Analysis and Identification of the Mechanism of Damage and Fracture of High-Filled Wood Fiber/Recycled High-Density Polyethylene Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Composite Preparation

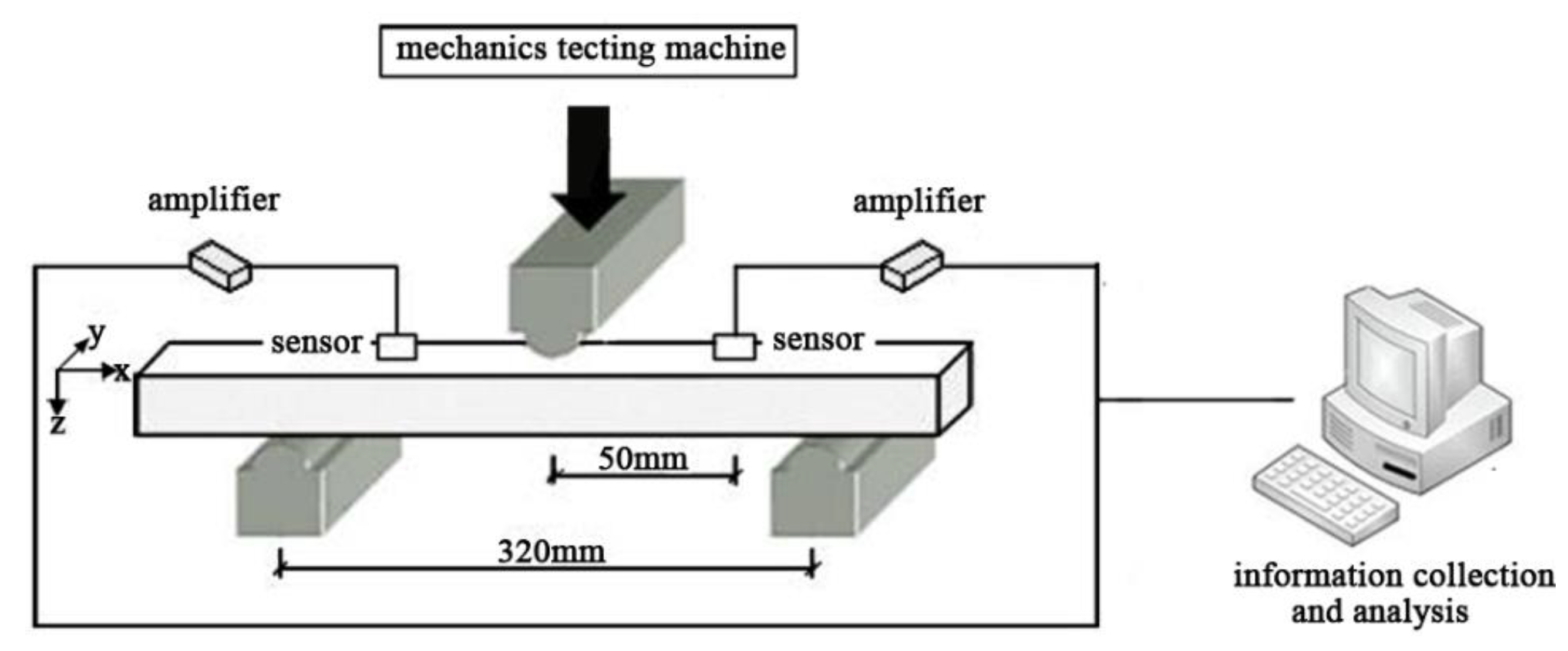

2.3. Characterization

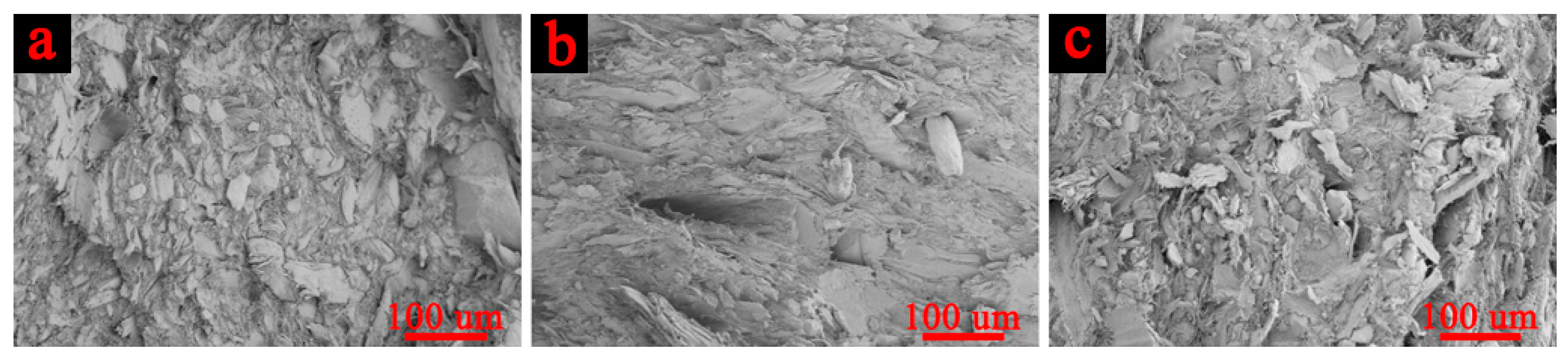

3. Results and Discussion

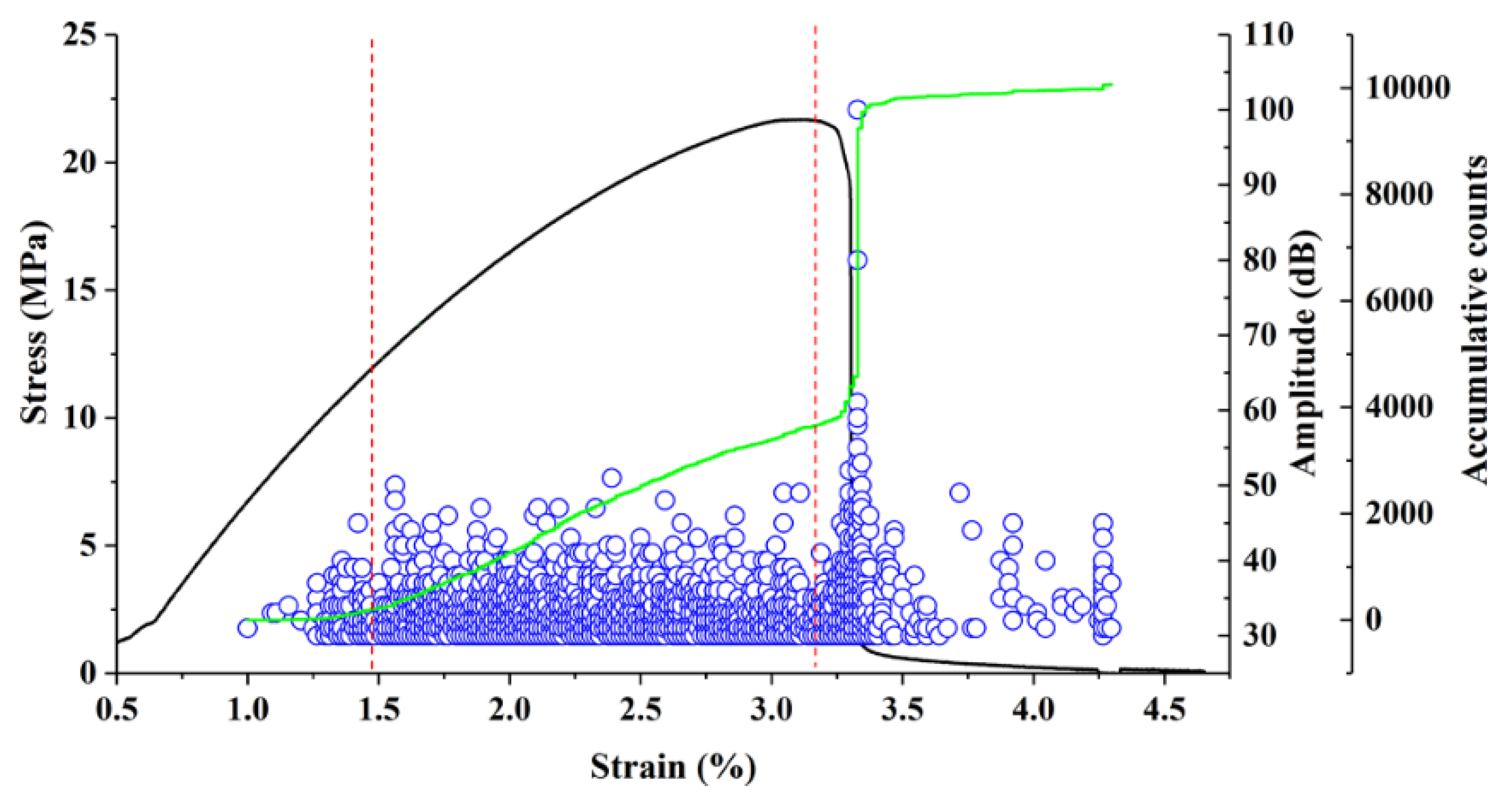

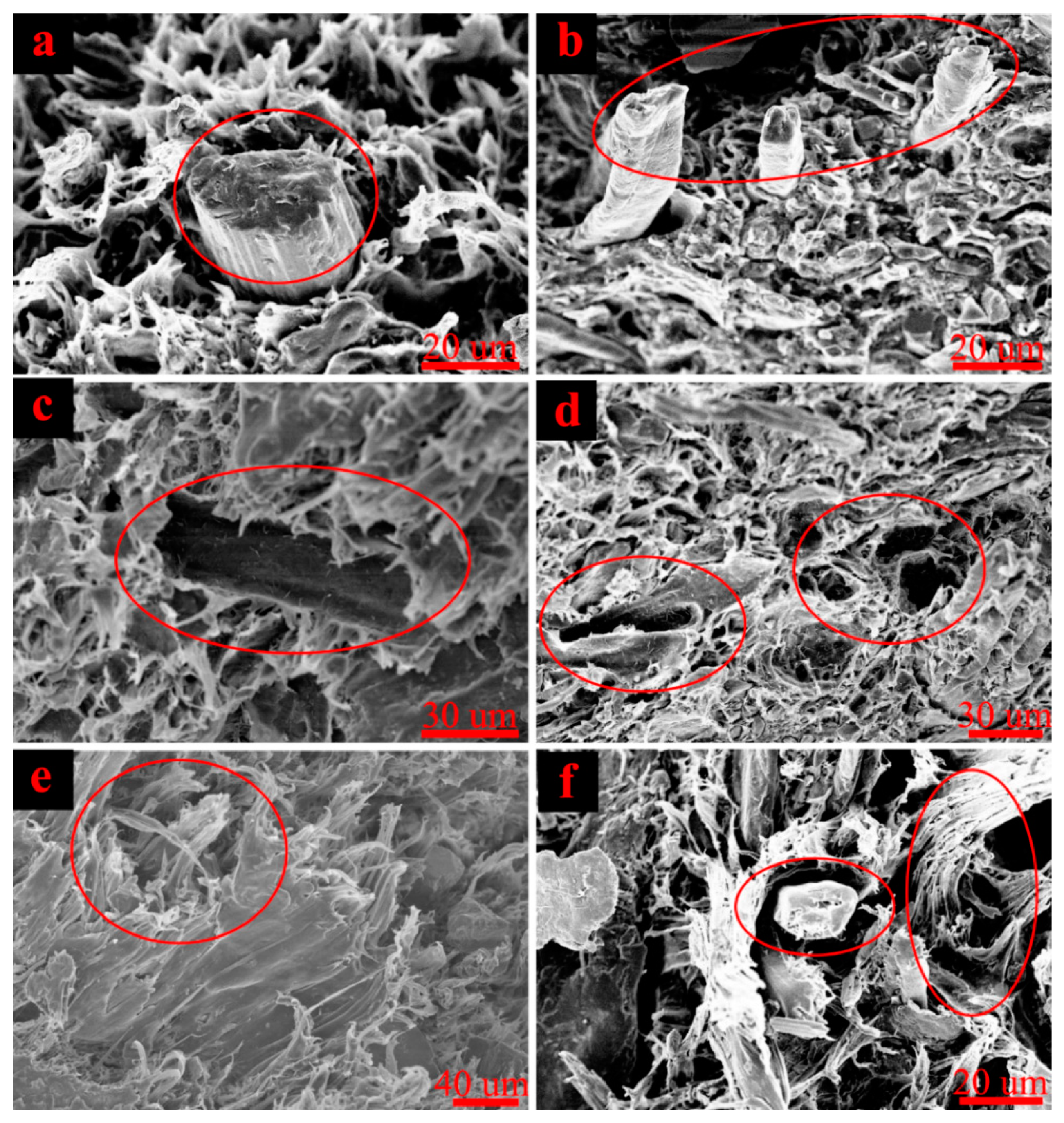

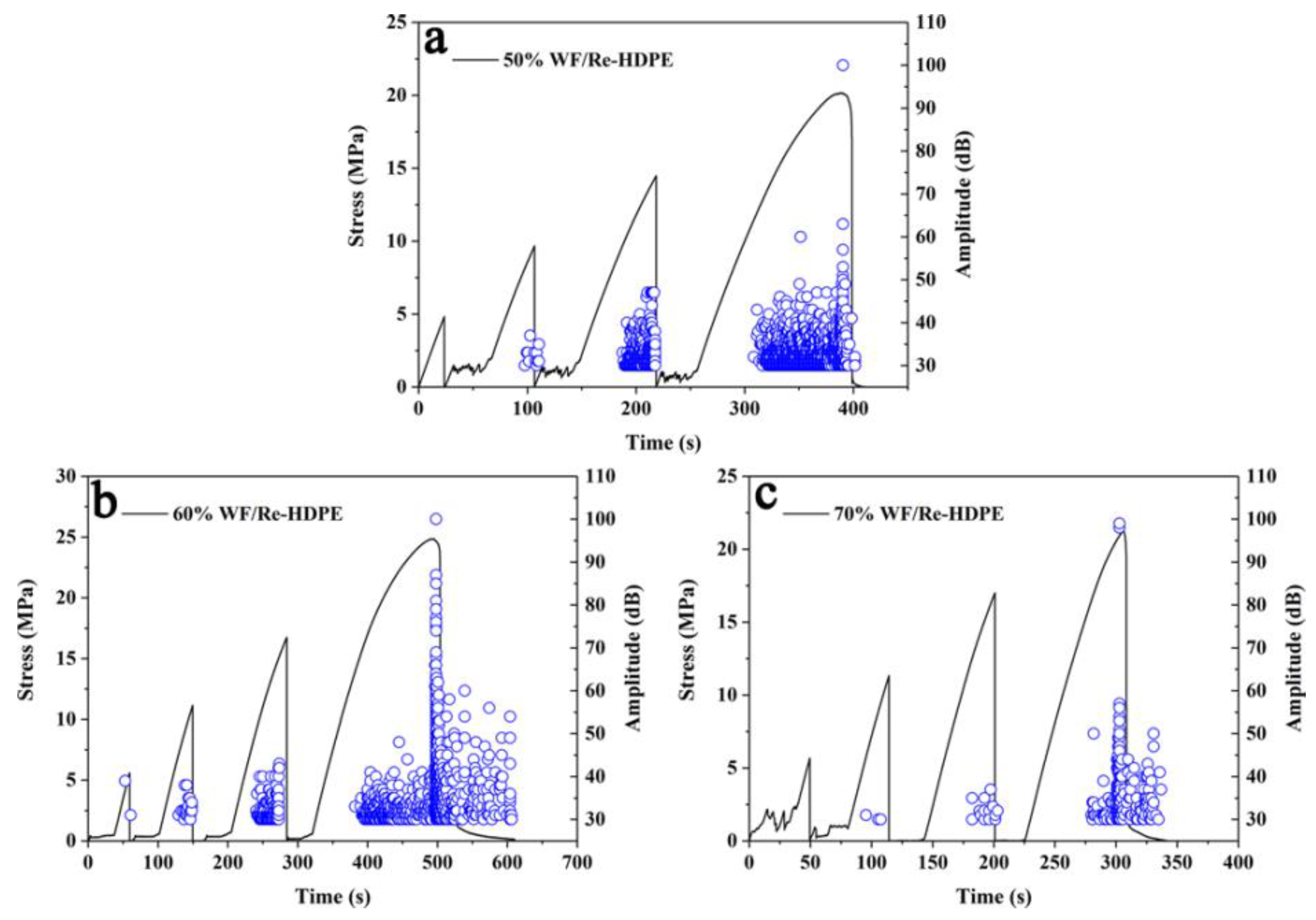

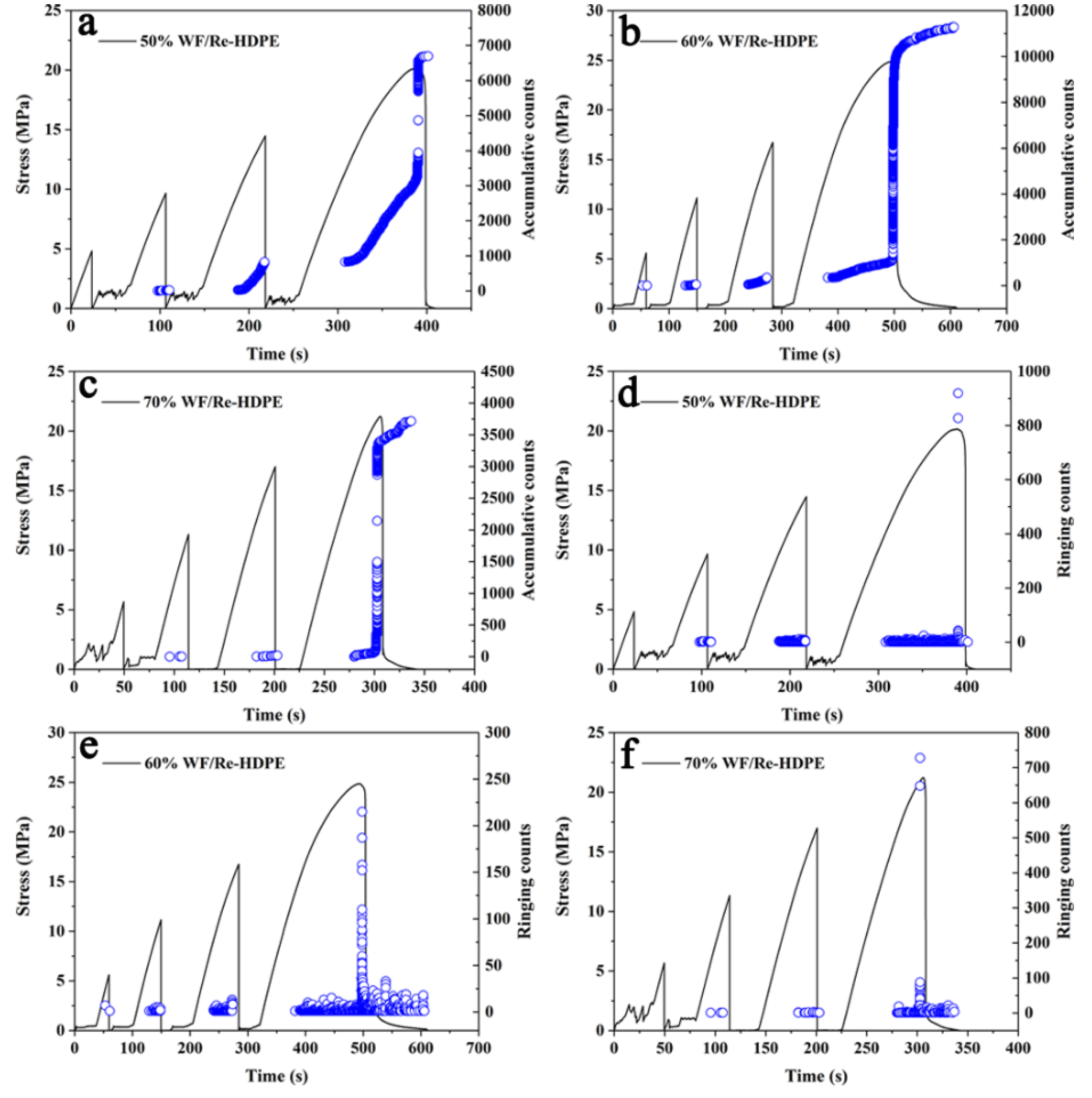

3.1. AE Signal Analysis of Composites Damage and Fracture Mode

