Frequency or Amplitude?—Rheo-Electrical Characterization of Carbon Nanoparticle Filled Epoxy Systems

Abstract

:1. Introduction

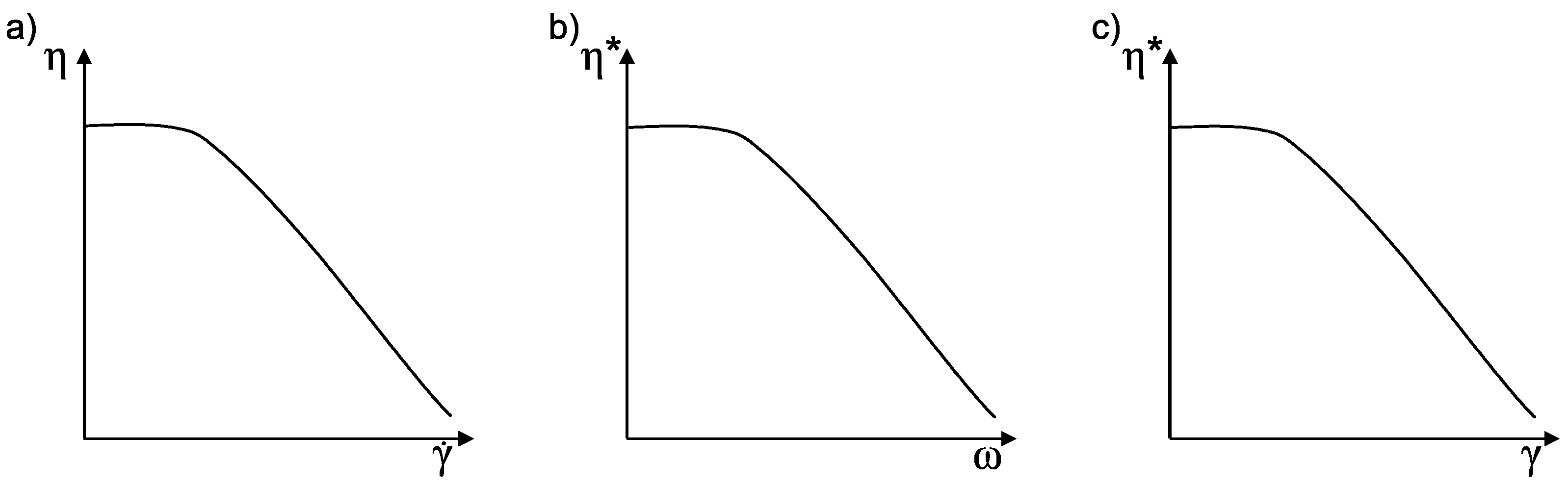

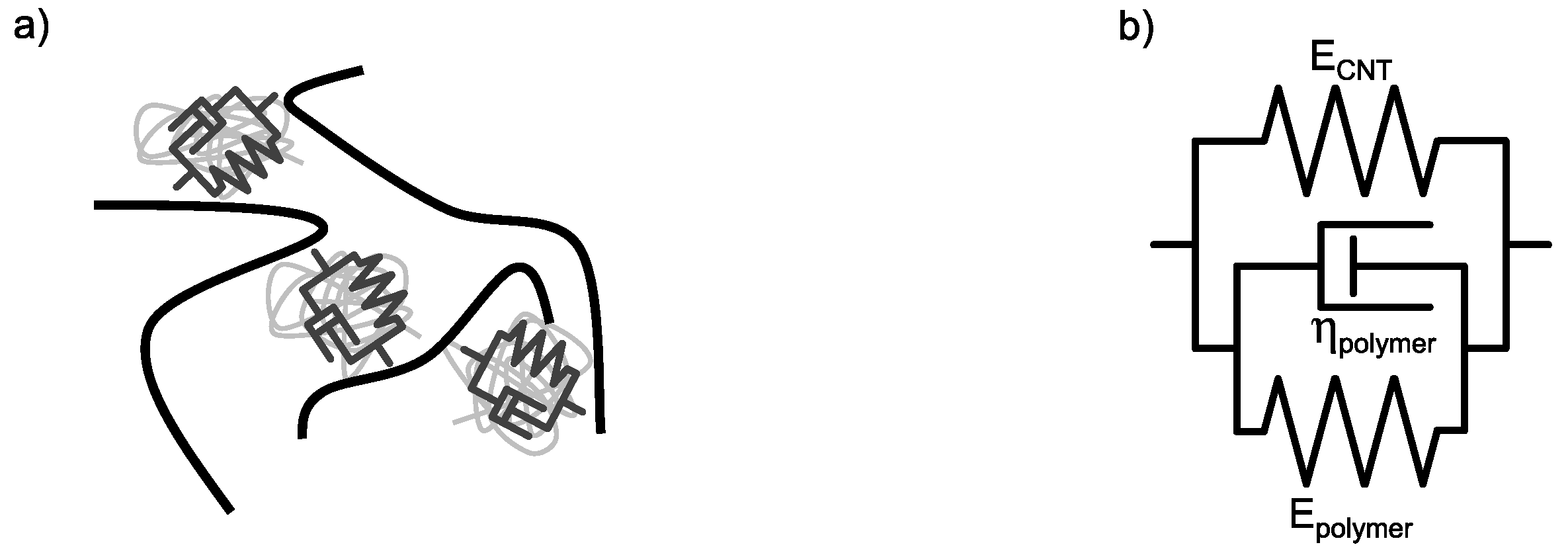

2. Theoretical Background and State of the Art

- I

- polymer network, by entanglements of chains

- II

- carbon nanotube network, by interconnected CNT

- III

- combined nanotube polymer network

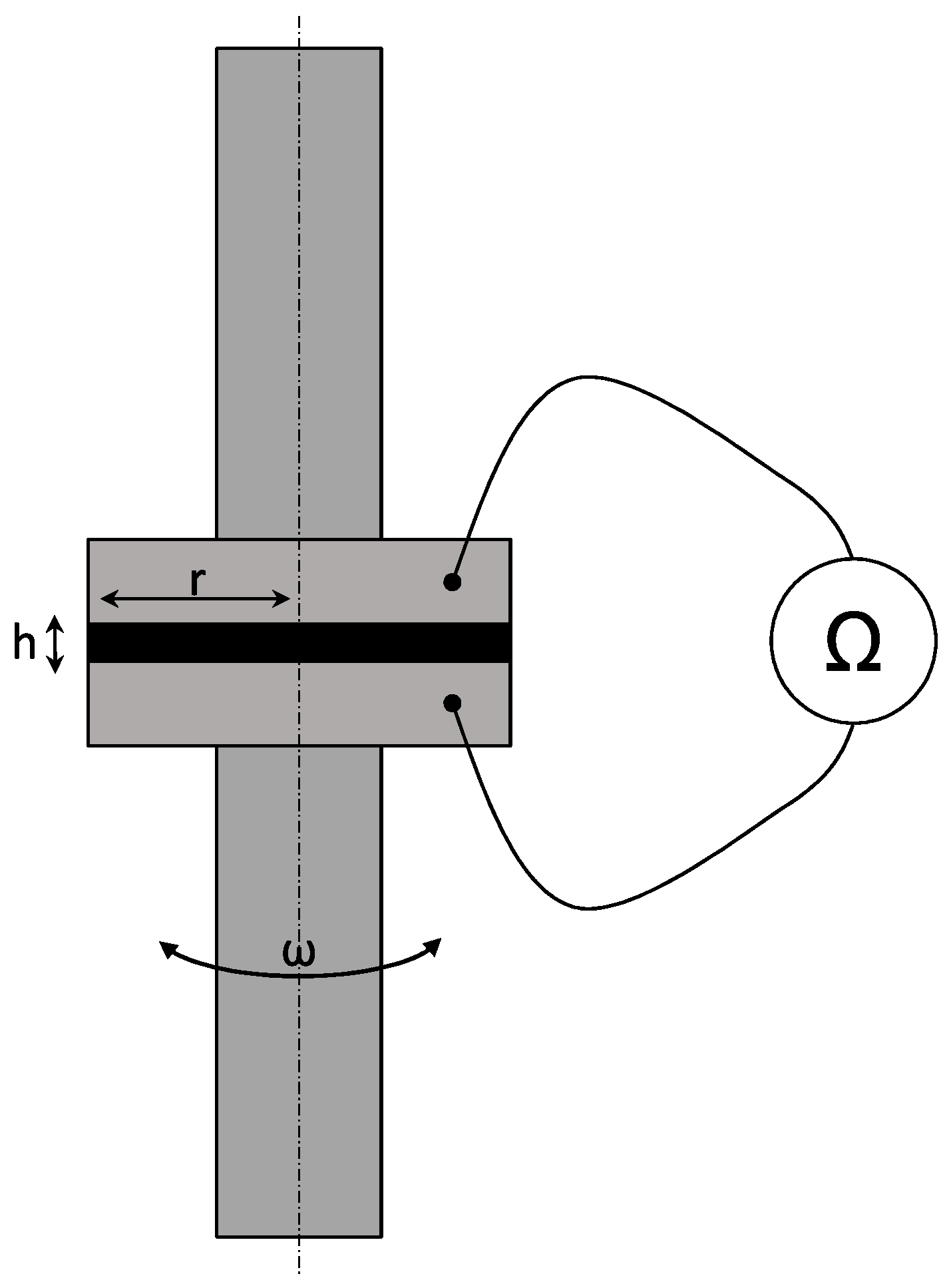

