Novel Ultrafine Fibrous Poly(tetrafluoroethylene) Hollow Fiber Membrane Fabricated by Electrospinning

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Membrane Preparation

2.3. Characterization

2.3.1. Membrane Morphologies

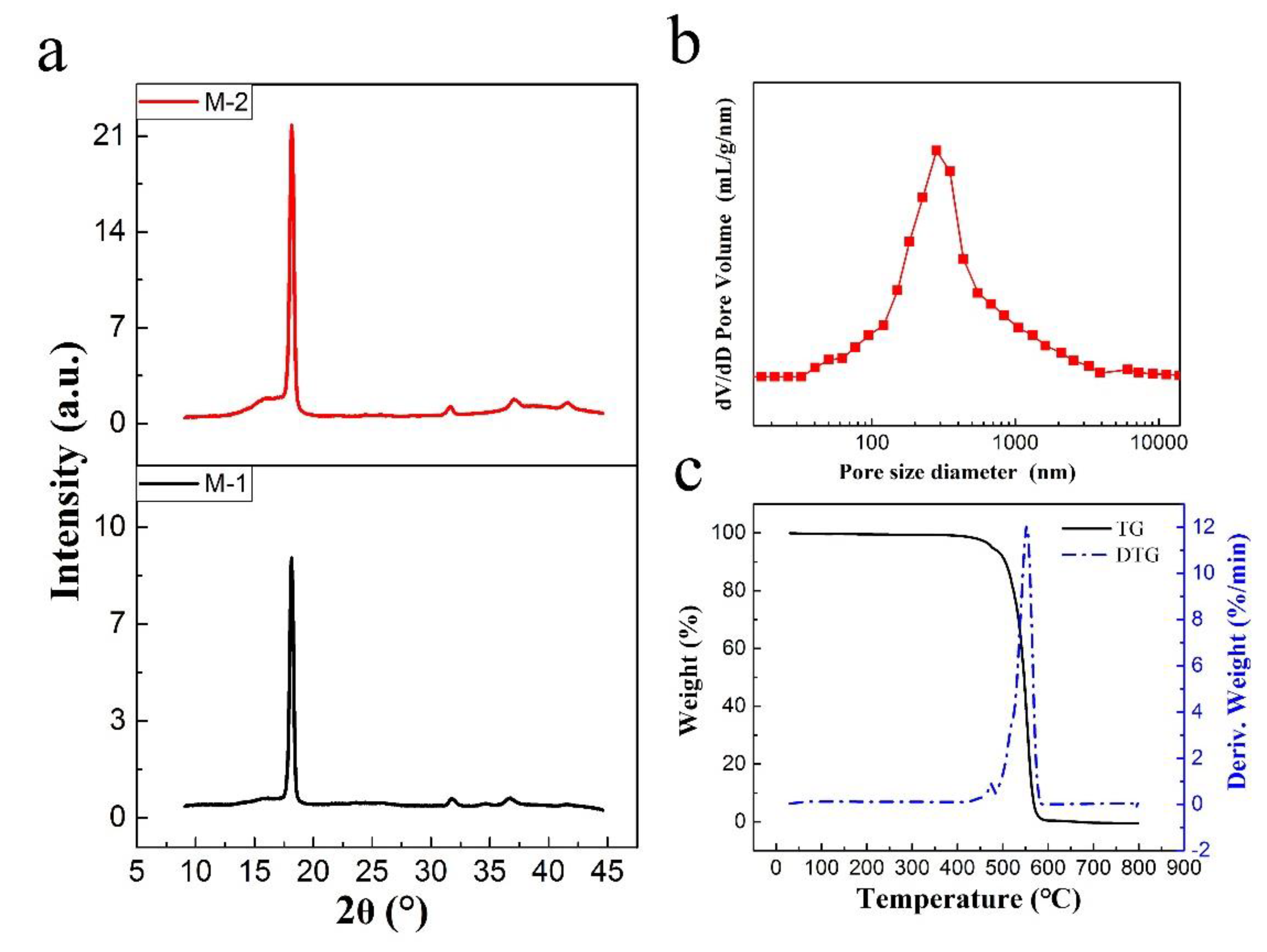

