The Effect of Maleated Polypropylene on the Non-Isothermal Crystallization Kinetics of Wood Fiber-Reinforced Polypropylene Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Differential Scanning Calorimetry Measurement

2.3. Crystallization Kinetics

3. Results and Discussion

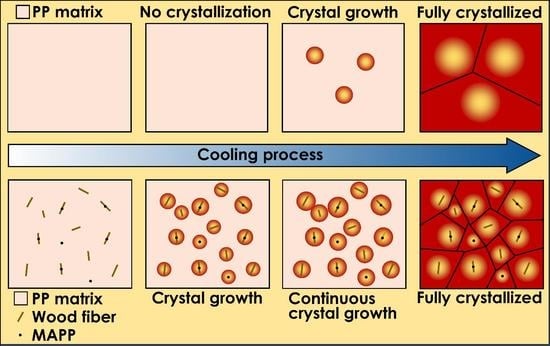

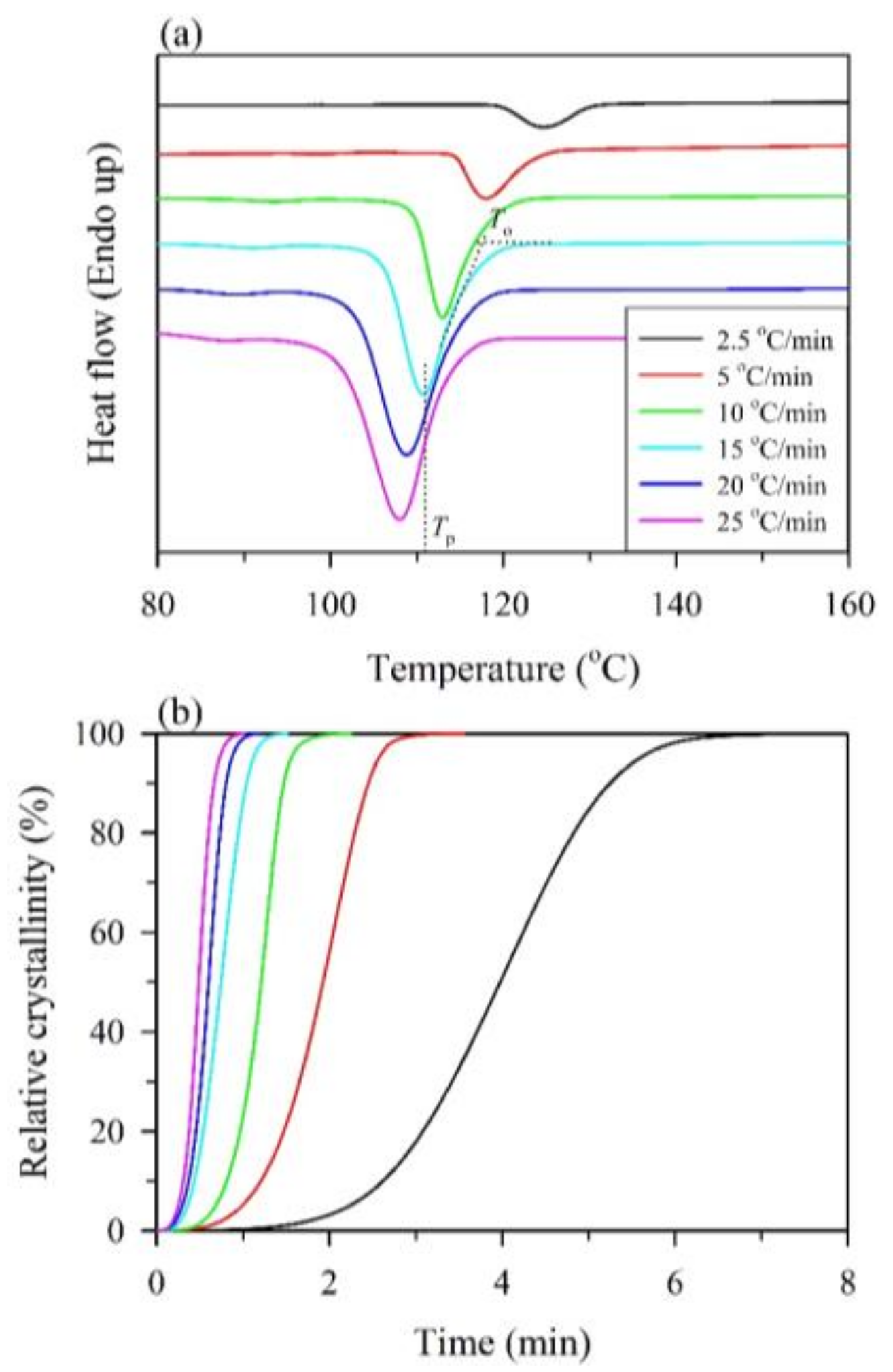

3.1. Non-Isothermal Crystallization Behavior

3.2. Kinetic Analysis with the Avrami Approach

3.3. Kinetic Analysis with the Avrami–Ozawa Approach

3.4. Activation Energy of Non-Isothermal Crystallization by the Kissinger Method and the Friedman Method

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bledzki, A.K.; Reihmane, S.; Gassan, J. Thermoplastics reinforced with wood fillers: A literature review. Polym. Plast. Technol. Eng. 1998, 37, 451–468. [Google Scholar] [CrossRef]

- Stark, N.M.; Matuana, L.M. Characterization of weathered wood-plastic composite surfaces using FTIR spectroscopy, contact angle, and XPS. Polym. Degrad. Stab. 2007, 92, 1883–1890. [Google Scholar] [CrossRef]

- Alsaeed, T.; Yousif, B.F.; Ku, H. The potential of using date palm fibres as reinforcement for polymeric composites. Mater. Des. 2013, 43, 177–184. [Google Scholar] [CrossRef]

- Hung, K.-C.; Yeh, H.; Yang, T.-C.; Wu, T.-L.; Xu, J.-W.; Wu, J.-H. Characterization of Wood-plastic composites made different lignocellulosic materials that vary in their morphology, chemical composition and thermal stability. Polymers 2017, 9, 726. [Google Scholar] [CrossRef]

- Georgiopoulos, P.; Kontou, E. The effect of wood-fiber type on the thermomechanical performance of biodegradable polymer matrix. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Mahlberg, R.; Paajanen, L.; Nurmi, A.; Kivistö, A.; Koskela, K.; Rowell, R.M. Effects of chemical modification of wood on the mechanical and adhesion properties of wood fiber/polypropylene fiber and polypropylene/veneer composites. Holz als Roh- und Werkstoff 2001, 59, 319–326. [Google Scholar] [CrossRef]

