1. Introduction

The majority of nonwoven polyolefin fibers are of great commercial interest because of their unique properties, including hydrophobicity, good mechanical properties, and excellent chemical resistance [

1,

2]. Among them, fibers fabricated from isotactic polypropylene (iPP) are one of the lightest and most widely utilized. Traditional commercial iPP is generally polymerized with a heterogeneous titanium-based Ziegler–Natta catalyst, whose tacticity, molecular weight (M

w), and polymer dispersity index (PDI) are tightly dependent on the catalysts and the polymerization conditions [

3,

4]. The development of metallocene catalytic systems offers new access for both the isospecific polymerization of olefins and the new polymer microstructures thanks to the single-site nature of metallocene catalysts. The metallocene polyolefins exhibit interesting physical properties, which are not attainable with conventional Ziegler–Natta catalysts [

5]. In comparison with the Ziegler–Natta-catalyzed polypropylene (PP), metallocene polypropylenes are uniform polymers with precisely controlled M

w, end groups, stereoregularity, and narrow PDI [

6]. Those characters make metallocene-based iPP a great candidate for producing high-quality industrial fibers by melt spinning.

Crystallization plays a crucial role in determining the structure of not only the iPP resin but also the resulting fibers [

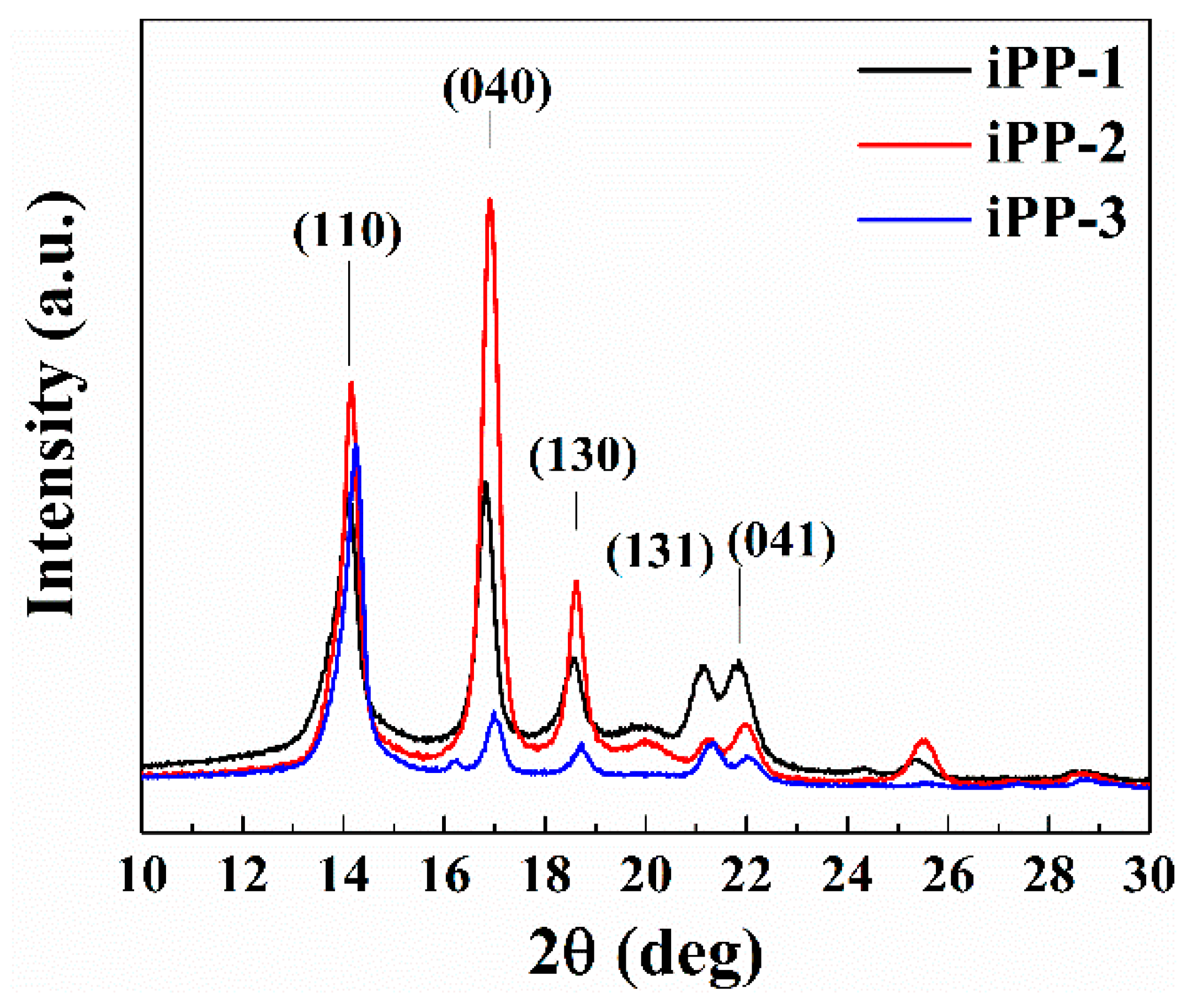

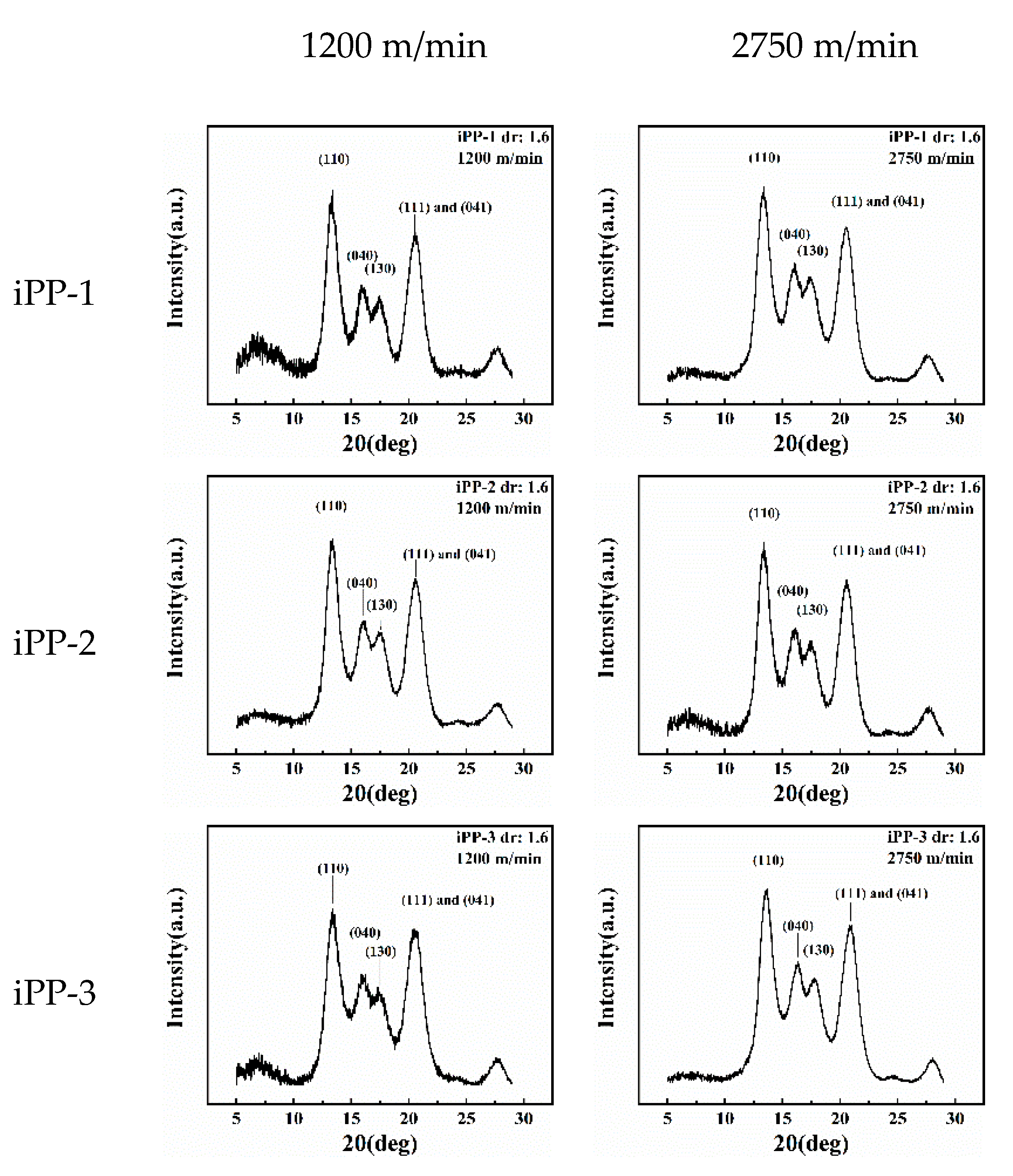

7]. Investigations on crystalline structures have revealed that the crystalline phase of iPP fibers is usually composed of the

α phase crystal. The

α form, which can be easily obtained by the crystallization of polymer in melts or solutions, is the most stable and the most common form in different iPP products [

4]. The

β form, which is produced during the crystallization of a sheared melt, crystallization in a temperature gradient, or during the addition of certain nucleating agents, has to be achieved under well-controlled conditions in iPP products [

