Enhancing the Interfacial Strength of Carbon Fiber/Poly(ether ether ketone) Hybrid Composites by Plasma Treatments

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

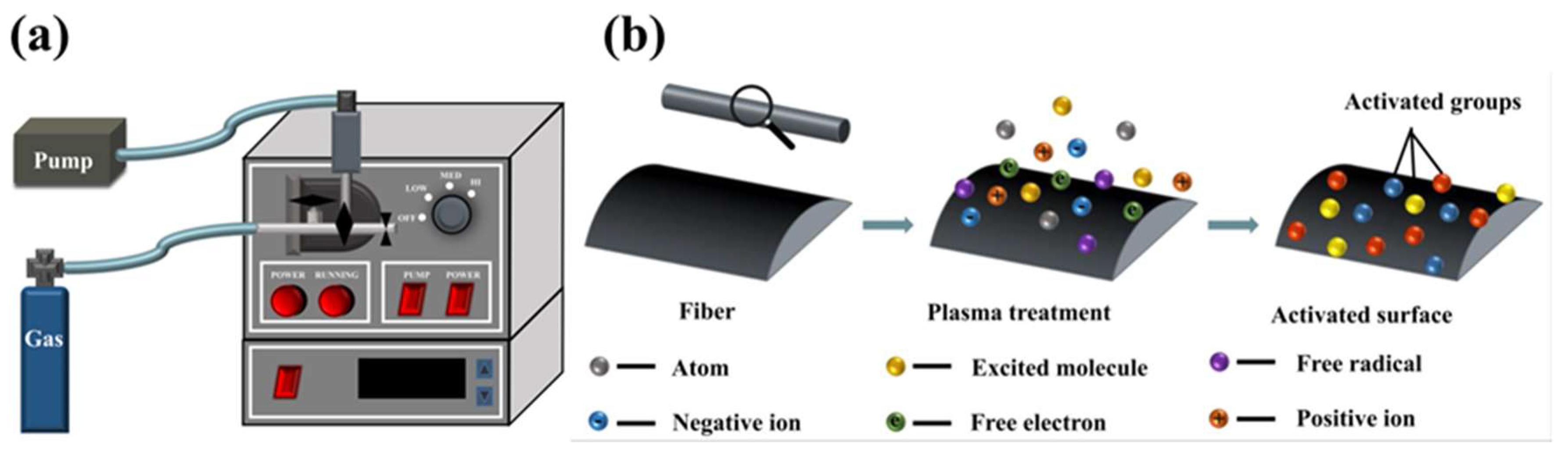

2.2. Plasma Treatments

2.3. Characterizations

2.3.1. Surface Morphology

2.3.2. Raman Spectroscopy

2.3.3. Single-Fiber Tensile Test

2.3.4. Fourier Transform Infrared Spectra (FTIR)

2.3.5. Thermal Analyses

2.3.6. X-Ray Photoelectron Spectroscopy (XPS)

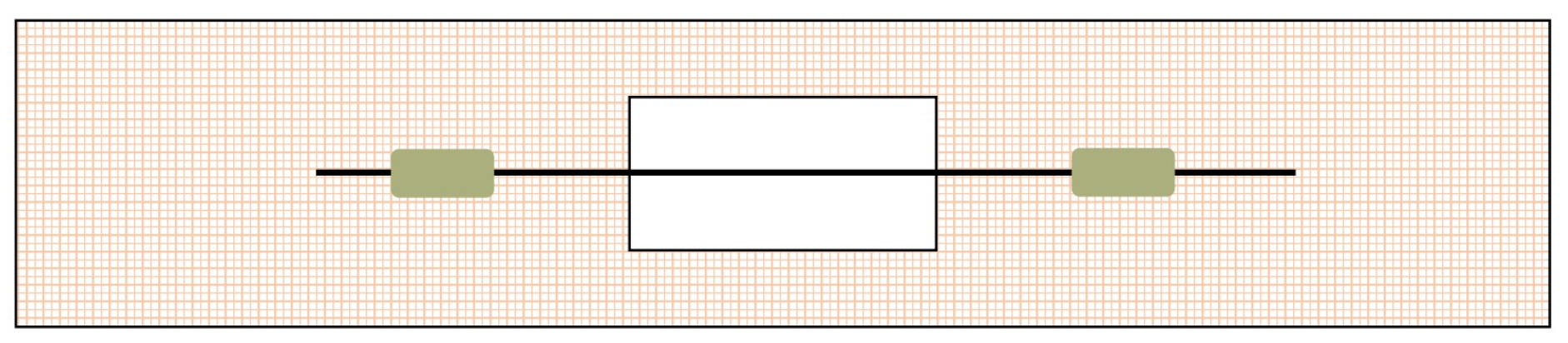

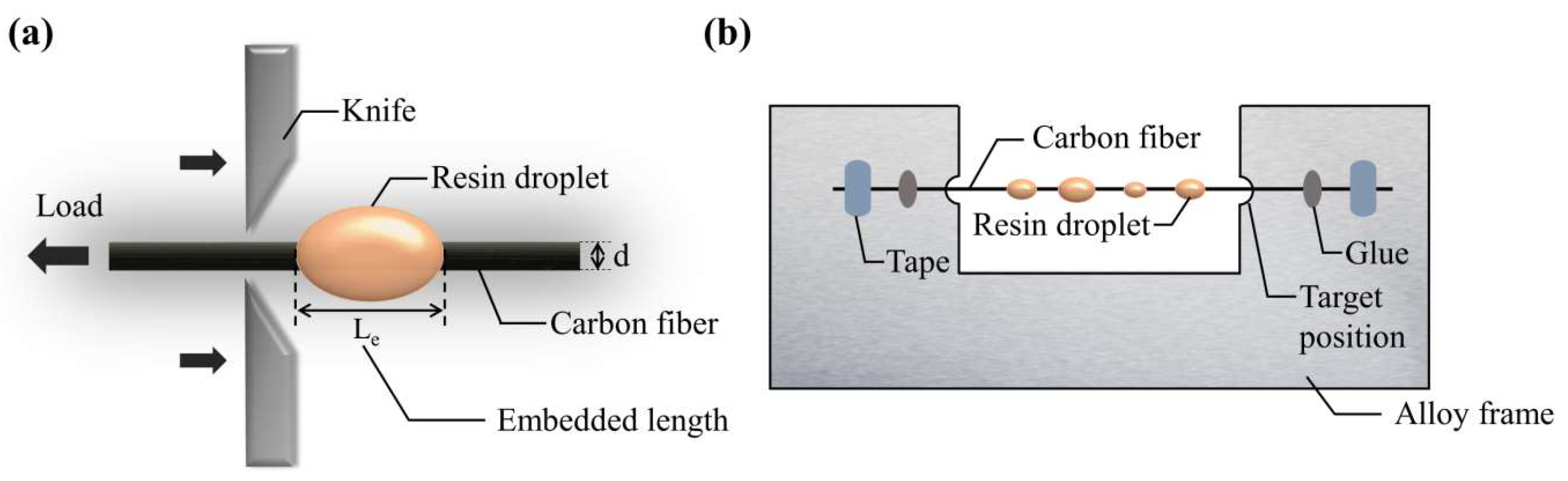

2.4. Interfacial Shear Strength

3. Results and Discussion

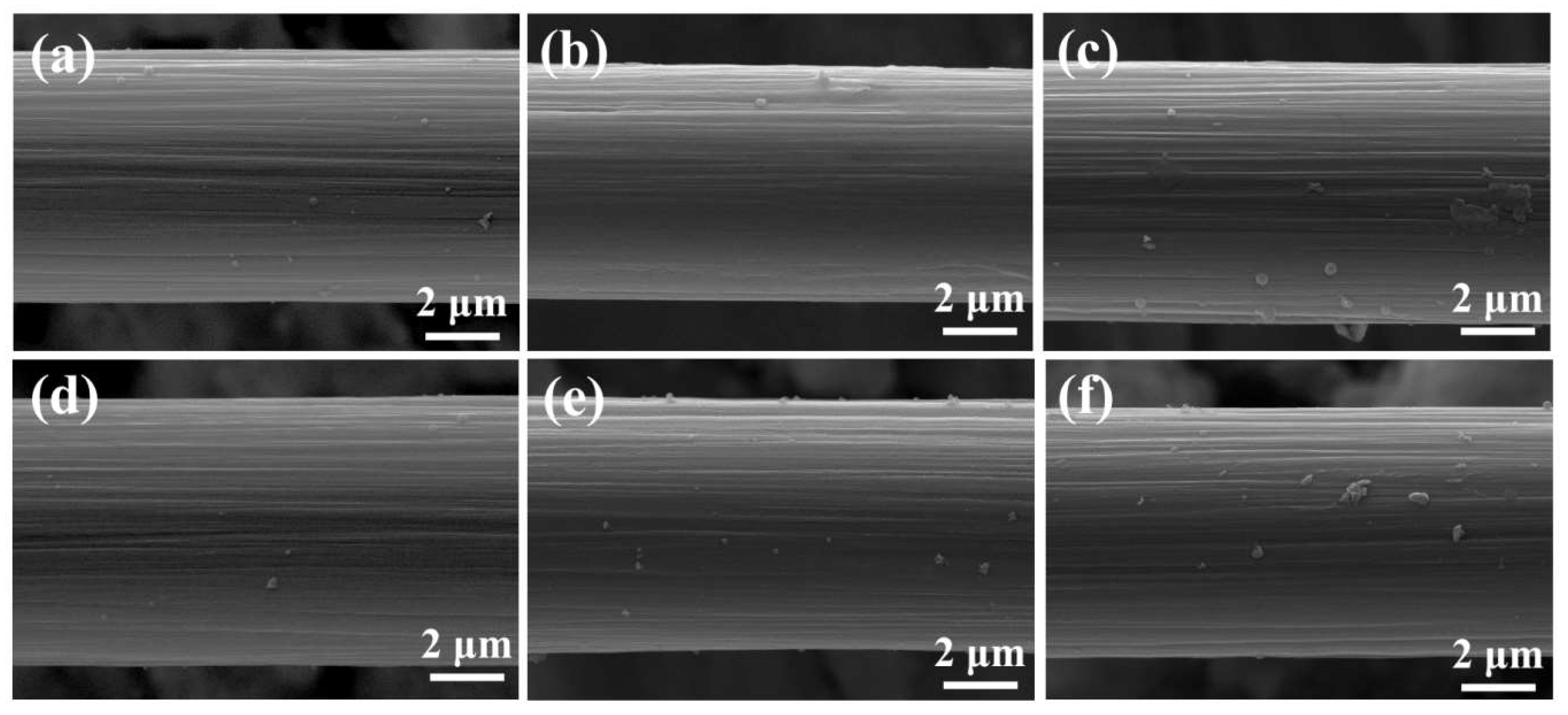

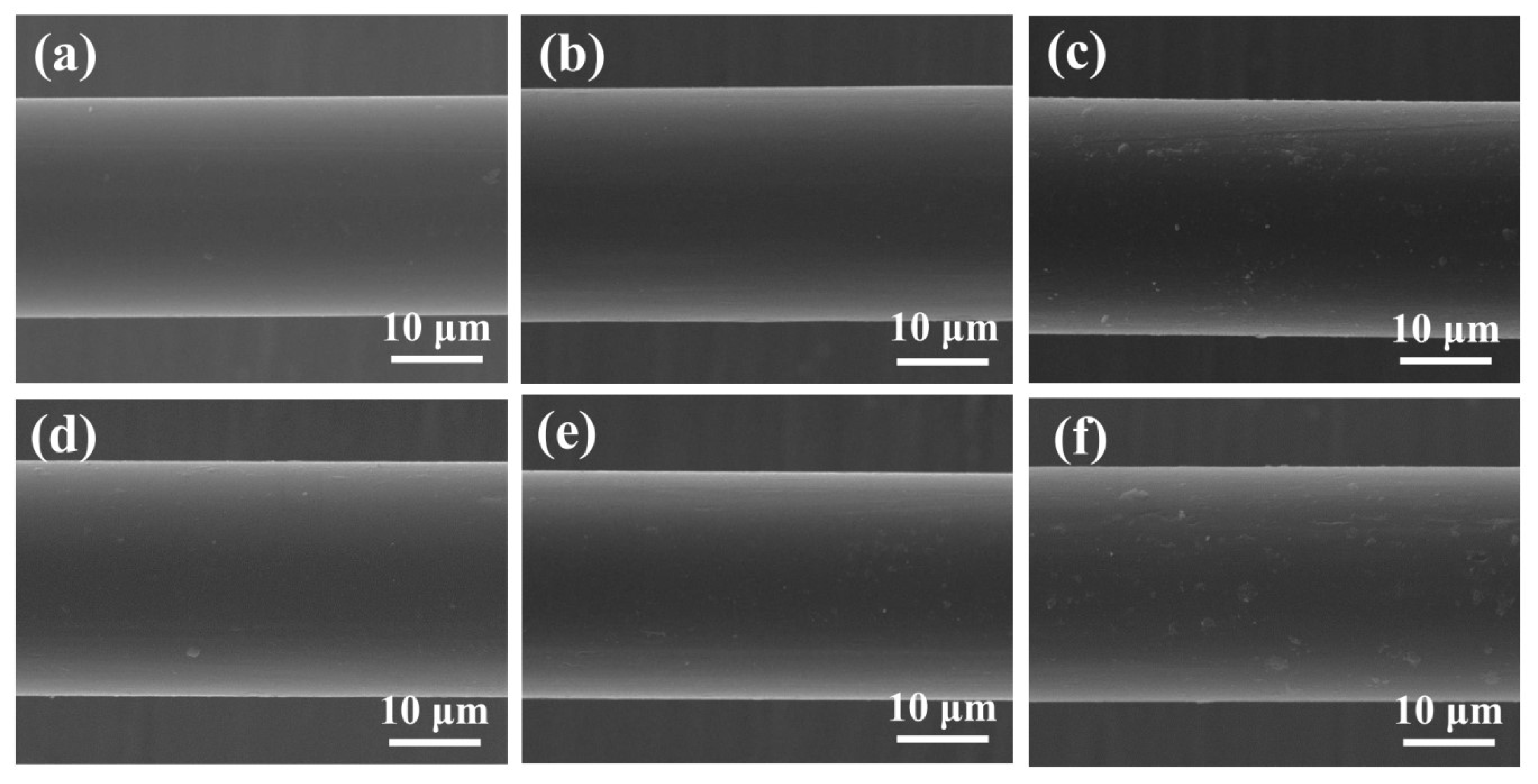

3.1. Morphology of CF and PEEK Fiber

