Composites of Semi-Rigid Polyurethane Foams with Keratin Fibers Derived from Poultry Feathers and Flame Retardant Additives

Abstract

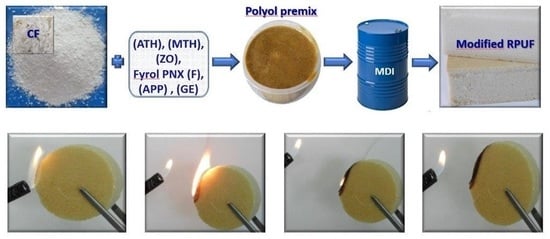

:1. Introduction

2. Experimental Part

2.1. Materials

- Arcol®Polyol 1374, a trifunctional polyetherol with a hydroxyl number LOH = 26, water content below 0.1% by mass; (Bayer, Bergkamen, Germany),

- Daltocel F526—polyetherol with LOH = 128 hydroxyl number, (Huntsman Corporation, The Woodlands, TX, USA),

- Diisocyanate Ongronate 4040, a mixture of monomeric isomers and oligomeric methylenediphenyl-4,4’-diisocyanate (MDI); (BorsodChem, Kazincbarcika, Hungary),

- Distilled water.

- Keratin filler (sulphur content of 2.9%, nitrogen content of 15.5% and ash content of about 1%) with particle size 0.01–0.04 mm (K), (Łukasiewicz Research Network—Institute of Biopolymers and Chemical Fibres, Łód’z, Poland), aspect ratio of fibers = 2.59, the SEM image of the fibers is shown in Figure 1.

- Fyrol PNX (F)—(ICL Industrial Products Ltd., Tel-Aviv, Israel), oligomeric non-reactive phosphate ester

- Expandable Graphite (GE)—(Sinograf SA, Toruń, Poland), the particle size 0.5 mm, expansion 250 mL/g starting expansion temperature 220 °C

- Aluminum hydroxide, MARTINAL (ATH)—(Albemarle, Charlotte, NC, USA), the particle sizes 10 µm

- Magnesium hydroxide, MAGNIFIN (MTH)—(Albemarle, Charlotte, NC, USA), the particle sizes 20 µm

- Zinc oxide (ZO)—Institute of High Pressure Physics (Unipress, Warsaw, Poland), the particle sizes 70 nm

- Ammonium polyphosphate, Exolit AP 422, (APP)—(Clariant, Muttenz, Switzerland).

