Flow Instabilities of Coupled Rotation and Thermal-Solutal Capillary Convection of Binary Mixture in Czochralski Configuration

Abstract

1. Introduction

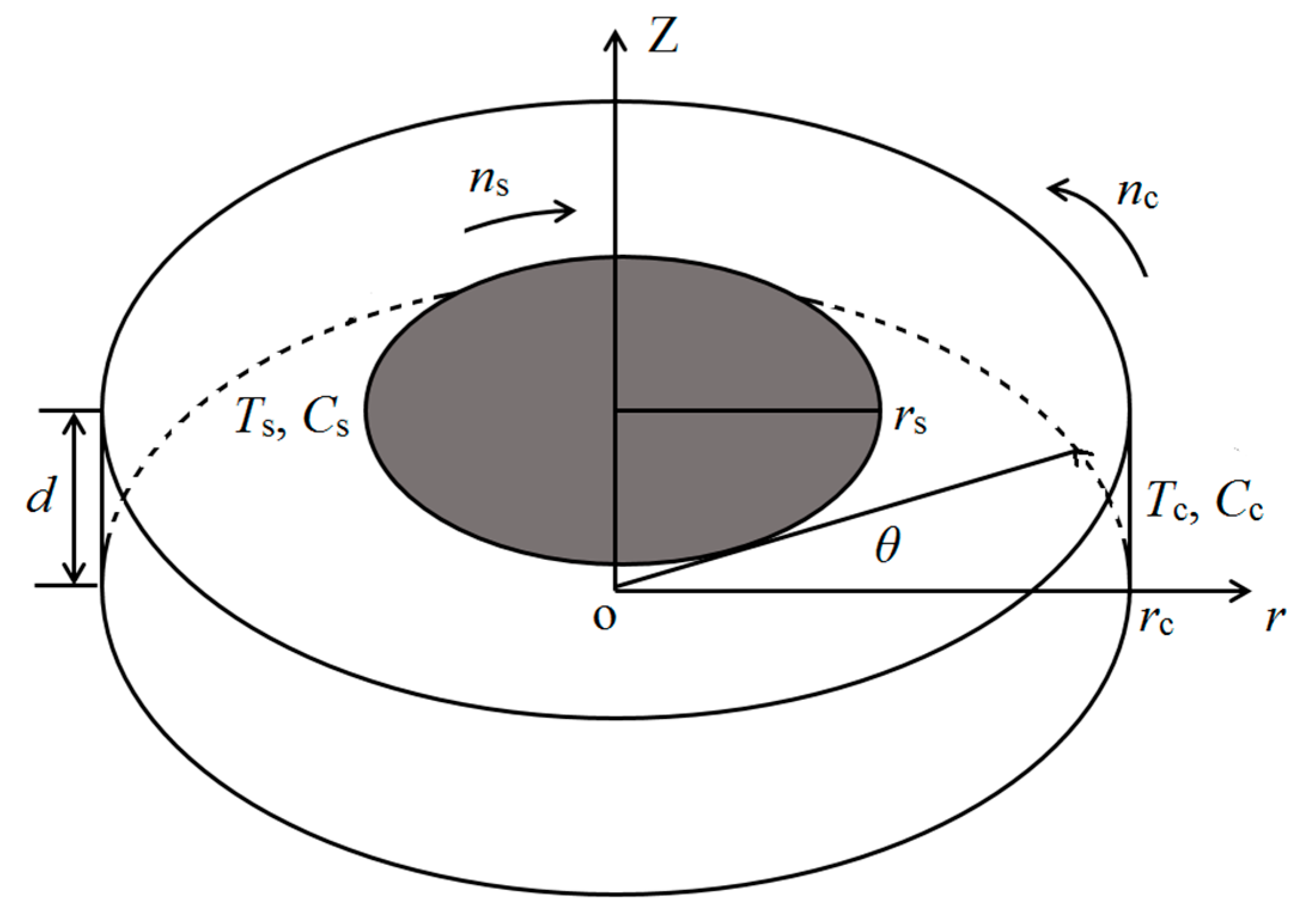

2. Physical and Mathematical Model

2.1. Basic Assumptions and Governing Equations

2.2. Boundary and Initial Conditions

2.3. Calculation Conditions and Numerical Method

3. Results and Discussion

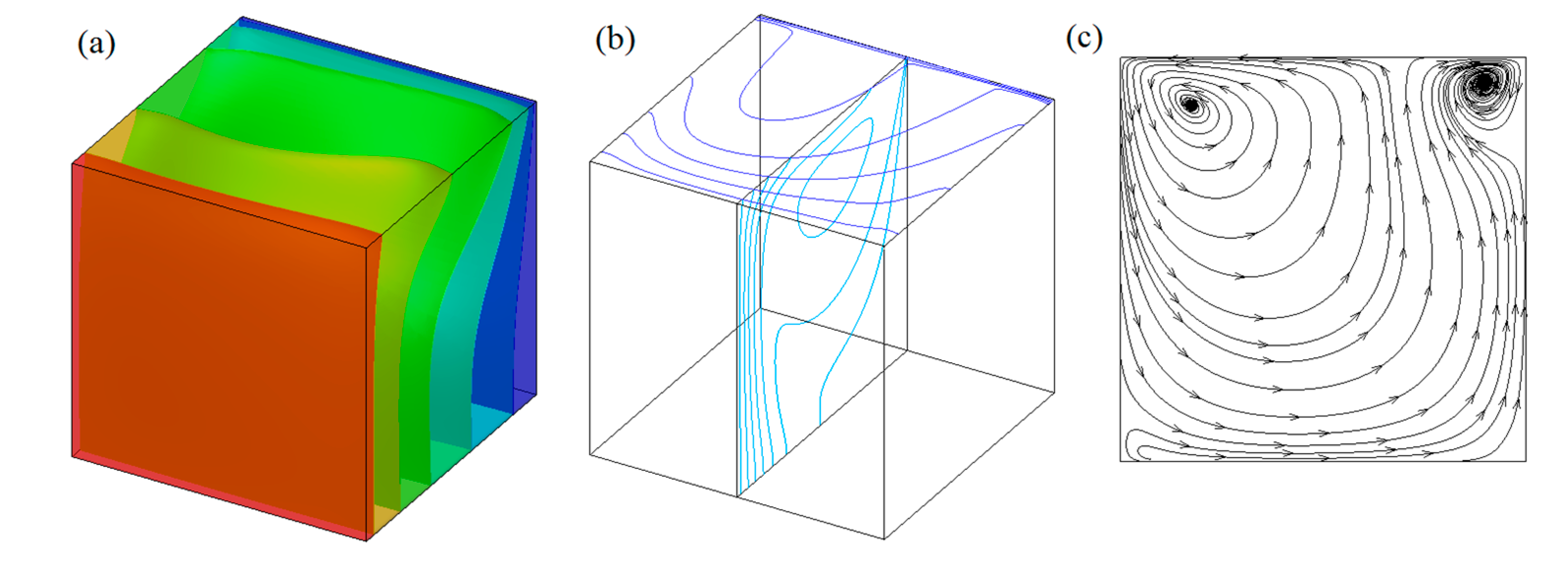

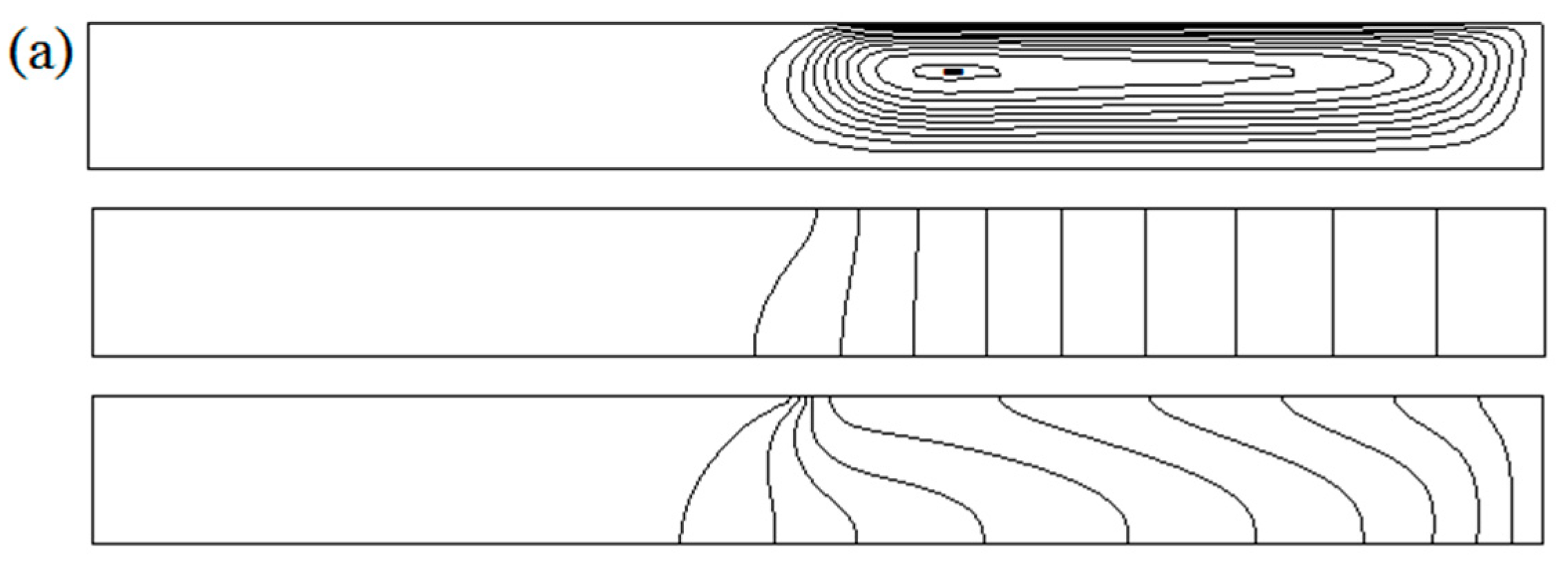

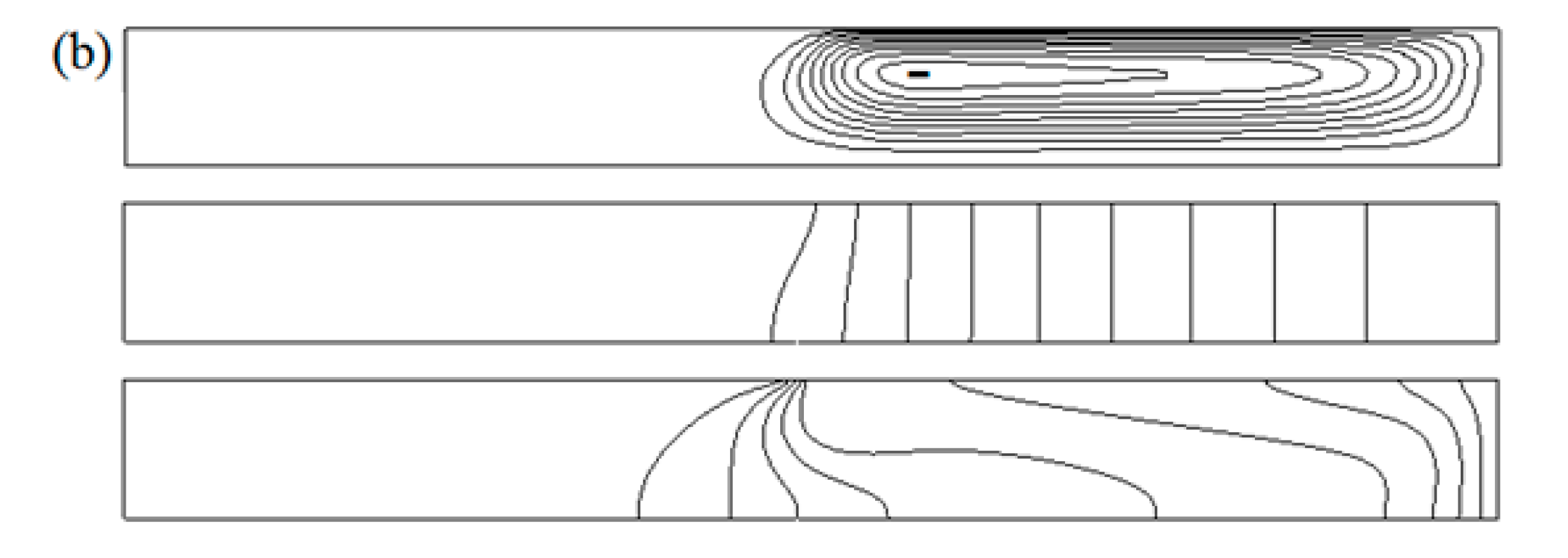

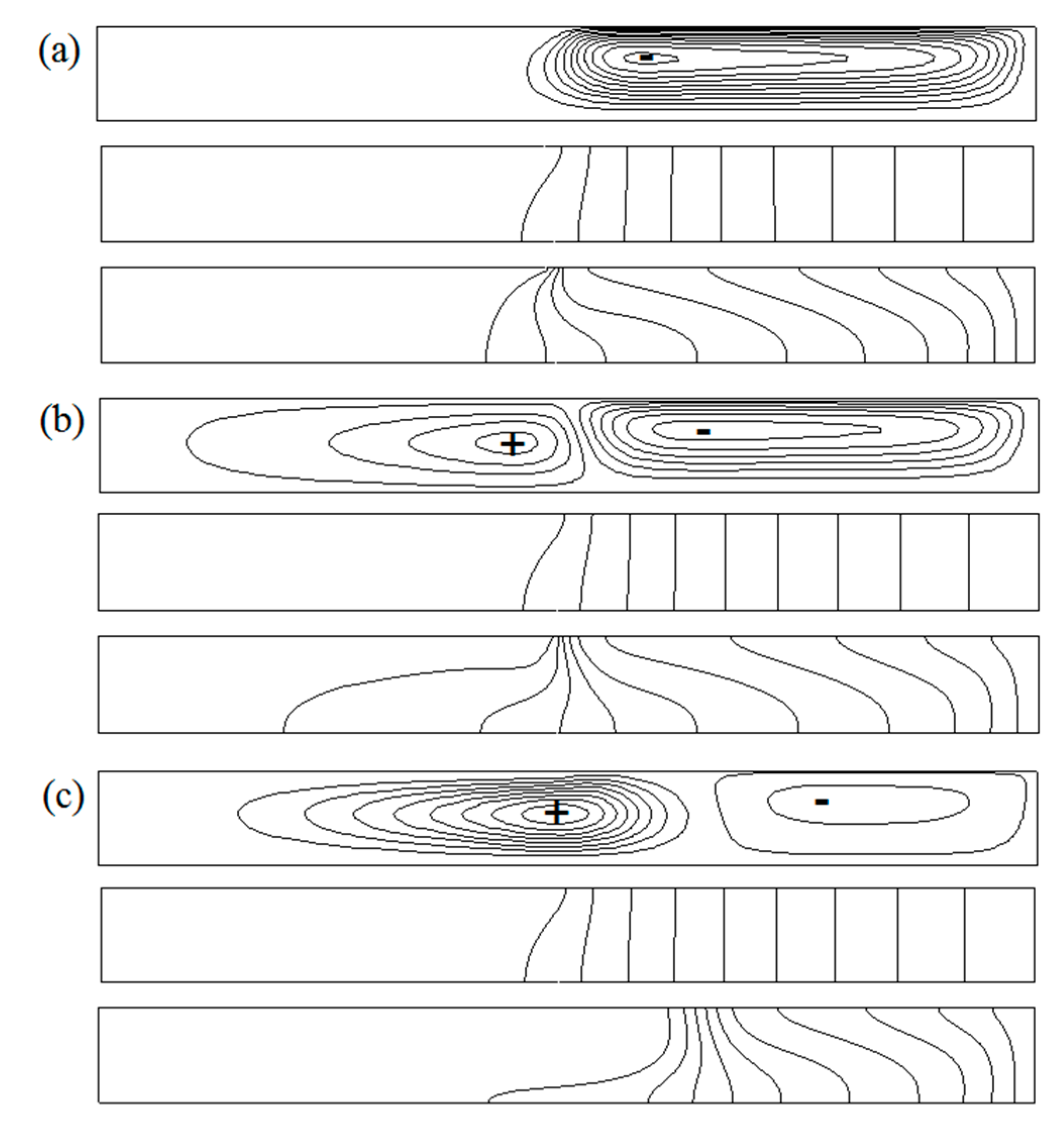

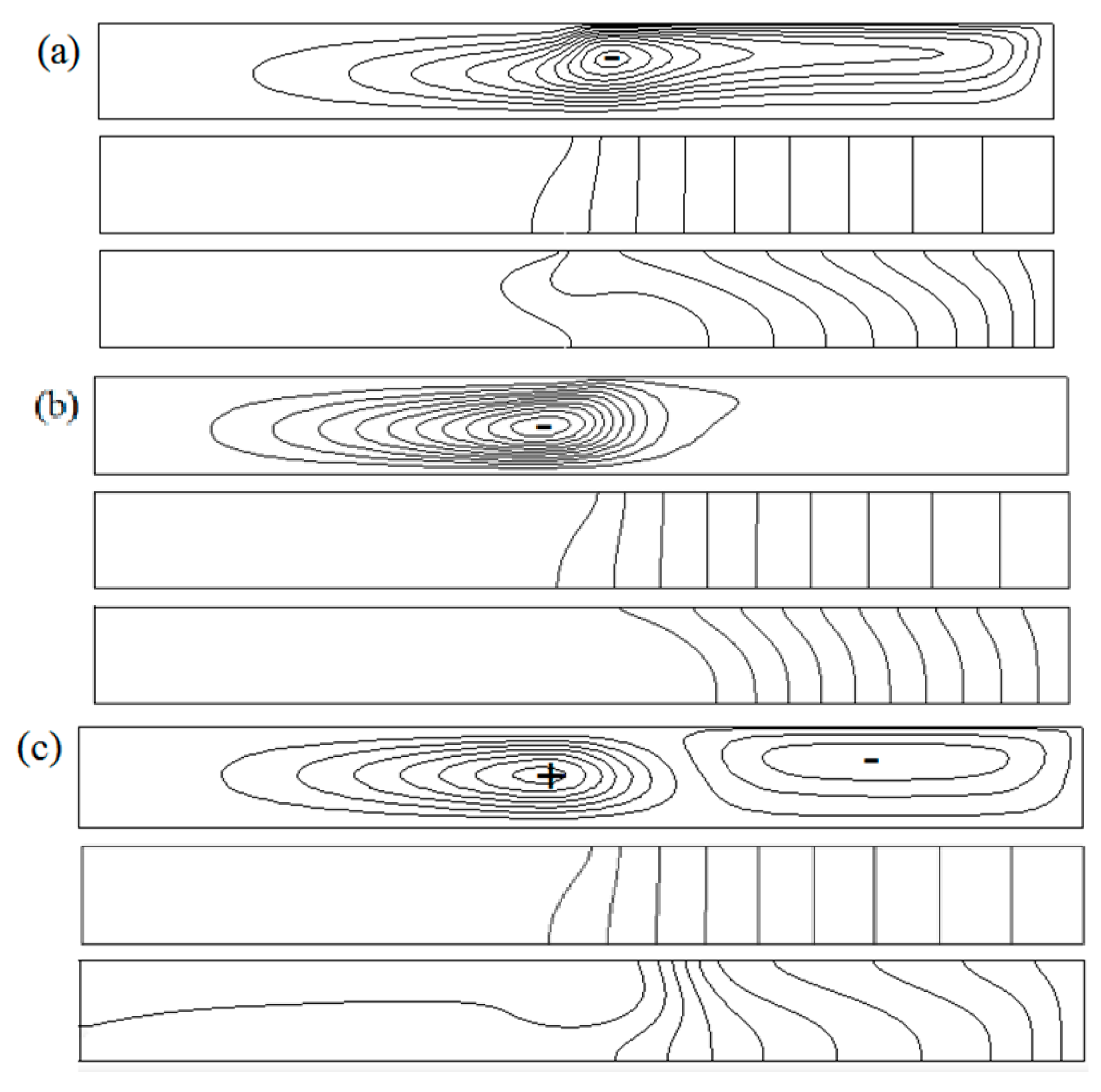

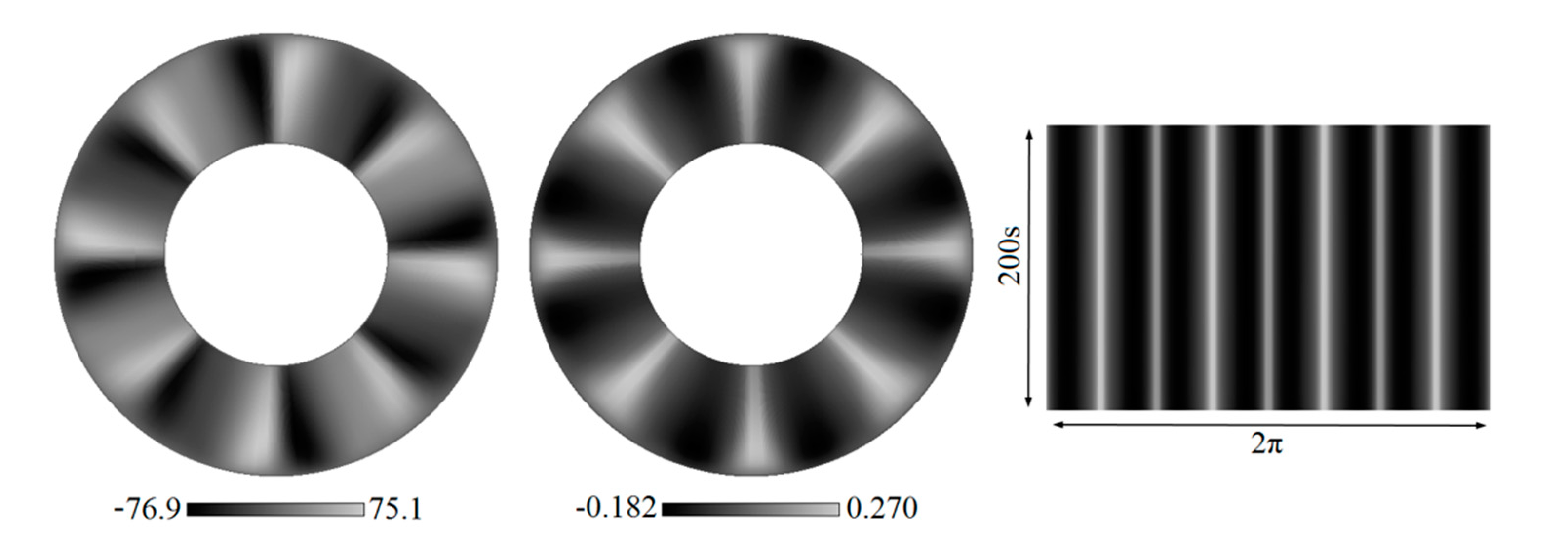

3.1. Basic Flow

3.2. Critical Conditions for the Flow Destabilization

