Surface Finishing of 3D-Printed Polymers with Selected Coatings

Abstract

:1. Introduction

2. Materials and Methods

2.1. 3D Printing of the Substrates

2.2. Surface Wettability and Determination of Surface Free Energy (SFE)

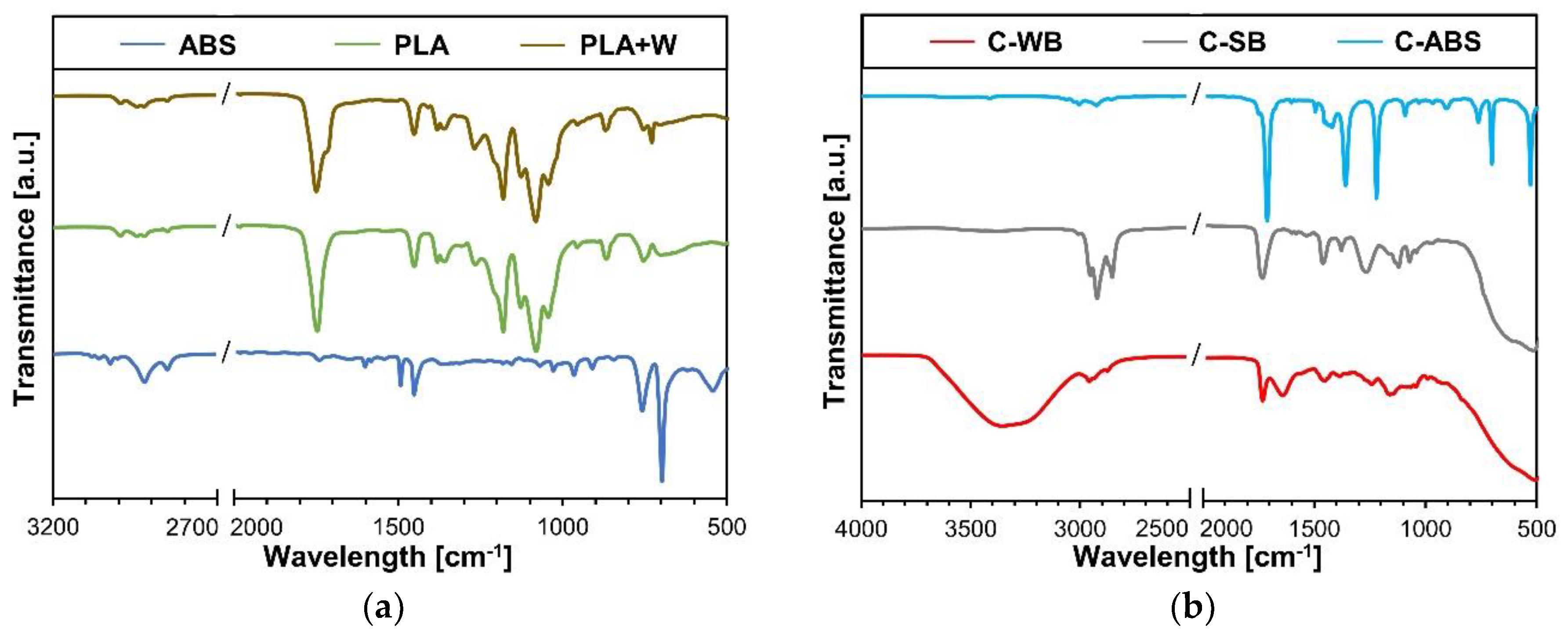

2.3. Attenuated Total Reflection Fourier Transform Infrared (ATR FT-IR) Spectroscopy

2.4. Coatings and Coating Films Formation

2.5. Determination of Visual Properties

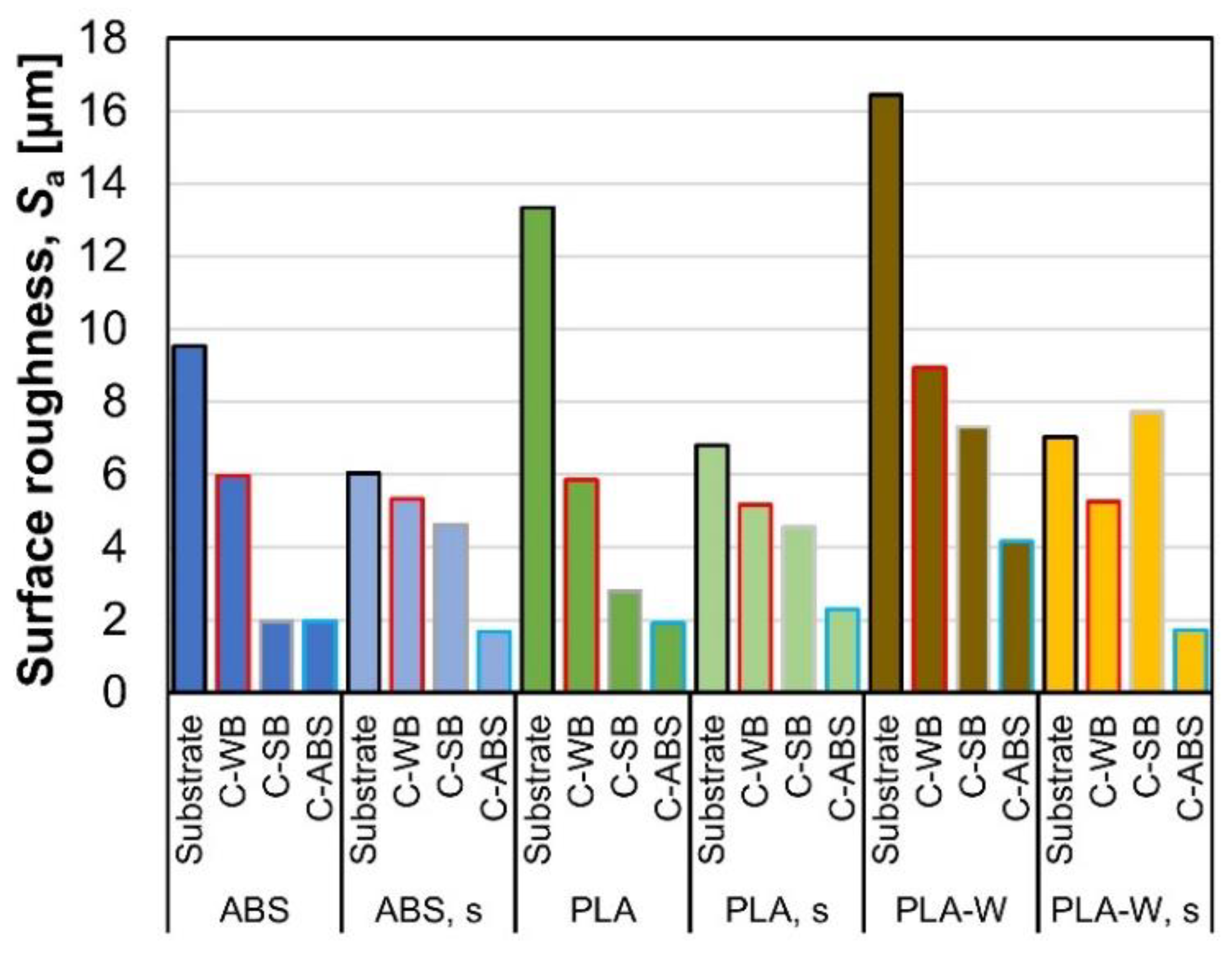

2.6. Determination of Surface Roughness

2.7. Microscopic Analysis

2.8. Determination of Coating Adhesion Strength

3. Results and Discussion

3.1. Surface Free Energy

3.2. ATR-FTIR Spectra

3.3. Surface Color and Gloss

3.4. Surface Roughness

3.5. Microscopic Structure of Coated Polymers

3.6. Coating Adhesion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Conner, B.P.; Manogharan, G.P.; Martof, A.N.; Rodomsky, L.M.; Rodomsky, C.M.; Jordan, D.C.; Limperos, J.W. Making sense of 3-D printing: Creating a map of additive manufacturing products and services. Addit. Manuf. 2014, 1–4, 64–76. [Google Scholar] [CrossRef]

- Sachs, E.; Cima, M.; Cornie, J.; Brancazio, D.; Bredt, J.; Curodeau, A.; Fan, T.; Khanuja, S.; Lauder, A.; Lee, J.; et al. Three-DimensionaI printing: The physics and implications of additive manufacturing. Ann. CIRP 1993, 42, 257–260. [Google Scholar] [CrossRef]

