Graphene-Based Thermal Interface Materials: An Application-Oriented Perspective on Architecture Design

Abstract

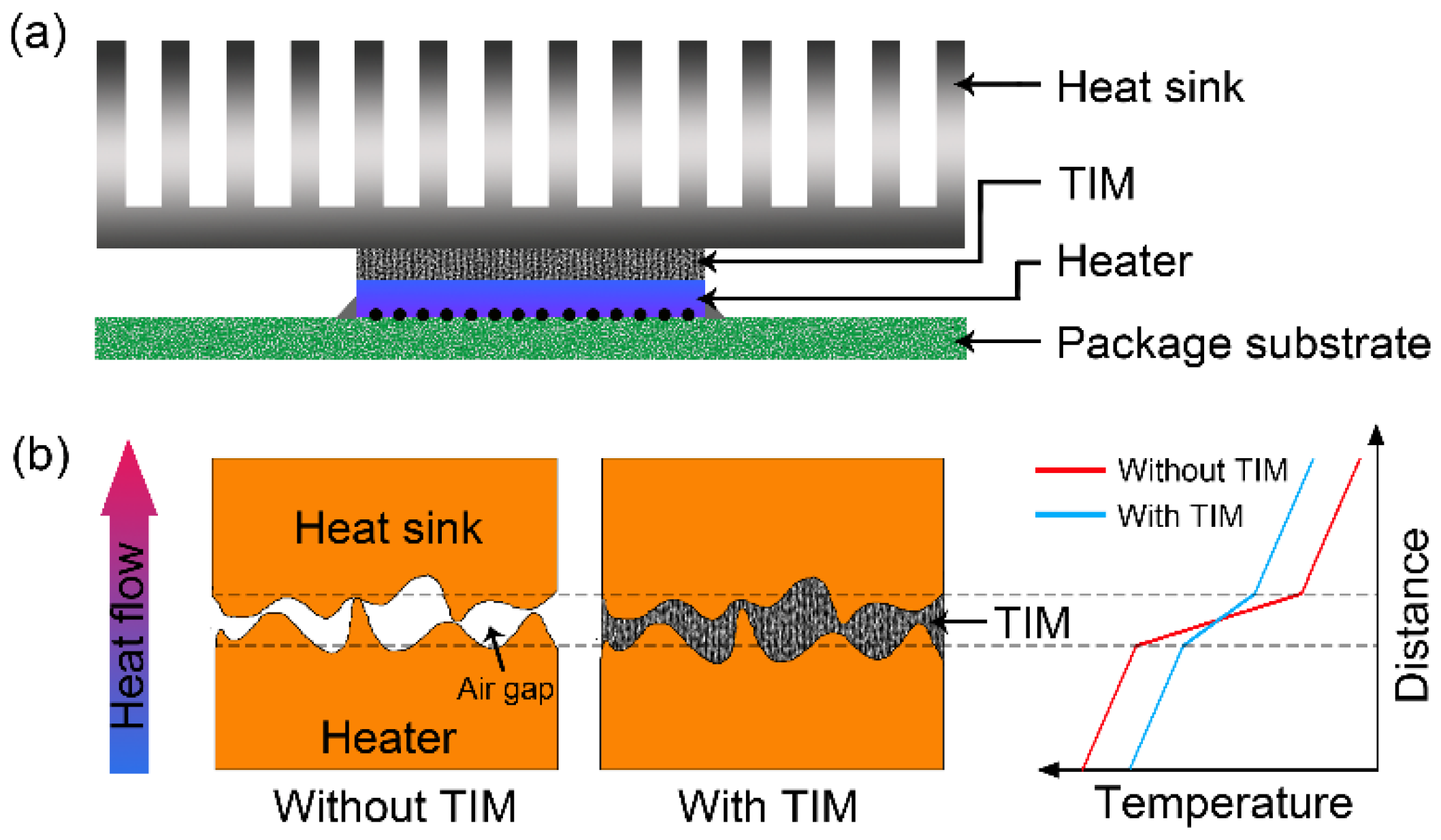

1. Introduction

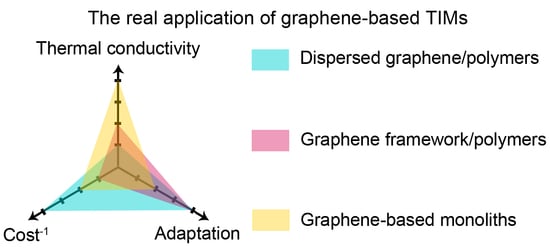

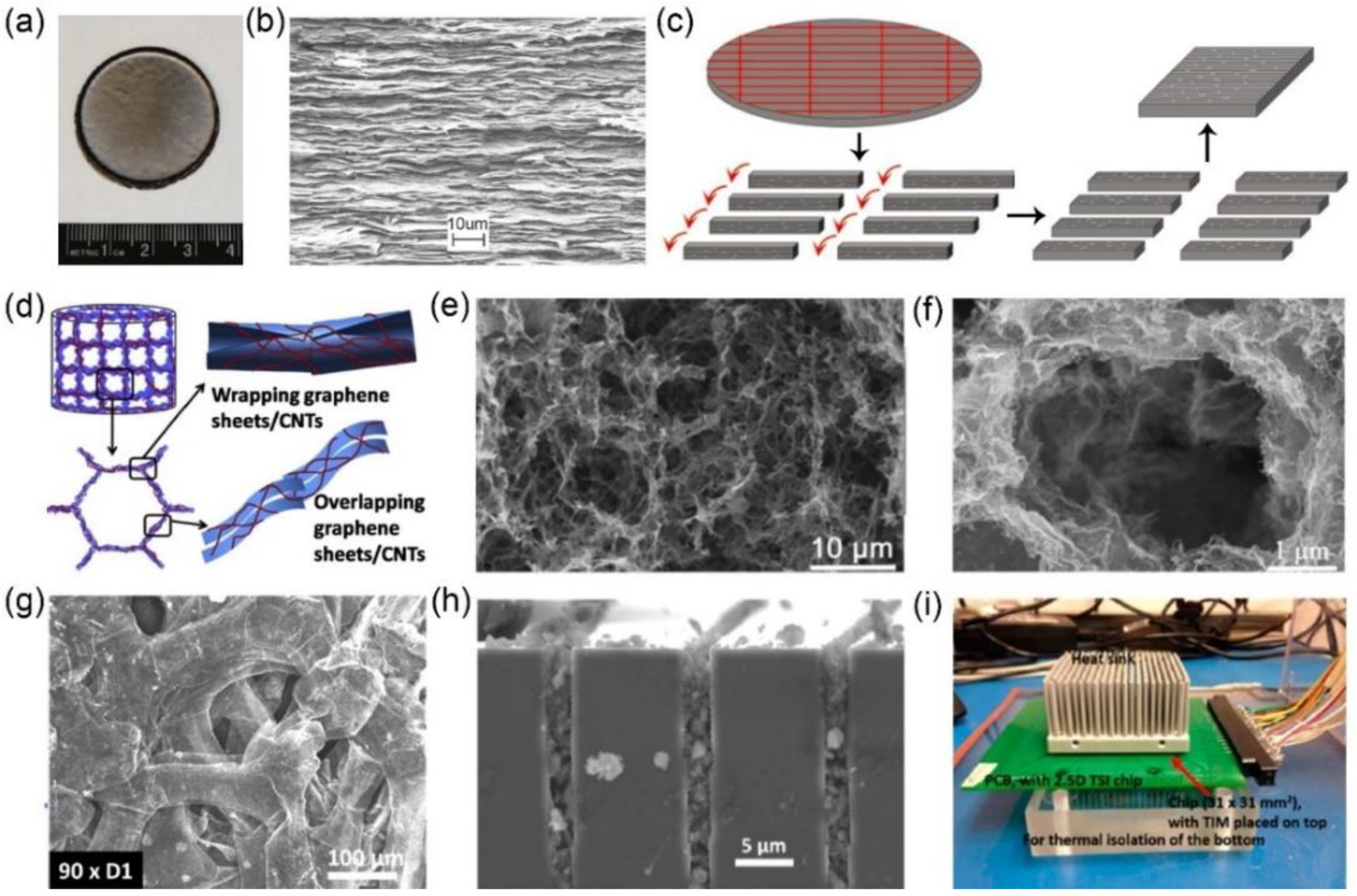

2. Graphene-Based TIMs

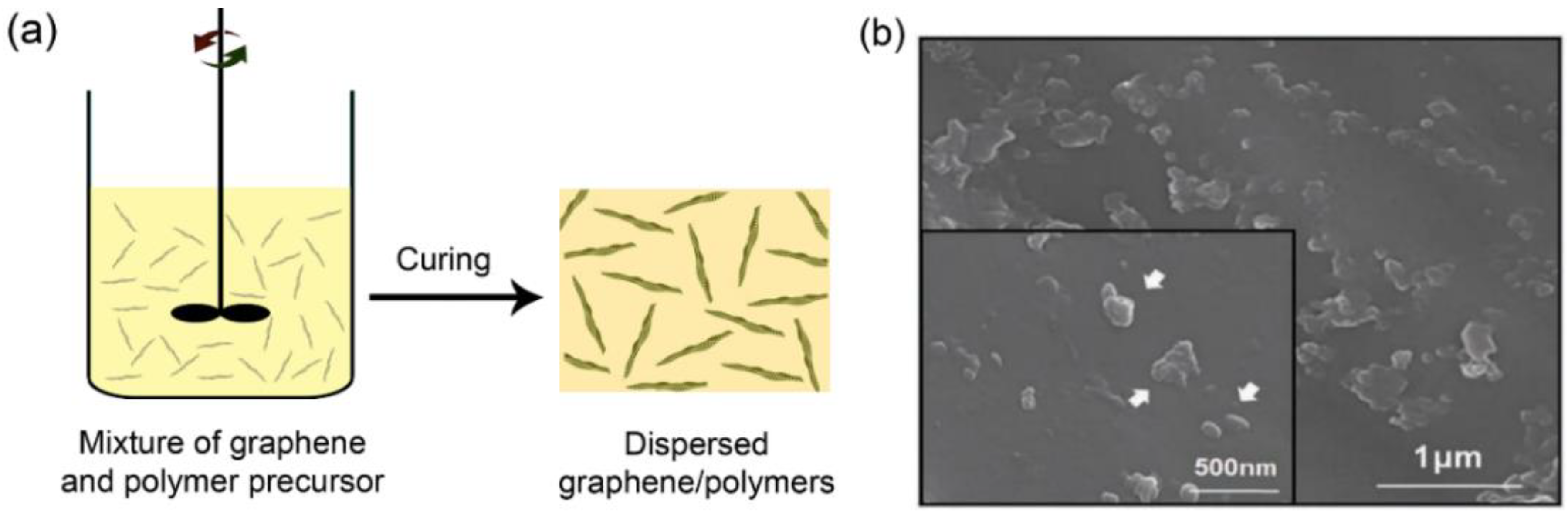

2.1. Dispersed Graphene/Polymers

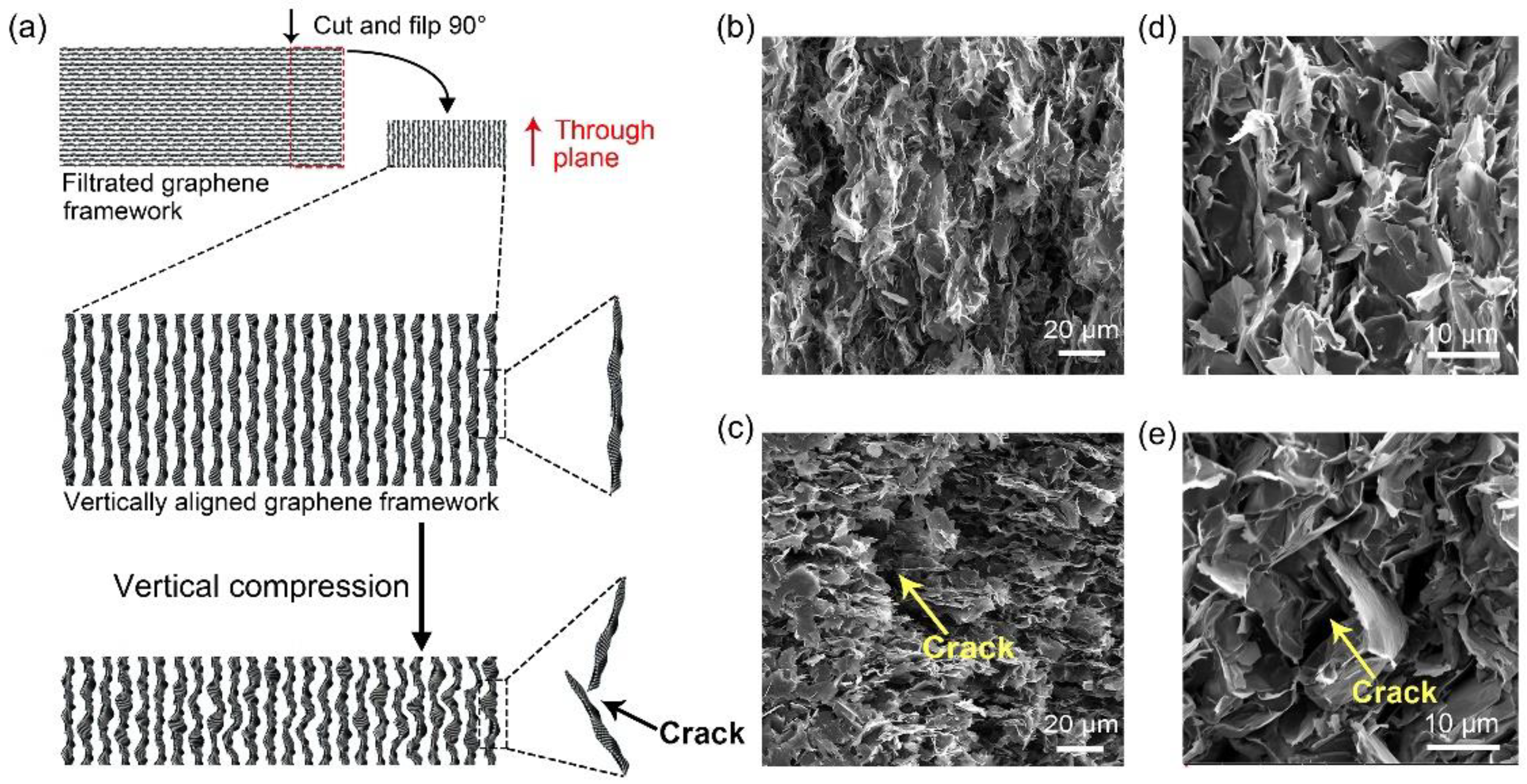

2.2. Graphene Framework/Polymers

- (i)

- Soft elastomers as matrix for good gap filling, such as PDMS.

- (ii)

- A relatively higher density of the graphene framework for higher graphene content in the polymer matrix, leading to high thermal conductivity.