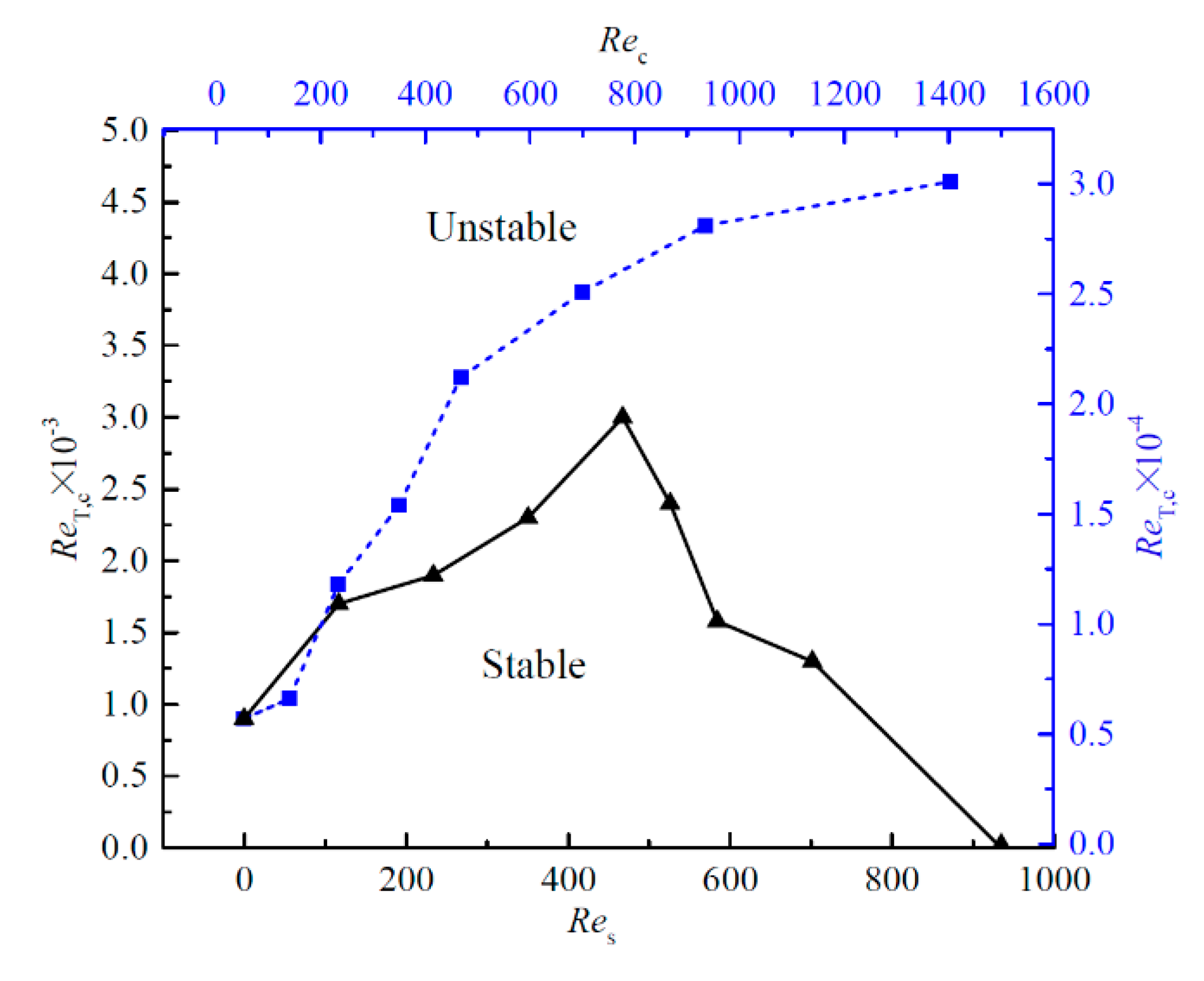

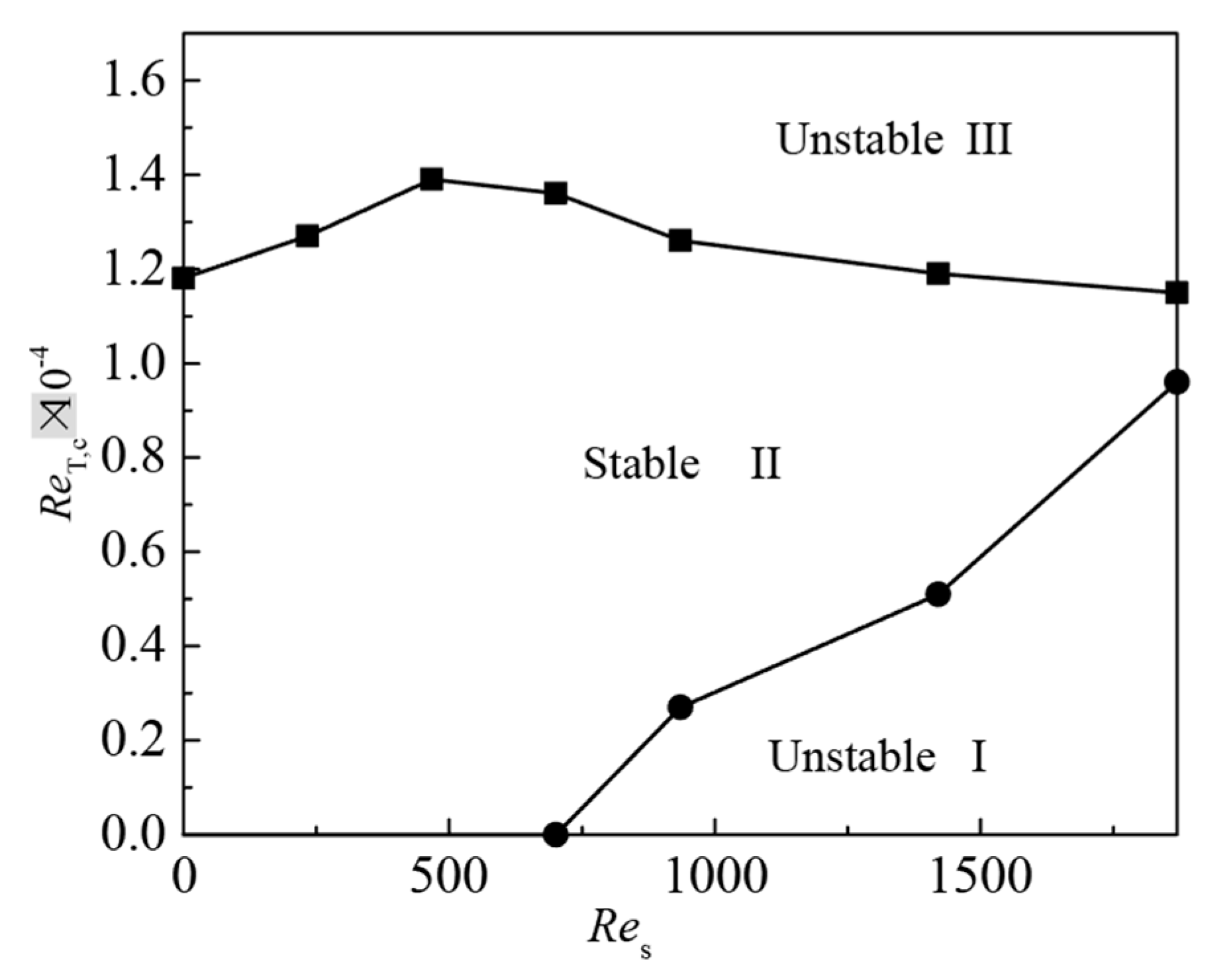

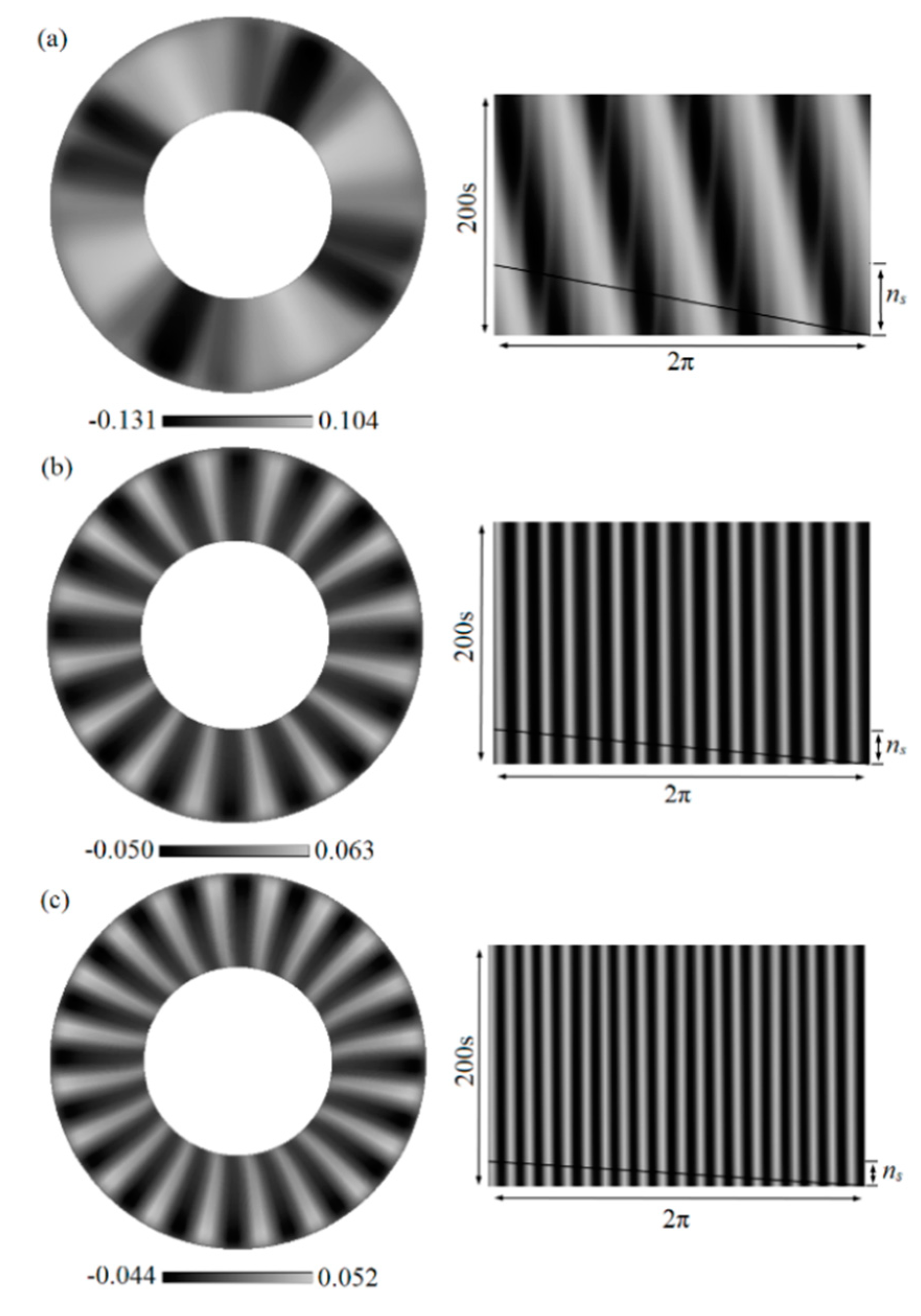

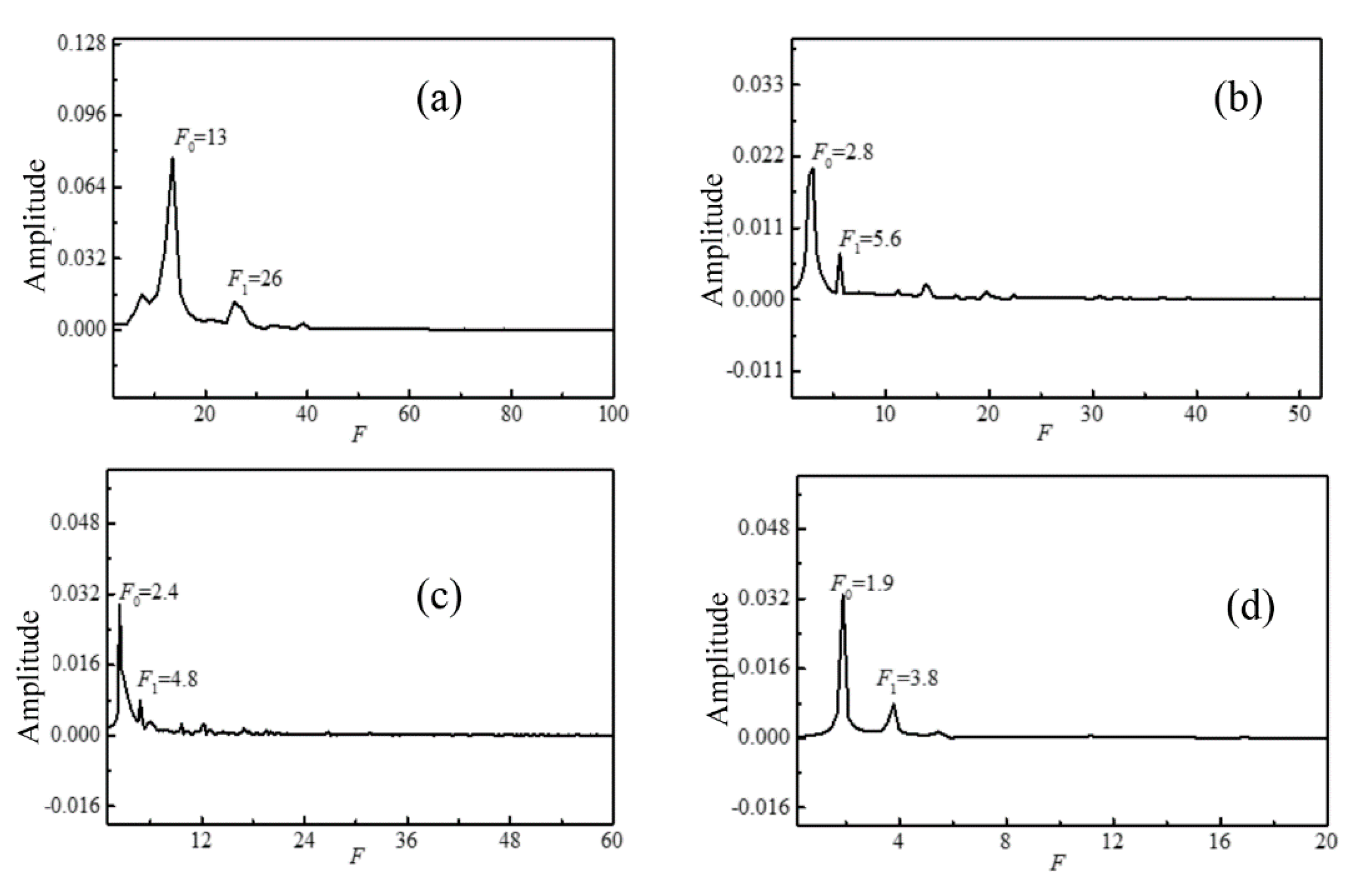

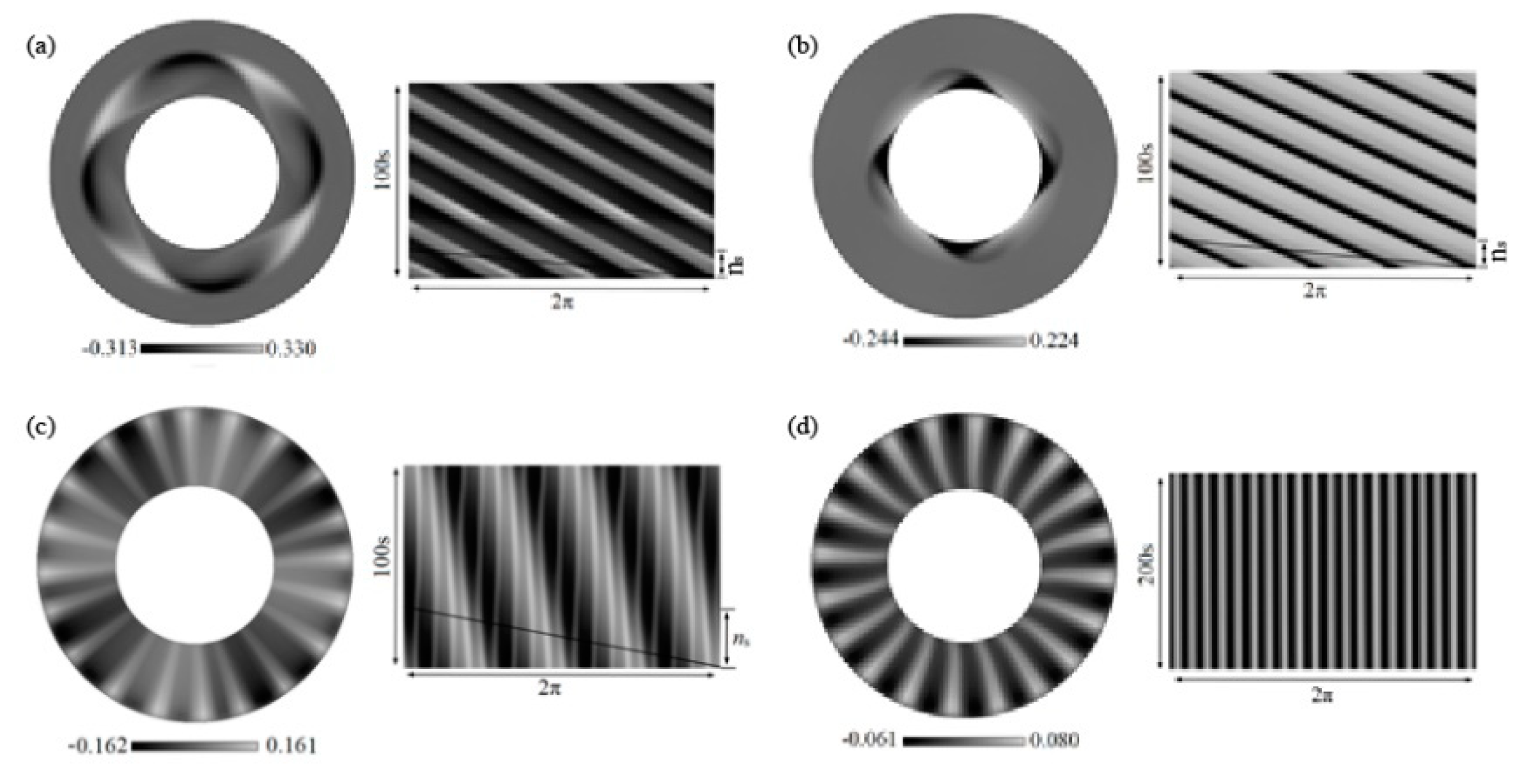

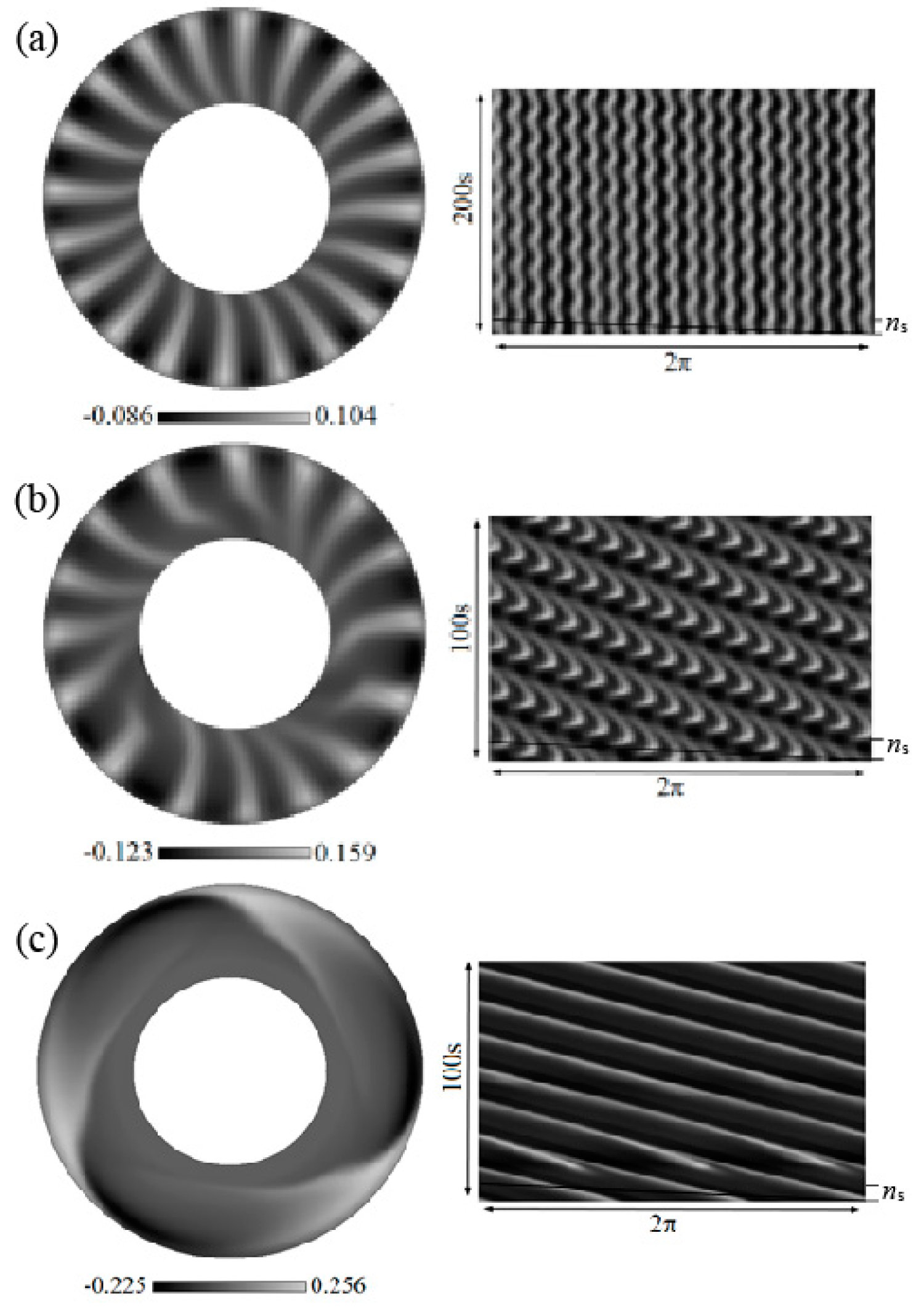

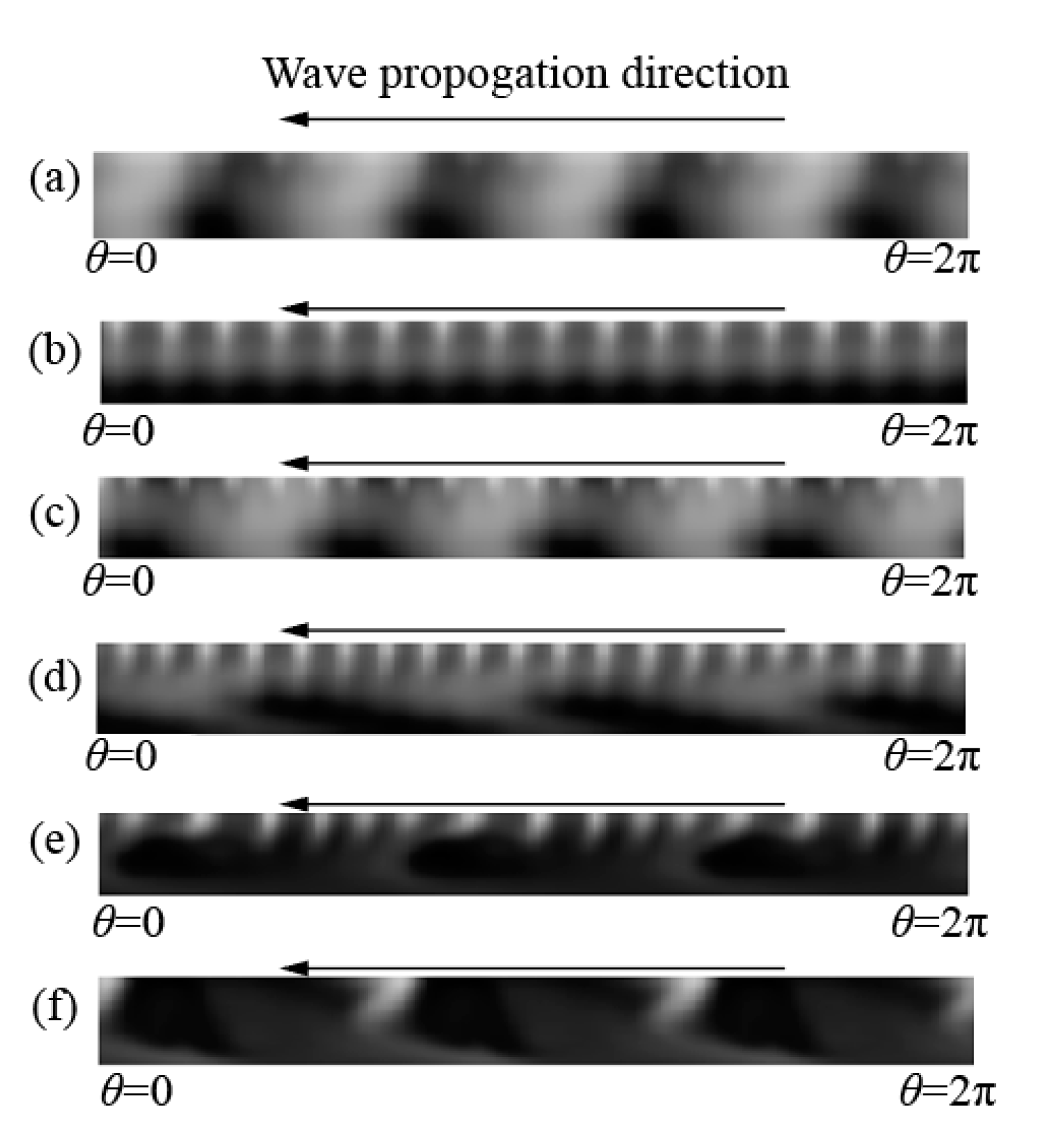

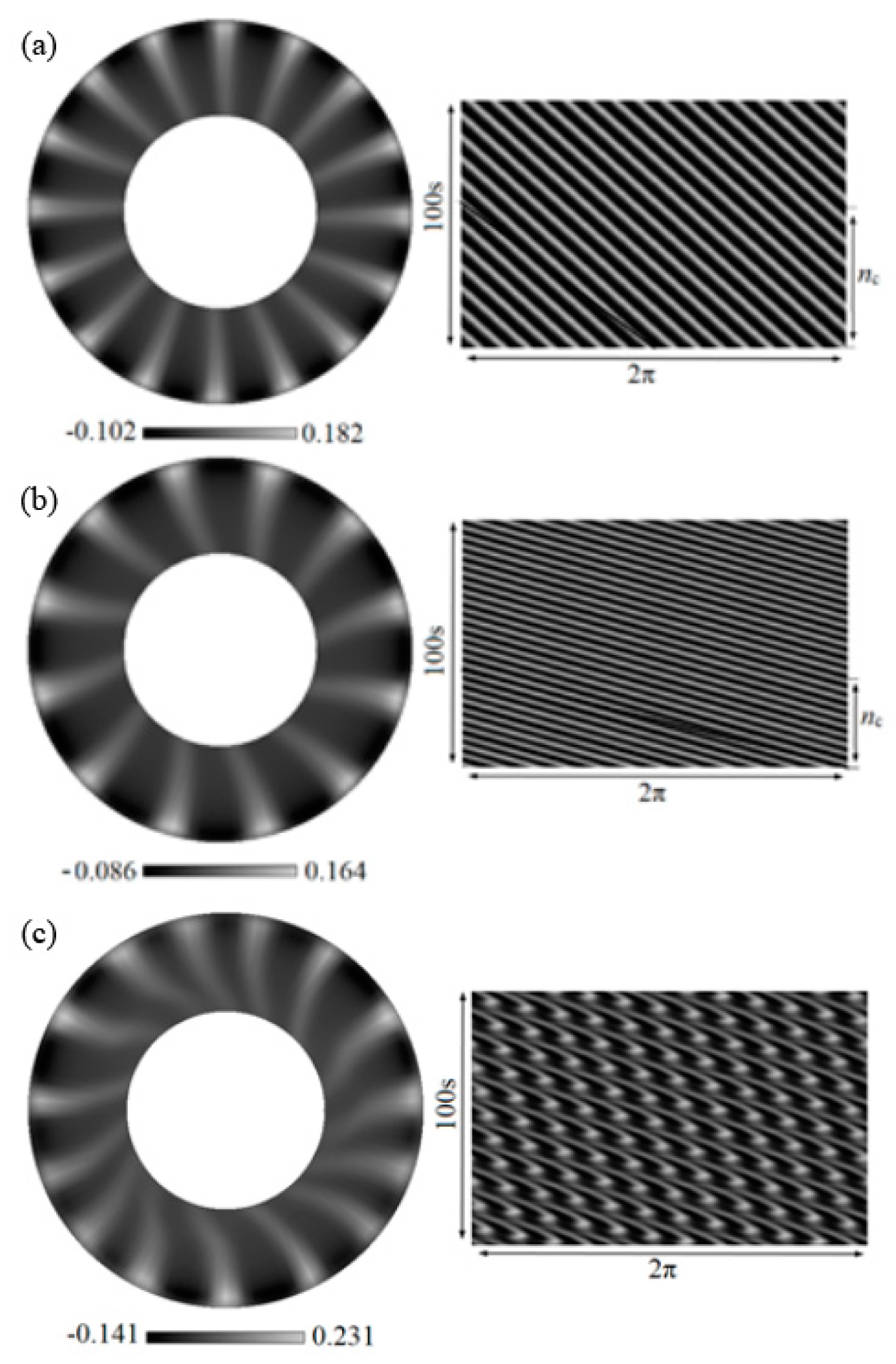

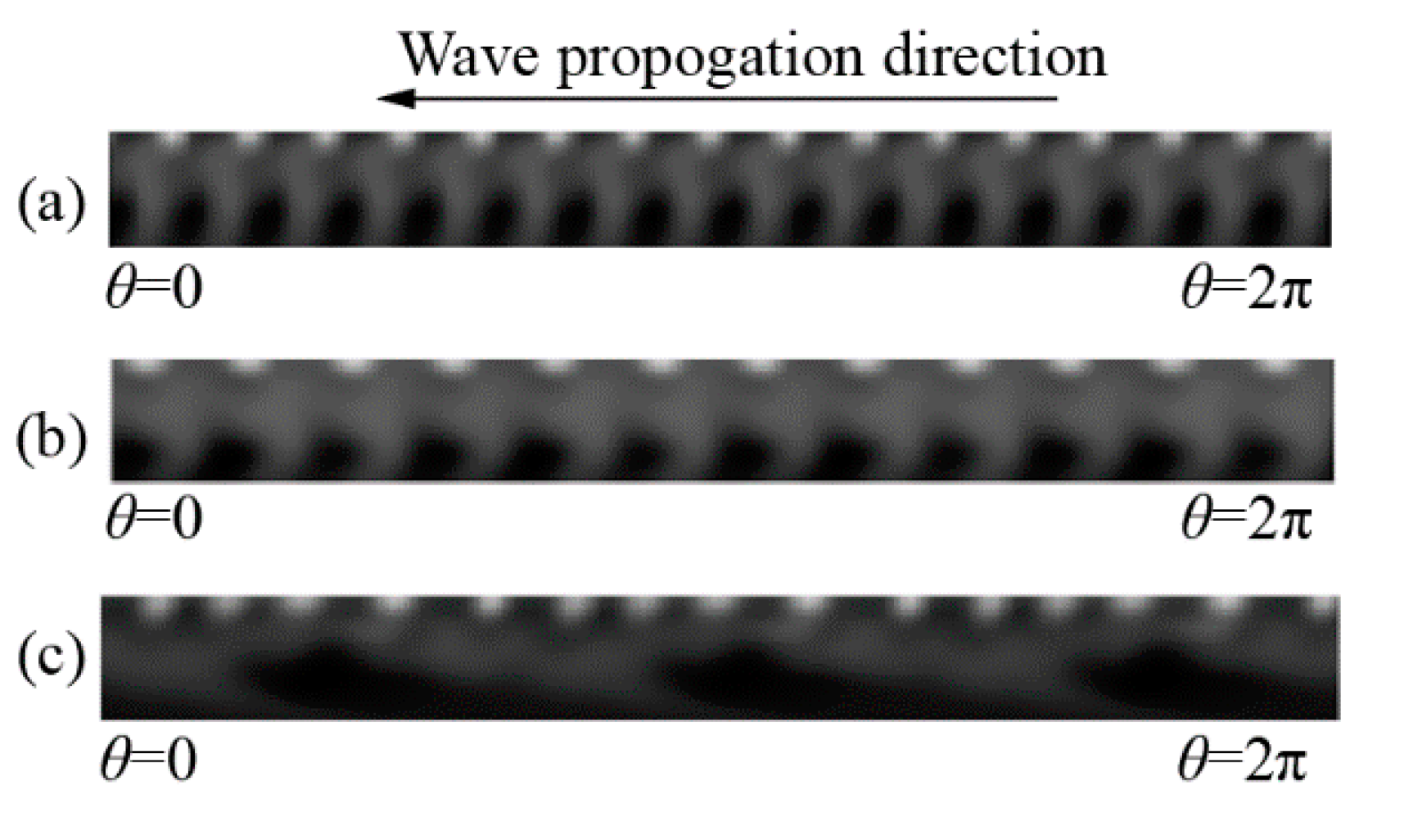

3.3. Three-Dimensional Oscillatory Flow

4. Conclusions

- (1)

- For the small Reynolds numbers, the basic flow represents as two-dimensional steady flow. Depending on the competitions among the driving forces, the flow structure is presented as meridional circulations in counter-clockwise or clockwise direction. When the strength of the driving forces are comparable, two opposite cells can coexist in the flow field.