2.2. Preparation of Foams

3. Research Methodology

3.1. Determination of Apparent Density

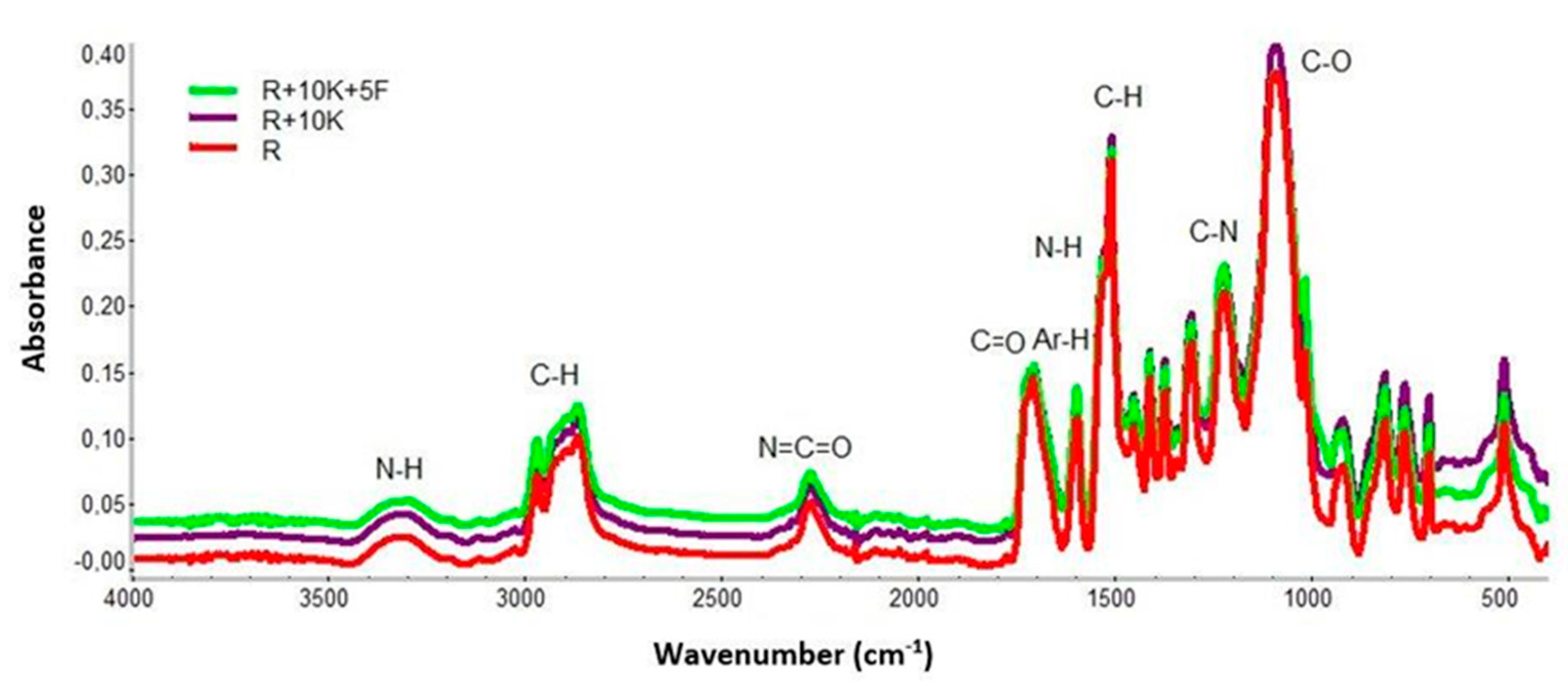

3.2. Description of the Chemical Constitution and Structure of the Foams (ATR-FTIR)

3.3. Differential Scanning Calorimetry (DSC)

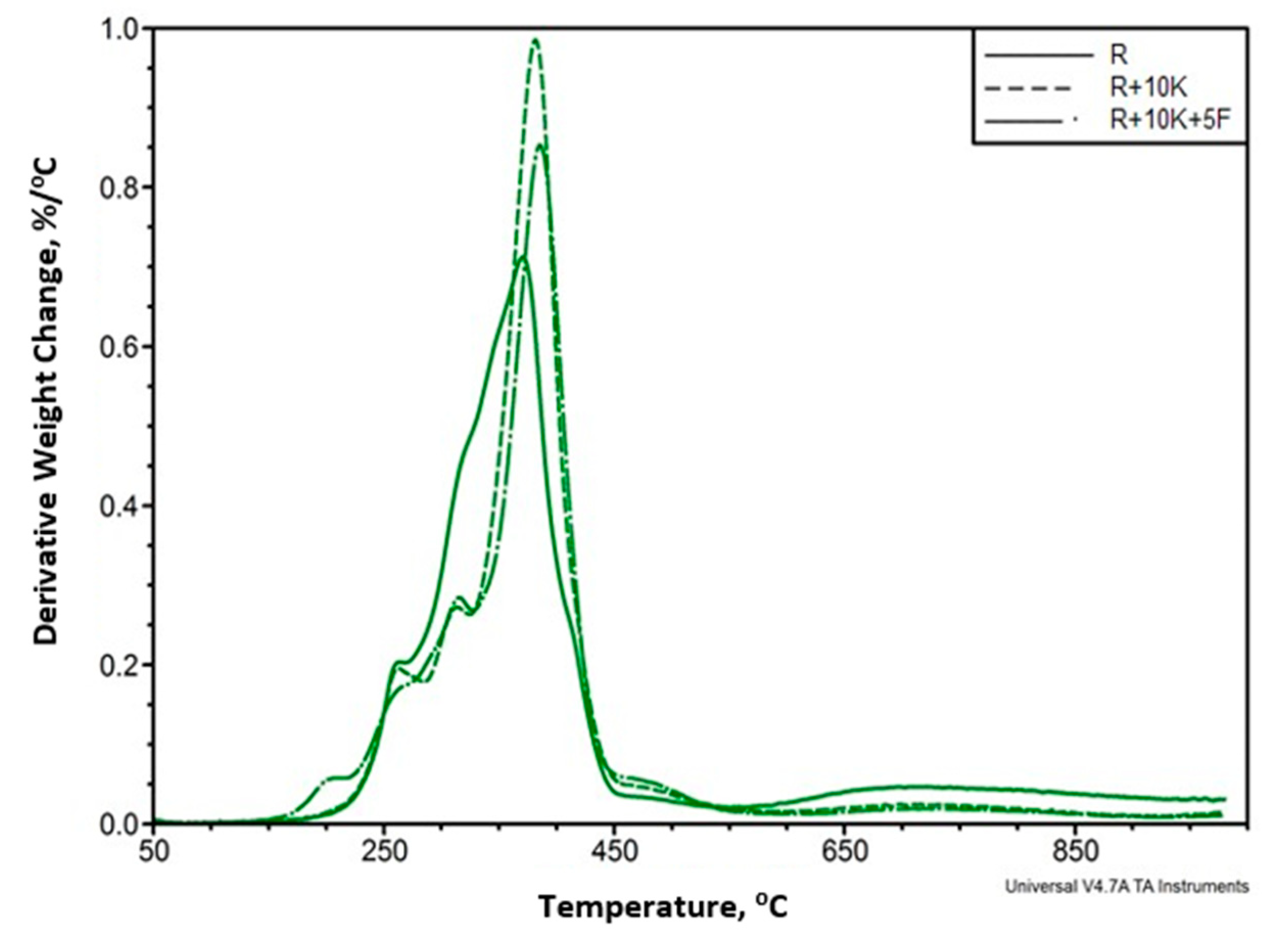

3.4. Thermal Degradation

3.5. Flame Resistance Test

3.6. Heat Transfer Coefficient, λ

3.7. Water Absorption Test

3.8. SEM Analysis

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| ∆H | Enthalpy of transformation |

| APP | Ammonium polyphosphate |

| ATH | Aluminum hydroxide |

| ATR-FTIR | Fourier Transform infrared spectroscopy |

| D | apparent density |

| DSC | Differential Scanning Calorimetry |

| DTG | Derivative Thermogravimetry |

| F | Fyrol PNX, oligomeric non-reactive phosphate ester |

| GE | Expandable Graphite |

| HRR | average heat release rate |

| K | Keratin filler with particle size 0.01–0.04 mm |

| MAHRE | maximum average heat emission factor |

| MDI | Diisocyanate Ongronate 4040—a mixture of monomeric isomers and oligomericmethylenediphenyl-4,4’-diisocyanate |

| MLR | mass loss rate |

| MTH | Magnesium hydroxide |

| pHRR | maximum heat release rate |

| R+10K+10ATH+5F | reference foam with addition of 10% keratin, 10% Aluminum hydroxide and 5% Fyrol |

| R+10K+10APP+5F | reference foam with addition of 10% keratin, 10% Ammonium polyphosphate and 5% Fyrol |

| R+10K+10APP | reference foam with addition of 10% keratin and 10% Ammonium polyphosphate |

| R+10K+10ATH | reference foam with addition of 10% keratin and 10% Aluminum hydroxide |

| R+10 K+10GE | reference foam with addition of 10% keratin and 10% Expanding graphite |

| R+10K+10GE+5F | reference foam with addition of 10% keratin, 10% Expanding graphite and 5% Fyrol |

| R+10 K+10MTH+5F | reference foam with addition of 10% keratin, 10% Magnesium hydroxide and 5% Fyrol |

| R+10K+10MTH | reference foam with addition of 10% keratin and 10% Magnesium hydroxide |

| R+10K+5F | reference foam with addition of 10% keratin and 5% Fyrol |

| R+10 K | reference foam with addition of 10% keratin |

| R+10K+10ZO+5F | reference foam with addition of 10% keratin, 10% Zinc oxide and 5% Fyrol |

| R+10K+10ZO | reference foam with addition of 10% keratin and 10% Zinc oxide |

| R | reference foam |

| SEA | specific extinction area |

| SRPUF | Semi-rigid foams |

| Tg | Glass transition temperature |

| TG | Thermogravimetric Analysis |

| THR | total heat released |

| TSP | total amount of smoke produced |

| TTF | end time of flame combustion |

| TTI | time to ignition |

| ZO | Zinc oxide |

| λ | thermal conductivity coefficient |

| SEM | Scanning Electron Microscope |

| d | mean pore diameter |

| AR | mean aspect ratio |

References

- Wu, J.-W.; Sung, W.-F.; Chun, H.-S. Thermal conductivity of polyurethane foams. Int. J. Heat Mass Transf. 1999, 42, 2211–2217. [Google Scholar] [CrossRef]