- (iii)

- An opportune arrangement of graphene in the framework for avoiding an unsatisfactory thermal conductivity in the through-plane direction.

- (iv)

- Graphene framework with reversible deformation for maintaining high thermal conductivity while under packaging.

2.3. Inorganic Graphene-Based Monoliths

3. Conclusions and Perspectives

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Suh, D.; Moon, C.M.; Kim, D.; Baik, S. Ultrahigh thermal conductivity of interface materials by silver-functionalized carbon nanotube phonon conduits. Adv. Mater. 2016, 28, 7220–7227. [Google Scholar] [CrossRef] [PubMed]

- Bhanushali, S.; Ghosh, P.C.; Simon, G.P.; Cheng, W. Copper nanowire-filled soft elastomer composites for applications as thermal interface materials. Adv. Mater. Interfaces 2017, 4, 1700387. [Google Scholar] [CrossRef]

- Hansson, J.; Nilsson, T.M.; Ye, L.; Liu, J. Novel nanostructured thermal interface materials: A review. Int. Mater. Rev. 2018, 63, 22–45. [Google Scholar] [CrossRef]

- Razeeb, K.M.; Dalton, E.; Cross, G.L.W.; Robinson, A.J. Present and future thermal interface materials for electronic devices. Int. Mater. Rev. 2018, 63, 1–21. [Google Scholar] [CrossRef]

- Kim, K.; Kim, M.; Hwang, Y.; Kim, J. Chemically modified boron nitride-epoxy terminated dimethylsiloxane composite for improving the thermal conductivity. Cream. Int. 2014, 40, 2047–2056. [Google Scholar] [CrossRef]

- Prasher, R. Thermal interface materials: Historical perspective, status, and future directions. Proc. IEEE 2006, 94, 1571–1586. [Google Scholar] [CrossRef]

- Shahil, K.M.; Balandin, A.A. Graphene-multilayer graphene nanocomposites as highly efficient thermal interface materials. Nano Lett. 2012, 12, 861–867. [Google Scholar] [CrossRef] [PubMed]