3. Materials and Methods

4. Results and Discussion

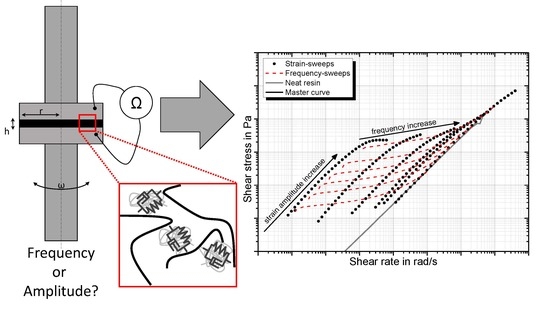

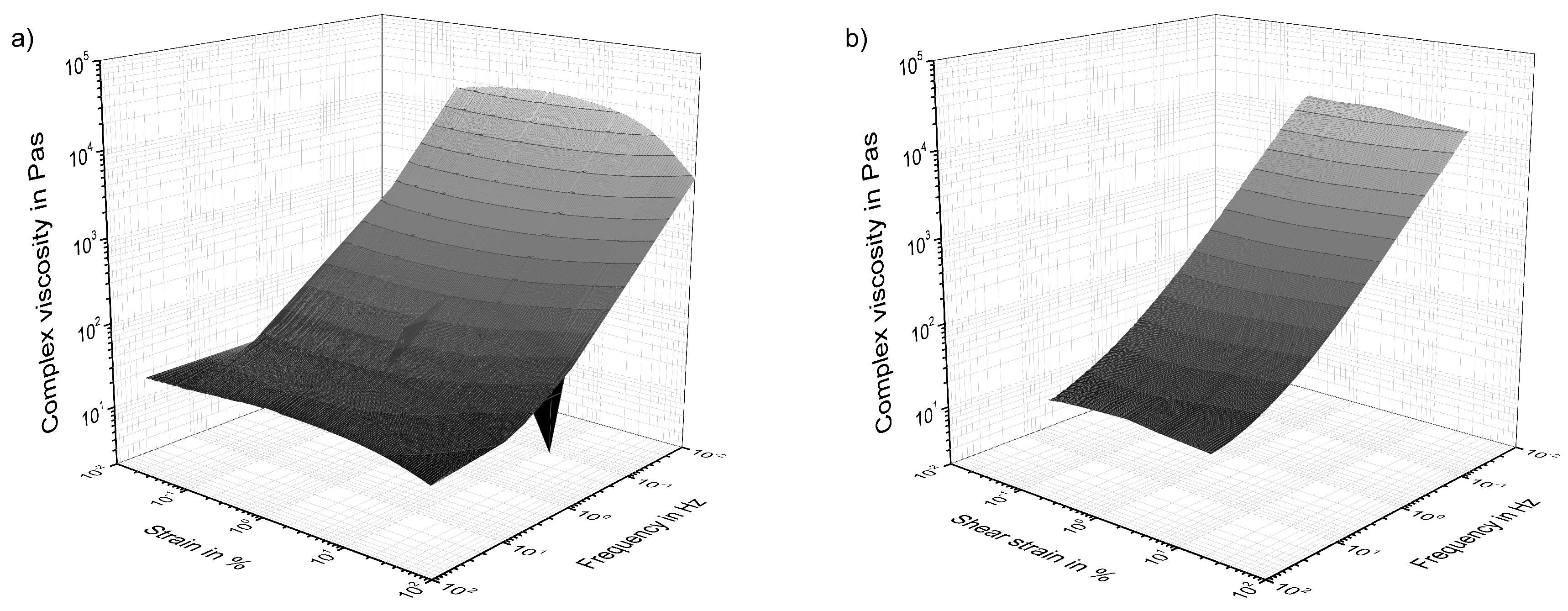

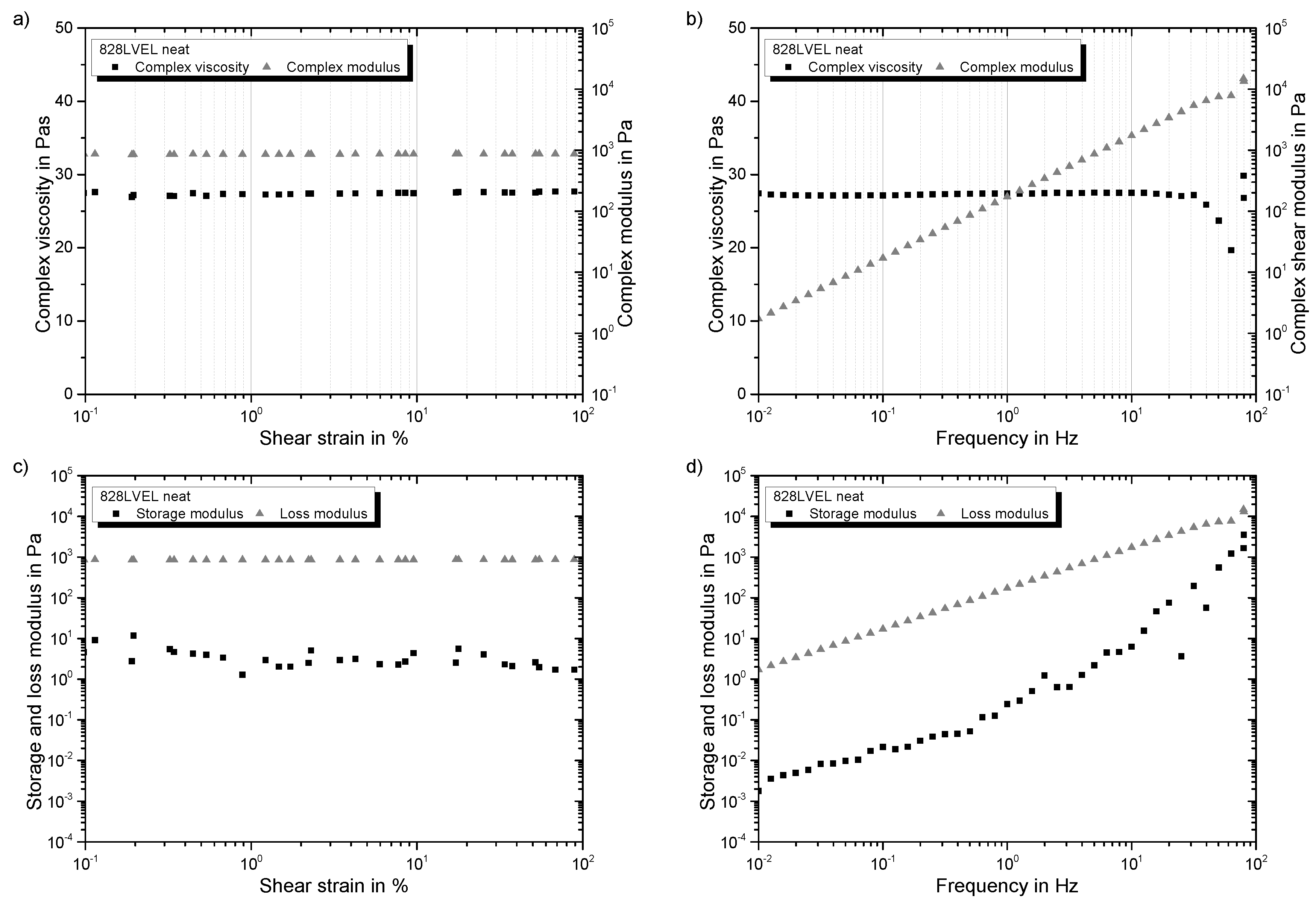

4.1. Rheological Properties of Neat Resin

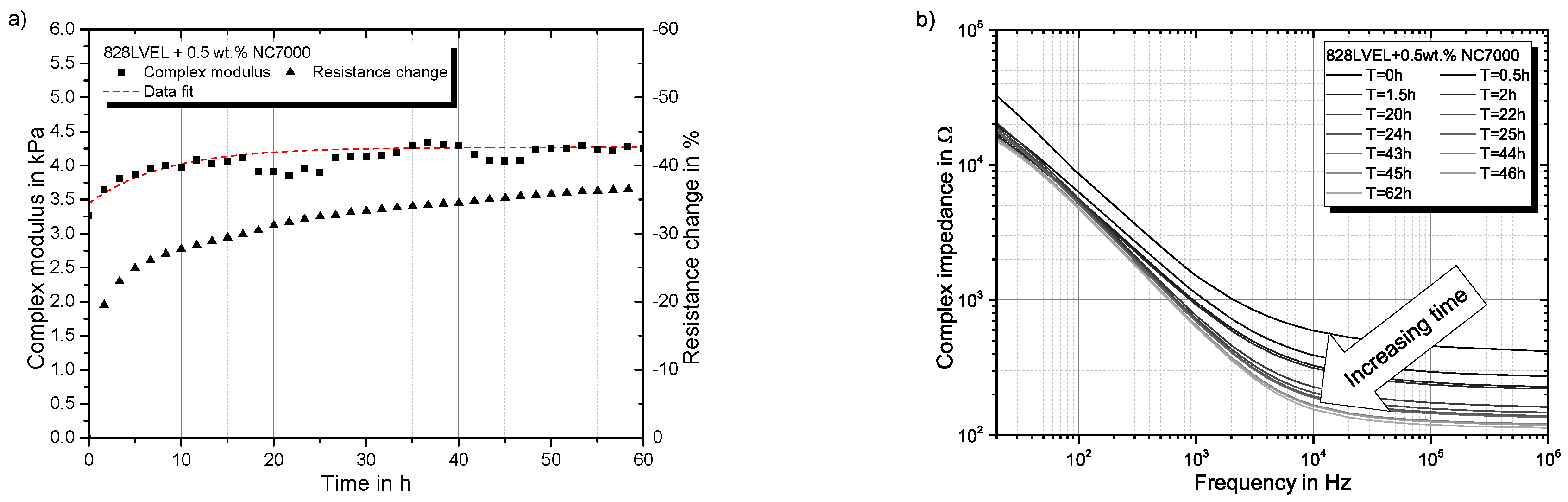

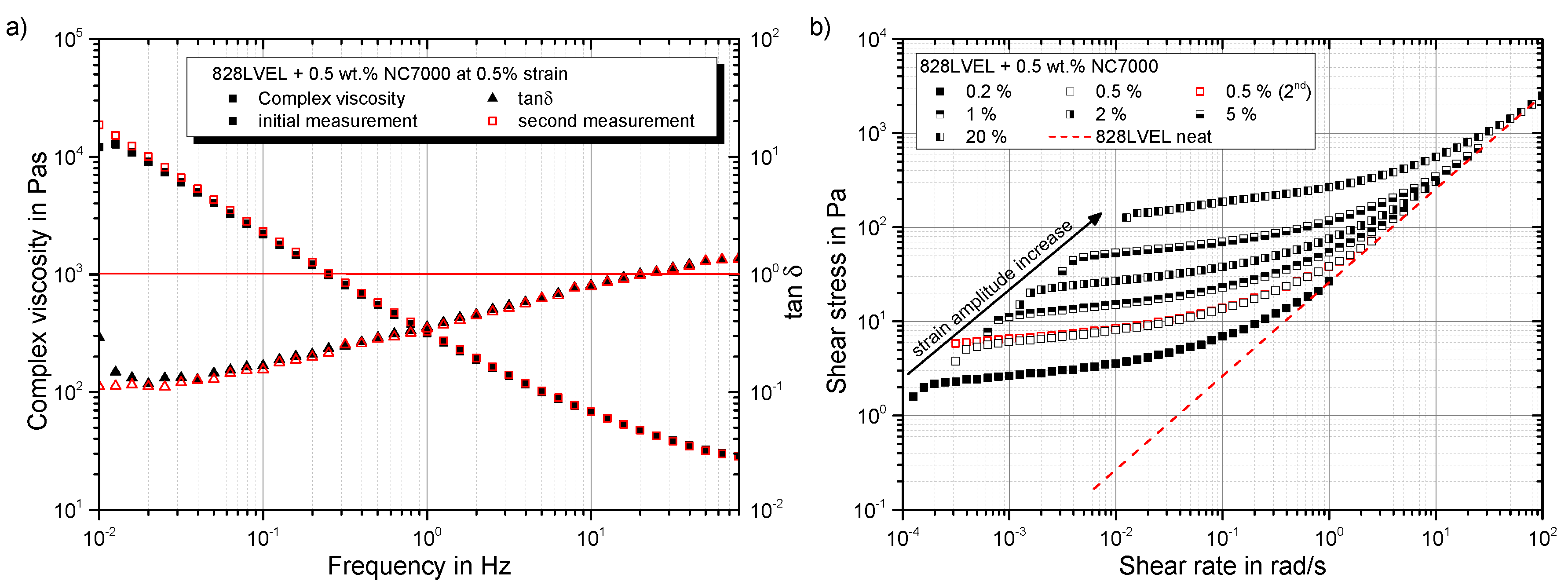

4.2. Time-Dependent Behavior of Nanocomposite

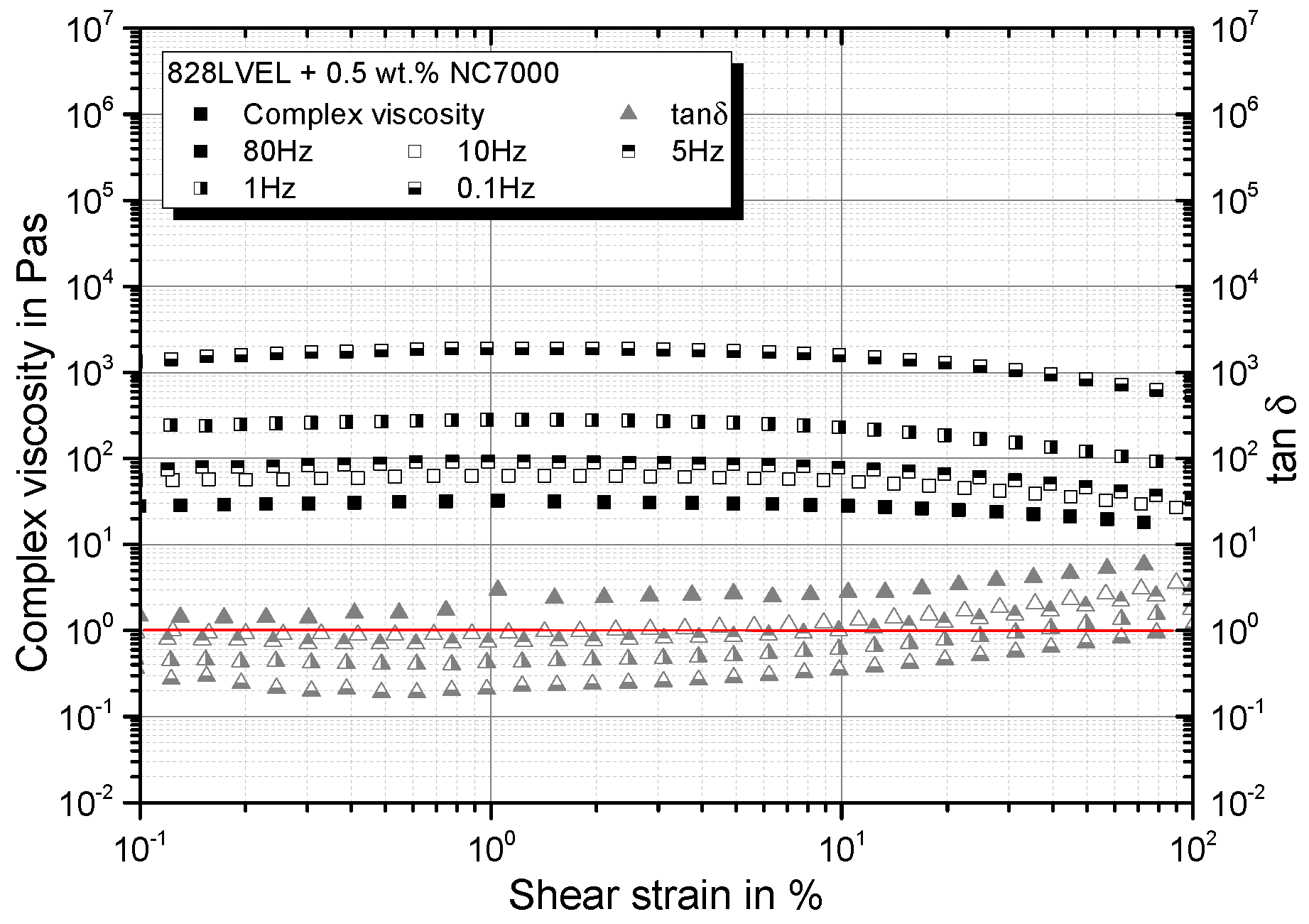

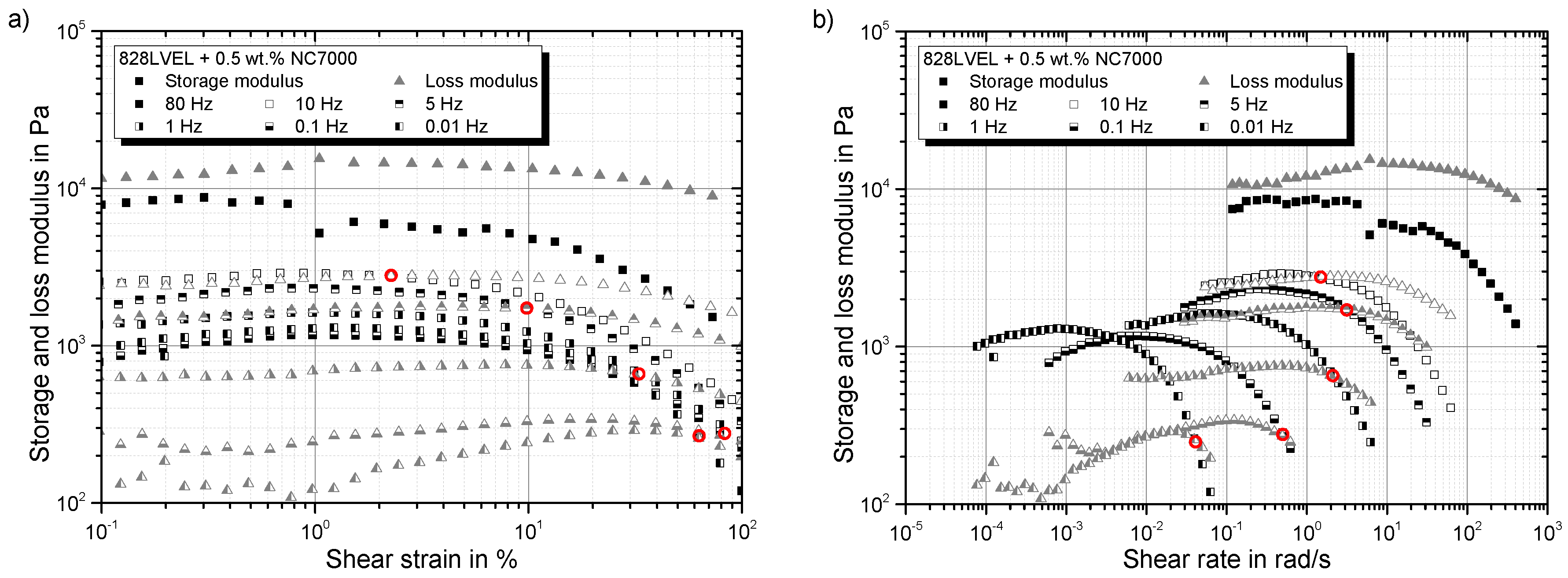

