A Magneto-Hyperelastic Model for Silicone Rubber-Based Isotropic Magnetorheological Elastomer under Quasi-Static Compressive Loading

Abstract

1. Introduction

2. Materials and Experiments

2.1. Materials Preparation

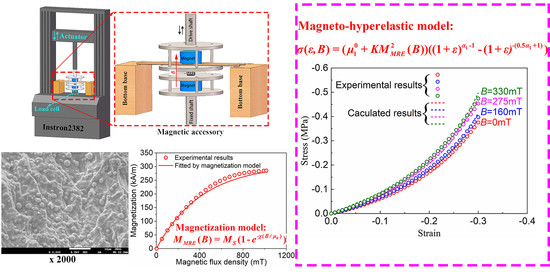

2.2. Microstructure, Magnetization Characterization and Compression Experiments

3. Experimental Results and Modeling

3.1. Microstructure

3.2. Magnetization Property and Magnetization Model

3.3. Compression Experimental Results

3.4. Magneto-Hyperelastic Model

3.4.1. Ogden Hyperelastic Model

3.4.2. Magnetic-Field-Dependent Function of Stiffness Parameter

3.4.3. Magneto-Hyperelastic Model and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Jolly, M.R.; Carlson, J.D.; Munoz, B.C. A model of the behaviour of magnetorheological materials. Smart Mater. Struct. 1996, 5, 607–614. [Google Scholar] [CrossRef]

- Davis, L.C. Model of magnetorheological elastomers. J. Appl. Phys. 1999, 85, 3348–3351. [Google Scholar] [CrossRef]

- Varga, Z.; Filipcsei, G.; Zrinyi, M. Magnetic field sensitive functional elastomers with tuneable elastic modulus. Polymer 2006, 47, 227–233. [Google Scholar] [CrossRef]

- Soriahernandez, C.G.; Palaciospineda, L.M.; Eliaszuniga, A.; Peralesmartinez, A.; Martinezromero, O. Investigation of the Effect of Carbonyl Iron Micro-Particles on the Mechanical and Rheological Properties of Isotropic and Anisotropic MREs: Constitutive Magneto-Mechanical Material Model. Polymers 2019, 11, 1705. [Google Scholar] [CrossRef] [PubMed]

- Schubert, G.; Harrison, P.G. Large-strain behaviour of magneto-rheological elastomers tested under uniaxial compression and tension, and pure shear deformations. Polym. Test. 2015, 42, 122–134. [Google Scholar] [CrossRef]

- Deng, H.; Gong, X.; Wang, L. Development of an adaptive tuned vibration absorber with magnetorheological elastomer. Smart Mater. Struct. 2006, 15, N111–N116. [Google Scholar] [CrossRef]

- Fu, J.; Lai, J.; Yang, Z.; Bai, J.; Yu, M. Fuzzy-neural network control for a magnetorheological elastomer vibration isolation system. Smart Mater. Struct. 2020, 29, 074001. [Google Scholar] [CrossRef]

- Hu, T.; Xuan, S.; Ding, L.; Gong, X. Stretchable and magneto-sensitive strain sensor based on silver nanowire-polyurethane sponge enhanced magnetorheological elastomer. Mater. Des. 2018, 156, 528–537. [Google Scholar] [CrossRef]

- Sedlacik, M.; Mrlik, M.; Babayan, V.; Pavlinek, V. Magnetorheological elastomers with efficient electromagnetic shielding. Compos. Struct. 2016, 135, 199–204. [Google Scholar] [CrossRef]

- Yun, G.; Tang, S.; Sun, S.; Yuan, D.; Zhao, Q.; Deng, L.; Yan, S.; Du, H.; Dickey, M.D.; Li, W. Liquid metal-filled magnetorheological elastomer with positive piezoconductivity. Nat. Commun. 2019, 10, 1–9. [Google Scholar] [CrossRef]

- Gordaninejad, F.; Wang, X.; Mysore, P. Behavior of thick magnetorheological elastomers. J. Intell. Mater. Syst. Struct. 2012, 23, 1033–1039. [Google Scholar] [CrossRef]

- Ivaneyko, D.; Toshchevikov, V.; Saphiannikova, M.; Heinrich, G. Effects of particle distribution on mechanical properties of magneto-sensitive elastomers in a homogeneous magnetic field. Condens. Matter Phys. 2012, 15, 33601. [Google Scholar] [CrossRef]

- Liao, G.; Gong, X.; Xuan, S.; Guo, C.; Zong, L. Magnetic-field-induced normal force of magnetorheological elastomer under compression status. Ind. Eng. Chem. Res. 2012, 51, 3322–3328. [Google Scholar] [CrossRef]

- Koo, J.; Khan, F.; Jang, D.; Jung, H. Dynamic characterization and modeling of magneto-rheological elastomers under compressive loadings. Smart Mater. Struct. 2010, 19, 117002. [Google Scholar] [CrossRef]

- Liao, G.; Gong, X.; Xuan, S. Magnetic field-induced compressive property of magnetorheological elastomer under high strain rate. Ind. Eng. Chem. Res. 2013, 52, 8445–8453. [Google Scholar] [CrossRef]

