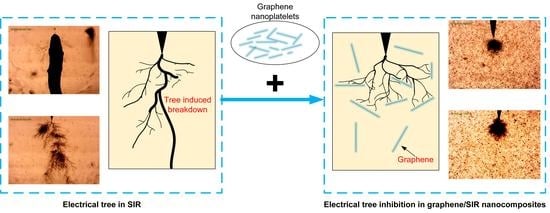

Inhibition Effect of Graphene Nanoplatelets on Electrical Degradation in Silicone Rubber

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Graphene/SIR Nanocomposites

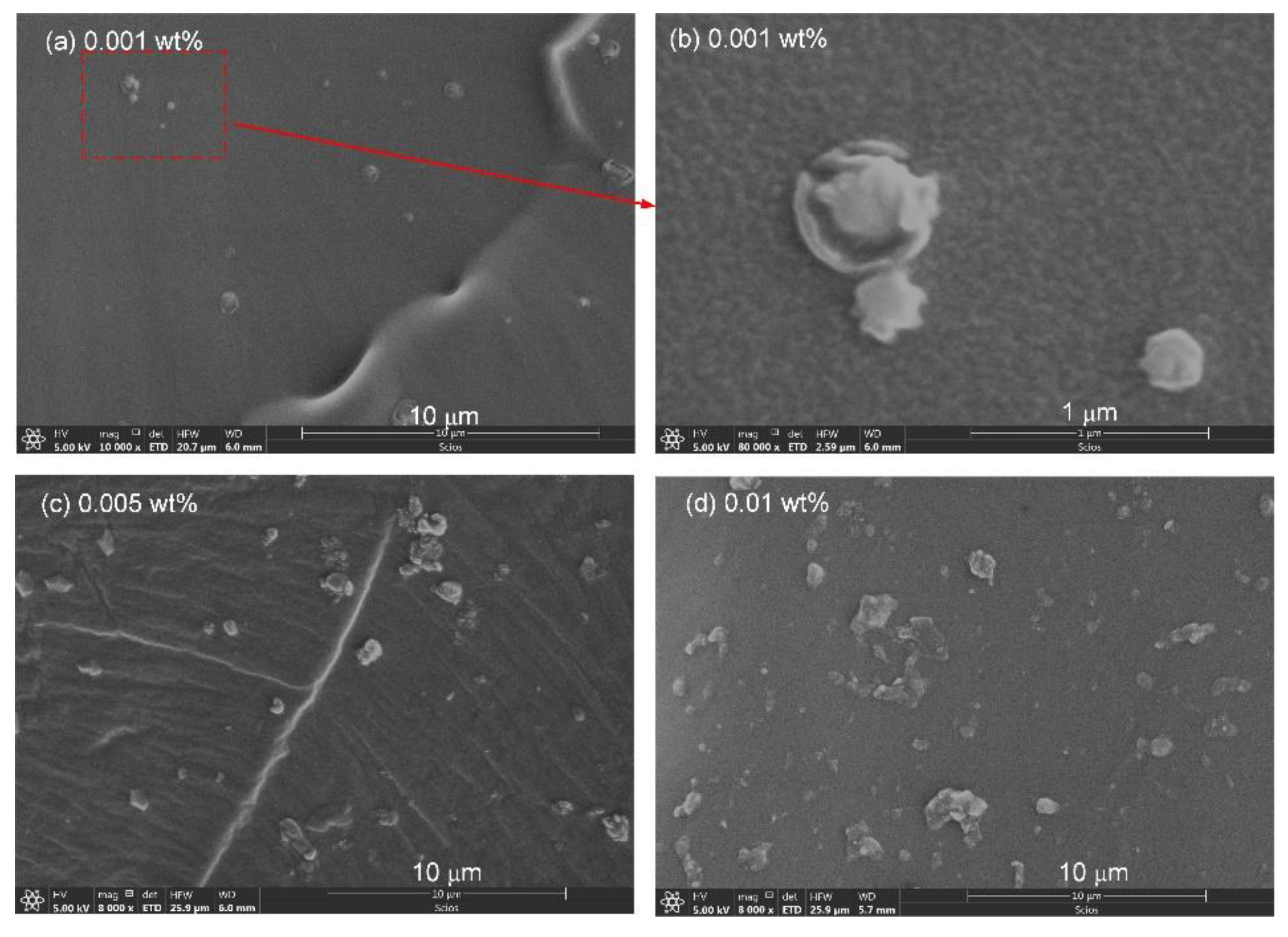

2.2. Morphology Analysis of Nanocomposites

2.3. Conductivity Measurement

