Study of a Novel Gemini Viscoelastic Surfactant with High Performance in Clean Fracturing Fluid Application

Abstract

1. Introduction

2. Experimental

2.1. Materials

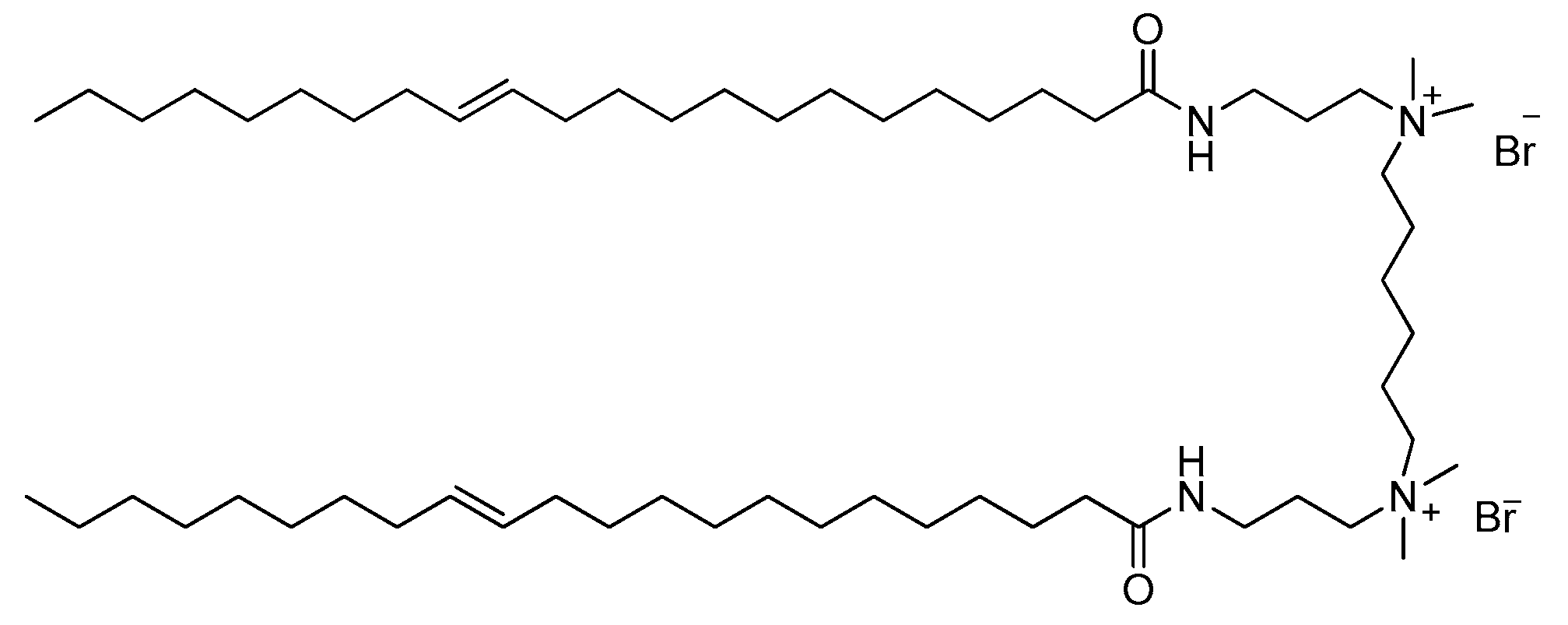