- Vatandoost, H.; Norouzi, M.; Alehashem, S.M.; Smoukov, S.K. A novel phenomenological model for dynamic behavior of magnetorheological elastomers in tension-compression mode. Smart Mater. Struct. 2017, 26, 065011. [Google Scholar] [CrossRef]

- Khanouki, M.A.; Sedaghati, R.; Hemmatian, M. Experimental characterization and microscale modeling of isotropic and anisotropic magnetorheological elastomers. Compos. Part B Eng. 2019, 176, 107311. [Google Scholar] [CrossRef]

- Nadzharyan, T.A.; Sorokin, V.V.; Stepanov, G.V.; Bogolyubov, A.N.; Kramarenko, E.Y. A fractional calculus approach to modeling rheological behavior of soft magnetic elastomers. Polymer 2016, 92, 179–188. [Google Scholar] [CrossRef]

- Liu, T.; Gong, X.; Xu, Y.; Xuan, S.; Jiang, W. Simulation of magneto-induced rearrangeable microstructures of magnetorheological plastomers. Soft Matter 2013, 9, 10069–10080. [Google Scholar] [CrossRef]

- Wang, Q.; Dong, X.; Li, L.; Ou, J. A nonlinear model of magnetorheological elastomer with wide amplitude range and variable frequencies. Smart Mater. Struct. 2017, 26, 065010. [Google Scholar] [CrossRef]

- Li, R.; Sun, L.Z. Viscoelastic responses of silicone-rubber-based magnetorheological elastomers under compressive and shear loadings. J. Eng. Mater. Technol. Trans. ASME 2013, 135, 021008. [Google Scholar] [CrossRef]

- Ogden, R.W. Large deformation isotropic elasticity-on the correlation of theory and experiment for incompressible rubberlike solids. Proc. R. Soc. A Math. Phys. Eng. Sci. 1972, 326, 565–584. [Google Scholar]

- Sasso, M.; Palmieri, G.; Chiappini, G.; Amodio, D. Characterization of hyperelastic rubber-like materials by biaxial and uniaxial stretching tests based on optical methods. Polym. Test. 2008, 27, 995–1004. [Google Scholar] [CrossRef]

- Li, W.; Xin, Z. Flexural fatigue life prediction of a tooth V-belt made of fiber reinforced rubber. Int. J. Fatigue 2018, 111, 269–277. [Google Scholar] [CrossRef]

- Beda, T. Optimizing the Ogden strain energy expression of rubber materials. J. Eng. Mater. Technol. Trans. ASME 2005, 127, 351–353. [Google Scholar] [CrossRef]

- Ivaneyko, D.; Toshchevikov, V.; Saphiannikova, M.; Heinrich, G. Magneto-sensitive Elastomers in a Homogeneous Magnetic Field: A Regular Rectangular Lattice Model. Macromol. Theory Simul. 2011, 20, 411–424. [Google Scholar] [CrossRef]

- Ivaneyko, D.; Toshchevikov, V.; Borin, D.; Saphiannikova, M.; Heinrich, G. Mechanical Properties of Magneto-Sensitive Elastomers in a Homogeneous Magnetic Field: Theory and Experiment. Macromol. Symp. 2014, 338, 96–107. [Google Scholar] [CrossRef]

- Fan, Y.C.; Gong, X.L.; Jiang, W.Q.; Zhang, W.; Wei, B.; Li, W.H. Effect of maleic anhydride on the damping property of magnetorheological elastomers. Smart Mater. Struct. 2010, 19, 055015. [Google Scholar] [CrossRef]

- Farshad, M.; Le Roux, M. Compression properties of magnetostrictive polymer composite gels. Polym. Test. 2005, 24, 163–168. [Google Scholar] [CrossRef]

| B (mT) | μ1 (Pa) | ±Δμ1 (Pa) | α1 |

|---|---|---|---|

| 0 | 44,705 | 524 | 10.13 |

| 160 | 47,869 | 864 | 10.13 |

| 275 | 55,045 | 869 | 10.13 |

| 330 | 57,431 | 291 | 10.13 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiao, Y.; Zhang, J.; Zhang, M.; Liu, L.; Zhai, P. A Magneto-Hyperelastic Model for Silicone Rubber-Based Isotropic Magnetorheological Elastomer under Quasi-Static Compressive Loading. Polymers 2020, 12, 2435. https://doi.org/10.3390/polym12112435

Qiao Y, Zhang J, Zhang M, Liu L, Zhai P. A Magneto-Hyperelastic Model for Silicone Rubber-Based Isotropic Magnetorheological Elastomer under Quasi-Static Compressive Loading. Polymers. 2020; 12(11):2435. https://doi.org/10.3390/polym12112435

Chicago/Turabian StyleQiao, Yanliang, Jiangtao Zhang, Mei Zhang, Lisheng Liu, and Pengcheng Zhai. 2020. "A Magneto-Hyperelastic Model for Silicone Rubber-Based Isotropic Magnetorheological Elastomer under Quasi-Static Compressive Loading" Polymers 12, no. 11: 2435. https://doi.org/10.3390/polym12112435

APA StyleQiao, Y., Zhang, J., Zhang, M., Liu, L., & Zhai, P. (2020). A Magneto-Hyperelastic Model for Silicone Rubber-Based Isotropic Magnetorheological Elastomer under Quasi-Static Compressive Loading. Polymers, 12(11), 2435. https://doi.org/10.3390/polym12112435