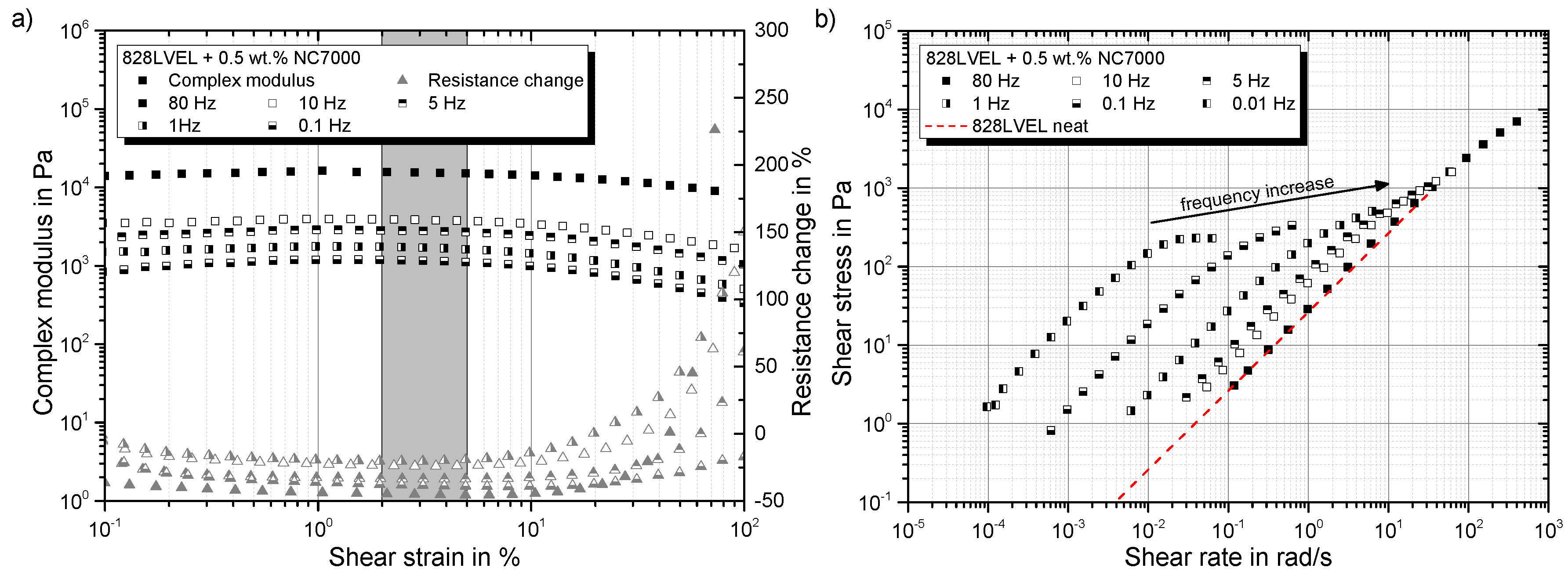

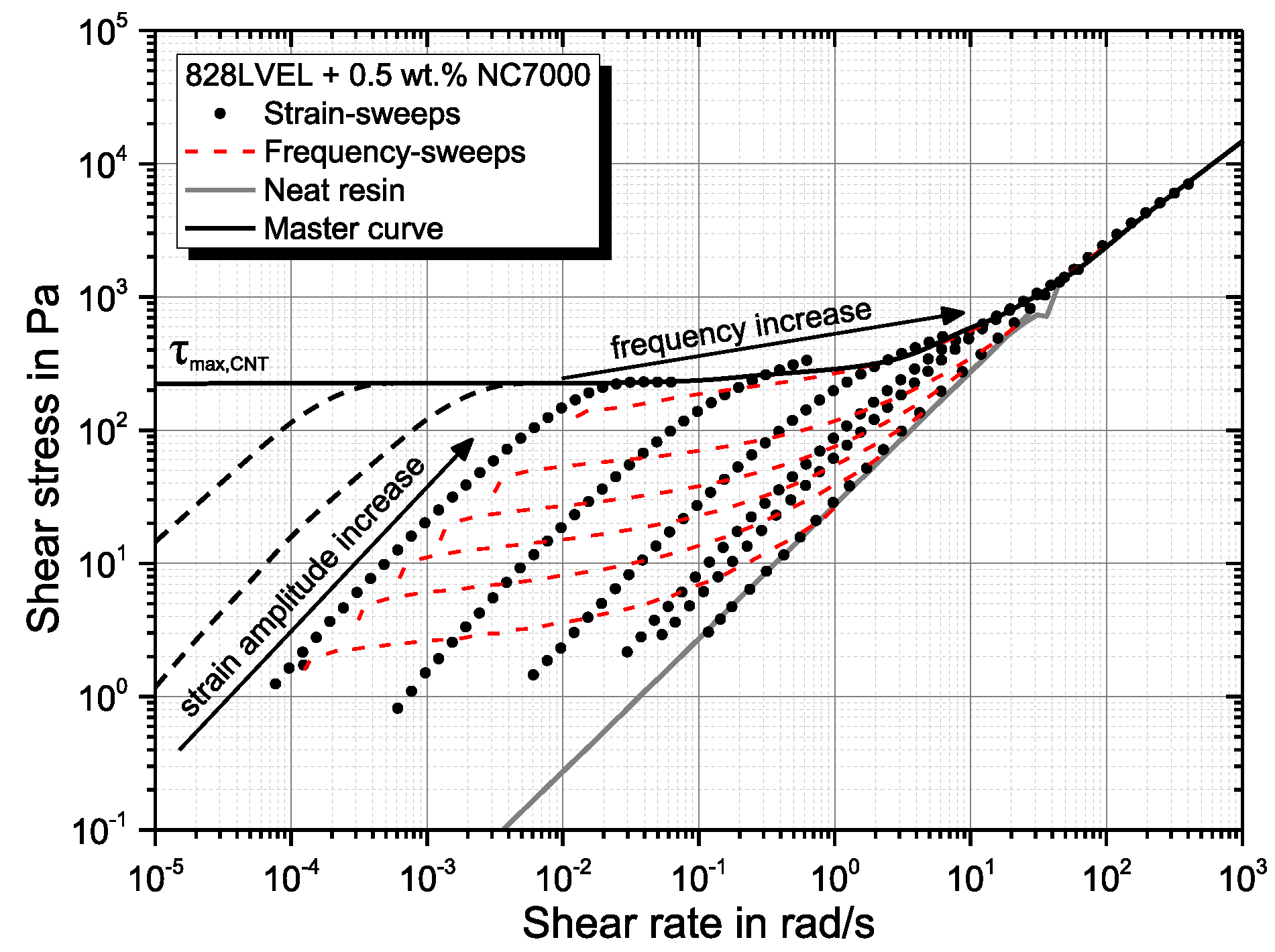

4.3. Strain Dependency of Nanocomposite

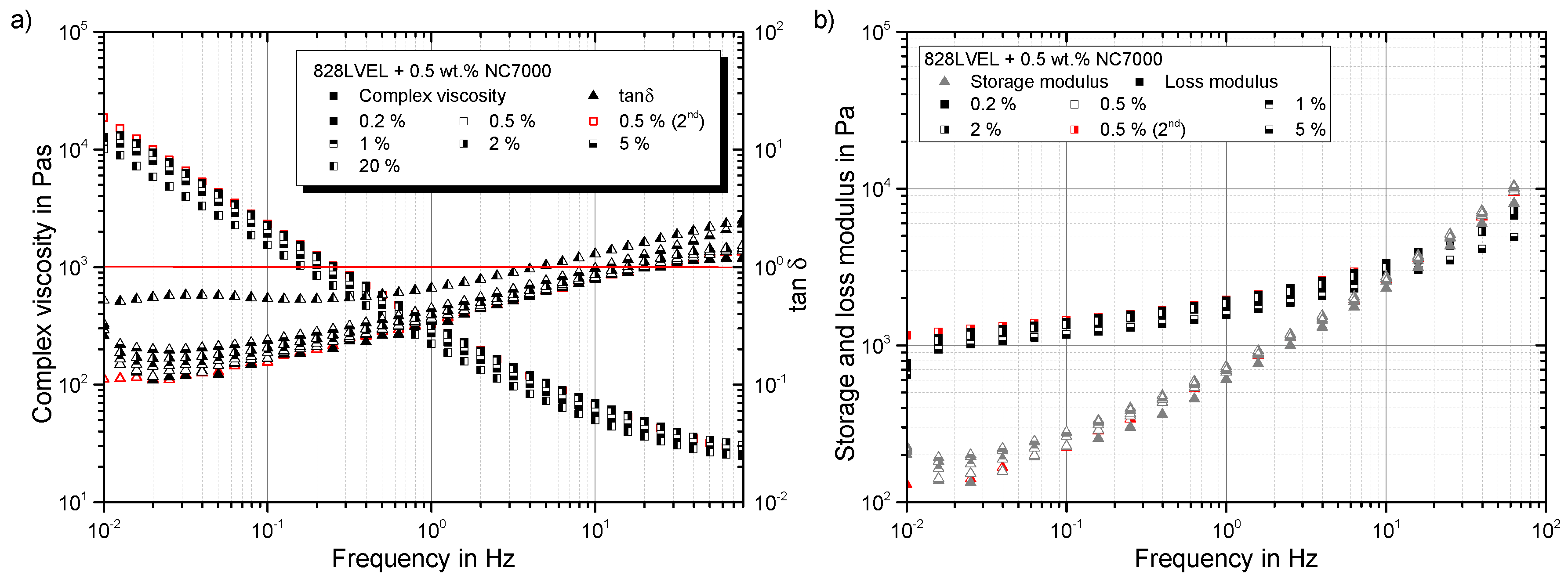

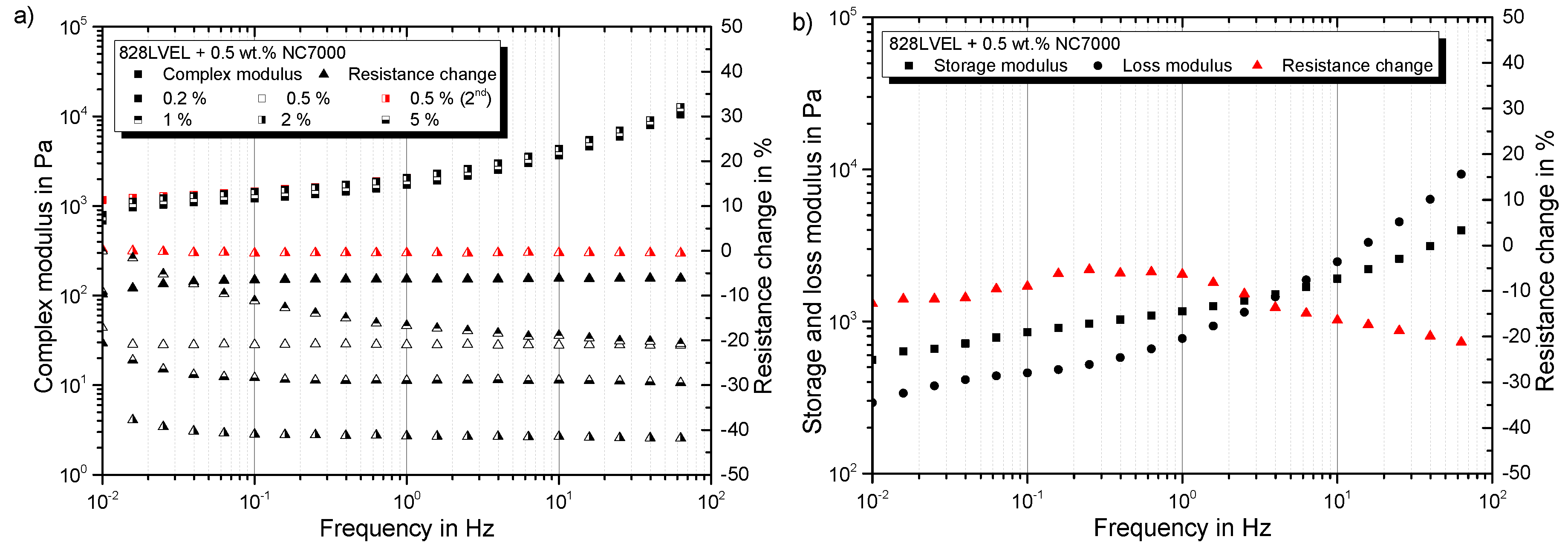

4.4. Frequency Dependency of Nanocomposite

- (a)

- Low strain amplitudes in the strain-sweeps lead to a build-up of the filler network (decreased resistance)

- (b)

- High strain amplitudes in the strain-sweeps destruct the filler network (exponential increase of resistance)

