Extraction of the Polyurethane Layer in Textile Composites for Textronics Applications Using Optical Coherence Tomography

Abstract

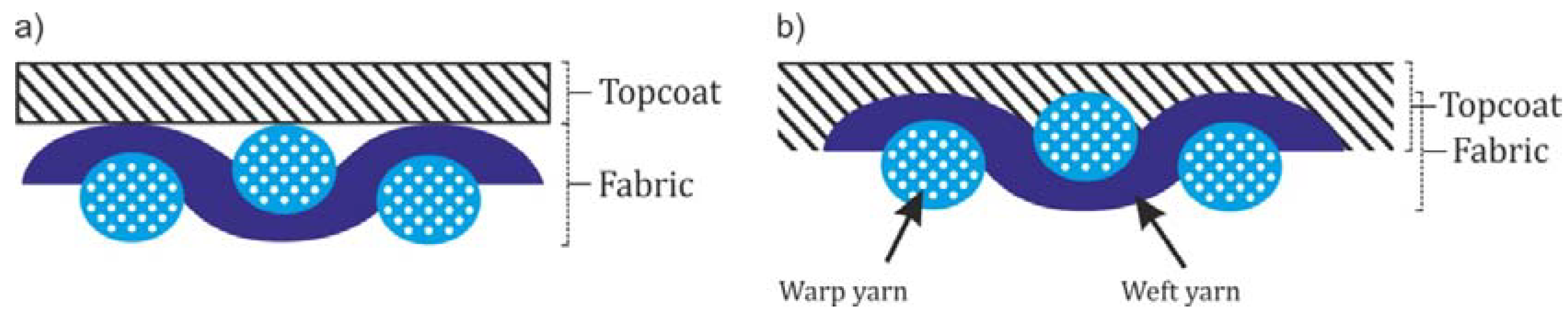

1. Introduction