2.2. Synthesis of the Gemini Cationic Surfactants

2.3. Experimental Tests

3. Results and Discussion

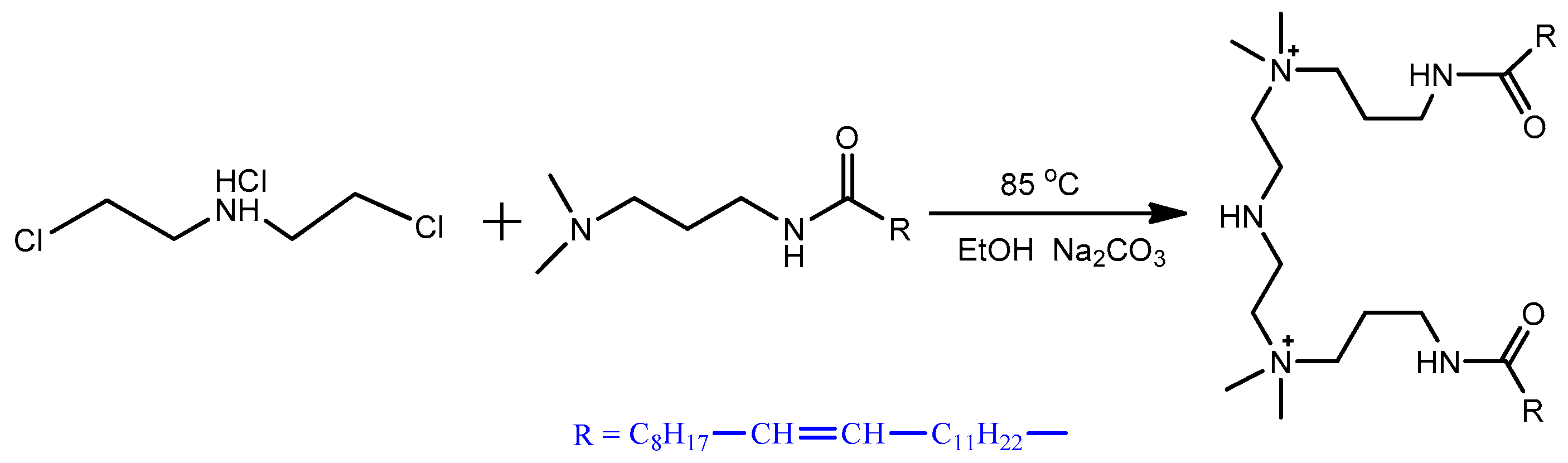

3.1. Structural Characterization

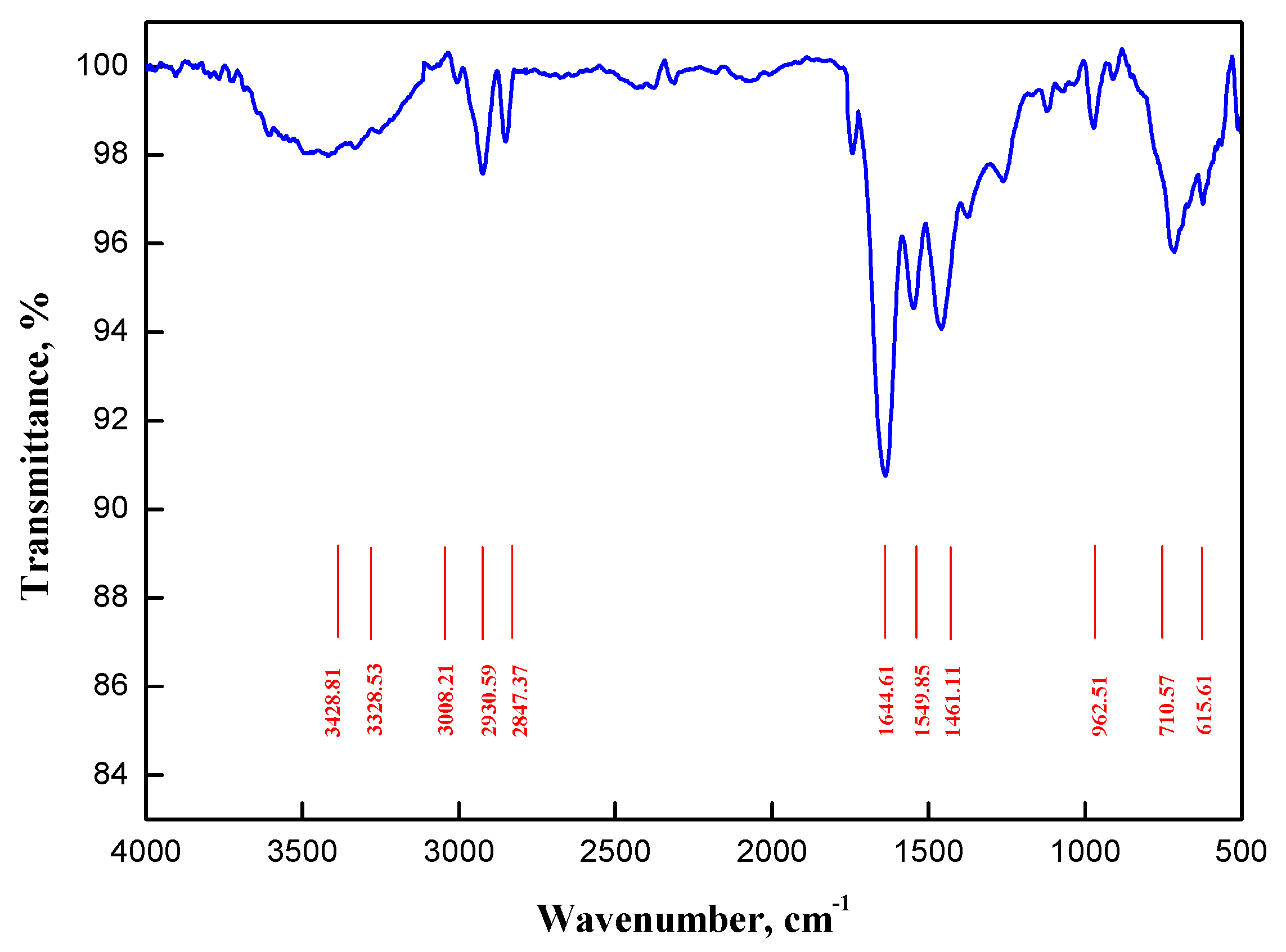

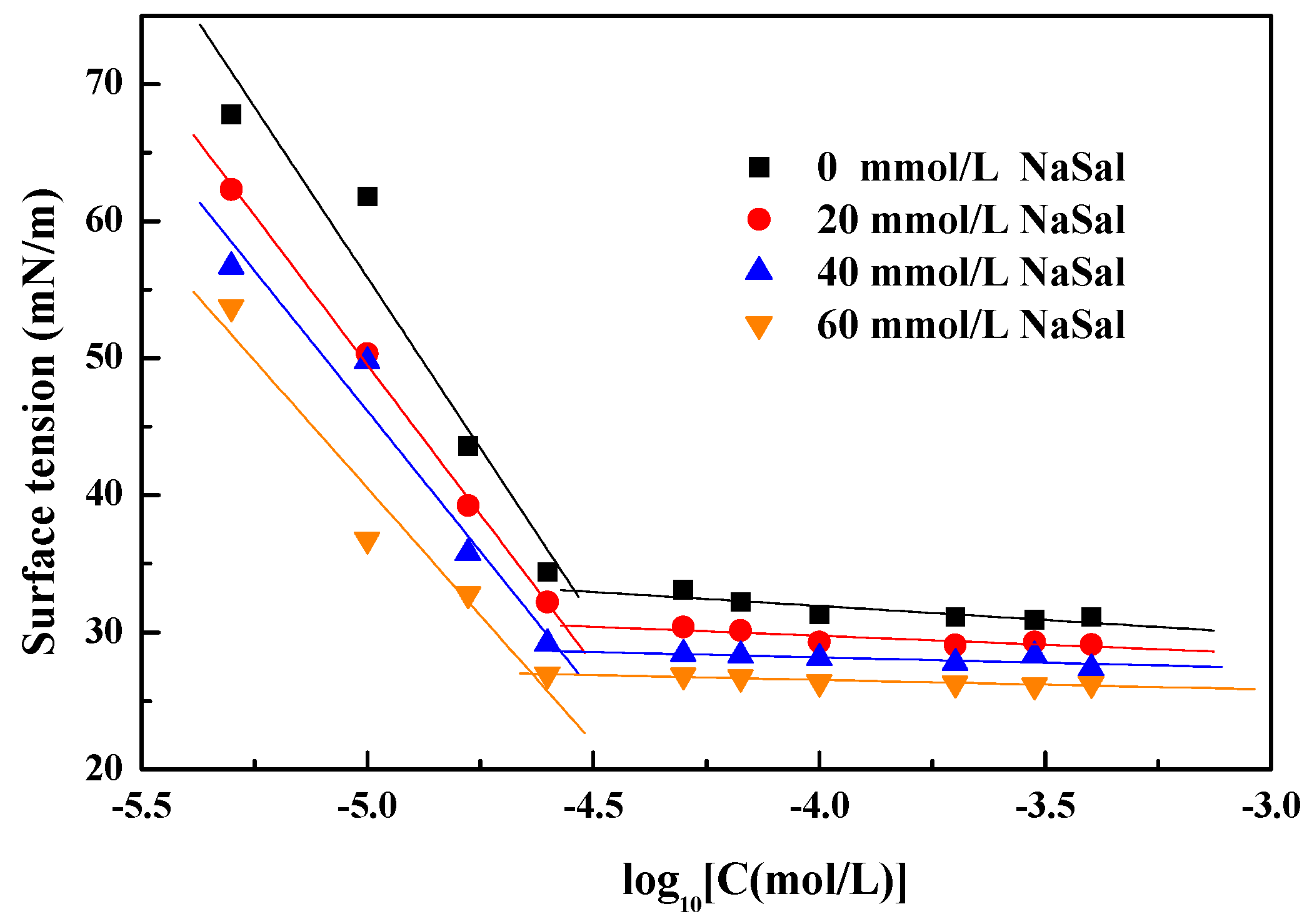