- (c)

- The same material response for high frequencies in strain-sweeps

- (d)

- Shear rate independent solid-liquid transition for the tested frequencies in strain-sweeps

- (e)

- After initial resistance decrease, there is no further resistance change in frequency-sweeps

- (f)

- Asymptotic convergence to the material behavior of the neat resin at high frequencies in frequency-sweeps

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| CNT | carbon nanotube |

| EP | epoxy resin |

| MW | molecular weight |

| MWCNT | multi-walled carbon nanotube |

| PC | polycarbonate |

| TRM | three-roll-mill |

References

- Ma, A.W.K.; Yearsley, K.M.; Chinesta, F.; Mackley, M.R. A review of the microstructure and rheology of carbon nanotube suspensions. Proc. Inst. Mech. Eng. 2009, 222, 71–94. [Google Scholar] [CrossRef]

- Gojny, F.H.; Wichmann, M.; Köpke, U.; Fiedler, B.; Schulte, K. Carbon nanotube-reinforced epoxy-composites: Enhanced stiffness and fracture toughness at low nanotube content. Compos. Sci. Technol. 2004, 64, 2363–2371. [Google Scholar] [CrossRef]

- Yoon, H.; Yamashita, M.; Ata, S.; Futaba, D.N.; Yamada, T.; Hata, K. Controlling exfoliation in order to minimize damage during dispersion of long SWCNTs for advanced composites. Sci. Rep. 2014, 4, 3907. [Google Scholar] [CrossRef] [PubMed]

