Enhanced Properties of Biodegradable Poly(Propylene Carbonate)/Polyvinyl Formal Blends by Melting Compounding

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of PVF

2.3. Preparation of PPC/PVF Blends

2.4. Charaterization Techniques

3. Results

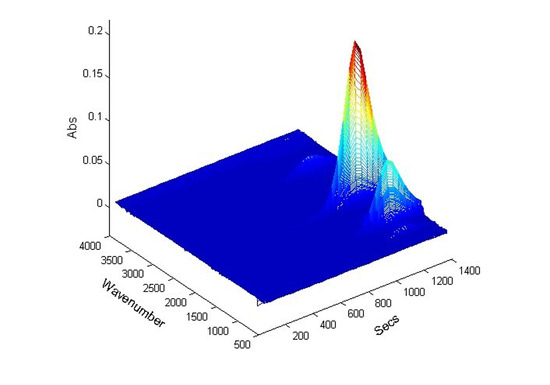

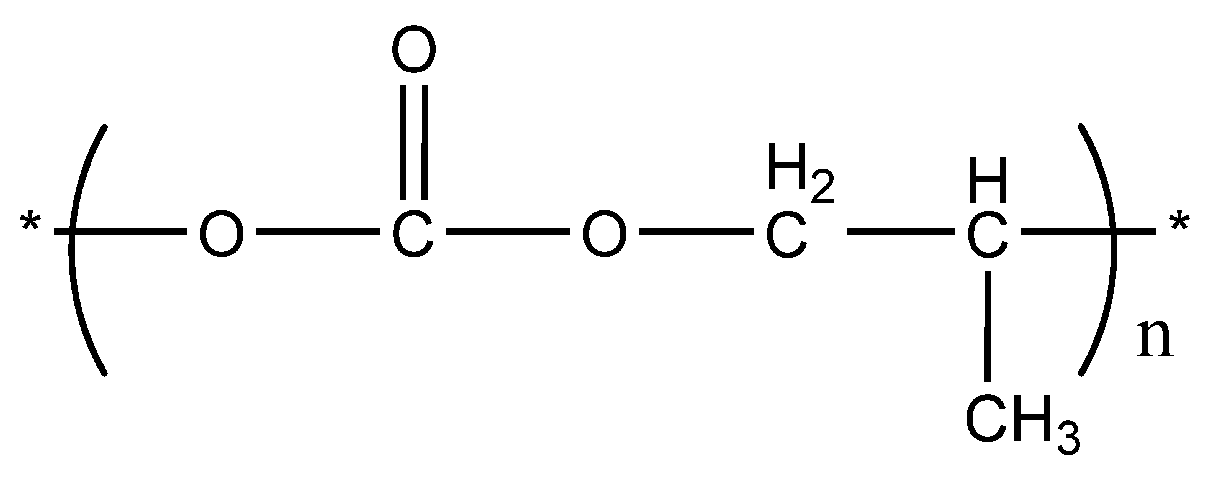

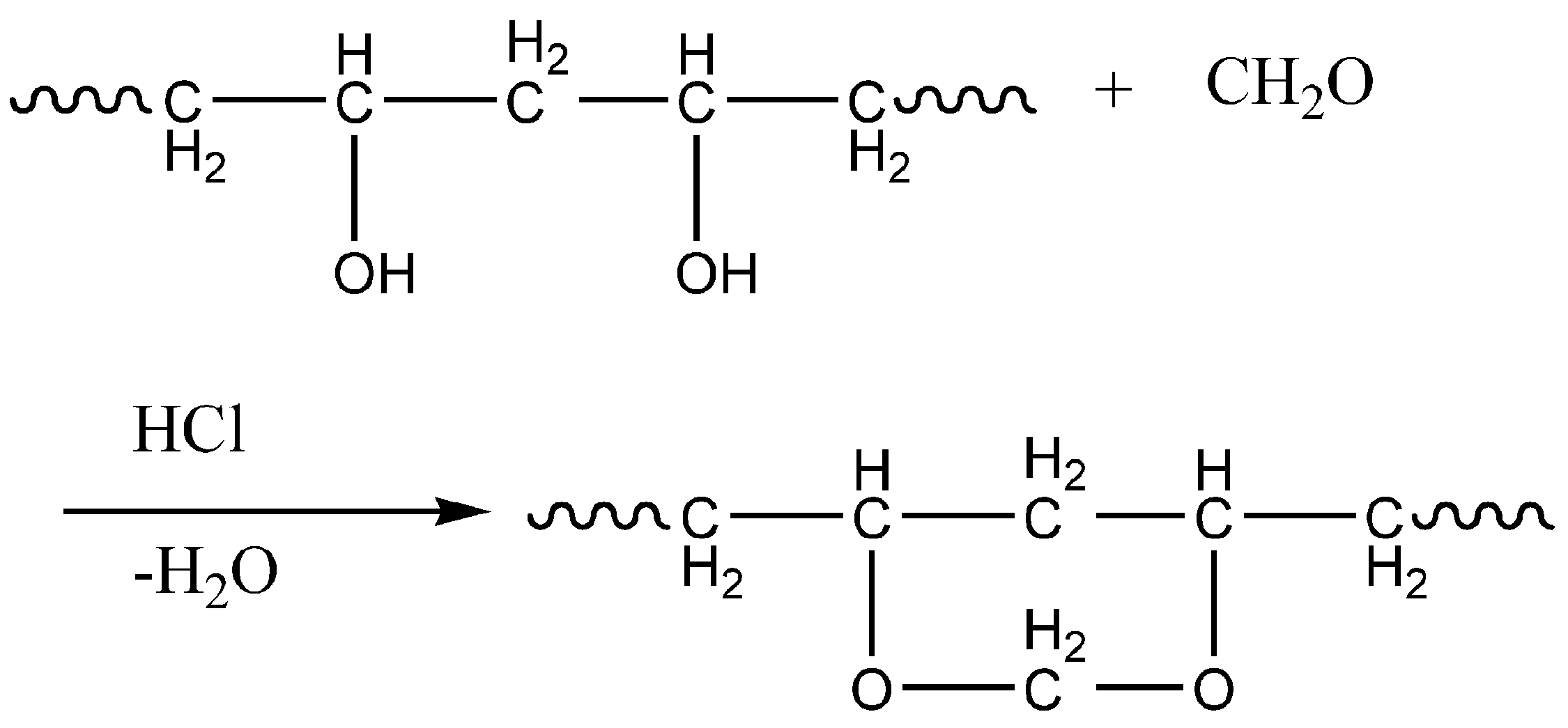