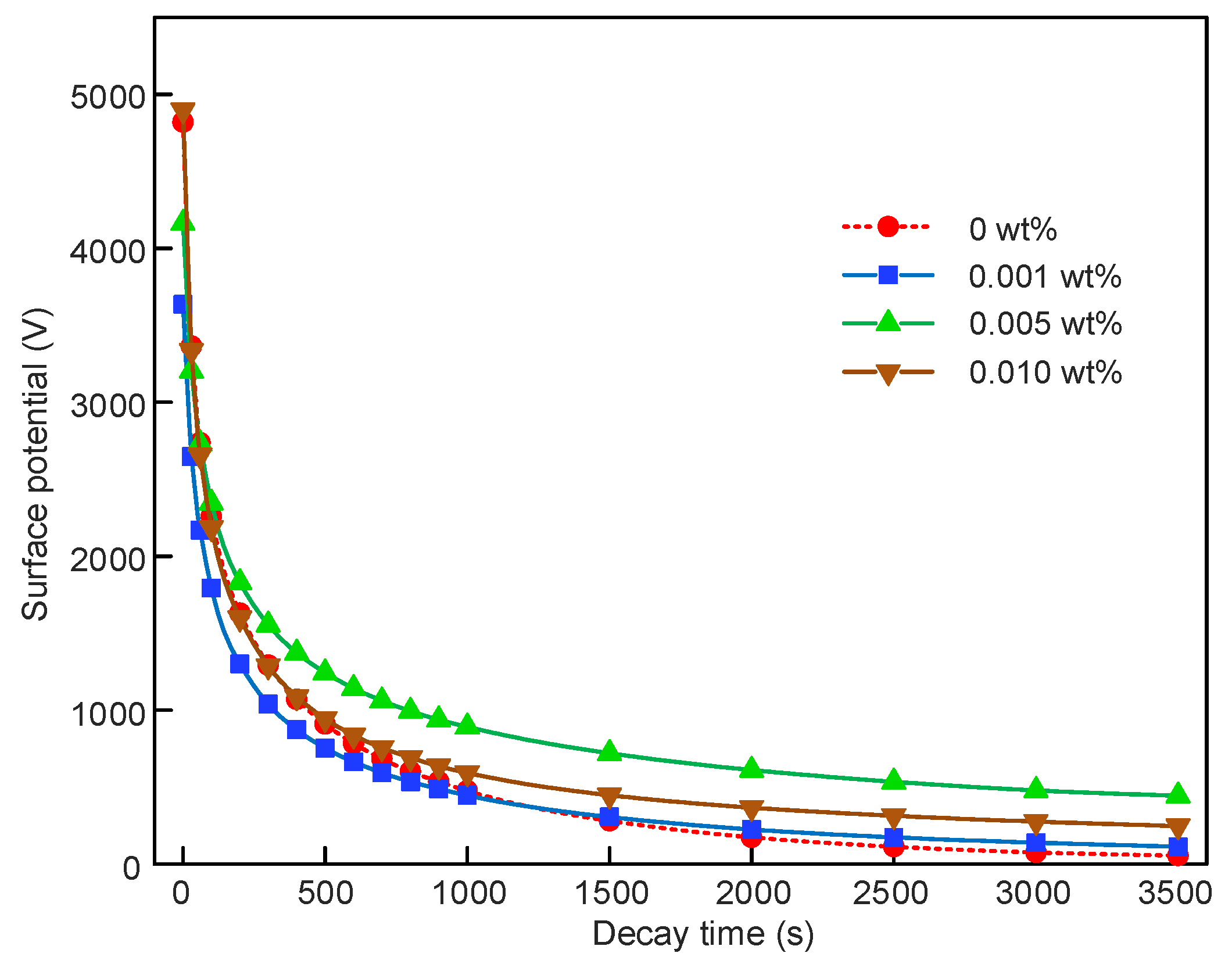

2.4. Surface Potential Decay and Trap Distribution Measurement

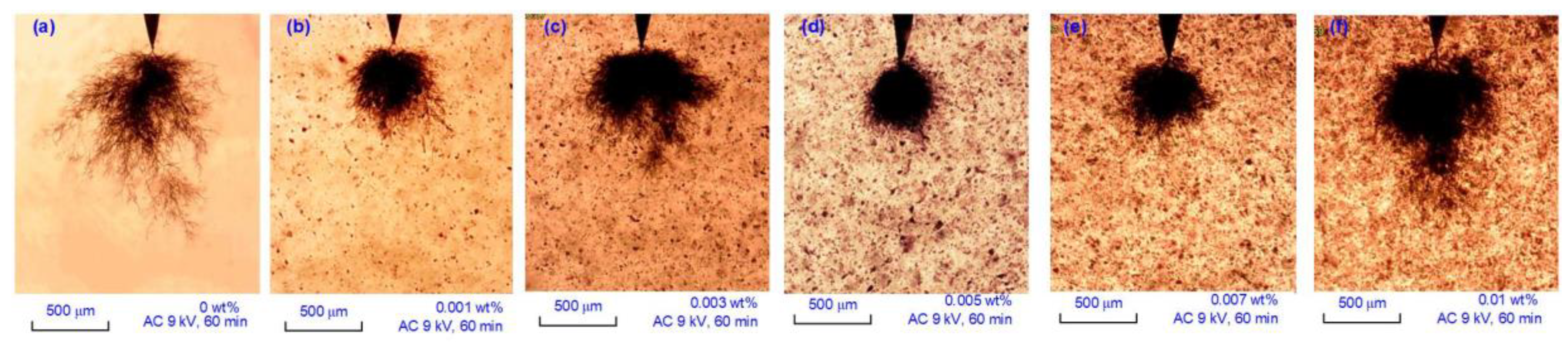

2.5. Electrical Treeing Experiments

3. Results

3.1. Morphology and SEM

3.2. DC Conductivity of Graphene/SIR Nanocomposites

3.3. SPD Characteristics and Trap Distribution of Graphene/SIR Nanocomposites

