Wood-PHA Composites: Mapping Opportunities

Abstract

1. Introduction

2. PHA and Wood-PHA Composites

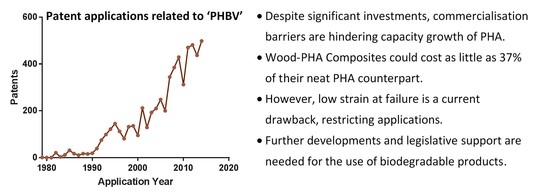

2.1. PHA and Its Commercialisation

2.2. Wood-PHA Composites as Novel WPCs

3. Markets and Production Capacities for Wood-PHA Composites

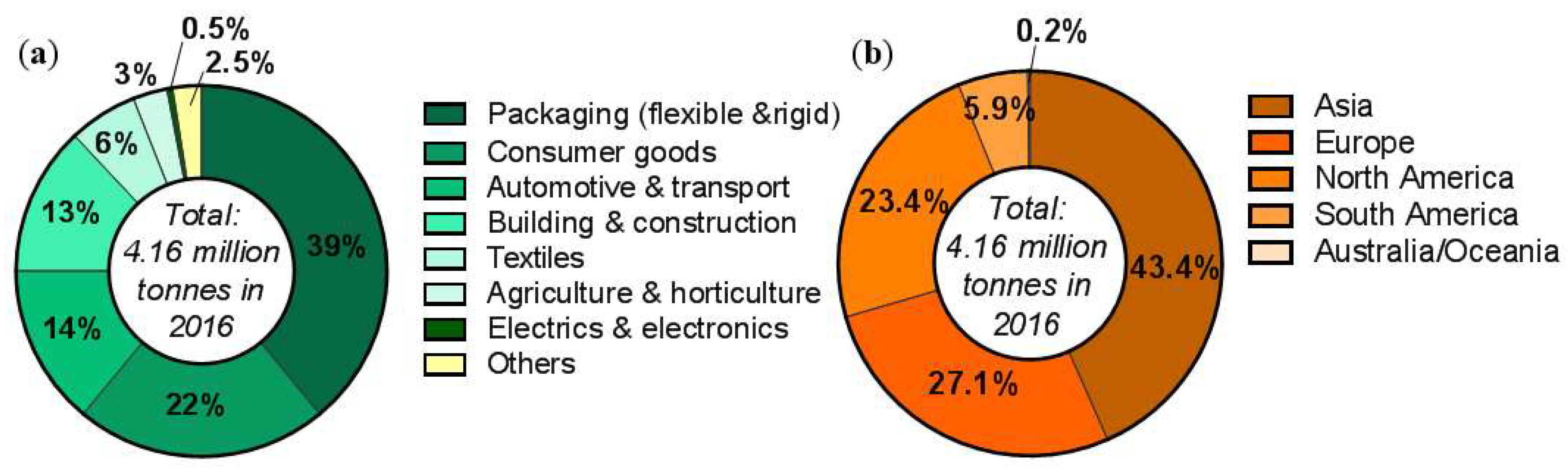

3.1. Applications and Markets for Wood-PHA Composites

3.2. Production Capacities for PHA and Wood-PHA Composites

4. Economic Assessment of Wood-PHA Composites

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Plastic Europe (PEMRG). Plastics—The Facts 2016. An Analysis of European Latest Plastics Production, Demand and Waste Data. Available online: https://www.plasticseurope.org/application/files/4315/1310/4805/plastic-the-fact-2016.pdf (accessed on 7 August 2017).

- Gourmelon, G. Global Plastic Production Rises, Recycling Lags—New Worldwatch Institute Analysis Explores Trends in Global Plastic Consumption and Recycling. Available online: http://www.worldwatch.org/global-plastic-production-rises-recycling-lags-0 (accessed on 14 August 2017).

- Aeschelmann, F.; Carus, M. Bio-Based Building Blocks and Polymers. Global Capacities and Trends 2016–2021; Nova Institute: Hürth, Germany, 2016. [Google Scholar]

- Zion Research Analysis 2015. Global Wood-Plastic Composites Market Set for Rapid Growth, to Reach around Usd 6.0 Billion by 2020. Available online: http://www.marketresearchstore.com/news/global-wood-plastic-composites-market-set-for-rapid-101 (accessed on 14 August 2017).

