Structural Design and Sound Absorption Properties of Nitrile Butadiene Rubber-Polyurethane Foam Composites with Stratified Structure

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Preparation of NBR-PUFM Composites

2.3. Characterization

3. Results

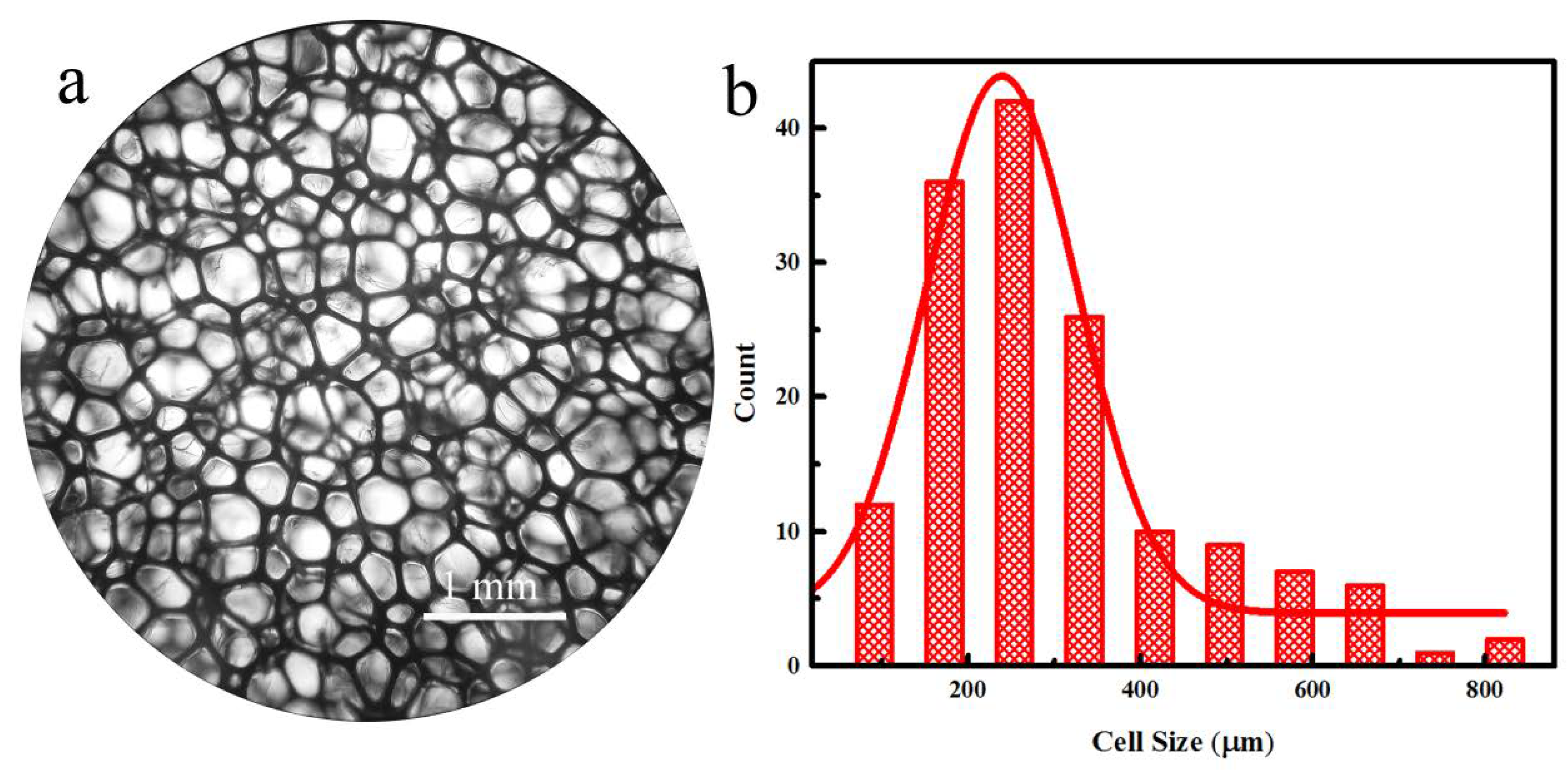

3.1. Morphology Analysis of the PUFM

3.2. Sound Absorption Properties of the NBR-PUFM Composites

3.2.1. Effect of the Thickness Ratio on SAC of the NBR-PUFM Composite with Double-Layer Structure

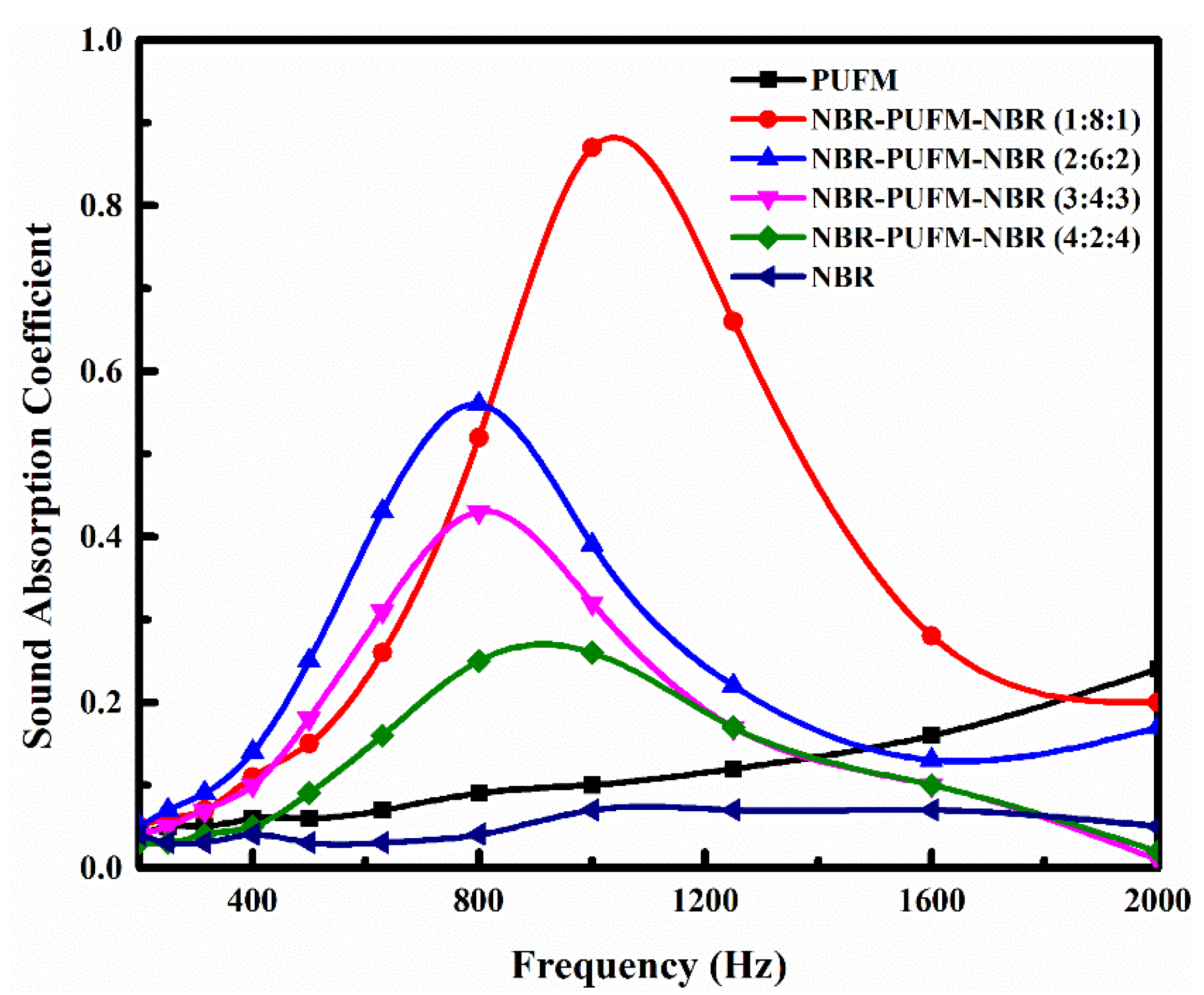