- Kirpluks, M.; Cabulis, U.; Zeltins, V.; Stiebra, L.; Avots, A. Rigid Polyurethane Foam Thermal Insulation Protected with Mineral Intumescent Mat. Autex Res. J. 2014, 14, 259–269. [Google Scholar] [CrossRef] [Green Version]

- Dos Santos, D.J.; Tavares, L.B.; Batalha, G.F. Mechanical and physical properties investigation of polyurethane material obtained from renewable natural source. J. Achiev. Mater. Manuf. 2012, 54, 211–217. [Google Scholar]

- Kurańska, M.; Prociak, A.; Kirpluks, M.; Ugis, C. Porous polyurethane composites based on bio-components. Compos. Sci. Technol. 2013, 75, 70–76. [Google Scholar] [CrossRef]

- Geller, S.; Weissenborn, O.; Gude, M.; Czulak, A. Impregnation studies and mechanical characterization of cellular, natural, fiber-reinforced, composite structures. Polimery 2016, 61, 125–132. [Google Scholar] [CrossRef]

- Hatakeyama, H.; Ohsuga, T.; Hatakeyama, T. Thermogravimetry on wood powder-filled polyurethane composites derived from lignin. J. Therm. Anal. Calorim. 2014, 118, 23–30. [Google Scholar] [CrossRef]

- Luo, X.; Mohanty, A.; Misra, A. Lignin as a reactive reinforcing filler for water-blown rigid biofoam composites from soy oil-based polyurethane. Ind. Crop. Prod. 2013, 47, 13–19. [Google Scholar] [CrossRef]

- Park, S.H.; Oh, K.W.; Kim, S.H. Reinforcement effect of cellulose nanowhisker on bio-based polyurethane. Compos. Sci. Technol. 2013, 86, 82–88. [Google Scholar] [CrossRef]

- Seydibeyoglu, M.O.; Oksman, K. Novel nanocomposites based on polyurethane and micro fibrillated cellulose. Compos. Sci. Technol. 2008, 68, 908–914. [Google Scholar] [CrossRef] [Green Version]

- Aranguren, M.I.; Gonzalez, J.F.; Mosiewicki, M.A. Biodegradation of a vegetable oil based polyurethane and wood flour composites. Polym. Test. 2012, 31, 7–15. [Google Scholar] [CrossRef]

- Paciorek-Sadowska, J.; Czupryński, B.; Liszkowska, J. Application of waste products from agricultural-food industry for production of rigid polyurethane-polyisocyanurate foams. J. Porous Mater. 2011, 18, 631–638. [Google Scholar]

- Kurańska, M.; Prociak, A. Flax fibres as natural filler for rigid polyurethane-polyisocyanurate foams based on bio-polyol from rapeseed oil. Czas. Tech. Chem. 2015, 17, 47–54. [Google Scholar]

- Prociak, A.; Kurańska, M.; Malewska, E.; Szczepkowski, L.; Zieleniewska, M.; Ryszkowska, J.; Ficoń, J.; Rząsa, A. Biobased polyurethane foams modified with natural fillers. Polimery 2015, 60, 592–599. [Google Scholar] [CrossRef]

- Mosiewicki, M.; Dell’Arciprete, G.A.; Aranguren, M.I.; Marcovich, N.E. Polyurethane Foams Obtained from Castor Oil-based Polyol and Filled with Wood Flour. J. Compos. Mater. 2009, 43, 3057–3072. [Google Scholar] [CrossRef]

- Aranguren, M.I.; Racz, I.; Marcovich, N.E. Microfoams Based on Castor Oil Polyurethanes and Vegetable Fibres. J. Appl. Polym. Sci. 2007, 105, 2791–2800. [Google Scholar] [CrossRef]

- Zieleniewska, M.; Leszczyński, M.K.; Szczepkowski, L.; Bryśkiewicz, A.; Krzyżowska, M.; Bień, K.; Ryszkowska, J. Development and applicational evaluation of the rigid polyurethane foam composites with egg shell waste. J. Polym. Degrad. Stab. 2016, 132, 78–86. [Google Scholar] [CrossRef]

- Kausar, A. Effect of Nanofiller Dispersion on Morphology, Mechanical and Conducting Properties of Electroactive Shape Memory Poly(Urethane-Urea)/Functional Nanodiamond Composite. Adv. Mater. Sci. 2015, 15, 14–28. [Google Scholar] [CrossRef] [Green Version]

- Thirumal, M.; Khastgir, D.; Singha, N.; Manjunath, B.; Naik, Y. Effect of foam density on the properties of water blown rigid polyurethane foam. J. Appl. Polym. Sci. 2008, 108, 1810–1817. [Google Scholar] [CrossRef]

- Brzozowski, Z.K.; Kijeńska, D.; Zatorski, W. Palność polimerów cz.2 Sposoby zmniejszania palności tworzyw sztucznych. Plastics Reviev 2001, 9, 22. [Google Scholar]

- Lin, M.-F.; Tsen, W.-C.; Shu, Y.-C.; Chuang, F.-S. Effect of silicon and phosphorus on the degradation of polyurethanes. J. Appl. Polym. Sci. 2001, 79, 881–899. [Google Scholar] [CrossRef]

- Duquesne, S.; Delobel, R.; Le Bras, M.; Camino, G. A Comparative Study of the Mechanism of Action of Ammonium Polyphosphate and Expandable Graphite in Polyurethane. Polym. Degrad. Stab. 2002, 77, 333–344. [Google Scholar] [CrossRef]

- Kulesza, K.; Pielichowski, K.; Kowalski, Z. Thermal characteristics of novel NaH2PO4/NaHSO4 flame retardant system for polyurethane foams. J. Therm. Anal. Calor. 2006, 86, 475–478. [Google Scholar] [CrossRef]

- Kicko-Walczak, E. Novel halogen-free rame retardants—Flame retardation of unsaturated polyester resins with use of boron compounds. Polimery 2008, 53, 126–132. [Google Scholar] [CrossRef] [Green Version]

- Modesti, M.; Lorenzetti, A.; Simioni, F.; Checchin, M. Influence of different flame retardants on fire behaviour of modified PIR/PUR polymers. Polym. Degrad. Stab. 2001, 74, 475–479. [Google Scholar] [CrossRef]