- Dietrich, K.; Dumont, M.-J.; Del Rio, L.F.; Orsat, V. Producing phas in the bioeconomy—Towards a sustainable bioplastic. Sustain. Prod. Consump. 2016. [Google Scholar] [CrossRef]

- Tan, G.-Y.; Chen, C.-L.; Li, L.; Ge, L.; Wang, L.; Razaad, I.; Li, Y.; Zhao, L.; Mo, Y.; Wang, J.-Y. Start a research on biopolymer polyhydroxyalkanoate (PHA): A review. Polymers 2014, 6, 706–754. [Google Scholar] [CrossRef]

- Singh Saharan, B.; Grewal, A.; Kumar, P. Biotechnological production of polyhydroxyalkanoates: A review on trends and latest developments. Chin. J. Biol. 2014, 2014, 802984. [Google Scholar] [CrossRef]

- Bartczak, Z.; Galeski, A.; Kowalczuk, M.; Sobota, M.; Malinowski, R. Tough blends of poly(lactide) and amorphous poly([R,S]-3-hydroxy butyrate)—Morphology and properties. Eur. Polym. J. 2013, 49, 3630–3641. [Google Scholar] [CrossRef]

- Ten, E.; Jiang, L.; Zhang, J.; Wolcott, M.P. 3—Mechanical performance of polyhydroxyalkanoate (PHA)-based biocomposites A2—Misra, manjusri. In Biocomposites; Pandey, J.K., Mohanty, A.K., Eds.; Woodhead Publishing: Sawston/Cambridge, UK, 2015; pp. 39–52. [Google Scholar]

- DiGregorio, B.E. Biobased performance bioplastic: Mirel. Chem. Biol. 2009, 16, 1–2. [Google Scholar] [CrossRef] [PubMed]

- United Nations Environment Programme. Plastic Waste Causes Financial Damage of US$13 Billion to Marine Ecosystems Each Year as Concern Grows Over Microplastics. Available online: http://www.unep.org/NewsCentre/default.aspx?DocumentID=2791&ArticleID=10903 (accessed on 14 August 2017).

- Christensen, C.M. The Innovator’s Dilemma: When New Technologies Cause Great Firms to Fail; Harvard Business School Press: Boston, MA, USA, 1997. [Google Scholar]

- Clemons, C. Wood-plastic composites in the united states: The interfacing of two industries. For. Prod. J. 2002, 52, 10–18. [Google Scholar]

- Chan, C.M.; Vandi, L.-J.; Pratt, S.; Halley, P.; Richardson, D.; Werker, A.; Laycock, B. Composites of wood and biodegradable thermoplastics: A review. Polym. Rev. 2017, 58, 444–494. [Google Scholar] [CrossRef]

- Singh, S.; Mohanty, A.K.; Sugie, T.; Takai, Y.; Hamada, H. Renewable resource based biocomposites from natural fiber and polyhydroxybutyrate-co-valerate (PHBV) bioplastic. Compos. Part A Appl. Sci. Manuf. 2008, 39, 875–886. [Google Scholar] [CrossRef]

- Thumm, A.; Dickson, A.; Warnes, J.; Even, D.; Fernyhough, A.; Markotsis, M. The use of pulp fibres for the production of wood/plastic composites. In Proceedings of the 65th Appita Annual Conference and Exhibition, Rotorua, New Zealand, 10–13 April 2011; Conference Technical Papers. Appita Inc.: Carlton, Australia, 2011. [Google Scholar]

- JELU-WERK. Bioplastic from Jelu. Available online: https://www.jeluplast.com/en/ (accessed on 21 August 2017).

- JELU-WERK. PC PE H70-800-0 Product Data Sheet. 2013, p. 2. Available online: https://www.jeluplast.com/wp-content/uploads/2013/09/WPC-PE-H70-800-03.pdf (accessed on 21 August 2017).

- Schirp, A. Recycling Material from Wood-Plastic Composites (WPC), Fraunhofer Institute for Wood Research. Available online: https://www.wki.fraunhofer.de/en/departments/vst/profile/research-projects/wpc-recycling.html (accessed on 7 August 2017).

