A Thermoplastic Multilayered Carbon-Fabric/Polycarbonate Laminate Prepared by a Two-Step Hot-Press Technique

Abstract

1. Introduction

2. Experimental Procedures

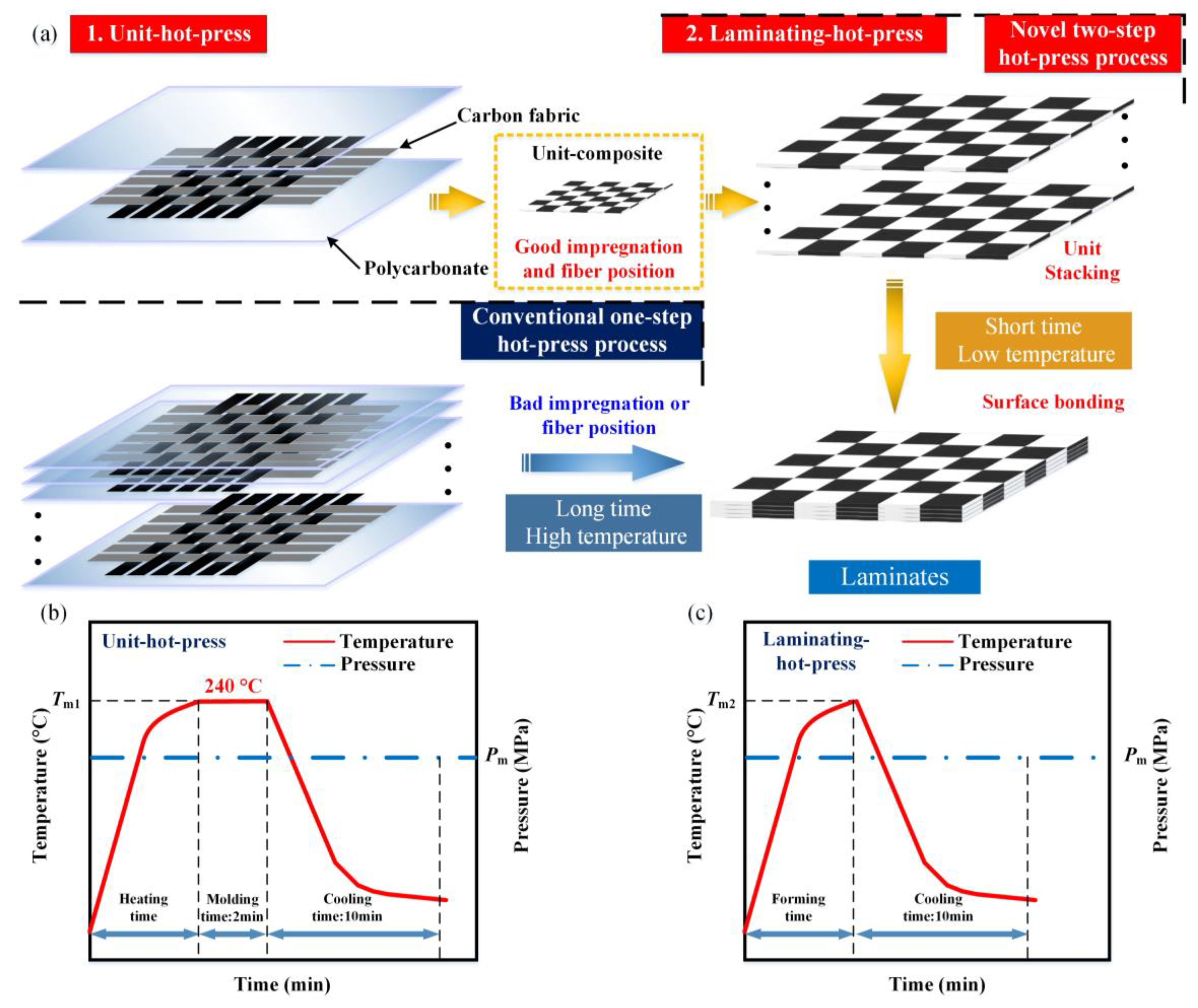

2.1. Multi-CFPL Preparation

2.2. Flexural and Uniaxial Tensile Testing

2.3. Impact Testing

2.4. Other Characterizations

3. Results and Discussion

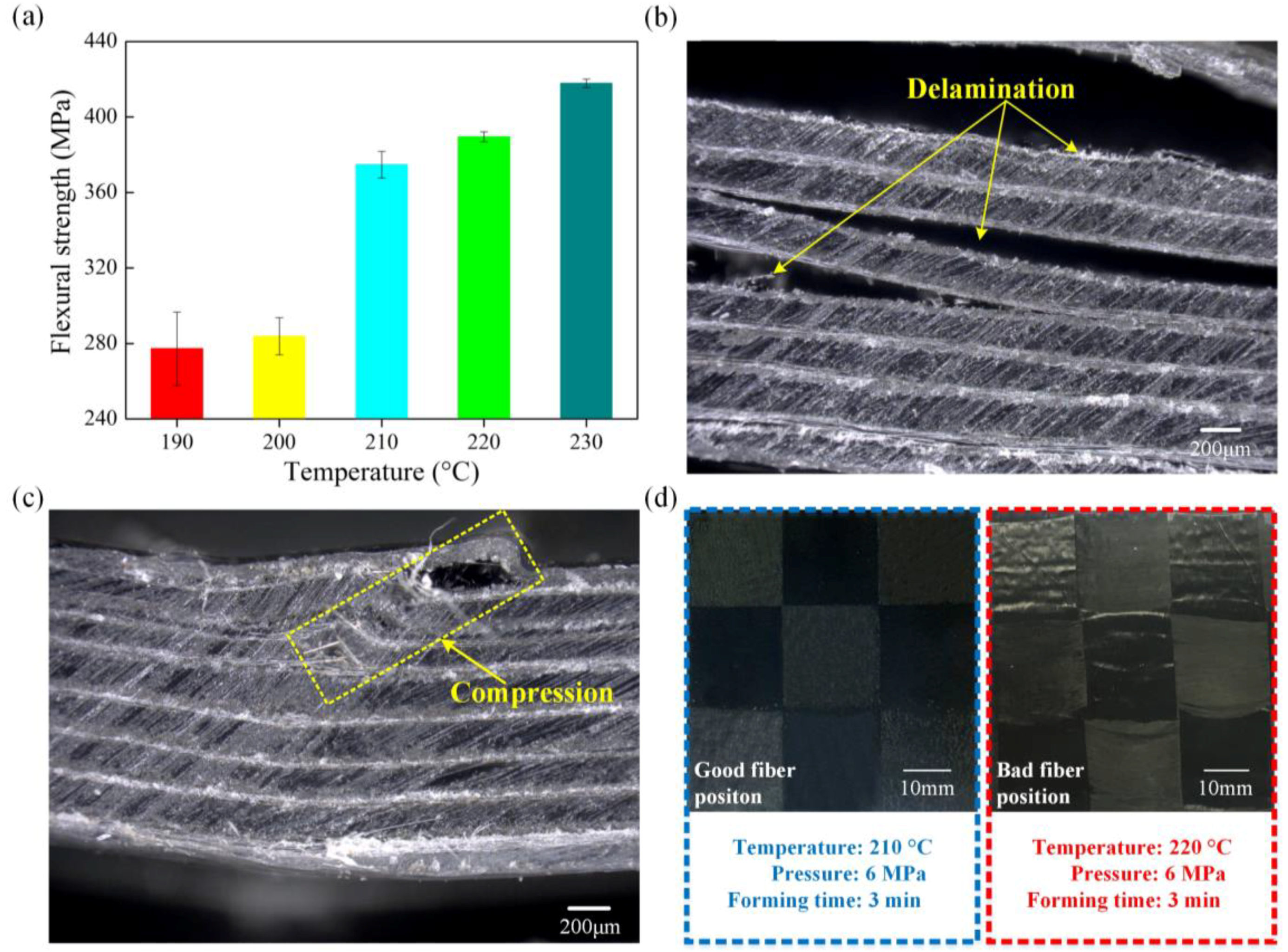

3.1. The Parameter Selection for the Laminating-Hot-Press Process

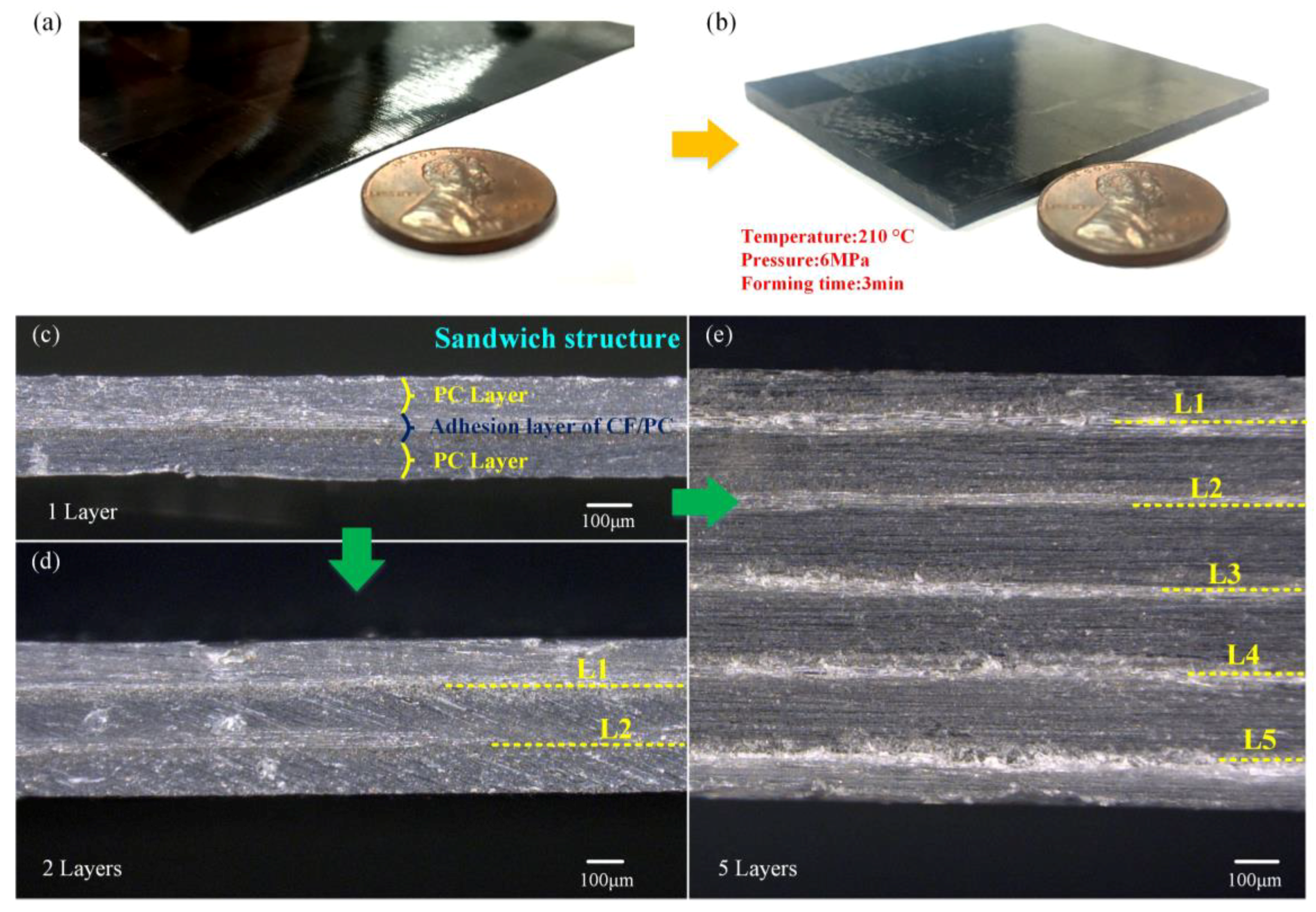