- Shahrubudin, N.; Lee, T.C.; Ramlan, R. An Overview on 3D Printing Technology: Technological, Materials, and Applications. 2nd International Conference on Sustainable Materials Processing and Manufacturing (SMPM 2019). Procedia Manuf. 2019, 35, 1286–1296. [Google Scholar] [CrossRef]

- Mikeš, J.; Pekárek, S.; Babčenko, O.; Hanuš, O.; Kákona, J.; Štenclová, P. 3D printing materials for generators of active particles based on electrical discharges. Plasma Process Polym. 2020, 17, e1900150. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies; Springer: New York, NY, USA, 2014; p. 484. [Google Scholar]

- Brinsko-Beckert, K.; Palenik, C.S. The analysis of 3D printer dust for forensic applications. J. Forensic. Sci. 2020, 65, 1480–1496. [Google Scholar] [CrossRef]

- Ramesh, P.; Vinodh, S. State of art review on Life Cycle Assessment of polymers. Int. J. Sustain. Eng. 2020, 1–12. [Google Scholar] [CrossRef]

- Torrado Perez, A.R.; Roberson, D.A.; Wicker, R.B. Fracture surface analysis of 3D-Printed tensile specimens of novel ABS-Based materials. J. Fail. Anal. Preven. 2014, 14, 343–353. [Google Scholar] [CrossRef]

- Faludi, G.; Dora, G.; Renner, K.; Móczó, J.; Pukánszky, B. Improving interfacial adhesion in PLA/wood biocomposites. Compos. Sci. Technol. 2013, 89, 77–82. [Google Scholar] [CrossRef] [Green Version]

- Ayrilmis, N.; Kariz, M.; Kwon, J.H.; Kitek Kuzman, M. Effect of printing layer thickness on water absorption and mechanical properties of 3D-printed wood/PLA composite materials. Int. J. Adv. Manuf. Technol. 2019, 102, 2195–2200. [Google Scholar] [CrossRef]

- Mazzanti, V.; Malagutti, L.; Mollica, F. FDM 3D printing of polymers containing natural fillers: A review of their mechanical properties. Polymers 2019, 11, 1094. [Google Scholar] [CrossRef] [Green Version]

- Ayrilmis, N.; Kariž, M.; Kitek Kuzman, M. Effect of wood flour content on surface properties of 3D printed materials produced from wood flour/PLA filament. Int. J. Polym. Anal. Charact. 2019, 24, 659–666. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Zolfagharian, A.; Jennings, M.; Reinicke, T. Structural performance of 3D-printed composites under various loads and environmental conditions. Polym. Test. 2020, 91, 106770. [Google Scholar] [CrossRef]

- Rintz, R.A. Adhesion to Plastics; Molding and Paintability: Polymer Surfaces and Interfaces, 1st ed.; Global Press: Chicago, IL, USA, 1998; p. 255. [Google Scholar]

- Wu, J.-Z.; Bouwman, E.; Reedijk, J. Chelating ligands as powerful additives to manganese driers for solvent-borne and water-borne alkyd paints. Prog. Org. Coat. 2004, 49, 103–108. [Google Scholar] [CrossRef]

- Lanzetta, M.; Sachs, E. Improved surface finish in 3D printing using bimodal powder distribution. Rapid Prototyp. J. 2003, 9, 157–166. [Google Scholar] [CrossRef]

- Meyer, P.; Döpke, C.; Ehrmann, A. Improving adhesion of three-dimensional printed objects on textile fabrics by polymer coating. J. Eng. Fibers. Fabr. 2019, 14, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Eom, A.-H.; Won, J.-P. Selection of functional materials for surface-coating of structural synthetic fibres and development of a 3D-printing system for their manufacture. Compos. Struct. 2020, 249, 112567. [Google Scholar] [CrossRef]

- Olakanmi, E.O.; Strydom, M.J. Critical materials and processing challenges affecting the interface and functional performance of wood polymer composites (WPCs). Mater. Chem. Phys. 2016, 171, 290–302. [Google Scholar] [CrossRef]

- Papadopoulos, A.N.; Taghiyari, H.R. Innovative wood surface treatments based on nanotechnology. Coatings 2019, 9, 866. [Google Scholar] [CrossRef] [Green Version]

- Kumbhar, N.N.; Mulay, A.V. Post processing methods used to improve surface finish of products which are manufactured by additive manufacturing technologies: A review. J. Inst. Eng. India Ser. C 2018, 99, 481–487. [Google Scholar] [CrossRef]