- Prociak, A.; Pielichowski, J.; Modesti, M.; Simioni, F.; Checchin, M. Influence of different phosphorus flame retardants on fire behaviour of rigid polyurethane foams blown with pentane. Polimery 2001, 46, 692–696. [Google Scholar] [CrossRef]

- Brzozowski, Z.K.; Zatorski, Z. New achievements in the chemical modification of fire-safe rigid polyurethane foams. In Proceedings of the International Conference: Innovative Materials and Technologies for Surface Transport (INMAT 2005), Gdańsk, Poland, 7–8 November 2005. [Google Scholar]

- Yuan, Y.; Yu, B.; Shi, Y.; Ma, C.; Song, L.; Hu, W.; Hu, Y. Highly efficient catalysts for reducing toxic gases generation change with temperature of rigid polyurethane foam nanocomposites: A comparative investigation. Compos. Part A Appl. Sci. Manuf. 2018, 112, 142–154. [Google Scholar] [CrossRef]

- Pinto, U.A.; Visconte, L.L.Y.; Gallo, J.; Nunes, R.C.R. Flame retardancy in thermoplastic polyurethane elastomers (TPU) with mica and aluminum trihydrate (ATH). Polym. Degrad. Stab. 2000, 69, 257–260. [Google Scholar] [CrossRef]

- Czupryński, B.; Liszkowska, J.; Paciorek-Sadowska, J. Modification of rigid polyurethane-polyisocyanurate foam with selected powder fillers. Polimery 2008, 53, 133–137. [Google Scholar] [CrossRef]

- Modesti, M.; Lorenzetti, A.; Besco, S.; Hrelja, D.; Semenzato, S.; Bertani, R.; Michelin, R.A. Synergism between flame retardant and modified layered silicate on thermal stability and fire behaviour of polyurethane nanocomposite foams. Polym. Degrad. Stab. 2008, 93, 2166–2171. [Google Scholar] [CrossRef]

- Semenzato, S.; Lorenzetti, A.; Modesti, M.; Ugel, E.; Hrelja, D.; Besco, S.; Michelin, R.A.; Sassi, A.; Facchin, G.; Zorzi, F.; et al. A novel phosphorus polyurethane FOAM/montmorillonite nanocomposite: Preparation, characterization and thermal behaviour. Appl. Clay Sci. 2009, 44, 35–42. [Google Scholar] [CrossRef]

- Zatorski, W.; Brzozowski, Z.K.; Kolbrecki, A. New developments in chemical modification of fire-safe rigid polyurethane foams. Polym. Degrad. Stab. 2008, 93, 2071–2076. [Google Scholar] [CrossRef]

- Bhagat, V.J. Behaviour of expandable graphite as a flame retardant in flexible polyurethane foam. In Proceedings of the Technical Program of the Polyurethane Foam Association, Arlington, VA, USA, 10 May 2001. [Google Scholar]

- Modesti, M.; Lorenzetti, L. Improvement on fire behaviour of water blown PIR–PUR foams: Use of an halogen-free flame retardant. Eur. Polym. J. 2003, 39, 263–268. [Google Scholar] [CrossRef]

- Bian, X.-C.; Tang, J.-H.; Li, Z.-M. Flame retardancy of whisker silicon oxide/rigid polyurethane foam composites with expandable graphite. J. Appl. Polym. Sci. 2008, 110, 3871–3879. [Google Scholar] [CrossRef]

- Shi, L.; Li, Z.-M.; Xie, B.-H.; Wang, J.-H.; Tian, C.-R.; Yang, M.-B. Flame retardancy of different-sized expandable graphite particles for high-density rigid polyurethane foams. Polym. Int. 2006, 55, 862–871. [Google Scholar] [CrossRef]

- Modesti, M.; Lorenzetti, A. Halogen-free flame retardants for polymeric foams. Polym. Degrad. Stab. 2002, 78, 167–173. [Google Scholar] [CrossRef]

- Modesti, M.; Lorenzetti, A.; Simioni, F.; Camino, G. Expandable graphite as an intumescent flame retardant in polyisocyanurate–polyurethane foams. Polym. Degrad. Stab. 2002, 77, 195–202. [Google Scholar] [CrossRef]

- Rodziewicz, A.; Łaba, W. Keratyny i ich biodegradacja. Biotechnologia 2006, 73, 130–147. [Google Scholar]

- Wrześniewska-Tosik, K.; Zajchowski, S.; Bryśkiewicz, A.; Ryszkowska, J. Feathers as a Flame-Retardant in Elastic Polyurethane Foam. Fibres Text. East Eur. 2014, 103, 119–128. [Google Scholar]

- Sobolczyk, J.; Rodziewicz, A.; Łaba, W.; Baranowska, K. Bioutylizacja odpadów keratynowych z przetwórstwa drobiowego przez mezo- i termofilne bakterie. In Ekotoksykologia w ochronie środowiska: Praca zbiorowa; PZITS: Wrocław, Poland, 2008; pp. 398–402. [Google Scholar]

- Uzun, M.; Sancak, E.; Patel, I.; Usta, I.; Akalin, M.; Yuksek, M. Mechanical behaviour of chicken quills and chicken feather fibres reinforced polymeric composites. Arch. Mater. Sci. Eng. 2011, 52, 82–86. [Google Scholar]

- Cheng, S.; Lau, K.; Liu, T.; Zhao, Y.; Lam, P.-M.; Yin, Y. Mechanical and thermal properties of chicken feather fibre/PLA green composites. Compos. Part B Eng. 2009, 40, 650–654. [Google Scholar] [CrossRef]

- Reddy, N.; Yang, Y. Light-weight polypropylene composites reinforced with whole chicken feathers. J. Appl. Polym. Sci. 2010, 116, 3668–3675. [Google Scholar] [CrossRef]

- Wirpsza, Z.; Horwood, E. Polyurethanes: Chemistry, Technology, and Applications; Wirpsza, Z., Kemp, T.J., Eds.; Ellis Harwood Ltd.: New York, NY, USA, 1993. [Google Scholar]

- Ribeiro da Silva, V.; Mosiewicki, M.A.; Yoshida, M.I.; Coelho da Silva, M.; Stefani, P.M.; Marcovich, N.E. Polyurethane foams based on modified tung oil and reinforced with rice husk ash I: Synthesis and physical chemical characterization. Polym. Test. 2013, 32, 438–445. [Google Scholar] [CrossRef]

