Thickness-Dependent DC Electrical Breakdown of Polyimide Modulated by Charge Transport and Molecular Displacement

Abstract

1. Introduction

2. Experimental Procedure

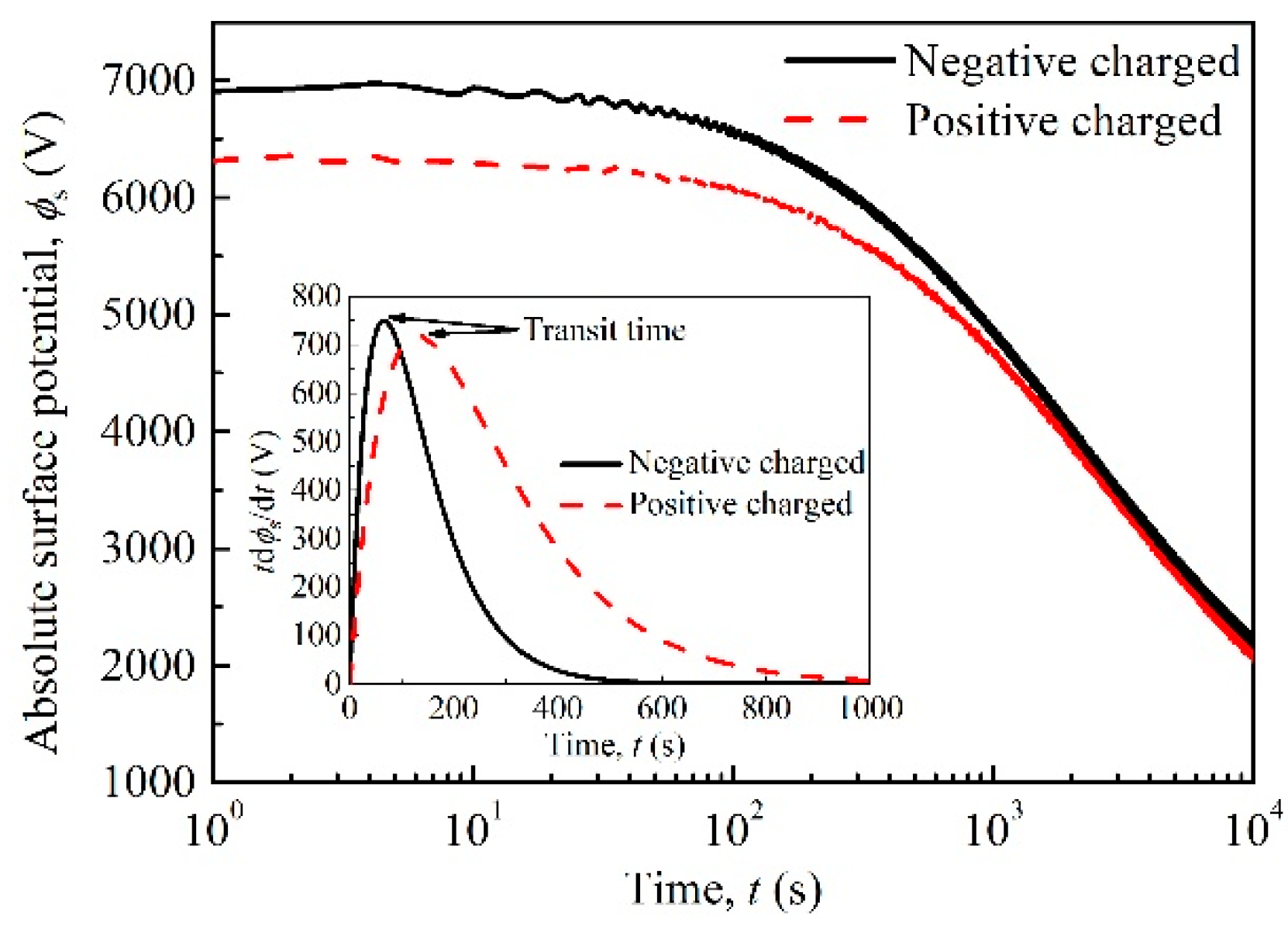

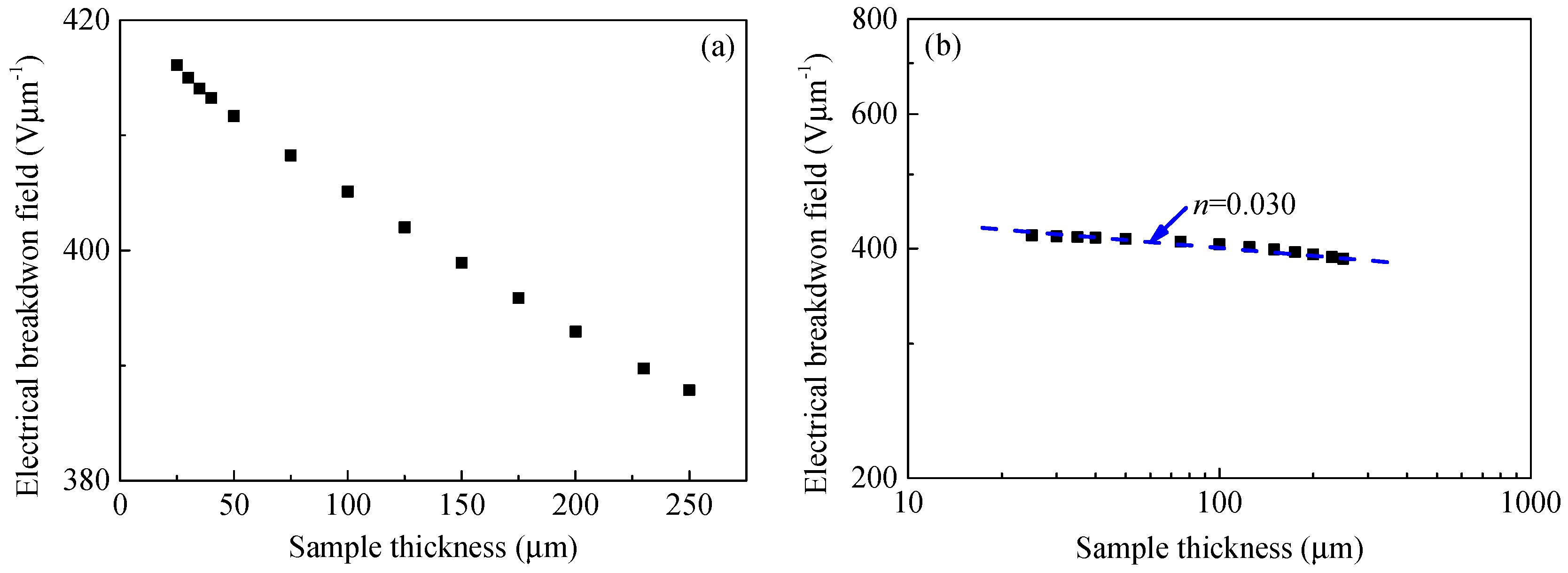