- Sauerbier, P.; Köhler, R.; Renner, G.; Militz, H. Surface activation of polylactic acid-based wood-plastic composite by atmospheric pressure plasma treatment. Materials 2020, 13, 4673. [Google Scholar] [CrossRef]

- Rodríguez, J.F.; Thomas, J.P.; Renaud, J.E. Mechanical behavior of acrylonitrile butadiene styrene (ABS). Experimental investigation. Rapid Prototyp. J. 2001, 7, 148–158. [Google Scholar] [CrossRef]

- Yeh, S.-K.; Agarwal, S.; Gupta, R.K. Wood–plastic composites formulated with virgin and recycled ABS. Compos. Sci. Technol. 2009, 69, 2225–2230. [Google Scholar] [CrossRef]

- Matuana, L.M.; Cam, S.; Yuhasz, K.B.; Armstrong, Q.J. Composites of Acrylonitrile-Butadiene-Styrene filled with wood flour. Polym. Polym. Compos. 2007, 15, 365–370. [Google Scholar] [CrossRef]

- Deng, W.; Long, M.; Zhou, Q.; Wen, N.; Deng, W. One-step preparation of superhydrophobic acrylonitrile-butadienestyrene copolymer coating for ultrafast separation of water-in-oil emulsions. J. Colloid Interface Sci. 2018, 511, 21–26. [Google Scholar] [CrossRef]

- Bateni, F.; Ahmad, F.; Shukri Yahya, A.; Azmi, M. Performance of oil palm empty fruit bunch fibres coated with acrylonitrile butadiene styrene. Constr. Build. Mater. 2011, 25, 124–1829. [Google Scholar] [CrossRef]

- Garlotta, D.A. Literature Review of Poly(Lactic Acid). J. Polym. Environ. 2001, 9, 63–84. [Google Scholar] [CrossRef]

- Oksman, K.; Skrifvars, M.; Selin, J.-F. Natural fibres as reinforcement in polylactic acid (PLA) composites. Compos. Sci. Technol. 2003, 63, 1317–1324. [Google Scholar] [CrossRef]

- Huda, M.S.; Drzal, L.T.; Misra, M.; Mohanty, A.K. Wood-Fiber-Reinforced poly(lactic acid) composites: Evaluation of the physicomechanical and morphological properties. J. Appl. Polym. Sci. 2006, 102, 4856–4869. [Google Scholar] [CrossRef]

- Kowalczyk, P.; Trzaskowska, P.; Łojszczyk, I.; Podgórski, R.; Ciach, T. Production of 3D printed polylactide scaffolds with surface grafted hydrogel coatings. Colloids Surf. B Biointerfaces 2019, 179, 136–142. [Google Scholar] [CrossRef]

- Lee, K.-M.; Park, H.; Kim, J.; Chun, D.-M. Fabrication of a superhydrophobic surface using a fused deposition modeling (FDM) 3D printer with poly lactic acid (PLA) filament and dip coating with silica nanoparticles. Appl. Surf. Sci. 2019, 467–468, 979–991. [Google Scholar] [CrossRef]

- Young, T. An essay on the cohesion of fluids. Philos. Trans. R. Soc. Lond. 1805, 95, 65–87. [Google Scholar] [CrossRef]

- Adam, N.K. Use of the term ‘Young’s equation’ for contact angles. Nature 1957, 180, 809–810. [Google Scholar] [CrossRef]

- Owens, D.K.; Wendt, R.C. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Unger, L.; Scheideler, M.; Meyer, P.; Harland, J.; Görzen, A.; Wortmann, M.; Dreyer, A.; Ehrmann, A. Increasing adhesion of 3D printing on textile fabrics by polymer coating. Tekstilec 2018, 61, 265–271. [Google Scholar] [CrossRef]

- Marciniak, D.; Szewczykowski, P.; Czyżewski, P.; Sykutera, D.; Bieliński, M. Effect of surface modification by acetone vaporization on the structure of 3D printed acrylonitrile-butadiene-styrene elements. Polimery 2018, 63, 11–12. [Google Scholar] [CrossRef]

- European Committee for Standardization. EN ISO 4624:2016 Paints and Varnishes—Pull-off Test for Adhesion (ISO 4624:2016); European Committee for Standardization: Brussels, Belgium, 2016. [Google Scholar]