3.1. Molecular Structural Characterization of PVF

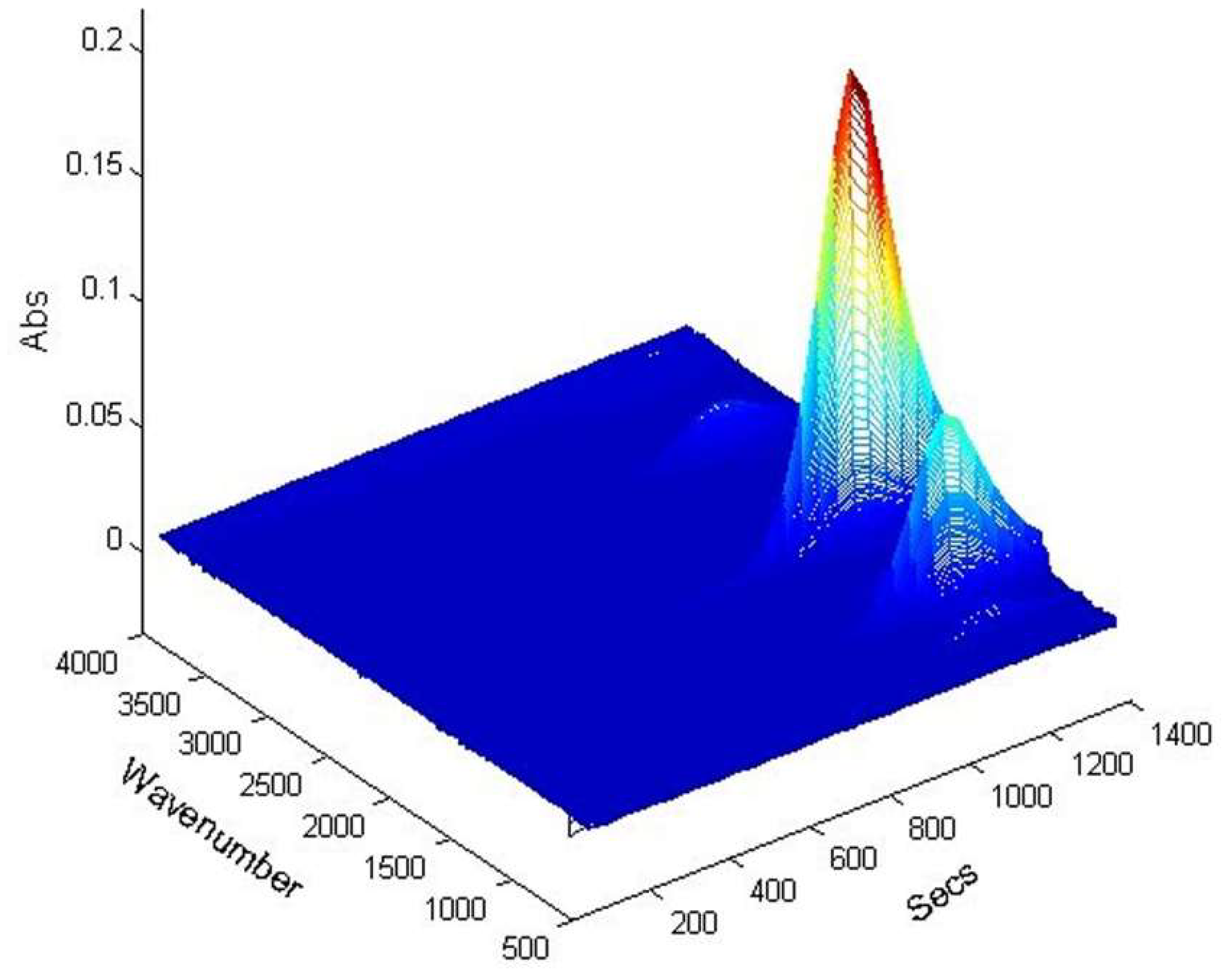

3.2. Thermal Properties of PVF

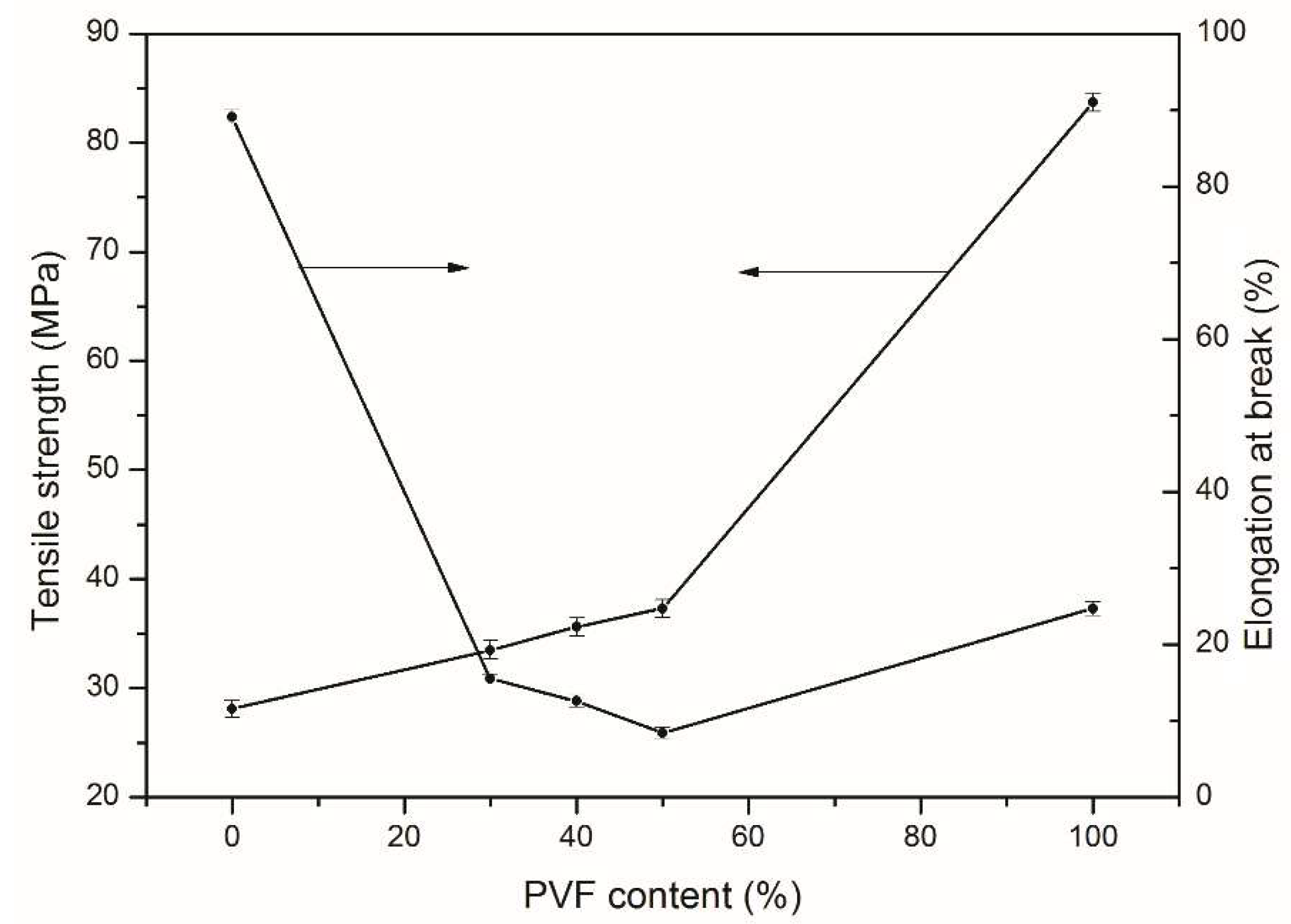

3.3. Mechanical Properties of PPC/PVF Blends

