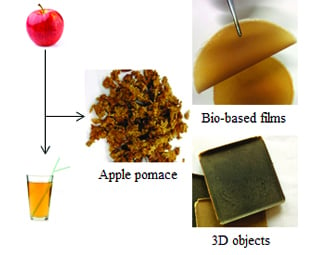

Development of Bio-Based Films and 3D Objects from Apple Pomace

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

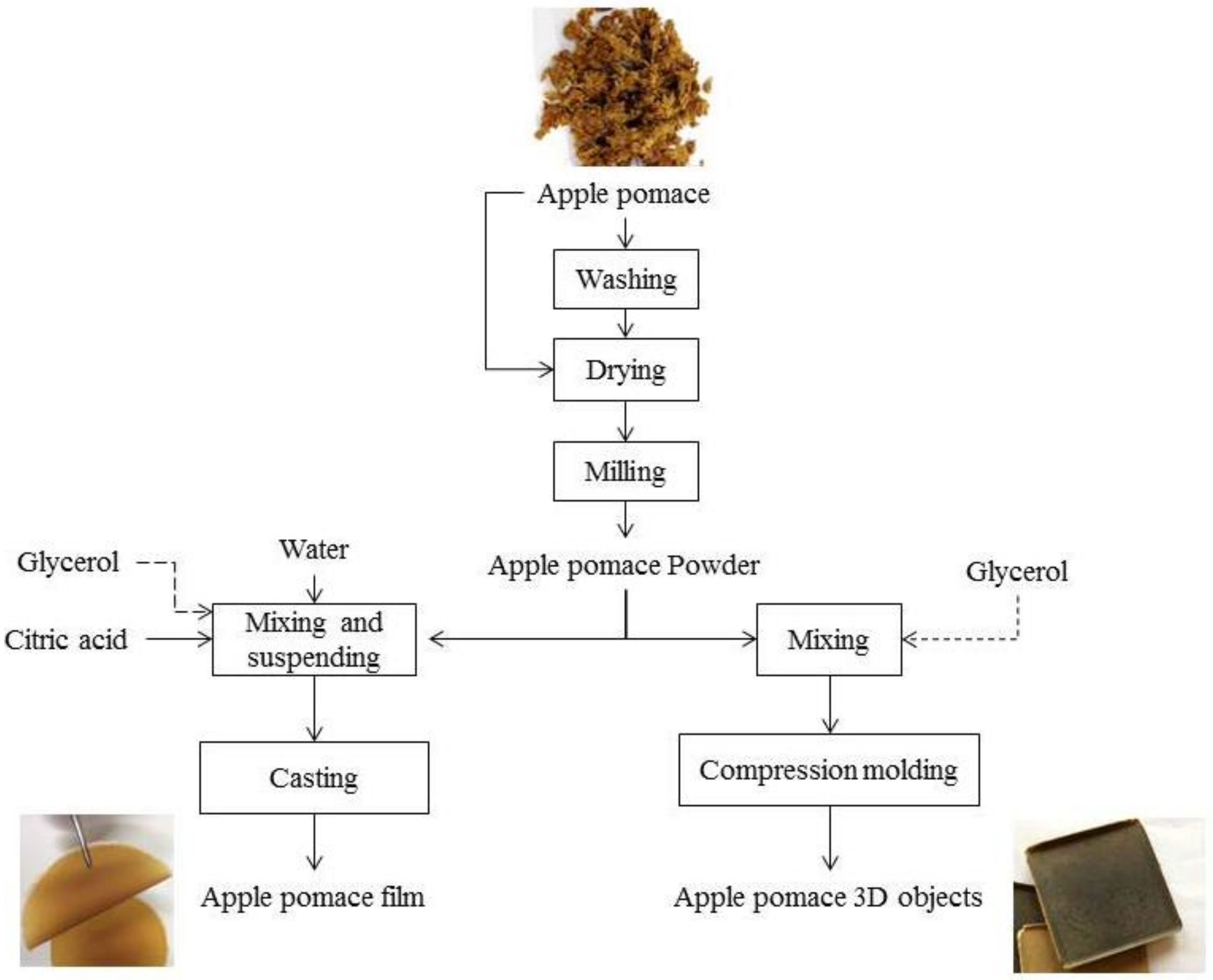

2.2. Pretreatment of Apple Pomace

2.3. Formation of Apple Pomace Powder

2.4. Preparation of Films and 3D Objects from Apple Pomace

2.4.1. Preparation of Bio-Based Films from Apple Pomace by Solution Casting Method

2.4.2. Preparation of 3D Biomaterials from Apple Pomace by Compression Molding Method

2.5. Compositional Analyses of Apple Pomace

2.5.1. Pectin Content

2.5.2. Starch Content

2.5.3. Sucrose, Fructose, and Glucose Content

2.5.4. Carbohydrate and Lignin Contents

2.6. Mechanical Testing of Bio-Based Films and Fiberboards

