Synthesis of Zwitterionic Copolymers via Copper-Mediated Aqueous Living Radical Grafting Polymerization on Starch

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Characterization

2.3. Synthesis of Starch-Based Macroinitiator (StBr)

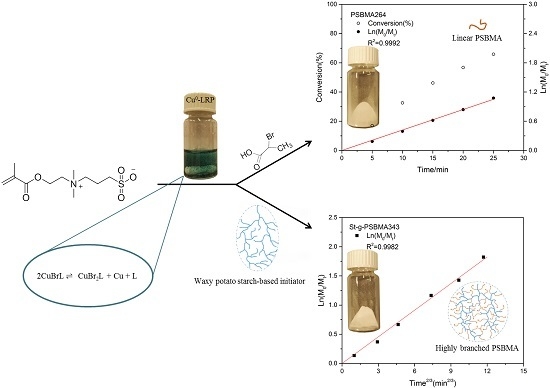

2.4. Aqueous Cu0-Mediated LRP of SBMA

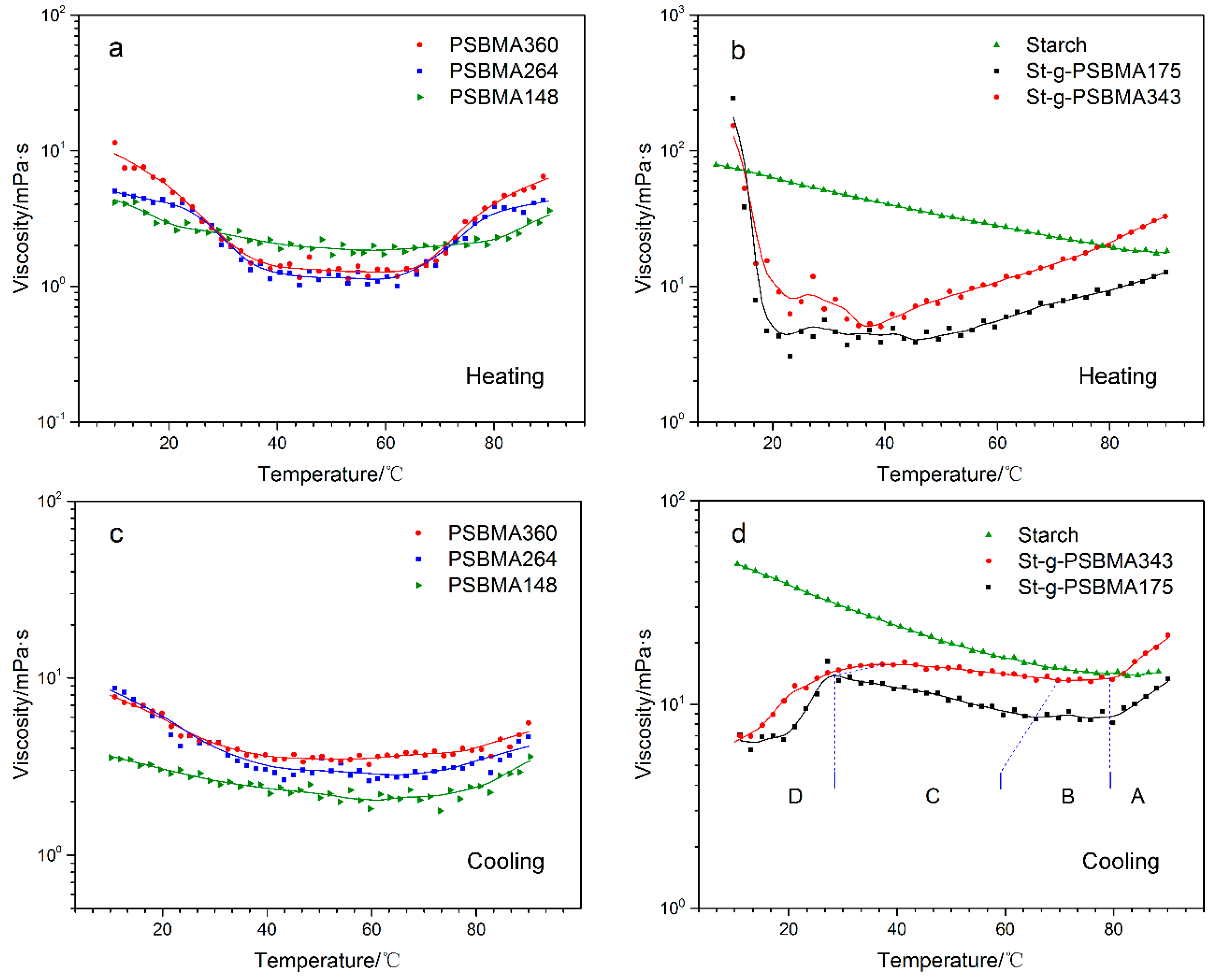

3. Results and Discussion

3.1. Synthesis of Waxy Potato-Based Macroinitiator StBr

3.2. Aqueous Cu0-Mediated LRP of SBMA

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kikuchi, M.; Terayama, Y.; Ishikawa, T.; Hoshino, T.; Kobayashi, M.; Ohta, N.; Jinnai, H.; Takahara, A. Salt dependence of the chain stiffness and excluded-volume strength for the polymethacrylate-type sulfopropylbetaine in aqueous nacl solutions. Macromolecules 2015, 48, 7194–7204. [Google Scholar] [CrossRef]

- Wang, F.; Yang, J.; Zhao, J. Understanding anti-polyelectrolyte behavior of a well-defined polyzwitterion at the single-chain level. Polym. Int. 2015, 64, 999–1005. [Google Scholar] [CrossRef]

- Ranka, M.; Brown, P.; Hatton, T.A. Responsive stabilization of nanoparticles for extreme salinity and high-temperature reservoir applications. ACS Appl. Mater. Interfaces 2015, 7, 19651–19658. [Google Scholar] [CrossRef]

- Laschewsky, A. Structures and synthesis of zwitterionic polymers. Polymers 2014, 6, 1544–1601. [Google Scholar] [CrossRef]