- Jiao, L.; Xiao, H.; Wang, Q.; Sun, J. Thermal degradation characteristics of rigid polyurethane foam and the volatile products analysis with TG-FTIR-MS. Polym. Degrad. Stab. 2013, 98, 2687–2696. [Google Scholar] [CrossRef]

- Newman, C.R.; Forciniti, D. Modeling the Ultraviolet Photodegradation of Rigid Polyurethane Foams. Ind. Eng. Chem. Res. 2001, 40, 3346–3352. [Google Scholar] [CrossRef]

- Ding, H.Y.; Wang, J.F.; Wang, C.P.; Chu, F.X. Synthesis of a novel phosphorus and nitrogen-containing bio-based polyols and its application in flame retardant polyurethane sealant. Polym. Degrad. Stab. 2016, 124, 43–50. [Google Scholar] [CrossRef]

- Leung, L.M.; Koberstein, J.T. Small-angle scattering analysis of hard-microdomain structure and microphase mixing in polyurethane elastomers. J. Polym. Sci. Polym. Phys. Ed. 1985, 23, 1883–1913. [Google Scholar] [CrossRef]

- Martin, D.J.; Meijs, G.F.; Gunatillake, P.A.; McCarthy, S.J.; Renwick, G.M. The effect of average soft segment length on morphology and properties of a series of polyurethane elastomers. II. SAXS-DSC annealing study. J. Appl. Polym. Sci. 1997, 64, 803–817. [Google Scholar] [CrossRef]

- Jin, J.; Song, M.; Yao, K.J. A MDSC analysis of phase transition in polyurethane-organoclay nanocomposites. Thermochim. Acta 2006, 447, 202–208. [Google Scholar] [CrossRef]

- Liu, L.; Xu, Y.; He, Y.; Xu, M.; Shi, Z.; Hu, H.; Yang, Z.; Li, B. An effective mono-component intumescent flame retardant for the enhancement of water resistance and fire safety of thermoplastic polyurethane composites. Polym. Degrad. Stab. 2019, 167, 146–156. [Google Scholar] [CrossRef]

- Huang, Y.; Jiang, S.; Liang, R.; Liao, Z.; You, G. A green highly-effective surface flame-retardant strategy for rigid polyurethane foam: Transforming UV-cured coating into intumescent self-extinguishing layer. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105534. [Google Scholar] [CrossRef]

- Gao, L.; Zheng, G.; Zhou, Y.; Hu, L.; Feng, G.; Zhang, M. Synergistic effect of expandable graphite, diethyl ethylphosphonate and organically-modified layered double hydroxide on flame retardancy and fire behavior of polyisocyanurate-polyurethane foam nanocomposite. Polym. Degrad. Stab. 2014, 101, 92–101. [Google Scholar] [CrossRef]

- Schartel, B.; Wilkie, C.A.; Camino, G. Recommendations on the scientific approach to polymer flame retardancy: Part 2—Concepts. J. Fire Sci. 2016, 35, 3–20. [Google Scholar] [CrossRef]

- Singh, H.; Jain, A.K. Ignition, Combustion, Toxicity, and Fire Retardancy of Polyurethane Foams: A Comprehensive Review. J. Appl. Polym. Sci. 2009, 111, 1115–1143. [Google Scholar] [CrossRef]

- Yu, B.; Xing, W.; Guo, W.; Qiu, S.; Wang, X.; Lo, S.; Hu, Y. Thermal exfoliation of hexagonal boron nitride for effective enhancements on thermal stability, flame retardancy and smoke suppression of epoxy resin nanocomposites via sol–gel process. J. Mater. Chem. A 2016, 4, 7330–7340. [Google Scholar] [CrossRef]

- Yu, B.; Yuen, A.C.Y.; Xu, X.; Zhang, Z.-C.; Yang, W.; Lu, H.; Fei, B.; Yeoh, G.H.; Song, P.; Wang, H. Engineering MXene surface with POSS for reducing fire hazards of polystyrene with enhanced thermal stability. J. Hazard. Mater. 2021, 401, 123342. [Google Scholar] [CrossRef]

- Fang, F.; Huo, S.; Shen, H.; Ran, S.; Wang, H.; Song, P.; Fang, Z. A bio-based ionic complex with different oxidation states of phosphorus for reducing flammability and smoke release of epoxy resins. Compos. Commun. 2020, 17, 104–108. [Google Scholar] [CrossRef]

- Günther, M.; Levchik, S.V.; Schartel, B. Bubbles and collapses: Fire phenomena of flame-retarded flexible polyurethane foams. Polym. Adv. Technol. 2020, 31, 2185–2198. [Google Scholar] [CrossRef]

- Akdogan, E.; Erdem, M.; Ureyen, M.E.; Kaya, M. Synergistic effects of expandable graphite and ammonium pentaborate octahydrate on the flame-retardant, thermal insulation, and mechanical properties of rigid polyurethane foam. Polym. Compos. 2020, 41, 1749–1762. [Google Scholar] [CrossRef]

- Aranberri, I.; Montes, S.; Wesołowska, E.; Rekondo, A.; Wrześniewska-Tosik, K.; Jürgen, H. Improved Thermal Insulating Properties of Renewable Polyol Based Polyurethane Foams Reinforced with Chicken Feathers. Polymers 2019, 11, 2002. [Google Scholar] [CrossRef] [Green Version]

- Liu, L.; Xu, Y.; Li, S.; Xu, M.; He, Y.; Shi, Z.; Li, B. A novel strategy for simultaneously improving the fire safety, water resistance and compatibility of thermoplastic polyurethane composites through the construction of biomimetic hydrophobic structure of intumescent flame retardant synergistic system. Compos. Part B Eng. 2019, 176, 107218. [Google Scholar] [CrossRef]

| Sample SRPUF | Addition | Amount of Additive % mas/Parts per Hundred Parts of Polyol | Growth Time, s | Gelation Time, s |

