Effects of Jet Path on Electrospun Polystyrene Fibers

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials Preparation

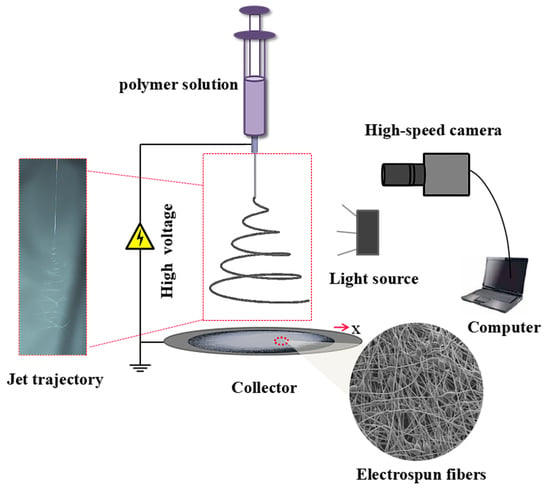

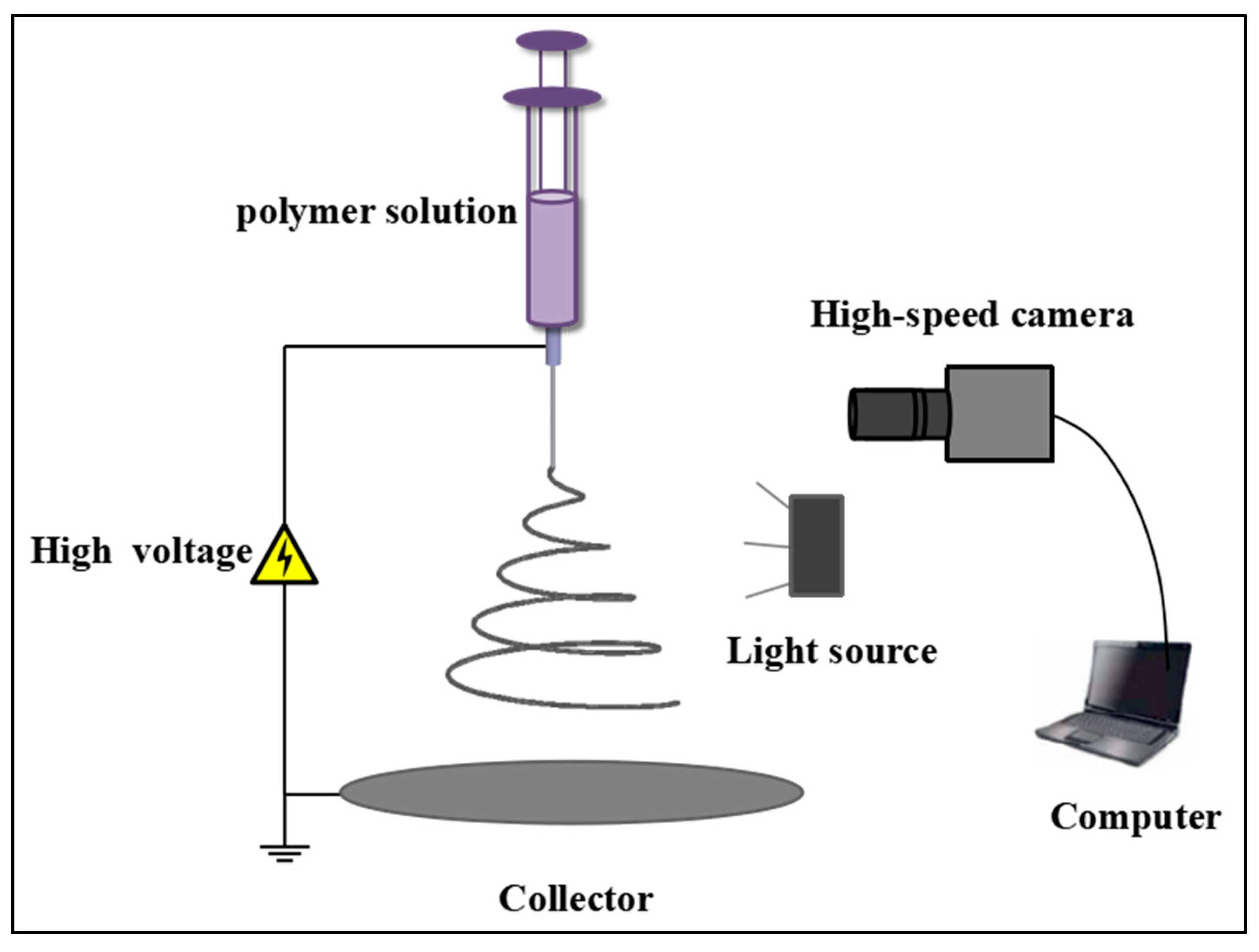

2.2. Experimental Setup

2.3. Characterization

3. Results and Discussion

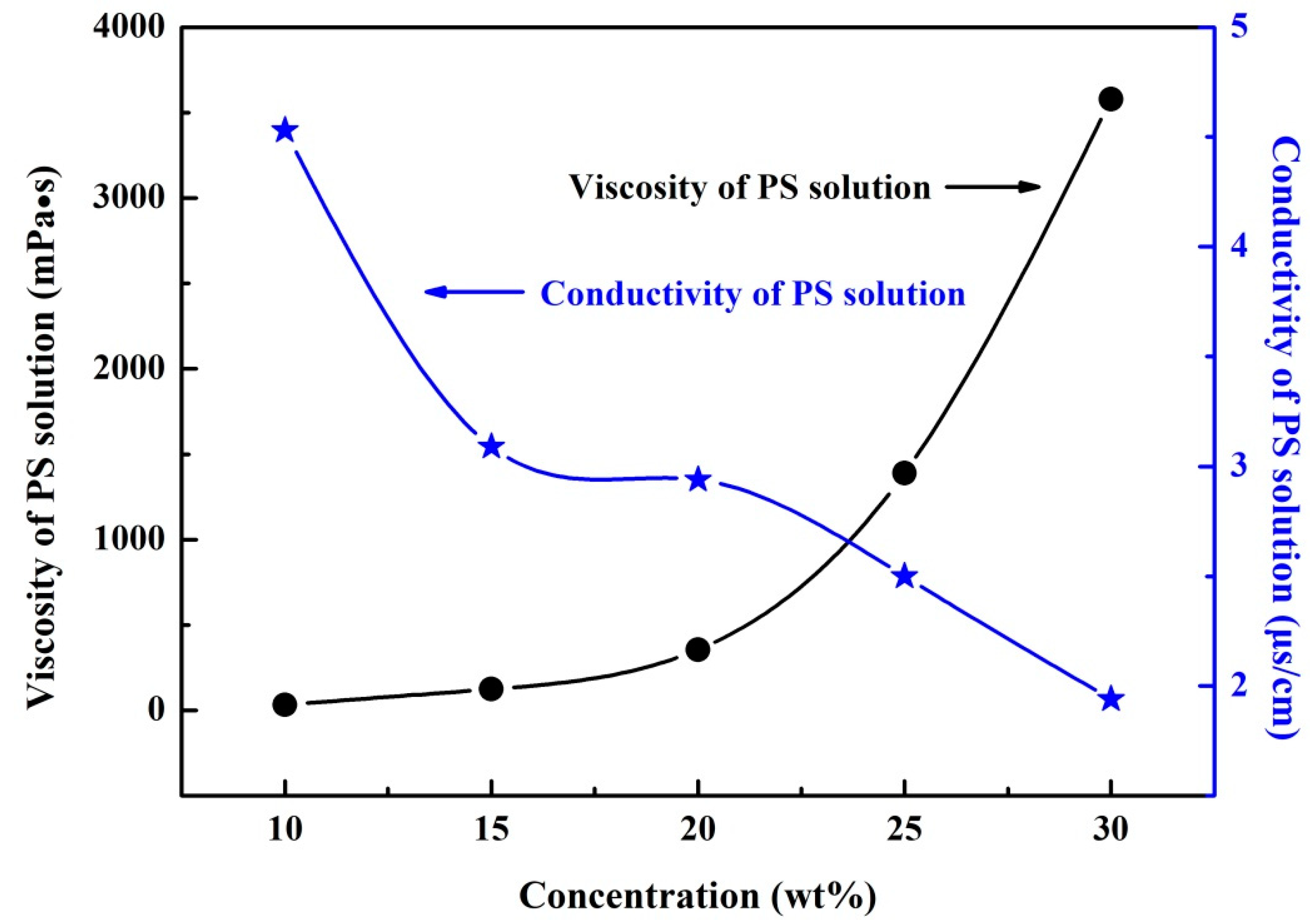

