A Note for Probabilistic Model of Polymer Crystallization in Temperature Gradients

Abstract

:1. Introduction

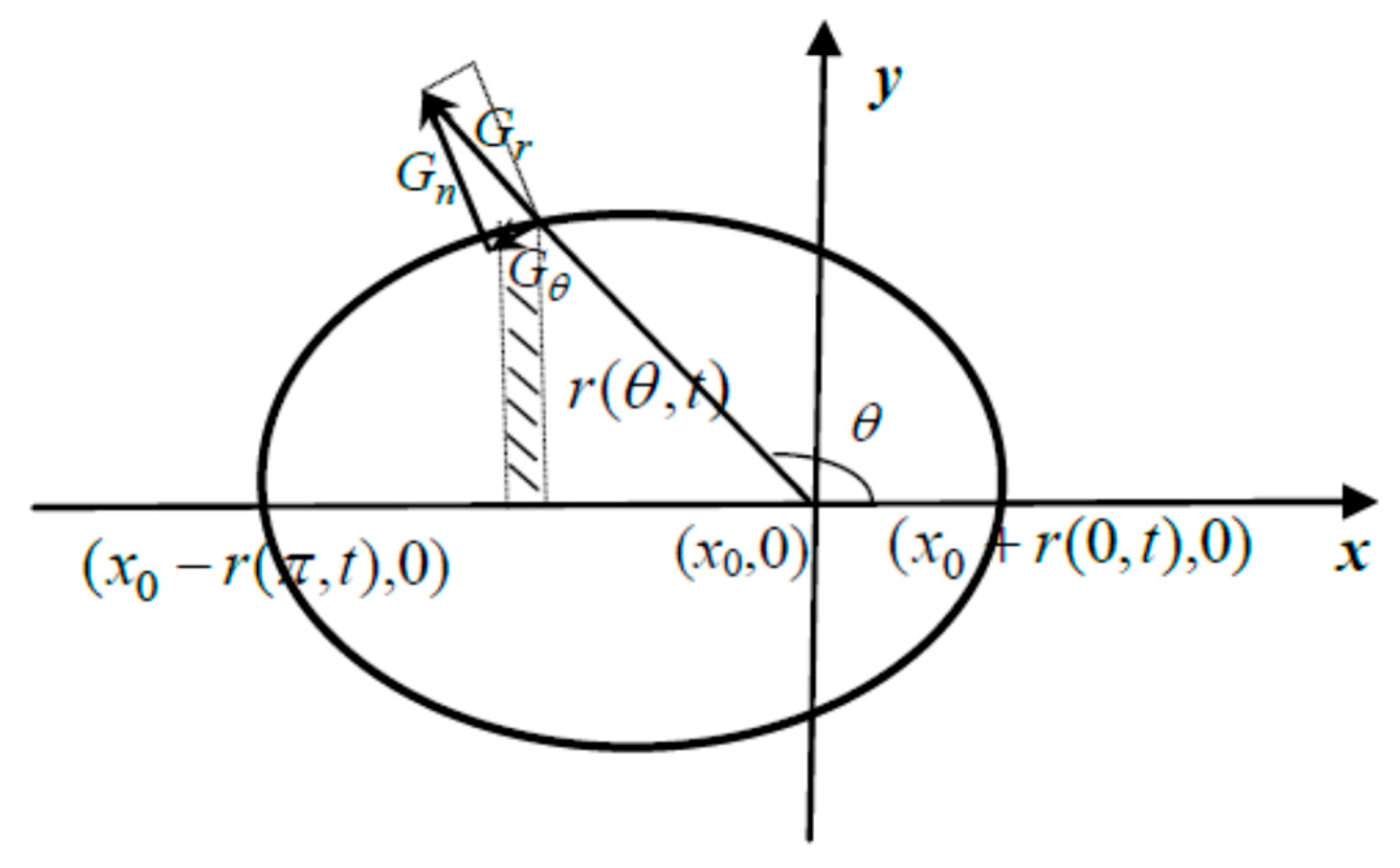