- Liu, H.; Xiong, C.; Tao, Z.; Fan, Y.; Tang, X.; Yang, H. Zwitterionic copolymer-based and hydrogen bonding-strengthened self-healing hydrogel. RSC Adv. 2015, 5, 33083–33088. [Google Scholar] [CrossRef]

- Ye, L.; Zhang, Y.; Wang, Q.; Zhou, X.; Yang, B.; Ji, F.; Dong, D.; Gao, L.; Cui, Y.; Yao, F. Physical cross-linking starch-based zwitterionic hydrogel exhibiting excellent biocompatibility, protein resistance, and biodegradability. ACS Appl. Mater. Interfaces 2016, 8, 15710–15723. [Google Scholar] [CrossRef]

- Vaterrodt, A.; Thallinger, B.; Daumann, K.; Koch, D.; Guebitz, G.M.; Ulbricht, M. Antifouling and antibacterial multifunctional polyzwitterion/enzyme coating on silicone catheter material prepared by electrostatic layer-by-layer assembly. Langmuir 2016, 32, 1347–1359. [Google Scholar] [CrossRef] [PubMed]

- Hui, L.; Qin, S.; Yang, L. Upper critical solution temperature polymer, photothermal agent, and erythrocyte membrane coating: An unexplored recipe for making drug carriers with spatiotemporally controlled cargo release. ACS Biomater. Sci. Eng. 2016, 2, 2127–2132. [Google Scholar] [CrossRef]

- Lee, H.; Puodziukynaite, E.; Zhang, Y.; Stephenson, J.C.; Richter, L.J.; Fischer, D.A.; DeLongchamp, D.M.; Emrick, T.; Briseno, A.L. Poly(sulfobetaine methacrylate)s as electrode modifiers for inverted organic electronics. J. Am. Chem. Soc. 2015, 137, 540–549. [Google Scholar] [CrossRef]