- Pendleton, D.E.; Hoffard, T.A.; Adcock, T.; Woodward, B.; Wolcott, M.P. Durability of an extruded HDPE/wood composite. For. Prod. J. 2002, 52, 21–27. [Google Scholar]

- Kazayawoko, M.; Balatinecz, J.J.; Matuana, L.M. Surface modification and adhesion mechanisms in wood fiber-polypropylene composites. J. Mater. Sci. 1999, 34, 6189–6199. [Google Scholar] [CrossRef]

- Hosseinaei, O.; Wang, S.; Enayati, A.A.; Rials, T.G. Effect of hemicellulose extraction on properties of wood flour and wood–plastic composites. Compos. A Appl. Sci. Manuf. 2012, 43, 686–694. [Google Scholar] [CrossRef]

- Georgiopoulos, P.; Christopoulos, A.; Koutsoumpis, S.; Kontou, E. The effect of surface treatment on the performance of flax/biodegradable composites. Compos. B Eng. 2016, 106, 88–98. [Google Scholar] [CrossRef]

- Fleix, J.M.; Gatenholm, P. The nature of adhesion in composites of modified cellulose fibers and polypropylene. J. Appl. Polym. Sci. 1991, 42, 609–620. [Google Scholar] [CrossRef]

- Keener, T.J.; Stuart, R.K.; Brown, T.K. Maleated coupling agents for natural fibre composites. Compos. A Appl. Sci. Manuf. 2004, 35, 357–362. [Google Scholar] [CrossRef]

- Ichazo, M.N.; Albano, C.; González, J.; Perera, R.; Candal, M.V. Polypropylene/wood flour composites: Treatments and properties. Compos. Struct. 2001, 54, 207–214. [Google Scholar] [CrossRef]

- Lee, S.H.; Wang, S. Biodegradable polymers/bamboo fiber biocomposite with bio-based coupling agent. Compos. A Appl. Sci. Manuf. 2006, 37, 80–91. [Google Scholar] [CrossRef]

- Mwaikambo, L.Y.; Ansell, M.P. The effect of chemical treatment on the properties of hemp, sisal, jute and kapok for composite reinforcement. Macromol. Mater. Eng. 1999, 272, 108–116. [Google Scholar] [CrossRef]