2.7. Morphological Analyses of Bio-Based Films and Biocomposites

3. Results and Discussion

3.1. Production of Thin Films from Apple Pomace by Solution Casting

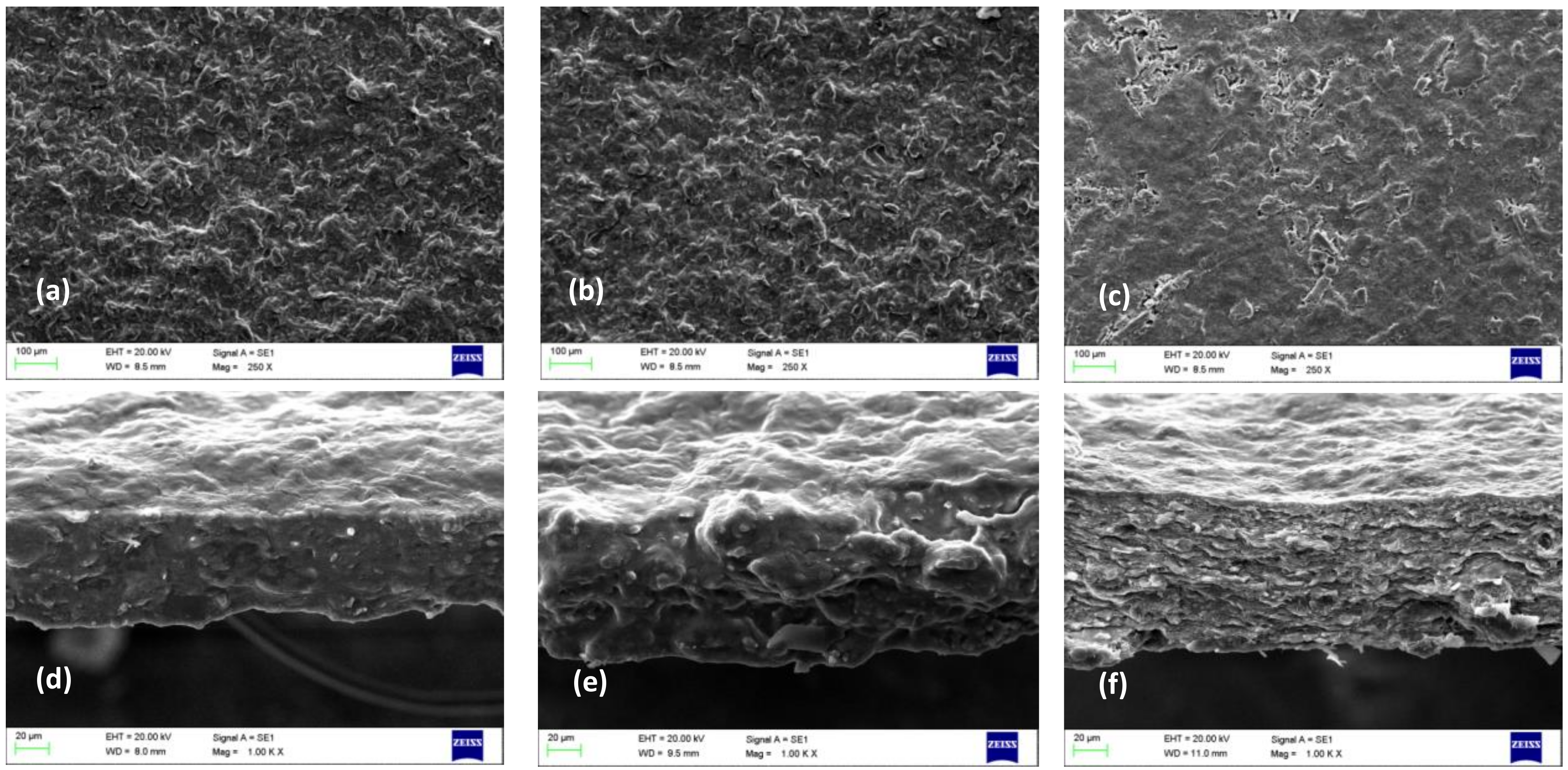

3.1.1. Morphology of Apple Pomace Films

3.1.2. Mechanical Properties of the Apple Pomace Films

3.2. Production of 3D Objects from Apple Pomace by Compression Molding

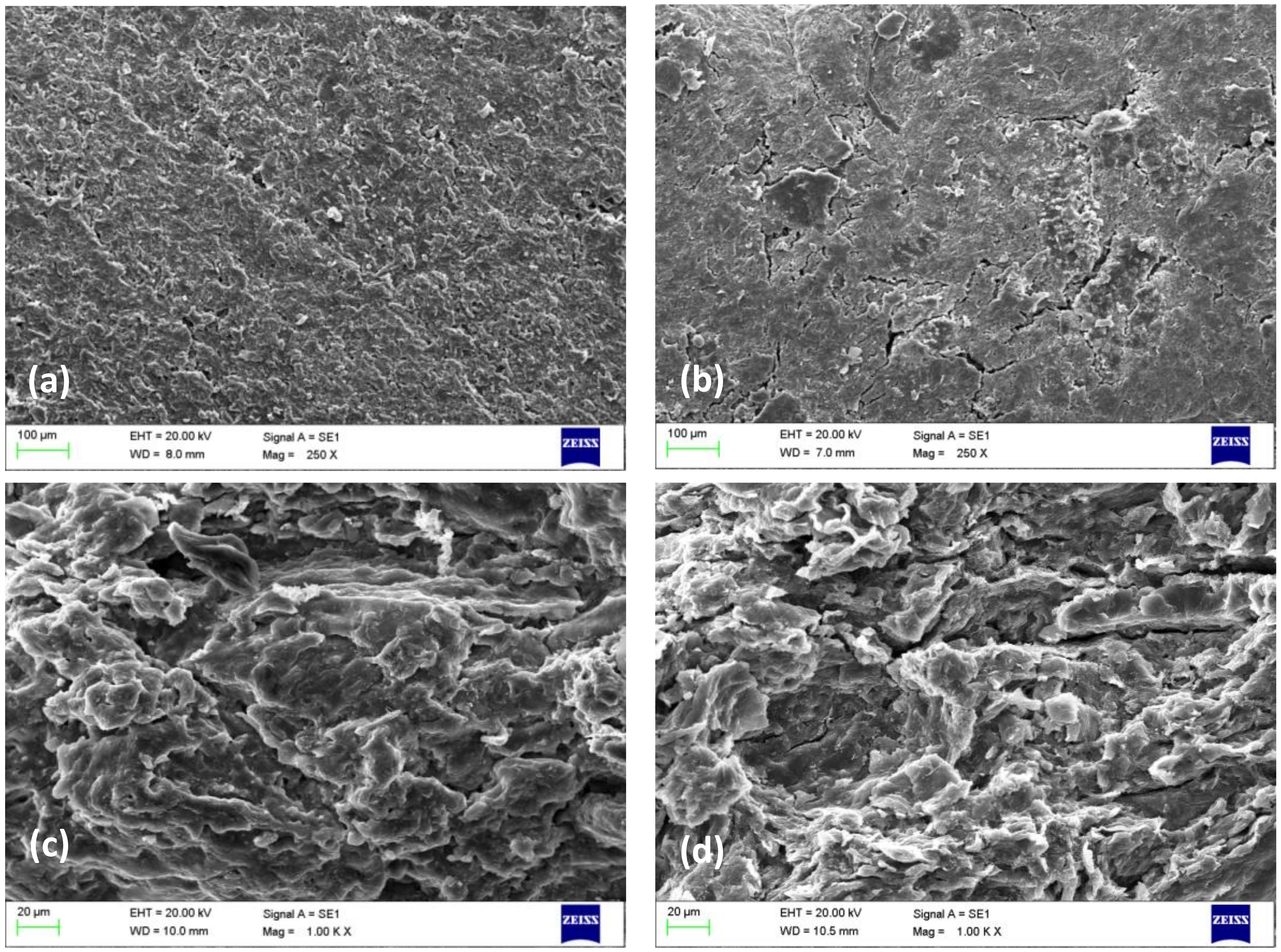

3.2.1. Morphology of Apple Pomace 3D Objects

3.2.2. Mechanical Properties of the Apple Pomace 3D Objects

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Avérous, L. Biodegradable Multiphase Systems Based on Plasticized Starch: A Review. J. Macromol. Sci. Part C 2004, 44, 231–274. [Google Scholar] [CrossRef]