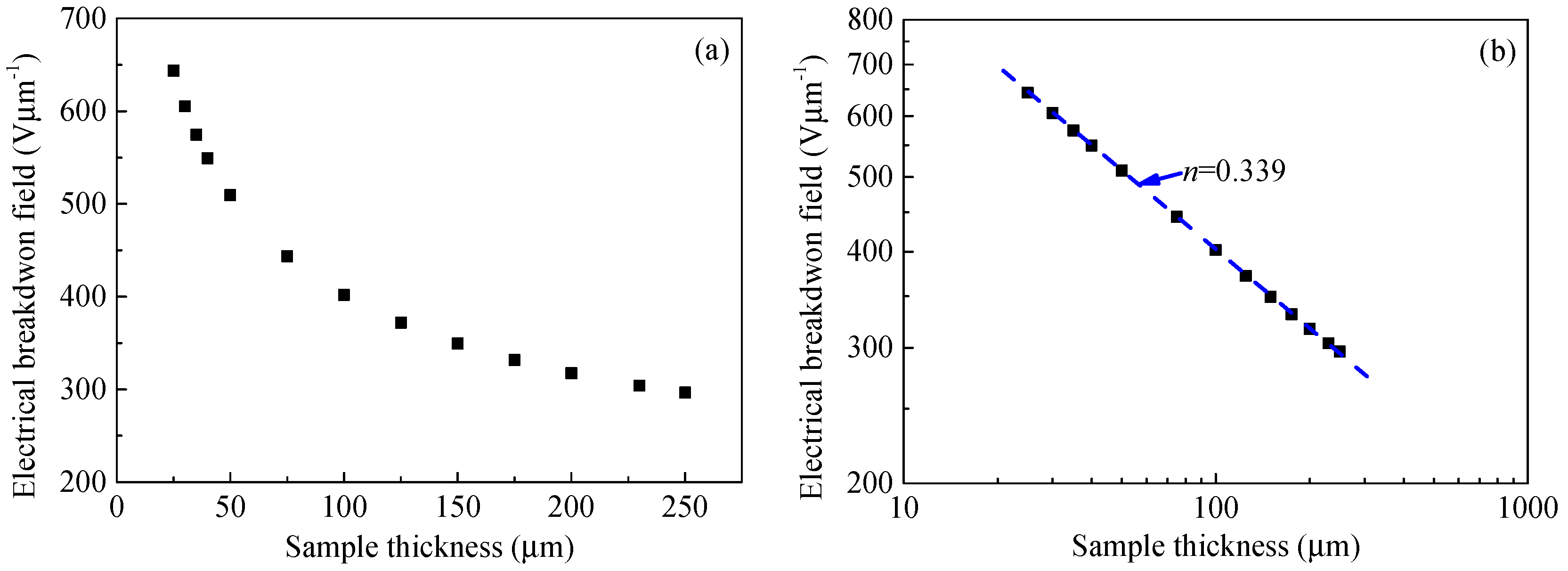

3. Experimental Results

4. Numerical Analysis of Sample Thickness-Dependent DC Electrical Breakdown

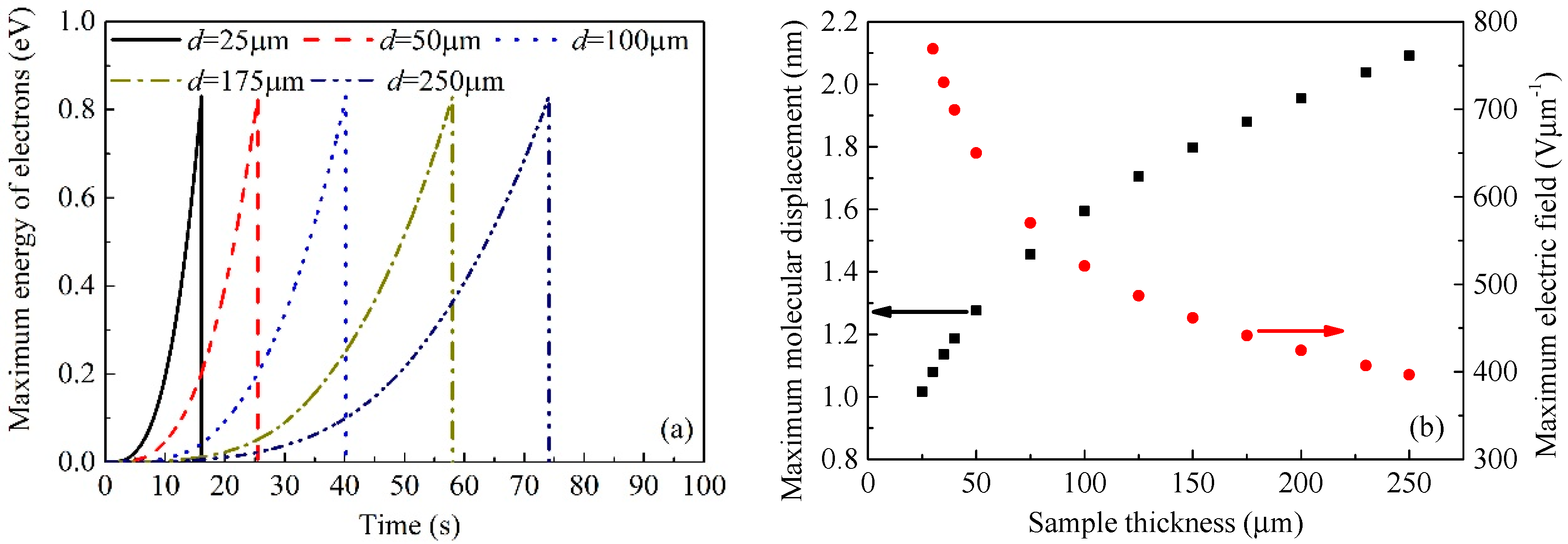

4.1. Numerical Analysis by Space Charge