3.1. PS Solution Performance

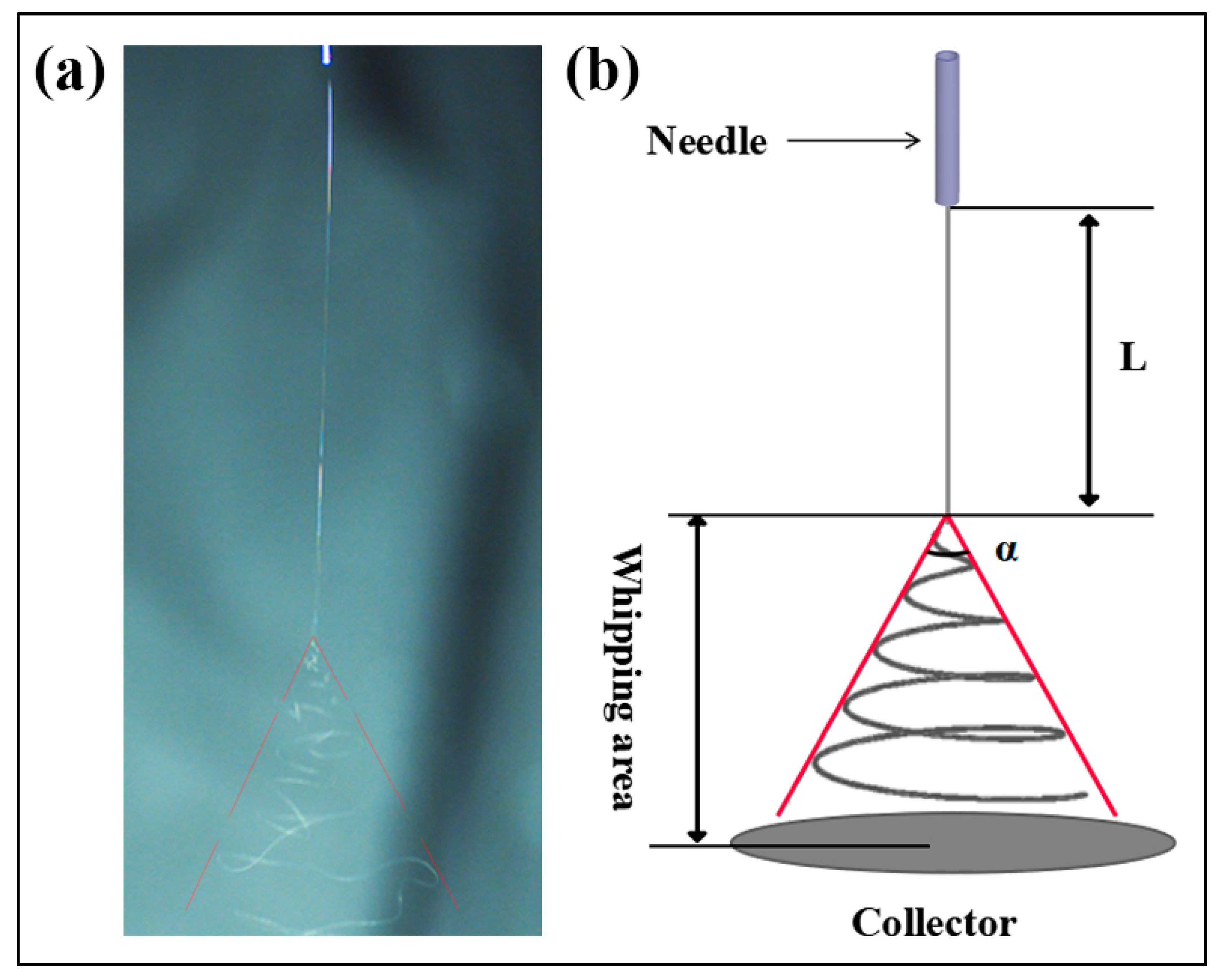

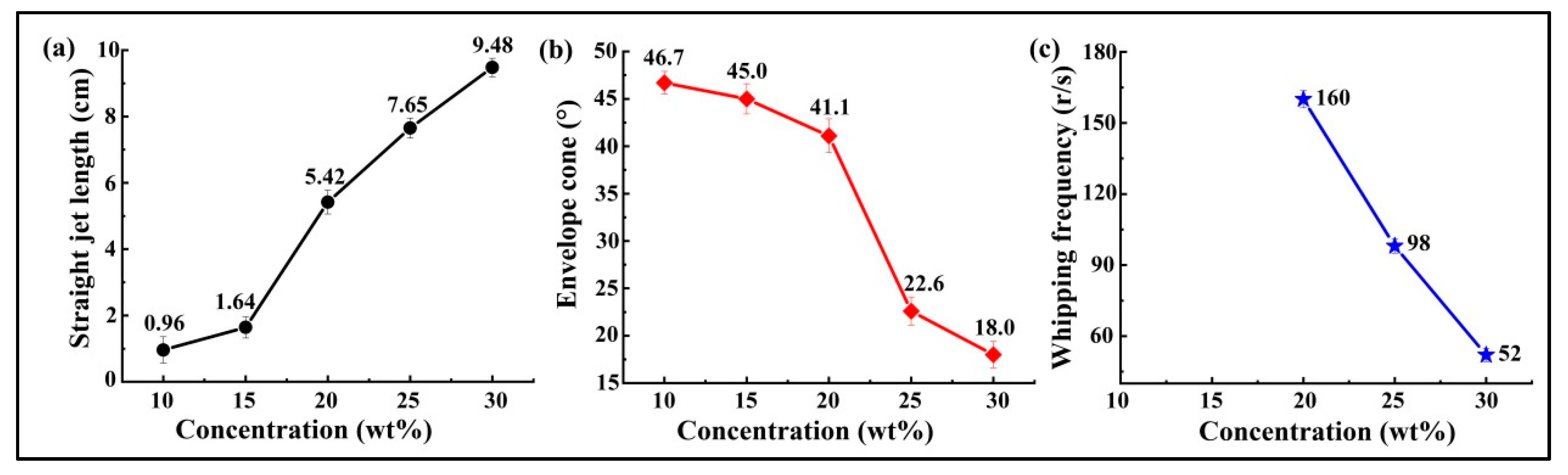

3.2. Jet Path Observations and Measurements