- Brodin, M.; Vallejos, M.; Opedal, M.T.; Area, M.C.; Chinga-Carrasco, G. Lignocellulosics as sustainable resources for production of bioplastics—A review. J. Cleaner Prod. 2017, 162, 646–664. [Google Scholar] [CrossRef]

- Hernandez-Izquierdo, V.M.; Krochta, J.M. Thermoplastic Processing of Proteins for Film Formation—A Review. J. Food Sci. 2008, 73, R30–R39. [Google Scholar] [CrossRef] [PubMed]

- Porta, R.; Mariniello, L.; Di Pierro, P.; Sorrentino, A.; Giosafatto, C.V. Transglutaminase crosslinked pectin- and chitosan-based edible films: A review. Crc. Cr. Rev. Food Sci. 2011, 51, 223–238. [Google Scholar] [CrossRef] [PubMed]

- Bátori, V.; Jabbari, M.; Åkesson, D.; Lennartsson, P.R.; Taherzadeh, M.J.; Zamani, A. Production of Pectin-Cellulose Biofilms: A New Approach for Citrus Waste Recycling. Int. J. Polym. Sci. 2017, 2017, 9. [Google Scholar] [CrossRef]

- Bayer, I.S.; Guzman-Puyol, S.; Heredia-Guerrero, J.A.; Ceseracciu, L.; Pignatelli, F.; Ruffilli, R.; Cingolani, R.; Athanassiou, A. Direct Transformation of Edible Vegetable Waste into Bioplastics. Macromolecules 2014, 47, 5135–5143. [Google Scholar] [CrossRef]

- Oliveira, T.Í.S.; Rosa, M.F.; Ridout, M.J.; Cross, K.; Brito, E.S.; Silva, L.M.A.; Mazzetto, S.E.; Waldron, K.W.; Azeredo, H.M.C. Bionanocomposite films based on polysaccharides from banana peels. Int. J. Biol. Macromol. 2017, 101, 1–8. [Google Scholar] [CrossRef]

- Perotto, G.; Ceseracciu, L.; Paul, U.C.; Guzam-Puyol, S.; Tran, T.-N.; Bayer, I.S.; Athanassiou, A. Bioplastics from vegetable waste via an eco-friendly water-based process. Green Chem. 2018, 20, 894–902. [Google Scholar] [CrossRef]