- Kobayashi, M.; Takahara, A. Environmentally friendly repeatable adhesion using a sulfobetaine-type polyzwitterion brush. Polym. Chem. 2013, 4, 4987. [Google Scholar] [CrossRef]

- Zhu, Y.; Noy, J.-M.; Lowe, A.B.; Roth, P.J. The synthesis and aqueous solution properties of sulfobutylbetaine (co)polymers: Comparison of synthetic routes and tuneable upper critical solution temperatures. Polym. Chem. 2015, 6, 5705–5718. [Google Scholar] [CrossRef]

- Tian, M.; Wang, J.; Zhang, E.; Li, J.; Duan, C.; Yao, F. Synthesis of agarose-graft-poly[3-dimethyl (methacryloyloxyethyl) ammonium propanesulfonate] zwitterionic graft copolymers via atrp and their thermally-induced aggregation behavior in aqueous media. Langmuir 2013, 29, 8076–8085. [Google Scholar] [CrossRef] [PubMed]

- Hatton, F.L.; Engström, J.; Forsling, J.; Malmström, E.; Carlmark, A. Biomimetic adsorption of zwitterionic–xyloglucan block copolymers to cnf: Towards tailored super-absorbing cellulose materials. RSC Adv. 2017, 7, 14947–14958. [Google Scholar] [CrossRef]

- Simula, A.; Anastasaki, A.; Haddleton, D.M. Methacrylic zwitterionic, thermoresponsive, and hydrophilic (co)polymers via Cu(0)-polymerization: The importance of halide salt additives. Macromol. Rapid Commun. 2016, 37, 356–361. [Google Scholar] [CrossRef] [PubMed]

- Zhai, S.; Ma, Y.; Chen, Y.; Li, D.; Cao, J.; Liu, Y.; Cai, M.; Xie, X.; Chen, Y.; Luo, X. Synthesis of an amphiphilic block copolymer containing zwitterionic sulfobetaine as a novel pH-sensitive drug carrier. Polym. Chem. 2014, 5, 1285–1297. [Google Scholar] [CrossRef]

- Lalani, R.; Liu, L. Synthesis, characterization, and electrospinning of zwitterionic poly(sulfobetaine methacrylate). Polymer 2011, 52, 5344–5354. [Google Scholar] [CrossRef]

- Chang, D.; Olsen, B.D. Self-assembly of protein-zwitterionic polymer bioconjugates into nanostructured materials. Polym. Chem. 2016, 7, 2410–2418. [Google Scholar] [CrossRef]

- Peng, C.-H.; Kong, J.; Seeliger, F.; Matyjaszewski, K. Mechanism of halogen exchange in atrp. Macromolecules 2011, 44, 7546–7557. [Google Scholar] [CrossRef]

- de Grooth, J.; Dong, M.; de Vos, W.M.; Nijmeijer, K. Building polyzwitterion-based multilayers for responsive membranes. Langmuir 2014, 30, 5152–5161. [Google Scholar] [CrossRef]

- Puodziukynaite, E.; Wang, H.W.; Lawrence, J.; Wise, A.J.; Russell, T.P.; Barnes, M.D.; Emrick, T. Azulene methacrylate polymers: Synthesis, electronic properties, and solar cell fabrication. J. Am. Chem. Soc. 2014, 136, 11043–11049. [Google Scholar] [CrossRef]

- Zhu, J.; Tian, M.; Hou, J.; Wang, J.; Lin, J.; Zhang, Y.; Liu, J.; Van der Bruggen, B. Surface zwitterionic functionalized graphene oxide for a novel loose nanofiltration membrane. J. Mater. Chem. A 2016, 4, 1980–1990. [Google Scholar] [CrossRef]