|---|---|---|---|---|

| R* | 75 | 88 | ||

| R+10K | K | 10 | 63 | 83 |

| R+10K+5F | K | 10 | 58 | 90 |

| F | 5 | |||

| R+10K+10ATH | K | 10 | 68 | 93 |

| ATH | 10 | |||

| R+10K+10ATH+5F | K | 10 | 61 | 93 |

| ATH | 10 | |||

| F | 5 | |||

| R+10 K+10MTH | K | 10 | 63 | 88 |

| MTH | 10 | |||

| R+10K+10MTH+5F | K | 10 | 62 | 88 |

| MTH | 10 | |||

| F | 5 | |||

| R+10K+10ZO | K | 10 | 55 | 74 |

| ZO | 10 | |||

| R+10K+10ZO+5F | K | 10 | 49 | 72 |

| ZO | 10 | |||

| F | 5 | |||

| R+10 K+10GE | K | 10 | 57 | 90 |

| GE | 10 | |||

| R+10K+10GE+5F | K | 10 | 54 | 85 |

| GE | 10 | |||

| F | 5 | |||

| R+10K+10APP | K | 10 | 70 | 93 |

| APP | 10 | |||

| R+10K+10APP+5F | K | 10 | 73 | 94 |

| APP | 10 | |||

| F | 5 |

| Sample SRPUF | Tg1, °C | T, °C | ∆H, J/g | Tg2, °C | Tg3, °C | Tg4, °C | D, kg/m3 |

|---|---|---|---|---|---|---|---|

| R* | −60.7 | 80.0 | 34.5 | −63.2 | 109.2 | n.d. | 64.6 ± 2.1 |

| R+10K | −61.0 | 83.2 | 35.5 | −62.5 | 108.8 | n.d. | 73.4 ± 0.4 |

| R+10K+5F | −61.8 | 84.3 | 41.4 | −64.0 | 107.1 | n.d. | 80.6 ± 1.5 |

| R+10K+10ATH | −61.4 | 84.7 | 31.8 | −64.0 | 108.2 | 150.0 | 78.6 ± 1.1 |

| R+10K+10ATH+5F | −61.4 | 82.2 | 36.7 | −63.8 | 106.3 | 148.1 | 85.2 ± 1.3 |

| R+10K+10MTH | −61.2 | 80.5 | 32.5 | −62.6 | 109.6 | 148.1 | 76.5 ± 1.3 |

| R+10K+10MTH+5F | −61.6 | 79.8 | 27..2 | −63.8 | 107..4 | 148..1 | 86.7 ± 1.5 |

| R+10K+10ZO | −62.0 | 75.3 | 34.6 | −62.8 | 108.3 | 148.5 | 85.0 ± 3.2 |

| R+10K+10ZO+5F | −61.7 | 80.6 | 33.4 | −63.8 | 107.6 | 151.6 | 87.4 ± 0.1 |

| R+10K+10GE | −61.7 | 81.9 | 34.0 | −64.6 | 108.0 | n.d. | 78.6 ± 0.2 |

| R+10K+10GE+5F | −61.6 | 81.9 | 41.0 | −64.0 | 107.1 | n.d. | 84.1 ± 0.1 |

| R+10K+10APP | −61.4 | 82.2 | 36.6 | −63.4 | 108.6 | n.d. | 77.4 ± 0.3 |

| R+10K+10APP+5F | −60.5 | 84.7 | 31.4 | −61.8 | 107.8 | n.d. | 78.6 ± 1.9 |

| Sample SRPUF | T2 %, °C | T5 %, °C | T10 %, °C | T50 %, °C | U700, °C |

|---|---|---|---|---|---|

| R* | 241 | 261 | 285 | 368 | 16.2 |

| R+10K | 232 | 258 | 285 | 380 | 15.6 |

| R+10K+5F | 202 | 244 | 276 | 384 | 19.0 |

| R+10K+10ATH | 202 | 244 | 276 | 384 | 19.0 |

| R+10K+10ATH+5F | 232 | 257 | 283 | 384 | 17.7 |

| R+10K+10MTH | 204 | 243 | 275 | 387 | 20.9 |

| R+10K+10MTH+5F | 236 | 260 | 288 | 383 | 17.8 |

| R+10K+10ZO | 206 | 252 | 282 | 387 | 21.1 |

| R+10K+10ZO+5F | 235 | 260 | 289 | 384 | 19.2 |

| R+10K+10GE | 204 | 249 | 281 | 389 | 21.4 |

| R+10K+10GE+5F | 233 | 259 | 285 | 381 | 17.9 |

| R+10 K+10APP | 227 | 256 | 282 | 367 | 22.7 |

| R+10K+10APP+5F | 203 | 243 | 276 | 369 | 22.9 |

| Sample RPUF | Stage1, °C | T1, °C | V1, %/°C | m1, % | Stage 2, °C | T2, °C | V2, %/°C | m2, % | Stage 3, °C | T3, °C | V3, %/°C | m3, % | Stage4, °C | T4, °C | V4, %/°C | m4, % |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R* | n.d. | n.d. | n.d. | n.d. | 221–273 | 262 | 0.20 | 7.3 | n.d. | n.d. | n.d. | n.d. | 273–442 | 370 | 0.71 | 68.3 |

| R+10K | n.d. | n.d. | n.d. | n.d. | 222–286 | 262 | 0.20 | 8.7 | 286–327 | 314 | 0.27 | 10.5 | 327–453 | 383 | 0.99 | 57.2 |

| R+10K+5F | 163–220 | 205 | 0.06 | 2.2 | 220–283 | 264 | 0.17 | 8.4 | 283–328 | 316 | 0.28 | 11.2 | 328–447 | 386 | 0.85 | 52.0 |

| R+10K+10ATH | n.d. | n.d. | n.d. | n.d. | 217–288 | 266 | 0.20 | 9.6 | 288–327 | 313 | 0.25 | 9.1 | 327–450 | 385 | 1.02 | 56.4 |

| R+10K+10ATH+5F | 171–216 | 204 | 0.06 | 1.9 | 216–297 | 260 | 0.17 | 12.0 | 297–326 | 315 | 0.26 | 7.3 | 326–447 | 388 | 0.84 | 50.8 |

| R+10K+10MTH | n.d. | n.d. | n.d. | n.d. | 220–286 | 261 | 0.18 | 8.5 | 286–328 | 312 | 0.26 | 9.6 | 328–450 | 384 | 1.01 | 56.5 |

| R+10K+10MTH+5F | 170–219 | 200 | 0.05 | 1.8 | 219–280 | 267 | 0.17 | 7.0 | 280–327 | 318 | 0.28 | 11.0 | 327–448 | 388 | 0.78 | 51.8 |

| R+10K+10ZO | n.d. | n.d. | n.d. | n.d. | 224–284 | 263 | 0.18 | 7.7 | 284–328 | 311 | 0.26 | 10.1 | 328–446 | 383 | 0.99 | 54.6 |