3.2. Surface Tension Measurement

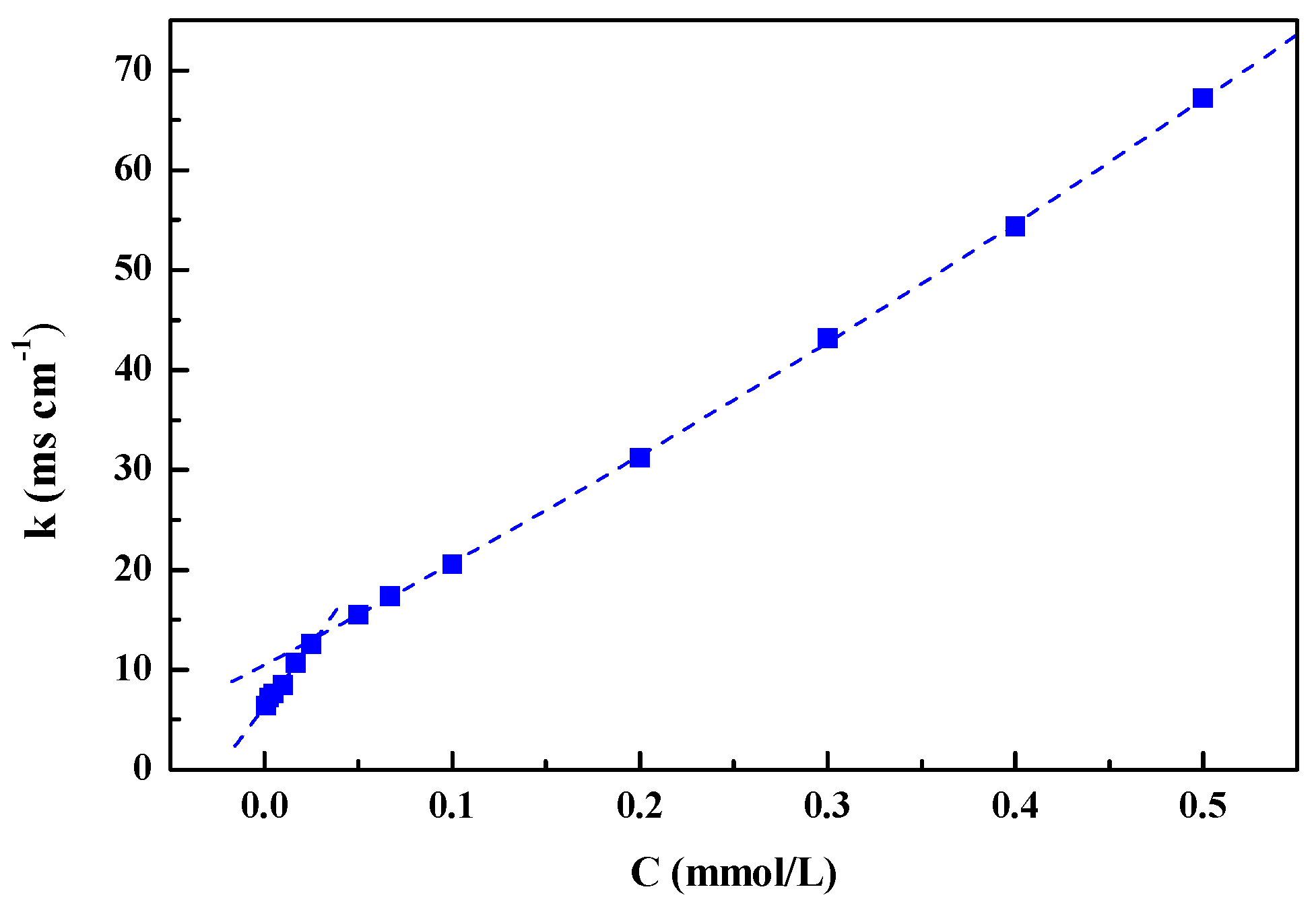

3.3. Conductance

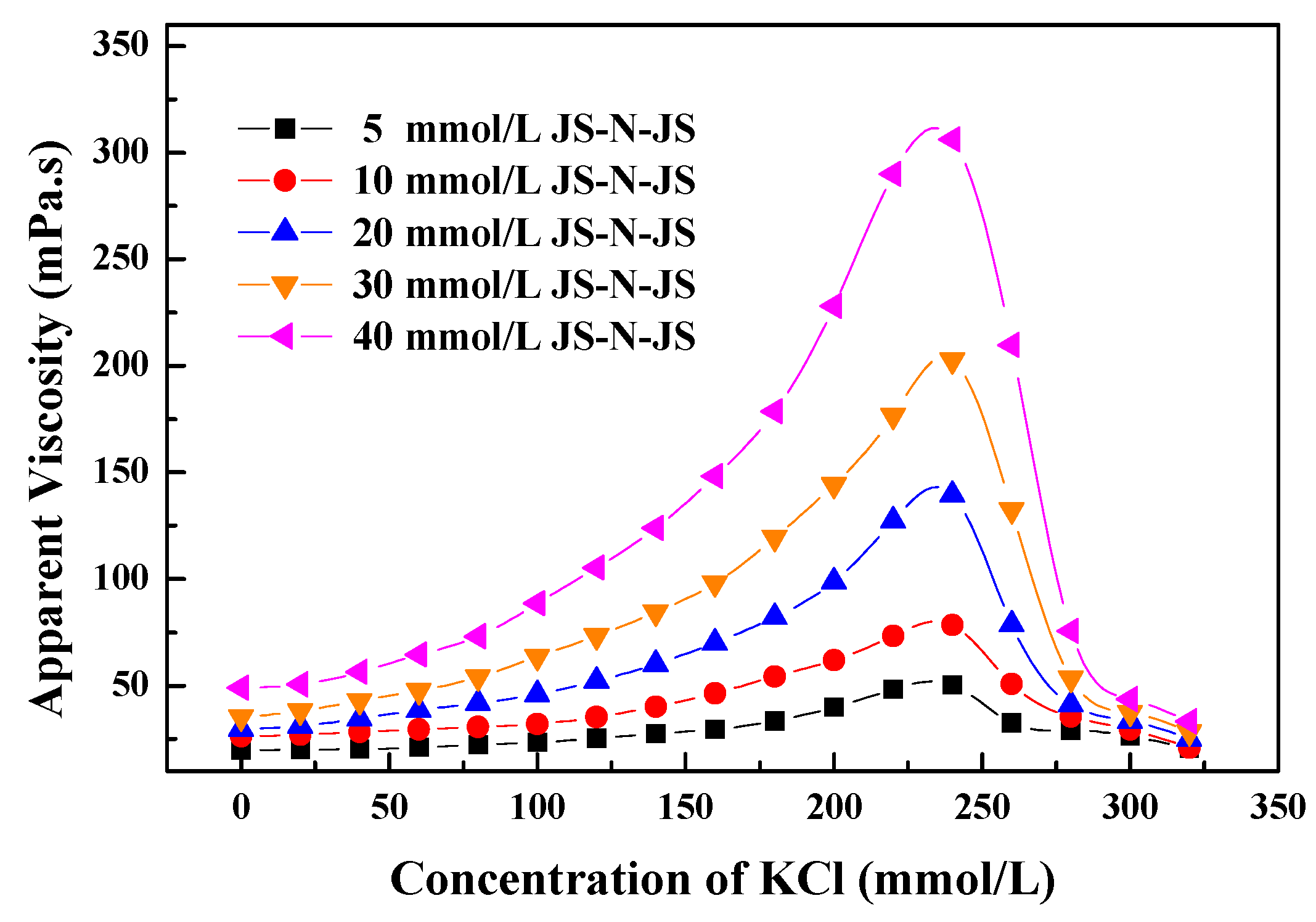

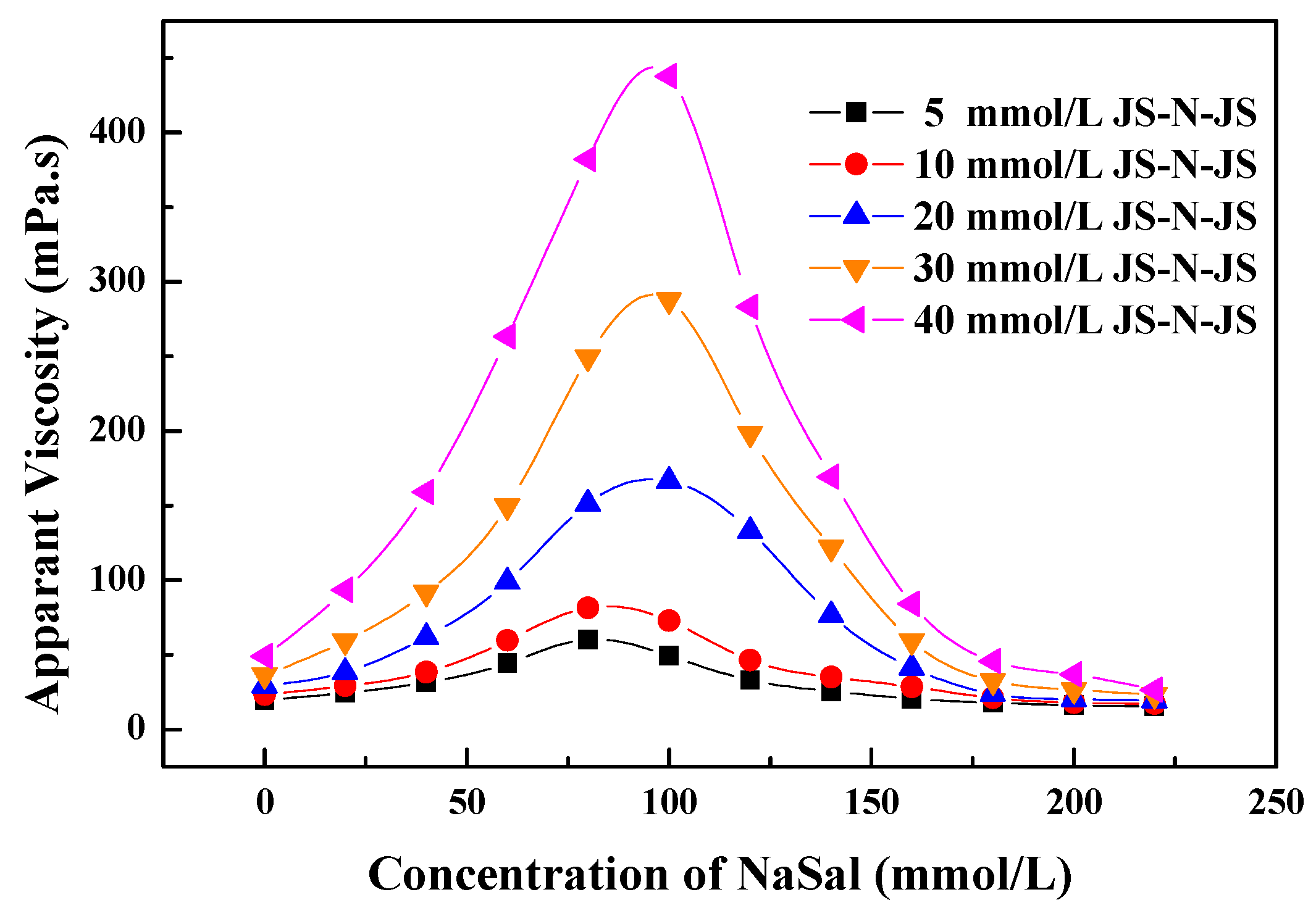

3.4. Salt Response