2. Material and Methods

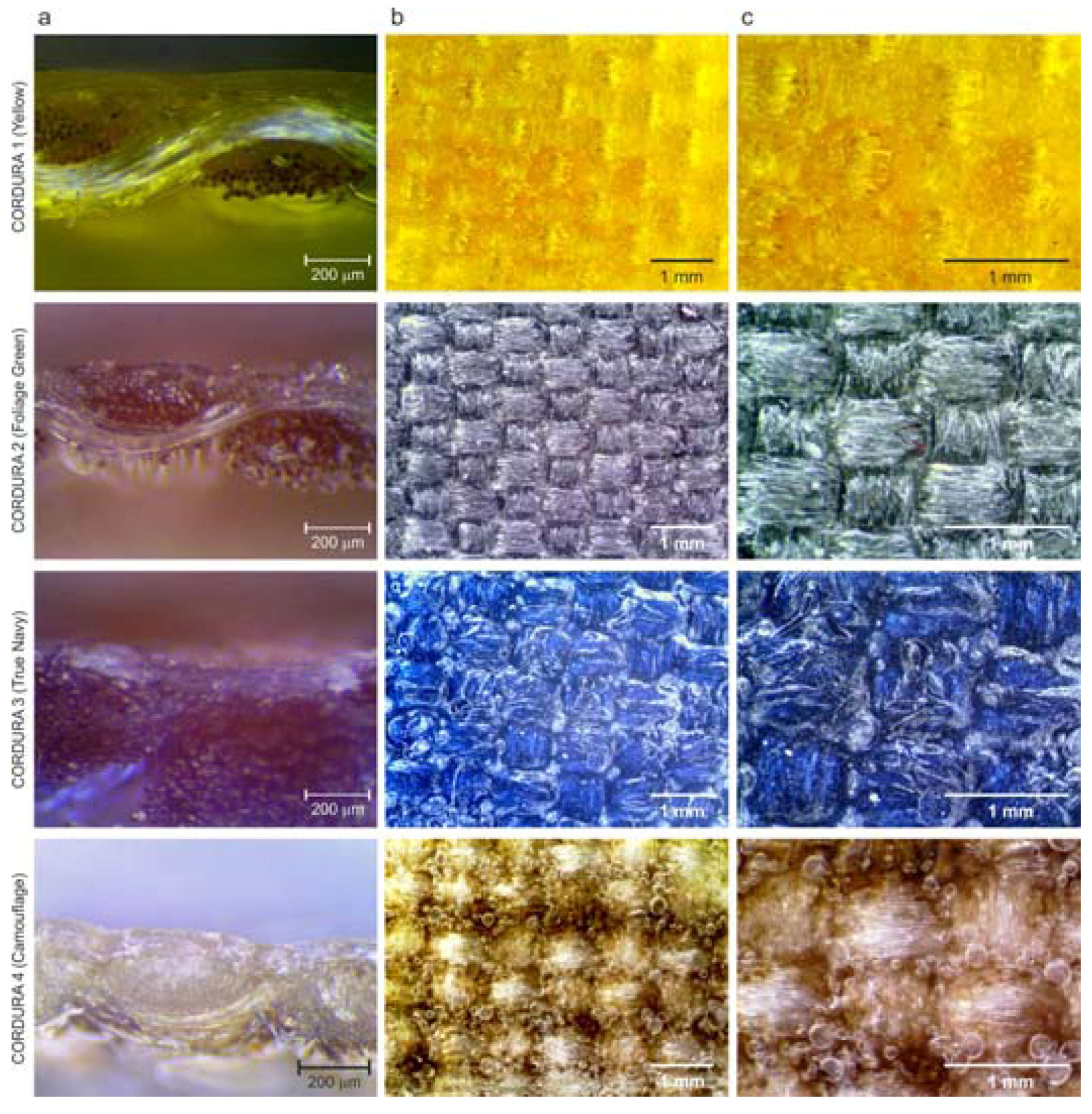

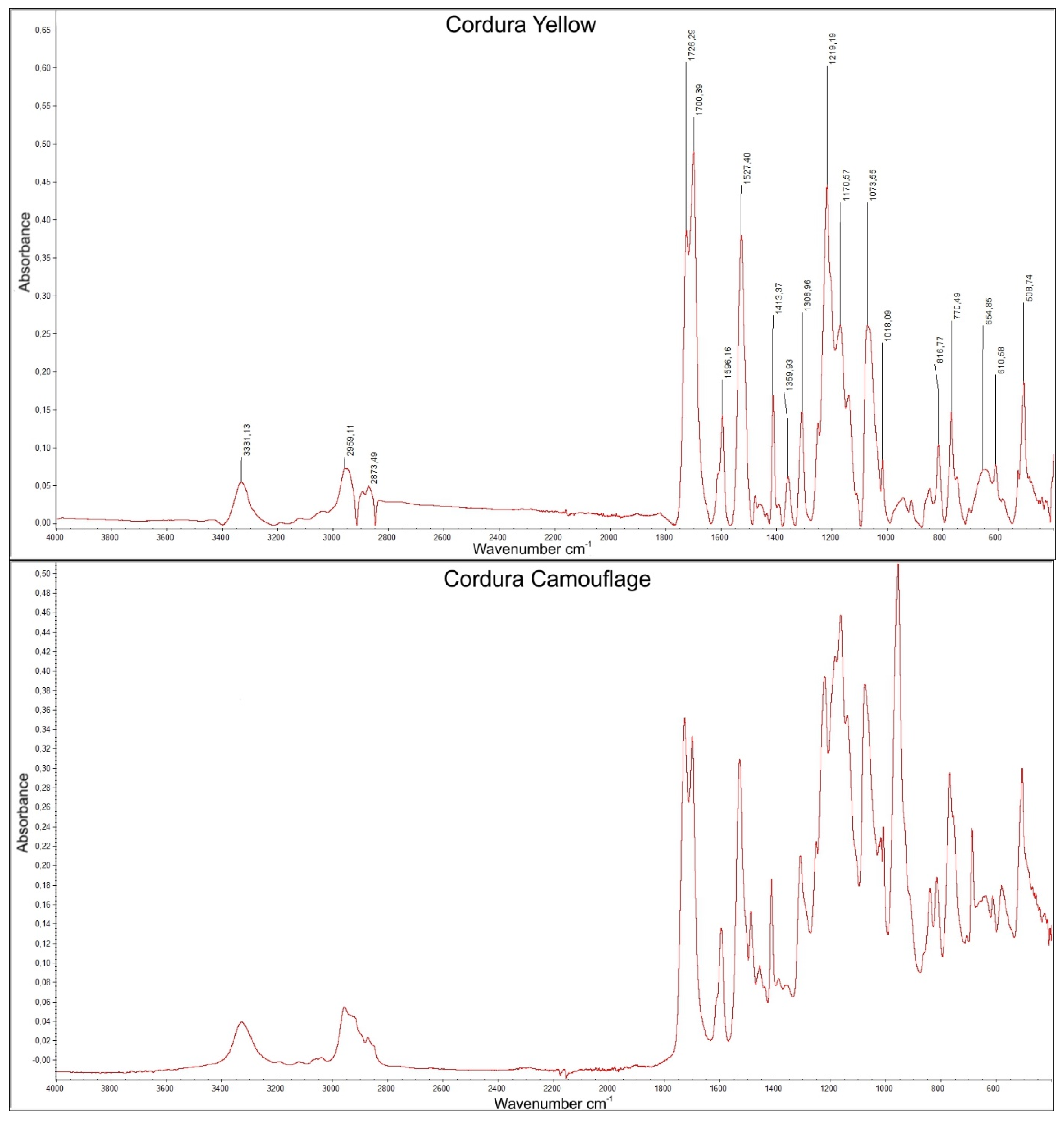

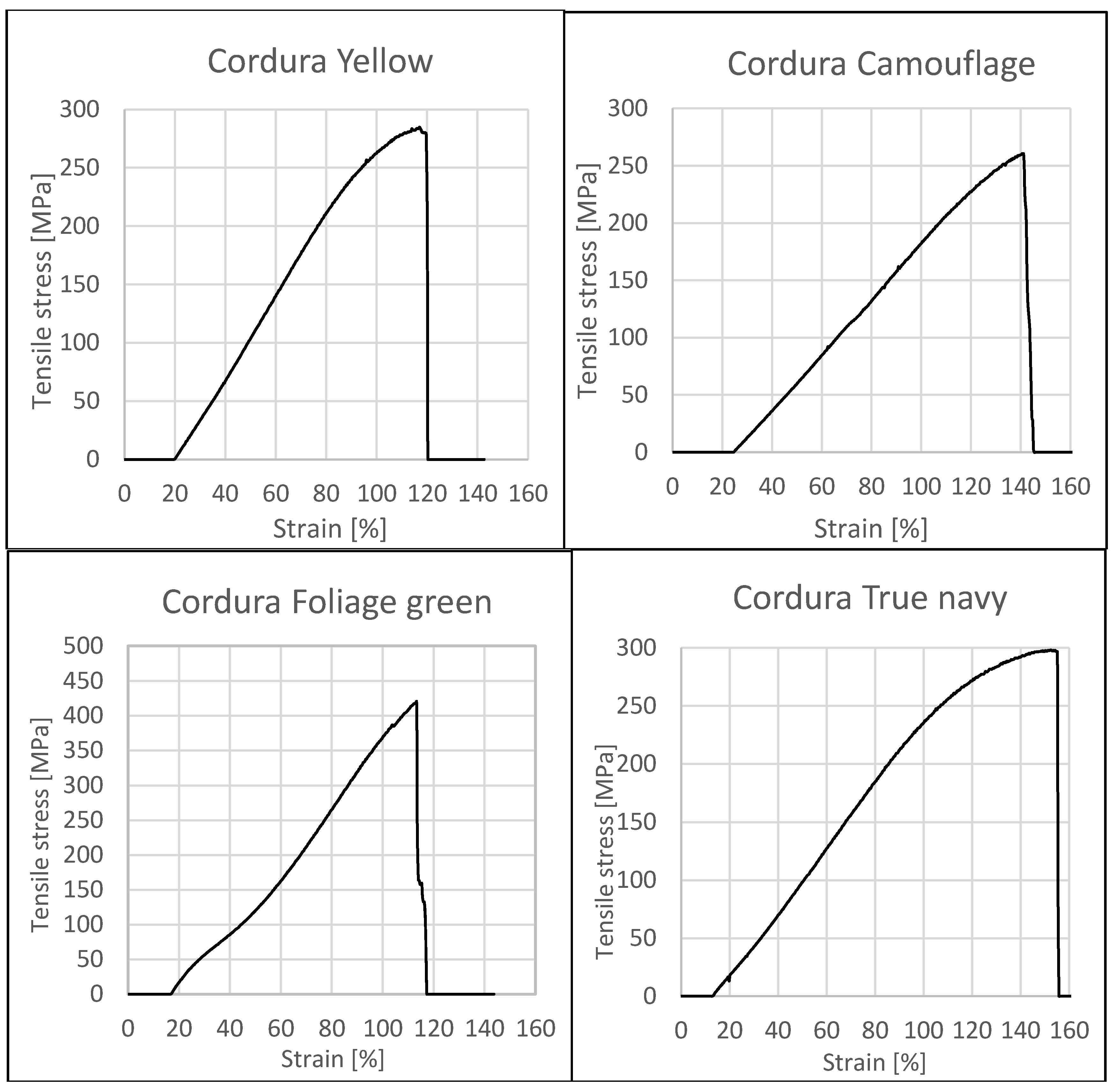

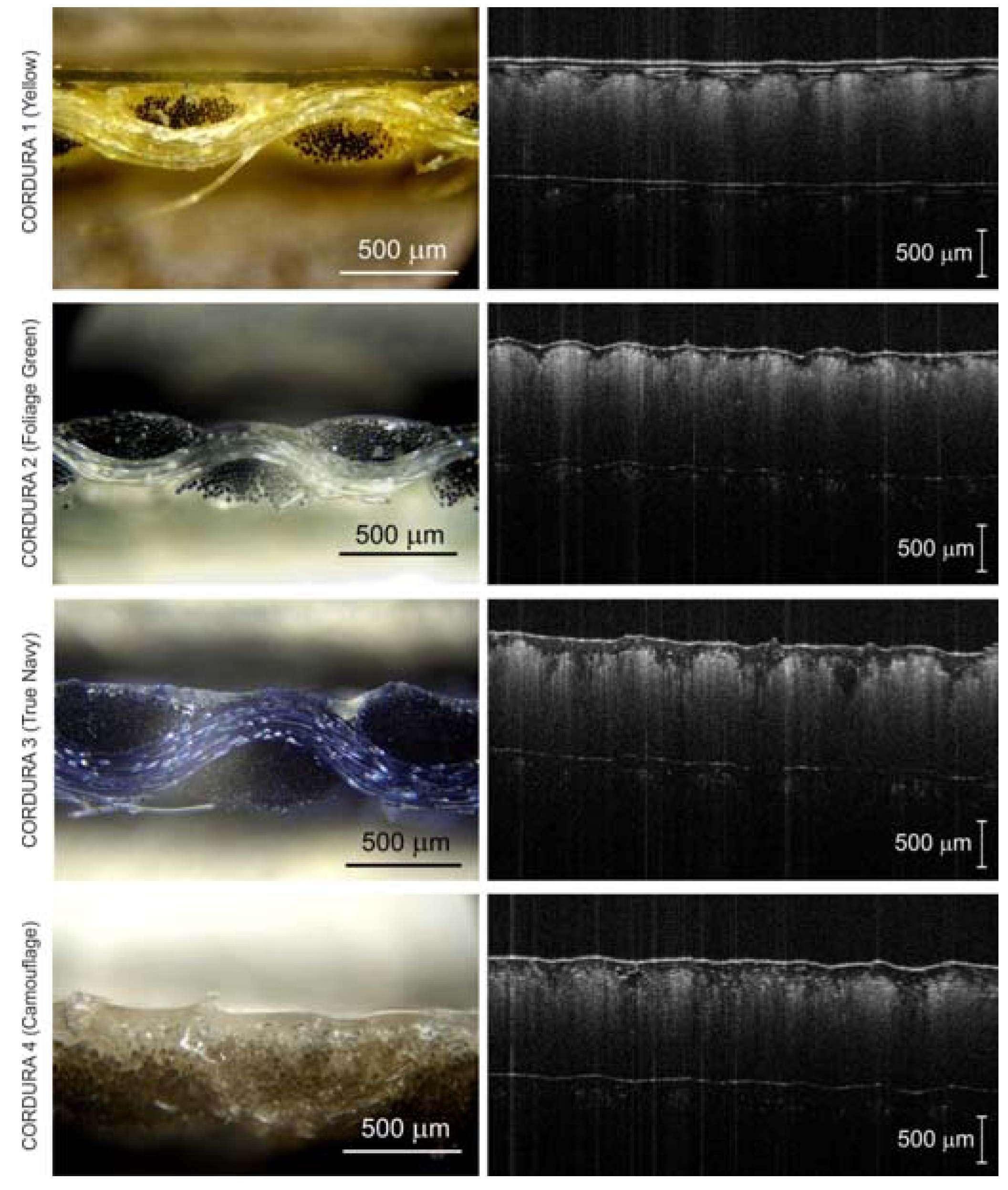