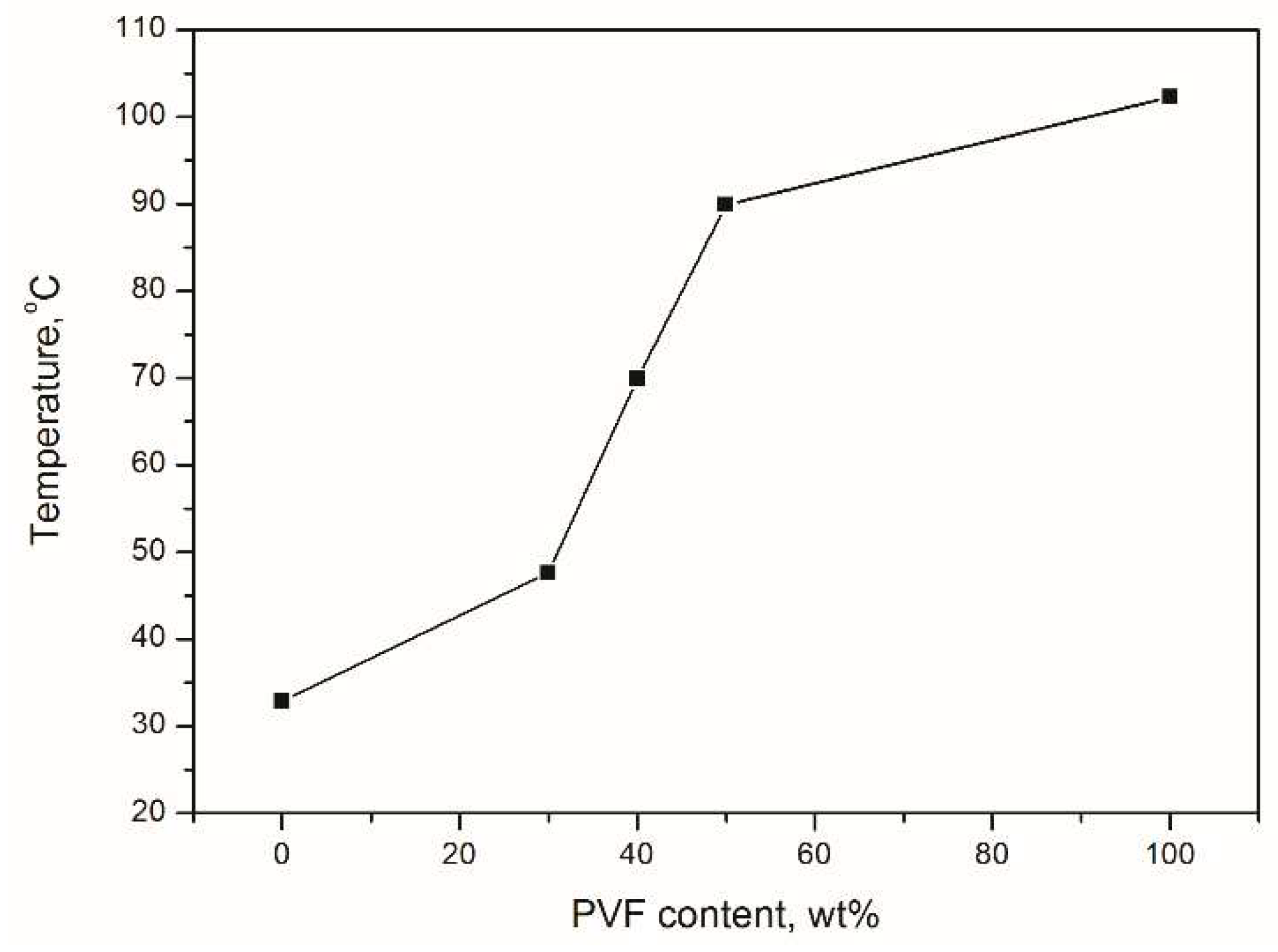

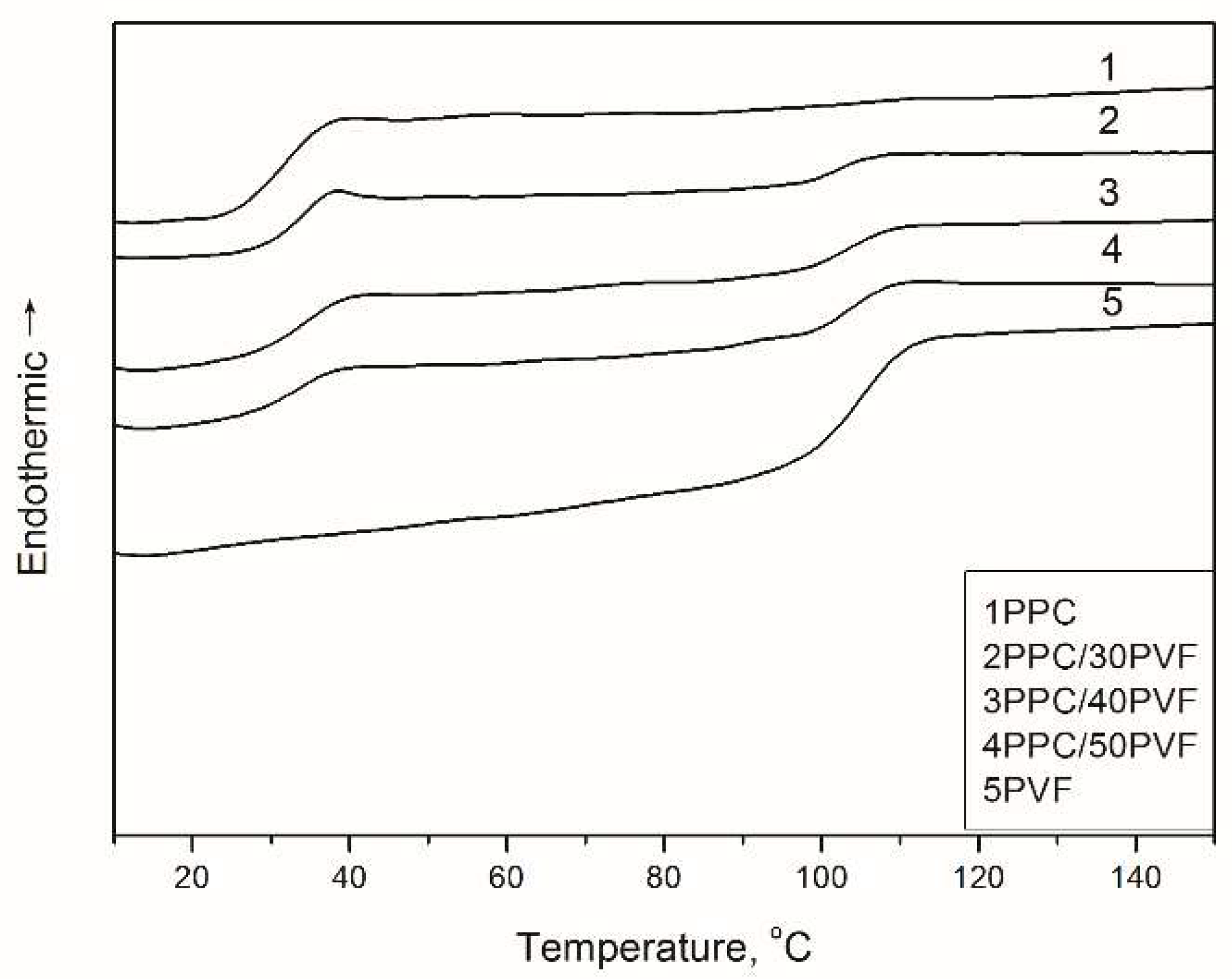

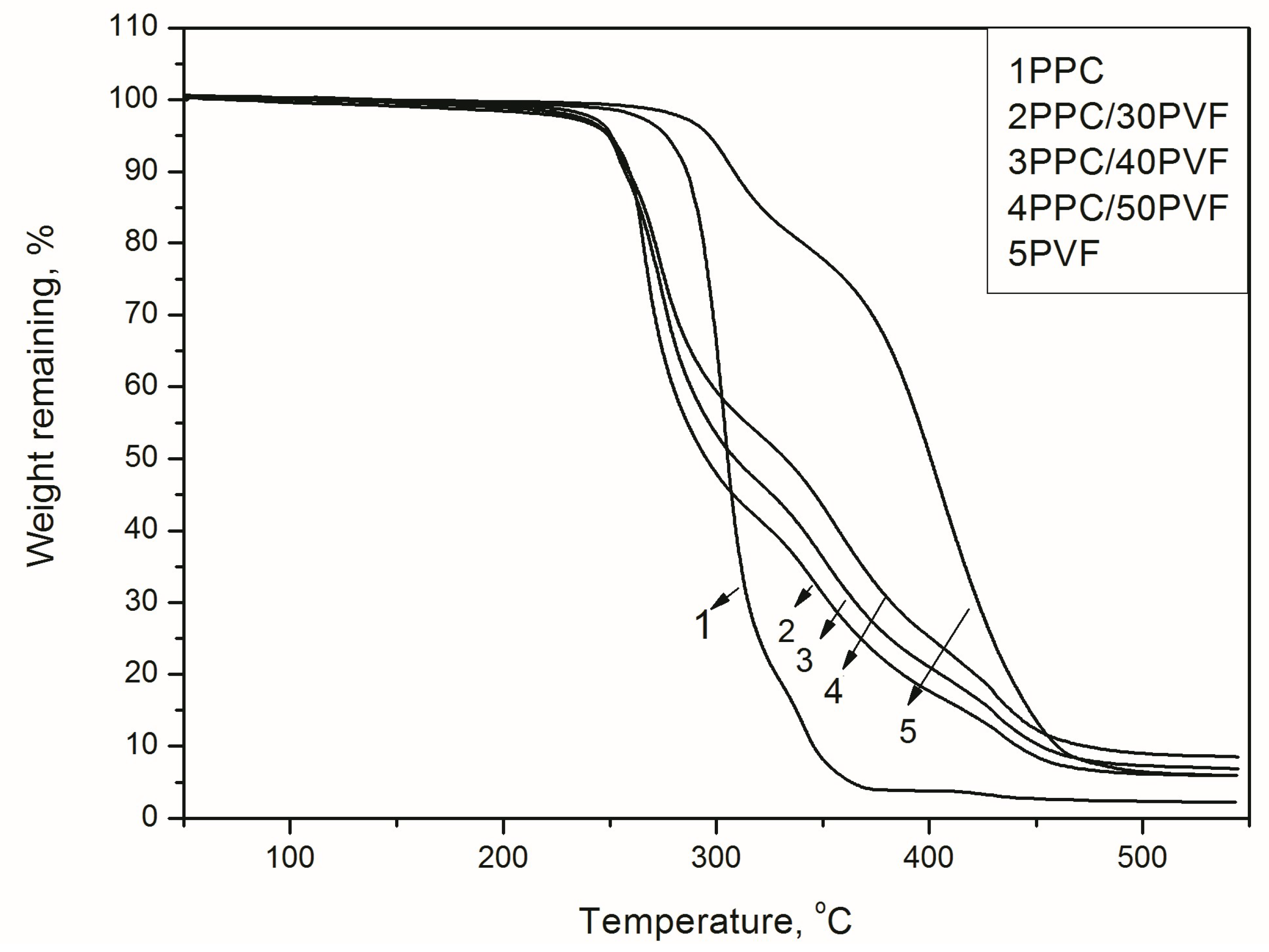

3.4. Thermal Properties of PPC/PVF Blends