3.2.2. Effect of the Thickness Ratio on SAC of the NBR-PUFM Composite with Sandwich Structure

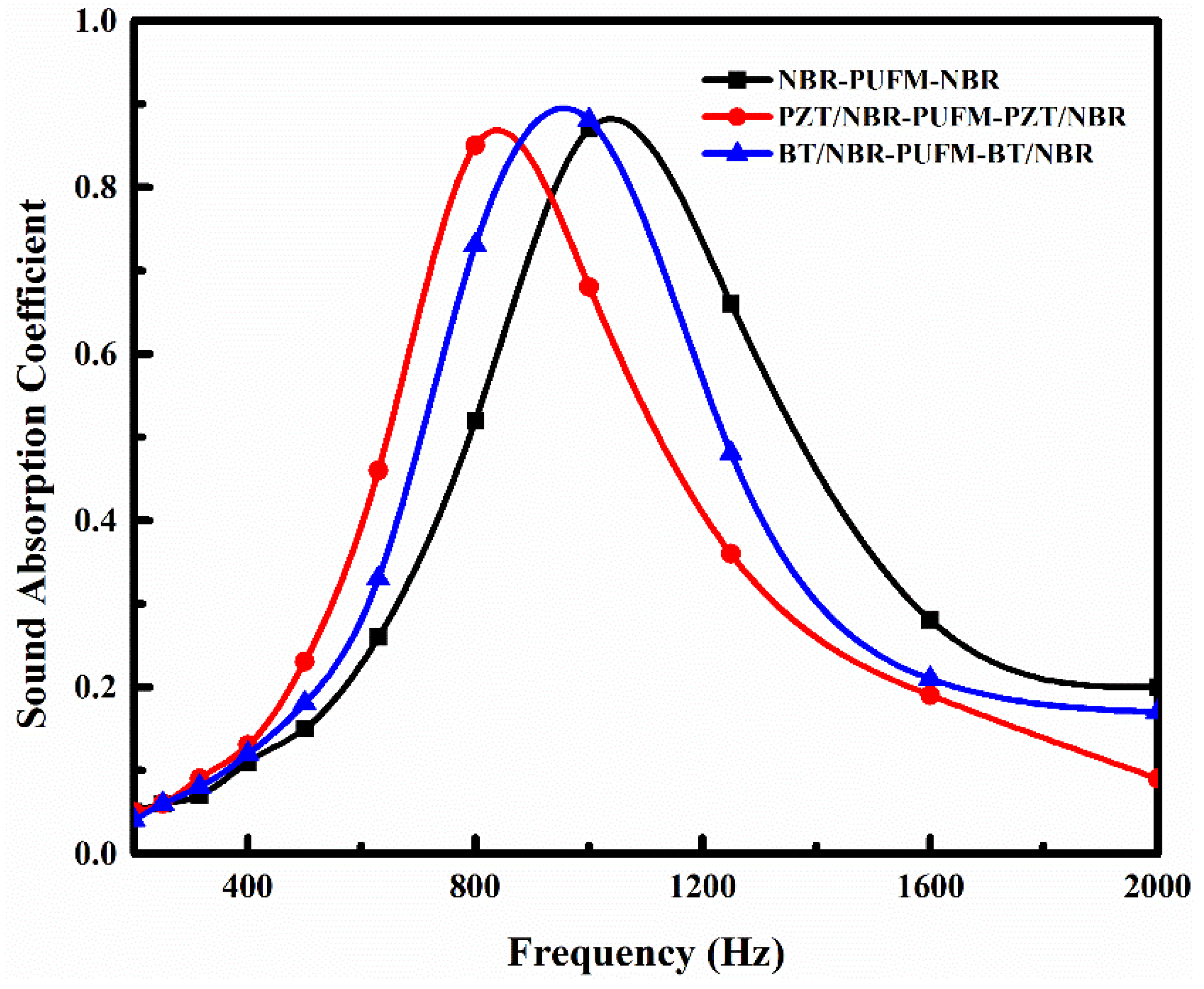

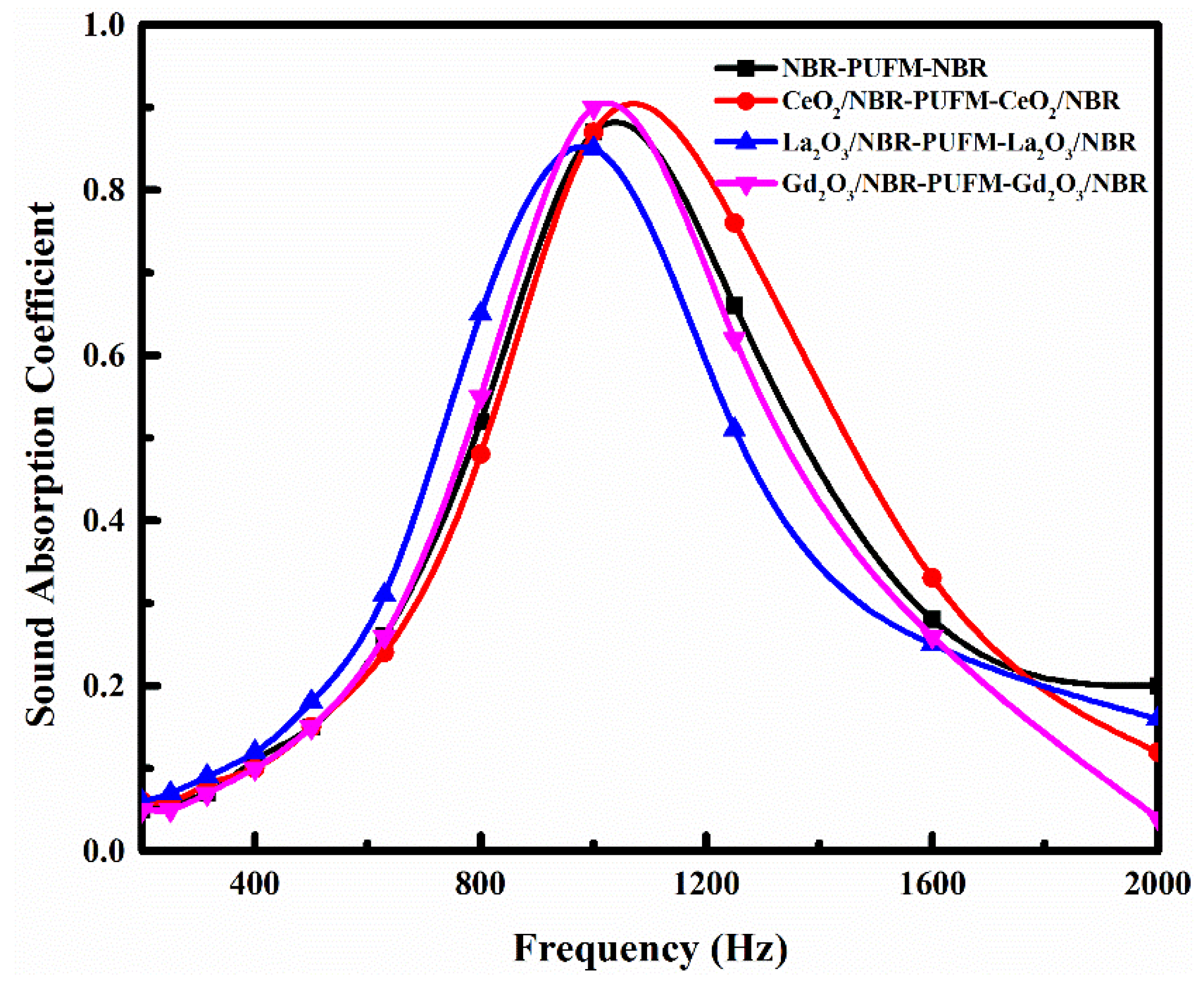

3.2.3. Effect of the Fillers on SAC of the NBR-PUFM Composite with Sandwich Structure

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Cai, Z.; Xiong, H.Z.; Zhu, Z.N.; Huang, H.B.; Li, L.; Huang, Y.N.; Yu, X.H. Electrochemical synthesis of graphene/polypyrrole nanotube composites for multifunctional applications. Synth. Met. 2017, 227, 100–105. [Google Scholar] [CrossRef]