- Balandin, A.A.; Ghosh, S.; Bao, W.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C.N. Superior thermal conductivity of single-layer graphene. Nano Lett. 2008, 8, 902–907. [Google Scholar] [CrossRef] [PubMed]

- Araj, H.; Smith, P.D. Effects of nanofluids containing graphene/graphene-oxide nanosheets on critical heat flux. Appl. Phys. Lett. 2010, 97, 023103. [Google Scholar]

- Lian, G.; Tuan, C.C.; Li, L.; Jiao, S.; Wang, Q.; Moon, K.S.; Cui, D.; Wong, C.P. Vertically aligned and interconnected graphene networks for high thermal conductivity of epoxy composites with ultralow loading. Chem. Mater. 2016, 28, 6096–6104. [Google Scholar] [CrossRef]

- Shen, X.; Wang, Z.; Wu, Y.; Liu, X.; He, Y.B.; Kim, J.K. Multilayer graphene enables higher efficiency in improving thermal conductivities of graphene/epoxy composites. Nano Lett. 2016, 16, 3585–3593. [Google Scholar] [CrossRef] [PubMed]

- Shen, X.; Wang, Z.; Wu, Y.; Liu, X.; Kim, J.K. Effect of functionalization on thermal conductivities of graphene/epoxy composites. Carbon 2016, 108, 412–422. [Google Scholar] [CrossRef]

- Alam, F.E.; Dai, W.; Yang, M.; Du, S.; Li, X.; Yu, J.; Jiang, N.; Lin, C.T. In situ formation of a cellular graphene framework in thermoplastic composites leading to superior thermal conductivity. J. Mater. Chem. A 2017, 5, 6164–6169. [Google Scholar] [CrossRef]

- Yu, A.; Ramesh, P.; Itkis, M.E.; Elena Bekyarova, A.; Haddon, R.C. Graphite nanoplatelet-epoxy composite thermal interface materials. J. Phys. Chem. C 2007, 111, 7565–7569. [Google Scholar] [CrossRef]

- Ganguli, S.; Roy, A.K.; Anderson, D.P. Improved thermal conductivity for chemically functionalized exfoliated graphite/epoxy composites. Carbon 2008, 46, 806–817. [Google Scholar] [CrossRef]

- Yang, S.Y.; Lin, W.N.; Huang, Y.L.; Tien, H.W.; Wang, J.Y.; Ma, C.C.M.; Li, S.M.; Wang, Y.S. Synergetic effects of graphene platelets and carbon nanotubes on the mechanical and thermal properties of epoxy composites. Carbon 2011, 49, 793–803. [Google Scholar] [CrossRef]

- Huang, X.; Zhi, C.; Jiang, P. Toward effective synergetic effects from graphene nanoplatelets and carbon nanotubes on thermal conductivity of ultrahigh volume fraction nanocarbon epoxy composites. J. Phys. Chem. C 2012, 116, 23812–23820. [Google Scholar] [CrossRef]

- Song, S.H.; Park, K.H.; Kim, B.H.; Choi, Y.W.; Jun, G.H.; Lee, D.J.; Kong, B.S.; Paik, K.W.; Jeon, S. Enhanced thermal conductivity of epoxy-graphene composites by using non-oxidized graphene flakes with non-covalent functionalization. Adv. Mater. 2013, 25, 732–737. [Google Scholar] [CrossRef] [PubMed]

- Jung, H.; Yu, S.; Bae, N.S.; Cho, S.M.; Kim, R.H.; Cho, S.H.; Hwang, I.; Jeong, B.; Ryu, J.S.; Hwang, J. High through-plane thermal conduction of graphene nanoflake filled polymer composites melt-processed in an L-shape kinked tube. ACS Appl. Mater. Interfaces 2015, 7, 15256–15262. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.S.; Bae, H.S.; Yu, J.; Kim, S.Y. Thermal conductivity of polymer composites with the geometrical characteristics of graphene nanoplatelets. Sci. Rep. 2016, 6, 26825. [Google Scholar] [CrossRef] [PubMed]

- Deng, W.; Fang, Q.; Huang, H.; Zhou, X.; Ma, J.; Liu, Z. Oriented arrangement: The origin of versatility for porous graphene materials. Small 2017, 13, 1701231. [Google Scholar] [CrossRef] [PubMed]