3.2. Structure and Mechanical Property Analysis of CFs

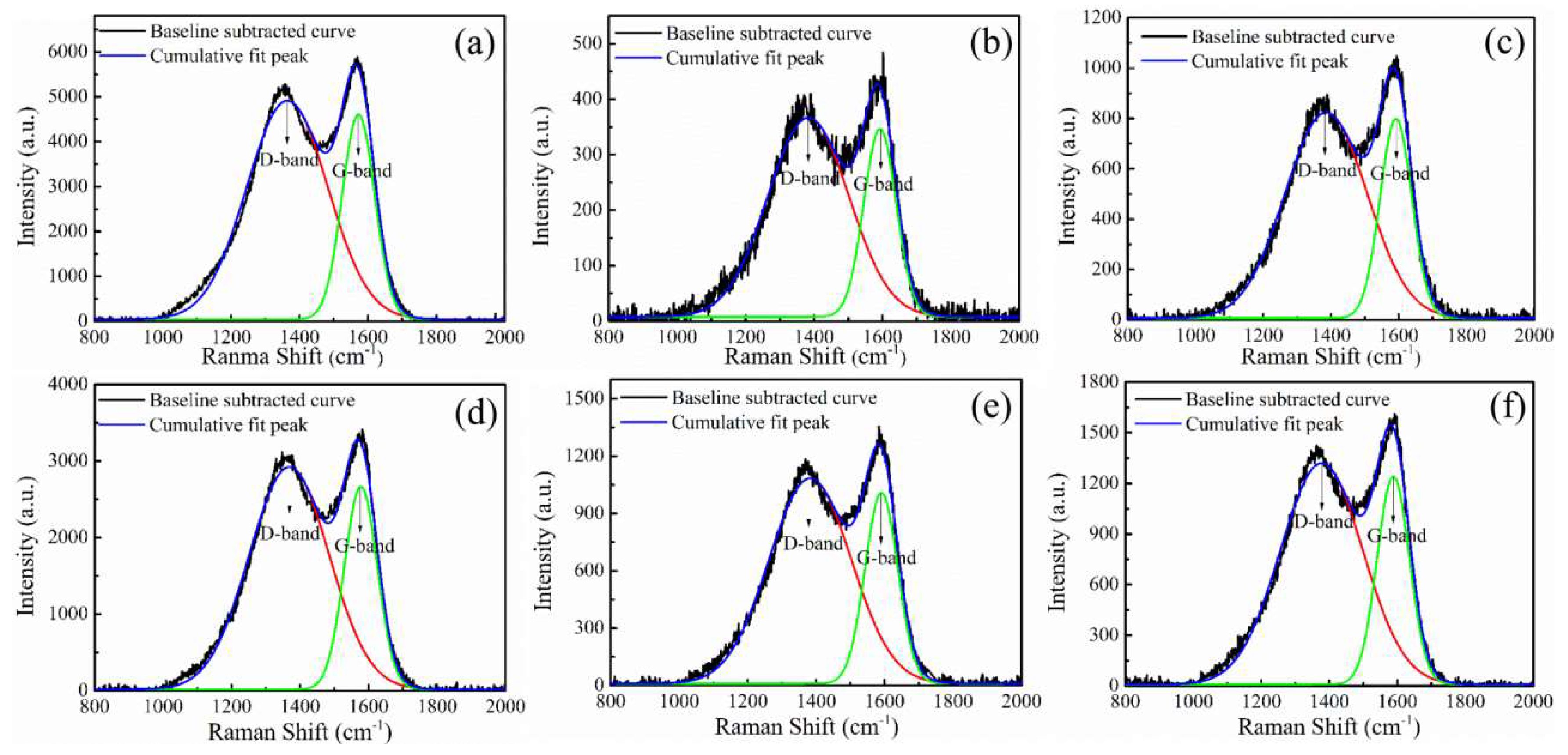

3.2.1. Structure Analysis

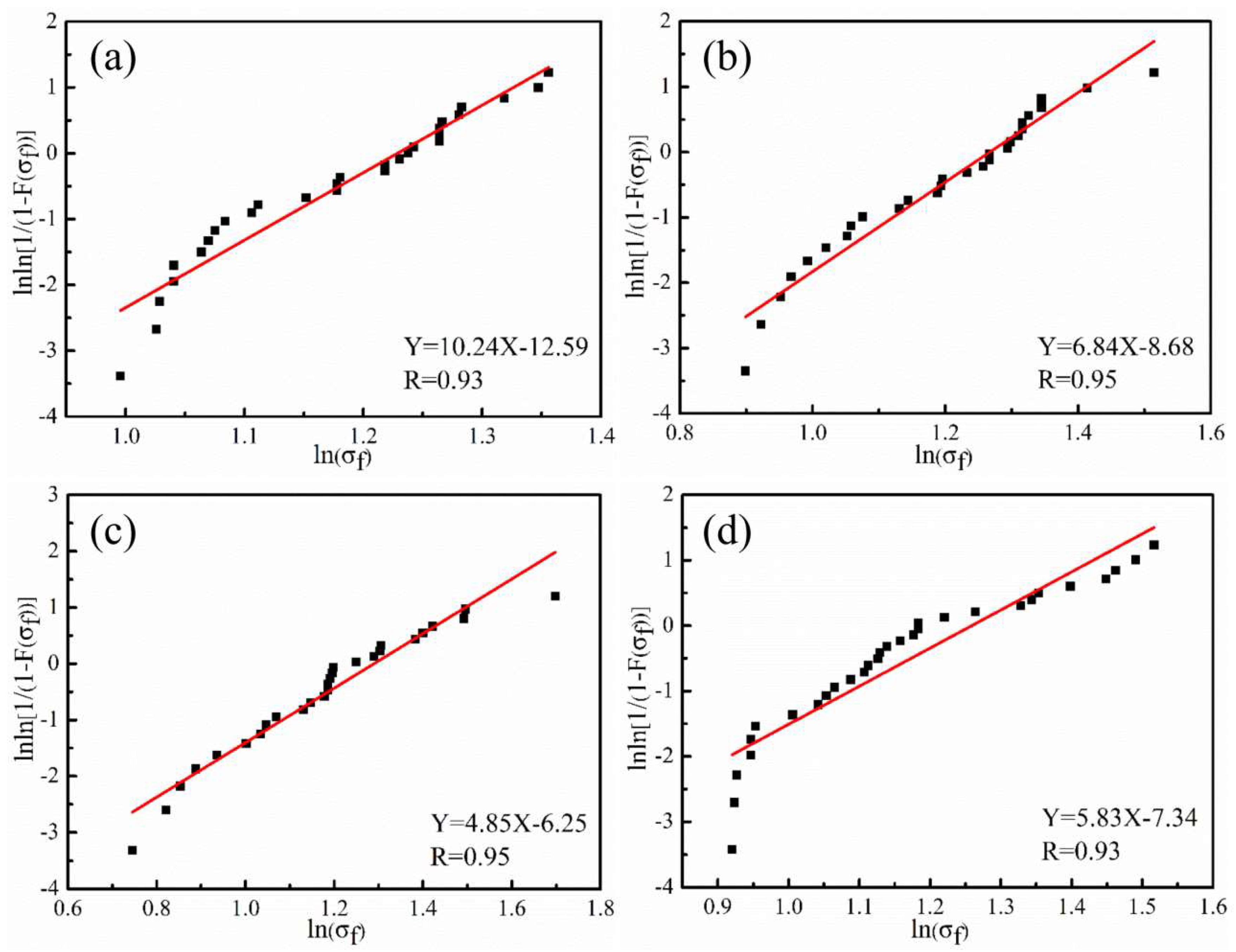

3.2.2. Tensile Strength of Carbon Fibers

3.3. Chemical Structure and Thermal Property Analysis of PEEK Fibers

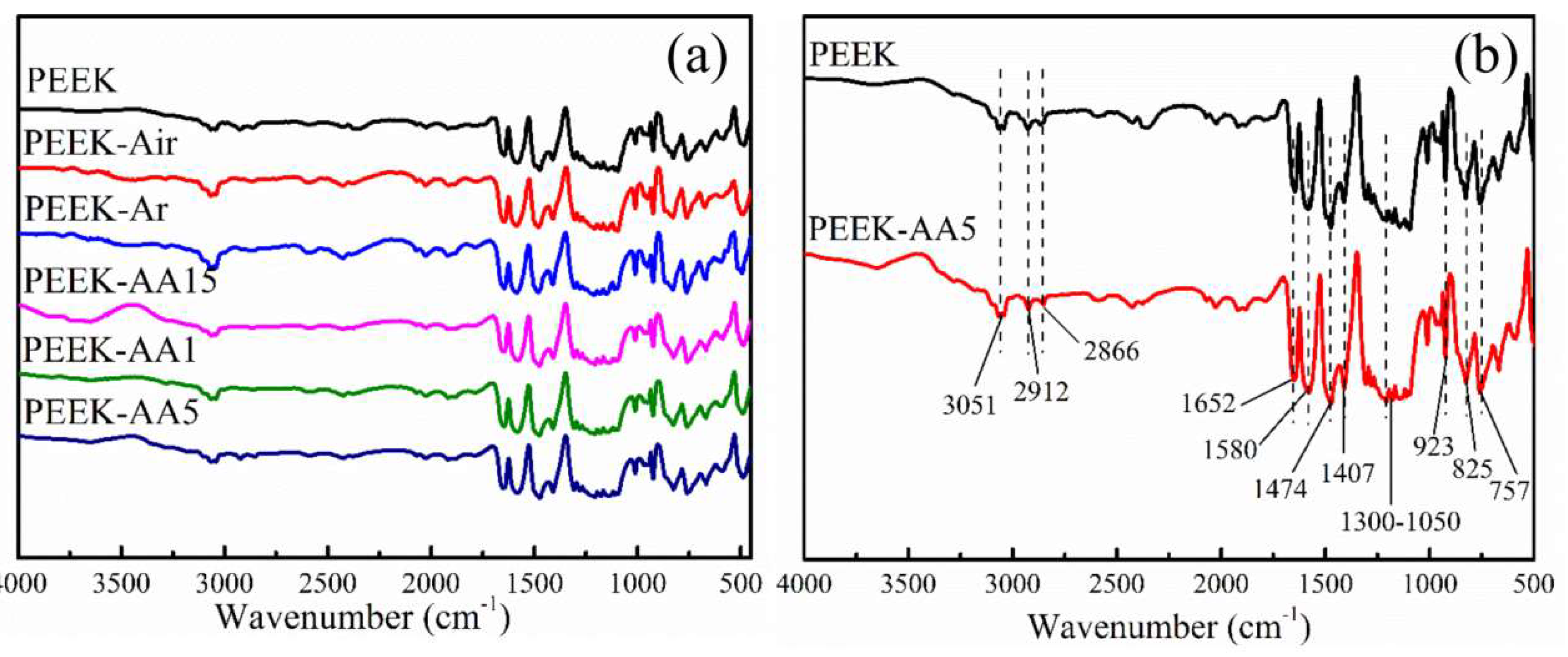

3.3.1. Chemical Structure of PEEK Fiber

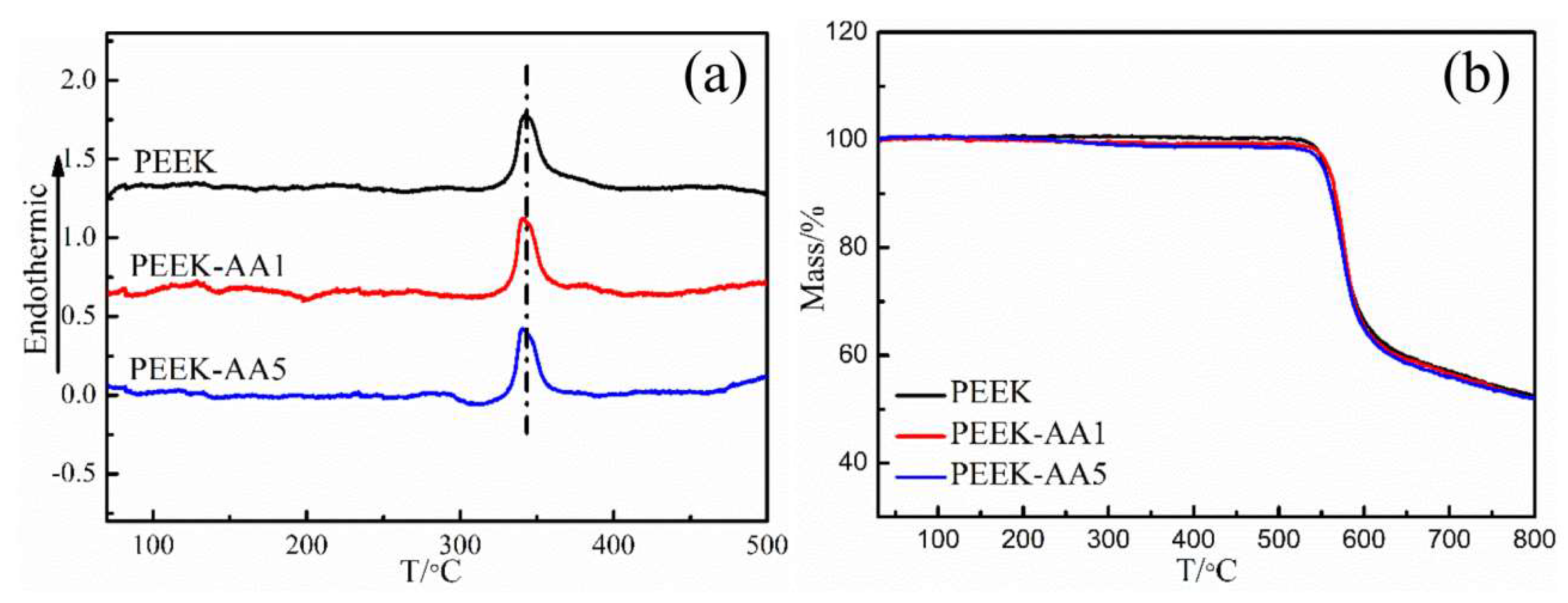

3.3.2. Thermal Property Analysis

3.4. Surface Chemical Analyses

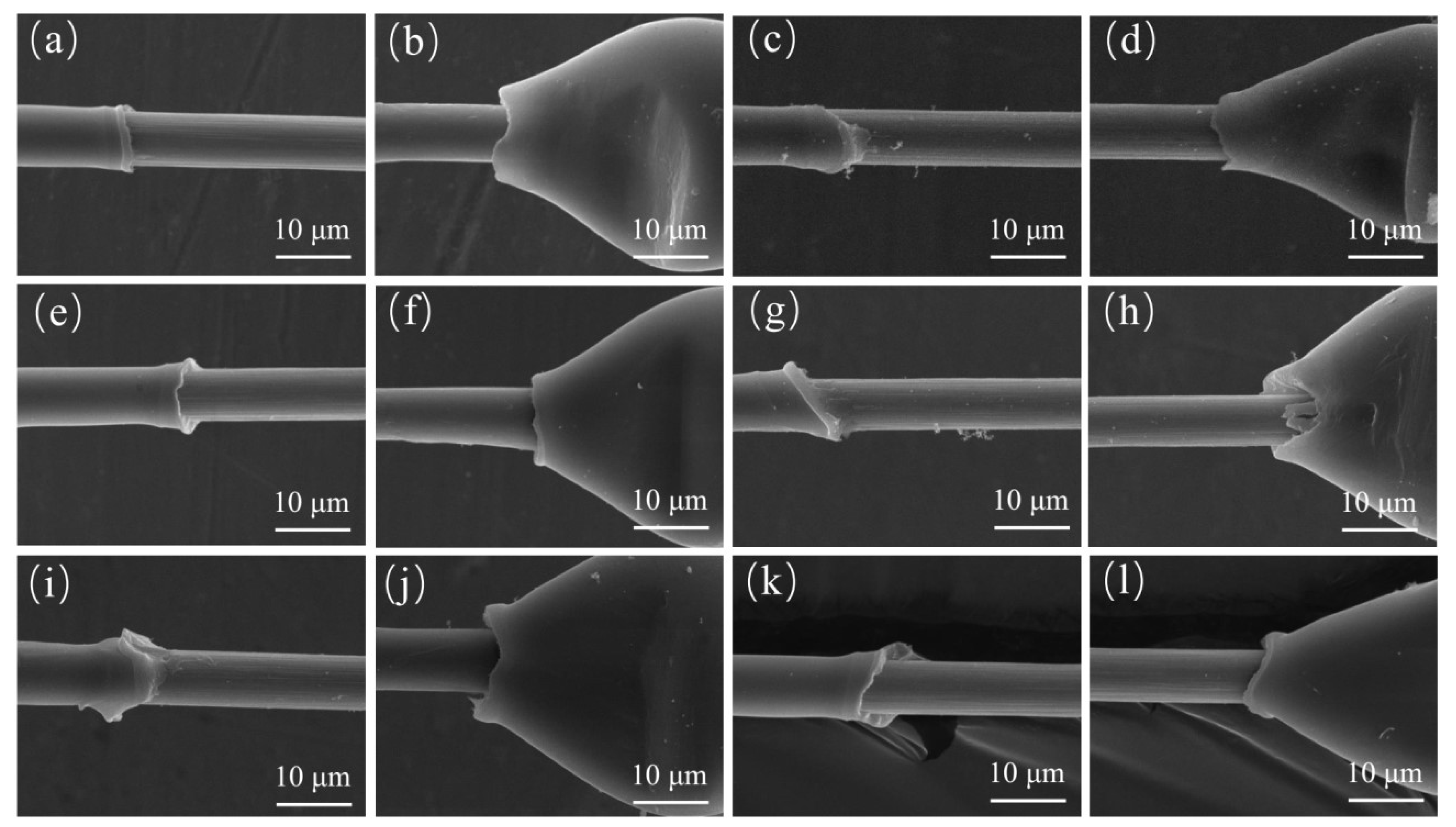

3.5. Interface Shear Strength

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling. Compos. Part B Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Yao, S.S.; Jin, F.L.; Rhee, K.Y.; Hui, D.; Park, S.J. Recent advances in