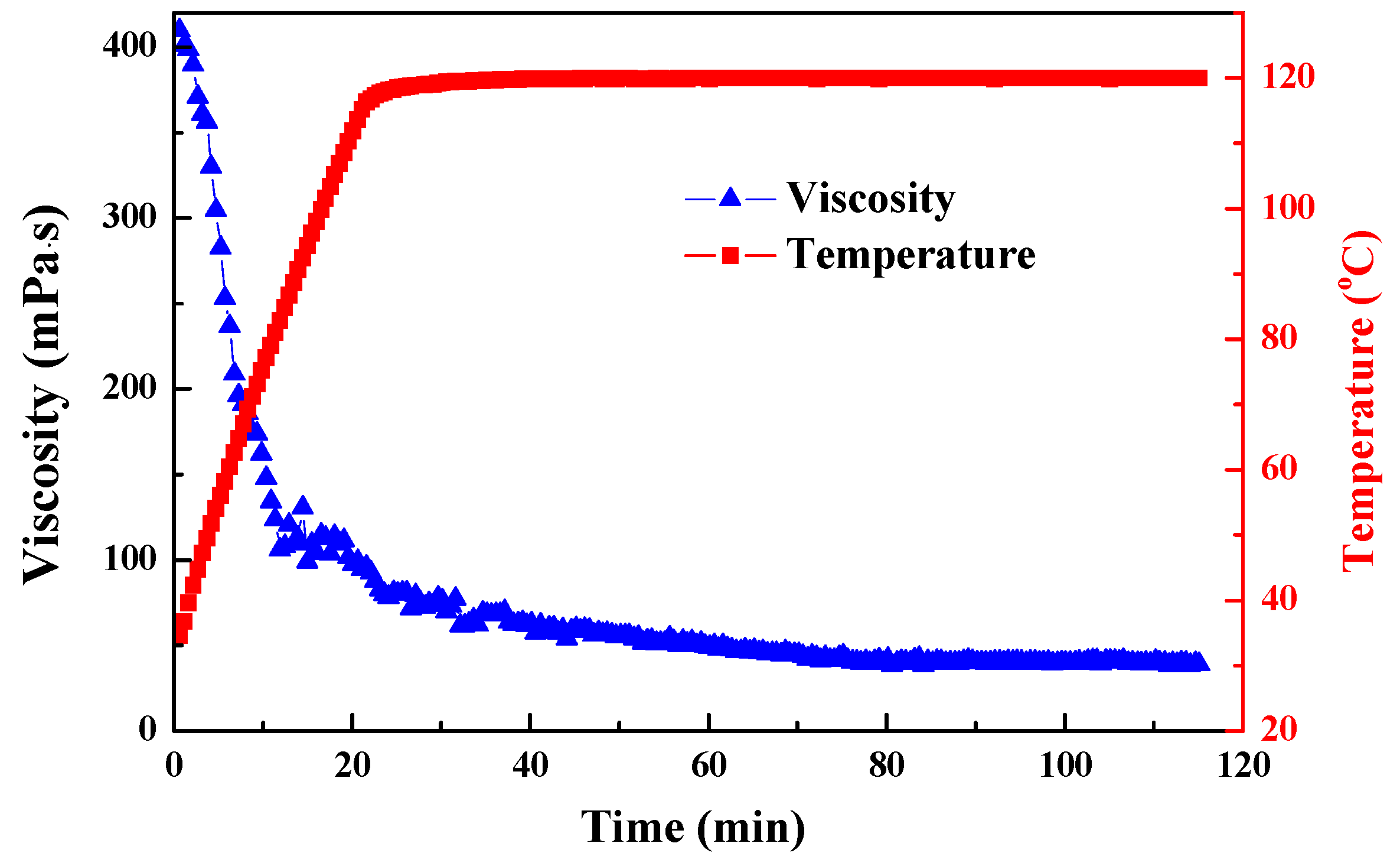

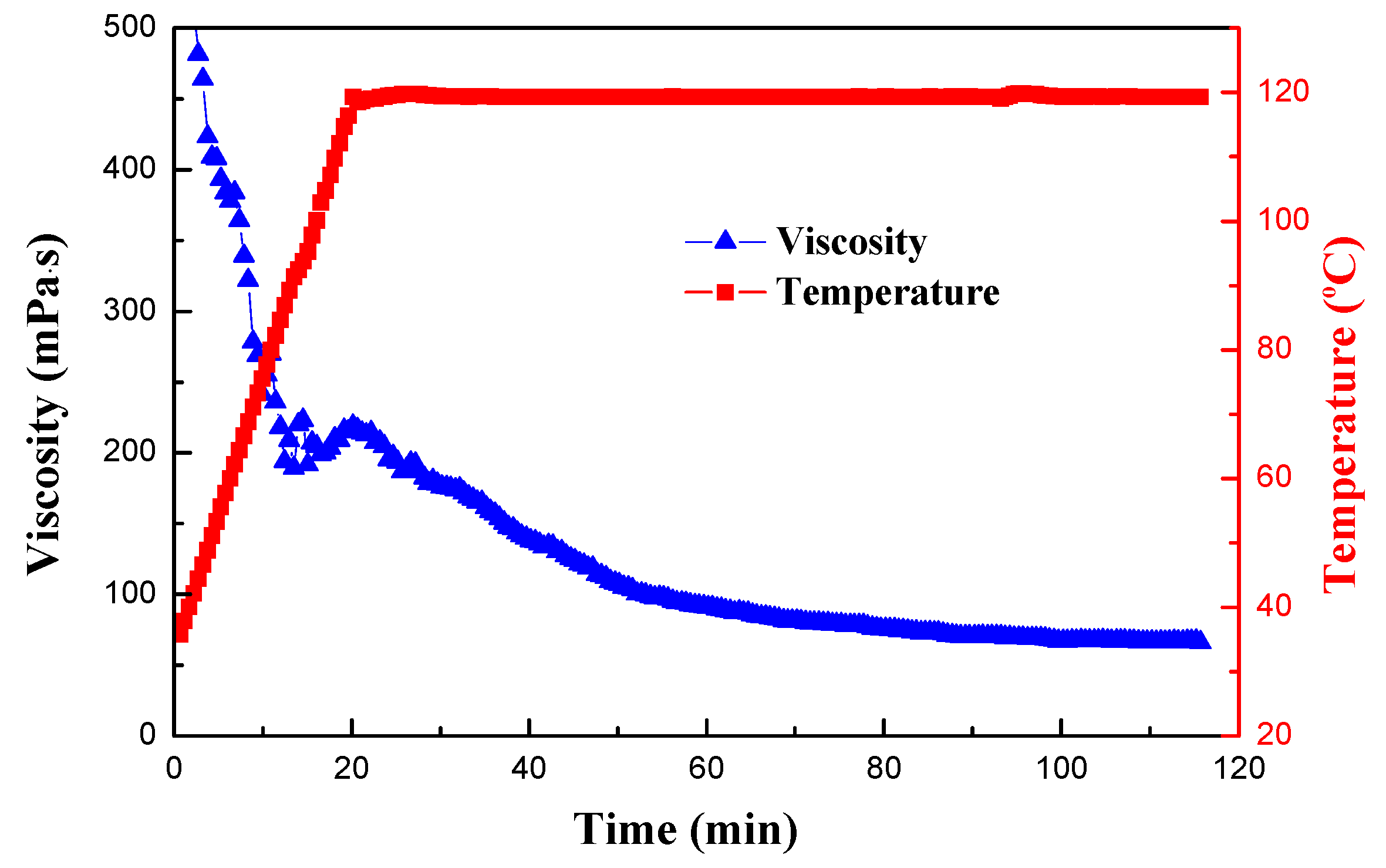

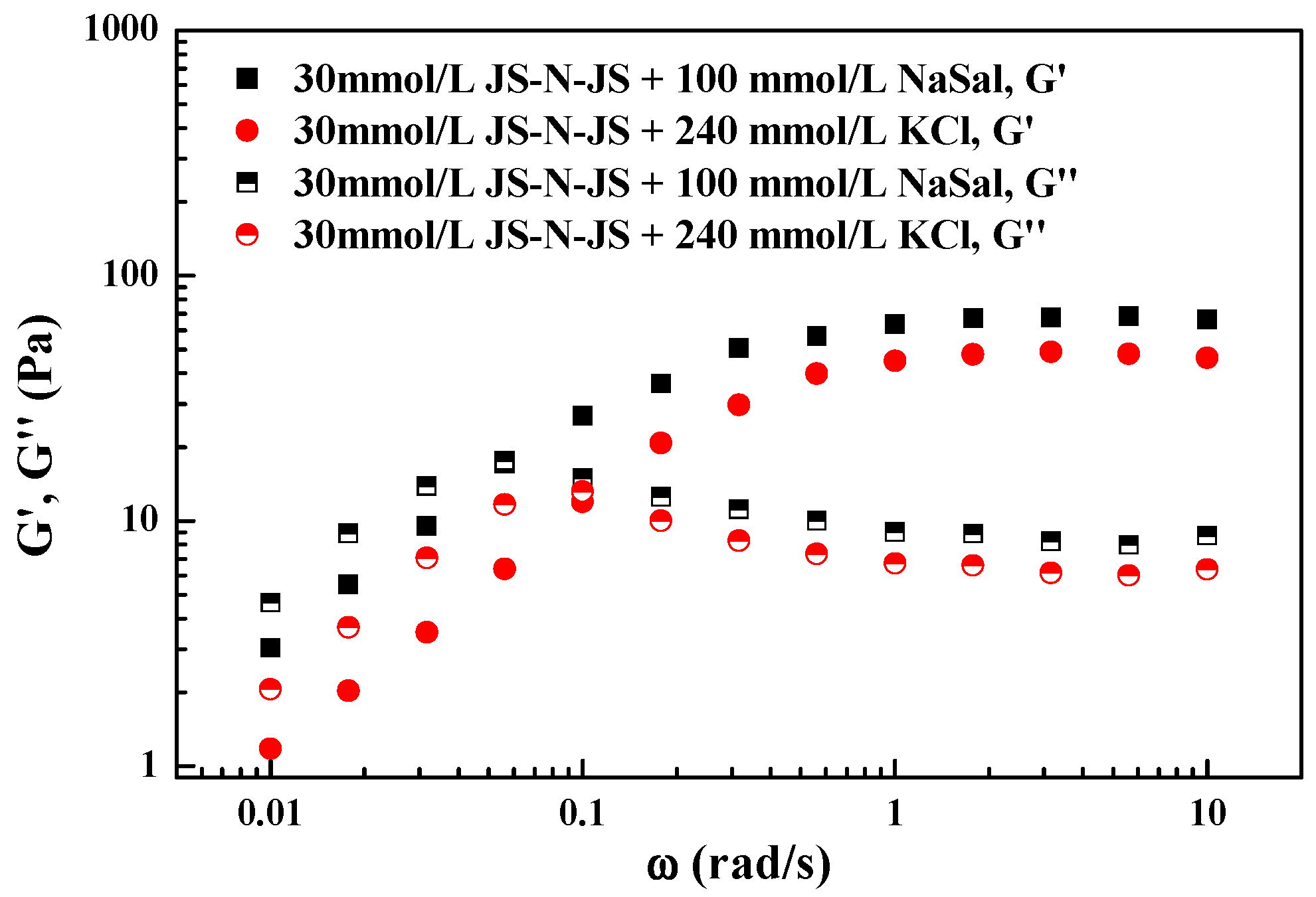

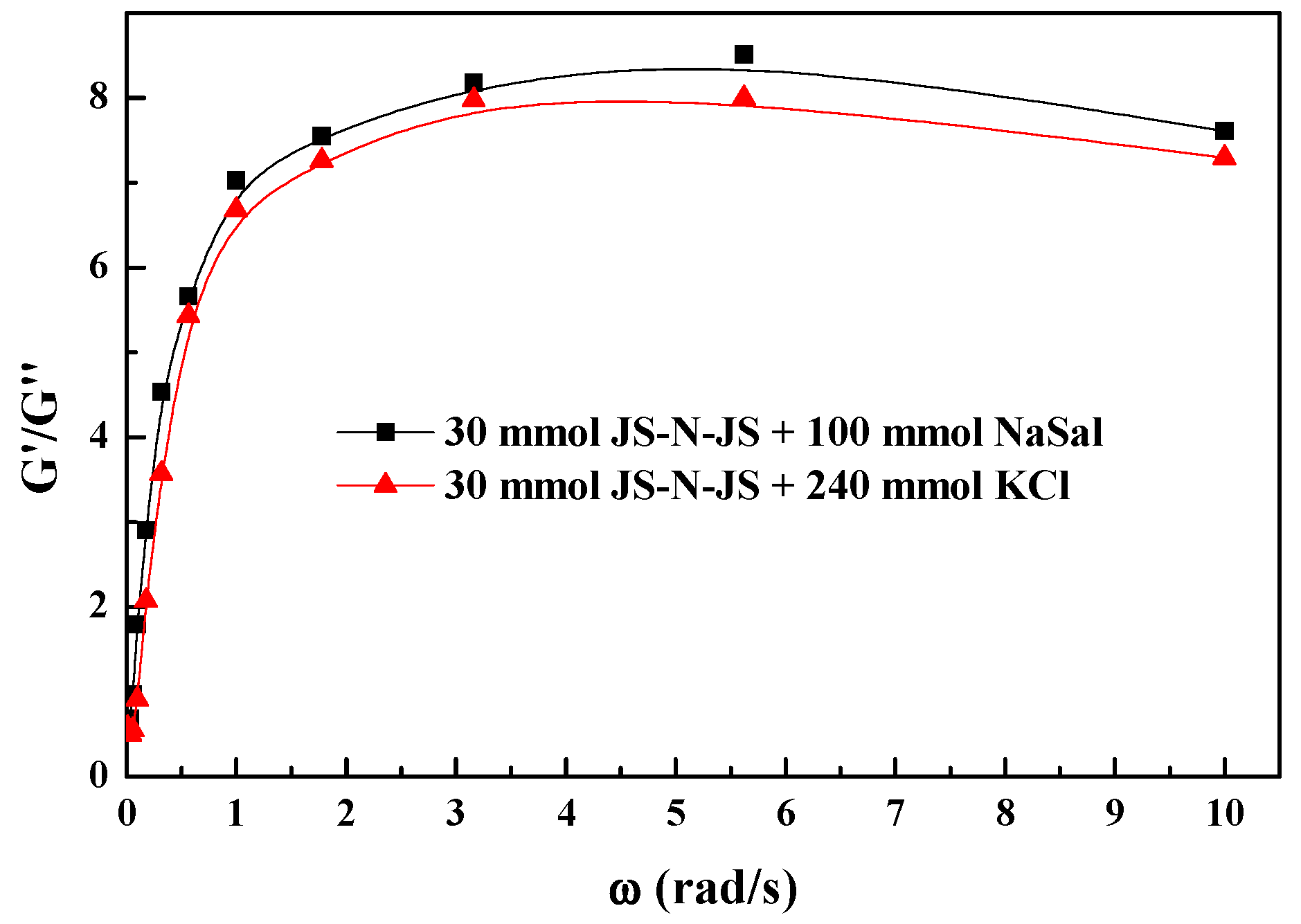

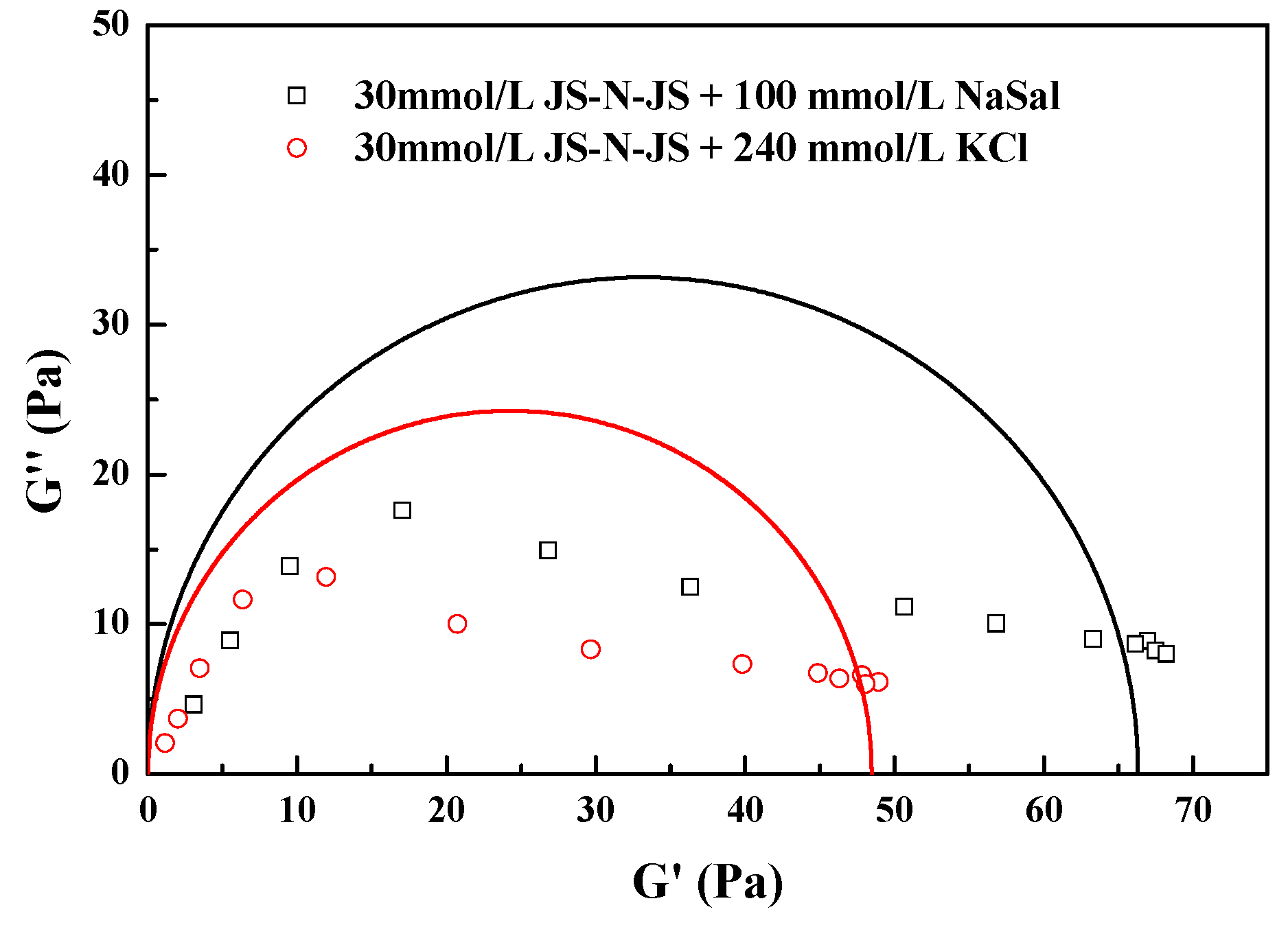

3.5. Rheological and Viscoelastic Measurement