- Li, S.H.; Kim, H.W.; Hwang, J.O.; Lee, W.J.; Kwon, J.; Bielawski, C.W.; Ruoff, R.S.; Kim, S.O. Three-dimensional self-assembly of graphene oxide platelets into mechanically flexible macroporous carbon films. Angew. Chem. Int. Ed. 2010, 122, 10282–10286. [Google Scholar]

- Cao, X.; Shi, Y.; Shi, W.; Lu, G.; Huang, X.; Yan, Q.; Zhang, Q.; Zhang, H. Preparation of novel 3D graphene networks for supercapacitor applications. Small 2011, 7, 3163–3168. [Google Scholar] [CrossRef] [PubMed]

- Li, B.; Yang, S.; Li, S.; Wang, B.; Liu, J. From commercial sponge toward 3D graphene-silicon networks for superior lithium storage. Adv. Energy Mater. 2015, 5, 1500289. [Google Scholar] [CrossRef]

- Shen, X.; Wang, Z.; Wu, Y.; Liu, X.; He, Y.B.; Zheng, Q.; Yang, Q.H.; Kang, F.; Kim, J.K. A three-dimensional multilayer graphene web for polymer nanocomposites with exceptional transport properties and fracture resistance. Mater. Horizons 2018, 5, 275–284. [Google Scholar] [CrossRef]

- An, F.; Li, X.; Min, P.; Liu, P.; Jiang, Z.G.; Yu, Z.Z. Vertically aligned high-quality graphene foams for anisotropically conductive polymer composites with ultrahigh through-plane thermal conductivities. ACS Appl. Mater. Interfaces 2018, 10, 17383–17392. [Google Scholar] [CrossRef] [PubMed]

- Hu, Z.; Yue, C.; Guo, X.; Liu, J. The effect of modulus on the performance of thermal conductive adhesives. In Proceedings of the 2010 11th International Conference on Electronic Packaging Technology & High Density Packaging (ICEPT-HDP), Xi’an, China, 16–19 Auust 2010; pp. 648–651. [Google Scholar]

- Yamini, S.; Young, R.J. The mechanical properties of epoxy resins. J. Mater. Sci. 1980, 15, 1823–1831. [Google Scholar] [CrossRef]

- Li, Q.; Guo, Y.; Li, W.; Qiu, S.; Zhu, C.; Wei, X.; Chen, M.; Liu, C.; Liao, S.; Gong, Y. Ultrahigh thermal conductivity of assembled aligned multilayer graphene/epoxy composite. Chem. Mater. 2012, 26, 4459–4465. [Google Scholar] [CrossRef]

- Liu, Z.; Shen, D.; Yu, J.; Dai, W.; Li, C.; Du, S.; Jiang, N.; Li, H.; Lin, C.T. Exceptionally high thermal and electrical conductivity of three dimensional graphene foam based polymer composites. RSC Adv. 2016, 6, 22364–22369. [Google Scholar] [CrossRef]

- Hou, H.; Dai, W.; Yan, Q.; Lv, L.; Alam, F.E.; Yang, M.; Yao, Y.; Zeng, X.; Xu, J.B.; Yu, J.; et al. Graphene size-dependent modulation of graphene frameworks contributing to the superior thermal conductivity of epoxy composites. J. Mater. Chem. A 2018, 6, 12091–12097. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Han, D.; Zhao, Y.H.; Bai, S.L. High-performance thermal interface materials consisting of vertically aligned graphene film and polymer. Carbon 2016, 109, 552–557. [Google Scholar] [CrossRef]

- Balachander, N.; Seshadri, I.; Mehta, R.J.; Schadler, L.S.; Borca-Tasciuc, T.; Keblinski, P.; Ramanath, G. Nanowire-filled polymer composites with ultrahigh thermal conductivity. Appl. Phys. Lett. 2013, 102, 093117. [Google Scholar] [CrossRef]

- Schneider, F.; Draheim, J.; Kamberger, R.; Wallrabe, U. Process and material properties of polydimethylsiloxane (PDMS) for optical MEMS. Sens. Actuators A Phys. 2009, 151, 95–99. [Google Scholar] [CrossRef]

- Chen, X.K.; Jiang, B.Y.; Zhou, Z. Investigation on viscosity of carbon nanofibers reinforced epoxy. In Advanced Materials Research; Trans Tech Publications: Stafa-Zurich, Switzerland, 2013; pp. 145–148. [Google Scholar]