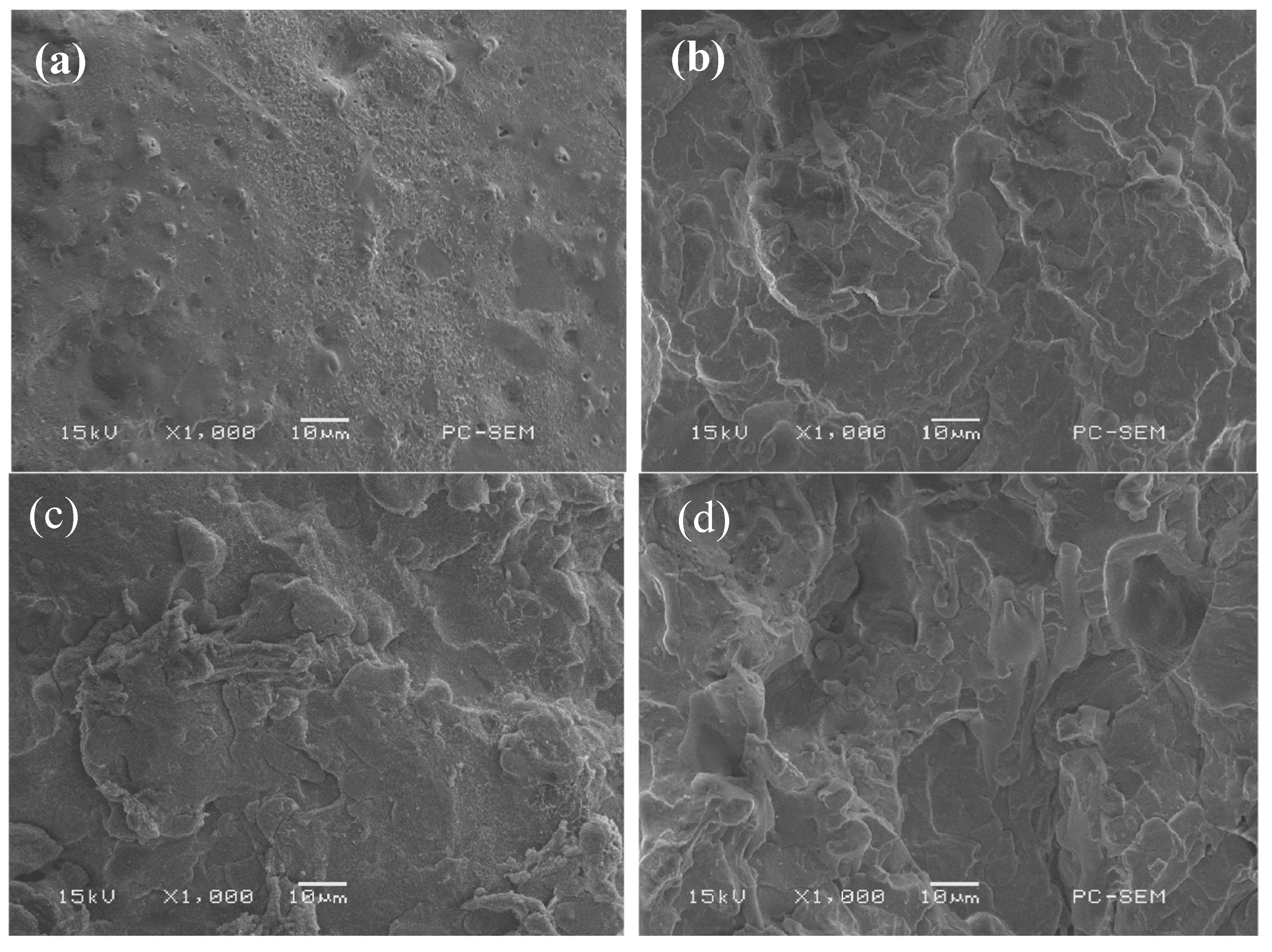

3.5. Microstructure of PVF/PPC Blends

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Xu, Y.H.; Lin, L.M.; Xiao, M.; Wang, S.J.; Smith, A.T.; Sun, L.Y.; Meng, Y.Z. Synthesis and properties of CO2-based plastics: Environmentally-friendly, energy-saving and biomedical polymeric materials. Prog. Polym. Sci. 2018, 80, 163–182. [Google Scholar] [CrossRef]