carbon-fiber-reinforced thermoplastic composites: A review. Compos. Part B Eng. 2018, 142, 241–250. [Google Scholar] [CrossRef]

- Parlevliet, P.P.; Bersee, H.E.N.; Beukers, A. Residual stresses in thermoplastic composites—A study of the literature. Part III: Effects of thermal residual stresses. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1581–1596. [Google Scholar] [CrossRef]

- Abounaim, M.; Diestel, O.; offmann, G.; Cherif, C. High performance thermoplastic composite from flat knitted multi-layer textile preform using hybrid yarn. Compos. Sci. Technol. 2011, 71, 511–519. [Google Scholar] [CrossRef]

- Harris, L. A Study of the crystallisation kinetics in PEEK and PEEK composites. Master’s Thesis, University of Birmingham, Birmingham, UK, 2011. [Google Scholar]

- Andrew, B.; Lin, Y. Role of cooling pressure on interlaminar fracture properties of commingled CF/PEEK composites. Compos. Part A 1996, 8, 175–182. [Google Scholar]

- Swolfs, Y.; Gorbatikh, L.; Verpoest, I. Fibre hybridisation in polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2014, 67, 181–200. [Google Scholar] [CrossRef]

- Peterson, A.M.; Jensen, R.E.; Palmese, G.R. Kinetic considerations for strength recovery at the fiber-matrix interface based on the Diels-Alder reaction. ACS Appl. Mater. Interfaces 2013, 5, 815–821. [Google Scholar] [CrossRef]

- Sharma, M.; Gao, S.; Mäder, E.; Sharma, H.; Wei, L.Y.; Bijwe, J. Carbon fiber surfaces and composite interphases. Compos. Sci. Technol. 2014, 102, 35–50. [Google Scholar] [CrossRef]