- Das, M.; Chakraborty, D. Evaluation of improvement of physical and mechanical properties of bamboo fibers due to alkali treatment. J. Appl. Polym. Sci. 2008, 107, 522–527. [Google Scholar] [CrossRef]

- Hung, K.-C.; Wu, J.-H. Mechanical and interfacial properties of plastic composite panels made from esterified bamboo particles. J. Wood Sci. 2010, 56, 216–221. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Jarusombuti, S.; Fueangvivat, V.; Bauchongkol, P. Effect of thermal-treatment of wood fibers on properties of flat–pressed wood plastic composites. Polym. Degrad. Stab. 2011, 96, 818–822. [Google Scholar] [CrossRef]

- Yang, T.-C.; Chien, Y.-C.; Wu, T.-L.; Hung, K.-C.; Wu, J.-H. Effects of heat-treated wood particles on the physico-mechanical properties and extended creep behavior of wood/recycled-HDPE composites using the time-temperature superposition principle. Materials 2017, 10, 365. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: A review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Ou, R.; Guo, C.; Xie, Y.; Wang, Q. Non-isothermal crystallization kinetics of kevlar fiber-reinforced wood flour/HDPE composites. BioResources 2011, 6, 4547–4565. [Google Scholar]

- Mishra, S.; Naik, J.B.; Patil, Y.P. The compatibilising effect of maleic anhydride on swelling and mechanical properties of plant-fiber-reinforced novolac composites. Compos. Sci. Technol. 2000, 60, 1729–1735. [Google Scholar] [CrossRef]

- Qiu, W.; Zhang, F.; Endo, T.; Hirotsu, T. Preparation and characteristics of composites of high-crystalline cellulose with polypropylene: Effects of maleated polypropylene and cellulose content. J. Appl. Polym. Sci. 2003, 87, 337–345. [Google Scholar] [CrossRef]

- Mohanty, S.; Nayak, S.K.; Verma, S.K.; Tripathy, S.S. Effect of MAPP as a coupling agent on the performance of jute-PP composites. J. Reinf. Plast. Compos. 2004, 23, 625–637. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Letman, M.; Viksne, A.; Rence, L. A comparison of compounding processes and wood type for wood fibre-PP composites. Compos. A Appl. Sci. Manuf. 2005, 36, 789–797. [Google Scholar] [CrossRef]

- Kamal, M.R.; Chu, E. Isothermal and nonisothermal crystallization of polyethylene. Polym. Eng. Sci. 1983, 23, 27–31. [Google Scholar] [CrossRef]

- Arbelaiz, A.; Fernández, B.; Ramos, J.A.; Mondragon, I. Thermal and crystallization studies of short flax fibre reinforced polypropylene matrix composites: Effect of treatments. Thermochim. Acta 2006, 440, 111–121. [Google Scholar] [CrossRef]

- Buzarovska, A.; Bogoeva-Gaceva, G.; Grozdanov, A.; Avella, M. Crystallization behavior of polyhydroxybutyrate in model composites with kenaf fibers. J. Appl. Polym. Sci. 2006, 102, 804–809. [Google Scholar] [CrossRef]

- Niu, P.; Wang, X.; Liu, B.; Long, S.; Yang, J. Melting and nonisothermal crystallization behavior of polypropylene/hemp fiber composites. J. Compos. Mater. 2012, 46, 203–210. [Google Scholar] [CrossRef]

- Hsu, C.-Y.; Yang, T.-C.; Wu, T.-L.; Hung, K.-C.; Wu, J.-H. The influence of bamboo fiber content on the non-isothermal crystallization kinetics of bamboo fiber-reinforced polypropylene composites (BPCs). Holzforschung 2018, 72, 329–336. [Google Scholar] [CrossRef]

- Phuong, N.T.; Gilbert, V. Non-isothermal crystallization kinetics of short bamboo fiber-reinforced recycled polypropylene composites. J. Reinf. Plast. Compos. 2010, 29, 2576–2591. [Google Scholar] [CrossRef]

- Marinelli, A.L.; Bretas, R.E.S. Blends of polypropylene resins with a liquid crystalline polymer. I. Isothermal crystallization. J. Appl. Polym. Sci. 2003, 87, 916–930. [Google Scholar] [CrossRef]

- Avrami, M. Kinetics of phase change. I: General theory. J. Chem. Phys. 1939, 7, 1103–1112. [Google Scholar] [CrossRef]