- Cecchini, C. Bioplastics made from upcycled food waste. Prospects for their use in the field of design. Design J. 2017, 20, S1596–S1610. [Google Scholar] [CrossRef]

- Tran, T.N.; Heredia-Guerrero, J.A.; Mai, B.T.; Ceseracciu, L.; Marini, L.; Athanassiou, A.; Bayer, I.S. Bioelastomers Based on Cocoa Shell Waste with Antioxidant Ability. Adv. Sustainable Syst. 2017, 1, 1700002. [Google Scholar] [CrossRef]

- Perussello, C.A.; Zhang, Z.; Marzocchella, A.; Tiwari, B.K. Valorization of Apple Pomace by Extraction of Valuable Compounds. Compr. Rev. Food Sci. Food Saf. 2017, 16, 776–796. [Google Scholar] [CrossRef]

- Shalini, R.; Gupta, D.K. Utilization of pomace from apple processing industries: A review. J. Food Sci. Technol. 2010, 47, 365–371. [Google Scholar] [CrossRef] [PubMed]

- Vendruscolo, F.; Albuquerque, P.M.; Streit, F.; Esposito, E.; Ninow, J.L. Apple Pomace: A Versatile Substrate for Biotechnological Applications. Crit. Rev. Biotechnol. 2008, 28, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Bhushan, S.; Kalia, K.; Sharma, M.; Singh, B.; Ahuja, P.S. Processing of Apple Pomace for Bioactive Molecules. Crit. Rev. Biotechnol. 2008, 28, 285–296. [Google Scholar] [CrossRef] [PubMed]

- Xu, A.; Chen, L.; Wang, J. Functionalized Imidazalium Carboxylates for Enhancing Practical Applicability in Cellulose Processing. Macromolecules 2018, 51, 4158–4166. [Google Scholar] [CrossRef]

- Xu, A.; Guo, X.; Zhang, Y.; Li, Z.; Wang, J. Efficient and sustainable solvents for lignin dissolution: Aqueous choline carboxylate solutions. Green Chem. 2017, 19, 4067–4073. [Google Scholar] [CrossRef]

- Xu, A.; Zhang, Y.; Lu, W.; Yao, K.; Xu, H. Effect of alkyl chain length in anion on dissolution of cellulose in 1-butyl-3-methylimidazolium carboxylate ionic liquids. J. Mol. Liq. 2014, 197, 211–214. [Google Scholar] [CrossRef]

- Xu, A.-R.; Wen, S.; Chen, L. Dissolution performance of cellulose in MIM plus tetrabutylammonium propionate solvent. J. Mol. Liq. 2017, 246, 153–156. [Google Scholar] [CrossRef]

- Guzman-Puyol, S.; Russo, D.; Penna, I.; Ceseracciu, L.; Palazon, F.; Scarpellini, A.; Cingolani, R.; Bertorelli, R.; Bayer, I.S.; Heredia-Guerrero, J.A.; et al. Facile production of seaweed-based biomaterials with antioxidant and anti-inflammatory activities. Algal Res. 2017, 27, 1–11. [Google Scholar] [CrossRef]

- Jerez, A.; Partal, P.; Martínez, I.; Gallegos, C.; Guerrero, A. Protein-based bioplastics: Effect of thermo-mechanical processing. Rheologica Acta 2007, 46, 711–720. [Google Scholar] [CrossRef]

- Anglès, M.N.; Reguant, J.; Montané, D.; Ferrando, F.; Farriol, X.; Salvadó, J. Binderless composites from pretreated residual softwood. J. Appl. Polym. Sci. 1999, 73, 2485–2491. [Google Scholar] [CrossRef]

- Arévalo, R.; Peijs, T. Binderless all-cellulose fibreboard from microfibrillated lignocellulosic natural fibres. Compos. Part A 2016, 83, 38–46. [Google Scholar] [CrossRef]