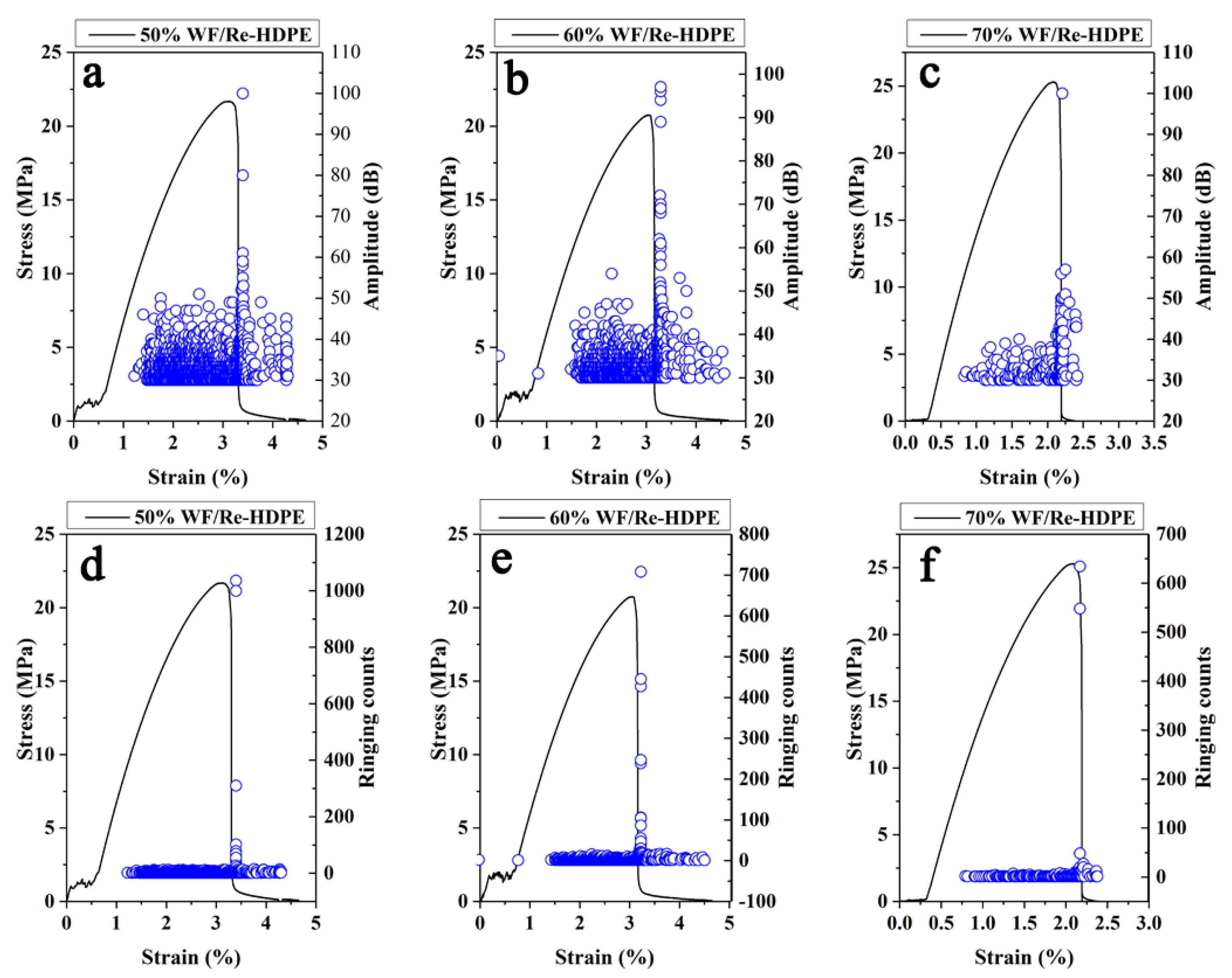

3.2. Relationship between AE Signal and Stress-Strain of WF/Re-HDPE Composites

3.3. AE Characteristics in Repeated Bending Loading Process

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sanjay, M.R.; Madhu, P.; Jawaid, M.; Senthamaraikannan, P.; Senthil, S.; Pradeep, S. Characterization and properties of natural fiber polymer composites: A comprehensive review. J. Clean. Prod. 2018, 172, 566–581. [Google Scholar] [CrossRef]