2.1. Cordura Samples

2.2. Measurement with Microscope Images

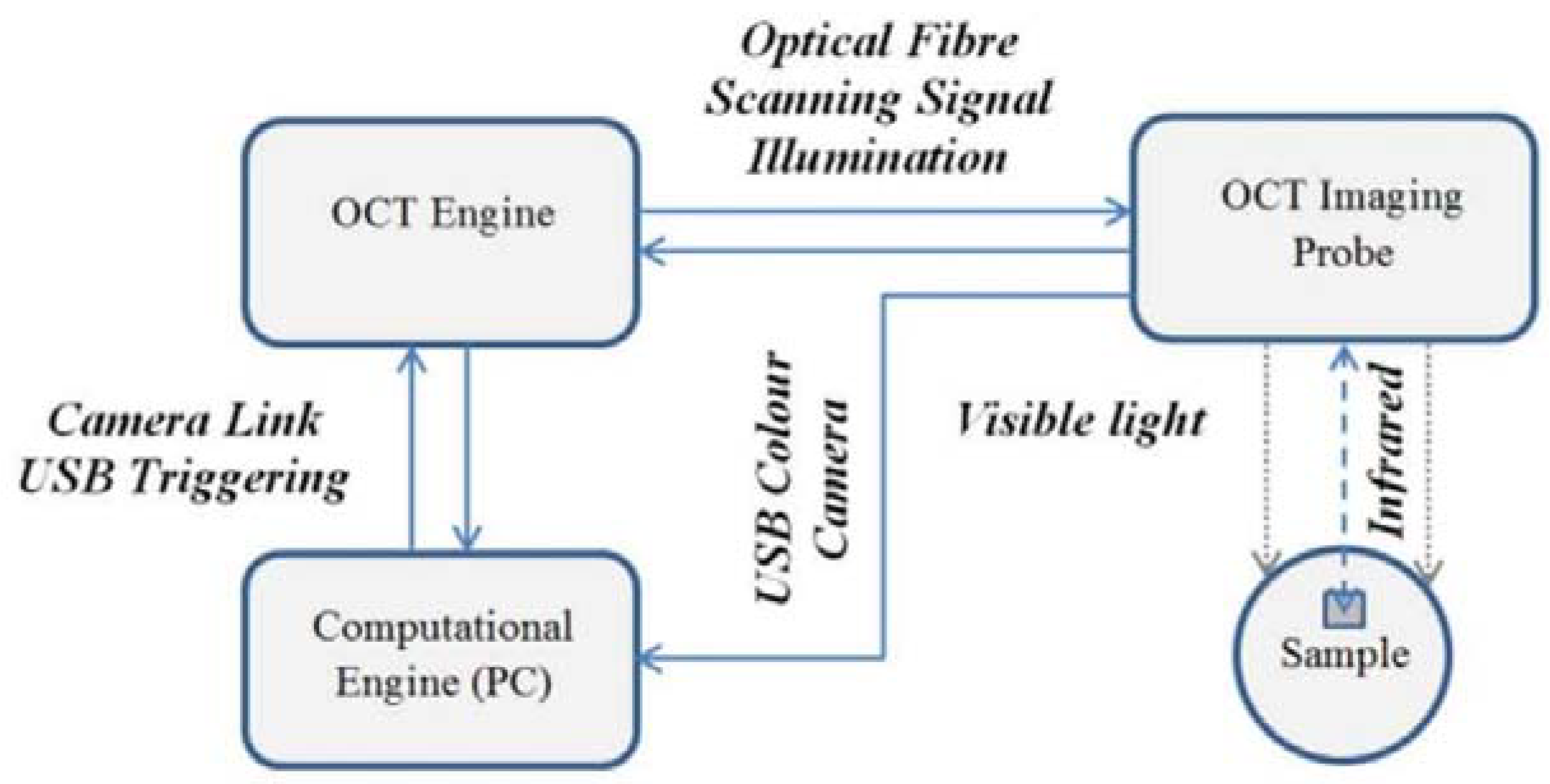

2.3. Acquisition of OCT Images

2.4. Computing Environment

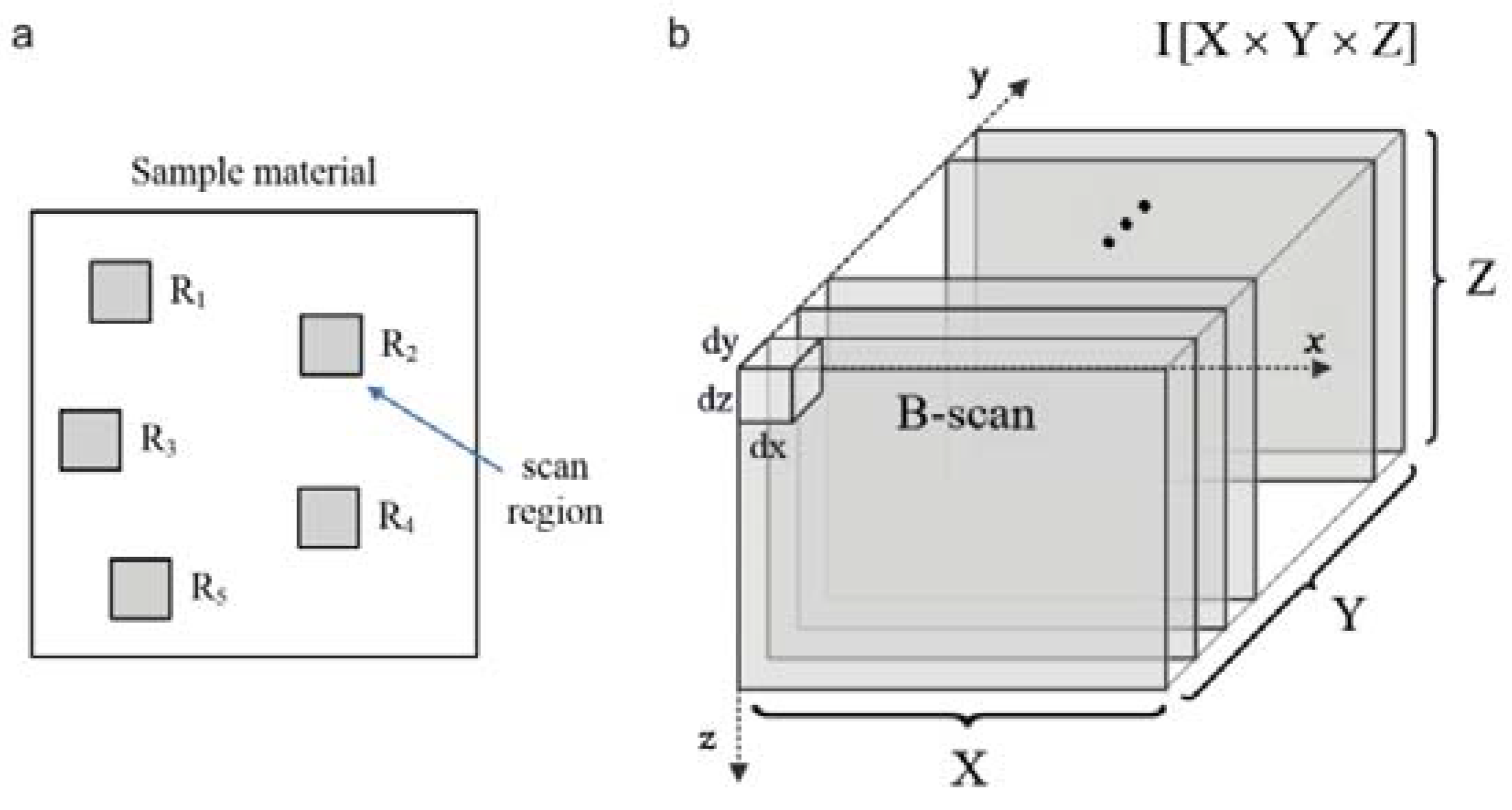