- Terayama, Y.; Kikuchi, M.; Kobayashi, M.; Takahara, A. Well-defined poly(sulfobetaine) brushes prepared by surface-initiated atrp using a fluoroalcohol and ionic liquids as the solvents. Macromolecules 2011, 44, 104–111. [Google Scholar] [CrossRef]

- Zhang, Q.; Wilson, P.; Li, Z.; McHale, R.; Godfrey, J.; Anastasaki, A.; Waldron, C.; Haddleton, D.M. Aqueous copper-mediated living polymerization: Exploiting rapid disproportionation of cubr with Me6TREN. J. Am. Chem. Soc. 2013, 135, 7355–7363. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Hu, X.; Cai, T. Construction of hierarchical fouling resistance surfaces onto poly(vinylidene fluoride) membranes for combating membrane biofouling. Langmuir 2017, 33, 4477–4489. [Google Scholar] [CrossRef] [PubMed]

- Chang, Y.; Chen, S.; Zhang, Z.; Jiang, S. Highly protein-resistant coatings from well-defined diblock copolymers containing sulfobetaines. Langmuir 2006, 22, 2222–2226. [Google Scholar] [CrossRef] [PubMed]

- Doncom, K.E.B.; Willcock, H.; O’Reilly, R.K. The direct synthesis of sulfobetaine-containing amphiphilic block copolymers and their self-assembly behavior. Eur. Polym. J. 2017, 87, 497–507. [Google Scholar] [CrossRef]

- Rajan, R.; Matsumura, K. A zwitterionic polymer as a novel inhibitor of protein aggregation. J. Mater. Chem. B 2015, 3, 5683–5689. [Google Scholar] [CrossRef]

- Roland, N.; Icke, B.B.W.; Gordon, A. β-phenylethyldimethylamine. Org. Synth. 1945, 25, 89–92. [Google Scholar]

- Jones, G.R.; Li, Z.; Anastasaki, A.; Lloyd, D.J.; Wilson, P.; Zhang, Q.; Haddleton, D.M. Rapid synthesis of well-defined polyacrylamide by aqueous Cu(0)-mediated reversible-deactivation radical polymerization. Macromolecules 2016, 49, 483–489. [Google Scholar] [CrossRef]

- Konkolewicz, D.; Wang, Y.; Krys, P.; Zhong, M.; Isse, A.A.; Gennaro, A.; Matyjaszewski, K. SARA ATRP or SET-LRP. End of controversy? Polym. Chem. 2014, 5, 4396–4417. [Google Scholar] [CrossRef]

- Tang, W.M.K. Effects of initiator structure on activation rate constants in atrp. Macromolecules 2007, 40, 1858–1863. [Google Scholar] [CrossRef]

- Goto, A.; Fukuda, T. Kinetics of living radical polymerization. Prog. Polym. Sci. 2004, 29, 329–385. [Google Scholar] [CrossRef]

- Wever, D.A.Z.; Picchioni, F.; Broekhuis, A.A. Branched polyacrylamides: Synthesis and effect of molecular architecture on solution rheology. Eur. Polym. J. 2013, 49, 3289–3301. [Google Scholar] [CrossRef]

- Chiotelli, E.; Pilosio, G.; Le Meste, M. Effect of sodium chloride on the gelatinization of starch: A multimeasurement study. Biopolymers 2002, 63, 41–58. [Google Scholar] [CrossRef] [PubMed]

- Saito, S. Salt effect on polymer solutions. J. Polym. Sci. Part A Polym. Chem. 1969, 7, 1789–1802. [Google Scholar] [CrossRef]

- Jung, J.C.; Zhang, K.; Chon, B.H.; Choi, H.J. Rheology and polymer flooding characteristics of partially hydrolyzed polyacrylamide for enhanced heavy oil recovery. J. Appl. Polym. Sci. 2013, 127, 4833–4839. [Google Scholar] [CrossRef]

- Chen, Q.; Wang, Y.; Lu, Z.; Feng, Y. Thermoviscosifying polymer used for enhanced oil recovery: Rheological behaviors and core flooding test. Polym. Bull. 2013, 70, 391–401. [Google Scholar] [CrossRef]