- Huang, H.B.; Yao, J.L.; Li, L.; Zhu, F.; Liu, Z.T.; Zeng, X.P.; Yu, X.H.; Huang, Z.L. Reinforced polyaniline/polyvinyl alcohol conducting hydrogel from a freezing–thawing method as self-supported electrode for supercapacitors. J. Mater. Sci. 2016, 51, 8728–8736. [Google Scholar] [CrossRef]

- Huang, H.B.; Yao, J.L.; Chen, H.Y.; Zeng, X.P.; Chen, C.L.; She, X.; Li, L. Facile preparation of halloysite/polyaniline nanocomposites via in situ polymerization and layer-by-layer assembly with good supercapacitor performance. J. Mater. Sci. 2016, 51, 4047–4054. [Google Scholar] [CrossRef]

- Huang, H.B.; Yao, J.L.; Liu, Y.L.; Tuo, X.; Da, Y.M.; Zeng, X.P.; Li, L. 3D Nanostructured Polypyrrole/Sodium Alginate Conducting Hydrogel from self-assembly with High Supercapacitor Performance. J. Macromol. Sci. B 2017, 56, 532–540. [Google Scholar] [CrossRef]

- Xu, P.; Zeng, W.; Luo, S.H.; Ling, C.X.; Xiao, J.W.; Zhou, A.J.; Sun, Y.M.; Liao, K. 3D Ni-Co selenide nanorod array grown on carbon fiber paper: Towards high-performance flexible supercapacitor electrode with new energy storage mechanism. Electrochim. Acta 2017, 241, 41–49. [Google Scholar] [CrossRef]

- Sun, Y.M.; Fang, Z.; Wang, C.X.; Ariyawansha, K.R.; Zhou, A.J.; Duan, H.W. Sandwich-structured nanohybrid paper based on controllable growth of nanostructured MnO2 on ionic liquid functionalized graphene paper as a flexible supercapacitor electrode. RSC Adv. 2015, 7, 7790–7801. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.L.; Wang, W.; Guan, J.; Yang, H.; Sun, G.; Ren, J. Preparation of CeO2 Hollow Nanospheres by PMMA Template and Their Low Frequency Damping Capacity. Rare Met. Mater. Eng. 2015, 44, 1249–1253. [Google Scholar]

- He, Q.J.; Huang, Z.L. Template-directed growth and characterization of flowerlike porous carbonated hydroxyapatite spheres. Cryst. Res. Technol. 2007, 42, 460–465. [Google Scholar] [CrossRef]

- Liu, E.T.; Zhao, H.; Li, H.; Li, G.F.; Liu, Y.L.; Chen, R. Hydrothermal synthesis of porous α-Fe2O3 nanostructures for highly efficient Cr(VI) removal. New J. Chem. 2014, 38, 2911–2916. [Google Scholar] [CrossRef]

- Qin, F.; Zhao, H.; Li, G.; Yang, H.; Li, J.; Wang, R.M.; Liu, Y.L.; Hu, J.C.; Sun, H.Z.; Chen, R. Size-tunable fabrication of multifunctional Bi2O3 porous nanospheres for photocatalysis, bacteria inactivation and template-synthesis. Nanoscale 2014, 6, 5402–5409. [Google Scholar] [CrossRef] [PubMed]

- Ma, D.Y. Theory and design of microperforated panel sound-absorbing constructions. Sci. Sin. 1975, 18, 55–71. [Google Scholar]

- Duan, X.H.; Wang, H.Q.; Li, Z.B.; Zhu, L.K.; Chen, R.; Kong, D.Y.; Zhao, Z. Sound absorption of a flexible micro-perforated panel absorber based on PVDF piezoelectric film. Appl. Acoust. 2015, 88, 84–89. [Google Scholar] [CrossRef]

- Zhao, X.D.; Wang, X.; Yu, Y.J. Enhancing low-frequency sound absorption of micro-perforated panel absorbers by combining parallel mechanical impedance. Appl. Acoust. 2018, 130, 300–304. [Google Scholar] [CrossRef]

- Sakagami, K.; Morimoto, M.; Yairi, M. A note on the effect of vibration of a microperforated panel on its sound absorption characteristics. Acoust. Sci. Technol. 2005, 26, 204–207. [Google Scholar] [CrossRef]