2.3.2. Structure Analyses

2.3.3. Membrane Properties

3. Results and Discussion

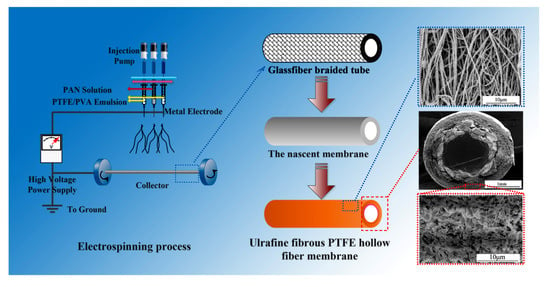

3.1. Formation mechanism

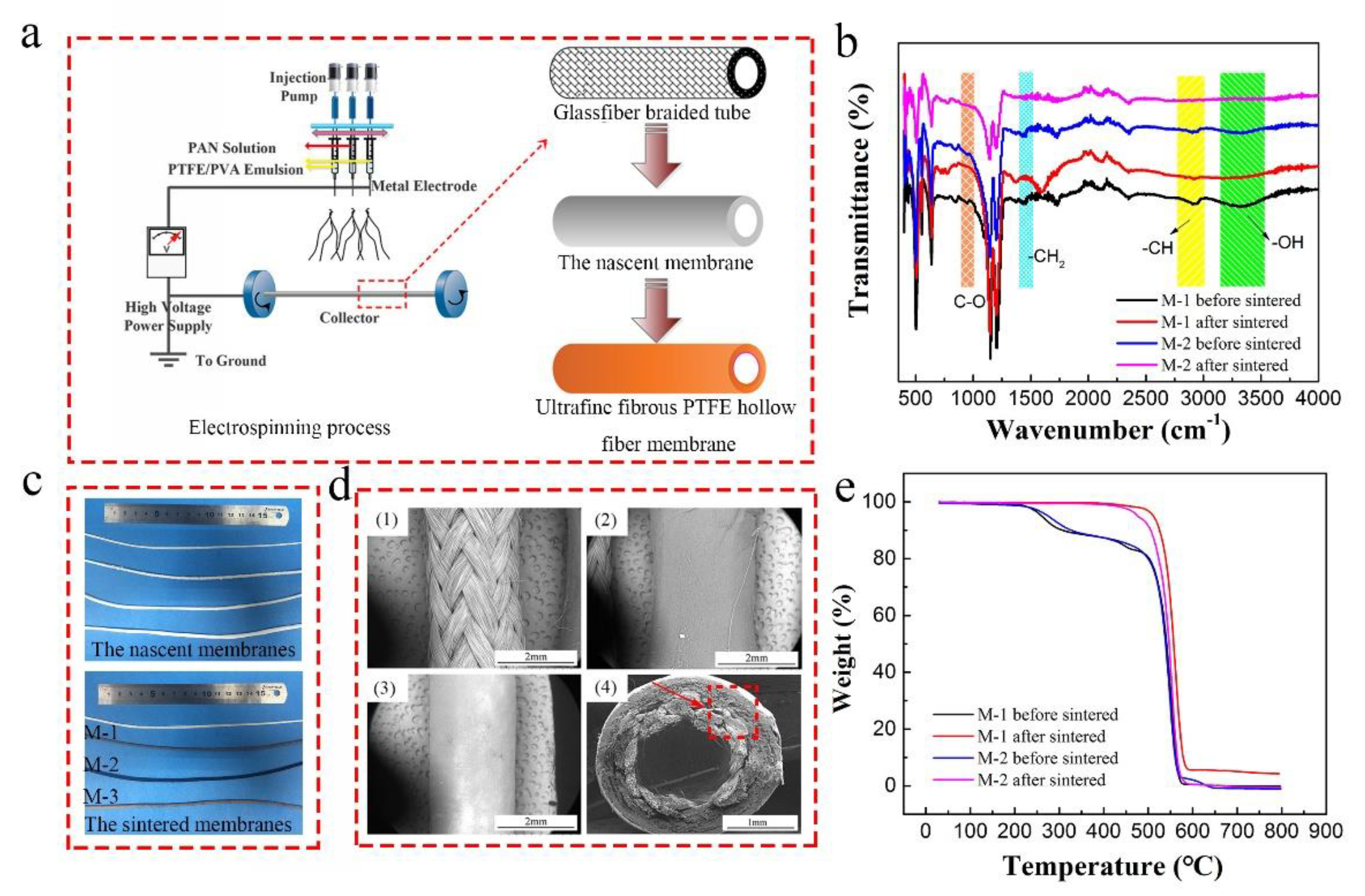

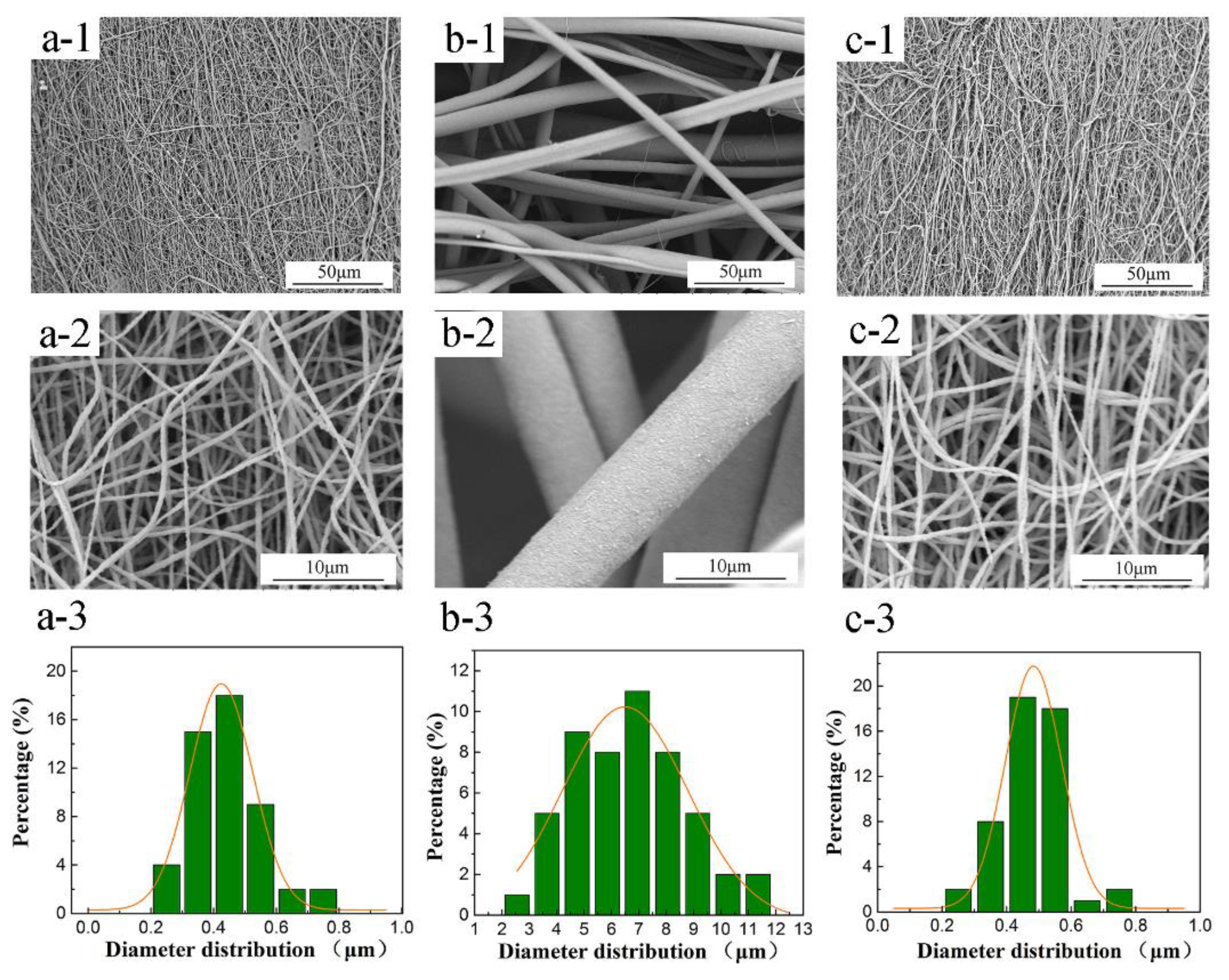

3.2. Morphology and structure

