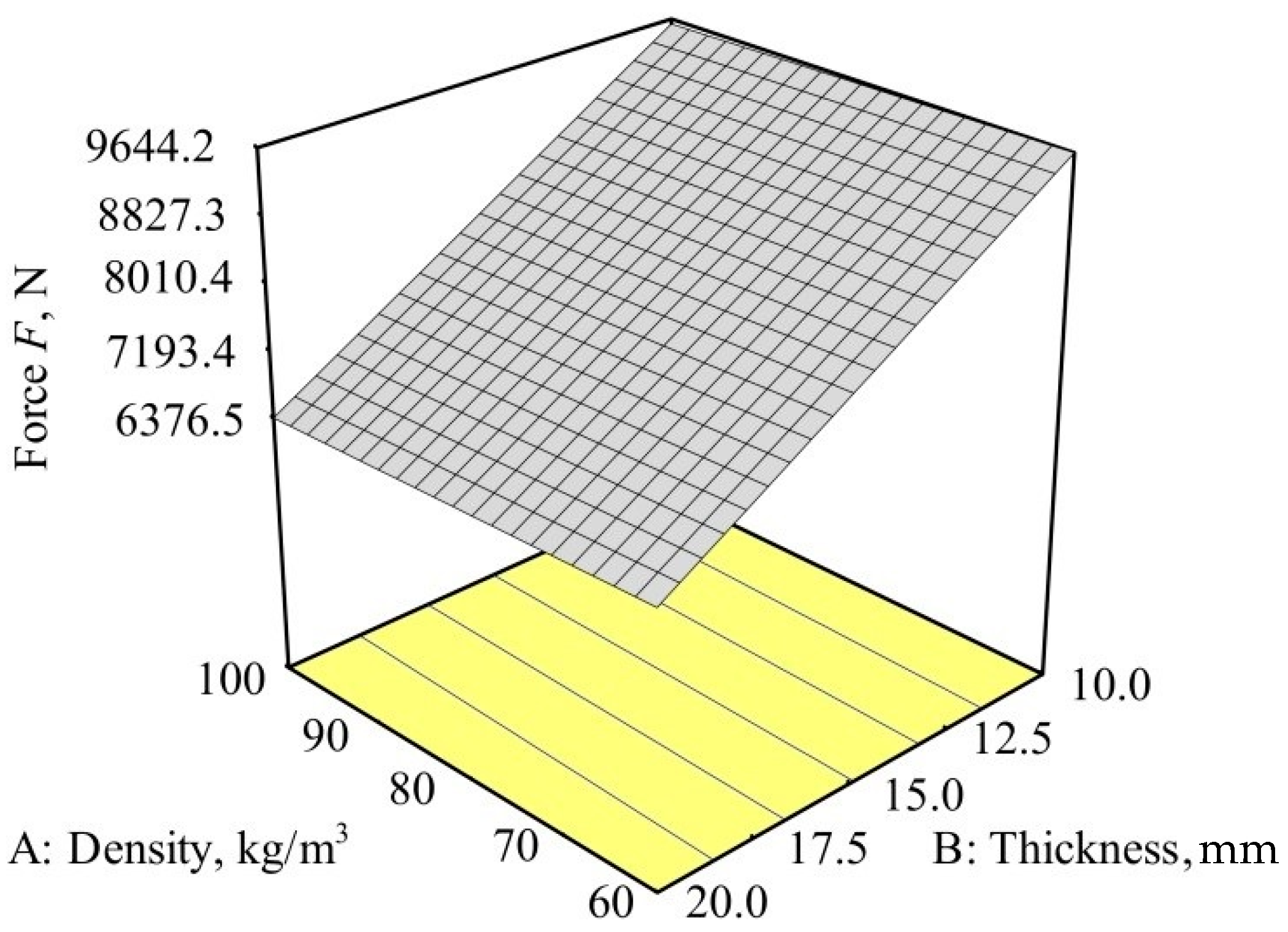

4.3. Results for Carbon/Glass Fiber/Epoxy Hybrid Composite

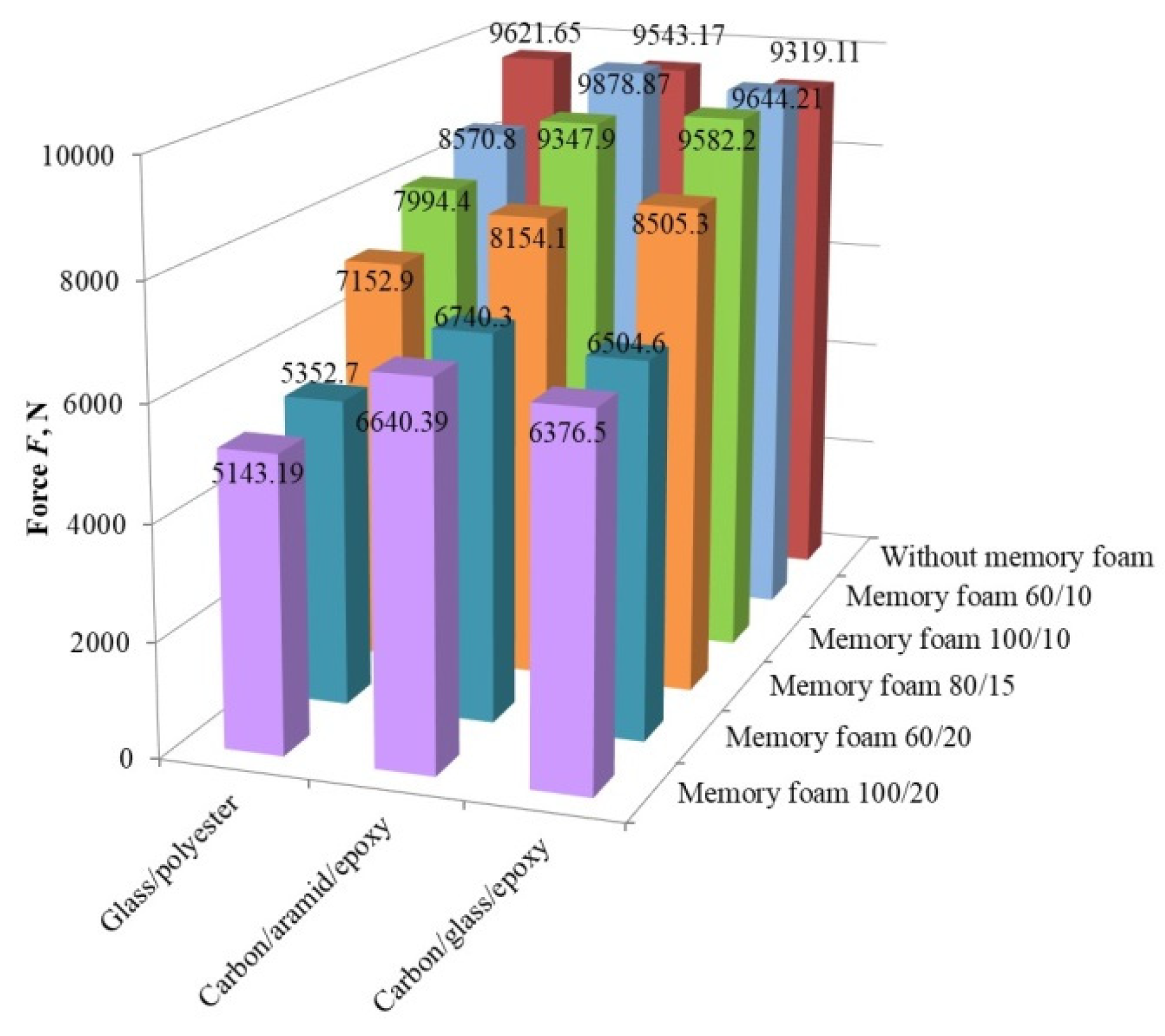

4.4. Discussion of the Results

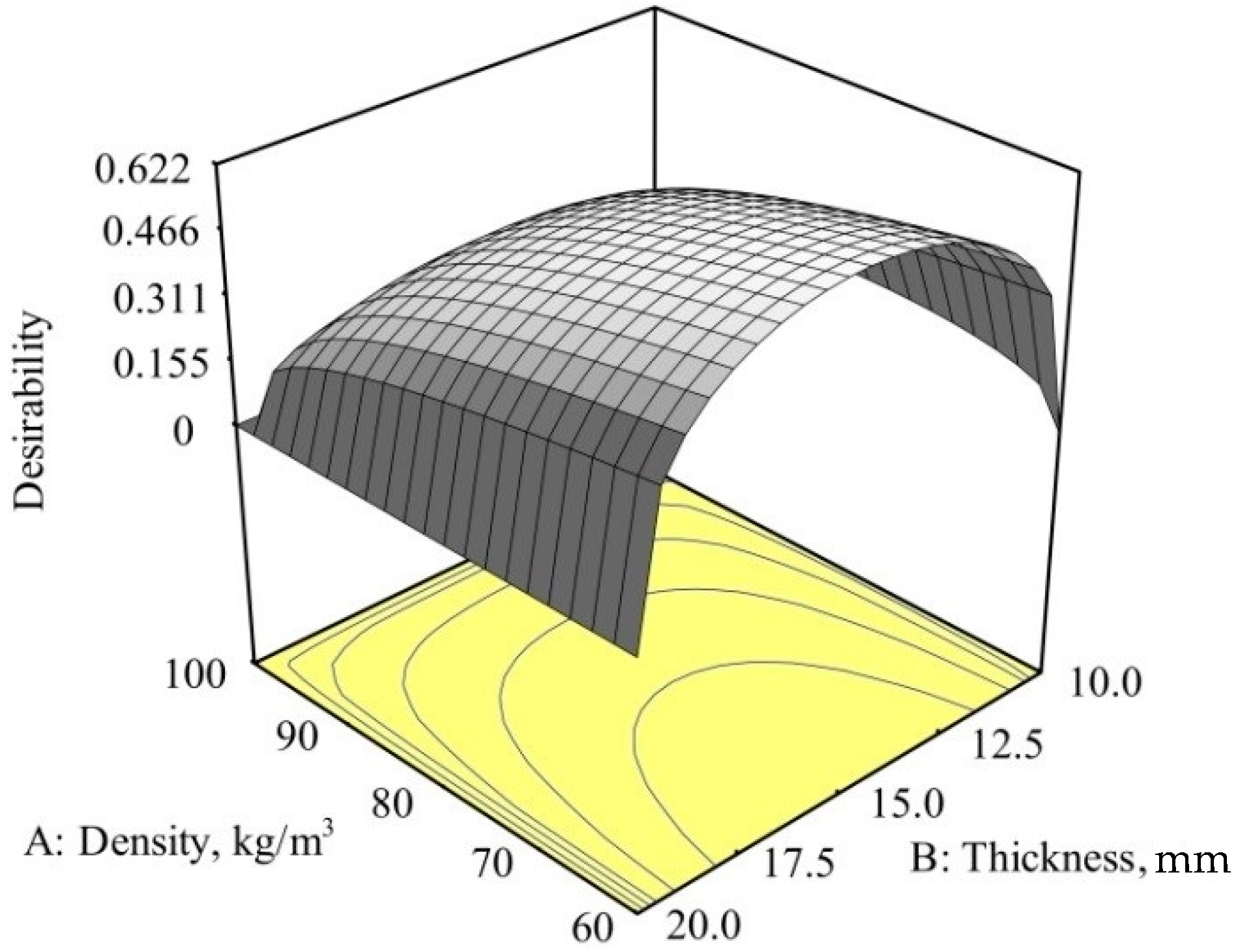

Optimization

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Prabhakaran, S.; Chinnarasu, K.; Senthil, K.M. Design and Fabrication of Composite Bumper for Light Passenger Vehicles. Int. J. Mod. Eng. Res. 2012, 2, 2552–2556. [Google Scholar]

- Tomašić, D.; Ilinčić, P.; Pilipović, A. Influence of layers lay-up on the mechanical properties of hybrid composites in field of aeronautics. Polim. J. Plast. Rubber 2015, 36, 5–10. [Google Scholar]

- Chatys, R.; Panich, A.; Jurecki, R.S.; Kleinhofs, M. Composite materials having a layer structure of “sandwich” construction as above used in car safety bumpers. In Proceedings of the 11th International Scientific and Technical Conference on Automotive Safety, Casta Papiernicka, Slovakia, 18–20 April 2018. [Google Scholar]

- Davoodi, M.; Sapuan, S.; Ahmad, D.; Ali, A.; Khalina, A.; Jonoobi, M. Mechanical properties of hybrid kenaf/glass reinforced epoxy composite for passenger car bumper beam. Mater. Des. 2010, 31, 4927–4932. [Google Scholar] [CrossRef]

- Wang, T.; Li, Y. Design and analysis of automotive carbon fiber composite bumper beam based on finite element analysis. Adv. Mech. Eng. 2015, 7, 1–12. [Google Scholar] [CrossRef]