- Chen, X.; Shen, Z.; Zhang, Y. New catalytic systems for the fixation of carbon dioxide. 1. Copolymerization of carbon dioxide and propylene oxide with new rare-earth catalysts-RE(P204)3-Al(i-Bu)3-R(OH)n. Macromolecules 1991, 24, 5305–5308. [Google Scholar]

- Eastmond, G.C.; Gibas, M.; Paprotny, J. Pendant adamantyl poly(ether imide)s: Synthesis and a preliminary study of properties. Eur. Polym. J. 1999, 35, 2097–2106. [Google Scholar] [CrossRef]

- Kuran, W.; Górecki, P. Degradation and depolymerization of poly(propylene carbonate) by diethylzinc. Die Makromol. Chem. 1983, 184, 907–912. [Google Scholar] [CrossRef]

- Kuran, W.; Listoś, T. Initiation and propagation reactions in the copolymerization of epoxide with carbon dioxide by catalysts based on diethylzinc and polyhydric phenol. Macromol. Chem. Phys. 1994, 195, 977–984. [Google Scholar] [CrossRef]

- Lee, S.-H.; Ohkita, T.; Kitagawa, K. Eco-composite from poly(lactic acid) and bamboo fiber. Holzforschung 2004, 58, 529–536. [Google Scholar] [CrossRef]

- Meehl, G.A.; Washington, W.M. El Niño-like climate change in a model with increased atmospheric CO2 concentrations. Nature 1996, 382, 56–60. [Google Scholar] [CrossRef]

- Nishimura, M.; Kasai, M.; Tsuchida, E. Copolymerization of carbon dioxide with propylene oxide catalyzed by poly(p-hydroxystyrene)/diethylzinc system. Die Makromol. Chem. 1978, 179, 1913–1920. [Google Scholar] [CrossRef]

- Qiu, Z.; Komura, M.; Ikehara, T.; Nishi, T. DSC and TMDSC study of melting behaviour of poly(butylene succinate) and poly(ethylene succinate). Polymer 2003, 44, 7781–7785. [Google Scholar] [CrossRef]

- Meng, Y.Z.; Du, L.C.; Tiong, S.C.; Zhu, Q.; Hay, A.S. Effects of the structure and morphology of zinc glutarate on the fixation of carbon dioxide into polymer. J. Polym. Sci. Polym. Chem. 2002, 40, 3579–3591. [Google Scholar] [CrossRef]

- Wang, S.J.; Du, L.C.; Zhao, X.S.; Meng, Y.Z.; Tjong, S.C. Synthesis and characterization of alternating copolymer from carbon dioxide and propylene oxide. J. Appl. Polym. Sci. 2002, 85, 2327–2334. [Google Scholar] [CrossRef]

- Chen, X.; Wang, S.; Xiao, M.; Han, D.; Meng, Y. Miscibility, properties and morphology of biodegradable blends of UHMW-PPC/PVA/EVOH. J. Polym. Res. 2011, 18, 715–720. [Google Scholar] [CrossRef]

- Chen, G.J.; Wang, Y.Y.; Wang, S.J.; Xiao, M.; Meng, Y.Z. Orientation microstructure and properties of poly(propylene carbonate)/poly(butylene succinate) blend films. J. Appl. Polym. Sci. 2013, 128, 390–399. [Google Scholar] [CrossRef]

- Jiao, J.; Wang, S.J.; Xiao, M.; Xu, Y.; Meng, Y.Z. Processability, property, and morphology of biodegradable blends of poly(propylene carbonate) and poly(ethylene-co-vinyl alcohol). Polym. Eng. Sci. 2007, 47, 174–180. [Google Scholar] [CrossRef]

- Lu, X.L.; Du, F.G.; Ge, X.C.; Xiao, M.; Meng, Y.Z. Biodegradability and thermal stabilityof poly(propylene carbonate)/starch composites. J. Biomed. Mater. Res. Part A 2006, 77A, 653–658. [Google Scholar] [CrossRef] [PubMed]

- Pang, M.Z.; Qiao, J.J.; Jiao, J.; Wang, S.J.; Xiao, M.; Meng, Y.Z. Miscibility and properties of completely biodegradable blends of poly(propylene carbonate) and poly(butylene succinate). J. Appl. Polym. Sci. 2006, 107, 2854–2860. [Google Scholar] [CrossRef]