- Ayrilmis, N. Combined effects of boron and compatibilizer on dimensional stability and mechanical properties of wood/HDPE composites. Compos. Part B Eng. 2013, 44, 745–749. [Google Scholar] [CrossRef]

- García, M.; Hidalgo, J.; Garmendia, I.; García-Jaca, J. Wood–plastics composites with better fire retardancy and durability performance. Compos. Part A 2009, 40, 1772–1776. [Google Scholar] [CrossRef]

- Assarar, M.; Scida, D.; Zouari, W.; Saidane, E.H.; Ayad, R. Acoustic emission characterization of damage in short hemp-fiber-reinforced polypropylene composites. Polym. Compos. 2016, 37, 1101–1112. [Google Scholar] [CrossRef]

- Zhuang, X.; Yan, X. Investigation of damage mechanisms in self-reinforced polyethylene composites by acoustic emission. Compos. Sci. Technol. 2006, 66, 444–449. [Google Scholar] [CrossRef]

- Tekalur, S.A.; Shivakumar, K.; Shukla, A. Mechanical behavior and damage evolution in E-glass vinyl ester and carbon composites subjected to static and blast loads. Compos. Part B 2008, 39, 57–65. [Google Scholar] [CrossRef]

- Malpot, A.; Touchard, F.; Bergamo, S. An investigation of the influence of moisture on fatigue damage mechanisms in a woven glass-fibre-reinforced PA66 composite