| R+10K+10ZO+5F | 170–222 | 203 | 0.05 | 2.1 | 222–278 | 265 | 0.16 | 6.6 | 279–327 | 315 | 0.27 | 11.2 | 327–445 | 391 | 0.76 | 51.2 |

| R+10K+10GE | n.d. | n.d. | n.d. | n.d. | 222–288 | 262 | 0.19 | 9.2 | 288–325 | 314 | 0.29 | 8.8 | 325–451 | 381 | 0.91 | 56.1 |

| R+10K+10GE+5F | 188–224 | 204 | 0.05 | 1.8 | 224–277 | 262 | 0.17 | 6.9 | 277–325 | 318 | 0.26 | 11.3 | 325–446 | 385 | 0.80 | 49.8 |

| R+10K+10APP | n.d. | 209 | 0.06 | n.d. | 217–275 | 257 | 0.16 | 6.9 | 275–333 | 317 | 0.42 | 19.3 | 333–445 | 365 | 1.02 | 43.8 |

| R+10K+10APP+5F | 170–218 | 207 | 0.05 | 2.1 | 218–334 | 317 | 0.38 | 25.9 | n.d. | n.d. | n.d. | n.d. | 334–441 | 368 | 1.00 | 42.7 |

| Sample SRPUF | T2%, °C | T5%, °C | T10%, °C | T50%, °C | U700, % |

|---|---|---|---|---|---|

| R* | 196 | 240 | 246 | 319 | 0.06 |

| R+10K | 217 | 239 | 243 | 332 | 0.13 |

| R+10K+5F | 219 | 239 | 243 | 338 | 3.51 |

| R+10K+10ATH | 196 | 232 | 245 | 351 | 3.95 |

| R+10K+10ATH+5F | 218 | 239 | 242 | 346 | 3.58 |

| R+10K+10MTH | 197 | 235 | 243 | 351 | 4.24 |

| R+10K+10MTH+5F | 219 | 239 | 245 | 351 | 5.25 |

| R+10K+10ZO | 219 | 239 | 242 | 351 | 5.25 |

| R+10K+10ZO+5F | 198 | 236 | 244 | 365 | 6.01 |

| R+10K+10GE | 219 | 238 | 242 | 342 | 0.81 |

| R+10K+10GE+5F | 198 | 233 | 246 | 358 | 4.04 |

| R+10K+10APP | 215 | 241 | 246 | 393 | 4.11 |

| R+10K+10APP+5F | 195 | 231 | 249 | 394 | 3.05 |

| Sample SRPUF | Stage1, °C | T1, °C | V1, %/°C | m1, % | Stage 2, °C | T2, °C | V2, %/°C | m2, % | Stage 3, °C | T3, °C | V3, %/°C | m3, % | Stage4, °C | T4, °C | V4, %/°C | m4, % |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R* | 226–306 | 248 | 1.81 | 44.6 | n.d. | n.d. | n.d. | n.d. | 306–379 | 338 | 0.16 | 9.8 | 374–663 | 520 | 0.48 | 42.4 |

| R+10K | 232–267 | 244 | 1.92 | 30.4 | 267–306 | 278 | 0.40 | 12.6 | 306–394 | 328 | 0.18 | 11.3 | 394–636 | 514 | 0.52 | 43.3 |

| R+10K+5F | 235–256 | 246 | 1.84 | 19.4 | 256–381 | 280 | 0.47 | 28.1 | n.d. | n.d. | n.d. | n.d. | 381–660 | 514 | 0.49 | 46.0 |

| R+10K+10ATH | 218–270 | 244 | 1.66 | 30.7 | 270–312 | 279 | 0.41 | 13.0 | 312–399 | 332 | 0.16 | 10.1 | 399–653 | 516 | 0.48 | 40.8 |

| R+10K+10ATH+5F | 223–263 | 246 | 1.70 | 23.0 | 263–383 | 280 | 0.48 | 25.2 | n.d. | n.d. | n.d. | n.d. | 383–699 | 514 | 0.46 | 43.8 |

| R+10K+10MTH | 222–269 | 245 | 1.62 | 29.0 | 269–304 | 280 | 0.37 | 14.0 | 304–408 | 366 | 0.12 | 14.0 | 408–663 | 513 | 0.46 | 43.4 |

| R+10K+10MTH+F | 221–265 | 245 | 1.81 | 25.1 | 265–340 | 280 | 0.43 | 20.0 | 340–400 | 368 | 0.11 | 5.9 | 400–668 | 513 | 0.44 | 41.1 |

| R+10K+10ZO | 227–266 | 243 | 1.71 | 27.6 | 266–310 | 278 | 0.38 | 13.4 | 310–391 | 329 | 0.16 | 9.8 | 391–650 | 511 | 0.54 | 41.4 |

| R+10 K+10 ZO+5F | 228–261 | 245 | 1.81 | 21.8 | 261–381 | 278 | 0.42 | 25.4 | n.d. | n.d. | n.d. | n.d. | 381–638 | 510 | 0.48 | 42.8 |

| R+10K+10GE | 222–268 | 245 | 1.67 | 28.7 | 268–394 | 276 | 0.43 | 23.8 | n.d. | n.d. | n.d. | n.d. | 394–630 | 519 | 0.49 | 41.7 |

| R+10K+10GE+5F | 227–265 | 248 | 1.36 | 21.1 | 265–382 | 284 | 0.52 | 26.4 | n.d. | n.d. | n.d. | n.d. | 382–660 | 520 | 0.46 | 44.0 |

| R+10 K+10APP | 229–263 | 247 | 1.24 | 19.3 | 263–381 | 277 | 0.48 | 26.8 | n.d. | n.d. | n.d. | n.d. | 381–622 | 517 | 0.46 | 42.6 |

| R+10K+10APP+5F | 231–267 | 252 | 0.94 | 17.8 | 267–385 | 285 | 0.52 | 26.6 | n.d. | n.d. | n.d. | n.d. | 385–612 | 515 | 0.45 | 40.7 |

| Sample SRPUF | TTI, s | TTF, s | pHRRm, kW/m2 | MARHE, kW/m2 | pHRR/ t(pHRR), kW/m2s | THR, MJ/m2 | MLR, g/s | SEA, m2/kg | TSP, m2/m2 | pCO, kg/kg | pCO2, kg/kg |