- Bouajila, J.; Limare, A.; Joly, C.; Dole, P. Lignin plasticization to improve binderless fiberboard mechanical properties. Polym. Eng. Sci. 2005, 45, 809–816. [Google Scholar]

- Mobarak, F.; Fahmy, Y.; Augustin, H. Binderless Lignocellulose Composite from Bagasse and Mechanism of Self-Bonding. Holzforschung 1982, 36, 131. [Google Scholar] [CrossRef]

- Quintana, G.; Velásquez, J.; Betancourt, S.; Gañán, P. Binderless fiberboard from steam exploded banana bunch. Ind. Crop. Prod. 2009, 29, 60–66. [Google Scholar] [CrossRef]

- Gurram, R.; Souza Filho, P.F.; Taherzadeh, M.J.; Zamani, A. A Solvent-Free Approach for Production of Films from Pectin and Fungal Biomass. J. Polym. Environ. 2018, 26, 4282–4292. [Google Scholar] [CrossRef]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of Structural Carbohydrates and Ligning in Biomass; NREL: Golden, CO, USA, 2008. [Google Scholar]

- Orsuwan, A.; Sothornvit, R. Development and characterization of banana flour film incorporated with montmorillonite and banana starch nanoparticles. Carbohyd. Polym. 2017, 174, 235–242. [Google Scholar] [CrossRef]

- Sultan, N.F.K.; Johari, W.L.W. The development of banana peel/corn starch bioplastic film: A preliminary study. BSTR 2017, 5, 12–17. [Google Scholar]

- Günkaya, Z.; Banar, M. An environmental comparison of biocomposite film based on orange peel-derived pectin jelly-corn starch and LDPE film: LCA and biodegradability. Int. J. Life Cycle Assess. 2016, 21, 465–475. [Google Scholar] [CrossRef]

- Moro, T.M.A.; Ascheri, J.L.R.; Ortiz, J.A.R.; Carvalho, C.W.P.; Meléndez-Arévalo, A. Bioplastics of Native Starches Reinforced with Passion Fruit Peel. Food Bioprocess Tech. 2017, 10, 1798–1808. [Google Scholar] [CrossRef]

- Du, W.-X.; Olsen, C.W.; Avena-Bustillos, R.J.; Friedman, M.; McHugh, T.H. Physical and Antibacterial Properties of Edible Films Formulated with Apple Skin Polyphenols. J. Food Sci. 2011, 76, M149–M155. [Google Scholar] [CrossRef] [PubMed]

- Sheetz, D.P. Formation of films by drying of latex. J. Appl. Polym. Sci. 1965, 9, 3759–3773. [Google Scholar] [CrossRef]

- Li, J.; He, Y.; Inoue, Y. Thermal and mechanical properties of biodegradable blends of poly(L-lactic acid) and lignin. Polym. Int. 2003, 52, 949–955. [Google Scholar] [CrossRef]

- Vieira, M.G.A.; da Silva, M.A.; dos Santos, L.O.; Beppu, M.M. Natural-based plasticizers and biopolymer films: A review. Eur. Polym. J. 2011, 47, 254–263. [Google Scholar] [CrossRef]

- Lourdin, D.; Coignard, L.; Bizot, H.; Colonna, P. Influence of equilibrium relative humidity and plasticizer concentration on the water content and glass transition of starch materials. Polymer 1997, 38, 5401–5406. [Google Scholar] [CrossRef]

- Zubeldía, F.; Ansorena, M.R.; Marcovich, N.E. Wheat gluten films obtained by compression molding. Polym. Test. 2015, 43, 68–77. [Google Scholar] [CrossRef]

- Cao, N.; Yang, X.; Fu, Y. Effects of various plasticizers on mechanical and water vapor barrier properties of gelatin films. Food Hydrocolloid. 2009, 23, 729–735. [Google Scholar] [CrossRef]

- Bourtoom, T. Plasticizer effect on the properties of biodegradable blend film from rice starch-chitosan. Songklanakarin J. Sci. Technol. 2008, 30, 149–165. [Google Scholar]