- Pettes, M.T.; Ji, H.; Ruoff, R.S.; Li, S. Thermal transport in three-dimensional foam architectures of few-layer graphene and ultrathin graphite. Nano Lett. 2012, 12, 2959–2964. [Google Scholar] [CrossRef] [PubMed]

- Fang, H.; Zhao, Y.; Zhang, Y.; Ren, Y.; Bai, S.L. Three-dimensional graphene foam-filled elastomer composites with high thermal and mechanical properties. ACS Appl. Mater. Interfaces 2017, 9, 26447–26459. [Google Scholar] [CrossRef] [PubMed]

- Fang, H.; Zhang, X.; Zhao, Y.; Bai, S.L. Dense graphene foam and hexagonal boron nitride filled PDMS composites with high thermal conductivity and breakdown strength. Compos. Sci. Technol. 2017, 152, 243–253. [Google Scholar] [CrossRef]

- Zhang, Q.; Xu, X.; Li, H.; Xiong, G.; Hu, H.; Fisher, T.S. Mechanically robust honeycomb graphene aerogel multifunctional polymer composites. Carbon 2015, 93, 659–670. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Wu, Z.K.; Bai, S.L. Study on thermal properties of graphene foam/graphene sheets filled polymer composites. Compos. Part A 2015, 72, 200–206. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Zhang, Y.F.; Bai, S.L. High thermal conductivity of flexible polymer composites due to synergistic effect of multilayer graphene flakes and graphene foam. Compos. Part A 2016, 85, 148–155. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Zhang, Y.F.; Bai, S.L.; Yuan, X.W. Carbon fibre/graphene foam/polymer composites with enhanced mechanical and thermal properties. Compos. Part B 2016, 94, 102–108. [Google Scholar] [CrossRef]

- Song, S.; Zhang, Y. Construction of a 3D multiple network skeleton by the thiol-Michael addition click reaction to fabricate novel polymer/graphene aerogels with exceptional thermal conductivity and mechanical properties. J. Mater. Chem. A 2017, 5, 22352–22360. [Google Scholar] [CrossRef]

- Liang, Q.; Yao, X.; Wang, W.; Liu, Y.; Wong, C.P. A three-dimensional vertically aligned functionalized multilayer graphene architecture: An approach for graphene-based thermal interfacial materials. ACS Nano 2011, 5, 2392–2401. [Google Scholar] [CrossRef] [PubMed]

- Lv, P.; Tan, X.W.; Yu, K.H.; Zheng, R.L.; Zheng, J.J.; Wei, W. Super-elastic graphene/carbon nanotube aerogel: A novel thermal interface material with highly thermal transport properties. Carbon 2016, 99, 222–228. [Google Scholar] [CrossRef]

- Loeblein, M.; Tsang, S.H.; Pawlik, M.; Phua, E.J.; Yong, H.; Zhang, X.W.; Gan, C.L.; Teo, E.H. High-density 3D-boron nitride and 3D-graphene for high-performance nano-thermal interface material. ACS Nano 2017, 11, 2033–2044. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Walther, J.H.; Koumoutsakos, P. Covalently bonded graphene-carbon nanotube hybrid for high-performance thermal interfaces. Adv. Funct. Mater. 2016, 25, 7539–7545. [Google Scholar] [CrossRef]

- Segal, M. Selling graphene by the ton. Nat. Nanotechnol. 2009, 4, 612–614. [Google Scholar] [CrossRef] [PubMed]

- Wada, K.; Tanaka, H.; Suyama, T.; Kimura, H.; Yamamoto, T. Numerical simulation of dust aggregate collisions. I. Compression and disruption of two-dimensional aggregates. Astrophys. J. 2007, 661, 320–333. [Google Scholar] [CrossRef]

- Spanu, L.; Sorella, S.; Galli, G. Nature and strength of interlayer binding in graphite. Phys. Rev. Lett. 2009, 103, 196401. [Google Scholar] [CrossRef] [PubMed]

- Cataldo, F.; Pontier-Johnson, M.A. Recent discoveries in carbon black formation and morphology and their implications on the structure of interstellar carbon dust. Fullerenes Nanotubes Carbon Nanostruct. 2002, 10, 1–14. [Google Scholar] [CrossRef]