|---|---|---|---|---|---|---|---|---|---|---|---|

| R* | 4 | 154 | 359 | 217 | 6 | 25 | 0.14 | 2298 | 502 | 0.31 | 15.31 |

| R+10K | 2 | 218 | 283 | 213 | 5 | 31 | 0.23 | 640 | 612 | 0.35 | 15.54 |

| R+10K+5F | 2 | 166 | 350 | 210 | 6 | 26 | 0.20 | 458 | 608 | 0.59 | 12.97 |

| R+10K+10ATH | 4 | 216 | 307 | 195 | 6 | 31 | 0.27 | 365 | 460 | 0.29 | 14.81 |

| R+10K+10ATH+5F | 12 | 322 | 248 | 177 | 3 | 39 | 0.24 | 1062 | 1102 | 0.47 | 13.06 |

| R+10K+10MTH | 4 | 226 | 301 | 215 | 6 | 35 | 0.23 | 805 | 1002 | 0.21 | 13.90 |

| R+10K+10MTH+5F | 14 | 260 | 298 | 169 | 4 | 29 | 0.26 | 697 | 973 | 0.32 | 12.41 |

| R+10K+10ZO | 6 | 196 | 491 | 251 | 8 | 40 | 0.32 | 688 | 975 | 0.32 | 14.00 |

| R+10K+10ZO+5F | 8 | 218 | 453 | 258 | 7 | 38 | 1.84 | 1295 | 987 | 0.41 | 14.67 |

| R+10K+10GE | 6 | 490 | 165 | 95 | 10 | 32 | 0.16 | 134 | 194 | 0.44 | 16.21 |

| R+10K+10GE+5F | 8 | 436 | 147 | 97 | 8 | 29 | 0.15 | 813 | 687 | 0.31 | 12.68 |

| R+10K+10APP | 4 | 170 | 341 | 235 | 4 | 30 | 0.28 | 757 | 1071 | 0.34 | 12.54 |

| R+10K+10APP+5F | 2 | 164 | 305 | 240 | 4 | 30 | 3.86 | 278 | 297 | 0.27 | 12.42 |

| Sample SRPUF | Dimensional Stability % | Water Absorption, % | ||

|---|---|---|---|---|

| X-Axis (Opposite to the Growth Direction) | Y-Axis (Opposite to the Growth Direction) | Z-Axis (According to the Growth Direction) | ||

| R* | 0.77 ± 0.42 | 0.73 ± 0.25 | 4.97 ± 1.62 | 8.78 ± 0.64 |

| R+10K | 0.60 ± 0.11 | 0.46 ± 0.21 | 0.86 ± 1.85 | 7.95 ± 1.06 |

| R+10K+5F | 1.29 ± 0.54 | 1.28 ± 0.79 | 4.11 ± 1.05 | 15.18 ± 4.34 |

| R+10K+10ATH | 1.09 ± 0.22 | 0.58 ± 0.19 | 4.76 ± 2.54 | 12.93 ± 1.11 |

| R+10K+10ATH+5F | 0.99 ± 0.31 | 1.80 ± 0.04 | 6.74 ± 4.71 | 13.19 ± 3.45 |

| R+10K+10MTH | 0.92 ± 0.02 | 1.50 ± 0.39 | 1.19 ± 0.30 | 16.17 ± 1.34 |

| R+10K+10MTH+5F | −0.81 ± 0.31 | 3.24 ± 1.38 | 2.66 ± 0.98 | 20.51 ± 3.65 |

| R+10K+10ZO | −1.26 ± 0.26 | 2.53 ± 0.48 | 4.51 ± 0.90 | 11.67 ± 1.66 |

| R+10K+10ZO+5F | 0.75 ± 0.19 | 1.74 ± 1.47 | 3.11 ± 0.19 | 14.98 ± 0.81 |

| R+10K+10GE | −6.84 ± 2.93 | 8.13 ± 3.02 | 3.15 ± 0.36 | 9.95 ± 1.25 |

| R+10K+10GE+5F | 0.98 ± 0.08 | 1.01 ± 0.19 | 2.71 ± 0.70 | 12.22 ± 1.14 |

| R+10K+10APP | −1.88 ± 0.46 | 4.67 ± 3.52 | 3.04 ± 1.06 | 10.48 ± 2.89 |

| R+10K+10APP+5F | 1.21 ± 0.16 | 1.26 ± 0.88 | 3.83 ± 1.80 | 12.66 ± 2.89 |

| Sample | d [um] | AR |

|---|---|---|

| R | 25.01 ± 15.90 | 1.30 ± 0.20 |

| R+10K | 23.80 ± 14.08 | 1.25 ± 0.21 |

| R+10K+5F | 23.71 ± 15.77 | 1.27 ± 0.20 |

| R+10K+10GE | 24.84 ± 14.30 | 1.32 ± 0.26 |

| R+10K+10GE+5F | 24.58 ± 17.21 | 1.25 ± 0.17 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wrześniewska-Tosik, K.; Ryszkowska, J.; Mik, T.; Wesołowska, E.; Kowalewski, T.; Pałczyńska, M.; Sałasińska, K.; Walisiak, D.; Czajka, A. Composites of Semi-Rigid Polyurethane Foams with Keratin Fibers Derived from Poultry Feathers and Flame Retardant Additives. Polymers 2020, 12, 2943. https://doi.org/10.3390/polym12122943

Wrześniewska-Tosik K, Ryszkowska J, Mik T, Wesołowska E, Kowalewski T, Pałczyńska M, Sałasińska K, Walisiak D, Czajka A. Composites of Semi-Rigid Polyurethane Foams with Keratin Fibers Derived from Poultry Feathers and Flame Retardant Additives. Polymers. 2020; 12(12):2943. https://doi.org/10.3390/polym12122943

Chicago/Turabian StyleWrześniewska-Tosik, Krystyna, Joanna Ryszkowska, Tomasz Mik, Ewa Wesołowska, Tomasz Kowalewski, Michalina Pałczyńska, Kamila Sałasińska, Damian Walisiak, and Anna Czajka. 2020. "Composites of Semi-Rigid Polyurethane Foams with Keratin Fibers Derived from Poultry Feathers and Flame Retardant Additives" Polymers 12, no. 12: 2943. https://doi.org/10.3390/polym12122943

APA StyleWrześniewska-Tosik, K., Ryszkowska, J., Mik, T., Wesołowska, E., Kowalewski, T., Pałczyńska, M., Sałasińska, K., Walisiak, D., & Czajka, A. (2020). Composites of Semi-Rigid Polyurethane Foams with Keratin Fibers Derived from Poultry Feathers and Flame Retardant Additives. Polymers, 12(12), 2943. https://doi.org/10.3390/polym12122943