3.4. Electrical Tree in Graphene/SIR Nanocomposites

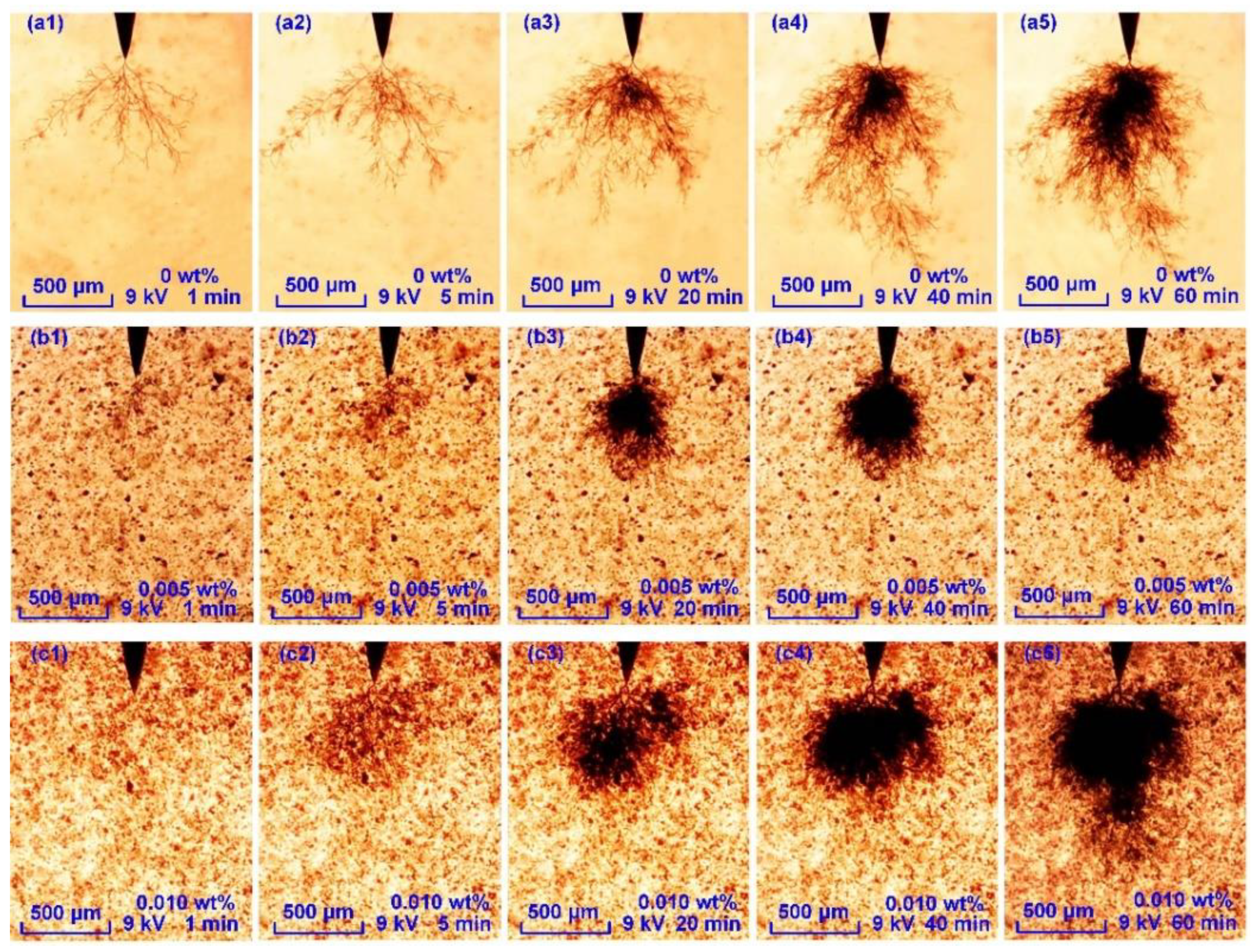

3.4.1. Tree Structure in Graphene/SIR Nanocomposites

3.4.2. Tree Inception Voltage in Graphene/SIR Nanocomposites

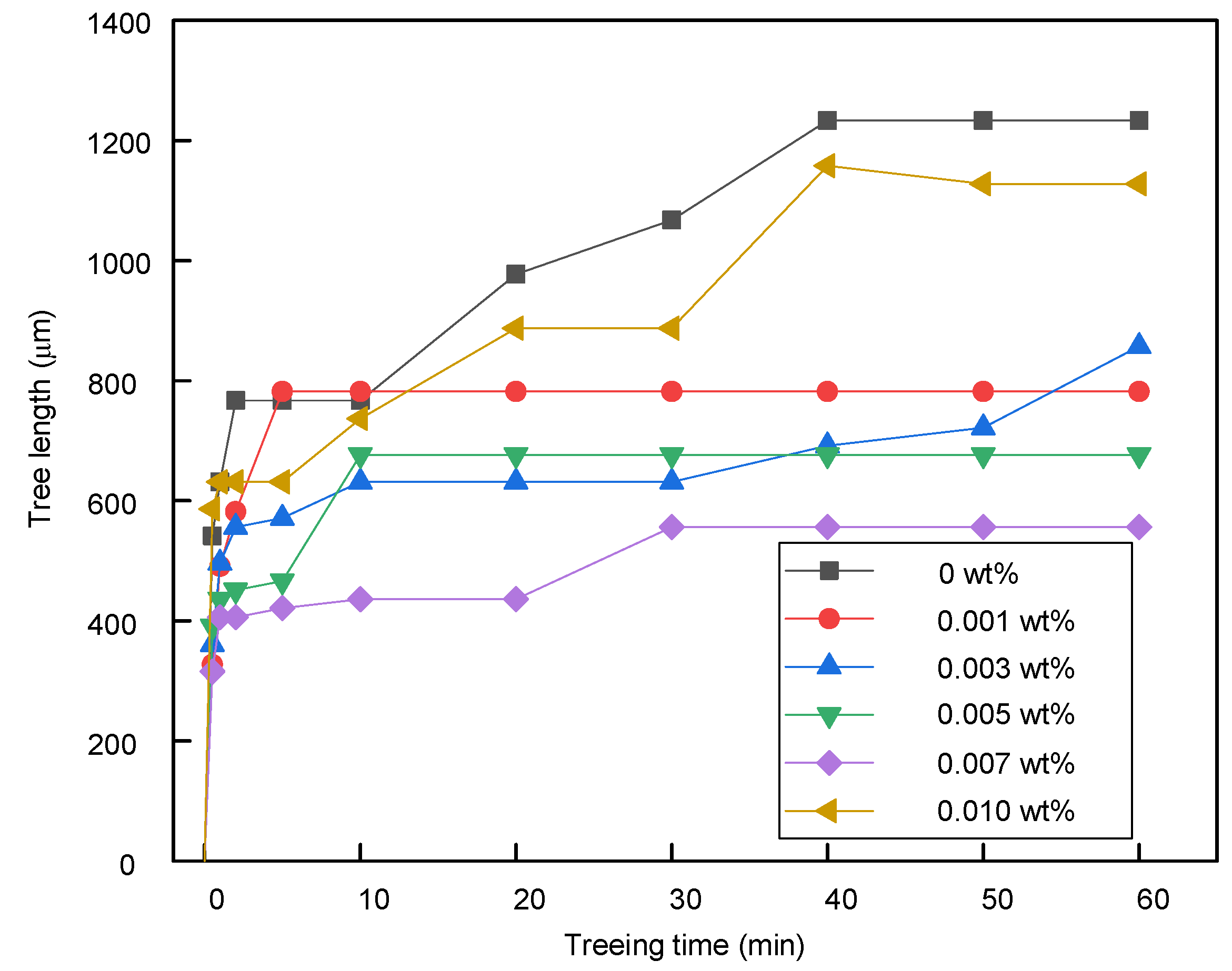

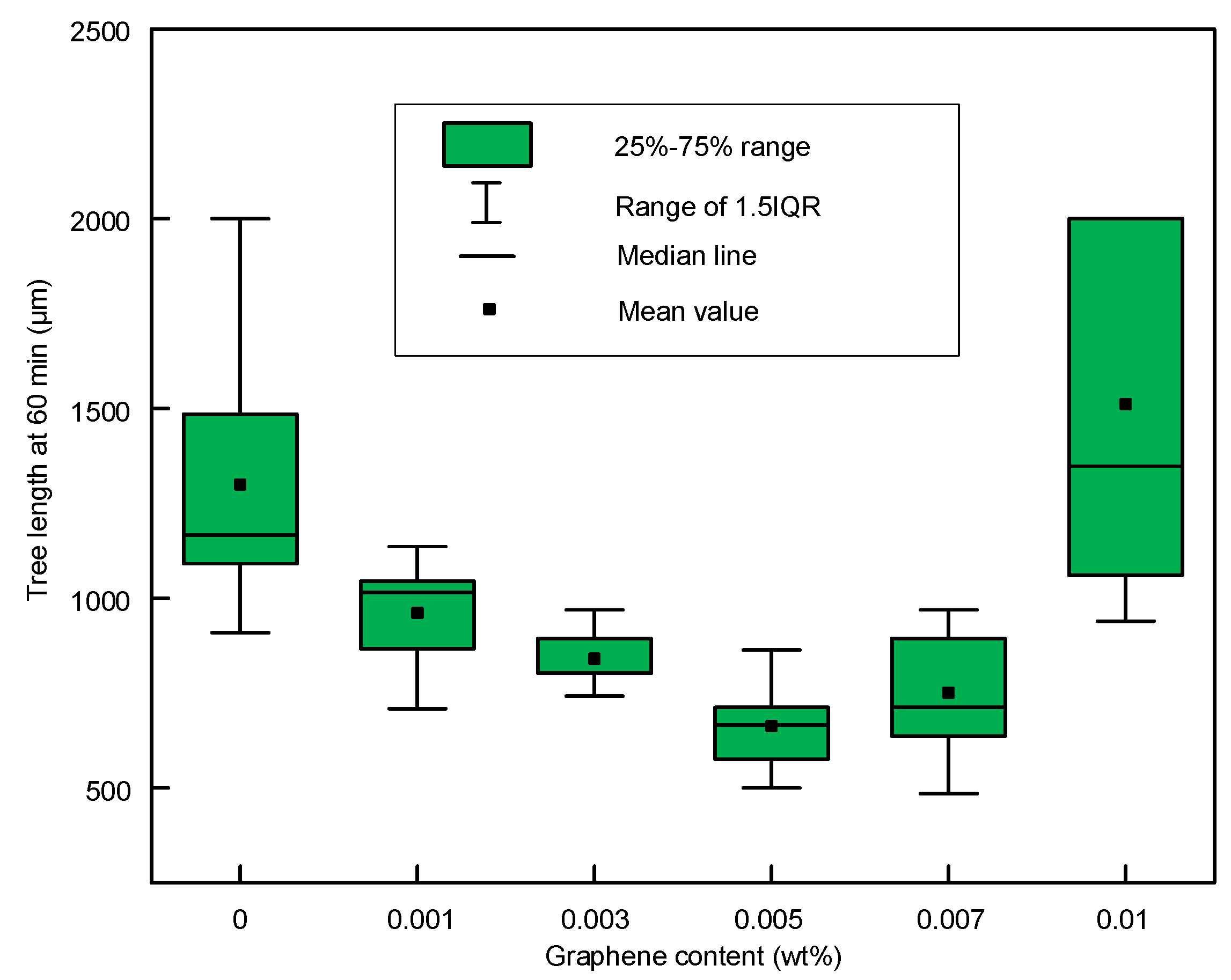

3.4.3. Tree Growth in Graphene/SIR Nanocomposites