- Hielscher, T. Ultrasonic Production of Nano-Size Dispersions and Emulsions. In Proceedings of the Dans European Nano Systems Worshop-ENS 2005, Paris, France, 14–16 December 2005. [Google Scholar]

- Li, Y.; Zhang, H.; Crespo, M.; Porwal, H.; Picot, O.; Santagiuliana, G.; Huang, Z.; Barbieri, E.; Pugno, N.M.; Peijs, T.; et al. In Situ Exfoliation of Graphene in Epoxy Resins: A Facile Strategy to Efficient and Large Scale Graphene Nanocomposites. ACS Appl. Mater. Interfaces 2016, 8, 24112–24122. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.Y.; Terentjev, E.M. Dispersion of Carbon Nanotubes: Mixing, Sonication, Stabilization, and Composite Properties. Polymers 2012, 4, 275–295. [Google Scholar] [CrossRef] [Green Version]

- Ma, P.C.; Siddiqui, N.A.; Marom, G.; Kim, J.K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1345–1367. [Google Scholar] [CrossRef]

- Schulz, S.C.; Faiella, G.; Buschhorn, S.T.; Prado, L.; Giordano, M.; Schulte, K.; Bauhofer, W. Combined electrical and rheological properties of shear induced multiwall carbon nanotube agglomerates in epoxy suspensions. Eur. Polym. J. 2011, 47, 2069–2077. [Google Scholar] [CrossRef]

- Faiella, G.; Antonucci, V.; Buschhorn, S.T.; Prado, L.A.; Schulte, K.; Giordano, M. Tailoring the electrical properties of MWCNT/epoxy composites controlling processing conditions. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1441–1447. [Google Scholar] [CrossRef]

- Taurozzi, J.S.; Hackley, V.A.; Wiesner, M.R. Preparation of Nanoparticle Dispersions from Powdered Material Using Ultrasonic Disruption—Version 1.1; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2012. [Google Scholar]

- Cox, W.P.; Merz, E.H. Correlation of dynamic and steady flow viscosities. J. Polym. Sci. 1958, 28, 619–622. [Google Scholar] [CrossRef]

- Shenoy, A.V. Rheology of Filled Polymer Systems; Springer: Dordrecht, The Netherlands, 1999. [Google Scholar]

- Ureña Benavides, E.E.; Kayatin, M.J.; Davis, V.A. Dispersion and Rheology of Multiwalled Carbon Nanotubes in Unsaturated Polyester Resin. Macromolecules 2013, 46, 1642–1650. [Google Scholar] [CrossRef]

- Skipa, T.; Lellinger, D.; Saphiannikova, M.; Alig, I. Shear-stimulated formation of multi-wall carbon nanotube networks in polymer melts. Phys. Status Solidi (b) 2009, 246, 2453–2456. [Google Scholar] [CrossRef]

- Sandler, J.K.; Windle, A.H.; Martin, C.A.; Schwarz, M.K.; Bauhofer, W.; Schulte, K.; Shaffer, M.S. Percolation in Multi-Wall Carbon Nanotube-Epoxy Composites Influence of processing parameters, nanotube aspect ratio and electric fields on the bulk conductivity. MRS Proc. 2003, 788. [Google Scholar] [CrossRef]

- Schulz, S.C.; Bauhofer, W. Shear influenced network dynamics and electrical conductivity recovery in carbon nanotube/epoxy suspensions. Polymer 2010, 51, 5500–5505. [Google Scholar] [CrossRef]

- Schulz, S.C.; Schlutter, J.; Buschhorn, S.T.; Schulte, K.; Bauhofer, W. Rheological properties and irreversible dispersion changes in carbon nanotube/epoxy systems. Polym. Eng. Sci. 2012, 52, 849–855. [Google Scholar] [CrossRef]

- Chapartegui, M.; Markaide, N.; Florez, S.; Elizetxea, C.; Fernandez, M.; Santamaría, A. Specific rheological and electrical features of carbon nanotube dispersions in an epoxy matrix. Compos. Sci. Technol. 2010, 70, 879–884. [Google Scholar] [CrossRef]

- Hilarius, K.; Lellinger, D.; Alig, I.; Villmow, T.; Pegel, S.; Pötschke, P. Influence of shear deformation on the electrical and rheological properties of combined filler networks in polymer melts: Carbon nanotubes and carbon black in polycarbonate. Polymer 2013, 54, 5865–5874. [Google Scholar] [CrossRef]

- Skipa, T.; Lellinger, D.; Böhm, W.; Saphiannikova, M.; Alig, I. Influence of shear deformation on carbon nanotube networks in polycarbonate melts: Interplay between build-up and destruction of agglomerates. Polymer 2010, 51, 201–210. [Google Scholar] [CrossRef]

- Yearsley, K.M.; Mackley, M.R.; Chinesta, F.; Leygue, A. The rheology of multiwalled carbon nanotube and carbon black suspensions. J. Rheol. 2012, 56, 1465–1490. [Google Scholar] [CrossRef]

- Bauhofer, W.; Schulz, S.C.; Eken, A.E.; Skipa, T.; Lellinger, D.; Alig, I.; Tozzi, E.J.; Klingenberg, D.J. Shear-controlled electrical conductivity of carbon nanotubes networks suspended in low and high molecular weight liquids. Polymer 2010, 51, 5024–5027. [Google Scholar] [CrossRef]

- Alig, I.; Pötschke, P.; Lellinger, D.; Skipa, T.; Pegel, S.; Kasaliwal, G.R.; Villmow, T. Establishment, morphology and properties of carbon nanotube networks in polymer melts. Polymer 2012, 53, 4–28. [Google Scholar] [CrossRef]

- Schulz, S.C.; Schlutter, J.; Bauhofer, W. Influence of Initial High Shearing on Electrical and Rheological Properties and Formation of Percolating Agglomerates for MWCNT/Epoxy Suspensions. Macromol. Mater. Eng. 2010, 295, 613–617. [Google Scholar] [CrossRef]

- Pötschke, P.; Abdel-Goad, M.; Alig, I.; Dudkin, S.; Lellinger, D. Rheological and dielectrical characterization of melt mixed polycarbonate-multiwalled carbon nanotube composites. Polymer 2004, 45, 8863–8870. [Google Scholar] [CrossRef]

- Kim, J.A.; Seong, D.G.; Kang, T.J.; Youn, J.R. Effects of surface modification on rheological and mechanical properties of CNT/epoxy composites. Carbon 2006, 44, 1898–1905. [Google Scholar] [CrossRef]

- Martin-Gallego, M.; Bernal, M.M.; Hernandez, M.; Verdejo, R.; Lopez-Manchado, M.A. Comparison of filler percolation and mechanical properties in graphene and carbon nanotubes filled epoxy nanocomposites. Eur. Polym. J. 2013, 49, 1347–1353. [Google Scholar] [CrossRef] [Green Version]

- Elias, L.; Fenouillot, F.; Majeste, J.C.; Cassagnau, P. Morphology and rheology of immiscible polymer blends filled with silica nanoparticles. Polymer 2007, 48, 6029–6040. [Google Scholar] [CrossRef]

- Pötschke, P.; Fornes, T.D.; Paul, D.R. Rheological behavior of multiwalled carbon nanotube/polycarbonate composites. Polymer 2002, 43, 3247–3255. [Google Scholar]