8]. The

γ phase is usually formed at high pressure and favored by the low-molecular-weight fraction of polydisperse melts [

9,

10]. In addition to these crystal phases, a mesomorphic phase could be obtained at high cooling rates, which is usually formed during high-speed spinning [

11,

12]. The mesomorphic phase is characterized by an order intermediate between those found in crystalline and in amorphous phases. However, the structure of this phase has been a matter of debate since its initial report. The mesomorphic phase is composed of bundles of parallel chains, which are typically observed in all polymorphic forms of the threefold helical conformation of PP. Bundles are terminated in the direction of the chain axis by helix reversals or other conformational defects [

13]. In the bundles, long-range ordering is maintained only along the chain axes, whereas a large amount of disorder is present in lateral packing [

3].

The melt spinning of iPP into fibers has been intensively studied during past decades [

14,

15,

16]. The fiber structure is mainly formed during crystallization, which starts below the spinneret orifices, in the cooling zone through the solidification of an extruded stream. During fiber formation, crystallization occurs under nonisothermal conditions and high tensile stress, and the cooling rate and tensile stress strongly affect the crystallization of iPP [

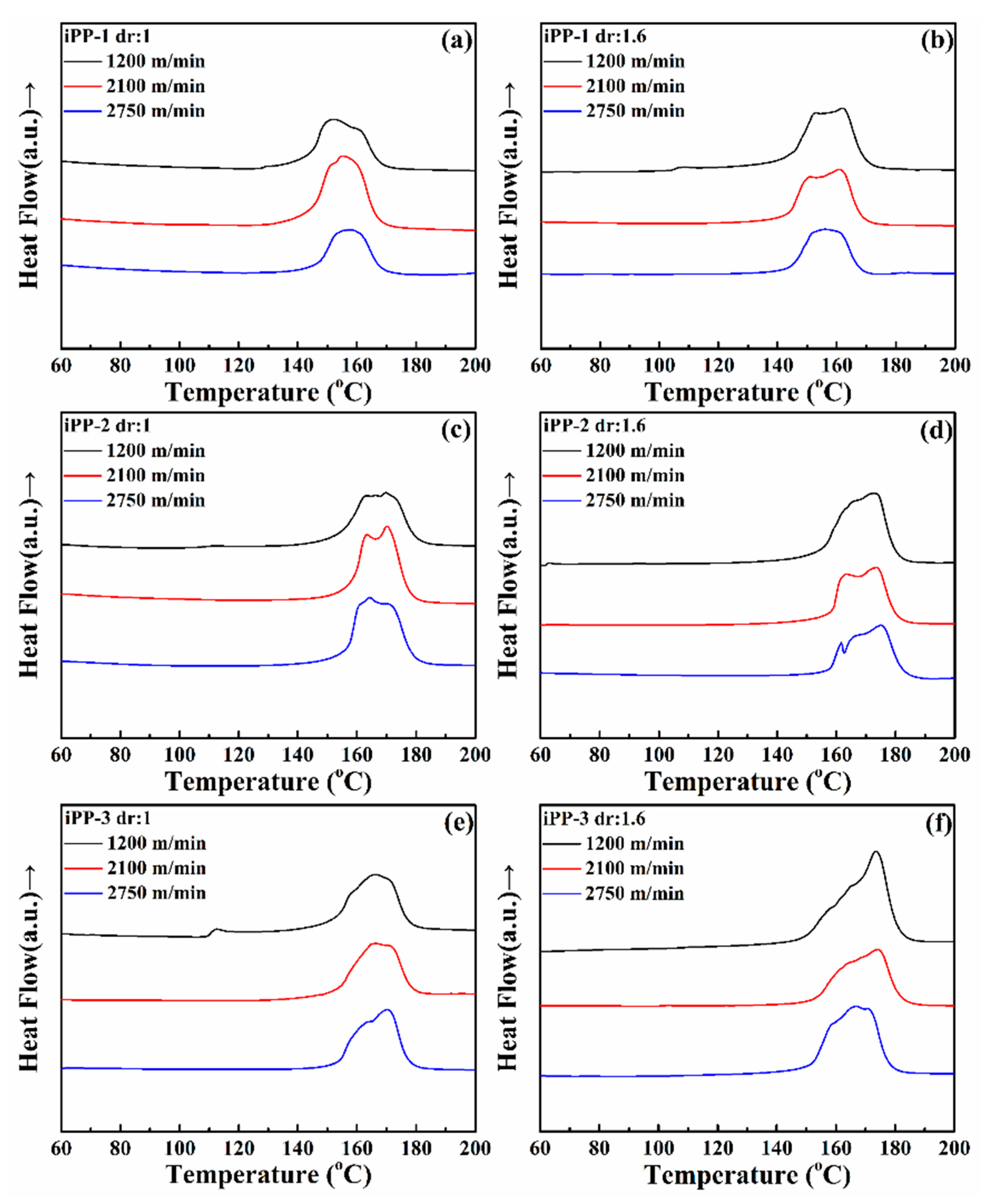

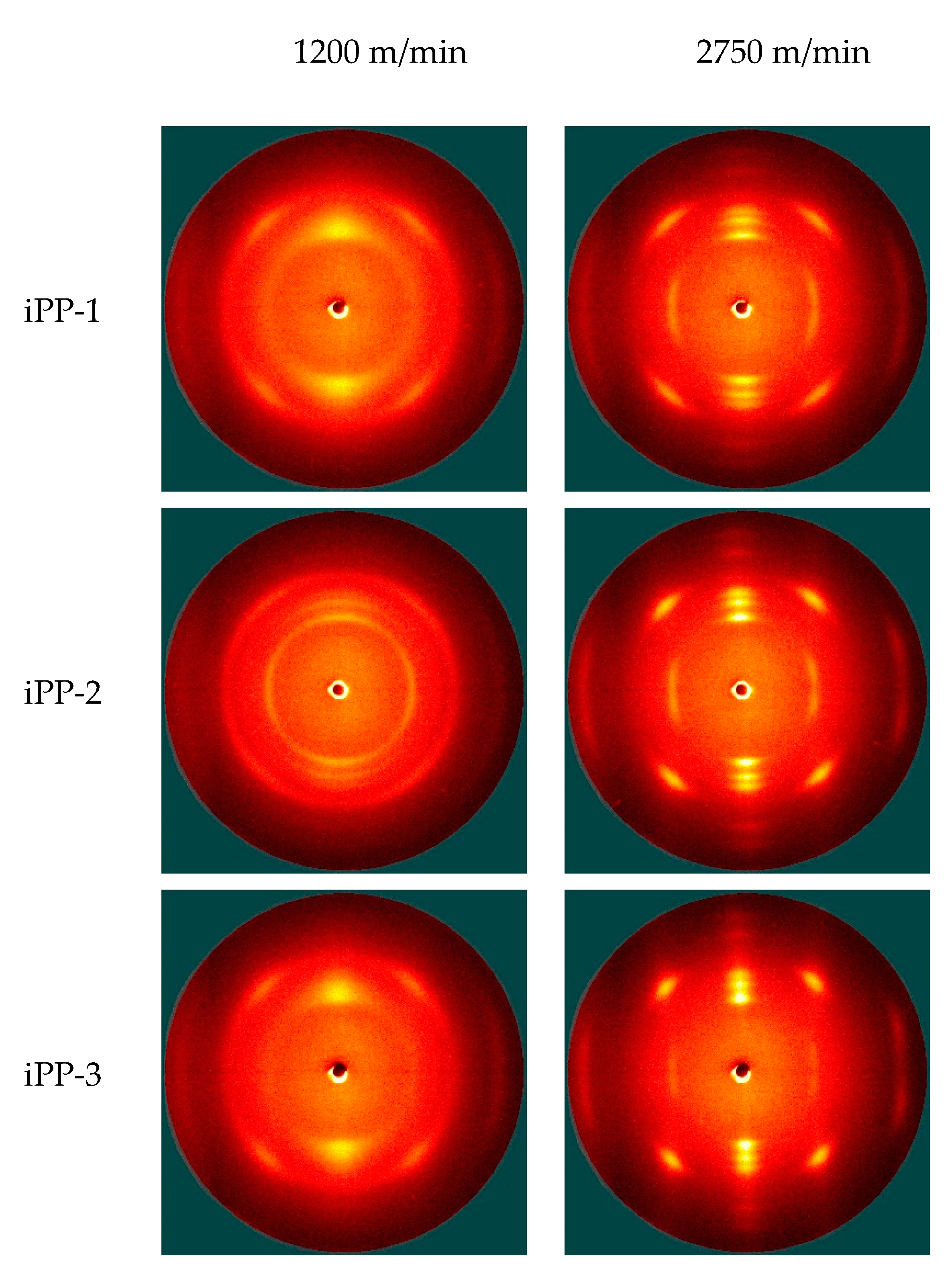

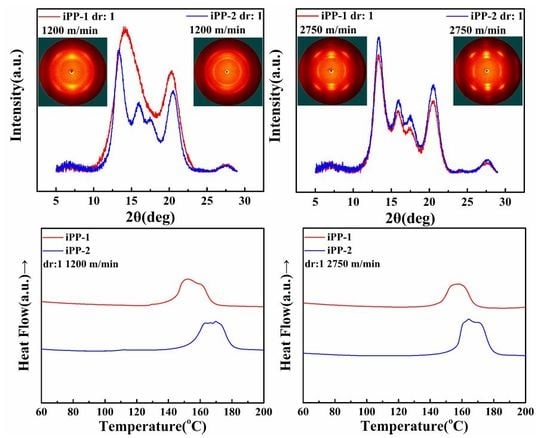

17]. At low take-up speeds, the cooling rate and the applied tensile stress are low, and the crystallization proceeds at relatively high temperatures, which favors the formation of a monoclinic α crystal in as-spun fibers. As the take-up speed increases, the cooling rate is enhanced, and the crystallization temperature decreases. Structures with high mesomorphic phase content are formed in major during crystallization under such conditions [

18,

19,

20].