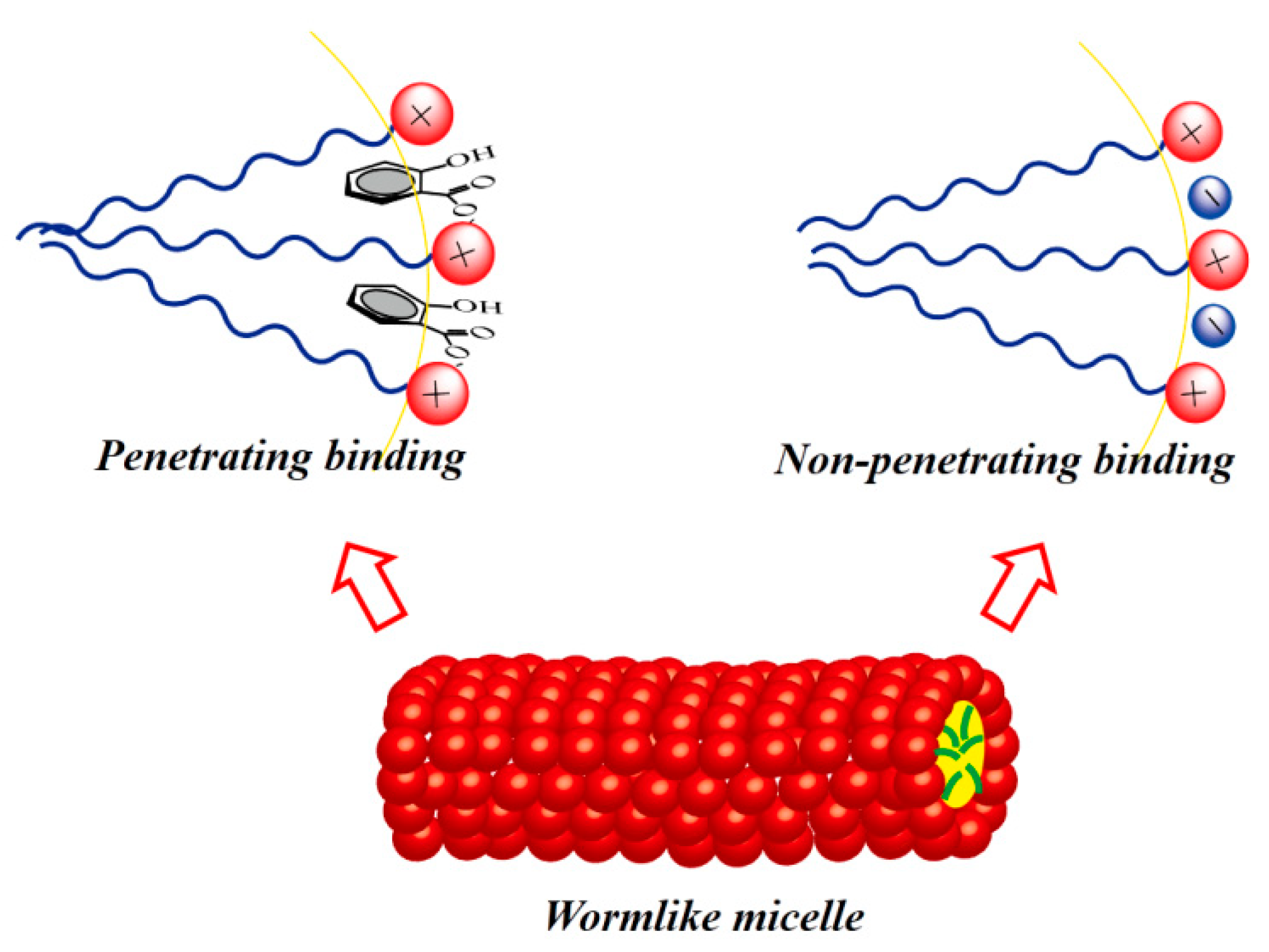

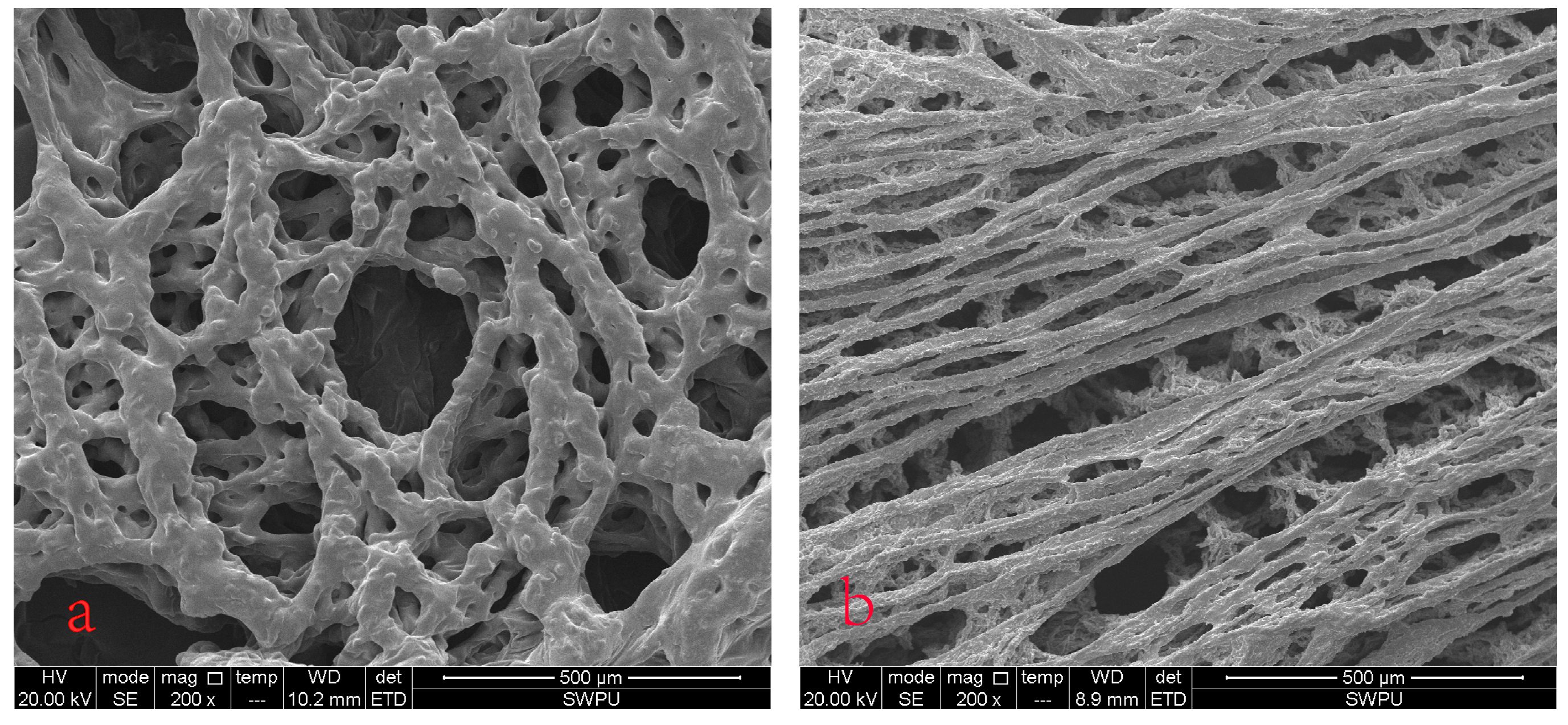

3.6. Microstructure

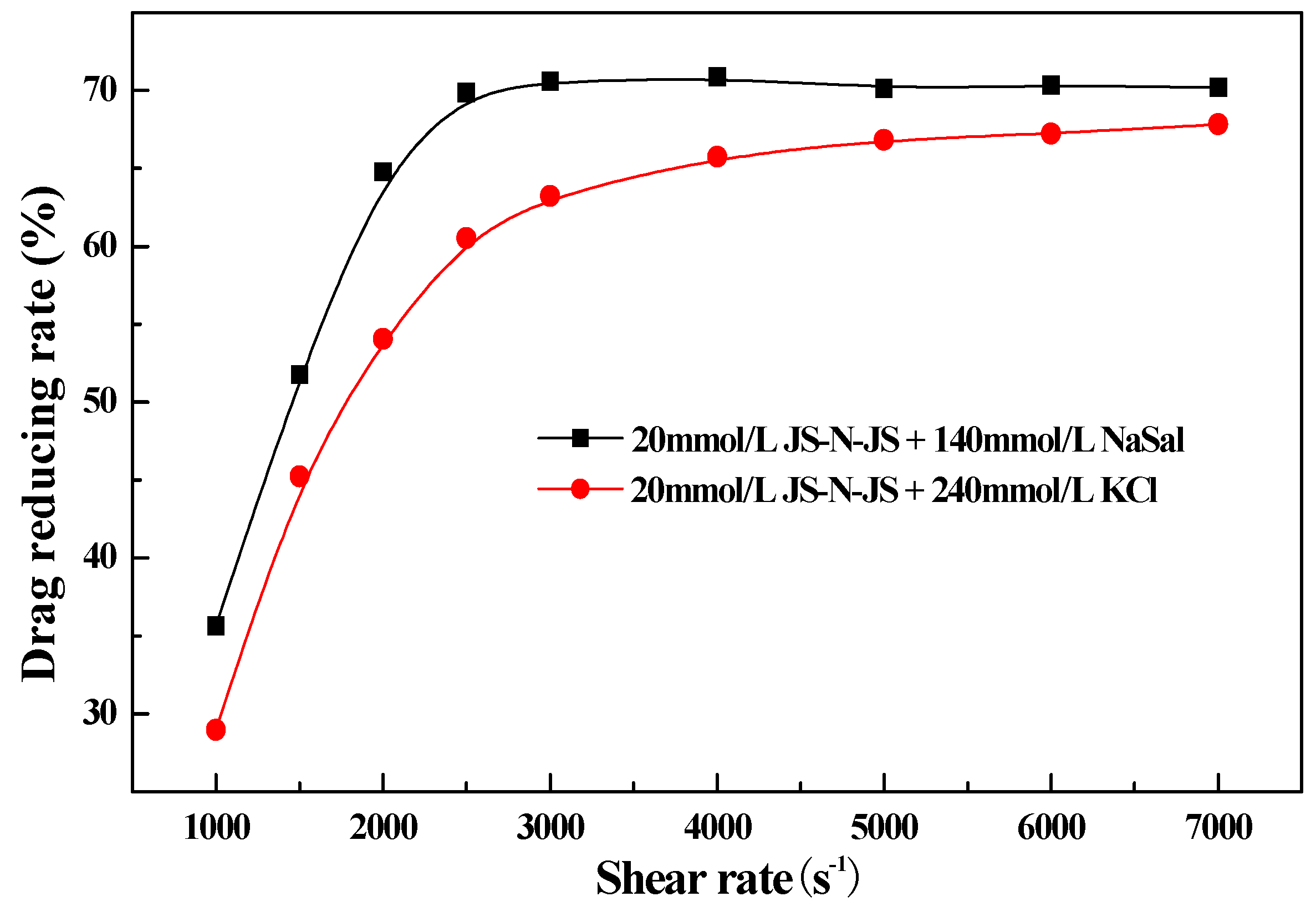

3.7. Drag Reduction Test

3.8. Proppant Suspension Measurement

3.9. Gel Breaking and Permeability Recovery Experiment

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chu, Z.; Dreiss, C.A.; Feng, Y. Smart wormlike micelles. Chem. Soc. Rev. 2013, 42, 7174–7203. [Google Scholar] [CrossRef] [PubMed]