- Ramyasree, L.; Venkataramaniah, D.; Naveen Kumar, G. Impact Analysis of Frontal Car Bumper using Long Fibre Reinforced Thermoplastics. Int. J. Curr. Eng. Technol. 2015, 5, 1861–1865. [Google Scholar]

- Kleisner, V.; Zemčik, R. Analysis of Composite Car Bumper Reinforcement. Appl. Comput. Mech. 2009, 3, 287–296. [Google Scholar]

- Abdulqadir, S.F. Design a new energy absorber longitudinal member and compare with S-shaped design to enhance the energy absorption capability. Alex. Eng. J. 2018, 57, 3405–3418. [Google Scholar] [CrossRef]

- Davoodi, M.M.; Sapuan, S.M.; Aidy, A.; Abu Osman, N.A.; Oshkour, A.A.; Wan Abas, W.A.B. Development process of new bumper beam for passenger car: A review. Mater. Des. 2012, 40, 304–313. [Google Scholar] [CrossRef]

- Schmidová, N.; Zavřelová, T.; Vašíček, M.; Zavadil, F.; Růžička, M.; Rund, M. Development of Adaptable CFRP Energy Absorbers for Car Crashes. Mater. Today 2018, 26784–26791. [Google Scholar] [CrossRef]

- Godara, S.S.; Nagar, S.N. Analysis of frontal bumper beam of automobile vehicle by using carbon fiber composite material. Mater. Today 2020, 1–7. [Google Scholar] [CrossRef]

- Motgi, N.S.; Naik, S.B.; Kulkarin, P.R. Impact Analysis of Front Bumper. Int. J. Eng. Trends Technol. 2013, 6, 287–291. [Google Scholar]

- Njuguna, J.; Michalowski, S.; Pielichowski, K.; Kayvantash, K.; Walton, A.C. Fabrication, Characterization and Low-Velocity Impact Testing of Hybrid Sandwich Composites with Polyurethane/Layered Silicate Foam Cores. Polym. Compos. 2011, 32, 1–13. [Google Scholar] [CrossRef]

- Mo, F.; Zhao, S.; Yu, C.; Xiao, Z.; Duan, S. Design of a Conceptual Bumper Energy Absorber Coupling Pedestrian Safety and Low-Speed Impact Requirements. Appl. Bionics Biomech. 2018, 2018, 9293454. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Wang, Y.; Han, B.; Wan, B.; Cai, G.; Chang, R. In Situ Strain and Damage Monitoring of GFRP Laminates Incorporating Carbon Nanofibers under Tension. Polymers 2018, 10, 777. [Google Scholar] [CrossRef]

- Sun, C.; Min, J.; Lin, J.; Wan, H. Effect of Atmospheric Pressure Plasma Treatment on Adhesive Bonding of Carbon Fiber Reinforced Polymer. Polymers 2019, 11, 139. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef]

- Rao, H.R.; Kumar, M.A.; Reddy, G.R. Hybrid composites: Effect of fibers on mechanical properties. Int. J. Macromol. Sci. 2011, 1, 9–14. [Google Scholar]

- Saman, S.D.; Leman, Z.; Sulotan, M.T.H.; Ishak, M.R.; Cardona, F. Kenaf/synthetic and Kevlar/Cellulosic Fiber-Reinforced Hybrid Composites: A Review. BioResources 2015, 10, 8580–8603. [Google Scholar]

- Marzbanrad, J.; Alijanpour, M.; Kiasat, M.S. Design and analysis of an automotive bumper beam in low-speed frontal crashes. Thin-Walled Struct 2009, 47, 902–911. [Google Scholar] [CrossRef]

- Cheon, S.S.; Choi, J.H.; Lee, D.G. Development of the composite beam for passenger cars. Compos. Struct. 1995, 32, 491–499. [Google Scholar] [CrossRef]

- General Motors. SMC bumper beams improve productivity for GM. Reinf Plast 1992, 36, 1–7. [Google Scholar]

- Belingardi, G.; Beyene, A.T.; Koricho, E.G.; Martorana, B. Lightweight solutions for vehicle frontal bumper: Crash design and manufacturing issues. In Dynamic Response and Failure of Composite Materials and Structures; Woodhead Publishing: Cambridge, UK, 2017. [Google Scholar] [CrossRef]

- Neale, G.; Dahale, M.; Yoo, S.; Toso, N.; McGarrigle, C.; Quinn, J.; Kelly, J.; McIlhagger, A.; Archer, E.; Harkin-Jones, E. Improved crush energy absorption in 3D woven composites by pick density modification. Compos. Part B 2020, 192, 1–9. [Google Scholar] [CrossRef]