- Avrami, M. Kinetics of phase change. II: Transformation-time relations for random distribution of nuclei. J. Chem. Phys. 1940, 8, 212–224. [Google Scholar] [CrossRef]

- Avrami, M. Kinetics of phase change. III: Granulation, phase change, and microstructure. J. Chem. Phys. 1941, 9, 177–184. [Google Scholar] [CrossRef]

- Ozawa, T. Kinetics of non-isothermal crystallization. Polymer 1971, 12, 150–158. [Google Scholar] [CrossRef]

- Cebe, P.; Hong, S.D. Crystallization behaviour of poly(ether-ether-ketone). Polymer 1986, 27, 1183–1192. [Google Scholar] [CrossRef]

- Eder, M.; Wlochowicz, A. Kinetics of non-isothermal crystallization of polyethylene and polypropylene. Polymer 1983, 24, 1593–1595. [Google Scholar] [CrossRef]

- Hao, W.; Yang, W.; Cai, H.; Huang, Y. Non-isothermal crystallization kinetics of polypropylene/silicon nitride nanocomposites. Polym. Test. 2010, 29, 527–533. [Google Scholar] [CrossRef]

- Liu, T.; Mo, Z.; Wang, S.; Zhang, H. Nonisothermal melt and cold crystallization kinetics of poly(aryl ether ether ketone ketone). Polym. Eng. Sci. 1997, 37, 568–575. [Google Scholar] [CrossRef]

- Liu, T.; Mo, Z.; Zhang, H. Nonisothermal crystallization behavior of a novel poly(aryl ether ketone): PEDEKmK. J. Appl. Polym. Sci. 1998, 67, 815–821. [Google Scholar] [CrossRef]

- Kissinger, H.E. Variation of peak temperature with heating rate in differential thermal analysis. J. Res. Nat. Inst. Stand. Technol. 1956, 57, 217–221. [Google Scholar] [CrossRef]

- Friedman, H.L. Kinetics of thermal degradation of char-forming plastics from thermogravimetry. Application to a phenolic plastic. J. Polym. Sci. Polym. Symp. 1964, 6, 183–195. [Google Scholar] [CrossRef]

- Grozdanov, A.; Buzarovska, A.; Bogoeva-Gaceva, G.; Avella, M.; Errico, M.E.; Gentile, G. Nonisothermal crystallization kinetics of kenaf fiber/polypropylene composites. Polym. Eng. Sci. 2007, 47, 745–749. [Google Scholar] [CrossRef]

- Lei, Y.; Wu, Q.; Clemons, C.M.; Yao, F.; Xu, Y. Influence of nanoclay on properties of HDPE/wood composites. J. Appl. Polym. Sci. 2007, 106, 3958–3966. [Google Scholar] [CrossRef]

- Regis, M.; Zanetti, M.; Pressacco, M.; Bracco, P. Opposite role of different carbon reinforcements on the non-isothermal crystallization behavior of poly(etheretherketone). Mater. Chem. Phys. 2016, 179, 223–231. [Google Scholar] [CrossRef]

- Lee, S.-H.; Ohkita, T. Bamboo fiber (BF)-filled poly(butylenes succinate) bio-composite—Effect of BF-e-MA on the properties and crystallization kinetics. Holzforschung 2004, 58, 537–543. [Google Scholar] [CrossRef]

- Jeziorny, A. Parameters characterizing the kinetics of the non-isothermal crystallization of poly(ethylene terephthalate) determined by d.s.c. Polymer 1978, 19, 1142–1144. [Google Scholar] [CrossRef]

- Yuan, Q.; Awate, S.; Misra, R.D.K. Nonisothermal crystallization behavior of polypropylene-clay nanocomposites. Eur. Polym. J. 2006, 42, 1994–2003. [Google Scholar] [CrossRef]

- Run, M.; Song, H.; Yao, C.; Wang, Y. Crystal morphology and nonisothermal crystallization kinetics of short carbon fiber/poly(trimethylene terephthalate) composites. J. Appl. Polym. Sci. 2007, 106, 868–877. [Google Scholar] [CrossRef]