3.2. Morphology Observation

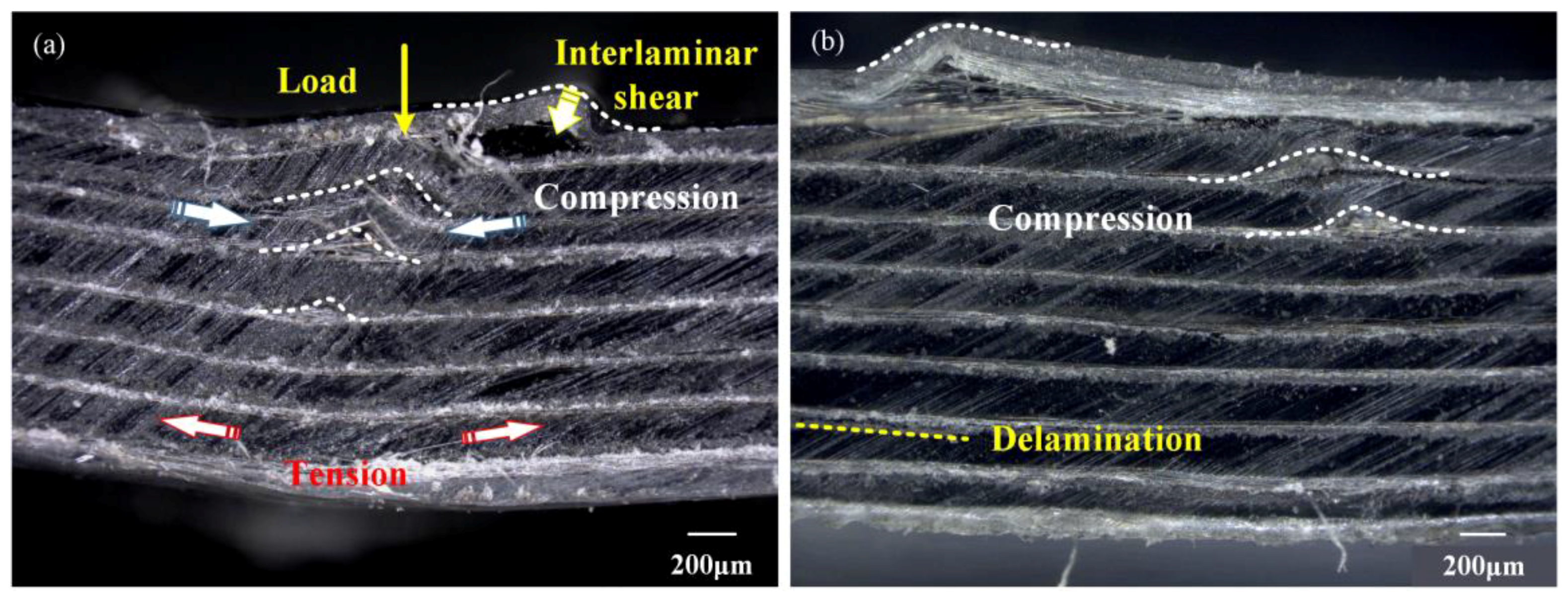

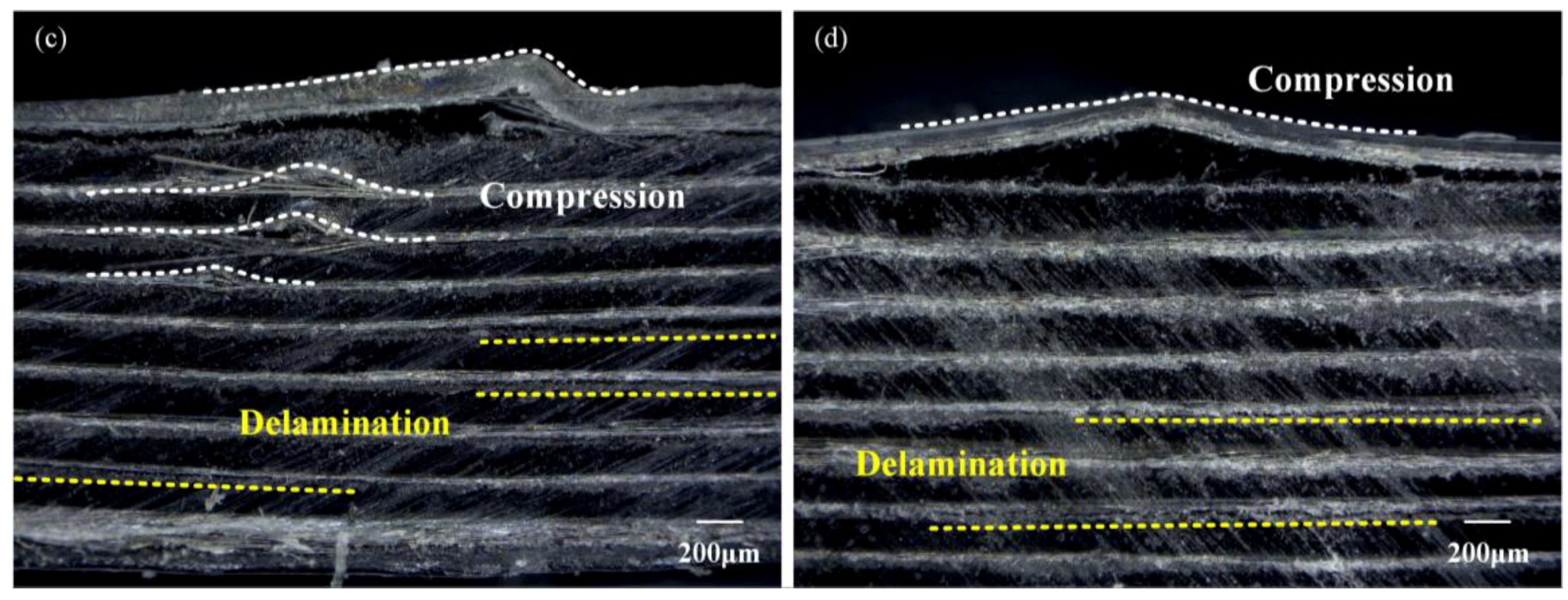

3.3. Flexural Analysis

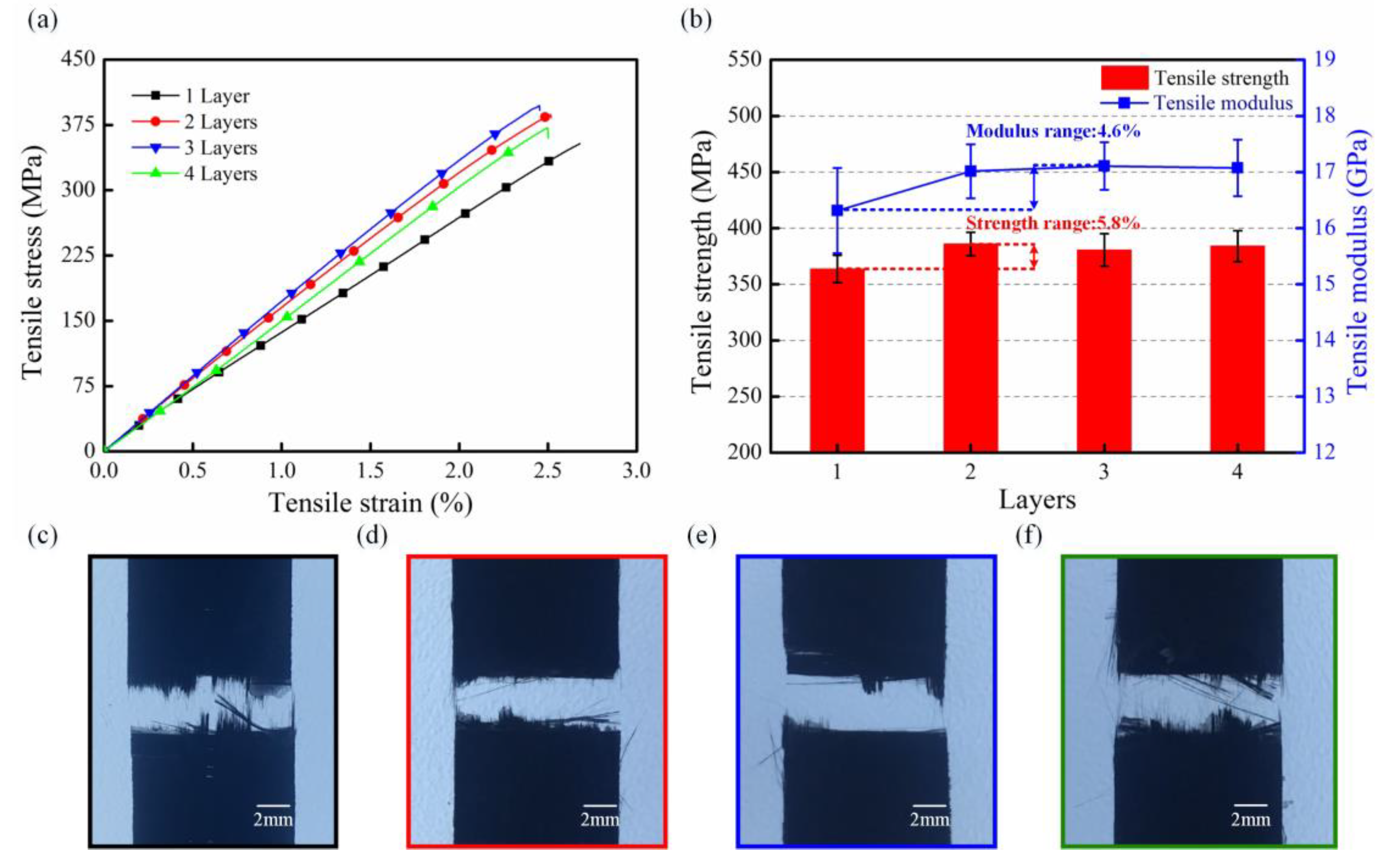

3.4. Uniaxial Tensile Analysis

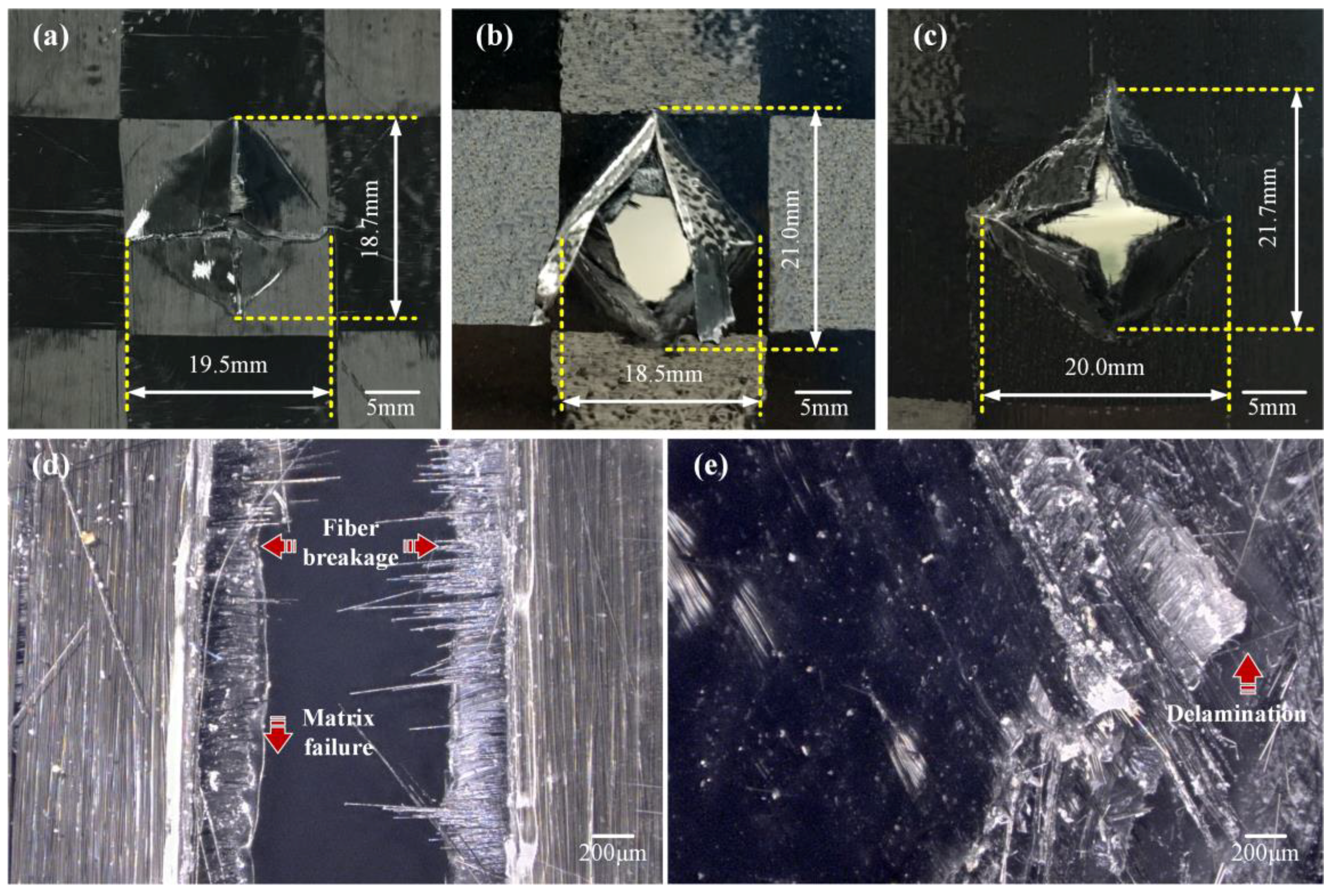

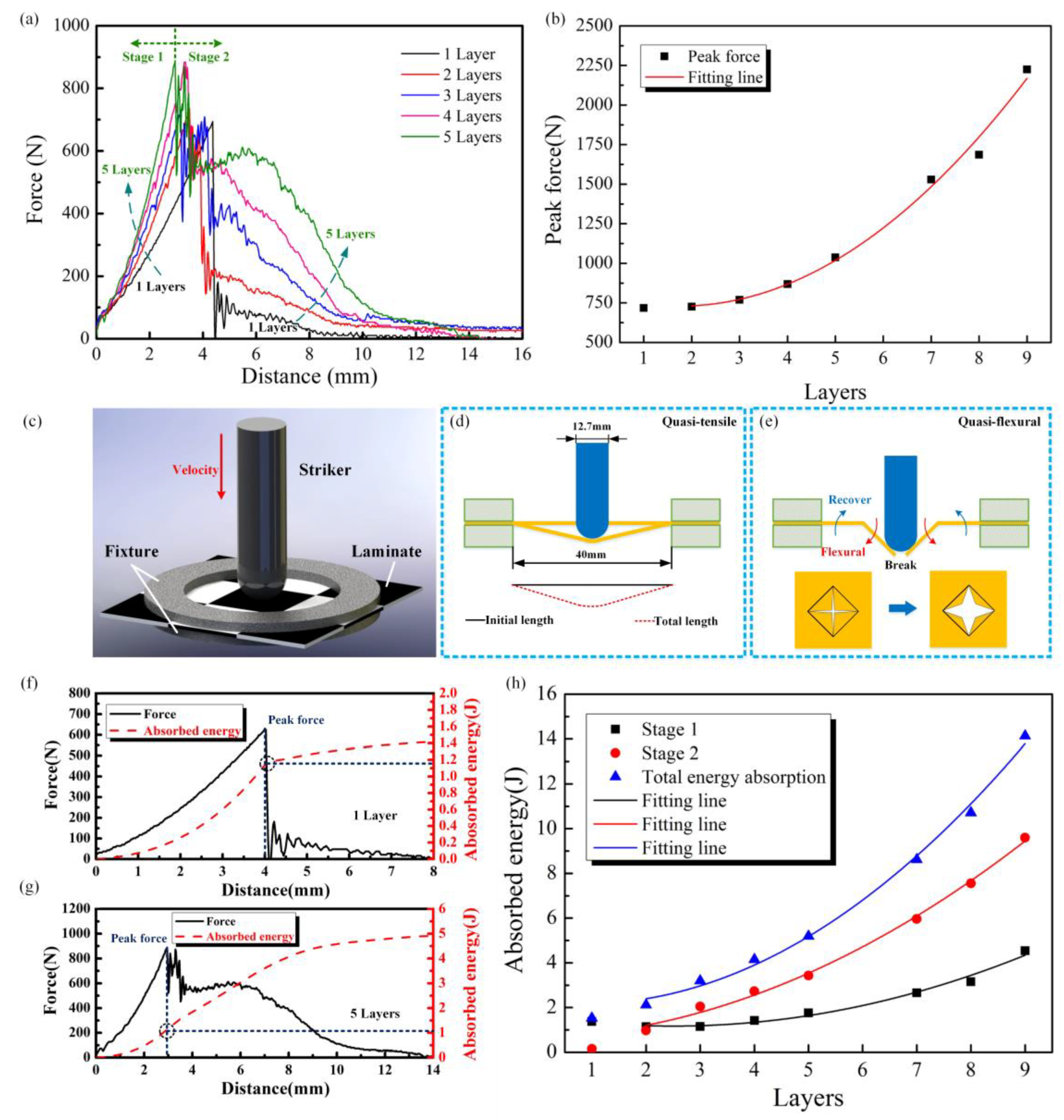

3.5. Impact Property Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Laforte, L.P.; Lebel, L.L. Thermal analysis and degradation of properties in carbon fiber/epoxy laminate riveting at high temperatures. Polym. Test. 2018, 67, 205–212. [Google Scholar] [CrossRef]