- Díaz-Álvarez, A.; Jiao-Wang, L.; Feng, C.; Santiuste, C. Energy absorption and residual bending behavior of biocomposites bumper beams. Compos. Struct. 2020, 245, 1–7. [Google Scholar] [CrossRef]

- Sharmin, E.; Zafar, F. Polyurethane: An Introduction. Intech 2012. [Google Scholar] [CrossRef]

- Uhlig, K. Discovering Polyurethanes; Hanser/Publications: Cincinnati, OH, USA, 1999. [Google Scholar]

- Chen, S.; Zhu, W.; Cheng, Y. Multi-Objective Optimization of Acoustic Performances of Polyurethane Foam Composites. Polymers 2018, 10, 788. [Google Scholar] [CrossRef]

- Agnieszka Przystas, A.; Jovic, M.; Salmeia, K.A.; Rentsch, D.; Ferry, L.; Mispreuve, H.; Perler, H.; Gaan, S. Some Key Factors Influencing the Flame Retardancy of EDA-DOPO Containing Flexible Polyurethane Foams. Polymers 2018, 10, 1115. [Google Scholar] [CrossRef]

- Linul, E.; Vălean, C.; Linul, P.A. Compressive Behavior of Aluminum Microfibers Reinforced Semi-Rigid Polyurethane Foams. Polymers 2018, 10, 1298. [Google Scholar] [CrossRef]

- SleepOnLatex: Choosing between Polyurethane Foam, Memory Foam and Latex Foam. Available online: https://sleeponlatex.com/blogs/news/8948719-choosing-between-polyurethane-foam-memory-foam-and-latex-foam (accessed on 16 December 2019).

- Elfarhani, M.; Jarraya, A.; Abid, S.; Haddar, M. Fractional derivative and hereditary combined model for memory effects on flexible polyurethane foam. Mech. Time-Depend. Mater. 2016, 20, 197–217. [Google Scholar] [CrossRef]

- Husson, J.M.; Dubois, F.; Sauvat, N. A finite element model for shape memory behavior. Mech. Time-Depend. Mater. 2011, 15, 213–217. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Kéki, S. Review of Progress in Shape Memory Epoxies and Their Composites. Polymers 2018, 10, 34. [Google Scholar] [CrossRef]

- Santo, L.; Bellisario, D.; Quadrini, F. Shape Memory Behavior of PET Foams. Polymers 2018, 10, 115. [Google Scholar] [CrossRef] [PubMed]

- Maček, M. Production of Protective Vests. Bachelor’s Thesis, Faculty of Mechanical Engineering and Naval Architecture, Zagreb, Croatia, 2011. [Google Scholar]

- Available online: http://www.polimix.hr/en/ (accessed on 1 December 2019).

- Herceg, D. Mechanical Properties of Composite Materials with Polymer Matrix Reinforced with Glass Fiber. Master’s Thesis, Faculty of Mechanical Engineering, Sarajevo, Bosnia and Herzegovina, 2017. [Google Scholar]

- Ilinčić, P.; Špoljar, M.; Pilipović, A. Comparison of the Hybrid Composites Production Processes for Application in the Automotive Industry. In Proceedings of the 16th International Scientific Conference on Production Engineering-CIM2017, Zadar, Croatia, 8–10 June 2017. [Google Scholar]

- Song, J. Pairing effect and tensile properties of laminated high-performance hybrid composites prepared using carbon/glass and carbon/aramid fibers. Compos. Part B 2015, 79, 61–66. [Google Scholar] [CrossRef]

- Reichhold. Available online: http://www.saadfg.com/wp-content/uploads/sites/124/2016/05/POLYLITE-440-800-E.pdf (accessed on 16 December 2019).

- Hexion Laminierharz MGS L 285. Available online: https://m.aircraftspruce.com/catalog/pdf/mgs285tech.pdf (accessed on 16 December 2019).