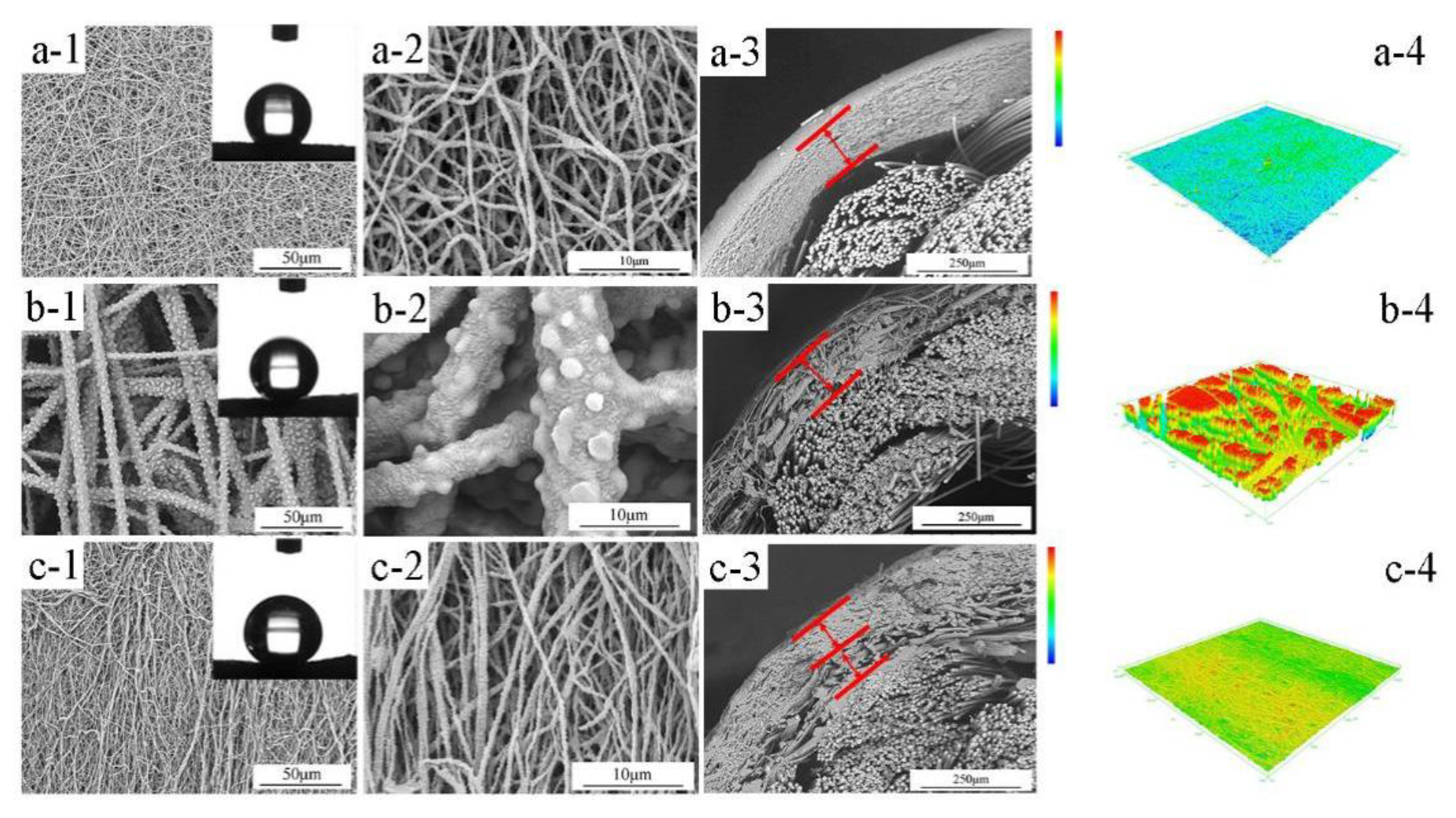

3.3. Properties

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Cui, Z.; Drioli, E.; Lee, Y.M. Recent progress in fluoropolymers for membranes. Prog. Polym. Sci. 2014, 39, 164–198. [Google Scholar] [CrossRef]

- Yong, J.; Fang, Y.; Chen, F.; Huo, J.; Yang, Q.; Bian, H.; Du, G.; Hou, X. Femtosecond laser ablated durable superhydrophobic PTFE films with micro-through-holes for oil/water separation: Separating oil from water and corrosive solutions. Appl. Surf. Sci. 2016, 389, 1148–1155. [Google Scholar] [CrossRef]