- Chan, C.; Vandi, L.-J.; Pratt, S.; Halley, P.; Richardson, D.; Werker, A.; Laycock, B. Processing and characterisation of polyhydroxyalkanoate (PHA)-based wood plastic composites: Effect of non-reactive additives. Appita J. 2016, 69, 352–360. [Google Scholar]

- Chan, C.M.; Vandi, L.J.; Pratt, S.; Halley, P.; Richardson, D.; Werker, A.; Laycock, B. Mechanical performance and long-term indoor stability of polyhydroxyalkanoate (PHA)-based wood plastic composites (WPCS) modified by non-reactive additives. Eur. Polym. J. 2018, 98, 337–346. [Google Scholar] [CrossRef]

- Chan, C.M.; Johansson, P.; Magnusson, P.; Vandi, L.J.; Arcos-Hernandez, M.; Halley, P.; Laycock, B.; Pratt, S.; Werker, A. Mixed culture polyhydroxyalkanoate-rich biomass assessment and quality control using thermogravimetric measurement methods. Polym. Degrad. Stab. 2017, 144, 110–120. [Google Scholar] [CrossRef]

- Chan, C.; Vandi, L.; Pratt, S.; Halley, P.; Richardson, D.; Werker, A.; Laycock, B. Processing and characterisation of polyhydroxyalkanoate (PHA)-based wood plastic composites: Effect of non-reactive additives. In Proceedings of the Fibre Value Chain Conference and Expo 2016: Pulp and Paper Bioenergy Bioproducts, Rotorua, New Zealand, 12–14 October 2016; pp. 57–66. [Google Scholar]

- European Bioplastics. Bioplastics Market Data. Available online: http://www.european-bioplastics.org/market/ (accessed on 7 August 2017).

- European Bioplastics. Applications for Bioplastics. Available online: http://www.european-bioplastics.org/market/applications-sectors/ (accessed on 14 August 2017).

- Carus, M.; Eder, A.; Korte, H. European and global markets 2012 and future trends. Bioplastics Mag. 2014. [Google Scholar]

- Carus, M.; Eder, A.; Dammer, L.; Korte, H.; Scholtz, L.; Essel, R.; Breitmayer, E.; Barth, M. Wood-Plastic Composites (WPC) and Natural Fibre Composites (NFC); Nova-Institute: Hürth, Germany, 2015; p. 16. [Google Scholar]

- Nastu, P. Italy Carries Out Plastic Bag Ban; Environmental Leader 06/01/2011; 2011. Available online: https://www.environmentalleader.com/2011/01/italy-carries-out-plastic-bag-ban/ (accessed on 22 August 2017).

- Kaeb, H.; Aeschelmann, F.; Dammer, L.; Carus, M. Market Study on the Consumption of Biodegradable and Compostable Plastic Products in Europe 2015 and 2020; Nova-Institute: Hürth, Germany, 2016; p. 6. [Google Scholar]

- Eastaugh, S. France Becomes First Country to Ban Plastic Cups and Plates. Available online: http://edition.cnn.com/2016/09/19/europe/france-bans-plastic-cups-plates/ (accessed on 20 September 2016).

- Williams, H. IKEA and Newlight Sign Major Partnership Agreement. Available online: https://www.biobasedworldnews.com/huge-investment-as-ikea-newlight-sign-10-billion-pounds-biotechnology-production-licence (accessed on 7 July 2016).

- Eder, A.; Carus, M. Global trends in wood-plastic composites (WPC). Bioplastics Mag. 2013, 8, 16–17. [Google Scholar]

- PlastEurope. Collaboration with Newlight Technologies on “Aircarbon” Methane-Based Biopackaging. Available online: https://www.plasteurope.com/news/detail.asp?id=233308 (accessed on 11 February 2016).

- Bio-On S.p.A. Flos to be World’s First Company to Use Revolutionary Bioplastic Designed by Bio-On. Available online: http://www.bio-on.it/project.php?lin=portoghese (accessed on 7 August 2017).

- Bio-On S.p.A. Revolution in Food Packaging. The Milk Carton Goes Bio. Available online: http://www.bio-on.it/news.php?lin=inglese (accessed on 14 April 2016).