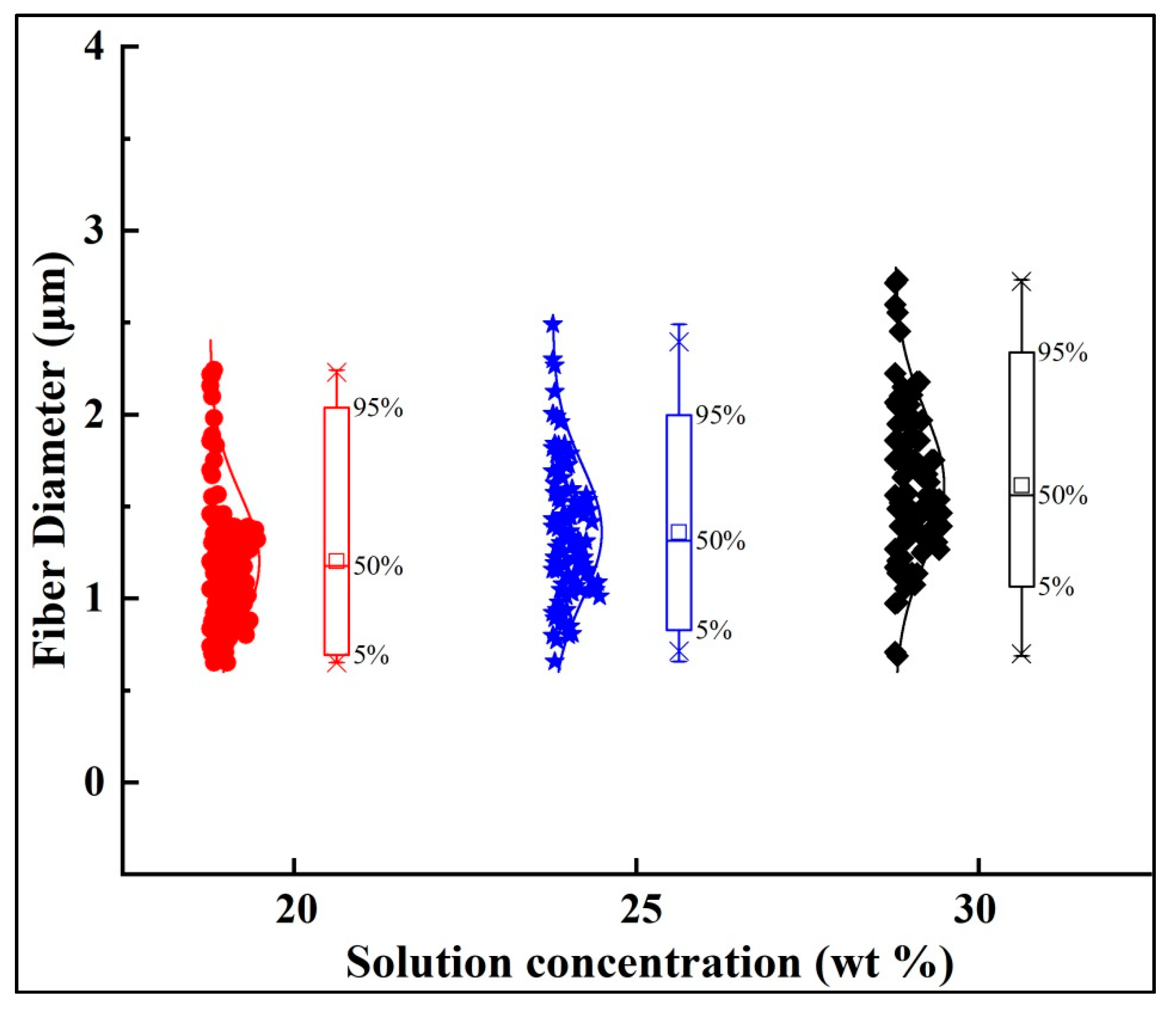

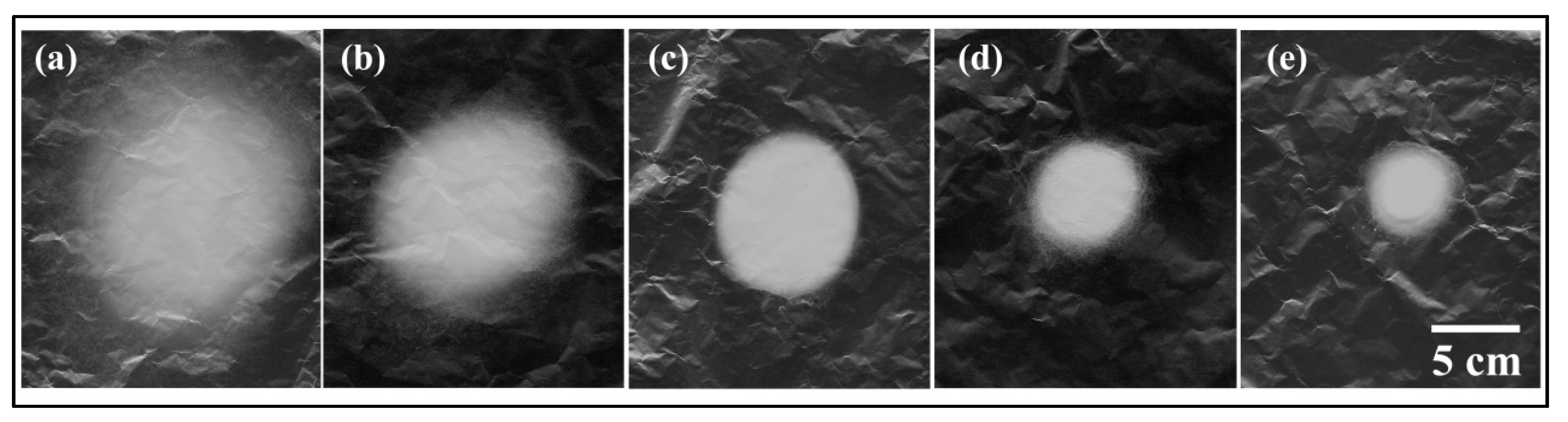

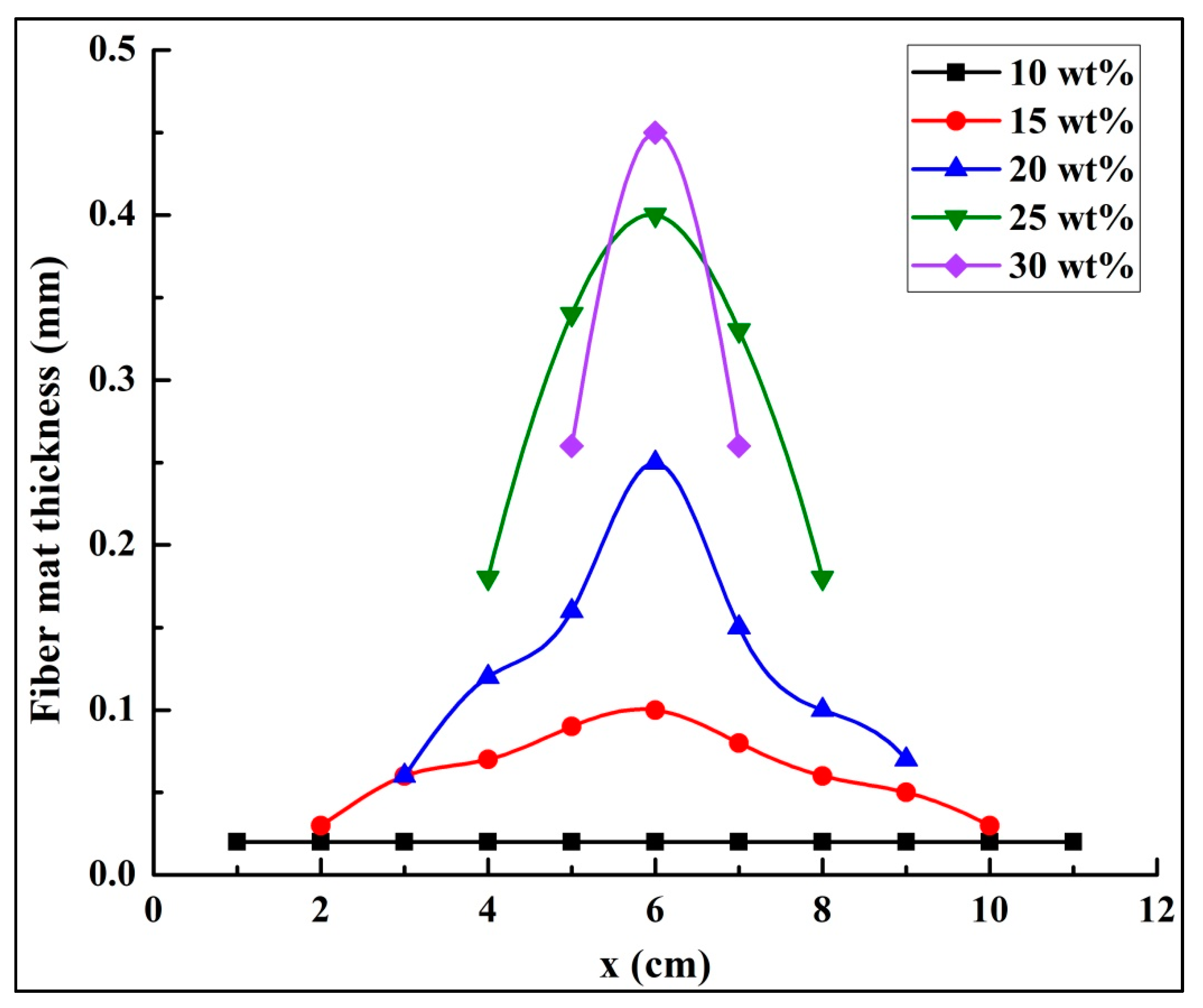

3.3. Fiber Diameters and Fiber Mats