using acoustic emission and infrared thermography. Compos. Part B Eng. 2017, 130, 11–20. [Google Scholar] [CrossRef]

- Bohse, J. Acoustic emission characteristics of micro-failure processes in polymer blends and composites. Compos. Sci. Technol. 2000, 60, 1213–1226. [Google Scholar] [CrossRef]

- Anuar, H.; Ahmad, S.; Rasid, R.; Surip, S.; Czigany, T.; Romhany, G. Essential work of fracture and acoustic emission study on TPNR composites reinforced by kenaf fiber. J. Compos. Mater. 2007, 41, 3035–3049. [Google Scholar] [CrossRef]

- Saeedifar, M.; Najafabadi, M.A.; Zarouchas, D.; Toudeshky, H.H.; Jalalvand, M. Clustering of interlaminar and intralaminar damages in laminated composites under indentation loading using Acoustic Emission. Compos. Part B Eng. 2018, 144, 206–219. [Google Scholar] [CrossRef]

- Nag-Chowdhury, S.; Bellégou, H.; Pillin, I.; Castro, M.; Longrais, P.; Feller, J. Crossed investigation of damage in composites with embedded quantum resistive strain sensors (sQRS), acoustic emission (AE) and digital image correlation (DIC). Compos. Sci. Technol. 2018, 160, 79–85. [Google Scholar] [CrossRef]