- Belingardi, G.; Beyene, A.; Koricho, E.; Martorana, B. Alternative lightweight materials and component manufacturing technologies for vehicle frontal bumper beam. Compos. Struct. 2015, 120, 483–495. [Google Scholar] [CrossRef]

- Maček, M. Influence of Foam on Absorption of Impact in Ballistic Helmets. Master’s Thesis, Faculty of Mechanical Engineering and Naval Architecture, Zagreb, Croatia, 2013. [Google Scholar]

- Belingardi, G.; Beyene, A.T.; Jichuan, D. Energy absorbing capability of GMT, GMTex and GMT-UD composite panels for static and dynamic loading–Experimental and numerical study. Compos. Struct. 2016, 143, 371–387. [Google Scholar] [CrossRef]

- Rujnić-Sokele, M. Influence of the stretch blow moulding processing parameters on PET bottles properties. Polimeri 2007, 284, 213–292. [Google Scholar]

- Lukaszewicz, D. Design drivers for enhanced crash performance of automotive CFRP structures. In Proceedings of the 23rd International Technical Conference on the Enhanced Safety of Vehicles (ESV), Seoul, Korea, 27–30 May 2013. [Google Scholar]

- Fazita, N.M.R.; Khalil, A.H.P.S.; Izzati, A.A.N.; Rizal, S. Effects of strain rate on failure mechanisms and energy absorption in polymer composites. In Failure Analysis in Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Jawaid, M., Thariq, M., Saba, N., Eds.; Elsevier WP Woodhead Publishing: Duxford, UK, 2019; pp. 51–78. [Google Scholar]

- Sounik, D.F.; Gansen, P.; Clemons, J.L.; Liddle, J.W. Head-Impact Testing of Polyurethane Energy-Absorbing (EA) Foams. In Proceedings of the International Congress & Exposition, Detroit, Michigan, 24–27 February 1997; pp. 1–10. [Google Scholar]

- Avalle, M.; Belingardi, G.; Montanini, R. Characterization of polymeric structural foams under compressive impact loading by means of energy-absorption diagram. Int. J. Impact Eng. 2001, 25, 455–472. [Google Scholar] [CrossRef]

| 1. Plate (Glass Fiber) | 2. Plate (Carbon/Aramid) | 3. Plate (Glass/Carbon) | ||||

|---|---|---|---|---|---|---|

| Layer Number | Fiber Type | Rotation of Fiber Layer | Fiber Type | Rotation Fiber Layer | Fiber type | Rotation of Fiber Layer |

| 1. | glass | 0° | carbon | 0° | carbon | 0° |

| 2. | glass | 0° | carbon | 0° | carbon | 0° |

| 3. | glass | 0° | carbon | 45° | glass | 0° |

| 4. | glass | 0° | carbon | 45° | glass | 0° |

| 5. | glass | 0° | aramid | 0° | carbon | 0° |

| 6. | glass | 0° | aramid | 0° | carbon | 0° |

| 7. | aramid | 0° | glass | 0° | ||

| 8. | aramid | 0° | glass | 0° | ||

| 9. | carbon | 45° | ||||

| 10. | carbon | 45° | ||||

| 11. | carbon | 0° | ||||

| 12. | carbon | 0° | ||||

| Memory Foam Density/Thickness kg/m3/mm | Glass Fiber/Polyester Resin + Memory Foam | |||||||

|---|---|---|---|---|---|---|---|---|

| 80/15 | 60/20 | 80/15 | 60/10 | 80/15 | 100/20 | 100/10 | - | |

| No. | 1 | 2 | 4 | 5 | 6 | 7 | 8 | |

| Force F, N | 6874.85 | 5503.41 | 8581.79 | 7494.84 | 4767.66 | 8338.5 | 9908.1 | |

| 7204.46 | 5473.98 | 8281.60 | 7578.23 | 5279.74 | 8201.16 | 9638.33 | ||

| 7332.98 | 5603.47 | 8583.75 | 6788.52 | 5061.96 | 7345.73 | 8946.72 | ||

| 7524.27 | 5150.25 | 8495.46 | 7269.21 | 5368.03 | 7910.78 | 9653.04 | ||

| 7425.19 | 5032.53 | 8911.40 | 6633.52 | 5238.54 | 8175.65 | 9962.06 | ||

| Mean , N | 7272.35 | 5352.73 | 8570.80 | 7152.86 | 5143.19 | 7994.37 | 9621.65 | |

| St. dev. S | 251.55 | 246.88 | 226.72 | 422.46 | 237.65 | 394.26 | 404.58 | |

| Sum of Squares | Degrees of Freedom DF | Mean Square | F Value | Risk of Rejection of Ho (Prob > F) | |