- Lyons Hardcastle, J. Will Lego’s $150 Million Sustainable Plastics Challenge Make Biobased the Norm? Available online: https://www.environmentalleader.com/2016/06/will-legos-150-million-sustainable-plastics-challenge-make-biobased-the-norm/ (accessed on 20 June 2016).

- Arcos-Hernández, M.; Montaño-Herrera, L.; Murugan Janarthanan, O.; Quadri, L.; Anterrieu, S.; Hjort, M.; Alexandersson, T.; Karlsson, A.; Karabegovic, L.; Magnusson, P.; et al. Value-added bioplastics from services of wastewater treatment. Water Pract. Technol. 2015, 10, 546–555. [Google Scholar]

- Bengtsson, S.; Werker, A.; Visser, C.; Korving, L. Stepping Stone to a Value Chain for Pha Bioplastic Using Municipal Activated Sludge; STOWA: Amersfoort, The Netherlands, 2017. [Google Scholar]

- Nikodinovic-Runic, J.; Guzik, M.; Kenny, S.T.; Babu, R.; Werker, A.; O Connor, K.E. Chapter four—Carbon-rich wastes as feedstocks for biodegradable polymer (polyhydroxyalkanoate) production using bacteria. In Advances in Applied Microbiology; Sariaslani, S., Gadd, G.M., Eds.; Academic Press: Cambridge, MA, USA, 2013; Volume 84, pp. 139–200. [Google Scholar]

- Valentino, F.; Morgan-Sagastume, F.; Campanari, S.; Villano, M.; Werker, A.; Majone, M. Carbon recovery from wastewater through bioconversion into biodegradable polymers. New Biotechnol. 2017, 37, 9–23. [Google Scholar] [CrossRef] [PubMed]

- Newlight Technologies/Paques. Newlight Technologies Signs 15-Year Production License Agreement with Paques Holdings BV. Available online: https://www.newlight.com/newlight-technologies-signs-15-year-production-license-agreement-with-paques-holdings-bv/ (accessed on 6 July 2016).

- Anjum, A.; Zuber, M.; Zia, K.M.; Noreen, A.; Anjum, M.N.; Tabasum, S. Microbial production of polyhydroxyalkanoates (PHAS) and its copolymers: A review of recent advancements. Int. J. Biol. Macromol. 2016, 89, 161–174. [Google Scholar] [CrossRef] [PubMed]

- Smock, D. Meredian Christens World’s Largest PHA Bioplastic Plant. Available online: http://www.themoldingblog.com/2012/10/26/meredian-christens-worlds-largest-pha-bioplastic-plant/ (accessed on 26 October 2012).

- Eagle, J. Bio-On and Cristal Union to Open ‘World First’ Advanced Biopolymer Plant as Terraverdae Bioworks Scales Up Commercial Production of Its PHA Bioplastics. Available online: http://www.bakeryandsnacks.com/Processing-Packaging/Bio-on-and-Cristal-Union-World-first-advanced-biopolymer-plant (accessed on 7 August 2017).

- Bio-On S.p.A. Bio-On Announces New Multi-License Maxi Agreement for Revolutionary PHAS Bioplastic. Available online: http://www.bio-on.it/news.php (accessed on 22 December 2016).

- Tianjin GreenBio Materials Co. Ltd. Enterprise Introduction. Available online: http://www.tjgreenbio.com/en/about.aspx?title=Enterprise%20Introduction&cid=25 (accessed on 14 August 2017).

- Bio Plastics Info. Companies Producing PHA for Bioplastics and Using PHA in Applications. Available online: http://bioplasticsinfo.com/polyhydroxy-alkonates/companies-concerned/ (accessed on 21 August 2017).

- TianAn Biopolymer. Tanan Biopolmer Enmat Company Details. 2012. Available online: http://www.tianan-enmat.com/# (accessed on 8 August 2017).

- PolyFerm Canada. Applications of PHAS. Available online: http://www.polyfermcanada.com/pha_applications.html (accessed on 21 August 2017).