3. Image Analysis

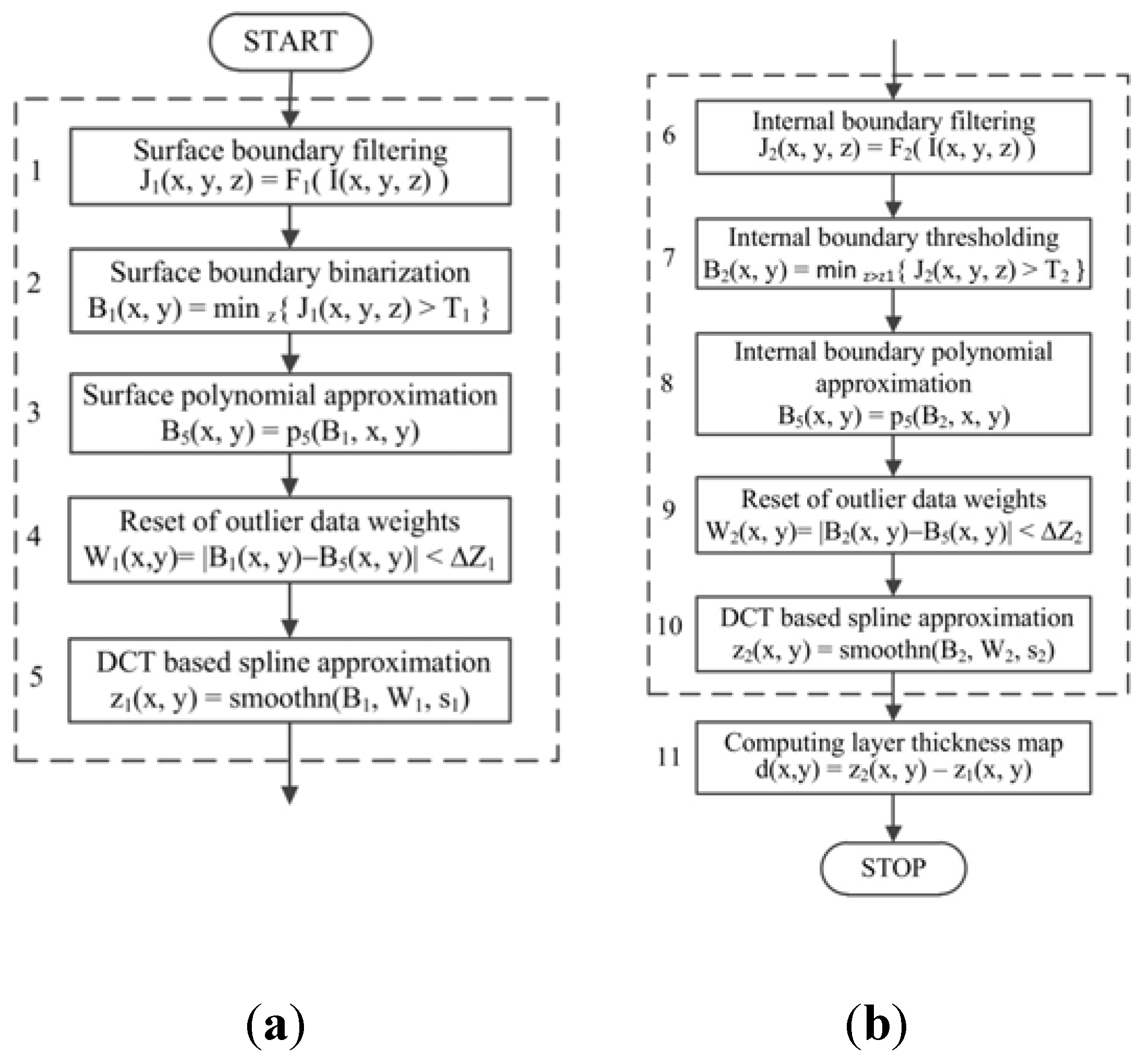

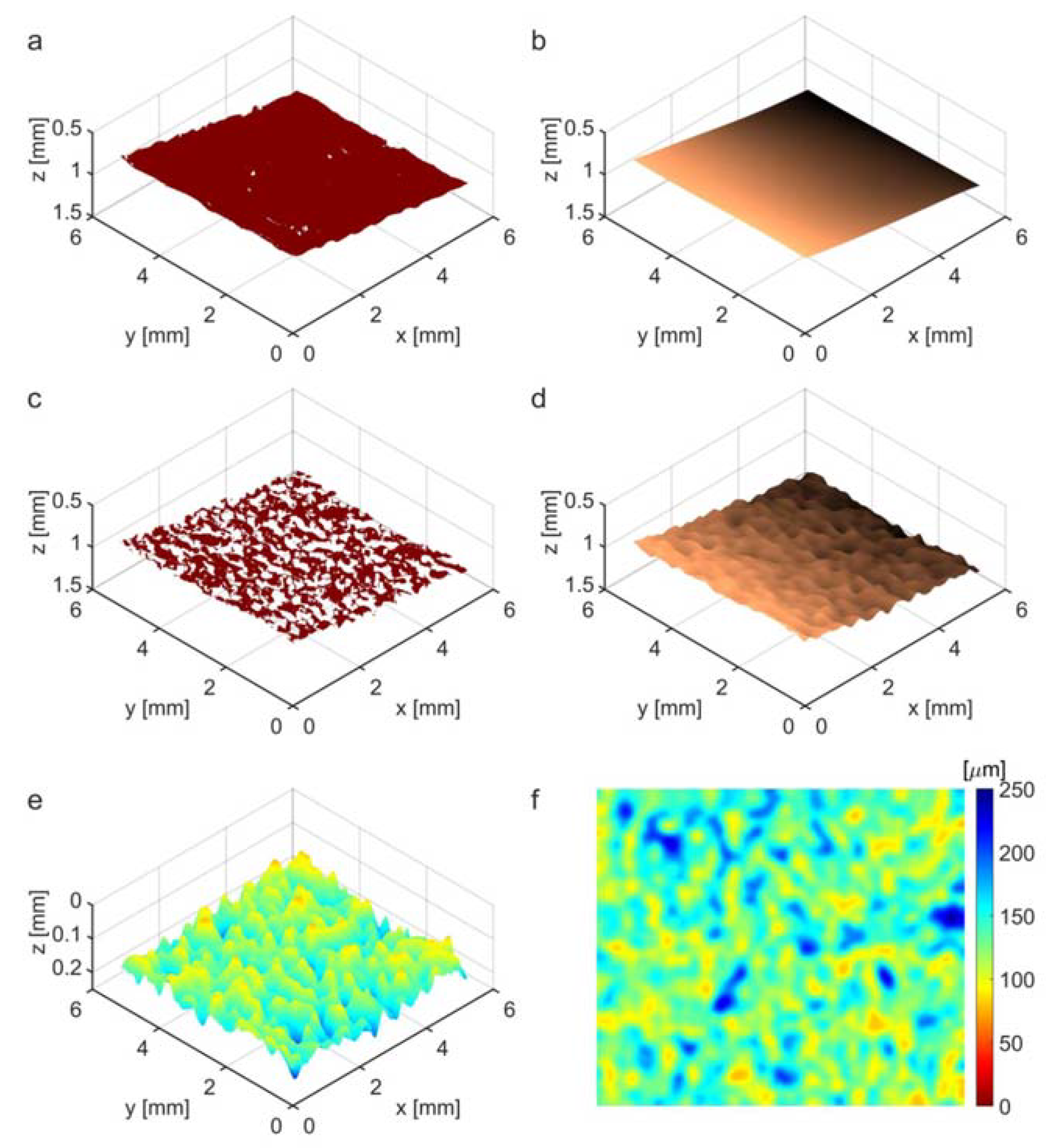

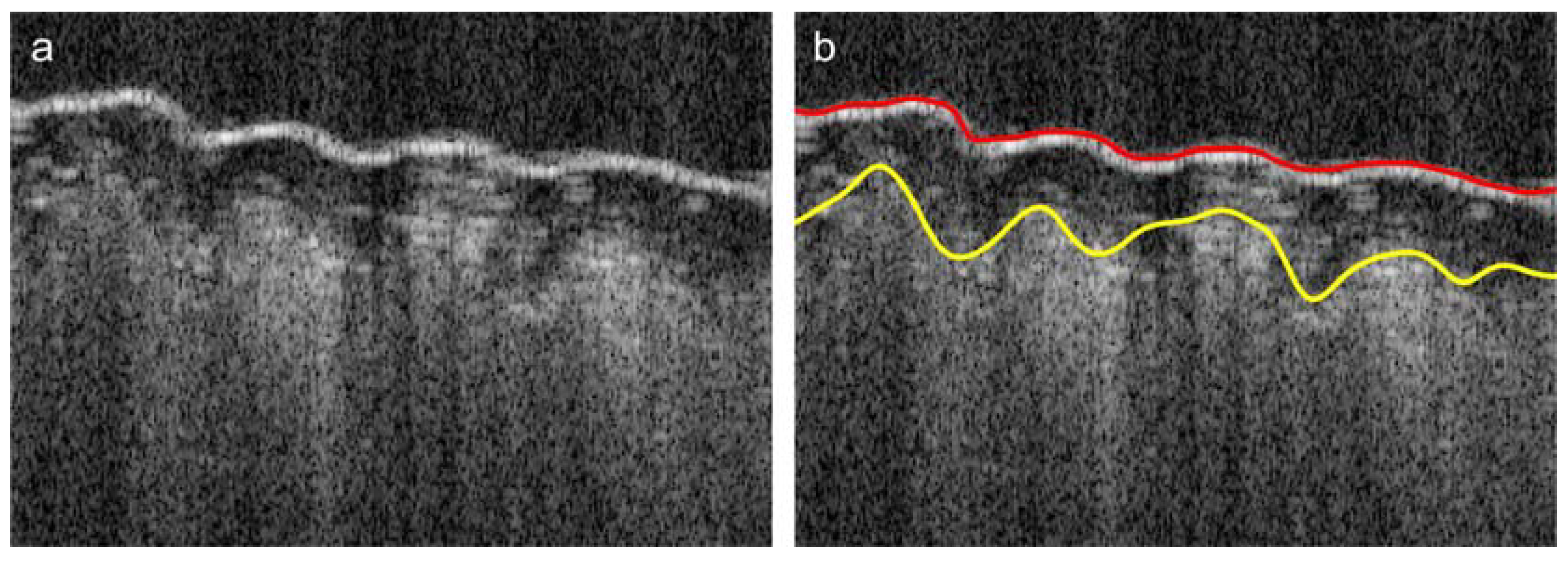

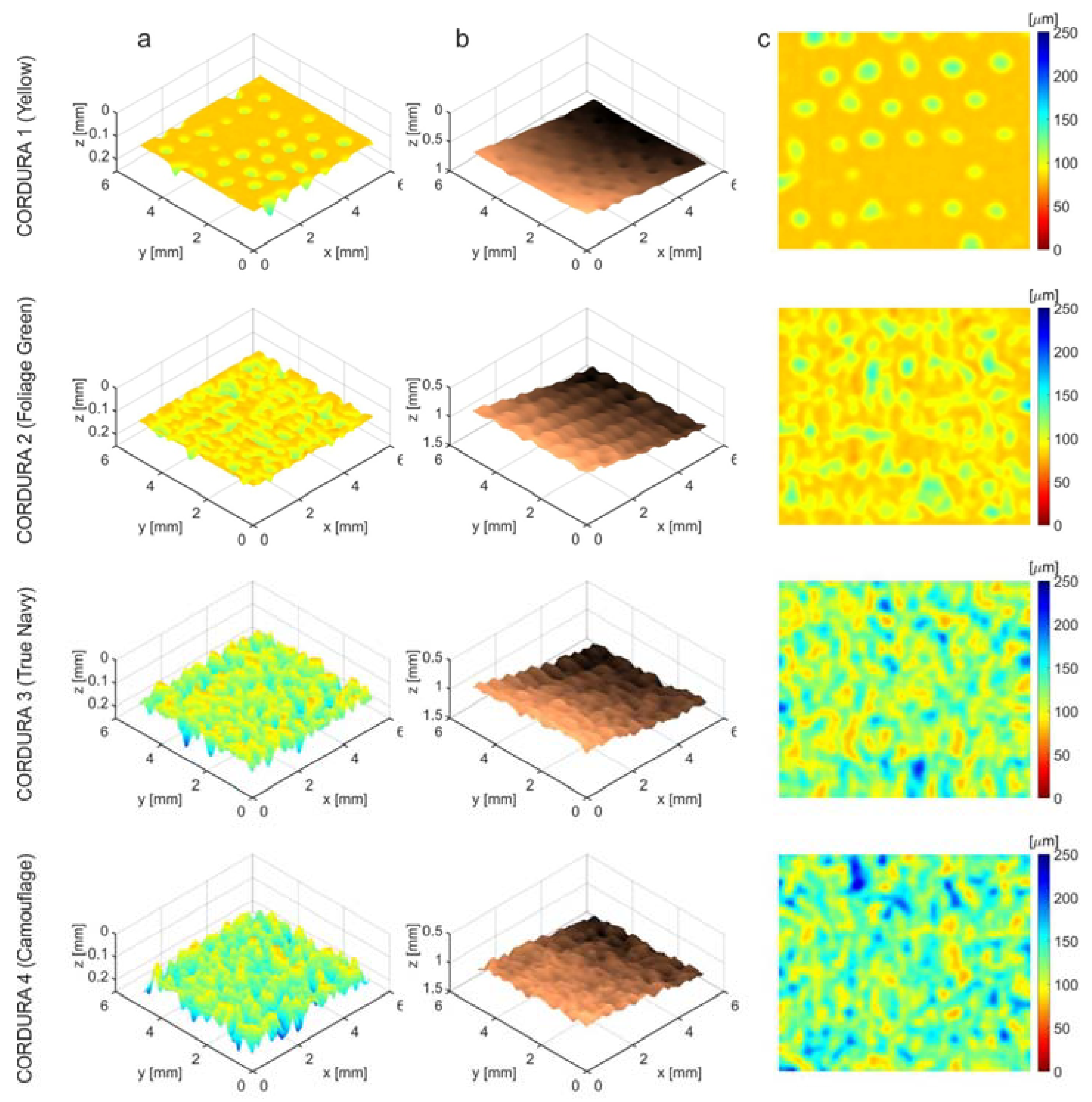