- Totry, E.; Molina-Aldareguía, J.M.; González, C.; LLorca, J. Effect of fiber, matrix and interface properties on the in-plane shear deformation of carbon-fiber reinforced composites. Compos. Sci. Technol. 2010, 70, 970–980. [Google Scholar] [CrossRef]

- Nardin, M.; Asloun, E.M.; Schultz, J. Study of the carbon fiber--poly (ether--ether--ketone)(PEEK) interfaces, 1: surface characterization of fibers and matrices, and interfacial adhesion energy. Polym. Adv. Technol. 1991, 2, 109–114. [Google Scholar] [CrossRef]

- Andideh, M.; Esfandeh, M. Statistical optimization of treatment conditions for the electrochemical oxidation of PAN-based carbon fiber by response surface methodology: Application to carbon fiber/epoxy composite. Compos. Sci. Technol. 2016, 134, 132–143. [Google Scholar] [CrossRef]

- Severini, F.; Formaro, L.; Pegoraro, M.; Posca, L. Chemical modification of carbon fiber surfaces. Carbon N. Y. 2002, 40, 735–741. [Google Scholar] [CrossRef]

- Ozkan, C.; Gamze Karsli, N.; Aytac, A.; Deniz, V. Short carbon fiber reinforced polycarbonate composites: Effects of different sizing materials. Compos. Part B Eng. 2014, 62, 230–235. [Google Scholar] [CrossRef]

- Xie, Y.; Wu, E.; Hu, R.; Qian, S.; Feng, Z.; Chen, X.; Zhang, H.; Xu, L.; Hu, X.; Liu, J.; et al. Enhancing electronic and optoelectronic performances of tungsten diselenide by plasma treatment. Nanoscale 2018, 10, 12436–12444. [Google Scholar] [CrossRef]