- Peptu, C.; Kowalczuk, M. 8—Biomass-derived polyhydroxyalkanoates: Biomedical applications. In Biomass as Renewable Raw Material to Obtain Bioproducts of High-Tech Value; Popa, V., Volf, I., Eds.; Elsevier: New York, NY, USA, 2018; pp. 271–313. [Google Scholar]

- Brum, L. Metabolix Completes $10 Million Sale of Biopolymer Assets to CJ Cheiljedang. Available online: https://globenewswire.com/news-release/2016/09/19/872954/0/en/Metabolix-Completes-10-Million-Sale-of-Biopolymer-Assets-to-CJ-CheilJedang.html (accessed on 19 September 2016).

- Koller, M.; Maršálek, L.; de Sousa Dias, M.M.; Braunegg, G. Producing microbial polyhydroxyalkanoate (pha) biopolyesters in a sustainable manner. New Biotechnol. 2016, 37, 24–38. [Google Scholar] [CrossRef] [PubMed]

- De Biagio, F. PHB Industrial Seeking Partner for Biopolymer Production. Available online: http://www.bnamericas.com/en/news/petrochemicals/PHB_Industrial_seeking_partner_for_biopolymer_production (accessed on 7 August 2017).

- BioCycle. Biocycle Website. Available online: http://www.biocycle.com.br/site.htm (accessed on 7 August 2017).

- Lane, J. Terraverdae Bioworks, Alberta Innovates Bio Solutions Hit Milestone in Scale-Up of Bioplastic Technology. Available online: http://www.biofuelsdigest.com/bdigest/2015/07/30/terraverdae-bioworks-alberta-innovates-bio-solutions-hit-milestone-in-scale-up-of-bioplastic-technology/ (accessed on 30 July 2015).

- Lane, J. Microbeads. Reviled, Yes. Useful, Yes. What’s the Alternative? Available online: http://www.biofuelsdigest.com/bdigest/2016/08/24/microbeads-reviled-yes-useful-yes-whats-the-alternative/ (accessed on 24 August 2016).

- Bio-Based News. Malaysia’s Pioneer Bioplastics Pilot Plant is Operational. Available online: http://news.bio-based.eu/malaysias-pioneer-bioplastics-pilot-plant-is-operational/ (accessed on 21 August 2017).

- Choi, J.-I.; Lee, S.Y. Process analysis and economic evaluation for poly(3-hydroxybutyrate) production by fermentation. Bioprocess Eng. 1997, 17, 335–342. [Google Scholar] [CrossRef]

- Mudliar, S.N.; Vaidya, A.N.; Suresh Kumar, M.; Dahikar, S.; Chakrabarti, T. Techno-economic evaluation of phb production from activated sludge. Clean Technol. Environ. Policy 2007, 10, 255. [Google Scholar] [CrossRef]

- Volova, T.G. Polyhydroxyalkanoates—Plastic Materials of the 21st Century: Production, Properties, Applications/Tatiana Volova; Nova Science Publishers: Hauppauge, NY, USA, 2004. [Google Scholar]

- Granta Design Ltd. Cambridge Engineering Selector CES Edupack; Granta Design Ltd.: Cambridge, UK, 2017. [Google Scholar]

| Tensile Strength 1 (MPa) | Tensile Modulus 1 (GPa) | Strain at Failure 1 (%) | Impact Strength 2 (kJ/m2) | |

|---|---|---|---|---|

| Pure PHA: Commercially available | ||||

| PHBV ENMATTM Y1000 (2% HV content) | 30 | 2.8 | 8.0 | - |

| WPCs: In development | ||||

| Wood-PHA Composites (PHBV + 50% wood content) | 27 | 6.1 | 1.0 | 4.0 |

| WPCs: Commercially available | ||||

| FKUR—Fibrolon® P7550 (PP + 50% wood content) | 22 | 3.3 | 3.0 | 7.9 |

| FKUR—Fibrolon® F8530 (PLA + 50% wood content) | 34 | 3.8 | 3.8 | 11.7 |

| Jeluplast—PP H50-500-14 (PP + 50% wood content) | 32 | 4.5 | 1.9 | 10.6 |

| Company | Country | Capacity (t/year) | Feedstock | Brand Name | PHA Type | Refs |

|---|---|---|---|---|---|---|

| Newlight Technologies | USA | 23,000 | Biogas and CO2 | AirCarbon™ | n.r. | [5,31] |