- Wang, p.; Zou, B.; Ding, S. Modeling of surface roughness based on heat transfer considering diffusion among deposition filaments for FDM 3D printing heat-resistant resin. Appl. Therm. Eng. 2019, 161, 114064. [Google Scholar] [CrossRef]

- Wu, S. Polar and nonpolar interactions in adhesion. J. Adhes. 1973, 5, 39–55. [Google Scholar] [CrossRef]

- Darmanin, T.; Guittard, F. Wettability of conducting polymers: From superhydrophilicity to superoleophobicity. Prog. Polym. Sci. 2014, 39, 656–682. [Google Scholar] [CrossRef]

- Saviello, D.; Pouyet, E.; Toniolo, L.; Cotte, M.; Nevin, A. Synchrotron-based FTIR microspectroscopy for the mapping of photo-oxidation and additives in acrylonitrile–butadiene–styrene model samples and historical objects. Anal. Chim. Acta 2014, 843, 59–72. [Google Scholar] [CrossRef]

- Aldoori, H.; Bouberka, Z.; Nadim, A.; Agguine, Y.; Eddarir, S.; Supiot, P.; Foissac, C.; Maschke, U. Photodegradation of decabromo diphenyl ether flame retardant in poly (acrylonitrile butadiene styrene) (ABS). J. Macromol. Sci. Part B Phys. 2020, 59, 609–620. [Google Scholar] [CrossRef]

- Ashwin, B.; Abinaya, B.; Prasith, T.P.; Chandran, V.; Roshini Yadav, L.; Vairamani, M.; Shantanu, P.; Selvamurugan, N. 3D-poly (lactic acid) scaffolds coated with gelatin and mucic acid for bone tissue engineering. Int. J. Biol. Macromol. 2020, 162, 523–532. [Google Scholar] [CrossRef] [PubMed]

- Mofokeng, J.P.; Luyt, A.S.; Tábi, T.; Kovács, J. Comparison of injection moulded, natural fibre-reinforced composites with PP and PLA as matrices. J. Thermoplast. Compos. Mater. 2011, 25, 927–948. [Google Scholar] [CrossRef]

- Csikós, Á.; Faludi, G.; Domján, A.; Renner, K.; Móczó, J.; Pukánszky, B. Modification of interfacial adhesion with a functionalized polymer in PLA/wood composites. Eur. Polym. J. 2015, 68, 592–600. [Google Scholar] [CrossRef] [Green Version]

- Prapruddivongs, C.; Sombatsompop, N. Roles and evidence of wood flour as an antibacterial promoter for triclosan-filled poly(lactic acid). Compos. Part B 2012, 43, 2730–2737. [Google Scholar] [CrossRef]

- Han, R.; Zhang, Y. Studies on performance of cured water-borne melamine-acrylic emulsion coatings. J. Adhes. Sci. Technol. 2011, 25, 883–892. [Google Scholar] [CrossRef]

- Pardini, O.R.; Amalvy, J.I. FTIR, 1H-NMR spectra, and thermal characterization of water-based polyurethane/acrylic hybrids. J. Appl. Polym. Sci. 2007, 107, 1207–1214. [Google Scholar] [CrossRef]

- Hayes, P.A.; Vahur, S.; Leito, I. ATR-FTIR spectroscopy and quantitative multivariate analysis of paints and coating materials. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2014, 133, 207–213. [Google Scholar] [CrossRef]

- Hasan, M.A.; Zaki, M.I.; Pasupulety, L. Oxide-catalyzed conversion of acetic acid into acetone: An FTIR spectroscopic investigation. Appl. Catal. A: Gen. 2003, 243, 1–81. [Google Scholar] [CrossRef]

- Zorll, U. New aspects of gloss of paint film and its measurement. Prog. Org. Coat. 1972, 1, 113–155. [Google Scholar] [CrossRef]

- Yang, H.; Ji, F.; Li, Z.; Tao, S. Preparation of hydrophobic surface on PLA and ABS by fused deposition modeling. Polymers 2020, 12, 1539. [Google Scholar] [CrossRef]

- Zhu, J.; Chen, J.L.; Lade, R.K., Jr.; Suszynski, W.J.; Francis, L.F. Water-based coatings for 3D printed parts. J. Coat. Technol. Res. 2015, 12, 889–897. [Google Scholar] [CrossRef]