- Wang, X.L.; Du, F.G.; Jiao, J.; Meng, Y.Z.; Li, R.K.Y. Preparation and properties of biodegradable polymeric blends from poly(propylene carbonate) and poly(ethylene-co-vinyl alcohol). J. Biomed. Mater. Res. Part B 2007, 83, 373–379. [Google Scholar] [CrossRef] [PubMed]

- Chuang, W.-Y.; Young, T.-H.; Yao, C.-H.; Chiu, W.-Y. Properties of the poly(vinyl alcohol)/chitosan blend and its effect on the culture of fibroblast in vitro. Biomaterials 1999, 20, 1479–1487. [Google Scholar] [CrossRef]

- Haralabakopoulos, A.A.; Tsiourvas, D.; Paleos, C.M. Modification of poly(vinyl alcohol) polymers by aliphatic carboxylic acids via reactive blending. J. Appl. Polym. Sci. 1998, 69, 1885–1890. [Google Scholar] [CrossRef]

- López, D.; Cendoya, I.; Torres, F.; Tejada, J.; Mijangos, C. Preparation and characterization of poly(vinyl alcohol)-based magnetic nanocomposites. 1. Thermal and mechanical properties. J. Appl. Polym. Sci. 2001, 82, 3215–3222. [Google Scholar]

- Mühlebach, A.; Müller, B.; Pharisa, C.; Hofmann, M.; Seiferling, B.; Guerry, D. New water-soluble photo crosslinkable polymers based on modified poly(vinyl alcohol). J. Polym. Sci. Polym. Chem. 1997, 35, 3603–3611. [Google Scholar] [CrossRef]

- Nishimura, H.; Donkai, N.; Miyamoto, T. Preparation and thermal properties of thermoplastic poly(vinyl alcohol) complexes with boronic acids. J. Polym. Sci. Polym. Chem. 1998, 36, 3045–3050. [Google Scholar] [CrossRef]

- Peesan, M.; Rujiravanit, R.; Supaphol, P. Characterisation of beta-chitin/poly(vinyl alcohol) blend films. Polym. Test. 2003, 22, 381–387. [Google Scholar] [CrossRef]

- Chetri, P.; Dass, N.N. Preparation of poly(vinyl formal) of high acetalization. Polymer 1997, 38, 3951–3956. [Google Scholar] [CrossRef]

- Chetri, P.; Dass, N.N. Preparation of poly(vinyl butyral) with high acetalization rate. J. Appl. Polym. Sci. 2001, 81, 1182–1186. [Google Scholar] [CrossRef]

- Bastida, S.; Eguiazábal, J.I.; Nazábal, J. The Vicat softening temperature as a method to assess the phase behaviour of amorphous polymer blends. Polym. Test. 1993, 12, 233–242. [Google Scholar] [CrossRef]

- Sugimoto, H.; Inoue, S. Copolymerization of carbon dioxide and epoxide. J. Polym. Sci. Polym. Chem. 2004, 42, 5561–5573. [Google Scholar] [CrossRef]

| PPC/PVF | Tg (°C) | T-5% (°C) | T-10% (°C) | Tmax (°C) | |

|---|---|---|---|---|---|

| 100/0 | 32.2 | / a | 257.9 | 275.3 | 284.0 |

| 70/30 | 33.6 | 102.5 | 250.2 | 259.1 | 267.1 |

| 60/40 | 34.2 | 103.9 | 249.4 | 257.0 | 275.7 |

| 50/50 | 34.4 | 104.3 | 249.3 | 258.7 | 273.6 |

| 0/100 | / a | 104.9 | 296.5 | 308.0 | 411.6 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, D.; Guo, Z.; Chen, S.; Xiao, M.; Peng, X.; Wang, S.; Meng, Y. Enhanced Properties of Biodegradable Poly(Propylene Carbonate)/Polyvinyl Formal Blends by Melting Compounding. Polymers 2018, 10, 771. https://doi.org/10.3390/polym10070771

Han D, Guo Z, Chen S, Xiao M, Peng X, Wang S, Meng Y. Enhanced Properties of Biodegradable Poly(Propylene Carbonate)/Polyvinyl Formal Blends by Melting Compounding. Polymers. 2018; 10(7):771. https://doi.org/10.3390/polym10070771

Chicago/Turabian StyleHan, Dongmei, Zhen Guo, Shou Chen, Min Xiao, Xiaohua Peng, Shuanjin Wang, and Yuezhong Meng. 2018. "Enhanced Properties of Biodegradable Poly(Propylene Carbonate)/Polyvinyl Formal Blends by Melting Compounding" Polymers 10, no. 7: 771. https://doi.org/10.3390/polym10070771

APA StyleHan, D., Guo, Z., Chen, S., Xiao, M., Peng, X., Wang, S., & Meng, Y. (2018). Enhanced Properties of Biodegradable Poly(Propylene Carbonate)/Polyvinyl Formal Blends by Melting Compounding. Polymers, 10(7), 771. https://doi.org/10.3390/polym10070771