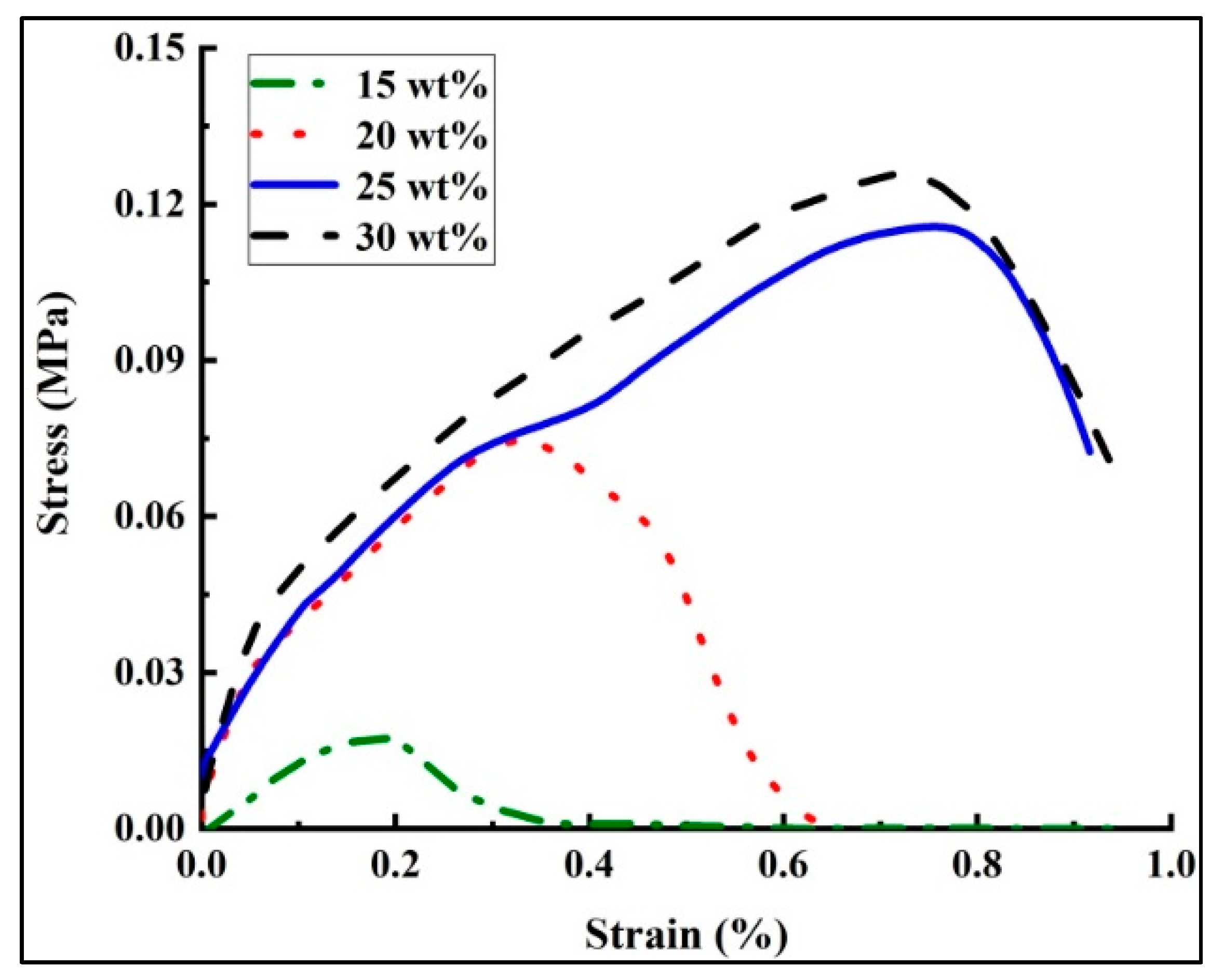

3.4. Mechanical Performance of PS Fiber Mats

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Maghsoodlou, S.; Noroozi, B.; Haghi, A.K. A Simple Model for Solvent Evaporation in Electrospinning Process. Nano 2016, 12, 1–12. [Google Scholar] [CrossRef]