- Sanatgar, R.H.; Campagne, C.; Nierstrasz, V. Investigation of the adhesion properties of direct 3D printing of polymers and nanocomposites on textiles: Effect of FDM printing process parameters. Appl. Surf. Sci. 2017, 403, 551–563. [Google Scholar] [CrossRef]

- Kim, J.K.; Thomas, S.; Saha, P. Multicomponent Polymeric Materials; Springer: Dordrecht, The Netherlands, 2016. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, R.; Farina, I.; Colangelo, F.; Feo, L.; Fraternali, F. Multi-Material additive manufacturing of sustainable innovative materials and structures. Polymers 2019, 11, 62. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Color Space Param. | Sample Type | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ABS | PLA | PLA-W | ||||||||||

| Subst. | C-WB | C-SB | C-ABS | Subst. | C-WB | C-SB | C-ABS | Subst. | C-WB | C-SB | C-ABS | |

| L* | 39.63 | 97.51 | 95.07 | 38.00 | 80.91 | 98.19 | 95.22 | 63.58 | 68.57 | 97.62 | 95.00 | 55.58 |

| a* | −7.51 | −1.09 | −1.27 | −7.21 | −1.12 | −0.72 | −1.12 | −19.40 | 5.69 | −0.92 | −1.24 | −15.00 |

| b* | −26.62 | 1.36 | 3.63 | −26.30 | 1.90 | 2.28 | 3.72 | −2.02 | 16.17 | 2.02 | 3.58 | −7.87 |

| ABS, s | PLA, s | PLA-W, s | ||||||||||

| Subst. | C-WB | C-SB | C-ABS | Subst. | C-WB | C-SB | C-ABS | Subst. | C-WB | C-SB | C-ABS | |

| L* | 43.84 | 96.97 | 94.84 | 40.43 | 81.43 | 98.1 | 95.28 | 67.04 | 70.24 | 97.09 | 94.68 | 60.71 |

| a* | −8.81 | −1.27 | −1.47 | −8.09 | −1.05 | −0.76 | −1.07 | −17.50 | 5.11 | −1.03 | −1.29 | −10.10 |

| b* | −24.72 | 0.83 | 3.15 | −26.02 | 1.98 | 2.15 | 3.80 | −17.10 | 14.88 | 1.56 | 2.71 | −0.80 |

| Film Thickness [µm] | Sample Type | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| ABS | PLA | PLA-W | |||||||

| C-WB | C-SB | C-ABS 1 | C-WB | C-SB | C-ABS 1 | C-WB | C-SB | C-ABS 1 | |

| Average | 64.7 | 81.8 | 49.7 | 77.2 | 85.8 | 67.7 | 74.8 | 90.4 | 76 |

| St. dev. | 8 | 5.1 | 20.9 | 2.5 | 3.3 | 9.2 | 4.1 | 7.4 | 12.2 |

| ABS, s | PLA, s | PLA-W, s | |||||||

| C-WB | C-SB | C-ABS 1 | C-WB | C-SB | C-ABS 1 | C-WB | C-SB | C-ABS 1 | |

| Average | 57.2 | 70.2 | 75.1 | 50.6 | 61.9 | 63.7 | 42.8 | 57.2 | 43.4 |

| St. dev. | 5.6 | 3.7 | 6.3 | 11.3 | 6.7 | 7.4 | 6.1 | 9.8 | 5.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Žigon, J.; Kariž, M.; Pavlič, M. Surface Finishing of 3D-Printed Polymers with Selected Coatings. Polymers 2020, 12, 2797. https://doi.org/10.3390/polym12122797

Žigon J, Kariž M, Pavlič M. Surface Finishing of 3D-Printed Polymers with Selected Coatings. Polymers. 2020; 12(12):2797. https://doi.org/10.3390/polym12122797

Chicago/Turabian StyleŽigon, Jure, Mirko Kariž, and Matjaž Pavlič. 2020. "Surface Finishing of 3D-Printed Polymers with Selected Coatings" Polymers 12, no. 12: 2797. https://doi.org/10.3390/polym12122797

APA StyleŽigon, J., Kariž, M., & Pavlič, M. (2020). Surface Finishing of 3D-Printed Polymers with Selected Coatings. Polymers, 12(12), 2797. https://doi.org/10.3390/polym12122797