- Gwons, J.G.; Kim, S.K.; Kim, J.H. Sound absorption behavior of flexible polyurethane foams with distinct cellular structures. Mater. Des. 2016, 89, 448–454. [Google Scholar] [CrossRef]

- Lin, J.H.; Chuang, Y.C.; Li, T.T.; Huang, C.H.; Huang, C.L.; Chen, Y.S.; Lou, C.W. Effects of Perforation on Rigid PU Foam Plates: Acoustic and Mechanical Properties. Materials 2016, 9, 1000. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Kessler, M.R. Bio-Polyurethane Foam Made from Compatible Blends of Vegetable Oil-Based Polyol and Petroleum-Based Polyol. ACS Sustain. Chem. Eng. 2015, 3, 743–749. [Google Scholar] [CrossRef]

- Liang, H.; Wang, S.; He, H.; Wang, M.Q.; Liu, L.X.; Lu, J.Y.; Zhang, Y.; Zhang, C.Q. Aqueous anionic polyurethane dispersions from castor oil. Ind. Crops Prod. 2018, 122, 182–189. [Google Scholar] [CrossRef]

- Zhang, C.; Garrison, T.F.; Madbouly, S.A.; Kessler, M.R. Recent advances in vegetable oil-based polymers and their composites. Prog. Polym. Sci. 2017, 71, 91–143. [Google Scholar] [CrossRef]

- Liang, H.; Liu, L.X.; Lu, J.Y.; Chen, M.T.; Zhang, C.Q. Castor oil-based cationic waterborne polyurethane dispersions: Storage stability, thermo-physical properties and antibacterial properties. Ind. Crops Prod. 2018, 117, 169–178. [Google Scholar] [CrossRef]

- Andersons, J.; Cābulis, U.; Stiebra, L.; Kirpļuks, M.; Spārniņš, E. Modeling the mode I fracture toughness of anisotropic low-density rigid PUR and PIR foams. Int. J. Fract. 2017, 205, 111–118. [Google Scholar] [CrossRef]

- Linul, E.; Serban, D.A.; Marsavina, L. Influence of Cell Topology on Mode I Fracture Toughness of Cellular Structures. Phys. Mesomech. 2018, 21, 178–186. [Google Scholar] [CrossRef]

- Chen, S.; Zhu, W.; Cheng, Y. Multi-Objective Optimization of Acoustic Performances of Polyurethane Foam Composites. Polymers 2018, 10, 788. [Google Scholar] [CrossRef]

- Fei, Y.; Fang, W.; Zhong, M.; Jin, J.M.; Fan, P.; Yang, J.T.; Fei, Z.D.; Chen, F.; Kuang, T.R. Morphological Structure, Rheological Behavior, Mechanical Properties and Sound Insulation Performance of Thermoplastic Rubber Composites Reinforced by Different Inorganic Fillers. Polymers 2018, 10, 276. [Google Scholar] [CrossRef]

- Kim, B.S.; Park, J. Double resonant porous structure backed by air cavity for low frequency sound absorption improvement. Compos. Struct. 2018, 183, 545–549. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, C.; Ren, L.; Ichchou, M.; Galland, M.A.; Bareille, O. Sound absorption of a new bionic multi-layer absorber. Compos. Struct. 2014, 108, 400–408. [Google Scholar] [CrossRef]

- Lee, B.C.; Kim, S.R. Effect of structure on sound absorption and sound transmission loss of composite sheet. Adv. Compos. Mater. 2014, 23, 319–325. [Google Scholar] [CrossRef]

- Sun, X.; Liang, W. Cellular structure control and sound absorption of polyolefin microlayer sheets. Compos. Part B 2016, 87, 21–26. [Google Scholar] [CrossRef]

- Kim, B.S.; Cho, S.J.; Min, D.K.; Park, J. Experimental study for improving sound absorption of a composite helical-shaped porous structure using carbon fiber. Compos. Struct. 2016, 145, 242–247. [Google Scholar] [CrossRef]