- Mäkinen, L.; Varadharajan, D.; Tenhu, H.; Hietala, S. Triple hydrophilic UCST–LCST block copolymers. Macromolecules 2016, 49, 986–993. [Google Scholar] [CrossRef]

- Ilčíková, M.; Tkáč, J.; Kasák, P. Switchable materials containing polyzwitterion moieties. Polymers 2015, 7, 2344–2370. [Google Scholar] [CrossRef]

| Entry | [M]:[I]:[CuBr]:[L] | Time/min | Temperature/°C | Concentration a/mol⋅L−1 | Conversion b/% | DP b | PDI c |

|---|---|---|---|---|---|---|---|

| 1 | 25:1:0.4:0.4 | 25 | 0 | 1.0 | 56.3 | 14 | 1.38 |

| 2 | 50:1:0.4:0.4 | 20 | 0 | 1.0 | 71.6 | 36 | 1.50 |

| 3 | 50:1:0.4:0.4 | 25 | 0 | 1.0 | 77.2 | 38 | 1.33 |

| 4 | 50:1:0.8:0.4 | 45 | 0 | 1.0 | 85.2 | 42 | 1.73 |

| 5 | 100:1:0.8:0.6 | 25 | 0 | 1.0 | 75.9 | 76 | 1.40 |

| 6 | 200:1:0.8:0.6 | 25 | 0 | 1.0 | 74.3 | 148 | - e |

| 7 | 400:1:0.8:0.6 | 25 | 0 | 1.0 | - d | - d | - d |

| 8 | 400:1:1.0:0.6 | 25 | 0 | 1.5 | 65.9 | 264 | -e |

| 9 | 600:1:1.0:0.6 | 25 | 25 | 0.75 | 55.9 | 336 | -e |

| 10 | 600:1:1.0:0.6 | 60 | 25 | 0.85 | 60.0 | 360 | -e |

| Entry | [M]:[I]:[CuBr]:[L] | Time/min | Temperature/°C | Concentration b/mol⋅L−1 | Conversion c/% | DP c |

|---|---|---|---|---|---|---|

| 1 | 200:1:1.2:0.6 | 25 | 25 | 0.67 | - d | - d |

| 2 | 200:1:1.2:0.6 | 40 | 25 | 0.75 | 87.4 | 175 |

| 3 | 200:1:1.2:0.6 | 25 | 25 | 0.85 | 90.2 | 180 |

| 4 | 400:1:1.2:0.6 | 40 | 25 | 0.83 | 85.9 | 343 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, Y.; Migliore, N.; Raffa, P.; Bose, R.K.; Picchioni, F. Synthesis of Zwitterionic Copolymers via Copper-Mediated Aqueous Living Radical Grafting Polymerization on Starch. Polymers 2019, 11, 192. https://doi.org/10.3390/polym11020192

Fan Y, Migliore N, Raffa P, Bose RK, Picchioni F. Synthesis of Zwitterionic Copolymers via Copper-Mediated Aqueous Living Radical Grafting Polymerization on Starch. Polymers. 2019; 11(2):192. https://doi.org/10.3390/polym11020192

Chicago/Turabian StyleFan, Yifei, Nicola Migliore, Patrizio Raffa, Ranjita K. Bose, and Francesco Picchioni. 2019. "Synthesis of Zwitterionic Copolymers via Copper-Mediated Aqueous Living Radical Grafting Polymerization on Starch" Polymers 11, no. 2: 192. https://doi.org/10.3390/polym11020192

APA StyleFan, Y., Migliore, N., Raffa, P., Bose, R. K., & Picchioni, F. (2019). Synthesis of Zwitterionic Copolymers via Copper-Mediated Aqueous Living Radical Grafting Polymerization on Starch. Polymers, 11(2), 192. https://doi.org/10.3390/polym11020192