Modulated Electrical Breakdown (SCEB) Model

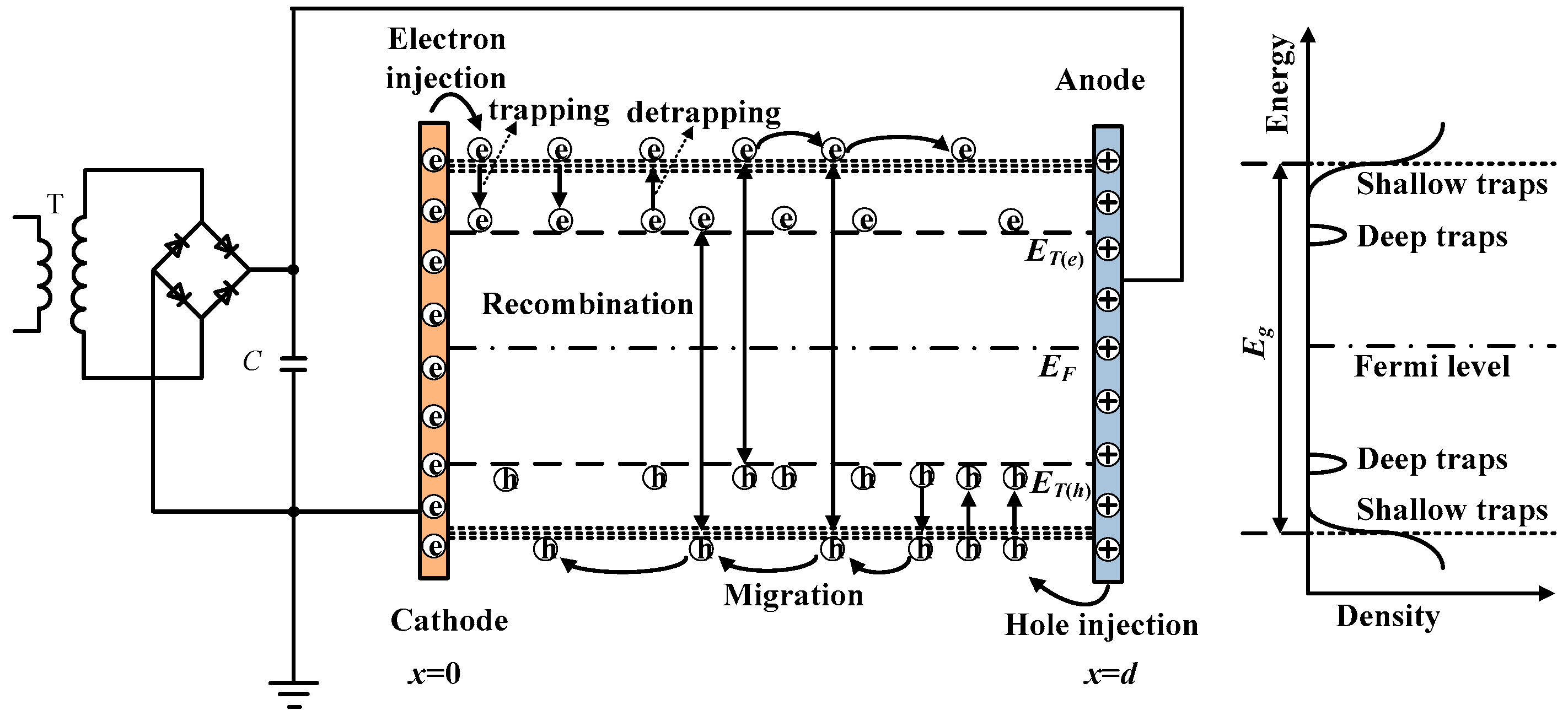

4.1.1. SCEB Model

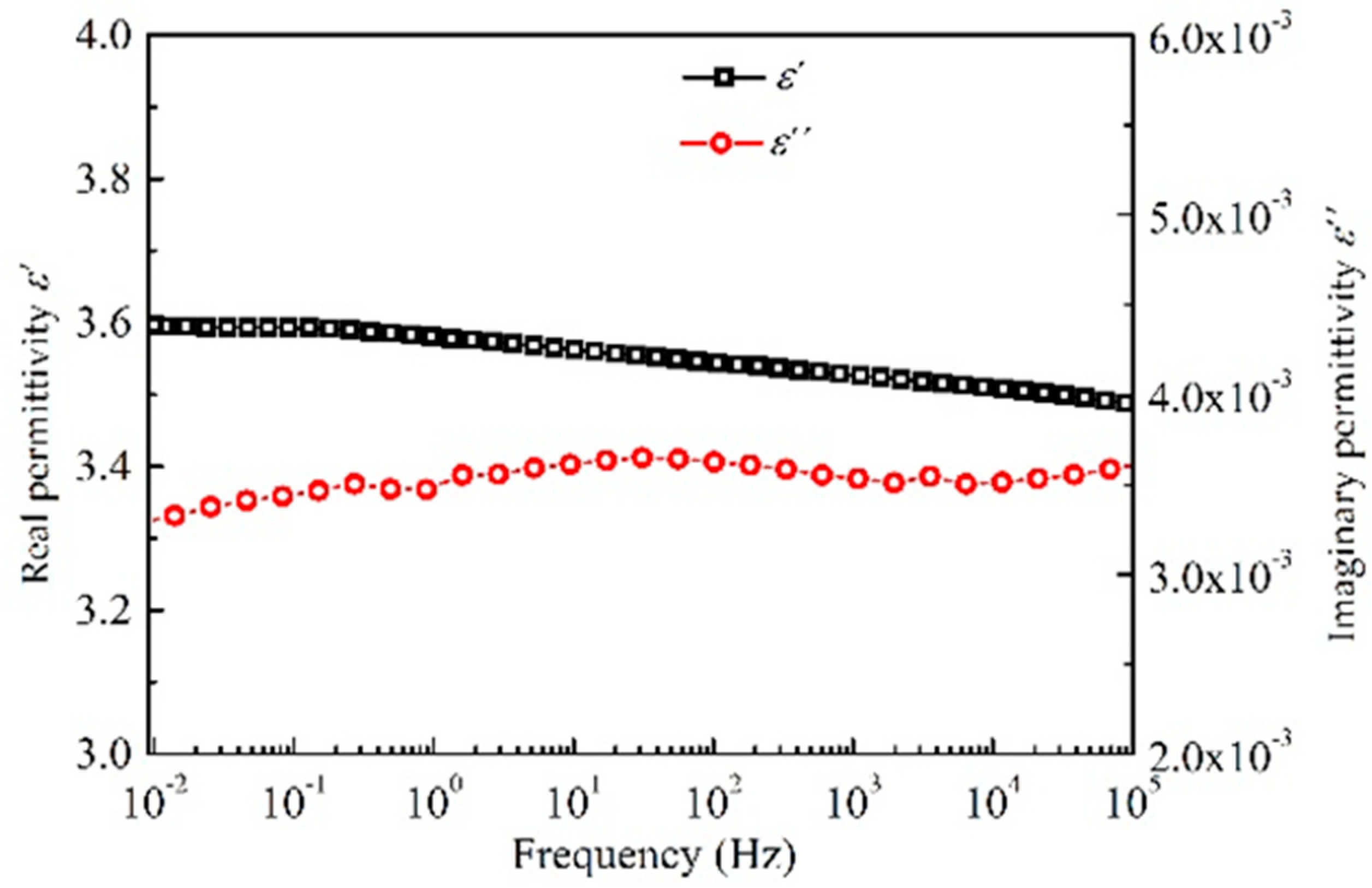

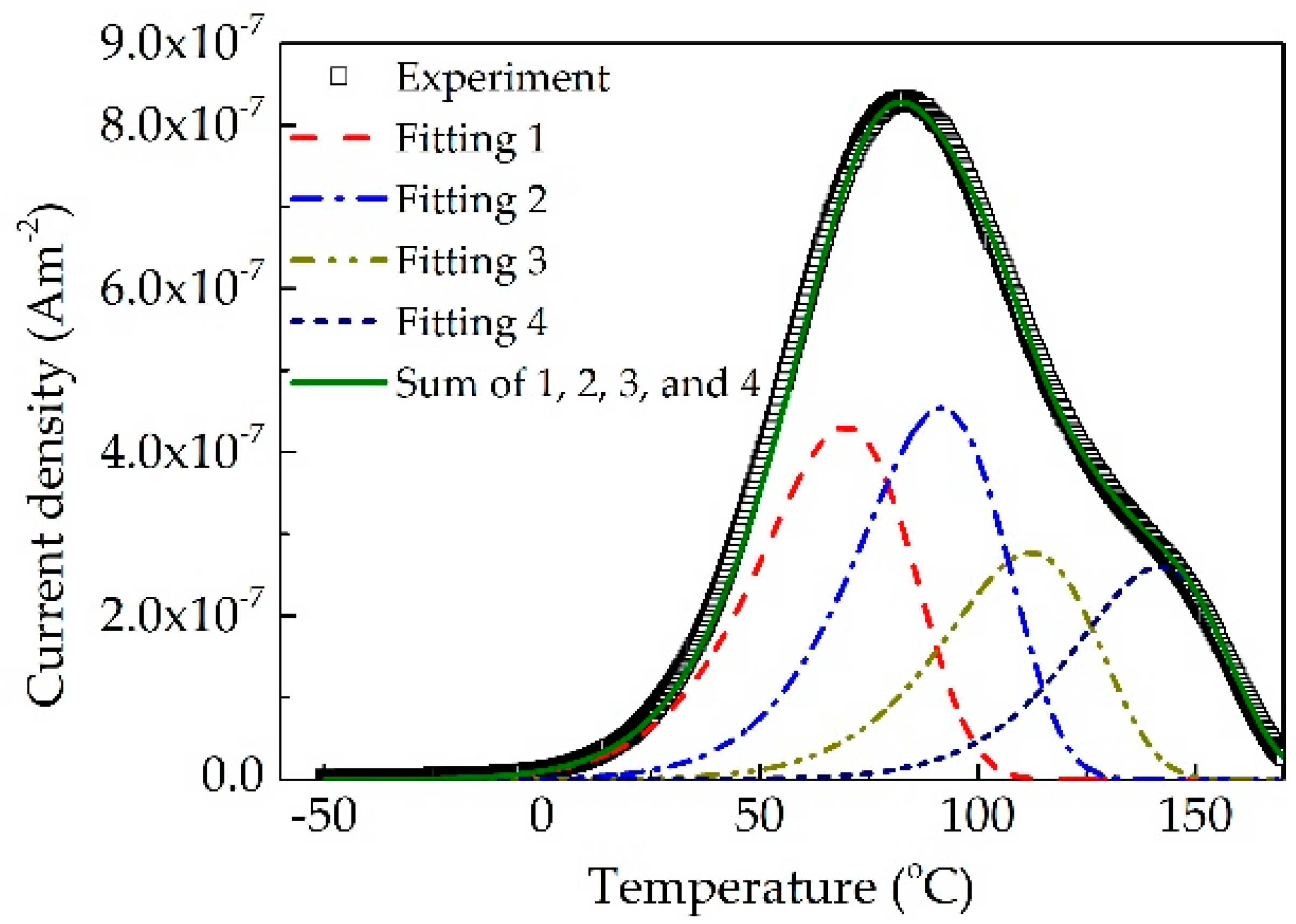

4.1.2. Parameters for SCEB Model