- Feng, S.S.; Li, D.Y.; Low, Z.X.; Liu, Z.Y.; Zhong, Z.X.; Hu, Y.X.; Wang, Y.; Xing, W.H. ALD-seeded hydrothermally-grown Ag/ZnO nanorod PTFE membrane as efficient indoor air filter. J. Membr. Sci. 2017, 531, 86–93. [Google Scholar] [CrossRef]

- Vincenzo, A.; Alessandro, G.; Giulio, T. High performance perfluoropolymer films and membranes. Ann. N. Y. Acad. Sci. 2003, 984, 226–244. [Google Scholar]

- Huang, Q.L.; Xiao, C.F.; Hu, X.Y.; Li, X.F. Study on the effects and properties of hydrophobic poly (tetrafluoroethylene) membrane. Desalination 2011, 277, 187–192. [Google Scholar] [CrossRef]

- Teoh, M.M.; Chung, T.S. Micelle-like macrovoids in mixed matrix PVDF-PTFE hollow fiber membranes. J. Membr. Sci. 2009, 338, 5–10. [Google Scholar] [CrossRef]

- Kurumada, K.; Kitamura, T.; Fukumoto, N.; Oshima, M.; Tanigaki, M.; Kanazawa, S. Structure generation in PTFE porous membranes induced by the uniaxial and biaxial stretching operations. J. Membr. Sci. 1998, 149, 51–57. [Google Scholar] [CrossRef]

- Xiong, J.; Huo, P.; Ko, F.K. Fabrication of ultrafine fibrous polytetrafluoroethylene porous membranes by electrospinning. J. Mater. Res. 2011, 24, 2755–2761. [Google Scholar] [CrossRef]

- Sun, A.C.; Kosar, W.; Zhang, Y.; Feng, X. Vacuum membrane distillation for desalination of water using hollow fiber membranes. J. Membr. Sci. 2014, 455, 131–142. [Google Scholar] [CrossRef]

- Kawai, T.; Katsu, T.; Yoshioka, T. Polytetrafluoroethylene Resin Porous Membrane, Separator Making Use of the Porous Membrane and Methods of Producing the Porous Membrane and the Separator. Patent US5286324, 15 February 1994. [Google Scholar]

- Zhu, H.; Wang, H.; Wang, F.; Guo, Y.; Zhang, H.; Chen, J. Preparation and properties of PTFE hollow fiber membranes for desalination through vacuum membrane distillation. J. Membr. Sci. 2013, 446, 145–153. [Google Scholar] [CrossRef]

- Wang, H.; Ding, S.; Zhu, H.; Wang, F.; Guo, Y.; Zhang, H.; Chen, J. Effect of stretching ratio and heating temperature on structure and performance of PTFE hollow fiber membrane in VMD for RO brine. Sep. Purif. Technol. 2014, 126, 82–94. [Google Scholar] [CrossRef]

- Huang, Q.L.; Xiao, C.F.; Hu, X.Y. Preparation and properties of polytetrafluoroethylene/CaCO3 hybrid hollow fiber membranes. J. Appl. Polym. Sci. 2012, 123, 324–330. [Google Scholar] [CrossRef]

- Hao, X.M.; Yang, Y.; Huang, B.X.; Huang, L.; Zhang, G.J. The effect of drawing process on the properties of split-film ptfe fiber. Adv. Mater. Res. 2013, 604, 1946–1950. [Google Scholar] [CrossRef]

- Su, C.; Lu, C.; Cao, H.; Gao, F.; Chang, J.; Li, Y.; He, C. Fabrication of a novel nanofibers-covered hollow fiber membrane via continuous electrospinning with non-rotational collectors. Mater. Lett. 2017, 204, 8–11. [Google Scholar] [CrossRef]

- Lee, S.; Kim, B.; Kim, S.H.; Kim, E.; Jang, J.H. Superhydrophobic, Reversibly Elastic, Moldable, and Electrospun (SupREME) Fibers with Multimodal Functions: From Oil Absorbents to Local Drug Delivery Adjuvants. Adv. Funct. Mater. 2017, 27, 1702310. [Google Scholar] [CrossRef]

- Teo, W.E.; Ramakrishna, S. A review on electrospinning design and nanofibre assemblies. Nanotechnology 2006, 17, R89. [Google Scholar] [CrossRef] [PubMed]