- Kravchuk, R.; Landis, E.N. Acoustic emission-based classification of energy dissipation mechanisms during fracture of fiber-reinforced ultra-high-performance concrete. Constr. Build. Mater. 2018, 176, 531–538. [Google Scholar] [CrossRef]

- Gholizadeh, S.; Leman, Z.; Baharudin, B. A review of the application of acoustic emission technique in engineering. Struct. Eng. Mech. 2015, 54, 1075. [Google Scholar] [CrossRef]

- De Rosa, I.M.; Santulli, C.; Sarasini, F. Acoustic emission for monitoring the mechanical behaviour of natural fibre composites: A literature review. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1456–1469. [Google Scholar] [CrossRef]

- Yu, F.-M.; Okabe, Y.; Wu, Q.; Shigeta, N. A novel method of identifying damage types in carbon fiber-reinforced plastic cross-ply laminates based on acoustic emission detection using a fiber-optic sensor. Compos. Sci. Technol. 2016, 135, 116–122. [Google Scholar] [CrossRef]

- Habibi, M.; Lebrun, G.; Laperrière, L. Experimental characterization of short flax fiber mat composites: Tensile and flexural properties and damage analysis using acoustic emission. J. Mater. Sci. 2017, 52, 6567–6580. [Google Scholar] [CrossRef]

- Czigány, T.; Marosfalvi, J.; Karger-Kocsis, J. An acoustic emission study of the temperature-dependent fracture behavior of polypropylene composites reinforced by continuous and discontinuous fiber mats. Compos. Sci. Technol. 2000, 60, 1203–1212. [Google Scholar] [CrossRef]

- Carvelli, V.; D’Ettorre, A.; Lomov, S.V. Acoustic emission and damage mode correlation in textile reinforced PPS composites. Compos Struct. 2017, 163, 399–409. [Google Scholar] [CrossRef]

- Dogossy, G.; Czigány, T. Failure mode characterization in maize hull filled polyethylene composites by acoustic emission. Polym. Test. 2006, 25, 353–357. [Google Scholar] [CrossRef]

- Zhou, W.; Zhao, W.-Z.; Zhang, Y.-N.; Ding, Z.-J. Cluster analysis of acoustic emission signals and deformation measurement for delaminated glass fiber epoxy composites. Compos. Struct. 2018, 195, 349–358. [Google Scholar] [CrossRef]

- Dányádi, L.; Renner, K.; Móczó, J.; Pukánszky, B. Wood flour filled polypropylene composites: Interfacial adhesion and micromechanical deformations. Polym. Eng. Sci. 2007, 47, 1246–1255. [Google Scholar] [CrossRef]

- El-Abbassi, F.E.; Assarar, M.; Ayad, R.; Lamdouar, N. Effect of alkali treatment on Alfa fibre as reinforcement for polypropylene based eco-composites: Mechanical behaviour and water ageing. Compos. Struct. 2015, 133, 451–457. [Google Scholar] [CrossRef]

- Marec, A.; Thomas, J.-H.; El Guerjouma, R. Damage characterization of polymer-based composite materials: Multivariable analysis and wavelet transform for clustering acoustic emission data. Mech. Syst. Signal Process. 2008, 22, 1441–1464. [Google Scholar] [CrossRef]

- Li, W.; Ho, S.C.M.; Patil, D.; Song, G. Acoustic emission monitoring and finite element analysis of debonding in fiber-reinforced polymer rebar reinforced concrete. Struct. Health Monit. 2017, 16, 674–681. [Google Scholar] [CrossRef]

- Li, D.; Shao, J.; Ou, J.; Wang, Y. Damage analysis of carbon nanofiber modified flax fiber composite by acoustic emission. Smart Struct. Syst. 2017, 19, 127–136. [Google Scholar] [CrossRef]

- Subramanya, S.R.; Satyanarayana, K.G.; Pilar, B.S. Evaluation of Structural, Tensile and Thermal Properties of Banana Fibers. J. Nat. Fibers 2016, 14, 485–497. [Google Scholar]

- Yue, L.I.; Zhang, R.; Yang, P.; Chen, Z.; Zongbei, H.E.; Xiong, X. Microstructure and mechanical properties of 2.5D curved shallow-crossing linking SiC_f/SiC composites fabricated by chemical vapor infiltration. Mater. Sci. Eng. Powder Metall. 2018, 23, 164–171. [Google Scholar]

- Barré, S.; Benzeggagh, M.L. On the use of acoustic emission to investigate damage mechanisms in glass-fibre-reinforced polypropylene. NDT E Int. 1997, 52, 369–376. [Google Scholar] [CrossRef]