- Matlack, K.H.; Bauhofer, A.; Krödel, S.; Palermo, A.; Daraio, C. Composite 3D-printed metastructures for low-frequency and broadband vibration absorption. Proc. Natl. Acad. Sci. USA 2016, 113, 8386–8390. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.L.; Yang, Z.; Wang, Z.J.; Zhang, F.Q.; You, F.; Chu, Y. Preparation and Sound Absorption Properties of a Barium Titanate/Nitrile Butadiene Rubber–Polyurethane Foam Composite with Multilayered Structure. Materials 2018, 11, 474. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.L.; Wang, Z.J.; Yang, Z.; Zhang, F.Q.; You, F.; Chu, Y. Preparation and sound absorption properties of barium titanate/nitrile butadiene rubber-polyurethane foam composites with stratified structure. RSC Adv. 2018, 8, 20968–20975. [Google Scholar] [CrossRef]

- Shimizu, T.; Koizumi, S. Study of the compatibility between sound insulation performance and ventilation performance in gaps by installing nonwoven fabrics. Build. Environ. 2015, 94, 335–343. [Google Scholar] [CrossRef]

- Yilmaz, N.D.; Lee, P.B.; Powell, N.B.; Michielsen, S. Effects of porosity, fiber size, and layering sequence on sound absorption performance of needle-punched nonwovens. J. Appl. Polym. Sci. 2011, 121, 3056–3069. [Google Scholar] [CrossRef]

- Cobo, P.; Fernández, A.; Doutres, O. Low-frequency absorption using a two-layer system with active control of input impedance. J. Acoust. Soc. Am. 2003, 114, 3211–3216. [Google Scholar] [CrossRef] [PubMed]

- Zhen, L.; Gong, Y.X.; Jiang, J.T.; Xu, C.Y.; Shao, W.Z. Synthesis of CoFe/Al2O3 composite nanoparticles as the impedance matching layer of wideband multilayer absorber. J. Appl. Phys. 2011, 109, 07A332. [Google Scholar] [CrossRef]

- Hörold, A.; Schartel, B.; Trappe, V.; Korzen, M.; Bunker, J. Fire stability of glass-fibre sandwich panels: The influence of core materials and flame retardants. Compos. Struct. 2017, 160, 1310–1318. [Google Scholar] [CrossRef]

- Gu, J.; Gu, H.; Zhang, Q.; Zhao, Y.; Li, N.; Xiong, J. Sandwich-structured composite fibrous membranes with tunable porous structure for waterproof, breathable, and oil-water separation applications. J. Colloid Interface Sci. 2018, 514, 386–395. [Google Scholar] [CrossRef] [PubMed]

- Tagarielli, V.L.; Deshpande, V.S.; Fleck, N.A. Prediction of the dynamic response of composite sandwich beams under shock loading. Int. J. Impact Eng. 2010, 37, 854–864. [Google Scholar] [CrossRef]

- Ma, G.; Yang, M.; Xiao, S.; Yang, Z.; Sheng, P. Acoustic metasurface with hybrid resonances. Nat. Mater. 2014, 13, 873–878. [Google Scholar] [CrossRef] [PubMed]

- Lapčík, L.; Vašina, M.; Lapčíková, B.; Otyepkova, E.; Waters, K.E. Investigation of advanced mica powder nanocomposite filler materials: Surface energy analysis, powder rheology and sound absorption performance. Compos. Part B 2015, 77, 304–310. [Google Scholar] [CrossRef]

- Wu, Y.; Sun, X.; Wu, W.; Liu, X.; Shen, X.; Wang, Z.; Li, R.K.; Yang, Z.; Lay, K.T.; Kim, J.K. Graphene foam/carbon nanotube/poly(dimethyl siloxane) composites as excellent sound absorber. Compos. Part A 2017, 102, 391–399. [Google Scholar] [CrossRef]