|---|---|---|---|---|---|

| Model | 9.397 × 106 | 3 | 3.132 × 106 | 438.77 | 0.0351 significant |

| A | 1.544 × 105 | 1 | 1.544 × 105 | 21.63 | 0.1348 |

| B | 9.209 × 106 | 1 | 9.209 × 106 | 1289.96 | 0.0177 |

| AB | 3.365 × 104 | 1 | 3.365 × 104 | 4.71 | 0.2748 |

| Curvature | 2.668 × 105 | 1 | 2.669 × 105 | 37.37 | 0.1032 not significant |

| Pure error | 7.138 × 103 | 1 | 7.138 × 103 | ||

| Cor Total | 9.671 × 106 | 5 |

| Force, F (N) | |

|---|---|

| Standard deviation | 84.49 |

| Mean | 6914.38 |

| Coefficient of determination r2 (R-squared) | 0.9992 |

| Factor | Coefficient Estimate | DF | Standard Error | 95% CI Low | 95% CI High | VIF |

|---|---|---|---|---|---|---|

| Intercept | 6765.27 | 1 | 42.25 | 6228.48 | 7302.06 | |

| A-density | −196.49 | 1 | 42.25 | −733.28 | 340.30 | 1 |

| B-thickness | −1517.31 | 1 | 42.25 | −2054.10 | −980.52 | 1 |

| AB | 91.72 | 1 | 42.25 | −445.07 | 628.51 | 1 |

| Centre Point | 447.33 | 1 | 73.17 | −482.41 | 1377.08 | 1 |

| Memory Foam Density/Thickness kg/m3/mm | Carbon/Aramid Fibers/Epoxy Resin + Memory Foam | |||||||

|---|---|---|---|---|---|---|---|---|

| 80/15 | 60/20 | 80/15 | 60/10 | 80/15 | 100/20 | 100/10 | - | |

| No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| Force F, N | 8870.20 | 6553.08 | 8717.17 | 9770.76 | 8110.91 | 6715.93 | 9422.51 | 9378.36 |

| 8699.51 | 6780.67 | 8711.28 | 9829.62 | 8152.11 | 6521.69 | 9429.37 | 9770.76 | |

| 8846.66 | 6749.28 | 9922.82 | 8191.35 | 6665.90 | 9323.42 | 9594.18 | ||

| 8558.24 | 6574.66 | 8593.56 | 9776.65 | 8252.17 | 6695.33 | 9158.62 | 9633.42 | |

| 8381.66 | 7043.58 | 8358.12 | 10094.49 | 6603.11 | 9405.83 | 9339.12 | ||

| Mean , N | 8671.26 | 6740.25 | 8241.18 | 9878.87 | 8154.07 | 6640.39 | 9347.95 | 9543.17 |

| St. dev., S | 204.80 | 197.60 | 167.89 | 135.08 | 60.12 | 78.83 | 114.0 | 181.21 |

| Sum of Squares | Degrees of Freedom DF | Mean Square | F Value | Risk of Rejection of Ho (Prob > F) | |

|---|---|---|---|---|---|

| Model | 8.690 × 106 | 3 | 2.897 × 106 | 40.85 | 0.0240 significant |

| A | 9.947 × 104 | 1 | 9.947 × 104 | 1.40 | 0.3580 |

| B | 8.544 × 106 | 1 | 8.544 × 106 | 120.48 | 0.0082 |

| AB | 4.645 × 104 | 1 | 4.645 × 104 | 0.66 | 0.5033 |

| Curvature | 1.857 × 105 | 1 | 1.857 × 105 | 2.62 | 0.2470 not significant |

| Pure error | 1.418 × 105 | 2 | 7.092 × 104 | ||

| Cor Total | 9.018 × 106 | 5 |

| Force, F (N) | |

|---|---|

| Standard deviation | 266.31 |

| Mean | 8292.91 |

| Coefficient of determination r2 (R-squared) | 0.9839 |

| Factor | Coefficient Estimate | DF | Standard Error | 95% CI Low | 95% CI High | VIF |

|---|---|---|---|---|---|---|

| Intercept | 8151.87 | 1 | 133.15 | 7578.96 | 8724.77 | |

| A-density | −157.70 | 1 | 133.15 | −730.60 | 415.21 | 1 |

| B-thickness | −1461.55 | 1 | 133.15 | −2034.45 | −888.64 | 1 |

| AB | 107.77 | 1 | 133.15 | −465.14 | 680.67 | 1 |

| Centre Point | 329.11 | 1 | 203.39 | −546.02 | 1204.24 | 1 |

| Memory Foam Density/Thickness kg/m3/mm | Carbon/Glass Fiber/Epoxy Resin + Memory Foam | |||||||