| Danimer Scientific (previously MHG) | USA | 13,600 | Canola oil | Nodax™ | n.r. | [5,43] |

| Bio-On | Italy | 10,000 | Sugar beet and cane | Minerv® | PHB, PHBV | [47,52] |

| Tianjin GreenBio Materials | China | 10,000 | Sugars | SoGreen™ | P(3HB-co-4HB) | [46] |

| Ecomann Biotechnology | China | 3000 | Sugars | AmBio® | n.r. | [47] |

| TianAn Biopolymers | China | 2000 | Corn Sugar | ENMAT™ | P3HB, PHBV | [48] |

| Kaneka | Japan | 1000 | Vegetable oil | Aonilex® | PHH | [47] |

| PHB Industrial S. A. | Brazil | 500 | Sugar cane | Biocycle® | P3HB, PHBV | [52,53,54] |

| Biomer | Germany | 500 | Corn starch | Biomer® | P3HB | [52] |

| Tepha Inc. | USA | <10 | Sugars, 4HB precursors | TephaFLEX® | P4HB, P(3HB-co-4HB) | [5,52] |

| PolyFerm Canada | Canada | <10 | Vegetable oils, sugars | VersaMerTM | PHOHHx, PHNHHp, | [5,52] |

| Terra Verdae Bioworks | Canada | n.r | Methanol | - | n.r | [55] |

| Yield10 Bioscience (previously, Metabolix 1, Monsanto, Zeneca) | USA | n.r. | Corn sugar | Mirel™ | P3HB | [5,10] |

| Mango Materials | USA | n.r | Methane | - | PHB | [56] |

| SIRIM | Malaysia | n.r. | Palm Oil | - | n.r. | [57] |

| Neat PHA Product | Standard Wood-PHA Composite Product | Low PHA-Content Wood-PHA Composite Product | |

|---|---|---|---|

| Materials | |||

| Composition of raw material by weight | 100 wt % PHA | 50 wt % PHA 50 wt % wood fibres | 40 wt % PHA 60 wt % fibres |

| Cost of raw material (US$/kg) | 7 US$/kg | 3.7 US$/kg (53% of initial cost) | 3.0 US$/kg (43% of initial cost) |

| Final Product | |||

| Density of raw material (g/cm3) | 1.25 g/cm3 | 1.11 g/cm3 | 1.08 g/cm3 |

| Composition of final product by volume | 100 vol % PHA | 44.4 vol % PHA 55.6 vol % wood fibres | 34.8 vol % PHA 65.2 vol % wood fibres |

| Cost of a final product of equal volume (800 cm3) | 7 US$ | 3.3 US$ (47% of neat PHA cost) | 2.6 US$ (37% of neat PHA cost) |

| Cost of a final product of equal stiffness | 7 US$ | 1.5 US$ (21% of neat PHA cost) | <1.5 US$ |

| Specific Tensile Strength (kN·m/kg) | Specific Tensile Modulus (MN·m/kg) | Specific Strain at Failure (%·m3/kg) | |

|---|---|---|---|

| PHA ENMATTM | 24 | 2.2 | 6.4 |

| Wood-PHA Composites (PHBV + 50% wood content) | 24 | 5.5 | 0.9 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vandi, L.-J.; Chan, C.M.; Werker, A.; Richardson, D.; Laycock, B.; Pratt, S. Wood-PHA Composites: Mapping Opportunities. Polymers 2018, 10, 751. https://doi.org/10.3390/polym10070751

Vandi L-J, Chan CM, Werker A, Richardson D, Laycock B, Pratt S. Wood-PHA Composites: Mapping Opportunities. Polymers. 2018; 10(7):751. https://doi.org/10.3390/polym10070751

Chicago/Turabian StyleVandi, Luigi-Jules, Clement Matthew Chan, Alan Werker, Des Richardson, Bronwyn Laycock, and Steven Pratt. 2018. "Wood-PHA Composites: Mapping Opportunities" Polymers 10, no. 7: 751. https://doi.org/10.3390/polym10070751

APA StyleVandi, L.-J., Chan, C. M., Werker, A., Richardson, D., Laycock, B., & Pratt, S. (2018). Wood-PHA Composites: Mapping Opportunities. Polymers, 10(7), 751. https://doi.org/10.3390/polym10070751