The melt-spinning of metallocene catalyst iPP has been investigated in the last period, Bond and Spruiell demonstrated that the molecular weight and molecular weight distribution (MWD) of metallocene iPP resins had a significant influence on the development of the structure and properties of fibers prepared from these resins. Compared to the Ziegler–Natta-catalyzed resins with similar average molecular weight, the narrower MWD of metallocene resins appeared to be the primary factor that produced differences in the structure and properties of fibers spun from these resins [

21]. In addition, the effect of the spinning speed on the density of fibers, crystallinity, and crystalline and non-crystalline orientation function was investigated. It was found that the density, birefringence, tensile strength, and crystalline and non-crystalline orientation function could be generally improved with increases in the spinning speed. The metallocene iPP fibers were identified to have a breaking tensile strength up to 50% higher than of the Ziegler–Natta iPP fiber at similar spinning speeds [

22]. Therefore, developing metallocene iPP for fiber applications may significantly improve the fiber strength and extend their applications.

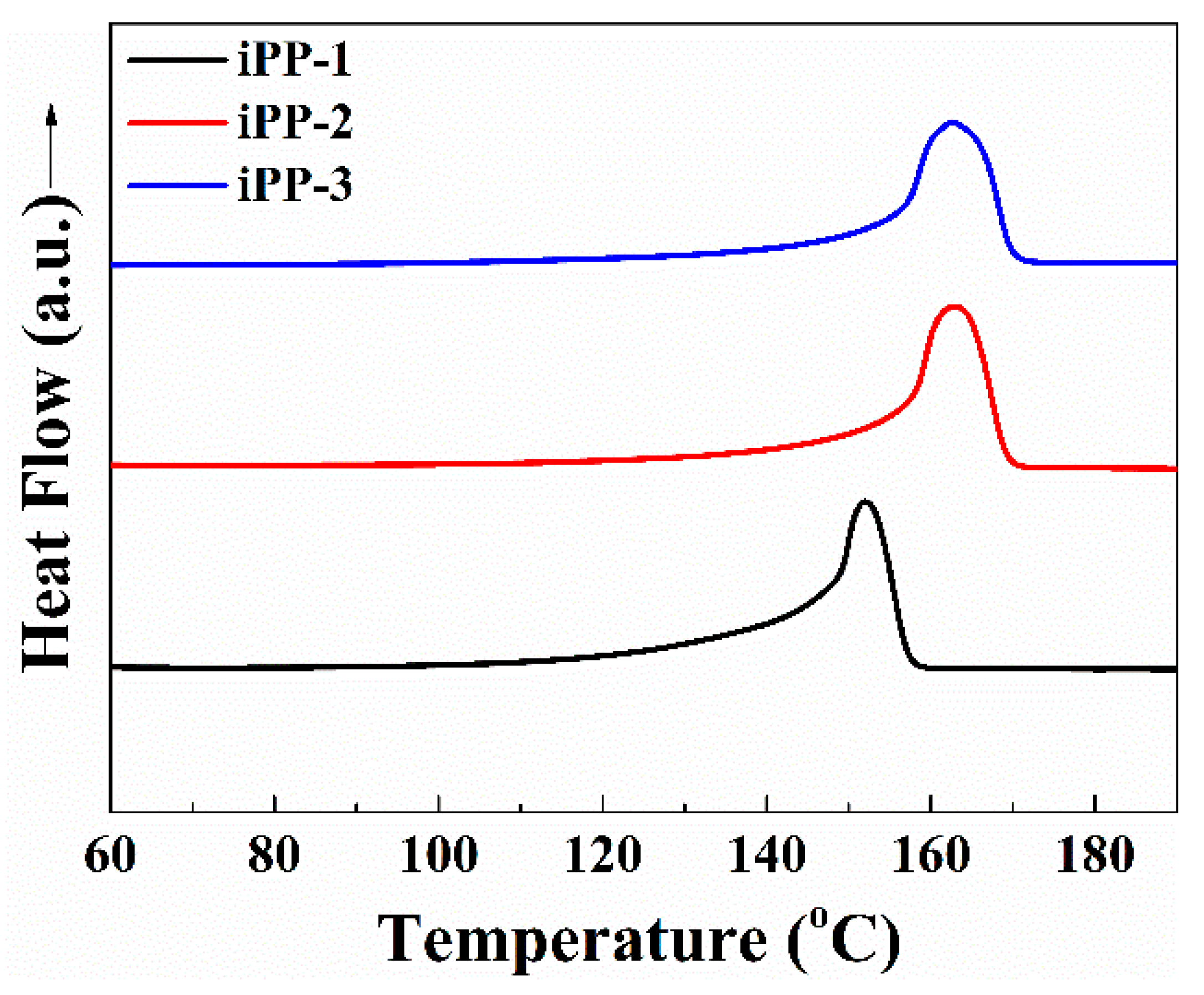

It has been reported that the crystallinity and melting temperature of metallocene-catalyzed iPP could be lower than those of conventional iPP fibers, which could be ascribed to the region-defects in the 2,1 and 3,1 insertions. At lower melting temperature, there exist more “tie” molecules between the PP crystallites, which lead to the enhanced tensile strength and elongation at break of metallocene-catalyzed iPP fibers [

6,