4. Discussion

4.1. Tree Inception

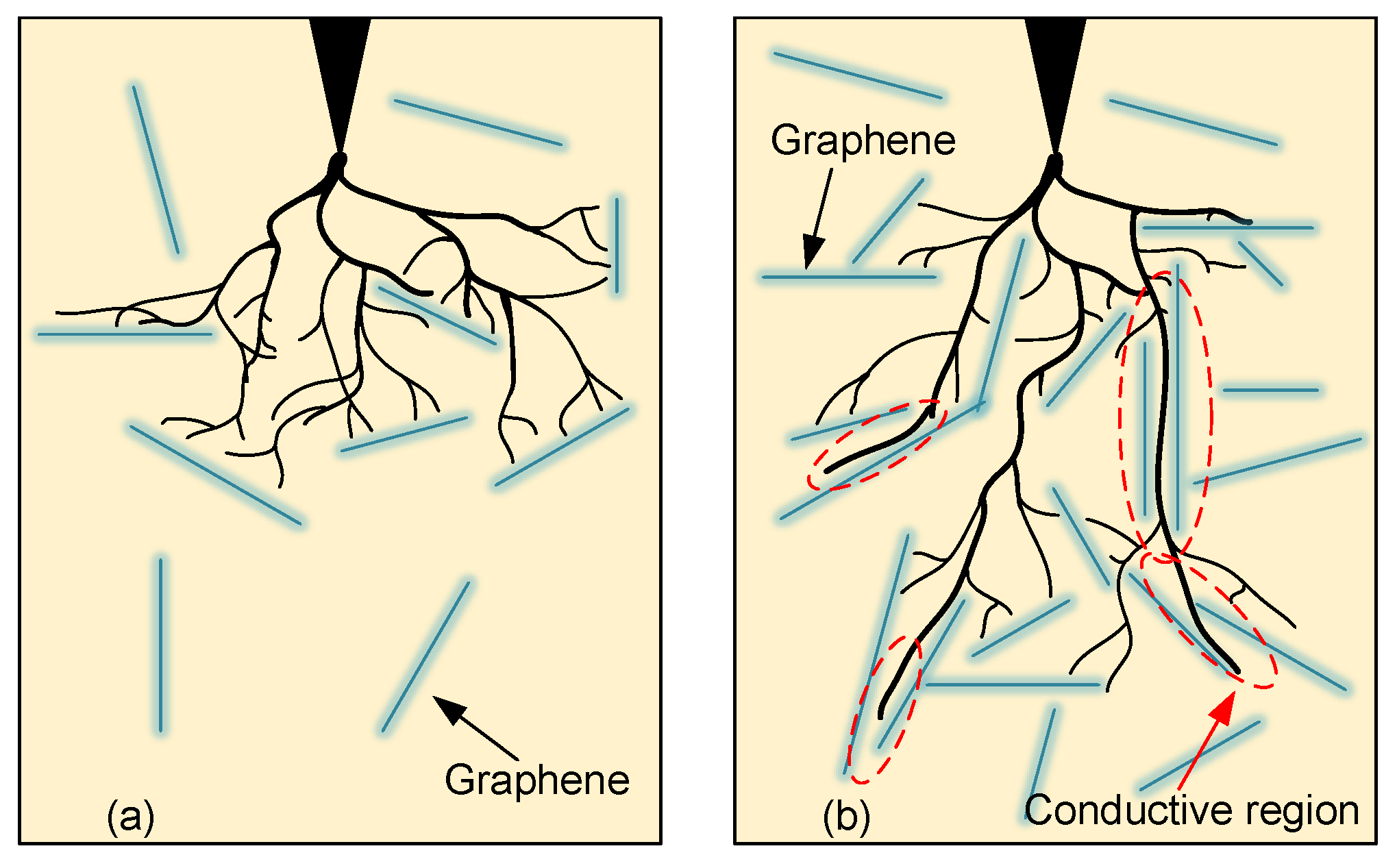

4.2. Tree Growth

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Shit, S.C.; Shah, P. A review on silicone rubber. Natl. Acad. Sci. Lett. 2013, 36, 355–365. [Google Scholar] [CrossRef]

- Wang, X.; Wang, C.C.; Wu, K.; Tu, D.M.; Liu, S.; Peng, J.K. An improved optimal design scheme for high voltage cable accessories. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 5–15. [Google Scholar] [CrossRef]

- Ye, H.Y.; Fechner, T.; Lei, X.Z.; Luo, Y.; Zhou, M.Y.; Han, Z.Y.; Wang, H.T.; Zhuang, Q.K.; Xu, R.Y.; Li, D. Review on HVDC cable terminations. High Volt. 2018, 3, 79–89. [Google Scholar] [CrossRef]

- Liu, T.; Hui, B.; Fu, M.; Hou, S.; Luo, B.; Wang, G. Experimental and simulation analysis of electrical breakdown for 220kV silicone rubber pre-moulded cable joints. In Proceedings of the 13th International Electrical Insulation Conference, Birmingham, UK, 16–18 May 2017. [Google Scholar]