- Ma, Y.; Yang, Y.; Sugahara, T.; Hamada, H. A study on the failure behavior and mechanical properties of unidirectional fiber reinforced thermosetting and thermoplastic composites. Compos. B 2016, 99, 162–172. [Google Scholar] [CrossRef]

- Liu, Z.; Li, P.F.; Srikanth, N.; Liu, T.; Chai, G.B. Quantification of flexural fatigue life and 3D damage in carbon fibre reinforced polymer laminates. Compos. A 2016, 90, 778–785. [Google Scholar] [CrossRef]

- Borba, N.Z.; Blaga, L.; Santos, J.F.D.; Amancio-Filho, S.T. Direct-Friction Riveting of polymer composite laminates for aircraft applications. Mater. Lett. 2018, 215, 31–34. [Google Scholar] [CrossRef]

- Li, H.G.; Xu, Y.W.; Hua, X.G.; Liu, C.; Tao, J. Bending failure mechanism and flexural properties of GLARE laminates with different stacking sequences. Compos. Struct. 2017, 187, 354–363. [Google Scholar] [CrossRef]

- Subagia, I.D.G.A.; Kim, Y.; Tijing, L.D.; Kim, C.S.; Shon, H.K. Effect of stacking sequence on the flexural properties of hybrid composites reinforced with carbon and basalt fibers. Compos. B 2014, 58, 251–258. [Google Scholar] [CrossRef]

- Srivathsan, A.; Vijayaram, B.; Ramesh, R.; Gokuldass. Investigation on mechanical behavior of woven fabric glass/kevlar hybrid composite laminates made of varying fibre inplane orientation and stacking sequence. Mater. Today Proc. 2017, 4, 8928–8937. [Google Scholar] [CrossRef]

- Singh, S.B.; Vummadisetti, S.; Chawla, H. Influence of curing on the mechanical performance of FRP laminates. J. Build. Eng. 2018, 16, 1–19. [Google Scholar] [CrossRef]

- Li, X.; Zhang, X.; Guo, Y.B.; Shim, V.P.W.; Yang, J.L.; Chai, G.B. Influence of fiber type on the impact response of titanium-based fiber-metal laminates. Int. J. Impact Eng. 2018, 114, 32–42. [Google Scholar] [CrossRef]

- Rahmani, H.; Najafi, S.H.M.; Ashori, A. Mechanical performance of epoxy/carbon fiber laminated composites. J. Reinf. Plast. Compos. 2014, 33, 733–740. [Google Scholar] [CrossRef]