23]. Therefore, the metallocene iPP with lower melting temperature is a promising polymer for fiber production. In this work, we present a low-melting-temperature metallocene iPP for melt spinning fiber application. The results from a commercial Ziegler–Natta iPP and a metallocene iPP are given for comparison. The structure, thermal properties, and mechanical properties of the three types of iPP are primarily tested. The iPP fibers are fabricated from three iPPs via melt spinning following the same process, and the tensile properties, orientation, and crystallization of the prepared iPP fibers are carefully investigated. The

Tm metallocene iPP exhibits remarkable advantages in both the processing and the mechanical performance of the resultant products.

2. Materials and Methods

2.1. Materials

Isotactic polypropylene sample 1 (iPP-1) is synthesized from C

2-symmetric metallocene catalysts (rac-Me

2Si(2-Me-4-Ph-Ind)

2ZrCl

2) [

24] with a M

w of 147,000 and PDI of 2.5, which is a pilot product synthesized by the China Petroleum Lanzhou Chemical Research Center (Lanzhou, China). Calcium stearate at 500 ppm (Guangdong Wei Lin Na New Material Technology Co. Ltd., Guangzhou, China, ≥98%), 750 ppm primary antioxidant (Irganox 1010), and 1500 ppm secondary antioxidant (Irgafos 168) (Basf Performance Chemicals (Shanghai) Co. Ltd.) were added into the iPP powder to prepare pellets via extrusion. Isotactic polypropylene sample 2 (iPP-2) is a commercial metallocene PP purchased from Lyondell Basell Industries (Basell HM562S, Rotterdam, Netherlands) with a M

w of 157,000 and PDI of 2.9. Isotactic polypropylene sample 3 (iPP-3) is a commercial Ziegler–Natta PP produced by Exxon Mobil Corporation (Exxon 3155E3) with a M

w of 157,000 and PDI of 2.4. All the samples are used as received without any further purification unless notified.