- (2)

- When the ReT exceeds a critical value, the basic flow will transit to the three-dimensional oscillatory state. For crucible rotation, the critical value of ReT increases monotonically with the increase of crucible rotation rate. For crystal rotation, the variation trend for the critical ReT increase first and then decreases with the increase of Res. For the co-rotation of crucible and crystal, two critical values of ReT are obtained. When the rotation driven flow is dominated, the flow is named as unstable state I; with the increase of ReT, the flow will transit to stable state II, then the thermal-solutal capillary will dominate the flow and drives the flow lose its stability again and transits to unstable state III.

- (3)

- The oscillatory flow patterns are closely related with the competitions among the rotation and thermal-solutal capillary forces. Without rotation, the surface spoke pattern is steady in time but oscillate in space. With crystal rotation, the surface will transit to spokes propagating in azimuthal direction, rotation waves, also, the spokes and rotation waves may coexist, these waves overlap and interweave in the flow field. The crucible rotation mainly dominants the propagation velocity of the surface fluctuation waves.

Author Contributions

Funding

Conflicts of Interest

References

- Platten, J.K.; Legros, J.C. Convection in Liquids; Springer: Berlin, Germany; New York, NY, USA, 1984. [Google Scholar]

- Fornari, R. Comprehensive Semiconductor Science and Technology; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Miller, W.; Böttcher, K.; Galazka, Z.; Schreuer, J. Numerical Modelling of the Czochralski Growth of β-Ga2O3. Crystals 2017, 7, 26. [Google Scholar] [CrossRef]

- Gallagher, A.; Nelson, W.L.; Chen, K.W.; Besara, T.; Siegrist, T.; Baumbach, R.E. Single Crystal Growth of URu2Si2 by the Modified Bridgman Technique. Crystals 2016, 6, 128. [Google Scholar] [CrossRef]

- Yu, Y.; Li, K.; Lin, H.; Li, J.-C. The Study of the Mechanism of Protein Crystallization in Space by Using Microchannel to Simulate Microgravity Environment. Crystals 2018, 8, 400. [Google Scholar] [CrossRef]