- Jing, Y.; Zhang, L.; Huang, R.; Bai, D.; Bai, H.; Zhang, Q.; Fu, Q. Ultrahigh-performance electrospun polylactide membranes with excellent oil/water separation ability via interfacial stereocomplex crystallization. J. Mater. Chem. A 2017, 5, 19729–19737. [Google Scholar] [CrossRef]

- Qing, W.; Shi, X.; Deng, Y.; Zhang, W.; Wang, J.; Tang, C.Y. Robust superhydrophobic-superoleophilic polytetrafluoroethylene nanofibrous membrane for oil/water separation. J. Membr. Sci. 2017, 540, 354–361. [Google Scholar] [CrossRef]

- Huang, Y.; Huang, Q.L.; Liu, H.; Zhang, C.X.; You, Y.W.; Li, N.N.; Xiao, C.F. Preparation, characterization, and applications of electrospun ultrafine fibrous PTFE porous membranes. J. Membr. Sci. 2017, 523, 317–326. [Google Scholar] [CrossRef]

- Huang, Q.L.; Huang, Y.; Xiao, C.F.; You, Y.W.; Zhang, C.X. Electrospun ultrafine fibrous PTFE-supported ZnO porous membrane with self-cleaning function for vacuum membrane distillation. J. Membr. Sci. 2017, 534, 73–82. [Google Scholar] [CrossRef]

- Huang, Q.L.; Xiao, C.F.; Hu, X.Y. A novel method to prepare hydrophobic poly (tetrafluoroethylene) membrane, and its properties. J. Mater. Sci. 2010, 45, 6569–6573. [Google Scholar] [CrossRef]

- Aslan, T.; Arslan, S.; Eyvaz, M.; Güçlü, S.; Yüksel, E.; Koyuncu, I. A novel nanofiber microfiltration membrane: Fabrication and characterization of tubular electrospun nanofiber (TuEN) membrane. J. Membr. Sci. 2016, 520, 616–629. [Google Scholar] [CrossRef]

- Ahmed, F.E.; Lalia, B.S.; Hashaikeh, R. A review on electrospinning for membrane fabrication: Challenges and applications. Desalination 2015, 356, 15–30. [Google Scholar] [CrossRef]

| Characteristic | Value |

|---|---|

| Voltage (kV) | 25 ± 0.1 |

| Relative humidity (%) | 70 ± 5 |

| Temperature (°C) | 25 ± 3 |

| Spinning distance (cm) | 8 ± 0.5 |

| Fluid flow rate (mL/min) | 0.008 |

| Collector diameter (mm) | 1.5 |

| Collector speed (rpm) | 400 |

| Samples | Average Roughness (μm) | WCA (°) | Porosity (%) | LEPw (MPa) | Mean Pore Size (nm) |

|---|---|---|---|---|---|

| M-1 | 0.534 | 136.4 ± 1.7 | 62.9 | 0.24 ± 0.02 | 555 |

| M-2 | 5.675 | 140.2 ± 0.9 | 73.6 | <0.02 | 1302 |

| M-3 | 0.615 | 135.2 ± 1.1 | 68.7 | 0.20 ± 0.02 | 548 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Q.; Huang, Y.; Gao, S.; Zhang, M.; Xiao, C. Novel Ultrafine Fibrous Poly(tetrafluoroethylene) Hollow Fiber Membrane Fabricated by Electrospinning. Polymers 2018, 10, 464. https://doi.org/10.3390/polym10050464

Huang Q, Huang Y, Gao S, Zhang M, Xiao C. Novel Ultrafine Fibrous Poly(tetrafluoroethylene) Hollow Fiber Membrane Fabricated by Electrospinning. Polymers. 2018; 10(5):464. https://doi.org/10.3390/polym10050464

Chicago/Turabian StyleHuang, Qinglin, Yan Huang, Shangpeng Gao, Mengyuan Zhang, and Changfa Xiao. 2018. "Novel Ultrafine Fibrous Poly(tetrafluoroethylene) Hollow Fiber Membrane Fabricated by Electrospinning" Polymers 10, no. 5: 464. https://doi.org/10.3390/polym10050464

APA StyleHuang, Q., Huang, Y., Gao, S., Zhang, M., & Xiao, C. (2018). Novel Ultrafine Fibrous Poly(tetrafluoroethylene) Hollow Fiber Membrane Fabricated by Electrospinning. Polymers, 10(5), 464. https://doi.org/10.3390/polym10050464