2.2. Instrumentation and Characterization

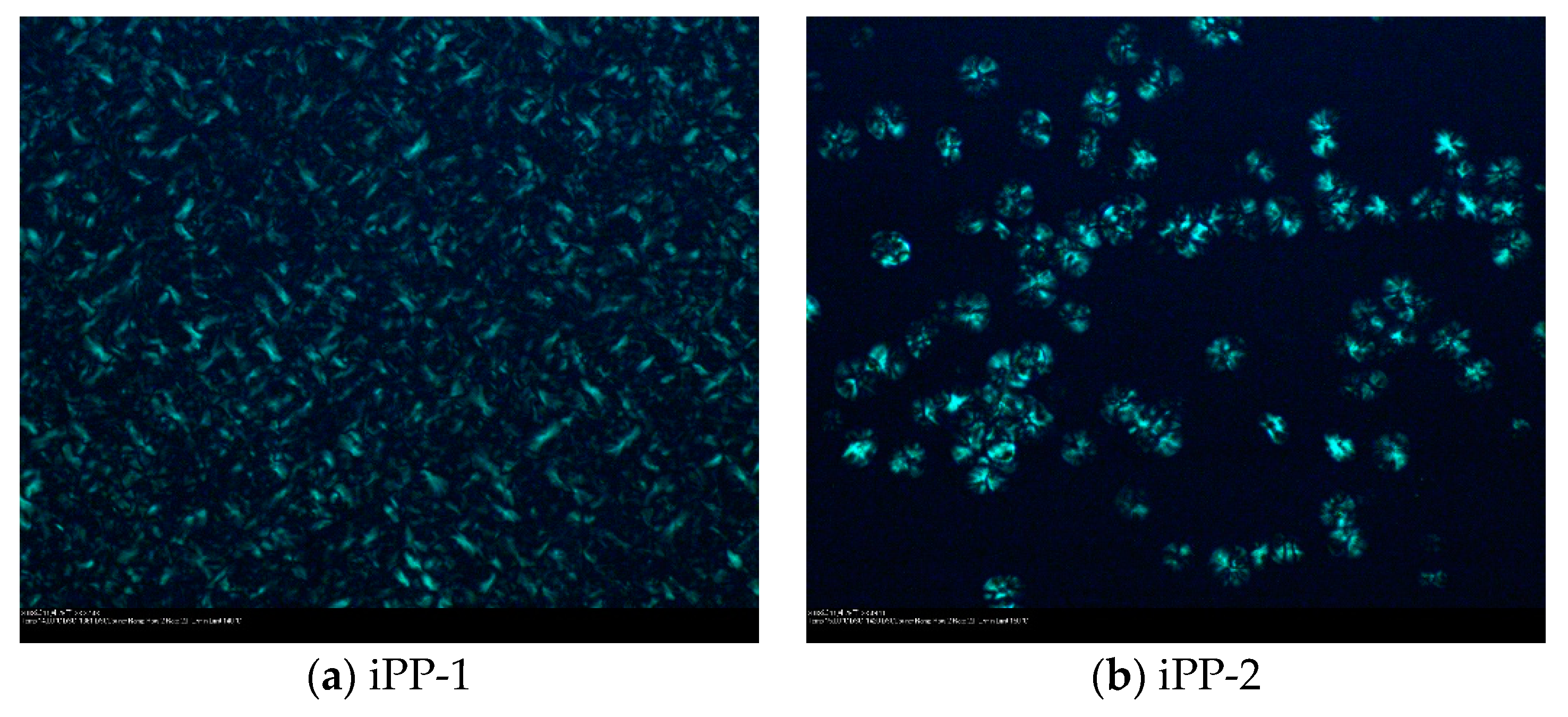

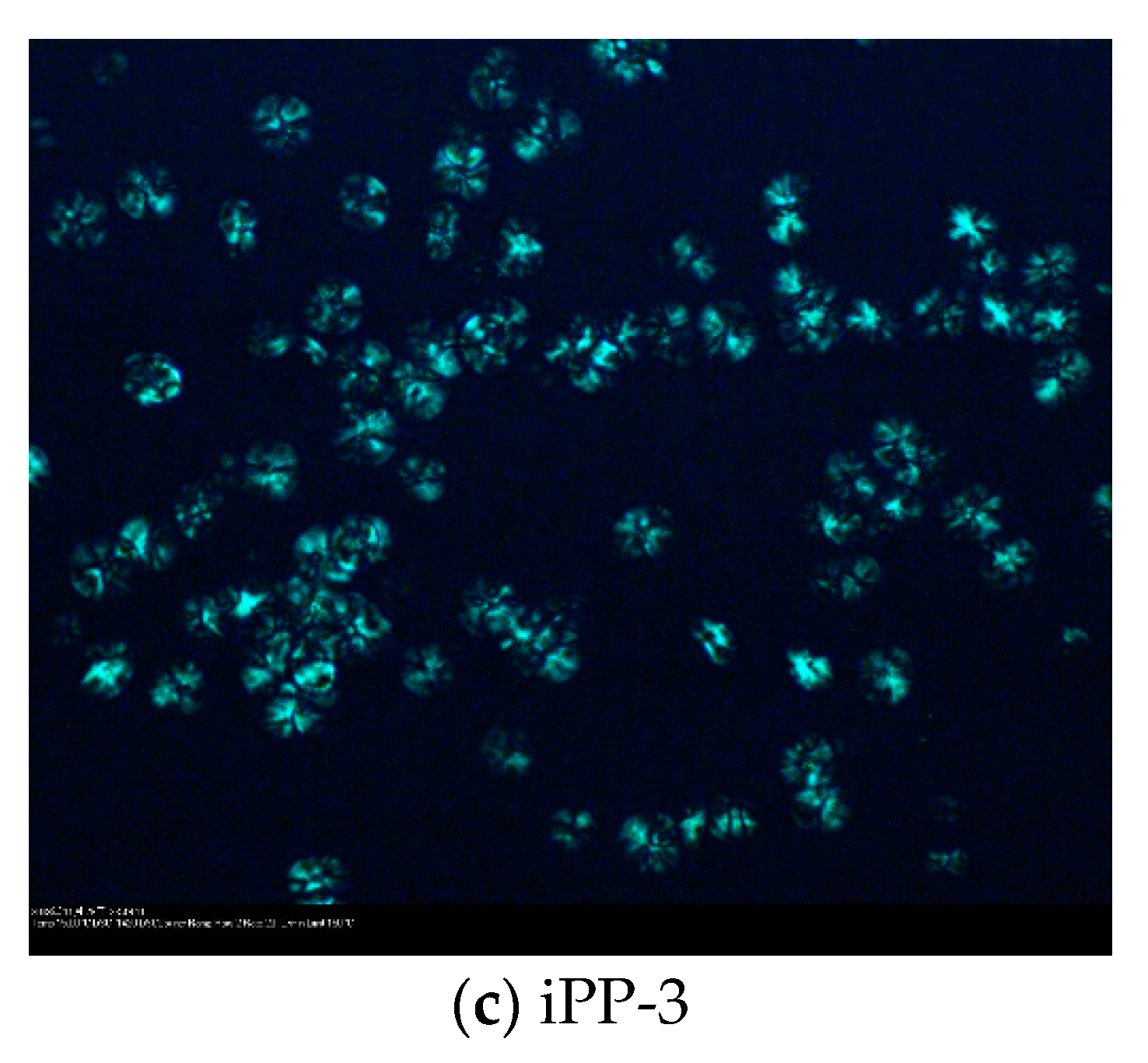

13C NMR spectra were recorded on a Bruker (Advance III) 400 MHz spectrometer with 1,2-dichlorobenzene-d4 as the solvent, at 120 °C. Gel permeation chromatography (GPC) was performed on a Waters GPC 1515 HPLC pump (Waters, Milford, MA, USA) and Wyatt DAWN HELEOS-II light scattering/Wyatt Optilab Rex refractive index detectors with 1,2,4-Trichlorobenzene as the eluent and polystyrene as an internal standard, at 135 °C. Differential scanning calorimetric (DSC) analysis was performed on a Netzsch DSC 200 PC (Netzsch, Free State of Bavaria, Germany) in a nitrogen atmosphere at a scanning rate of 15 °C min−1 from 30 to 180 °C and the results were collected from the second heating circle. The melt flow rate (MFR) analysis was performed on a Melt Flow Testers 7028 (Ceast, Turin, Italy) according to the GB/T 3682-2000. Tensile properties, bending properties, and impact strength analysis were performed on a universal testing machine 5566 according to the China-National Standard System (GB/T 1040-2006, GB/T 9341-2008 and GB/T 1843-2008, respectively). The crystallization property was performed on a polarizing microscope (POM) DM2500P (Leica, Solms, Germany). The polarized optical microscopic photographs were obtained by using a German Leica DMLP microscope. The temperature-rising elution fractionation (TREF) profiles were generated using Polymer Char 300 TREF (Polymer Char, Valencia, Spain) in a nitrogen atmosphere with 1,2,4-Trichlorobenzene as the solvent. The rheological behavior was studied at 230 °C by using a capillary rheometer (GOTTFERT, RHEO-TESTER 