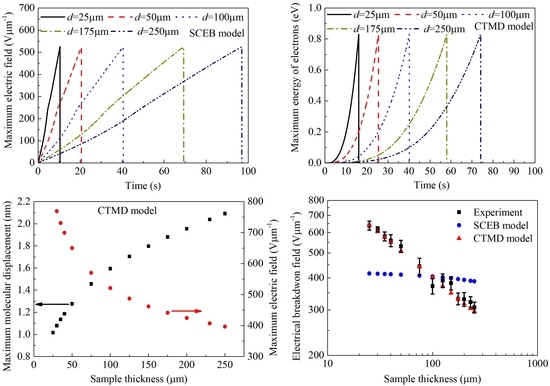

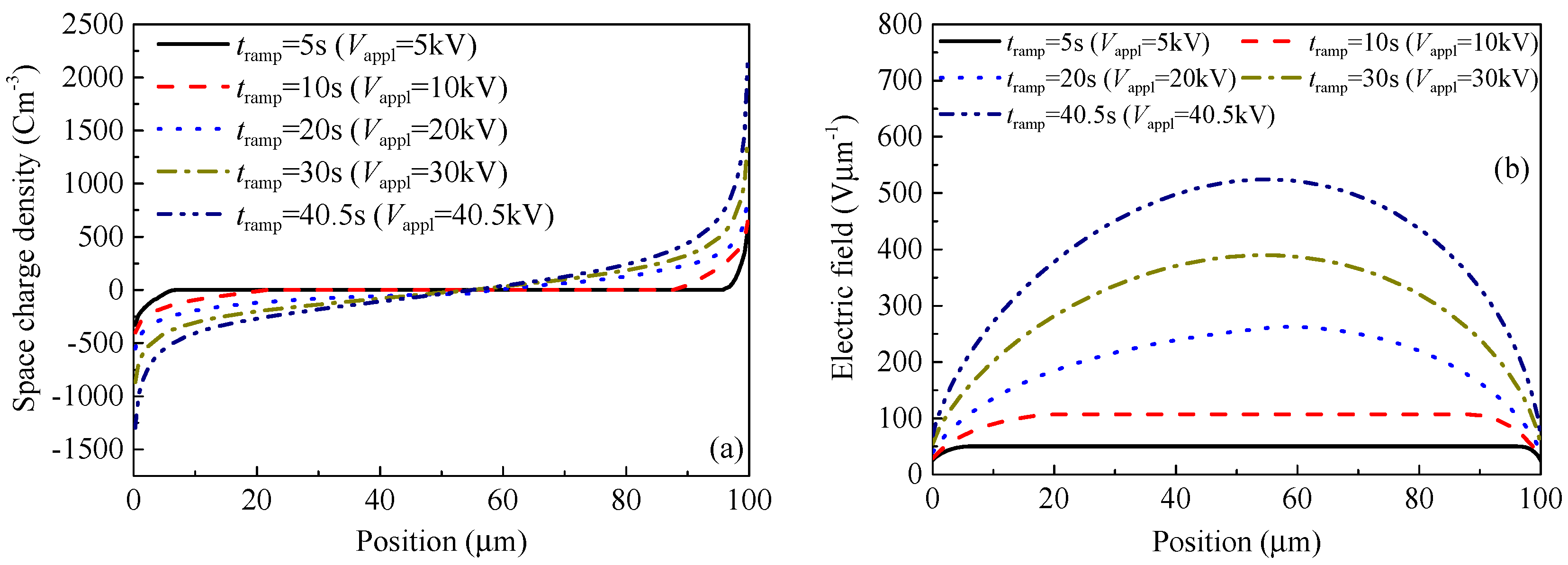

4.1.3. Simulation Results of SCEB Model

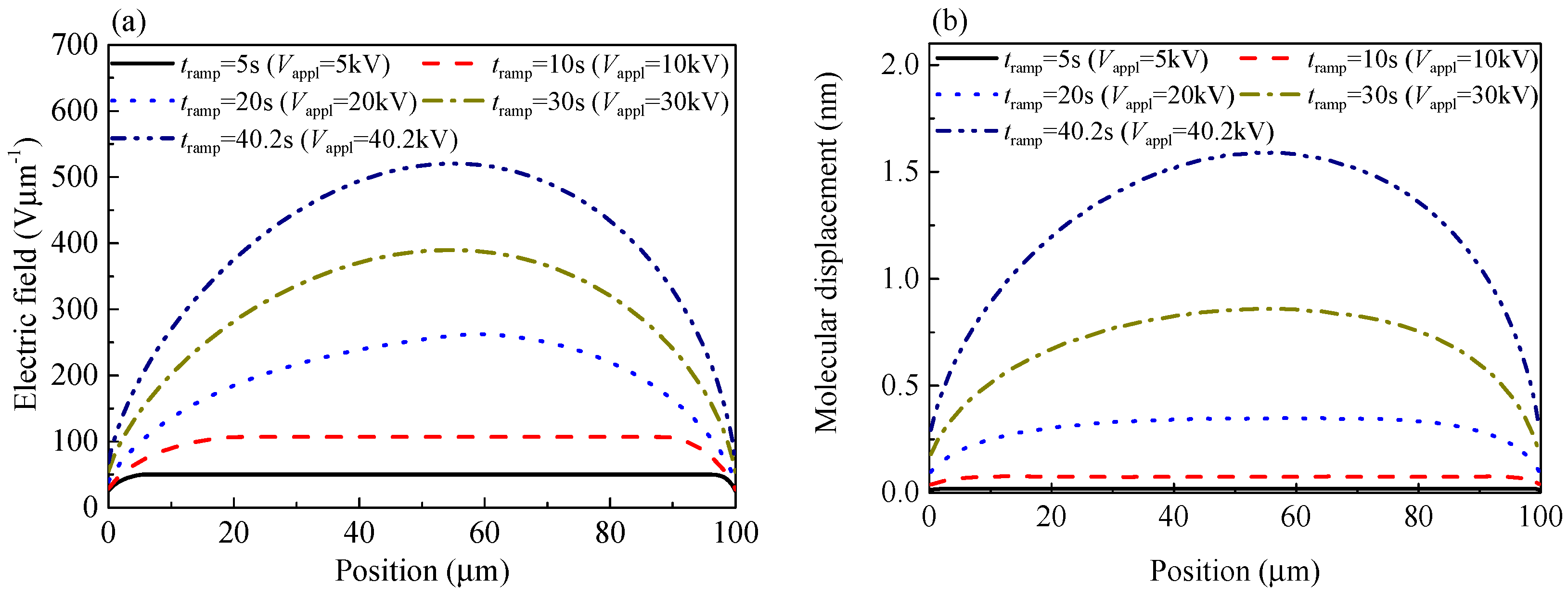

4.2. Numerical Analysis by Charge Transport and Molecular Displacement Modulated (CTMD) Model