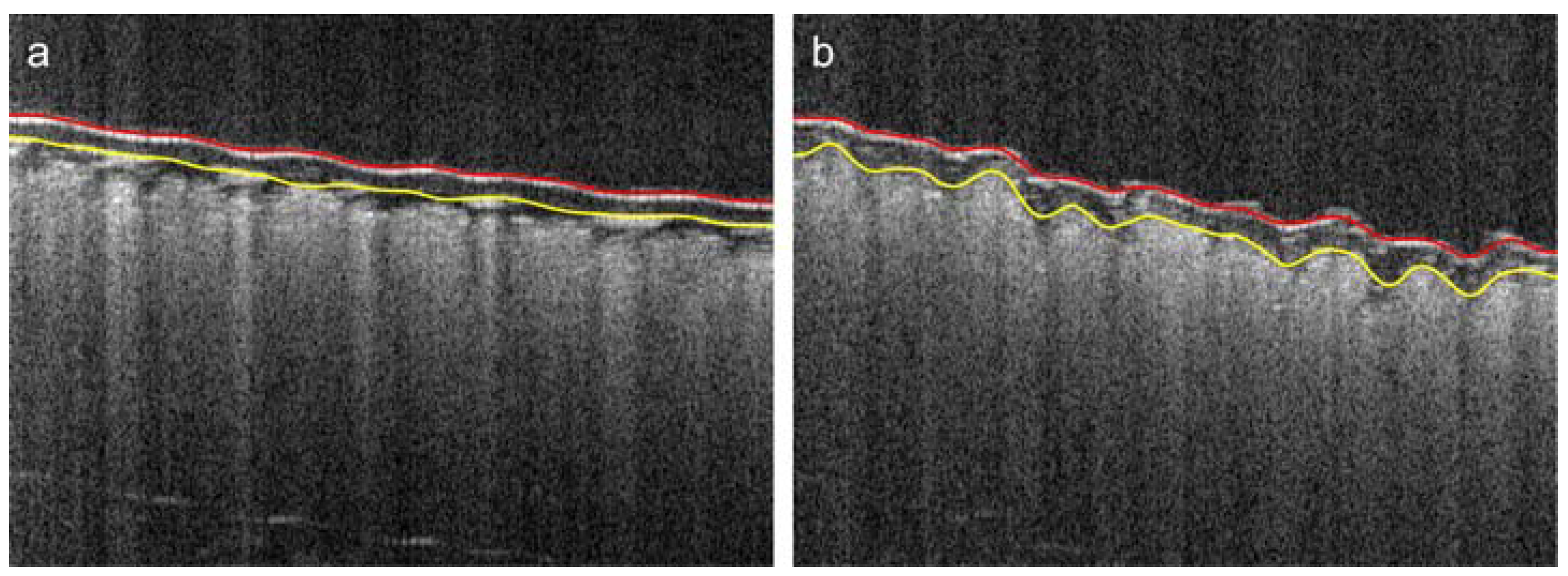

- Detection and approximation of the composite surface boundary in the XY plane of the imaging region (Figure 9a).

- Detection and approximation of the internal boundary of the composite cover layer in the XY plane of the imaging region (Figure 9b).

- Evaluation of the thickness maps of the cover layer by subtraction of the approximated boundaries (Figure 9b).