- Han, T.; Du, B.X.; Su, J.G. Electrical Tree Initiation and Growth in Silicone Rubber under Combined DC-Pulse Voltage. Energies 2018, 11, 764. [Google Scholar] [CrossRef]

- Zhou, Y.X.; Liu, R.; Hou, F.; Zhang, X.; Xue, W.B. Morphology of electrical trees in silicon rubber. J. Electrost. 2013, 71, 440–448. [Google Scholar] [CrossRef]

- Eichhorn, R.M. Treeing, a mechanism of breakdown in solid dielectrics. In Proceedings of the IEEE International Symposium on Electrical Insulation, Toronto, ON, Canada, 3–6 June 1990. [Google Scholar]

- Shimizu, N.; Laurent, C. Electrical tree initiation. IEEE Trans. Dielectr. Electr. Insul. 1998, 5, 651–659. [Google Scholar] [CrossRef]

- Bian, W.C.; Wang, W.X.; Yang, Y. A self-healing and electrical-tree-inhibiting epoxy composite with hydrogen-bonds and SiO2 particles. Polymers 2017, 9, 431. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.R.; Xu, Y.; Cao, X.L.; Gubanski, S.M. Electrical treeing behavior at high temperature in XLPE cable insulation samples. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 2015. [Google Scholar] [CrossRef]

- Alapati, S.; Thomas, M.J. Influence of nano-fillers on electrical treeing in epoxy insulation. IET Sci. Meas. Technol. 2012, 6, 21–28. [Google Scholar] [CrossRef]

- Yamano, Y. Control of electrical tree at initiation stage in LDPE by mixed addition of Al2O3 nano-particle and azobenzoic compound. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 209–216. [Google Scholar] [CrossRef]

- Sridhar, A.; Thomas, M.J. Electrical treeing in polyethylene: Effect of nano fillers on tree inception and growth. In Proceedings of the 2010 International Conference on High Voltage Engineering and Application, New Orleans, LA, USA, 11–14 October 2010. [Google Scholar]

- Chi, X.H.; Gao, J.G.; Zhang, X.H. Electrical tree propagating characteristics of polyethylene/nano-montmorillonite composites. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 1530–1536. [Google Scholar] [CrossRef]

- Du, B.X.; Han, T.; Su, J.G. Tree characteristics in silicone rubber/SiO2 nanocomposites under low temperature. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 503–510. [Google Scholar] [CrossRef]

- Jamil, A.A.A.; Bashir, N.; Ahmad, M.H.; Arief, Y.Z.; Kamarol, M.; Mariatti, M. Electrical treeing initiation and propagation in silicone rubber nanocomposites. In Proceedings of the 2013 IEEE Conference on Electrical Insulation and Dielectric Phenomena, Shenzhen, China, 20–23 October 2013. [Google Scholar]

- Hafiz, M.; Fairus, M.; Mariatti, M.; Kamarol, M. A comparative study on electrical tree growth in silicone rubber containing nanoalumina and halloysite nanoclay. IEEE Access 2019, 7, 24452–24462. [Google Scholar] [CrossRef]

- Tanaka, T.; Kozako, M.; Fuse, N.; Ohki, Y. Proposal of a multi-core model for polymer nanocomposite dielectrics. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 669–681. [Google Scholar] [CrossRef]

- Vogelsang, R.; Farr, T.; Frohlich, K. The effect of barriers on electrical tree propagation in composite insulation materials. IEEE Trans. Dielectr. Electr. Insul. 2006, 13, 373–382. [Google Scholar] [CrossRef]

- Danikas, M.G.; Tanaka, T. Nanocomposites—A review of electrical treeing and breakdown. IEEE Electr. Insul. Mag. 2009, 25, 19–25. [Google Scholar] [CrossRef]

- Yang, H.; Yao, X.F.; Zheng, Z.; Gong, L.H.; Yuan, L.; Yuan, Y.N.; Liu, Y.H. Highly sensitive and stretchable graphene-silicone rubber composites for strain sensing. Compos. Sci. Technol. 2018, 167, 371–378. [Google Scholar] [CrossRef]

- Zhang, G.W.; Wang, F.Z.; Dai, J.; Huang, Z.X. Effect of functionalization of graphene nanoplatelets on the mechanical and thermal properties of silicone rubber composites. Materials 2016, 9, 92. [Google Scholar] [CrossRef]