- Kim, S.T.; Lee, Y.T. Characteristics of damage and fracture process of carbon fiber reinforced plastic under loading-unloading test by using AE method. Mater. Sci. Eng. A 1997, 234, 322–326. [Google Scholar] [CrossRef]

- Dányádi, L.; Renner, K.; Szabo, Z.; Nagy, G.; Móczó, J.; Pukanszky, B. Wood flour filled PP composites: Adhesion, deformation, failure. Polym. Adv. Technol. 2006, 17, 967–974. [Google Scholar] [CrossRef]

- Kaiser, J. Erkenntnisse und Folgerungen aus der Messung von Geräuschen bei Zugbeanspruchung von metallischen Werkstoffen. Arch. Für Das Eisenhüttenw. 1953, 24, 43–45. [Google Scholar] [CrossRef]

- Kaiser, E. A Study of Acoustic Phenomena in Tensile Test. Ph.D. Dissertation, Technical University of Munich, München, Germany, 1950. [Google Scholar]

- Lavrov, A. Kaiser effect observation in brittle rock cyclically loaded with different loading rates. Mech. Mater. 2001, 33, 669–677. [Google Scholar] [CrossRef]

- Li, C.; Nordlund, E. Experimental verification of the Kaiser effect in rocks. Rock Mech. Rock Eng. 1993, 26, 333–351. [Google Scholar] [CrossRef]

- Adams, C.H. Recommended practice for acoustic emission testing of fiberglass tanks/vessels. In Proceedings of the 37th Annual Conference of the Society of Plastics Industry (SPI) Reinforced Plastics/Composites Institute, Washington, DC, USA, 11–15 January 1982. [Google Scholar]

| Signal Type | Rise-Time/μs | Duration/μs | Ringing Counts | Absolute Energy·10−9 J | Amplitude/dB |

|---|---|---|---|---|---|

| Matrix deformation | 8.95 | 48.63 | 5.34 | 76.46 | 34.31 |

| Fiber breakage | 2.13 | 108.47 | 13.70 | 339.31 | 55.29 |

| Interface delamination | 40.43 | 252.72 | 24.96 | 229.54 | 45.61 |

| Interface friction | 75.92 | 864.25 | 39.53 | 2577.12 | 48.36 |

| Matrix cracking | 577.84 | 2358.92 | 84.88 | 3479.46 | 61.38 |

| Sample | Loading Times | Maximum Strain% | Strain at AE Signals Generated% | Felicity Ratio |

|---|---|---|---|---|

| 50%WF/Re-HDPE | 1 | 0.37 | — | — |

| 50%WF/Re-HDPE | 2 | 1.30 | 1.16 | 3.15 |

| 50%WF/Re-HDPE | 3 | 1.75 | 1.27 | 0.98 |

| 50%WF/Re-HDPE | 4 | 2.67 | 1.41 | 0.80 |

| 60%WF/Re-HDPE | 1 | 0.92 | 0.83 | — |

| 60%WF/Re-HDPE | 2 | 1.41 | 1.09 | 1.18 |

| 60%WF/Re-HDPE | 3 | 2.10 | 1.40 | 0.99 |

| 60%WF/Re-HDPE | 4 | 3.28 | 1.53 | 0.73 |

| 70%WF/Re-HDPE | 1 | 0.77 | — | — |

| 70%WF/Re-HDPE | 2 | 1.01 | 0.72 | 0.93 |

| 70%WF/Re-HDPE | 3 | 1.35 | 0.91 | 0.90 |

| 70%WF/Re-HDPE | 4 | 1.64 | 1.08 | 0.80 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Y.; Zhu, S.; Chen, Y.; Li, D. Analysis and Identification of the Mechanism of Damage and Fracture of High-Filled Wood Fiber/Recycled High-Density Polyethylene Composites. Polymers 2019, 11, 170. https://doi.org/10.3390/polym11010170

Guo Y, Zhu S, Chen Y, Li D. Analysis and Identification of the Mechanism of Damage and Fracture of High-Filled Wood Fiber/Recycled High-Density Polyethylene Composites. Polymers. 2019; 11(1):170. https://doi.org/10.3390/polym11010170

Chicago/Turabian StyleGuo, Yong, Shiliu Zhu, Yuxia Chen, and Dagang Li. 2019. "Analysis and Identification of the Mechanism of Damage and Fracture of High-Filled Wood Fiber/Recycled High-Density Polyethylene Composites" Polymers 11, no. 1: 170. https://doi.org/10.3390/polym11010170

APA StyleGuo, Y., Zhu, S., Chen, Y., & Li, D. (2019). Analysis and Identification of the Mechanism of Damage and Fracture of High-Filled Wood Fiber/Recycled High-Density Polyethylene Composites. Polymers, 11(1), 170. https://doi.org/10.3390/polym11010170