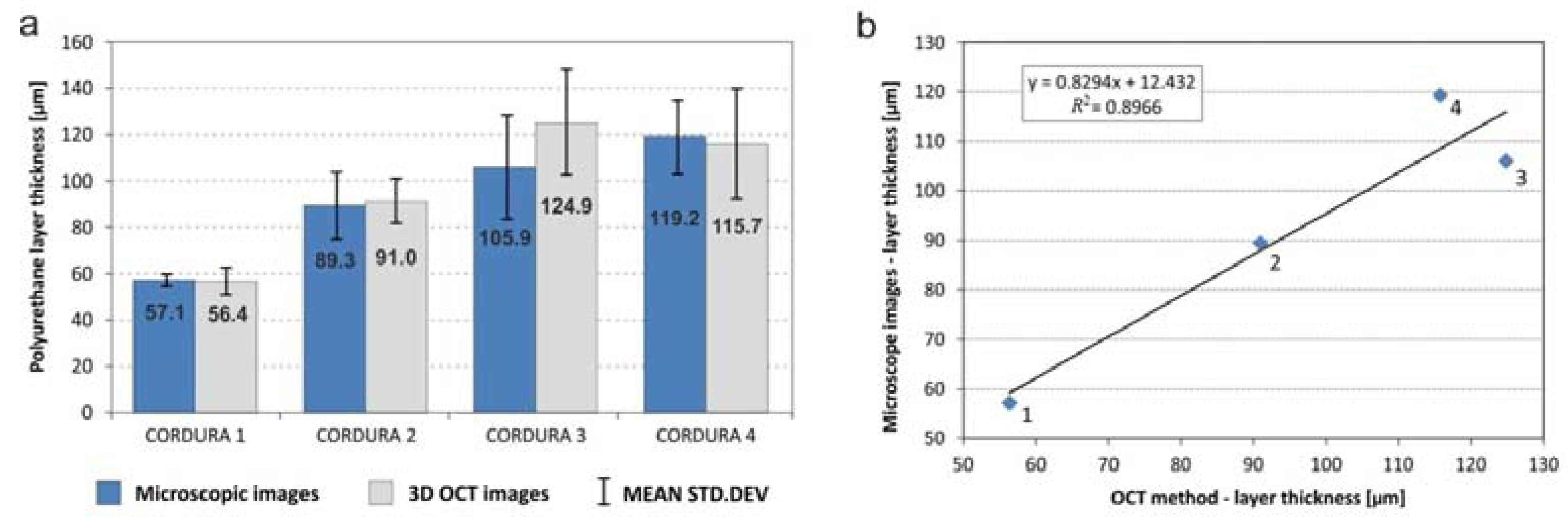

4. Results and Discussion

- = or voxels—MF filter dimensions in Equation (1) respectively for or boundary filtering,

- = or voxels—LoG filter dimensions in Equation (3) respectively for or boundary filtering,

- = voxel—standard deviations of Gaussian smoothing in LoG filter used in Equation (4),

- , —thresholds for the normalized boundary image in Equations (5) and (6), respectively,

- voxels, voxels—initial z-limit for searching the surface and internal boundaries,

- voxels—distance from the approximated surface at which to start searching for the internal boundary,

- , —the smoothing factors in Equations (12) and (14), respectively,

- equal to the doubled standard deviation of in Equation (8),

- voxels—the limit for corrected searching for the internal layer boundary.

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Singha, K. A Review on Coating and Lamination in Textiles: Processes and Applications. Am. J. Polym. Sci. 2012, 2, 39–49. [Google Scholar] [CrossRef]

- Kovacevic, S.; Ujevic, D.; Brnada, S. Coated Textile Materials. In Woven Fabric Engineering; Dubrovski, P.D., Ed.; Sciyo: Rijeka, Croatia, 2010; pp. 241–254. [Google Scholar]

- Dembicky, J. Simulation of the coating process. Fibres Text. East. Eur. 2010, 18, 79–83. [Google Scholar]

- Sen, A.K. Coated Textiles: Principles and Applications; CRC Press: Florida, FL, USA, 2001. [Google Scholar]

- Potocic-Matkovic, V.M.; Skenderi, Z. Mechanical properties of polyurethane coated knitted fabrics. Fibres Text. East. Eur. 2013, 21, 86–91. [Google Scholar]

- Kos, I.; Schwarz, I.G.; Suton, K. Influence of warp density on physical-mechanical properties of coated fabric. Procedia Eng. 2014, 69, 881–889. [Google Scholar] [CrossRef][Green Version]

- Huang, J.; Zhang, J.; Hao, X.; Guo, Y. Study of a new novel process for preparing and co-stretching PTFE membrane and its properties. Eur. Polym. J. 2004, 40, 667–671. [Google Scholar] [CrossRef]

- Visan, A.L.; Alexandrescu, N.; Belforte, G.; Eula, G.; Ivanov, A. Experimental researches on textile laminate materials. Ind. Text. 2012, 63, 315–321. [Google Scholar]

- Masteikaite, V.; Saceviciene, V. Study on tensile properties of coated fabrics and laminates. India J. Fibre Text. Res. 2005, 30, 267–272. [Google Scholar]

- Akovali, G. Advances in Polymer Coated Textiles; Smithers Rapra: Shawbury, UK, 2014. [Google Scholar]

- Cho, J.W.; Jung, J.C.; Chun, B.C.; Chung, Y.C. Water vapor permeability and mechanical properties of fabrics coated with shape-memory polyurethane. J. Appl. Polym. Sci. 2004, 92, 2812–2816. [Google Scholar] [CrossRef]

- Jeong, J.; Lim, Y.; Parka, J. Improving thermal stability and mechanical performance of polypropylene/polyurethane blend prepared by radiation-based techniques. Eur. Polym. J. 2017, 94, 366–375. [Google Scholar] [CrossRef]

- Korzeniewska, E.; Walczak, M.; Rymaszewski, J. Elements of elastic electronics created on textile substrate. In Proceedings of the 24th International Conference on Mixed Design of Integrated Circuits and Systems, Bydgoszcz, Poland, 22–24 June 2017; pp. 447–450. [Google Scholar]

- Goddard, J.M.; Hotchkiss, J.H. Polymer surface modification for the attachment of bioactive compounds. Prog. Polym. Sci. 2007, 32, 698–725. [Google Scholar] [CrossRef]

- Hao, X.; Zhang, J.; Guo, Y. Study of new protective clothing against sars using semi-permeable PTFE/PU membrane. Eur. Polym. J. 2004, 40, 673–678. [Google Scholar] [CrossRef]

- Lam, S.J.; Wong, E.H.; Boyer, C.; Qiao, G.G. Antimicrobial polymeric nanoparticles. Prog. Polym. Sci. 2018, 76, 40–64. [Google Scholar] [CrossRef]

- Munoz-Bonilla, A.; Fernández-García, M. Polymeric materials with antimicrobial activity. Prog. Polym. Sci. 2012, 37, 281–339. [Google Scholar] [CrossRef]

- Pawlak, R.; Korzeniewska, E.; Koneczny, C.; Hałgas, B. Properties of thin metal layers deposited on textile composites by using the pvd method for textronic applications. Autex Res. J. 2017, 17, 229–237. [Google Scholar] [CrossRef]

- Pawlak, R.; Lebioda, M.; Tomczyk, M.; Rymaszewski, J.; Korzeniewska, R.; Walczak, M. Surface heat sources on textile composites—Modeling and implementation. In Proceedings of the 18th International Symposium on Electromagnetic Fields in Mechatronics, Electrical and Electronic Engineering (ISEF), Lodz, Poland, 14–16 September 2017; pp. 1–2. [Google Scholar]

- Korzeniewska, E.; Duraj, A.; Koneczny, C.; Krawczyk, A. Thin film electrodes as elements of telemedicine systems. Prz. Elektrotech. 2015, 91, 162–165. [Google Scholar] [CrossRef]

- Frydrysiak, M.; Korzeniewska, E.; Tesiorowski, Ł. The textile resistive humidity sensor manufacturing via (PVD) sputtering method. Sens. Lett. 2015, 13, 998–1001. [Google Scholar] [CrossRef]

- Stempien, Z.; Kozicki, M.; Pawlak, R.; Korzeniewska, E.; Owczarek, G.; Poscik, A.; Sajna, D. Ammonia gas sensors ink-jet printed on textile substrates. Sensors 2017. [Google Scholar] [CrossRef]

- Bistricic, L.; Baranovic, G.; Leskovac, M.; Bajsic, E.G. Hydrogen bonding and mechanical properties of thin films of polyether-based polyurethane-silica nanocomposites. Eur. Polym. J. 2010, 46, 1975–1987. [Google Scholar] [CrossRef]