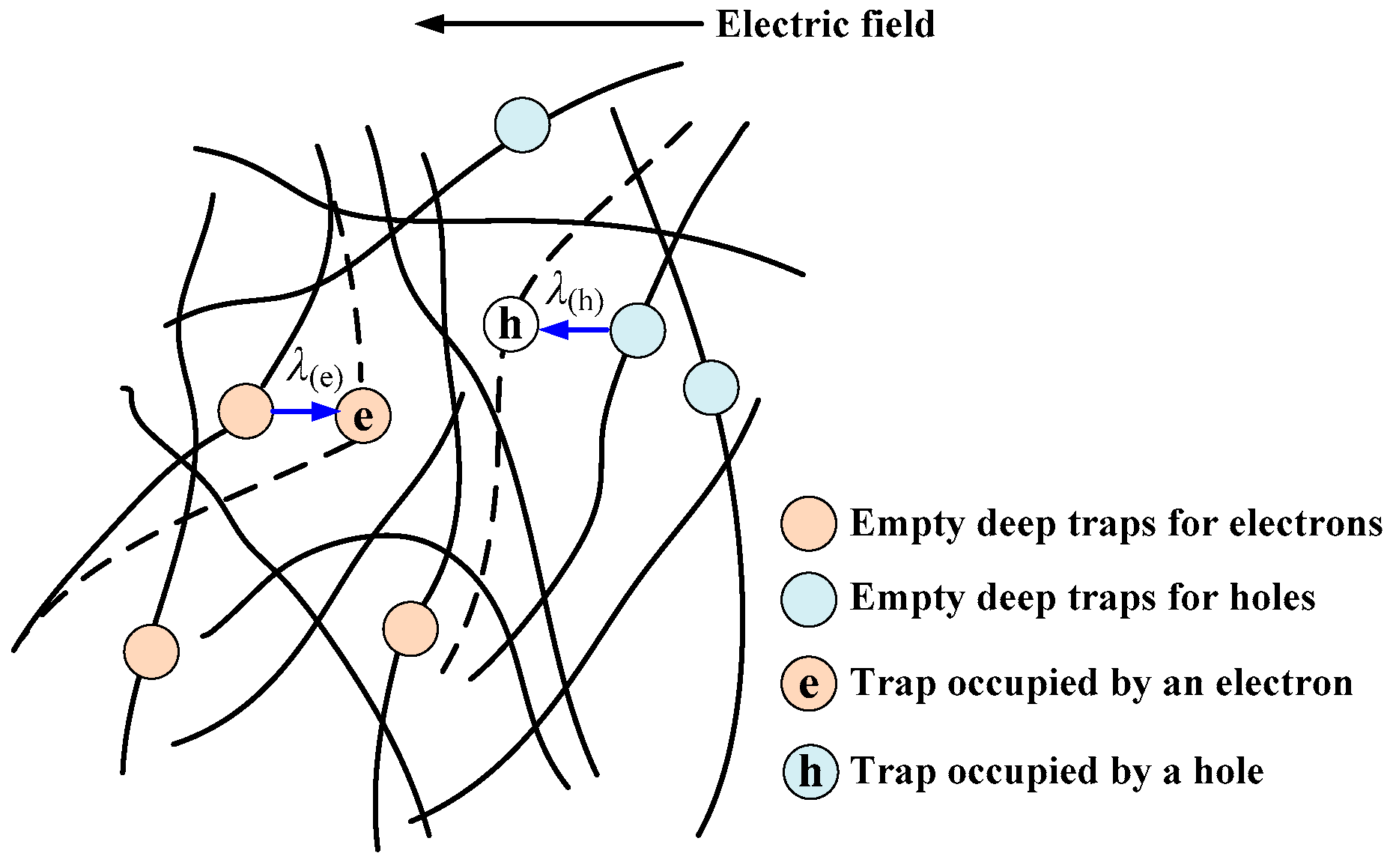

4.2.1. Dynamics of Molecular Displacement under Electric Field

4.2.2. Simulation Results of CTMD Model

4.3. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Dang, Z.M.; Zhou, T.; Yao, S.H.; Yuan, J.K.; Zha, J.W.; Song, H.T.; Li, J.Y.; Chen, Q.; Yang, W.T.; Bai, J.B. Advanced calcium copper titanate/polyimide functional hybrid films with high dielectric permittivity. Adv. Mater. 2009, 21, 2077–2082. [Google Scholar] [CrossRef]