- Nobile, M.R.; Valentino, O.; Morcom, M.; Simon, G.P.; Landi, G.; Neitzert, H.C. The effect of the nanotube oxidation on the rheological and electrical properties of CNT/HDPE nanocomposites. Polym. Eng. Sci. 2017, 57, 665–673. [Google Scholar] [CrossRef]

- Wu, G.; Asai, S.; Sumita, M.; Hattori, T.; Higuchi, R.; Washiyama, J. Estimation of flocculation structure in filled polymer composites by dynamic rheological measurements. Coll. Polym. Sci. 2000, 278, 220–228. [Google Scholar] [CrossRef]

- Du, F.; Scogna, R.C.; Zhou, W.; Brand, S.; Fischer, J.E.; Winey, K.I. Nanotube Networks in Polymer Nanocomposites: Rheology and Electrical Conductivity. Macromolecules 2004, 37, 9048–9055. [Google Scholar] [CrossRef]

- Prashantha, K.; Soulestin, J.; Lacrampe, M.F.; Krawczak, P.; Dupin, G.; Claes, M. Masterbatch-based multi-walled carbon nanotube filled polypropylene nanocomposites: Assessment of rheological and mechanical properties. Compos. Sci. Technol. 2009, 69, 1756–1763. [Google Scholar] [CrossRef]

- Hobbie, E.K.; Fry, D.J. Rheology of concentrated carbon nanotube suspensions. J. Chem. Phys. 2007, 126, 124907. [Google Scholar] [CrossRef] [PubMed]

- Handge, U.A.; Pötschke, P. Deformation and orientation during shear and elongation of a polycarbonate/carbon nanotubes composite in the melt. Rheol. Acta 2007, 46, 889–898. [Google Scholar] [CrossRef]

- Sumfleth, J.; Buschhorn, S.T.; Schulte, K. Comparison of rheological and electrical percolation phenomena in carbon black and carbon nanotube filled epoxy polymers. J. Mater. Sci. 2011, 46, 659–669. [Google Scholar] [CrossRef]

- Palza, H.; Kappes, M.; Hennrich, F.; Wilhelm, M. Morphological changes of carbon nanotubes in polyethylene matrices under oscillatory tests as determined by dielectrical measurements. Compos. Sci. Technol. 2011, 71, 1361–1366. [Google Scholar] [CrossRef]

- Fogel, M.; Parlevliet, P.; Geistbeck, M.; Olivier, P.; Dantras, É. Thermal, rheological and electrical analysis of MWCNTs/epoxy matrices. Compos. Sci. Technol. 2015, 110, 118–125. [Google Scholar] [CrossRef] [Green Version]

- Cassagnau, P.; Mélis, F. Non-linear viscoelastic behaviour and modulus recovery in silica filled polymers. Polymer 2003, 44, 6607–6615. [Google Scholar] [CrossRef]

- Richter, S.; Saphiannikova, M.; Jehnichen, D.; Bierdel, M.; Heinrich, G. Experimental and theoretical studies of agglomeration effects in multi-walled carbon nanotube-polycarbonate melts. Exp. Polym. Lett. 2009, 3, 753–768. [Google Scholar] [CrossRef]

- Handge, U.A.; Zeiler, R.; Dijkstra, D.J.; Meyer, H.; Altstädt, V. On the determination of elastic properties of composites of polycarbonate and multi-wall carbon nanotubes in the melt. Rheol. Acta 2011, 50, 503–518. [Google Scholar] [CrossRef]

- Zeiler, R.; Handge, U.A.; Dijkstra, D.J.; Meyer, H.; Altstädt, V. Influence of molar mass and temperature on the dynamics of network formation in polycarbonate/carbon nanotubes composites in oscillatory shear flows. Polymer 2011, 52, 430–442. [Google Scholar] [CrossRef]

- Bai, J.; Goodridge, R.D.; Hague, R.J.; Song, M.; Okamoto, M. Influence of carbon nanotubes on the rheology and dynamic mechanical properties of polyamide-12 for laser sintering. Polym. Test. 2014, 36, 95–100. [Google Scholar] [CrossRef] [Green Version]

- Meeuw, H.; Körbelin, J.; von Bernstorff, D.; Augustin, T.; Liebig, W.V.; Fiedler, B. Smart dispersion: Validation of OCT and impedance spectroscopy as solutions for in-situ dispersion analysis of CNP/EP-composites. Materialia 2018. [Google Scholar] [CrossRef]

- Meeuw, H.; Viets, C.; Liebig, W.V.; Schulte, K.; Fiedler, B. Morphological influence of carbon nanofillers on the piezoresistive response of carbon nanoparticle/epoxy composites under mechanical load. Eur. Polym. J. 2016, 85, 198–210. [Google Scholar] [CrossRef]

- Koya, P.R.; Goshu, A.T. Generalized Mathematical Model for Biological Growths. Open J. Model. Simul. 2013, 1, 42–53. [Google Scholar] [CrossRef]

| Step | GapFeeding m | GapDispersion m | n1 Rpm | n2 Rpm | n3 Rpm |

|---|---|---|---|---|---|

| 1 | 120 | 40 | 50 | 150 | 450 |

| 2 | 40 | 13 | 50 | 150 | 450 |

| 3–7 | 13 | 5 | 50 | 150 | 450 |

| Property | Unit | Value | Method of Measurement |

|---|---|---|---|

| Average diameter | m | 10 | TEM |

| Length | m | 0.1–10 | TEM |

| Carbon purity | % | 90 | TGA |

| Metal oxide (impurity) | % | 10 | TGA |

| Surface area | m/g | 250–300 | BET |

| Amplitude in % | in | in | in s |

|---|---|---|---|

| 0.2 | 150.80 | 24.00 | 0.041 |

| 0.5 | 125.35 | 19.95 | 0.050 |

| 0.5 | 125.35 | 0.2 | 0.050 |

| 1 | 114.35 | 18.20 | 0.055 |

| 2 | 95.13 | 15.14 | 0.066 |

| 5 | 68.86 | 10.96 | 0.091 |

| 20 | 27.39 | 4.36 | 0.229 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meeuw, H.; Wisniewski, V.K.; Fiedler, B. Frequency or Amplitude?—Rheo-Electrical Characterization of Carbon Nanoparticle Filled Epoxy Systems. Polymers 2018, 10, 999. https://doi.org/10.3390/polym10090999

Meeuw H, Wisniewski VK, Fiedler B. Frequency or Amplitude?—Rheo-Electrical Characterization of Carbon Nanoparticle Filled Epoxy Systems. Polymers. 2018; 10(9):999. https://doi.org/10.3390/polym10090999

Chicago/Turabian StyleMeeuw, Hauke, Valea Kim Wisniewski, and Bodo Fiedler. 2018. "Frequency or Amplitude?—Rheo-Electrical Characterization of Carbon Nanoparticle Filled Epoxy Systems" Polymers 10, no. 9: 999. https://doi.org/10.3390/polym10090999

APA StyleMeeuw, H., Wisniewski, V. K., & Fiedler, B. (2018). Frequency or Amplitude?—Rheo-Electrical Characterization of Carbon Nanoparticle Filled Epoxy Systems. Polymers, 10(9), 999. https://doi.org/10.3390/polym10090999