- Satinderpal, K.; Subramanian, S.; Rana, D.; Matsuura, T.; Ramakrishna, S. Influence of electrospun fiber size on the separation efficiency of thin film nanofiltration composite membrane. J. Membr. Sci. 2012, 392, 101–111. [Google Scholar]

- Zheng, Y.S.; Gong, H.H.; Zeng, Y.C. Multijet motion and deviation in electrospinning. Rsc. Adv. 2015, 5, 48533–48540. [Google Scholar] [CrossRef]

- Bhardwaj, N.; Kundu, S.C. Electrospinning: A fascinating fiber fabrication technique. Biotechnol. Adv. 2010, 28, 325–347. [Google Scholar] [CrossRef] [PubMed]

- Ramakrishna, S.; Fujihara, K.; Teo, W.E.; Lim, T.C.; Ma, Z. “An Introduction to Electrospinning and Nanofibers”. J. Eng. Fibre Fabr. 2008, 3, 396–397. [Google Scholar]

- Kamalha, E.; Zheng, Y.S.; Zeng, Y.C.; Mwasiagi, I.J. Effect of solvent concentration on morphology of electrospun bombyx mori silk. Indian J. Fibre Text. Res. 2014, 39, 201–203. [Google Scholar]

- Zheng, Y.S.; Zeng, Y.C. Electric field analysis of spinneret design for multihole electrospinning system. J. Mater. Sci. 2014, 49, 1964–1972. [Google Scholar] [CrossRef]

- Zheng, Y.S.; Zhuang, C.M.; Gong, R.H.; Zeng, Y.C. Electric Field Design for Multijet Electropsinning with Uniform Electric Field. Ind. Eng. Chem. Res. 2014, 53, 14876–14884. [Google Scholar] [CrossRef]

- Wang, X.F.; Ding, B.; Li, B.Y. Biomimetic electrospun nanofibrous structures for tissue engineering. Mater. Today 2013, 16, 229–241. [Google Scholar] [CrossRef] [PubMed]

- Unal, B.; Yalcinkaya, E.E.; Demirkol, D.O.; Timura, S. An electrospun nanofiber matrix based on organo-clay for biosensors: PVA/PAMAM-Montmorillonite. Appl. Surf. Sci. 2018, 444, 542–551. [Google Scholar] [CrossRef]

- Zandesh, G.R.; Gheibi, A.; Bafqi, M.S.S.; Bagherzadeh, R.; Ghoorchian, M.; Latifi, M. Piezoelectric electrospun nanofibrous energy harvesting devices: Influence of the electrodes position and finite variation of dimensions. J. Ind. Text. 2016, 47, 1–15. [Google Scholar] [CrossRef]

- Zafar, M.; Najeeb, S.; Khurshid, Z.; Vazirzadeh, M.; Zohaib, S.; Najeeb, B.; Sefat, F. Potential of electrospun nanofibers for biomedical and dental applications. Materials 2016, 2, 73–94. [Google Scholar] [CrossRef] [PubMed]

- Qasim, S.B.; Zafar, M.S.; Najeeb, S.; Khurshid, Z.; Shah, A.H.; Husain, S.; Rehman, I.U. Electrospinning of chitosan-based solutions for tissue engineering and regenerative medicine. Int. J. Mol. Sci. 2018, 2, 407–433. [Google Scholar] [CrossRef] [PubMed]

- Huan, S.; Liu, G.; Han, G.; Cheng, W.; Fu, Z.; Wu, Q.; Wang, Q. Effect of experimental parameters on morphological, mechanical and hydrophobic properties of electrospun polystyrene fibers. Materials 2015, 8, 2718–2734. [Google Scholar] [CrossRef]

- Li, X.; Lin, J.Y.; Zeng, Y.C. Electric field distribution and initial jet motion induced by spinneret configuration for molecular orientation in electrospun fibers. Eur. Polym. J. 2017, 98, 330–336. [Google Scholar] [CrossRef]

- Rezaei, B.; Shoushtari, A.M.; Rabiee, M.; Uzun, L.; Turner, A.P.F.; Mak, W.C. Multifactorial modeling and optimization of solution and electrospinning parameters to generate superfine polystyrene nanofibers. Adv. Polym. Technol. 2018, 1–13, 1–13. [Google Scholar] [CrossRef]

- Zheng, Y.S.; Sheng, X.; Zeng, Y.X. Electric field distribution and jet motion in electrospinning process: From needle to hole. J. Mater. Sci. 2013, 48, 6647–6655. [Google Scholar] [CrossRef]

- Zheng, Y.S.; Liu, X.; Zeng, Y.C. Electrospun nanofibers from a multihole spinneret with uniform electric field. J. Appl. Polym. Sci. 2014, 130, 3221–3228. [Google Scholar] [CrossRef]