- Lombardo, A.; Novoselov, K.S.; Geim, A.K. Making Graphene Luminescent by Oxygen Plasma Treatment. ACS Nano 2009, 3, 3963–3968. [Google Scholar]

- Meng, J.; Nie, W.; Zhang, K.; Xu, F.; Ding, X.; Wang, S.; Qiu, Y. Enhancing Electrochemical Performance of Graphene Fiber-Based Supercapacitors by Plasma Treatment. ACS Appl. Mater. Interfaces 2018, 10, 13652–13659. [Google Scholar] [CrossRef] [PubMed]

- López-Santos, C.; Yubero, F.; Cotrino, J.; González-Elipe, A.R. Surface functionalization, oxygen depth profiles, and wetting behavior of PET treated with different nitrogen plasmas. ACS Appl. Mater. Interfaces 2010, 2, 980–990. [Google Scholar] [CrossRef] [PubMed]

- Chien, H.H.; Ma, K.J.; Kuo, C.H.; Huang, S.W. Effects of plasma power and reaction gases on the surface properties of ePTFE materials during a plasma modification process. Surf. Coat. Technol. 2013, 228, S477–S481. [Google Scholar] [CrossRef]

- Cheng, X.; Meng, B.; Chen, X.; Han, M.; Chen, H.; Su, Z.; Shi, M.; Zhang, H. Single-Step Fluorocarbon Plasma Treatment-Induced Wrinkle Structure for High-Performance Triboelectric Nanogenerator. Small 2016, 12, 229–236. [Google Scholar] [CrossRef] [PubMed]

- Cech, V.; Knob, A.; Hosein, H.A.; Babik, A.; Lepcio, P.; Ondreas, F.; Drzal, L.T. Enhanced interfacial adhesion of glass fibers by tetravinylsilane plasma modification. Compos. Part A Appl. Sci. Manuf. 2014, 58, 84–89. [Google Scholar] [CrossRef]

- Chatelier, R.C.; Xie, X.; Gengenbach, T.R.; Griesser, H.J. Effects of Plasma Modification Conditions on Surface Restructuring. Langmuir 1995, 11, 2585–2591. [Google Scholar] [CrossRef]

- Steen, M.L.; Butoi, C.I.; Fisher, E.R. Identification of gas-phase reactive species and chemical mechanisms occurring at plasma-polymer surface interfaces. Langmuir 2001, 17, 8156–8166. [Google Scholar] [CrossRef]

- Aziz, G.; Cools, P.; De Geyter, N.; Declercq, H.; Cornelissen, R.; Morent, R. Dielectric barrier discharge plasma treatment of ultrahigh molecular weight polyethylene in different discharge atmospheres at medium pressure: A cell-biomaterial interface study. Biointerphases 2015, 10, 029502. [Google Scholar] [CrossRef]

- Fukunaga, A.; Komami, T.; Ueda, S.; Nagumo, M. Plasma treatment of pitch-based ultra high modulus carbon fibers. Carbon N. Y. 1999, 37, 1087–1091. [Google Scholar] [CrossRef]

- Ma, K.; Chen, P.; Wang, B.; Cui, G.; Xu, X. A study of the effect of oxygen plasma treatment on the interfacial properties of carbon fiber/epoxy composites. J. Appl. Polym. Sci. 2010, 118, 1606–1614. [Google Scholar] [CrossRef]

- Kim, S.Y.; Baek, S.J.; Youn, J.R. New hybrid method for simultaneous improvement of tensile and impact properties of carbon fiber reinforced composites. Carbon N. Y. 2011, 49, 5329–5338. [Google Scholar] [CrossRef]

- Rymuszka, D.; Terpiłowski, K.; Borowski, P.; Holysz, L. Time-dependent changes of surface properties of polyether ether ketone caused by air plasma treatment. Polym. Int. 2016, 65, 827–834. [Google Scholar] [CrossRef]

- Lieberman, M.A.; Lichtenberg, A.J. Principles of Plasma Discharges and Materials Processing; Wiley-Interscience: New York, NY, USA, 2005; ISBN 9786468600. [Google Scholar]

- Hao, X.; Yonggen, L. Effect of gamma-irradiation on the mechanical properties of polyacrylonitrile-based carbon fiber. Carbon N. Y. 2012, 52, 427–439. [Google Scholar]

- Lee, E. seok; Lee, C. hyun; Chun, Y.S.; Han, C. ji; Lim, D.S. Effect of hydrogen plasma-mediated surface modification of carbon fibers on the mechanical properties of carbon-fiber-reinforced polyetherimide composites. Compos. Part B Eng. 2017, 116, 451–458. [Google Scholar] [CrossRef]

- Xie, J.; Xin, D.; Cao, H.; Wang, C.; Zhao, Y.; Yao, L.; Ji, F.; Qiu, Y. Improving carbon fiber adhesion to polyimide with atmospheric pressure plasma treatment. Surf. Coat. Technol. 2011, 206, 191–201. [Google Scholar] [CrossRef]

- Wilson, A.; Jones, I.; Salamat-Zadeh, F.; Watts, J.F. Laser surface modification of poly(etheretherketone) to enhance surface free energy, wettability and adhesion. Int. J. Adhes. Adhes. 2015, 62, 69–77. [Google Scholar] [CrossRef]

- Pan, L.; Yapici, U. A comparative study on mechanical properties of carbon fiber/PEEK composites. Adv. Compos. Mater. 2016, 25, 359–374. [Google Scholar] [CrossRef]

- Poncin-Epaillard, F.; Brosse, J.C.; Falher, T. Cold plasma treatment: Surface or bulk modification of polymer films? Macromolecules 1997, 30, 4415–4420. [Google Scholar] [CrossRef]

- Chen, C.; Liang, B.; Ogino, A.; Wang, X.; Nagatsu, M. Oxygen Functionalization of Multiwall Carbon Nanotubes by Microwave-Excited Surface-Wave Plasma Treatment. J. Phys. Chem. C 2009, 113, 7659–7665. [Google Scholar] [CrossRef]