| Code | WF (wt %) | PP (wt %) | MAPP (wt %) |

|---|---|---|---|

| Neat PP | 0 | 100 | 0 |

| WPC0 | 60 | 40 | 0 |

| WPCM1 | 60 | 39 | 1 |

| WPCM3 | 60 | 37 | 3 |

| WPCM5 | 60 | 35 | 5 |

| WPCM7 | 60 | 33 | 7 |

| Code | Cooling Rate (°C/min) | K | KJ | n | R2 |

|---|---|---|---|---|---|

| Neat PP | 2.5 | 0.19 ± 0.01 | 0.52 ± 0.01 | 1.77 ± 0.05 | 0.9856 |

| 5 | 0.28 ± 0.02 | 0.78 ± 0.01 | 1.74 ± 0.04 | 0.9873 | |

| 10 | 0.69 ± 0.10 | 0.96 ± 0.01 | 1.67 ± 0.06 | 0.9823 | |

| 15 | 1.31 ± 0.59 | 1.01 ± 0.03 | 1.83 ± 0.02 | 0.9817 | |

| 20 | 5.17 ± 1.51 | 1.08 ± 0.02 | 1.87 ± 0.22 | 0.9878 | |

| 25 | 14.23 ± 0.52 | 1.11 ± 0.00 | 1.99 ± 0.05 | 0.9931 | |

| WPC0 | 2.5 | 0.63 ± 0.04 | 0.83 ± 0.02 | 2.04 ± 0.35 | 0.9889 |

| 5 | 0.14 ± 0.04 | 0.67 ± 0.04 | 1.84 ± 0.00 | 0.9885 | |

| 10 | 1.08 ± 0.26 | 1.00 ± 0.02 | 1.77 ± 0.70 | 0.9923 | |

| 15 | 0.73 ± 0.03 | 0.98 ± 0.01 | 1.70 ± 0.16 | 0.9836 | |

| 20 | 1.12 ± 0.05 | 1.01 ± 0.02 | 1.73 ± 0.13 | 0.9854 | |

| 25 | 5.74 ± 1.62 | 1.07 ± 0.01 | 1.65 ± 0.32 | 0.9951 | |

| WPCM1 | 2.5 | 0.20 ± 0.04 | 0.52 ± 0.05 | 1.57 ± 0.10 | 0.9770 |

| 5 | 0.26 ± 0.03 | 0.76 ± 0.02 | 1.62 ± 0.12 | 0.9776 | |

| 10 | 0.63 ± 0.05 | 0.96 ± 0.01 | 1.82 ± 0.29 | 0.9487 | |

| 15 | 3.08 ± 1.14 | 1.07 ± 0.03 | 1.93 ± 0.11 | 0.9807 | |

| 20 | 1.24 ± 0.39 | 1.01 ± 0.02 | 1.71 ± 0.08 | 0.9673 | |

| 25 | 1.59 ± 0.52 | 1.02 ± 0.01 | 1.93 ± 0.01 | 0.9925 | |

| WPCM3 | 2.5 | 0.79 ± 0.47 | 0.87 ± 0.23 | 2.03 ± 0.88 | 0.9984 |

| 5 | 0.40 ± 0.01 | 0.83 ± 0.00 | 1.75 ± 0.28 | 0.9660 | |

| 10 | 1.82 ± 0.30 | 1.06 ± 0.02 | 1.61 ± 0.25 | 0.9655 | |

| 15 | 3.33 ± 0.07 | 1.08 ± 0.00 | 1.99 ± 0.09 | 0.9859 | |

| 20 | 2.27 ± 0.06 | 1.04 ± 0.00 | 1.42 ± 0.08 | 0.9886 | |

| 25 | 2.27 ± 0.09 | 1.03 ± 0.00 | 1.50 ± 0.20 | 0.9819 | |

| WPCM5 | 2.5 | 0.22 ± 0.02 | 0.55 ± 0.02 | 1.55 ± 0.03 | 0.9872 |

| 5 | 0.16 ± 0.10 | 0.67 ± 0.09 | 1.43 ± 0.10 | 0.9385 | |

| 10 | 0.92 ± 0.21 | 0.99 ± 0.02 | 1.89 ± 0.04 | 0.9679 | |

| 15 | 0.78 ± 0.07 | 0.98 ± 0.01 | 1.40 ± 0.55 | 0.9711 | |

| 20 | 1.11 ± 0.31 | 1.00 ± 0.01 | 1.37 ± 0.27 | 0.9449 | |

| 25 | 2.77 ± 0.20 | 1.04 ± 0.00 | 1.61 ± 0.44 | 0.9906 | |

| WPCM7 | 2.5 | 0.11 ± 0.01 | 0.42 ± 0.01 | 1.56 ± 0.18 | 0.9697 |

| 5 | 0.17 ± 0.02 | 0.70 ± 0.01 | 1.28 ± 0.03 | 0.9808 | |

| 10 | 0.63 ± 0.11 | 0.95 ± 0.02 | 1.32 ± 0.03 | 0.9752 | |

| 15 | 5.35 ± 0.44 | 1.12 ± 0.01 | 1.68 ± 0.40 | 0.9848 | |