- Yang, Y.; Jia, Z.D.; Liu, J.N.; Li, Q.; Hou, L.; Wang, L.M.; Guan, Z.C. Effect of electric field distribution uniformity on electrospinning. J. Appl. Phys. 2008, 103, 1–11. [Google Scholar] [CrossRef]

- Xie, S.; Zeng, Y.C. Effects of electric field on multineedle electrospinning: experiment and simulation study. Ind. Eng. Chem. Res. 2012, 51, 5336–5345. [Google Scholar] [CrossRef]

- Khan, Z.; Kafiah, F.; Hafiz, Z. Morphology, mechanical properties and surface characteristics of electrospun polyacrylonitrile (PAN) nanofiber mats. Int. J. Adv. Eng. Nano Technol. 2015, 2, 15–22. [Google Scholar]

- Wu, H.H.; Zheng, Y.S.; Zeng, Y.C. Fabrication of helical nanofibers via co-electrospinning. Ind. Eng. Chem. Res. 2015, 54, 987–993. [Google Scholar] [CrossRef]

- Yang, H.; Wang, L.H.; Xiang, C.H.; Li, L.L. Electrospun porous PLLA and poly(LLA-co-CL) fibers by phase separation. New J. Chem. 2018, 42, 1–9. [Google Scholar] [CrossRef]

- Liu, M.H.; Gu, M.; Tian, Y.; Huang, P.; Wang, L.; Shi, Q.F.; Cui, C. Multifunctional CaSc2O4:Yb3+/Er3+ one-dimensional nanofibers: Electrospinning synthesis and concentration-modulated upconversion luminescent properties. J. Mater. Chem. C 2017, 16, 4025–4033. [Google Scholar] [CrossRef]

- Lee, K.H.; Kim, H.Y.; Bang, H.J.; Jung, Y.H.; Lee, S.G. The change of bead morphology formed on electrospun polystyrene fibers. Polymer 2003, 14, 4029–4034. [Google Scholar] [CrossRef]

- Wang, C.; Chiahung, H.A.; Lin, J.H. Scaling laws in electrospinning of polystyrene solutions. Macromolecules 2006, 22, 7662–7672. [Google Scholar] [CrossRef]

- Emo, B.; Eberlin, C.T.; Hixon, K.R.; Kalaf, E.A.G.; Laktas, J.M.; Sell, S.A. A study on the potential of doped electrospun polystyrene fibers in arsenic filtration. J. Environ. Chem. Eng. 2017, 1, 232–239. [Google Scholar] [CrossRef]

- Zhang, M.X.; Chen, J.F.; Chen, B.J.; Cao, J.J.; Hong, M.; Zhou, C.X.; Xu, Q. Fabrication of polystyrene fibers with tunable co-axial hollow tubing structure for oil spill cleanup. Appl. Surf. Sci. 2016, 367, 126–133. [Google Scholar] [CrossRef]

- Ji, Y.; Li, B.; Ge, S.; Sokolov, J.C.; Rafailovich, M.H. Structure and nanomechanical characterization of electrospun PS/clay nanocomposite fibers. Langmuir 2006, 22, 1321–1328. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.Y.; Ding, B.; Yu, J.Y. Direct fabrication of highly nanoporous polystyrene fibers via electrospinning. ACS Appl. Mater. Interface 2010, 2, 521–528. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.Y.; Shang, Y.W.; Ding, B.; Yang, J.M.; Yu, J.Y.; Al-Deyab, S.S. Nanoporous polystyrene fibers for oil spill cleanup. Mar. Pollut. Bull. 2012, 64, 347–352. [Google Scholar] [CrossRef] [PubMed]

- Meng, N.; Zheng, Y.S.; Xin, B.J. Fabrication and characterization of graphene enriched polysulfon amide nanocomposites by electrospinning system. Fiber Polym. 2018, 19, 357–363. [Google Scholar] [CrossRef]

- Carlisle, C.R.; Coulais, C.; Guthold, M. The mechanical stress-strain properties of single electrospun collagen type I nanofibers. Acta Biomater. 2010, 8, 2997–3003. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Y.; Meng, N.; Xin, B. Effects of Jet Path on Electrospun Polystyrene Fibers. Polymers 2018, 10, 842. https://doi.org/10.3390/polym10080842

Zheng Y, Meng N, Xin B. Effects of Jet Path on Electrospun Polystyrene Fibers. Polymers. 2018; 10(8):842. https://doi.org/10.3390/polym10080842

Chicago/Turabian StyleZheng, Yuansheng, Na Meng, and Binjie Xin. 2018. "Effects of Jet Path on Electrospun Polystyrene Fibers" Polymers 10, no. 8: 842. https://doi.org/10.3390/polym10080842

APA StyleZheng, Y., Meng, N., & Xin, B. (2018). Effects of Jet Path on Electrospun Polystyrene Fibers. Polymers, 10(8), 842. https://doi.org/10.3390/polym10080842