- Dang, Z.M.; Lin, Y.Q.; Xu, H.P.; Shi, C.Y.; Li, S.T.; Bai, J.B. Fabrication and Dielectric Characterization of Advanced BaTiO3/Polyimide Nanocomposite Films with High Thermal Stability. Adv. Funct. Mater. 2008, 18, 1509–1517. [Google Scholar] [CrossRef]

- Huan, T.D.; Boggs, S.; Teyssedre, G.; Laurent, C.; Cakmak, M.; Kumar, S.; Ramprasad, R. Advanced polymeric dielectrics for high energy density applications. Prog. Mater. Sci. 2016, 83, 236–269. [Google Scholar] [CrossRef]

- Dennison, J.R.; Brunson, J.; Swaminathan, P.; Green, N.W.; Frederickson, A.R. Methods for high resistivity measurements related to spacecraft charging. IEEE Trans. Plasma Sci. 2006, 34, 2191–2203. [Google Scholar] [CrossRef]

- Min, D.M.; Cho, M.; Khan, A.R.; Li, S.T. Surface and Volume Charge Transport Properties of Polyimide Revealed by Surface Potential Decay with Genetic Algorithm. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 600–608. [Google Scholar] [CrossRef]

- Fang, Q.R.; Zhuang, Z.B.; Gu, S.; Kaspar, R.B.; Zheng, J.; Wang, J.H.; Qiu, S.L.; Yan, Y.S. Designed synthesis of large-pore crystalline polyimide covalent organic frameworks. Nat. Commun. 2014, 5, 4503. [Google Scholar] [CrossRef] [PubMed]

- Diaham, S.; Zelmat, S.; Locatelli, M.L.; Dinculescu, S.; Decup, M.; Lebey, T. Dielectric Breakdown of Polyimide Films: Area, Thickness and Temperature Dependence. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 18–27. [Google Scholar] [CrossRef]

- Kim, H.K.; Shi, F.G. Thickness Dependent Dielectric Strength of a Low-permittivity Dielectric Film. IEEE Trans. Dielectr. Electr. Insul. 2001, 8, 248–252. [Google Scholar] [CrossRef]

- Huang, J.S.; Shian, S.; Diebold, R.M.; Suo, Z.G.; Clarke, D.R. The thickness and stretch dependence of the electrical breakdown strength of an acrylic dielectric elastomer. Appl. Phys. Lett. 2012, 101, 122901–122905. [Google Scholar] [CrossRef]

- Mason, J.H. Effects of Thickness and Area on the Electric Strength of Polymers. IEEE Trans. Electr. Insul. 1991, 26, 318–322. [Google Scholar] [CrossRef]

- Zhao, L.; Liu, G.Z.; Su, J.C.; Pan, Y.F.; Bo, Z.X. Investigation of thickness effect on electric breakdown strength of polymers under nanosecond pulses. IEEE Trans. Plasma Sci. 2011, 39, 1613–1618. [Google Scholar] [CrossRef]

- Dissado, L.A.; Fothergill, J.C. Electrical Degradation and Breakdown in Polymers; The Institution of Engineering and Technology: London, UK, 1992; pp. 24–316. [Google Scholar]

- Kao, K.C. Dielectric Phenomena in Solids; Elsevier: San Diego, CA, USA, 2004; pp. 515–569. [Google Scholar]

- Chen, G.; Zhao, J.; Li, S.; Zhong, L. Origin of thickness dependent dc electrical breakdown in dielectrics. Appl. Phys. Lett. 2012, 100, 222904. [Google Scholar] [CrossRef]

- Li, S.T.; Zhu, Y.W.; Min, D.M.; Chen, G. Space charge modulated electrical breakdown. Sci. Rep. 2016, 6, 32588. [Google Scholar] [CrossRef] [PubMed]

- Li, S.T.; Min, D.M.; Wang, W.W.; Chen, G. Modelling of dielectric breakdown through charge dynamics for polymer nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 3476–3485. [Google Scholar] [CrossRef]

- Artbauer, J. Electric strength of polymers. J. Phys. D Appl. Phys. 1996, 29, 446–456. [Google Scholar] [CrossRef]

- Zha, J.W.; Dang, Z.M.; Song, H.T.; Yin, Y.; Chen, G. Dielectric properties and effect of electrical aging on space charge accumulation in polyimide/TiO2 nanocomposite films. J. Appl. Phys. 2010, 108, 94113–94116. [Google Scholar] [CrossRef]

- Nelson, J.K. Dielectric Polymer Nanocomposites; Springer: New York, NY, USA, 2010; pp. 1–285. [Google Scholar]

- Matsui, K.; Tanaka, Y.; Takada, T.; Fukao, T. Space Charge Behavior in Low-density Polyethylene at Pre-breakdown. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 406–415. [Google Scholar] [CrossRef]

- Laurent, C.; Teyssedre, G.; Le Roy, S.; Baudoin, F. Charge Dynamics and its Energetic Features in Polymeric Materials. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 357–381. [Google Scholar] [CrossRef]

- Takada, T.; Hayase, Y.; Tanaka, Y.; Okamoto, T. Space Charge Trapping in Electrical Potential Well Caused by Permanent and Induced Dipoles for LDPE/MgO Nanocomposite. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 152–160. [Google Scholar] [CrossRef]

- Mark, J.E. Physical Properties of Polymers Handbook; Springer: New York, NY, USA, 2007; pp. 339–535. [Google Scholar]

- Lowell, J. Absorption and conduction currents in polymers: A unified model. J. Phys. D Appl. Phys. 1990, 23, 205–210. [Google Scholar] [CrossRef]

- Das-Gupta, D.K. Dielectric and related molecular processes in polymers. IEEE Trans. Dielectr. Electr. Insul. 2001, 8, 6–14. [Google Scholar] [CrossRef]

- Min, D.M.; Li, S.T.; Ohki, Y. Numerical Simulation on Molecular Displacement and DC Breakdown of LDPE. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 507–516. [Google Scholar] [CrossRef]

- Van Turnhout, J. Electrets; Springer-Verlag: Berlin, Germany, 1987; pp. 81–215. [Google Scholar]