- Shin, S.; Jang, J. Toughness improvement of high-performance epoxy resin using aminated polyetherimide. J. Appl. Polym. Sci. 2015, 65, 2237–2246. [Google Scholar] [CrossRef]

- Saurín, N.; Sanes, J.; Bermúdez, M.D. Self-Healing of Abrasion Damage in Epoxy Resin–Ionic Liquid Nanocomposites. Tribol. Lett. 2015, 58, 4. [Google Scholar] [CrossRef]

- Vaidya, U.K.; Chawla, K.K. Processing of fibre reinforced thermoplastic composites. Metall. Rev. 2008, 53, 185–218. [Google Scholar] [CrossRef]

- Mathijsen, D. The black magic of carbon fiber reinforced thermoplastics. Reinf. Plast. 2015, 59, 185–189. [Google Scholar] [CrossRef]

- Sorrentino, L.; Vasconcellos, D.S.; D’Auria, M.; Sarasini, F.; Tirillo, J. Effect of temperature on static and low velocity impact properties of thermoplastic composites. Compos. B 2017, 113, 100–110. [Google Scholar] [CrossRef]

- Katsiropoulos, C.V.; Pantelakis, S.G.; Meyer, B.C. Mechanical behavior of non-crimp fabric PEEK/C thermoplastic composites. Theor. Appl. Fract. Mech. 2009, 52, 122–129. [Google Scholar] [CrossRef]

- Ozaki, H.; Nakada, M.; Uzawa, K.; Miyano, Y. Effect of molding condition on flexural strength of textile carbon fiber reinforced polycarbonate laminates. J. Reinf. Plast. Compos. 2014, 33, 1893–1901. [Google Scholar] [CrossRef]

- Tanaka, K.; Suzue, M.; Isshiki, S.; Shinohara, M.; Katayama, T. Interfacial and interlaminar shear strength of carbon fiber reinforced polycarbonates made with unidirectional sheets. J. Text. Stud. 2016, 42, 82–94. [Google Scholar]

- Qian, X.; Kravchenko, O.G.; Pedrazzoli, D.; Manas-Zloczower, I. Effect of polycarbonate film surface morphology and oxygen plasma treatment on mode I and II fracture toughness of interleaved composite laminates. Compos. A 2018, 105, 138–149. [Google Scholar] [CrossRef]

- Choi, E.Y.; Kim, J.Y.; Kim, C.K. Fabrication and properties of polycarbonate composites with polycarbonate grafted multi-walled carbon nanotubes by reactive extrusion. Polymer 2015, 60, 18–25. [Google Scholar] [CrossRef]

- Yurgartis, S.W. Measurement of small angle fiber misalignments in continuous fiber composites. Compos. Sci. Technol. 1987, 30, 279–293. [Google Scholar] [CrossRef]

- El-Dessouky, H.M.; Lawrence, C.A. Ultra-lightweight carbon fibre/thermoplastic composite material using spread tow technology. Compos. B 2013, 50, 91–97. [Google Scholar] [CrossRef]

- Yang, B.B.; Lu, L.S.; Liu, X.K.; Xie, Y.X.; Li, J.W.; Tang, Y. Uniaxial tensile and impact investigation of carbon-fabric/polycarbonate composites with different weave tows widths. Mater. Des. 2017, 131, 470–480. [Google Scholar] [CrossRef]

- Ramalakshmi, P. Investigation of interlaminar shear strength in carbon epoxy and carbon epoxy carbon nanotubes using experimental and finite element technique. Int. J. Eng. Res. Appl. 2013, 2, 587–592. [Google Scholar]

- Bensadoun, F.; Depuydt, D.; Baets, J.; Verpoest, I.; Vuure, A.W.V. Low velocity impact properties of flax composites. Compos. Struct. 2017, 176, 933–944. [Google Scholar] [CrossRef]

- Lou, X.F.; Cai, H.N.; Yu, P.F.; Jiao, F.; Han, X.C. Failure analysis of composite laminate under low-velocity impact based on micromechanics of failure. Compos. Struct. 2017, 163, 238–247. [Google Scholar] [CrossRef]

- Mehndiratta, A.; Bandyopadhyaya, S.; Kumar, V.; Kumar, D. Experimental investigation of span length for flexural test of fiber reinforced polymer composite laminates. J. Mater. Res. Technol. 2018, 7, 89–95. [Google Scholar] [CrossRef]

- Dong, C.S.; Sudarisman; Davies, I.J. Flexural properties of E glass and TR50S carbon fiber reinforced epoxy hybrid composites. J. Mater. Eng. Perform. 2013, 22, 41–49. [Google Scholar] [CrossRef]

- Qin, W.Z.; Vautard, F.; Askeland, P.; Yu, J.R.; Drzal, L.T. Incorporation of silicon dioxide nanoparticles at the carbon fiber-epoxy matrix interphase and its effect on composite mechanical properties. Polym. Compos. 2015, 38, 1474–1482. [Google Scholar] [CrossRef]

- Lu, L.S.; Xing, D.; Xie, Y.X.; The, K.S.; Zhang, B.; Chen, S.M.; Yong, T. Electrical conductivity investigation of a nonwoven fabric composed of carbon fibers and polypropylene/polyethylene core/sheath bicomponent fibers. Mater. Des. 2016, 112, 383–391. [Google Scholar] [CrossRef]

- Chen, J.C.; Chao, C.G. Numerical simulation and experimental investigation for design of a carbon fiber tow pneumatic spreading system. Carbon 2005, 43, 2514–2529. [Google Scholar] [CrossRef]

- ASTM, Standard D790, Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. 2010. Available online: https://doi.org/10.1520/D790_D790M-10 (accessed on 30 June 2018).