| 20 | 1.21 ± 0.35 | 1.01 ± 0.02 | 1.77 ± 0.52 | 0.9476 | |

| 25 | 4.09 ± 1.61 | 1.05 ± 0.02 | 2.03 ± 0.22 | 0.9762 |

| Code | X (%) | F(T) | α | R2 |

|---|---|---|---|---|

| Neat PP | 20 | 8.8 ± 0.1 | 1.2 ± 0.0 | 0.9891 |

| 40 | 10.8 ± 0.1 | 1.1 ± 0.0 | 0.9952 | |

| 60 | 12.6 ± 0.1 | 1.1 ± 0.0 | 0.9954 | |

| 80 | 14.7 ± 0.1 | 1.1 ± 0.0 | 0.9941 | |

| WPC0 | 20 | 7.4 ± 0.2 | 1.0 ± 0.1 | 0.9611 |

| 40 | 8.8 ± 0.4 | 1.0 ± 0.0 | 0.9636 | |

| 60 | 9.9 ± 0.4 | 1.1 ± 0.1 | 0.9687 | |

| 80 | 11.5 ± 0.5 | 1.1 ± 0.0 | 0.9661 | |

| WPCM1 | 20 | 7.6 ± 0.3 | 1.2 ± 0.0 | 0.9685 |

| 40 | 9.7 ± 0.1 | 1.2 ± 0.1 | 0.9869 | |

| 60 | 11.1 ± 0.1 | 1.2 ± 0.1 | 0.9885 | |

| 80 | 12.9 ± 0.2 | 1.3 ± 0.1 | 0.9898 | |

| WPCM3 | 20 | 7.1 ± 0.0 | 1.1 ± 0.1 | 0.9711 |

| 40 | 8.5 ± 0.1 | 1.1 ± 0.1 | 0.9765 | |

| 60 | 9.4 ± 0.1 | 1.1 ± 0.1 | 0.9774 | |

| 80 | 11.3 ± 0.2 | 1.2 ± 0.1 | 0.9786 | |

| WPCM5 | 20 | 7.9 ± 0.7 | 1.0 ± 0.1 | 0.9705 |

| 40 | 9.3 ± 0.9 | 1.1 ± 0.1 | 0.9780 | |

| 60 | 10.8 ± 1.3 | 1.1 ± 0.1 | 0.9821 | |

| 80 | 12.4 ± 1.4 | 1.2 ± 0.1 | 0.9846 | |

| WPCM7 | 20 | 8.6 ± 0.2 | 1.2 ± 0.0 | 0.9818 |

| 40 | 10.3 ± 0.2 | 1.2 ± 0.0 | 0.9846 | |

| 60 | 11.7 ± 0.2 | 1.2 ± 0.0 | 0.9853 | |

| 80 | 13.7 ± 0.0 | 1.2 ± 0.0 | 0.9849 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, C.-W.; Yang, T.-C.; Hung, K.-C.; Xu, J.-W.; Wu, J.-H. The Effect of Maleated Polypropylene on the Non-Isothermal Crystallization Kinetics of Wood Fiber-Reinforced Polypropylene Composites. Polymers 2018, 10, 382. https://doi.org/10.3390/polym10040382

Huang C-W, Yang T-C, Hung K-C, Xu J-W, Wu J-H. The Effect of Maleated Polypropylene on the Non-Isothermal Crystallization Kinetics of Wood Fiber-Reinforced Polypropylene Composites. Polymers. 2018; 10(4):382. https://doi.org/10.3390/polym10040382

Chicago/Turabian StyleHuang, Chung-Wei, Teng-Chun Yang, Ke-Chang Hung, Jin-Wei Xu, and Jyh-Horng Wu. 2018. "The Effect of Maleated Polypropylene on the Non-Isothermal Crystallization Kinetics of Wood Fiber-Reinforced Polypropylene Composites" Polymers 10, no. 4: 382. https://doi.org/10.3390/polym10040382

APA StyleHuang, C.-W., Yang, T.-C., Hung, K.-C., Xu, J.-W., & Wu, J.-H. (2018). The Effect of Maleated Polypropylene on the Non-Isothermal Crystallization Kinetics of Wood Fiber-Reinforced Polypropylene Composites. Polymers, 10(4), 382. https://doi.org/10.3390/polym10040382