- Sessler, G.M.; Hahn, B.; Yoon, D.Y. Electrical Conduction in Polyimide Films. J. Appl. Phys. 1986, 60, 318–326. [Google Scholar] [CrossRef]

- Sonnonstine, T.J.; Perlman, M.M. Surface-potential decay in insulators with field-dependent mobility and injection efficiency. J. Appl. Phys. 1975, 46, 3975–3981. [Google Scholar] [CrossRef]

- Hoang, A.T.; Pallon, L.; Liu, D.M.; Serdyuk, Y.V.; Gubanski, S.M.; Gedde, U.W. Charge transport in LDPE nanocomposites part I–experimental approach. Polymers 2016, 8, 87. [Google Scholar] [CrossRef]

- Molinié, P. A Review of Mechanisms and Models Accouting for Surface Potential Decay. IEEE Trans. Plasma Sci. 2012, 40, 167–176. [Google Scholar] [CrossRef]

- Hoang, A.T.; Serdyuk, Y.V.; Gubanski, S.M. Charge transport in LDPE nanocomposties part II—computational approach. Polymers 2016, 8, 103. [Google Scholar] [CrossRef]

- Le Roy, S.; Teyssedre, G.; Laurent, C.; Montanari, G.C.; Palmieri, F. Description of charge transport in polyethylene using a fluid model with a constant mobility: Fitting model and experiments. J. Phys. D Appl. Phys. 2006, 39, 1427–1436. [Google Scholar] [CrossRef]

- Kuik, M.; Koster, L.J.A.; Wetzelaer, G.A.H.; Blom, P.W.M. Trap-assisted recombination in disordered organic semiconductors. Phys. Rev. Lett. 2011, 107, 256805. [Google Scholar] [CrossRef] [PubMed]

- Kuik, M.; Koster, L.J.A.; Dijkstra, A.G.; Wetzelaer, G.A.H.; Blom, P.W.M. Non-radiative recombination losses in polymer light-emitting diodes. Org. Electron. 2012, 13, 969–974. [Google Scholar] [CrossRef]

- Shockley, W.; Read, W.T. Statistics of the Recombinations of Holes and Electrons. Phys. Rev. 1952, 87, 835–842. [Google Scholar] [CrossRef]

- Quamara, J.K.; Pillai, A.S. Surface potential decay characteristics and TSDC studies in corona charged Kapton polyimide film. Acta Polym. 1983, 34, 265–267. [Google Scholar] [CrossRef]

- Lin, J.Q.; Xie, Z.B.; Yang, W.L.; Zhang, P.P.; Liu, Y.; Lin, H.; Li, X.K. Effect of K0.5Na0.5NbO3 Filling Particles on the Charge Carrier Trap Distribution of Polyimide Films. J. Appl. Polym. Sci. 2014, 131, 39821–39828. [Google Scholar] [CrossRef]

- Takada, T.; Kikuchi, H.; Miyake, H.; Tanaka, Y.; Yoshida, M. Determination of charge-trapping sites in saturated and aromatic polymers by quantum chemical calculation. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 1240–1249. [Google Scholar] [CrossRef]

- Chen, Q.; Chu, B.; Zhou, X.; Zhang, Q.M. Effect of metal-polymer interface on the breakdown electric field of poly(vinylidene fluoride-trifluoroethylene-chlorofluoroethylene) terpolymer. Appl. Phys. Lett. 2007, 91, 62903–62907. [Google Scholar] [CrossRef]

- Kremer, F.; Schönhals, A. Broadband Dielectric Spectroscopy; Springer: Berlin, Germany, 2003; pp. 1–98. [Google Scholar]

- Zhou, X.; Zhao, X.H.; Suo, Z.G.; Zou, C.; Runt, J.; Liu, S. Electrical Breakdown and Ultrahigh Electrical Energy Density in Poly(Vinylidene Fluoride-Hexafluoropropylene) Copolymer. Appl. Phys. Lett. 2009, 94, 162901–162903. [Google Scholar] [CrossRef]

- Huang, X.Y.; Zhi, C.Y. Polymer Nanocomposites: Electrical and Thermal Properties; Springer: Basel, Switzerland, 2016; pp. 1–346. [Google Scholar]

| Peak Temperature (°C) | EA (eV) | B (Am−2) | τ0 (s) |

|---|---|---|---|

| 69 | 0.60 | 2.63 × 10−4 | 7.50 × 10−7 |

| 87 | 0.65 | 2.01 × 10−4 | 4.23 × 10−7 |

| 109 | 0.70 | 1.80 × 10−4 | 3.23 × 10−7 |

| 135.5 | 0.83 | 1.60 × 10−4 | 3.09 × 10−8 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Min, D.; Li, Y.; Yan, C.; Xie, D.; Li, S.; Wu, Q.; Xing, Z. Thickness-Dependent DC Electrical Breakdown of Polyimide Modulated by Charge Transport and Molecular Displacement. Polymers 2018, 10, 1012. https://doi.org/10.3390/polym10091012

Min D, Li Y, Yan C, Xie D, Li S, Wu Q, Xing Z. Thickness-Dependent DC Electrical Breakdown of Polyimide Modulated by Charge Transport and Molecular Displacement. Polymers. 2018; 10(9):1012. https://doi.org/10.3390/polym10091012

Chicago/Turabian StyleMin, Daomin, Yuwei Li, Chenyu Yan, Dongri Xie, Shengtao Li, Qingzhou Wu, and Zhaoliang Xing. 2018. "Thickness-Dependent DC Electrical Breakdown of Polyimide Modulated by Charge Transport and Molecular Displacement" Polymers 10, no. 9: 1012. https://doi.org/10.3390/polym10091012

APA StyleMin, D., Li, Y., Yan, C., Xie, D., Li, S., Wu, Q., & Xing, Z. (2018). Thickness-Dependent DC Electrical Breakdown of Polyimide Modulated by Charge Transport and Molecular Displacement. Polymers, 10(9), 1012. https://doi.org/10.3390/polym10091012