- Wang, Y.; Qiu, X.; Zheng, J. Effect of the sheet size on the thermal stability of silicone rubber–reduced graphene oxide nanocomposites. J. Appl. Polym. Sci. 2019, 136, 47034. [Google Scholar] [CrossRef]

- Sanchez-Hidalgo, R.; Blanco, C.; Menendez, R.; Verdejo, R.; Lopez-Manchado, M.A. Multifunctional silicone rubber nanocomposites by controlling the structure and morphology of graphene material. Polymers 2019, 11, 449. [Google Scholar] [CrossRef]

- Li, Z.L.; Du, B.X.; Yang, Z.R.; Han, C.L. Temperature dependent trap level characteristics of graphene/LDPE nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 137–144. [Google Scholar] [CrossRef]

- Li, Z.L.; Su, J.G.; Du, B.X.; Hou, Z.H.; Han, C.L. Inhibition effect of graphene on space charge injection and accumulation in low-density polyethylene. Nanomaterials 2018, 8, 956. [Google Scholar] [CrossRef]

- Du, B.X.; Su, J.G.; Tian, M.; Han, T.; Li, J. Understanding trap effects on electrical treeing phenomena in EPDM/POSS composites. Sci. Rep. 2019, 8, 8481. [Google Scholar] [CrossRef]

- Du, B.X.; Yang, Z.R.; Li, Z.L.; Li, J. Temperature-dependent nonlinear conductivity and carrier mobility of silicone rubber/SiC composites. IEEE Trans. Dielectr. Electr. Insul. 2008, 25, 1080–1087. [Google Scholar] [CrossRef]

- Han, T.; Du, B.X.; Ma, T.T.; Wang, F.Y.; Gao, Y.; Lei, Z.P.; Li, C.Y. Electrical Tree in HTV Silicone Rubber with Temperature Gradient under Repetitive Pulse Voltage. IEEE Access 2019, 7, 41250–41260. [Google Scholar] [CrossRef]

- Simmons, J.G.; Tam, M.C. Theory of isothermal currents and the direct determination of trap parameters in semiconductors and insulators containing arbitrary trap distributions. Phys. Rev. B 1973, 7, 3706–3712. [Google Scholar] [CrossRef]

- Kindersberger, J.; Lederle, C. Surface charge decay on insulators in air and sulfurhexafluorid-Part II: Measurements. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 949–957. [Google Scholar] [CrossRef]

- Li, C.; Lin, C.; Chen, G.; Tu, Y.; Zhou, Y.; Li, Q.; Zhang, B.; He, J. Field-dependent charging phenomenon of HVDC spacers based on dominant charge behaviors. Appl. Phys. Lett. 2019, 114, 202904. [Google Scholar] [CrossRef]

- Tanaka, T.; Greenwood, A. Effects of space charge injection and extraction on tree initiation in polyethylene. IEEE Trans. Power Appar. Syst. 1978, 97, 1749–1759. [Google Scholar] [CrossRef]

- Alapati, S.; Thomas, M.J. Electrical Treeing and the Associated PD Characteristics in LDPE Nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 697–704. [Google Scholar] [CrossRef]

| Graphene Content (wt %) | 0 | 0.001 | 0.003 | 0.005 | 0.007 | 0.010 |

|---|---|---|---|---|---|---|

| Relative permittivity | 3.16 | 3.05 | 3.18 | 3.19 | 3.22 | 3.28 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, T.; Du, B.; Su, J.; Gao, Y.; Xing, Y.; Fang, S.; Li, C.; Lei, Z. Inhibition Effect of Graphene Nanoplatelets on Electrical Degradation in Silicone Rubber. Polymers 2019, 11, 968. https://doi.org/10.3390/polym11060968

Han T, Du B, Su J, Gao Y, Xing Y, Fang S, Li C, Lei Z. Inhibition Effect of Graphene Nanoplatelets on Electrical Degradation in Silicone Rubber. Polymers. 2019; 11(6):968. https://doi.org/10.3390/polym11060968

Chicago/Turabian StyleHan, Tao, Boxue Du, Jingang Su, Yu Gao, Yunqi Xing, Shengchen Fang, Chuanyang Li, and Zhipeng Lei. 2019. "Inhibition Effect of Graphene Nanoplatelets on Electrical Degradation in Silicone Rubber" Polymers 11, no. 6: 968. https://doi.org/10.3390/polym11060968

APA StyleHan, T., Du, B., Su, J., Gao, Y., Xing, Y., Fang, S., Li, C., & Lei, Z. (2019). Inhibition Effect of Graphene Nanoplatelets on Electrical Degradation in Silicone Rubber. Polymers, 11(6), 968. https://doi.org/10.3390/polym11060968