|---|---|---|---|---|---|---|---|---|

| 80/15 | 60/20 | 80/15 | 60/10 | 80/15 | 100/20 | 100/10 | - | |

| No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| Force F, N | 8622.99 | 6132.23 | 8583.75 | 9711.9 | 8517.04 | 6543.27 | 9579.47 | 9405.83 |

| 8128.57 | 6662.95 | 8730.9 | 9682.47 | 8546.47 | 6333.34 | 9613.8 | 9309.69 | |

| 8393.44 | 6626.66 | 8913.37 | 9594.18 | 8499.38 | 6445.17 | 9488.23 | 9262.60 | |

| 8564.13 | 6562.89 | 8721.09 | 9732.50 | 8505.27 | 6180.3 | 9588.29 | 9417.6 | |

| 8456.22 | 6538.37 | 8784.86 | 9500.0 | 8458.18 | 6380.42 | 9641.29 | 9199.82 | |

| Mean , N | 8433.07 | 6504.62 | 8746.79 | 9644.21 | 8505.27 | 6376.5 | 9582.21 | 9319.11 |

| St. dev., S | 192.41 | 214.0 | 119.05 | 96.36 | 31.97 | 135.0 | 57.80 | 93.18 |

| Sum of Squares | Degrees of Freedom DF | Mean Square | F Value | Risk of Rejection of Ho (Prob > F) | |

|---|---|---|---|---|---|

| Model | 1.001 × 107 | 3 | 3.359 × 106 | 124.42 | 0.0080 significant |

| A | 9.036 × 103 | 1 | 9.036 × 103 | 0.33 | 0.6213 |

| B | 1.007 × 107 | 1 | 1.007 × 107 | 372.88 | 0.0027 |

| AB | 1.092 × 103 | 1 | 1.092 × 103 | 0.04 | 0.8591 |

| Curvature | 4.904 × 105 | 1 | 4.904 × 105 | 18.17 | 0.0509 not significant |

| Pure error | 5.399 × 104 | 2 | 2.699 × 104 | ||

| Cor Total | 1.062 × 107 | 5 |

| Force, F (N) | |

|---|---|

| Standard deviation | 164.30 |

| Mean | 8256.10 |

| Coefficient of determination r2 (R-squared) | 0.9947 |

| Factor | Coefficient Estimate | DF | Standard Error | 95% CI Low | 95% CI High | VIF |

|---|---|---|---|---|---|---|

| Intercept | 8026.89 | 1 | 82.15 | 7673.42 | 8380.35 | |

| A-density | −47.53 | 1 | 82.15 | −400.99 | 305.93 | 1 |

| B-thickness | −1586.33 | 1 | 82.15 | −1939.79 | −1232.86 | 1 |

| AB | −16.53 | 1 | 82.15 | −369.99 | 336.93 | 1 |

| Centre Point | 534.82 | 1 | 125.49 | −5.10 | 1074.75 | 1 |

| Name | Goal | Lower Limit | Upper Limit | Solution |

|---|---|---|---|---|

| Density, kg/m3 | minimize | 60 | 100 | 60 |

| Thickness, mm | minimize | 10 | 20 | 15 |

| Force, N | minimize | 6376.5 | 9644.21 | 8073.57 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pilipović, A.; Ilinčić, P.; Petruša, J.; Domitran, Z. Influence of Polymer Composites and Memory Foam on Energy Absorption in Vehicle Application. Polymers 2020, 12, 1222. https://doi.org/10.3390/polym12061222

Pilipović A, Ilinčić P, Petruša J, Domitran Z. Influence of Polymer Composites and Memory Foam on Energy Absorption in Vehicle Application. Polymers. 2020; 12(6):1222. https://doi.org/10.3390/polym12061222

Chicago/Turabian StylePilipović, Ana, Petar Ilinčić, Jelena Petruša, and Zoran Domitran. 2020. "Influence of Polymer Composites and Memory Foam on Energy Absorption in Vehicle Application" Polymers 12, no. 6: 1222. https://doi.org/10.3390/polym12061222

APA StylePilipović, A., Ilinčić, P., Petruša, J., & Domitran, Z. (2020). Influence of Polymer Composites and Memory Foam on Energy Absorption in Vehicle Application. Polymers, 12(6), 1222. https://doi.org/10.3390/polym12061222