- Chu, Z.; Feng, Y. H-switchable wormlike micelles. Chem. Commun. 2010, 46, 9028–9030. [Google Scholar] [CrossRef] [PubMed]

- Lin, Z.; Cai, J.J.; Scriven, L.E.; Davis, H.T. Spherical-to-wormlike micelle transition in CTAB solutions. J. Phys. Chem. 1994, 98, 5984–5993. [Google Scholar] [CrossRef]

- Chu, Z.; Feng, Y. Thermo-switchable surfactant gel. Chem. Commun. 2011, 47, 7191–7193. [Google Scholar] [CrossRef] [PubMed]

- Chu, Z.; Feng, Y.; Su, X.; Han, Y. Wormlike micelles and solution properties of a c22-tailed amidosulfobetaine surfactant. Langmuir 2010, 26, 7783–7791. [Google Scholar] [CrossRef] [PubMed]

- Degre, G.; Morvan, M.; Beaumont, J.; Colin, A.; Dupuis, G.; Zaitoun, A.; Al-Maamari, R.; Al-Hashmi, A.A.R.; Al-Sharji, H.H. Viscosifying Surfactant Technology for Chemical EOR: A Reservoir Case; Society of Petroleum Engineers: Houston, TX, USA, 2012. [Google Scholar]

- Lu, T.; Lan, Y.; Liu, C.; Huang, J.; Wang, Y. Surface properties, aggregation behavior and micellization thermodynamics of a class of gemini surfactants with ethyl ammonium headgroups. J. Colloid Interface Sci. 2012, 377, 222–230. [Google Scholar] [CrossRef] [PubMed]

- Mao, J.; Yang, X.; Wang, D.; Li, Y.; Zhao, J. A novel gemini viscoelastic surfactant (VES) for fracturing fluid with good temperature stability. RSC Adv. 2016, 6, 88426–88432. [Google Scholar] [CrossRef]

- Pucci, A.; Bizzarri, R.; Ruggeri, G. Polymer composites with smart optical properties. Soft Matter 2011, 7, 3689–3700. [Google Scholar] [CrossRef]

- Moon, J.R.; Jeon, Y.S.; Dong, J.C.; Kim, D.; Kim, J.H. In situ gelling and drug release behavior from novel temperature-sensitive polyaspartamides. Macromol. Res. 2011, 19, 515–518. [Google Scholar] [CrossRef]

- Sing, M.K.; Wang, Z.G.; Mckinley, G.H.; Olsen, B.D. Celebrating soft matter’s 10th anniversary: Chain configuration and rate-dependent mechanical properties in transient networks. Soft Matter 2015, 11, 2085–2096. [Google Scholar] [CrossRef] [PubMed]

- Tokarev, I.; Gopishetty, V.; Jian, Z.; Pita, M.; Motornov, M.; Katz, E.; Minko, S. Stimuli-responsive hydrogel membranes coupled with biocatalytic processes. ACS Appl. Mater. Interface 2009, 1, 532–536. [Google Scholar] [CrossRef] [PubMed]

- Abdulbari, H.A.; Yunus, R.M.; Abdurahman, N.H.; Charles, A. Going against the flow—A review of non-additive means of drag reduction. J. Ind. Eng. Chem. 2013, 19, 27–36. [Google Scholar] [CrossRef]

- Del Río, J.A.; López de Haro, M.; Whitaker, S. Enhancement in the dynamic response of a viscoelastic fluid flowing in a tube. Phys. Rev. E 1998, 58, 6323–6327. [Google Scholar] [CrossRef]

- Tamano, S.; Ikarashi, H.; Morinishi, Y.; Taga, K. Drag reduction and degradation of nonionic surfactant solutions with organic acid in turbulent pipe flow. J. Non-Newtonian Fluid Mech. 2015, 215, 1–7. [Google Scholar] [CrossRef]

- Al-Sadat, W.; Nasser, M.S.; Chang, F.; Nasr-El-Din, H.A.; Hussein, I.A. Laboratory evaluation of the effects of additives and pH on the thermorheological behavior of a viscoelastic zwitterionic surfactant used in acid stimulation. J. Pet. Sci. Eng. 2014, 122, 458–467. [Google Scholar] [CrossRef]

- Chang, F.; Qi, Q.; Wayne, F. A novel self-diverting-acid developed for matrix stimulation of carbonate reservoirs. In Proceedings of the SPE International Symposium on Oilfield Chemistry, Houston, TX, USA, 13–16 February 2001. [Google Scholar]

- Samuel, M.; Card, R.J.; Nelson, E.B.; Brown, J.E.; Vinod, P.S.; Temple, H.L.; Qu, Q.; Fu, D.K. Polymer-free fluid for hydraulic fracturing. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 5–8 October 1997. [Google Scholar]

- Samuel, M.M.; Card, R.J.; Nelson, E.B.; Brown, J.E.; Vinod, P.S.; Temple, H.L.; Qi, Q.; Fu, D.K. Polymer-free fluid for fracturing applications. SPE Drill. Complet. 1999, 14, 240–246. [Google Scholar] [CrossRef]

- Zhao, Y.; LÜ, G. Visco-elastic properties of VES diverting acid for carbonate reservoirs. Chin. J. Chem. Eng. 2010, 18, 511–514. [Google Scholar] [CrossRef]

- Baldygin, A.; Nobes, D.S.; Mitra, S.K. New laboratory core flooding experimental system. Ind. Eng. Chem. Res. 2014, 53, 13497–13505. [Google Scholar] [CrossRef]

- Morvan, M.; Moreau, P.; Degre, G.; Leng, J.; Masselon, C.; Bouillot, J.; Zaitoun, A. New viscoelastic fluid for chemical EOR. In Proceedings of the SPE International Symposium on Oilfield Chemistry, The Woodlands, TX, USA, 2009. [Google Scholar]

- Samuel, M.; Obianwu, C.; Chao, W.R.; Samuel, E.; Alim, H.; Hashim, F.; Rohaya, D. An Engineered Fiber for the Fracturing of Unconsolidated Sand in Highly Deviated Wells in the Tali Field of Brunei; Society of Petroleum Engineers: Houston, TX, USA, 2007. [Google Scholar]

- Waters, G.A.; Dean, B.K.; Downie, R.C.; Kerrihard, K.; Austbo, L.; Mcpherson, B. Simultaneous Hydraulic fracturing of adjacent horizontal wells in the woodford shale. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 19–21 January 2009. [Google Scholar]

- Zhao, H.; Nasr-El-Din, H.A.; Al-Bagoury, M. In A new fracturing fluid for HP/HT applications. In Proceedings of the SPE European Formation Damage Conference and Exhibition, Budapest, Hungary, 3–5 June 2015. [Google Scholar]

- Ellis, R.C. An overview of frac packs: A technical revolution (evolution) process. J. Pet. Technol. 1998, 50, 66–68. [Google Scholar] [CrossRef]

- Holtsclaw, J.; Funkhouser, G.P. A crosslinkable synthetic-polymer system for high-temperature hydraulic-fracturing applications. SPE Drill. Complet. 2010, 25, 555–563. [Google Scholar] [CrossRef]

- Fardin, M.A.; Lerouge, S. Flows of living polymer fluids. Soft Matter 2014, 10, 8789–8799. [Google Scholar] [CrossRef] [PubMed]

- Haward, S.J.; Galindorosales, F.J.; Ballesta, P.; Alves, M.A. Spatiotemporal flow instabilities of wormlike micellar solutions in rectangular microchannels. Appl. Phys. Lett. 2014, 104, 667–720. [Google Scholar] [CrossRef]

- Pei, X.; Xu, Z.; Song, B.; Cui, Z.; Zhao, J. Wormlike micelles formed in catanionic systems dominated by cationic gemini surfactant: Synergistic effect with high efficiency. Colloids Surf. A Physicochem. Eng. Asp. 2014, 443, 508–514. [Google Scholar] [CrossRef]

- Yue, L.; Wang, Y.; He, Z.; Chen, J.; Shang, Y.; Liu, H. Effect of ionic liquid c2mimbr on rheological behavior of gemini surfactant 12-2-12 aqueous solution. Colloid Polym. Sci. 2015, 293, 2373–2383. [Google Scholar] [CrossRef]

- Dogon, D.; Golombok, M. Wellbore to fracture proppant-placement-fluid rheology. J. Unconv. Oil Gas Resour. 2016, 14, 12–21. [Google Scholar] [CrossRef]