- ASTM, Standard D3039/D3039, Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. 2000. Available online: https://doi.org/10.1520/D3039_D3039M-00 (accessed on 30 June 2018).

- ASTM, Standard D7136, Standard Test Method for Measuring the Damage Resistance of a Fiber-Reinforced Polymer Matrix Composite to a Drop-Weight Impact Event. 2015. Available online: https://doi.org/10.1520/D7136_D7136M-15 (accessed on 30 June 2018).

- Hao, A.; Zhao, H.; Chen, J.Y. Kenaf/polypropylene nonwoven composites: The influence of manufacturing conditions on mechanical, thermal, and acoustical performance. Compos. B 2013, 54, 44–51. [Google Scholar] [CrossRef]

- ASTM, Standard D2344/D2344M, Standard Test Method for Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates. 2000. Available online: https://doi.org/10.1520/D2344_D2344M-00 (accessed on 30 June 2018).

- Serna Moreno, M.C.; Romero Gutierrez, A.; Martínez Vicente, J.L. Flexural testing on carbon fibre laminates taking into account their different behaviour under tension and compression. Mater. Sci. Eng. 2016, 139, 12–47. [Google Scholar]

- Moaseri, E.; Maghrebi, M.; Baniadam, M. Improvements in mechanical properties of carbon fiber-reinforced epoxy composites: A microwave-assisted approach in functionalization of carbon fiber via diamines. Mater. Des. 2014, 55, 644–652. [Google Scholar] [CrossRef]

- Chen, Q.; Zhao, Y.; Zhou, Z.P.; Rahman, A.; Wu, X.F.; Wu, W.D.; Xu, T.; Fong, H. Fabrication and mechanical properties of hybrid multi-scale epoxy composites reinforced with conventional carbon fiber fabrics surface-attached with electrospun carbon nanofiber mats. Compos. B 2013, 44, 1–7. [Google Scholar] [CrossRef]

- Moreno, M.C.S.; Muñoz, S.H.; Gutiérrez, A.R.; Rappold, C.; Martínez Vicente, J.L.; Morales-Rodríguez, P.A.; Cela, J.J.L. Pseudo-ductility in flexural testing of symmetric ±45° angle-ply CFRP laminates. Compos. Sci. Tech. 2018, 156, 8–18. [Google Scholar] [CrossRef]

- Lee, J.H.; Rhee, K.Y.; Park, S.J. Silane modification of carbon nanotubes and its effects on the material properties of carbon/CNT/epoxy three-phase composites. Compos. A 2011, 42, 478–483. [Google Scholar] [CrossRef]

- Soliman, E.M.; Sheyka, M.P.; Taha, M.R. Low-velocity impact of thin woven carbon fabric composites incorporating multi-walled carbon nanotubes. Int. J. Impact Eng. 2012, 47, 39–47. [Google Scholar] [CrossRef]

- Thanomsilp, C.; Hogg, P.J. Penetration impact resistance of hybrid composites based on commingled yarn fabrics. Compos. Sci. Technol. 2003, 63, 467–482. [Google Scholar] [CrossRef]

- Huber, T.; Bickerton, S.; Müssig, J.; Pang, S.S.; Staiger, M.P. Flexural and impact properties of all-cellulose composite laminates. Compos. Sci. Technol. 2013, 88, 92–98. [Google Scholar] [CrossRef]

| Objection | Fitting Equation | Adj. R-Square |

|---|---|---|

| Peak force | y = 27.41823x2 − 96.38021x + 814.63241 | 0.98564 |

| Absorbed energy in the quasi-tensile stage | y = 0.07501x2 − 0.37486x + 1.6387 | 0.97704 |

| Absorbed energy in the quasi-flexural stage | y = 0.09994x2 + 0.07799x + 0.64861 | 0.99477 |

| Total absorbed energy | y = 0.17494x2 − 0.29687x + 2.28731 | 0.99326 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Yang, B.; Lu, L.; Wan, Z.; Tang, Y. A Thermoplastic Multilayered Carbon-Fabric/Polycarbonate Laminate Prepared by a Two-Step Hot-Press Technique. Polymers 2018, 10, 720. https://doi.org/10.3390/polym10070720

Liu X, Yang B, Lu L, Wan Z, Tang Y. A Thermoplastic Multilayered Carbon-Fabric/Polycarbonate Laminate Prepared by a Two-Step Hot-Press Technique. Polymers. 2018; 10(7):720. https://doi.org/10.3390/polym10070720

Chicago/Turabian StyleLiu, Xiaokang, Binbin Yang, Longsheng Lu, Zhenping Wan, and Yong Tang. 2018. "A Thermoplastic Multilayered Carbon-Fabric/Polycarbonate Laminate Prepared by a Two-Step Hot-Press Technique" Polymers 10, no. 7: 720. https://doi.org/10.3390/polym10070720

APA StyleLiu, X., Yang, B., Lu, L., Wan, Z., & Tang, Y. (2018). A Thermoplastic Multilayered Carbon-Fabric/Polycarbonate Laminate Prepared by a Two-Step Hot-Press Technique. Polymers, 10(7), 720. https://doi.org/10.3390/polym10070720