- Shevtsova, V.; Melnikov, D.; Mialdun, A.; Legros, J.C. Development of convection in binary mixture with soret effect. Microgravity Sci. Technol. 2006, 18, 38–41. [Google Scholar] [CrossRef]

- Smorodin, B.L.; Myznikova, B.I.; Legros, J.C. Parametrical convection of a binary mixture in the modulated gravity field. Microgravity Sci. Technol. 2007, 19, 165–166. [Google Scholar] [CrossRef]

- Bahloul, A.; Delahaye, R.; Vasseur, P.; Robillard, L. Effect of surface tension on convection in a binary fluid layer under a zero gravity environment. Int. J. Heat Mass Trans. 2003, 46, 1759–1771. [Google Scholar] [CrossRef]

- Gudzenko, L.; Kosmyna, M.; Shekhovtsov, A.; Paszkowicz, W.; Sulich, A.; Domagała, J.; Popov, P.; Skrobov, S. Crystal Growth and Glass-Like Thermal Conductivity of Ca3RE2(BO3)4 (RE = Y, Gd, Nd) Single Crystals. Crystals 2017, 7, 88. [Google Scholar] [CrossRef]

- Jiang, C.; Chen, F.; Yu, F.; Tian, S.; Cheng, X.; Zhang, S.; Zhao, X. Thermal Expansion and Electro-Elastic Features of Ba2TiSi2O8 High Temperature Piezoelectric Crystal. Crystals 2018, 9, 11. [Google Scholar] [CrossRef]

- McTaggart, C.L. Convection driven by concentration-dependent and temperature-dependent surface-tension. J. Fluid Mech. 1983, 134, 301–310. [Google Scholar] [CrossRef]

- Lyubimova, T.; Zubova, N.; Shevtsova, V. Onset and non-linear regimes of Soret-induced convection in binary mixtures heated from above. Eur. Phys. J. E 2017, 40, 1–8. [Google Scholar] [CrossRef]