- Peng, W.; Zhang, T.; Yu, S.; Zhen, Y. Graphite dust resuspension in a depressurization accident of HTR. Nucl. Eng. Des. 2013, 265, 785–790. [Google Scholar] [CrossRef]

| Filler | Matrix | κ (W/mK) | Fraction | Years |

|---|---|---|---|---|

| Graphite nanoplatelet | Epoxy | 6.44 | ≈34 wt % | 2007 [14] |

| Functionalized exfoliated graphite | Epoxy | 5.80 | 20 wt % | 2008 [15] |

| Graphene + CNT | Epoxy | 0.32 | 1 wt % | 2011 [16] |

| Graphene + Multilayer graphene | Epoxy | 5.10 | ≈15 wt % | 2012 [7] |

| Graphene + CNT | Epoxy | 7.30 | 50 wt % | 2012 [17] |

| Functionalized graphene flakes | Epoxy | 1.53 | 10 wt % | 2013 [18] |

| Graphene nanoflake | Polytetrafluoroethylene | 10.00 | ≈24 wt % | 2015 [19] |

| Graphene nanoplatelets | Polycarbonate | 7.30 | 20 wt % | 2016 [20] |

| Multilayer graphene | Epoxy | 1.50 | 5.7 wt % | 2016 [11] |

| Filler | κ (W/mK) | Fraction | Form | Years |

|---|---|---|---|---|

| Graphene aerogel | 2.13 (⊥) | ≈1.4 wt % | Hard bulk | 2014 [10] |

| 0.63 (//) | ||||

| Filtrated graphene framework | 16.7 (//) | ≈11.8 wt% | Hard bulk | 2014 [29] |

| 5.44 (⊥) | ||||

| Templated graphene framework | 1.51 | 5 wt% | Hard bulk | 2016 [30] |

| Templated graphene framework | 8.80 (//) | 8.3 wt% | Hard lamella | 2018 [25] |

| 2.00 (⊥) | ||||

| Filtrated graphene framework | 10.0 (//) | 5.5 wt% | Hard bulk | 2018 [31] |

| 5.40 (⊥) | ||||

| Vertically aligned graphene framework | 17.2 (//) | ≈33 wt% | Hard bulk | 2018 [26] |

| 35.5 (⊥) |

| Filler | κ (W/mK) | Fraction | Form | Years |

|---|---|---|---|---|

| Graphene aerogel | 0.68 | 1 wt % | Macroporous | 2015 [39] |

| Graphene aerogel | 0.56 | 0.7 wt % | Macroporous | 2015 [40] |

| Graphene aerogel + graphene flakes | 1.08 | ≈0.4 + 5.3 wt % | Macroporous | 2016 [41] |

| Graphene aerogel + carbon fiber | 0.55 | ≈1.1 + 19.4 wt % | Macroporous | 2016 [42] |

| Graphene aerogel | 0.82 | 2 wt % | Macroporous | 2017 [43] |

| Templated graphene framework | 1.62 (⊥) | 11.6 wt % | Densely packed | 2017 [37] |

| 28.8 (//) | ||||

| Templated graphene framework + BN | 2.11 (⊥) | 33.8 wt % | Densely packed | 2017 [38] |

| 23.5 (//) |

| Graphene-Based TIMs | Thermal Conductivity | Cost | Adaptability |

|---|---|---|---|

| Dispersed graphene/polymers | Low | Low | Good |

| Graphene framework/polymers | Medium | High | Good |

| Graphene-based monoliths | High | High | Medium |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, L.; Dai, W.; Li, A.; Lin, C.-T. Graphene-Based Thermal Interface Materials: An Application-Oriented Perspective on Architecture Design. Polymers 2018, 10, 1201. https://doi.org/10.3390/polym10111201

Lv L, Dai W, Li A, Lin C-T. Graphene-Based Thermal Interface Materials: An Application-Oriented Perspective on Architecture Design. Polymers. 2018; 10(11):1201. https://doi.org/10.3390/polym10111201

Chicago/Turabian StyleLv, Le, Wen Dai, Aijun Li, and Cheng-Te Lin. 2018. "Graphene-Based Thermal Interface Materials: An Application-Oriented Perspective on Architecture Design" Polymers 10, no. 11: 1201. https://doi.org/10.3390/polym10111201

APA StyleLv, L., Dai, W., Li, A., & Lin, C.-T. (2018). Graphene-Based Thermal Interface Materials: An Application-Oriented Perspective on Architecture Design. Polymers, 10(11), 1201. https://doi.org/10.3390/polym10111201