- You, L.Y.; Chen, S.G.; Zhao, X.; Liu, Y.; Lan, W.X.; Zhang, Y.; Lu, H.J.; Cao, C.Y.; Li, Z.T. CH···O hydrogen bonding induced triazole foldamers: Efficient halogen bonding receptors for organohalogens. Angew. Chem. 2012, 124, 1689–1693. [Google Scholar] [CrossRef]

- Zhang, Y.; An, P.; Liu, X. A “worm”-containing viscoelastic fluid based on single amine oxide surfactant with an unsaturated c22-tail. RSC Adv. 2015, 5, 19135–19144. [Google Scholar] [CrossRef]

- Zhao, J.; Fan, J.; Mao, J.; Yang, X.; Zhang, H.; Zhang, W. High performance clean fracturing fluid using a new tri-cationic surfactant. Polymers 2018, 10, 535. [Google Scholar] [CrossRef]

- Mao, J.; Yang, X.; Chen, Y.; Zhang, Z.; Zhang, C.; Yang, B.; Zhao, J. Viscosity reduction mechanism in high temperature of a gemini viscoelastic surfactant (VES) fracturing fluid and effect of counter-ion salt (KCL) on its heat resistance. J. Pet. Sci. Eng. 2018, 164, 189–195. [Google Scholar] [CrossRef]

- Bunton, C.A.; Robinson, L.B.; Schaak, J.; Stam, M.F. Catalysis of nucleophilic substitutions by micelles of dicationic detergents. J. Org. Chem. 1971, 36, 2346–2350. [Google Scholar] [CrossRef]

- Zana, R. Dimeric and oligomeric surfactants. Behavior at interfaces and in aqueous solution: A review. Adv. Colloid Interface Sci. 2002, 97, 205–253. [Google Scholar] [CrossRef]

- Yang, C.; Hu, Z.; Song, Z.; Bai, J.; Zhang, Y.; Luo, J.Q.; Du, Y.; Jiang, Q. Self—Assembly properties of ultra-long chain gemini surfactant with high performance in a fracturing fluid application. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Commission, N.D.A.R. Recommended Practices on Measuring the Properties of Waterbased Fracturing Fluid; Chinese Oil and Gas Industry Standards: Beijing, China, 2008. [Google Scholar]

- Rodriguez, A.; Del, M. Effects of ethylene glycol addition on the aggregation and micellar growth of gemini surfactants. Langmuir 2006, 22, 9519–9525. [Google Scholar] [CrossRef] [PubMed]

- Akram, M.; Bhat, I.A.; Kabir-ud-Din. Self-aggregation of surfactant ethane-1,2-diyl bis(N,N-dimethyl-N-hexadecylammoniumacetoxy) dichloride: Tensiometric, microscopic, and spectroscopic studies. J. Phys. Chem. B 2015, 119, 3499–3509. [Google Scholar] [CrossRef] [PubMed]

- Mao, J.; Zhang, H.; Zhang, W.; Fan, J.; Zhang, C.; Zhao, J. Dissymmetric beauty: A novel design of heterogemini viscoelastic surfactant for the clean fracturing fluid. J. Ind. Eng. Chem. 2017, 60, 133–142. [Google Scholar] [CrossRef]

- Zhu, H.L.; Hu, Z.Y.; Liang, D.; Wang, J.L.; Cao, D.L. Aggregation of diester-bonded cationic gemini surfactants in the presence of ethylene glycol: An electrical conductivity study. J. Mol. Liquids 2016, 216, 565–570. [Google Scholar] [CrossRef]

- And, Y.Q.; Zakin, J.L. Chemical and rheological characterization of drag-reducing cationic surfactant systems. Ind. Eng. Chem. Res. 2002, 41, 6326–6336. [Google Scholar]

- Israelachvili, J.N. Intermolecular and surface forces: With applications to colloidal and biological systems. Q. Rev. Biol. 1985, 63, 77. [Google Scholar]

- Wang, M.; Fan, Y.; Han, Y.; Nie, Z.; Wang, Y. Coacervation of cationic Gemini surfactant with N-benzoylglutamic acid in aqueous solution. Langmuir 2013, 29, 14839–14847. [Google Scholar] [CrossRef] [PubMed]

- Malhotra, S.; Sharma, M.M. Settling of spherical particles in unbounded and confined surfactant-based shear thinning viscoelastic fluids: An experimental study. Chem. Eng. Sci. 2012, 84, 646–655. [Google Scholar] [CrossRef]

- Sharma, M.M. Proppant settling in viscoelastic surfactant (VES) fluids. In Viscoelastic Surfactant Fluids; The University of Texas at Austin: Austin, TX, USA, 2010. [Google Scholar]

- Zhang, Y.; Luo, Y.; Wang, Y.; Zhang, J.; Feng, Y. Single-component wormlike micellar system formed by a carboxylbetaine surfactant with c22 saturated tail. Colloids Surf. A Physicochem. Eng. Asp. 2013, 436, 71–79. [Google Scholar] [CrossRef]

- Yang, J.; Wang, H.; Wang, J.; Guo, X.; Pei, X. Structural transition of cinnamate-based light-responsive ionic liquids in aqueous solutions and their light-tunable rheological properties. Langmuir 2016, 32, 66–72. [Google Scholar] [CrossRef] [PubMed]

- Khair, E.; Shicheng, Z.; Shanbo, M.; Mei, Z. Performance and application of new anionic D3F-AS05 viscoelastic fracturing fluid. J. Pet. Sci. Eng. 2011, 78, 131–138. [Google Scholar] [CrossRef]

| Surfactant | T (°C) | CMC (µmol/L) | γCMC (mN/m) | Γmax (µmol/m2) | Amin (nm2) |

|---|---|---|---|---|---|

| JS-N-JS | 25 | 28.84 | 33.12 | 1.59 | 1.04 |

| C25-6-C25 [39] | 25 | 32.96 | 45.26 | 1.41 | 1.18 |

| YS-YS [43] | 25 | 196 | 35.2 | 1.18 | 1.41 |

| 18-18 [43] | 25 | 191 | 44.7 | 0.99 | 1.73 |

| YS-18 [43] | 25 | 194 | 33.9 | 1.45 | 1.14 |

| 16-E2-16 [42] | 25 | 1200 | 42.6 | 1.1 | 1.46 |

| Surfactant | α | β | CMC (µmol/L) | (kJ/mol) | (kJ/mol) |

|---|---|---|---|---|---|

| JS-N-JS | 0.45 | 0.55 | 27.86 | −36.63 | −61.08 |

| C25-6-C25 | 0.67 | 0.33 | 44.28 | −28.88 | −47.84 |

| Salt (mmol/L) | CMC (µmol/L) | (mN/m) | (kJ/mol) | Salt (mmol/L) | CMC (µmol/L) | (mN/m) | (kJ/mol) |

|---|---|---|---|---|---|---|---|

| KCl | NaSal | ||||||

| 0 | 28.84 | 33.12 | −36.63 | 0 | 28.84 | 33.12 | −36.63 |

| 20 | 27.69 | 31.82 | −37.74 | 20 | 26.87 | 30.78 | −37.82 |

| 40 | 27.45 | 30.38 | −37.77 | 40 | 25.64 | 28.70 | −37.94 |

| 60 | 27.44 | 29.85 | −37.77 | 60 | 24.85 | 26.73 | −38.03 |

| Fracturing Fluid | Gel Breaking Time (h) | Broken Viscosity (mPa·s) | Residue (mg/L) | Kerosene Permeability (mD) | Regained Permeability (mD) | Permeability Recovery Rate (%) |

|---|---|---|---|---|---|---|

| JS-N-JS/NaSal | 1.2 | 2.7 | 46 | 6.49 | 5.52 | 85.05% |

| JS-N-JS/KCl | 2.5 | 2.3 | 38 | 7.31 | 6.27 | 85.77% |

| SY/T6376-2008 | ≤12 | ≤5 | ≤100 | ≥80 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Mao, J.; Yang, X.; Zhang, H.; Zhang, Z.; Yang, B.; Zhang, Y.; Zhao, J. Study of a Novel Gemini Viscoelastic Surfactant with High Performance in Clean Fracturing Fluid Application. Polymers 2018, 10, 1215. https://doi.org/10.3390/polym10111215

Zhang W, Mao J, Yang X, Zhang H, Zhang Z, Yang B, Zhang Y, Zhao J. Study of a Novel Gemini Viscoelastic Surfactant with High Performance in Clean Fracturing Fluid Application. Polymers. 2018; 10(11):1215. https://doi.org/10.3390/polym10111215

Chicago/Turabian StyleZhang, Wenlong, Jincheng Mao, Xiaojiang Yang, Heng Zhang, Zhaoyang Zhang, Bo Yang, Yang Zhang, and Jinzhou Zhao. 2018. "Study of a Novel Gemini Viscoelastic Surfactant with High Performance in Clean Fracturing Fluid Application" Polymers 10, no. 11: 1215. https://doi.org/10.3390/polym10111215

APA StyleZhang, W., Mao, J., Yang, X., Zhang, H., Zhang, Z., Yang, B., Zhang, Y., & Zhao, J. (2018). Study of a Novel Gemini Viscoelastic Surfactant with High Performance in Clean Fracturing Fluid Application. Polymers, 10(11), 1215. https://doi.org/10.3390/polym10111215