- Dilsiz, N.; Wightman, J.P. Surface analysis of unsized and sized carbon fibers. Carbon N. Y. 1999, 37, 1105–1114. [Google Scholar] [CrossRef]

- Nohara, L.B.; Petraconi Filho, G.; Nohara, E.L.; Kleinke, M.U.; Rezende, M.C. Evaluation of carbon fiber surface treated by chemical and cold plasma processes. Mater. Res. 2006, 8, 3. [Google Scholar] [CrossRef]

| Sample | Peak Position | R (ID/IG) | La (Å) | |

|---|---|---|---|---|

| D-Band | G-Band | |||

| Untreated CF | 1364.19 | 1572.40 | 2.64 ± 0.04 | 16.67 |

| CF–air | 1383.35 | 1592.91 | 2.65 ± 0.06 | 16.60 |

| CF–Ar | 1385.62 | 1592.01 | 2.66 ± 0.05 | 16.54 |

| CF–AA15 | 1368.41 | 1577.59 | 2.66 ± 0.04 | 16.54 |

| CF–AA1 | 1382.37 | 1590.71 | 2.70 ± 0.05 | 16.30 |

| CF–AA5 | 1377.20 | 1588.05 | 2.70 ± 0.04 | 16.30 |

| Sample | A | B | σ0 (GPa) | Γ(σ0) | |

|---|---|---|---|---|---|

| Untreated CF | −12.59 | 10.24 | 2.33 | 0.9514 | 3.25 |

| CF–AA15 | −8.68 | 6.84 | 2.00 | 0.9330 | 3.31 |

| CF–AA1 | −6.25 | 4.85 | 1.62 | 0.9156 | 3.32 |

| CF–AA5 | −7.34 | 5.83 | 1.80 | 0.9267 | 3.26 |

| Wavenumber (cm−1) | Assignment |

|---|---|

| 3051 | C=C–H stretch vibration |

| 2912, 2866 | –CH2 stretch vibration |

| 1652 | C=O stretch in ketone |

| 1580 | Skeletal in-plane vibration of aromatic ring |

| 1474, 1407 | Aromatic rotations |

| 1300–1050 | Diphenyl ether group, C–O–C rotation and stretch |

| 923 | Aromatic out-of-plane bending |

| 825, 757 | C–H out-of-plane bending substitution patterns |

| Samples | Relative Concentration of Elements (%) | O:C | N:C | ||

|---|---|---|---|---|---|

| C | O | N | |||

| Untreated CF | 85.15 | 14.85 | - | 0.17 | - |

| CF–air | 61.51 | 34.65 | 3.84 | 0.56 | 0.06 |

| CF–Ar | 75.44 | 21.85 | 2.71 | 0.29 | 0.04 |

| CF–AA1 | 59.86 | 35.77 | 4.38 | 0.60 | 0.07 |

| CF–AA5 | 53.24 | 41.82 | 4.94 | 0.79 | 0.09 |

| PEEK | 86.13 | 13.87 | - | 0.16 | - |

| PEEK–AA1 | 67.48 | 31.21 | 1.31 | 0.46 | 0.02 |

| Samples | C1 | C2 | C3 | C4 | C5 | Polar/Nonpolar | Ratio |

|---|---|---|---|---|---|---|---|

| C=C | C–C | C–O | –C=O | O–C=O | |||

| Untreated CF | 26.85 | 45.25 | 21.02 | 3.43 | 3.45 | 0.39 | 0.07 |

| CF–air | 25.24 | 31.64 | 27.92 | 11.30 | 3.89 | 0.76 | 0.48 |

| CF–Ar | 23.00 | 33.60 | 22.77 | 12.96 | 7.66 | 0.77 | 0.25 |

| CF–AA1 | 22.70 | 33.20 | 21.30 | 7.16 | 15.65 | 0.79 | 0.53 |

| CF–AA5 | 23.20 | 42.90 | 16.44 | 10.33 | 7.13 | 0.51 | 0.45 |

| PEEK | 36.32 | 13.81 | 40.73 | 1.99 | 7.15 | 0.99 | 0.16 |

| PEEK–AA1 | 29.35 | 9.41 | 41.65 | 9.32 | 10.28 | 1.58 | 0.76 |

| Sample | IFSS (MPa) | Increment (%) |

|---|---|---|

| Untreated | 42.36 ± 4.23 | - |

| Air | 48.37 ± 2.87 | 14.19 |

| Ar | 47.62 ± 3.25 | 12.42 |

| AA15 | 50.87 ± 1.79 | 20.09 |

| AA1 | 59.73 ± 3.88 | 41.01 |

| AA5 | 47.85 ± 4.51 | 12.96 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, C.; Qiu, S.; Lu, X.; Wang, J.; Xiao, L.; Zheng, T.; Wang, X.; Zhang, D. Enhancing the Interfacial Strength of Carbon Fiber/Poly(ether ether ketone) Hybrid Composites by Plasma Treatments. Polymers 2019, 11, 753. https://doi.org/10.3390/polym11050753

Lu C, Qiu S, Lu X, Wang J, Xiao L, Zheng T, Wang X, Zhang D. Enhancing the Interfacial Strength of Carbon Fiber/Poly(ether ether ketone) Hybrid Composites by Plasma Treatments. Polymers. 2019; 11(5):753. https://doi.org/10.3390/polym11050753

Chicago/Turabian StyleLu, Chunrui, Si Qiu, Xue Lu, Jian Wang, Lin Xiao, Ting Zheng, Xiaodong Wang, and Dongxing Zhang. 2019. "Enhancing the Interfacial Strength of Carbon Fiber/Poly(ether ether ketone) Hybrid Composites by Plasma Treatments" Polymers 11, no. 5: 753. https://doi.org/10.3390/polym11050753

APA StyleLu, C., Qiu, S., Lu, X., Wang, J., Xiao, L., Zheng, T., Wang, X., & Zhang, D. (2019). Enhancing the Interfacial Strength of Carbon Fiber/Poly(ether ether ketone) Hybrid Composites by Plasma Treatments. Polymers, 11(5), 753. https://doi.org/10.3390/polym11050753