2000, Berlin, Germany) equipped with a capillary die (D = 0.5 mm, L/D = 60). The capillary die was sufficiently long so that the Bagley correction was not applied while the Rabinowitsch correction was applied. Crystallization and orientation were evaluated using a 2D wide angle X-ray diffraction (WAXD) (D8 DISCOVER, Bruker, Karlsruhe, Germany) under a voltage of 40 kV and a current of 40 mA with Cu Kα radiation (λ = 0.154 nm). Thermal analysis was carried out on a differential scanning calorimeter (DSC-I, Mettler Toledo, Switzerland) with samples of ca. 5 mg sealed in aluminum pans heated from 50 to 220 °C at 10 °C min−1 in a nitrogen atmosphere.

2.3. Melt-Spinning and Hot-Drawing

The melt-extrusion and spinning were conducted by using a single-screw extruder equipped with a 2.4 mL/rev metering-pump and an eight-hole spinneret, and the diameter of each hole was 0.6 mm. The extrusion temperature was set at 215, 265, 265, and 265 °C from the feed zone to the end of the extruder, respectively, and the spinneret temperature was set at 265 °C. The as-spun fibers were taken up at 1200, 2100, and 2750 m/min, respectively. The as-spun fibers were then hot-drawn by passing through five rollers (D = 125 mm) and two heat plates (L = 500 mm) between the 3rd and 4th rollers and the 4th and 5th rollers, respectively. The 2nd, 3rd, and 4th rollers were heated to 70, 130, and 145 °C, respectively, while the 1st and 5th rollers were at room temperature. Both the heat plates were kept at 130 °C. For comparison, the winding speed was fixed at 200 m/min during drawing, and the total draw ratio (DR) was fixed at 1.6, which was the maximum achievable DR for the fibers spun at the highest speed, i.e., 2750 m/min.