- Demirel, E.; Durmaz, H.; Hizal, G.; Tunca, U. A Route toward Multifunctional Polyurethanes Using Triple Click Reactions. J. Polym. Sci. A 2016, 54, 480–486. [Google Scholar] [CrossRef]

- Reddy, K.R.; Raghu, A.V.; Jeong, H.M. Synthesis and characterization of novel polyurethanes based on 4,4′-{1,4-phenylenebis [methylylidenenitrilo]} diphenol. Polym. Bull. 2008, 60, 609–616. [Google Scholar] [CrossRef]

- Reddy, K.R.; Raghu, A.V.; Jeong, H.M. Synthesis and characterization of pyridine-based polyurethanes. Des. Monomers Polym. 2009, 12, 109–118. [Google Scholar] [CrossRef]

- Choi, S.H.; Kim, D.H.; Raghu, A.V.; Reddy, K.R.; Lee, H.I.; Yoon, K.S.; Jeong, H.M.; Kim, B.K. Properties of Graphene/Waterborne Polyurethane Nanocomposites Cast from Colloidal Dispersion Mixtures. J. Macromol. Sci. 2012, 51, 197–207. [Google Scholar] [CrossRef]

- Chen, H.; Yuan, L.; Song, W.; Wu, Z.; Li, D. Biocompatible polymer materials: Role of protein-surface interactions. Prog. Polym. Sci. 2008, 33, 1059–1087. [Google Scholar] [CrossRef]

- Son, D.R.; Raghu, A.V.; Reddy, K.R.; Jeong, H.M. Compatibility of Thermally Reduced Graphene with Polyesters. J. Macromol. Sci. 2016, 55, 1099–1110. [Google Scholar] [CrossRef]

- Han, S.J.; Lee, H.; Jeong, H.M.; Kim, B.K.; Raghu, A.V.; Reddy, K.R. Graphene Modified Lipophilically by Stearic Acid and its Composite with Low Density Polyethylene. J. Macromol. Sci. 2014, 53, 1193–1204. [Google Scholar] [CrossRef]

- Dunkers, J.P.; Parnas, R.S.; Zimba, C.G.; Peterson, R.C.; Flynn, K.M.; Fujimoto, J.G.; Bouma, B.E. Optical coherence tomography of glass reinforced polymer composites. Compos. A 1999, 30, 139–145. [Google Scholar] [CrossRef]

- Dunkers, J.P.; Phela, F.; Sanders, D.P.; Everett, M.J.; Green, W.H.; Hunston, D.L.; Parnas, R.S. The application of optical coherence tomography to problems in polymer matrix composites. Opt. Lasers Eng. 2001, 35, 135–147. [Google Scholar] [CrossRef]

- Gliscinska, E.; Sankowski, D.; Krucinska, I.; Gocławski, J.; Michalak, M.; Rowinska, Z.; Sekulska-Nalewajko, J. Optical coherence tomography image analysis of polymer surface layers in sound-absorbing fibrous composite materials. Polym. Test. 2017, 63, 194–203. [Google Scholar] [CrossRef]

- WP OCT 1300-nm: Ultra Deep Imaging. 2017. Available online: http://wasatchphotonics.com/product-category/optical-coherence-tomography/wp-oct-1300/ (accessed on 12 April 2018).

- Sanders, J.; Kandrot, E. CUDA by Example: An Introduction to General-Purpose GPU Programming, 1st ed.; Addison-Wesley: Boston, MA, USA, 2011. [Google Scholar]

- Image Processing Toolbox. 2016. Available online: http://www.mathworks.com/help/images/ (accessed on 12 April 2018).

- CUDA Toolkit Documentation v9.1.85. 2017. Available online: http://docs.nvidia.com/cuda (accessed on 12 April 2018).

- Schmitt, J.; Xiang, S.; Yung, K. Speckle in optical coherence tomography. J. Biomed. Opt. 1999, 4, 95–105. [Google Scholar] [CrossRef] [PubMed]

- Zgou, Z.; Guo, Z.; Dong, G.; Sun, J.; Zhang, D.; Wu, B. A doubly degenerate diffusion model based on the gray level indicator for multiplicative noise removal. IEEE Trans. Image Process. 2015, 24, 249–258. [Google Scholar]

- Gocławski, J.; Sekulska-Nalewajko, J. A new idea of fast three-dimensional median filtering for despeclinkg of optical coherence tomography images. Image Process. Commun. 2015, 20, 25–34. [Google Scholar] [CrossRef]

- Rogers, S. 2D Weighted Polynomial Fitting and Evaluation. 2017. Available online: https://www.mathworks.com/matlabcentral/fileexchange/13719-2d-weighted-polynomial-fitting-and-evaluation (accessed on 12 April 2018).

- Garcia, D. Robust smoothing of gridded data in one and higher dimensions with missing values. Comput. Stat. Data Anal. 2010, 54, 1167–1178. [Google Scholar] [CrossRef] [PubMed]

| Cordura No. | Trade Name | Manufacturer | Surface Weight [g/m2] |

|---|---|---|---|

| Cordura 1 | Yellow (unknown serial number) | Miranda Ltd. Turek, Poland | 195 |

| Cordura 2 | CTD1000MS—Foliage Green | Rockwoods Ltd. Loveland, CO, USA | 380 |

| Cordura 3 | CTD1000—True Navy | Rockwoods Ltd. Loveland, CO, USA | 365 |

| Cordura 4 | Camouflage (unknown serial number) | Miranda Ltd. Turek, Poland | 460 |

| Cordura Type | [s] | [s] | [s] | [s] | [s] |

|---|---|---|---|---|---|

| 1 | 22.36 | 1.14 | 7.14 | 15.86 | 46.50 |

| 2 | 22.40 | 1.65 | 6.72 | 46.66 | 77.41 |

| 3 | 22.37 | 1.53 | 6.73 | 35.26 | 65.88 |

| 4 | 21.67 | 1.20 | 7.01 | 23.71 | 53.89 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gocławski, J.; Korzeniewska, E.; Sekulska-Nalewajko, J.; Sankowski, D.; Pawlak, R. Extraction of the Polyurethane Layer in Textile Composites for Textronics Applications Using Optical Coherence Tomography. Polymers 2018, 10, 469. https://doi.org/10.3390/polym10050469

Gocławski J, Korzeniewska E, Sekulska-Nalewajko J, Sankowski D, Pawlak R. Extraction of the Polyurethane Layer in Textile Composites for Textronics Applications Using Optical Coherence Tomography. Polymers. 2018; 10(5):469. https://doi.org/10.3390/polym10050469

Chicago/Turabian StyleGocławski, Jarosław, Ewa Korzeniewska, Joanna Sekulska-Nalewajko, Dominik Sankowski, and Ryszard Pawlak. 2018. "Extraction of the Polyurethane Layer in Textile Composites for Textronics Applications Using Optical Coherence Tomography" Polymers 10, no. 5: 469. https://doi.org/10.3390/polym10050469

APA StyleGocławski, J., Korzeniewska, E., Sekulska-Nalewajko, J., Sankowski, D., & Pawlak, R. (2018). Extraction of the Polyurethane Layer in Textile Composites for Textronics Applications Using Optical Coherence Tomography. Polymers, 10(5), 469. https://doi.org/10.3390/polym10050469