- Sim, S.; Kwon, O.M.; Ahn, K.H.; Lee, H.R.; Kang, Y.J.; Cho, E.B. Preparation of polycarbonate/poly(acrylonitrile-butadiene-styrene)/mesoporous silicanano composite films and its rheological, mechanical, and sound absorption properties. J. Appl. Polym. Sci. 2017, 135, 45777. [Google Scholar] [CrossRef]

| Content (phr) | Piezoelectric Ceramics | Rare Earth Oxides | Common Fillers | ||||||

|---|---|---|---|---|---|---|---|---|---|

| BT | PZT | CeO2 | La2O3 | Gd2O3 | CW | Talc | CaCO3 | CB | |

| NBR | 100 | 100 | 100 | ||||||

| ZnO | 5 | 5 | 5 | ||||||

| Stearic acid | 1.5 | 1.5 | 1.5 | ||||||

| Tetramethyl thiuram disulphide | 2 | 2 | 2 | ||||||

| N-Cyclohexyl-2-benzothiazole sulfenamide | 1 | 1 | 1 | ||||||

| N-isopropyl-N′-phenyl-p-phenylene | 1 | 1 | 1 | ||||||

| Conductive carbon black | 2 | 0 | 0 | ||||||

| CB | 18 | 20 | 20 | 20 | 20 | 45 | |||

| BT | 25 | 0 | 0 | 0 | |||||

| PZT | 0 | 25 | 0 | 0 | |||||

| CeO23 | 0 | 25 | 0 | 0 | 0 | ||||

| La2O3 | 0 | 0 | 25 | 0 | 0 | ||||

| Gd2O3 | 0 | 0 | 0 | 25 | 0 | ||||

| CW | 0 | 0 | 25 | 0 | 0 | 0 | |||

| Talc | 0 | 0 | 0 | 25 | 0 | 0 | |||

| CaCO3 | 0 | 0 | 0 | 0 | 25 | 0 | |||

| Sulfur | 1.5 | 1.5 | 1.5 | ||||||

| Sound Absorption Coefficient (α) | NBR | PUFM | Double-Layer Structure (NBR:PUFM) | Sandwich Structure (NBR:PUFM:NBR) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 2:8 | 4:6 | 6:4 | 8:2 | 1:8:1 | 2:6:2 | 3:4:3 | 4:2:4 | |||

| Maximum | 0.07 | 0.24 | 0.65 | 0.36 | 0.26 | 0.19 | 0.87 | 0.56 | 0.43 | 0.26 |

| Average | 0.06 | 0.11 | 0.37 | 0.18 | 0.14 | 0.14 | 0.53 | 0.32 | 0.25 | 0.19 |

| Sound Absorption Coefficient (α) | Without Fillers | Piezoelectric Ceramics | Rare Earth Oxides | Common Fillers | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| PZT | BT | CeO2 | La2O3 | Gd2O3 | CW | Talc | CaCO3 | CB | ||

| Maximum | 0.87 | 0.85 | 0.88 | 0.87 | 0.85 | 0.90 | 0.87 | 0.76 | 0.86 | 0.83 |

| Average | 0.53 | 0.49 | 0.52 | 0.56 | 0.52 | 0.53 | 0.51 | 0.40 | 0.52 | 0.50 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, X.; Wang, Z.; Yang, Z.; Zhang, F.; You, F.; Yao, C. Structural Design and Sound Absorption Properties of Nitrile Butadiene Rubber-Polyurethane Foam Composites with Stratified Structure. Polymers 2018, 10, 946. https://doi.org/10.3390/polym10090946

Jiang X, Wang Z, Yang Z, Zhang F, You F, Yao C. Structural Design and Sound Absorption Properties of Nitrile Butadiene Rubber-Polyurethane Foam Composites with Stratified Structure. Polymers. 2018; 10(9):946. https://doi.org/10.3390/polym10090946

Chicago/Turabian StyleJiang, Xueliang, Zhijie Wang, Zhen Yang, Fuqing Zhang, Feng You, and Chu Yao. 2018. "Structural Design and Sound Absorption Properties of Nitrile Butadiene Rubber-Polyurethane Foam Composites with Stratified Structure" Polymers 10, no. 9: 946. https://doi.org/10.3390/polym10090946

APA StyleJiang, X., Wang, Z., Yang, Z., Zhang, F., You, F., & Yao, C. (2018). Structural Design and Sound Absorption Properties of Nitrile Butadiene Rubber-Polyurethane Foam Composites with Stratified Structure. Polymers, 10(9), 946. https://doi.org/10.3390/polym10090946