- Ho, K.L.; Chang, H.C. On nonlinear doubly-diffusive marangoni instability. Aiche J. 1988, 34, 705–722. [Google Scholar] [CrossRef]

- Skarda, J.R.L.; Jacqmin, D.; McCaughan, F.E. Exact and approximate solutions to the double-diffusive Marangoni-Benard problem with cross-diffusive terms. J. Fluid Mech. 1998, 366, 109–133. [Google Scholar] [CrossRef]

- Chen, Z.W.; Li, Y.S.; Zhan, J.M. Double-diffusive Marangoni convection in a rectangular cavity: Onset of convection. Phys. Fluids 2010, 22, 034106. [Google Scholar] [CrossRef]

- Yu, Y.; Chan, C.L.; Chen, C.F. Effect of gravity modulation on the stability of a horizontal double-diffusive layer. J. Fluid Mech. 2007, 589, 183–213. [Google Scholar] [CrossRef]

- Bergeon, A.; Knobloch, E. Oscillatory Marangoni convection in binary mixtures in square and nearly square containers. Phys. Fluids 2004, 16, 360–372. [Google Scholar] [CrossRef]

- Morozov, M.; Oron, A.; Nepomnyashchy, A.A. Nonlinear dynamics of long-wave Marangoni convection in a binary mixture with the Soret effect. Phys. Fluids 2013, 25, 052107. [Google Scholar] [CrossRef]

- Podolny, A.; Nepomnyashchy, A.A.; Oron, A. Long-wave Marangoni instability in a binary liquid layer on a thick solid substrate. Phys. Rev. E 2007, 76, 026309. [Google Scholar] [CrossRef]

- Bergman, T.L. Numerical-simulation of double-diffusive marangoni convection. Phys. Fluids 1986, 29, 2103–2108. [Google Scholar] [CrossRef]

- Zhan, J.M.; Chen, Z.W.; Li, Y.S.; Nie, Y.H. Three-dimensional double-diffusive Marangoni convection in a cubic cavity with horizontal temperature and concentration gradients. Phys. Rev. E 2010, 82, 066305. [Google Scholar] [CrossRef]

- Chen, Z.W.; Zhan, J.M.; Li, Y.S.; Luo, Y.Y.; Cai, S. Double-diffusive buoyancy convection in a square cuboid with horizontal temperature and concentration gradients. Int. J. Heat Mass Trans. 2013, 60, 422–431. [Google Scholar] [CrossRef]

- Yu, J.J.; Wu, C.M.; Li, Y.R.; Chen, J.C. Thermal-solutal capillary-buoyancy flow of a low Prandtl number binary mixture with a-1 capillary ratio in an annular pool. Phys. Fluids 2016, 28, 084102. [Google Scholar] [CrossRef]

- Chen, J.C.; Zhang, L.; Li, Y.R.; Yu, J.-J. Three-dimensional numerical simulation of pure solutocapillary flow in a shallow annular pool for mixture fluid with high schmidt number. Microgravity Sci. Technol. 2016, 28, 49–57. [Google Scholar] [CrossRef]

- Chen, J.C.; Wu, C.M.; Li, Y.R.; Yu, J.J. Effect of capillary ratio on thermal-solutal capillary-buoyancy convection in a shallow annular pool with radial temperature and concentration gradients. Int. J. Heat Mass Trans. 2017, 109, 367–377. [Google Scholar] [CrossRef]

- Jones, A.D.W. Flow in a model czochralski oxide melt. J. Cryst. Growth 1989, 94, 421–432. [Google Scholar] [CrossRef]

- Lappa, M. Assessment of the role of axial vorticity in the formation of particle accumulation structures in supercritical Marangoni and hybrid thermocapillary-rotation-driven flows. Phys. Fluids 2013, 25, 012101. [Google Scholar] [CrossRef]

- Lappa, M. Crystal Growth from the Melt and Rotating Machinery. In Rotating Thermal Flows in Natural and Industrial Processes; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2012; pp. 371–429. [Google Scholar]

- Lopez, J.M. Three-dimensional swirling flows in a tall cylinder driven by a rotating endwall. Phys. Fluids 2012, 24, 014101. [Google Scholar] [CrossRef]

- Ding, L.; Zou, Q.; Zhang, L.; Wang, H. Research on flow-induced vibration and energy harvesting of three circular cylinders with roughness strips in tandem. Energies 2018, 11, 2977. [Google Scholar] [CrossRef]

- Wu, C.M.; Li, Y.R.; Ruan, D.F. Aspect ratio and radius ratio dependence of flow pattern driven by differential rotation of a cylindrical pool and a disk on the free surface. Phys. Fluids 2013, 25, 084101. [Google Scholar] [CrossRef]

- Wu, C.M.; Ruan, D.F.; Li, Y.R.; Liao, R.J. Flow pattern transition driven by the combined Marangoni effect and rotation of crucible and crystal in a Czochralski configuration. Int. J. Therm. Sci. 2014, 86, 394–407. [Google Scholar] [CrossRef]

- Wu, C.M.; Li, Y.R.; Liao, R.J. Rotating and thermocapillary-buoyancy-driven flow in a cylindrical enclosure with a partly free surface. Phys. Fluids 2014, 26, 28. [Google Scholar] [CrossRef]

- Takagi, Y.; Okano, Y.; Dost, S. A Numerical simulation study on the effects of crucible rotation and magnetic fields in growth of SiGe by the traveling heater method. J. Heat Transf. 2012, 134, 012301. [Google Scholar] [CrossRef]

- Glicksman, M.E. Capillary-mediated interface perturbations: Deterministic pattern formation. J. Cryst. Growth 2016, 450, 119–139. [Google Scholar] [CrossRef]

- Li, Y.R.; Akiyama, Y.; Imaishi, N.; Tsukada, T. Global analysis of a small Czochralski furnace with rotating crystal and crucible. J. Cryst. Growth 2003, 255, 81–92. [Google Scholar] [CrossRef]

- Minakuchi, H.; Okano, Y.; Dost, S. A three-dimensional numerical simulation study of the Marangoni convection occurring in the crystal growth of SixGe1−x by the float-zone technique in zero gravity. J. Cryst. Growth 2004, 266, 140–144. [Google Scholar] [CrossRef]

- Li, Y.R.; Peng, L.; Akiyama, Y.; Imaishi, N. Three-dimensional numerical simulation of thermocapillary flow of moderate Prandtl number fluid in an annular pool. J. Cryst. Growth 2003, 259, 374–387. [Google Scholar] [CrossRef]

- Shen, T.; Wu, C.M.; Li, Y.R. Experimental investigation on the effect of crystal and crucible rotation on thermocapillary convection in a Czochralski configuration. Int. J. Therm. Sci. 2016, 104, 20–28. [Google Scholar] [CrossRef]

| Property | Symbol | Unit | Value |

|---|---|---|---|

| Density | ρ | kg/m3 | 5246.00 |

| Thermal diffusivity | α | m2/s | 2.20 × 10−5 |

| Viscosity | μ | kg/(m·s) | 7.34 × 10−4 |

| Mass diffusivity of species | D | m2/s | 1.00 × 10−8 |

| Temperature coefficient of surface tension | γT | N/(m·k) | 8.10 × 10−5 |

| Concentration coefficient of surface tension | γC | N/m | −0.54 |

| Prandtl number | Pr | - | 6.37 × 10−3 |

| Schmidt | Sc | 2.90 | |

| Lewis number | Le | - | 2197.80 |

| Grids | m | Vave |

|---|---|---|

| 40R × 20Z × 90θ | 8 | 50.40 |

| 60R × 20Z × 90θ | 8 | 50.10 |

| 80R × 30Z × 120θ | 8 | 50.05 |

| 120R × 40Z × 160θ | 8 | 50.47 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, C.; Yuan, B.; Li, Y. Flow Instabilities of Coupled Rotation and Thermal-Solutal Capillary Convection of Binary Mixture in Czochralski Configuration. Crystals 2019, 9, 72. https://doi.org/10.3390/cryst9020072

Wu C, Yuan B, Li Y. Flow Instabilities of Coupled Rotation and Thermal-Solutal Capillary Convection of Binary Mixture in Czochralski Configuration. Crystals. 2019; 9(2):72. https://doi.org/10.3390/cryst9020072

Chicago/Turabian StyleWu, Chunmei, Bo Yuan, and Yourong Li. 2019. "Flow Instabilities of Coupled Rotation and Thermal-Solutal Capillary Convection of Binary Mixture in Czochralski Configuration" Crystals 9, no. 2: 72. https://doi.org/10.3390/cryst9020072

APA StyleWu, C., Yuan, B., & Li, Y. (2019). Flow Instabilities of Coupled Rotation and Thermal-Solutal Capillary Convection of Binary Mixture in Czochralski Configuration. Crystals, 9(2), 72. https://doi.org/10.3390/cryst9020072