- Gällstedt, M.; Mattozzi, A.; Johansson, E.; Hedenqvist, M.S. Transport and Tensile Properties of Compression-Molded Wheat Gluten Films. Biomacromolecules 2004, 5, 2020–2028. [Google Scholar] [CrossRef]

- Singh, H.; MacRitchie, F. Application of Polymer Science to Properties of Gluten. J. Cereal. Sci. 2001, 33, 231–243. [Google Scholar] [CrossRef]

| Component | Proportion (%) 1 | |

|---|---|---|

| Recovery of sugar-free water insoluble fraction 1 | 39.41 | |

| Water insoluble fraction | Pectin 2 | 8.94 ± 1.20 |

| Starch 2 | 2.91 ± 0.00 | |

| Cellulose 2 | 38.99 ± 0.42 | |

| Hemicelluloses 2 | 29.42 ± 0.44 | |

| Acid soluble lignin 2 | 6.51 ± 0.12 | |

| Acid insoluble Lignin 2 | 16.43 ± 0.12 | |

| Water soluble fraction | Total free sugars 1,3 | 55.47 (50.39) |

| Sucrose | 17.53 | |

| Fructose | 26.92 | |

| Glucose | 11.01 (16.63) | |

| Non-determined water-soluble fraction 1,3 | 5.12 (10.2) | |

| Moisture in wet apple pomace | 82.725 ± 0.07 |

| Washing Step | Glycerol (%) | Particle Size 1 (mm) | Thickness (mm) | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|---|---|

| yes | 7 | ~0.08 | 0.11 ± 0.01 | 16.49 ± 2.54 | 10.77 ± 3.19 |

| no | 7 | ~0.08 | 0.11 ± 0.01 | 3.27 ± 0.31 | 55.41 ± 5.38 |

| no | 0 | ~0.08 | 0.09 ± 0.00 | 4.20 ± 0.70 | 37.39 ± 10.38 |

| Washing Step | Plasticizer (%) | Particle Size 1 (mm) | Thickness (mm) | Tensile Strength (MPa) | Elongation (%) | Young’s Modulus (MPa) |

|---|---|---|---|---|---|---|

| yes | Glycerol 30% | 0.2 | 3.18 ± 0.07 | 5.79 ± 0.79 | 1.54 ± 0.09 | 633.4 ± 65.6 |

| no | Free sugars 2 | 0.2 | 2.17 ± 0.51 | 3.71 ± 0.80 | 1.56 ± 0.13 | 367.1 ± 82.6 |

| no | Free sugars 2 | 1 | 2.91 ± 0.02 | 3.02 ± 0.65 | 0.93 ± 0.21 | 485.7 ± 94.7 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gustafsson, J.; Landberg, M.; Bátori, V.; Åkesson, D.; Taherzadeh, M.J.; Zamani, A. Development of Bio-Based Films and 3D Objects from Apple Pomace. Polymers 2019, 11, 289. https://doi.org/10.3390/polym11020289

Gustafsson J, Landberg M, Bátori V, Åkesson D, Taherzadeh MJ, Zamani A. Development of Bio-Based Films and 3D Objects from Apple Pomace. Polymers. 2019; 11(2):289. https://doi.org/10.3390/polym11020289

Chicago/Turabian StyleGustafsson, Jesper, Mikael Landberg, Veronika Bátori, Dan Åkesson, Mohammad J. Taherzadeh, and Akram Zamani. 2019. "Development of Bio-Based Films and 3D Objects from Apple Pomace" Polymers 11, no. 2: 289. https://doi.org/10.3390/polym11020289

APA StyleGustafsson, J., Landberg, M., Bátori, V., Åkesson, D., Taherzadeh, M. J., & Zamani, A. (2019). Development of Bio-Based Films and 3D Objects from Apple Pomace. Polymers, 11(2), 289. https://doi.org/10.3390/polym11020289