2. Mathematical Model and Numerical Method

2.1. Probabilistic Model

2.2. Nucleation and Growth Model of iPP

2.3. Monte Carlo Method

3. Results and Discussion

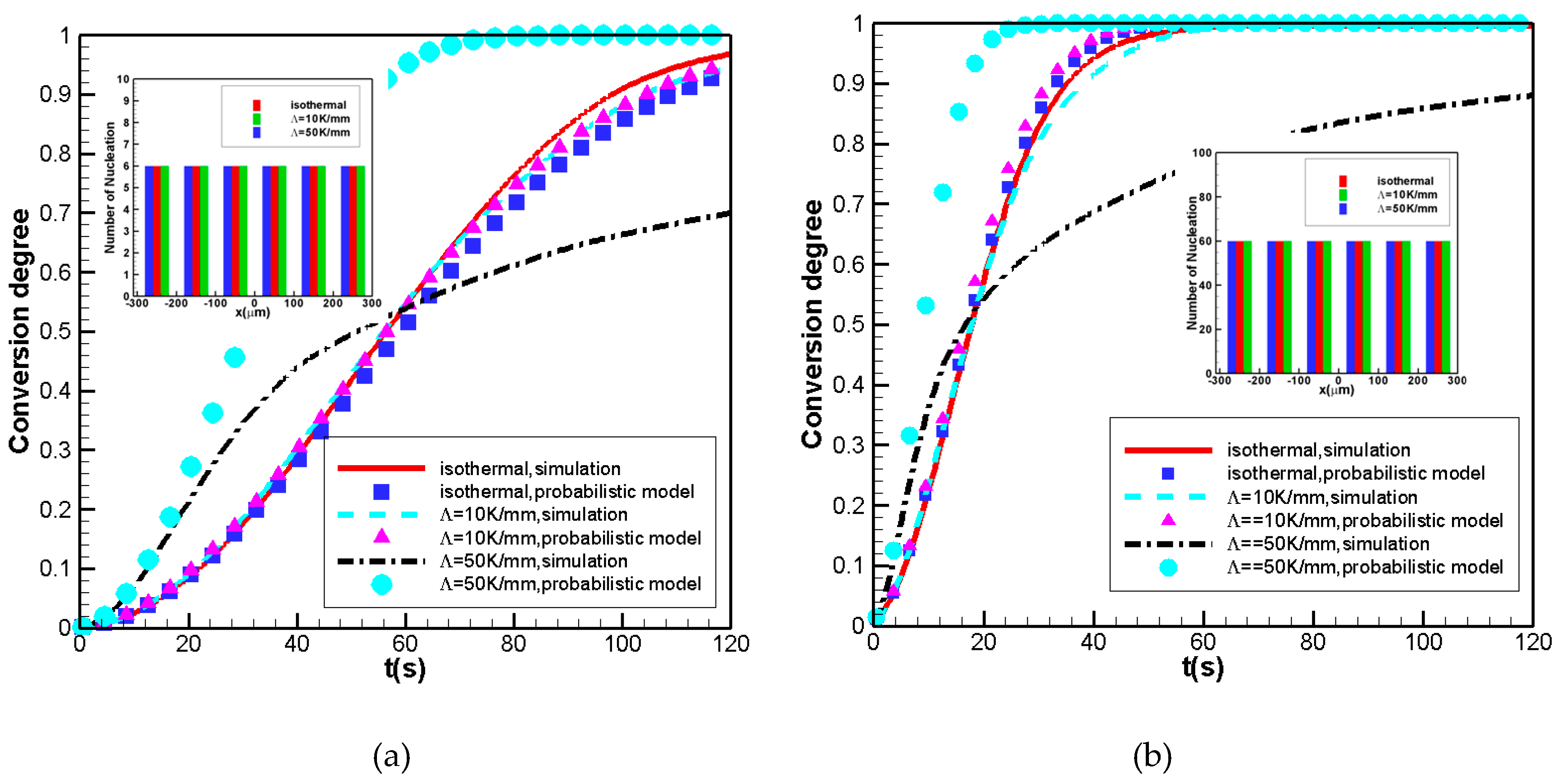

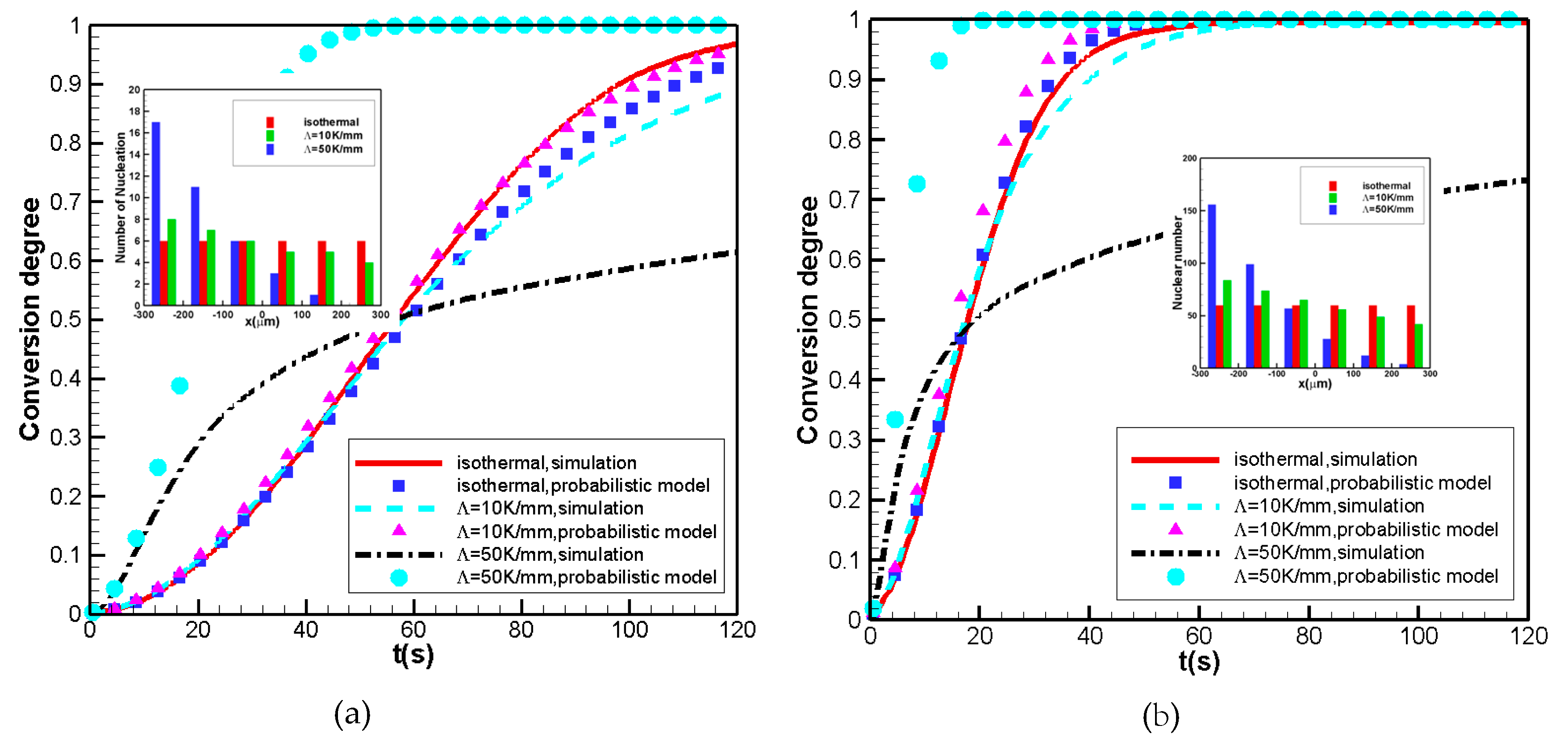

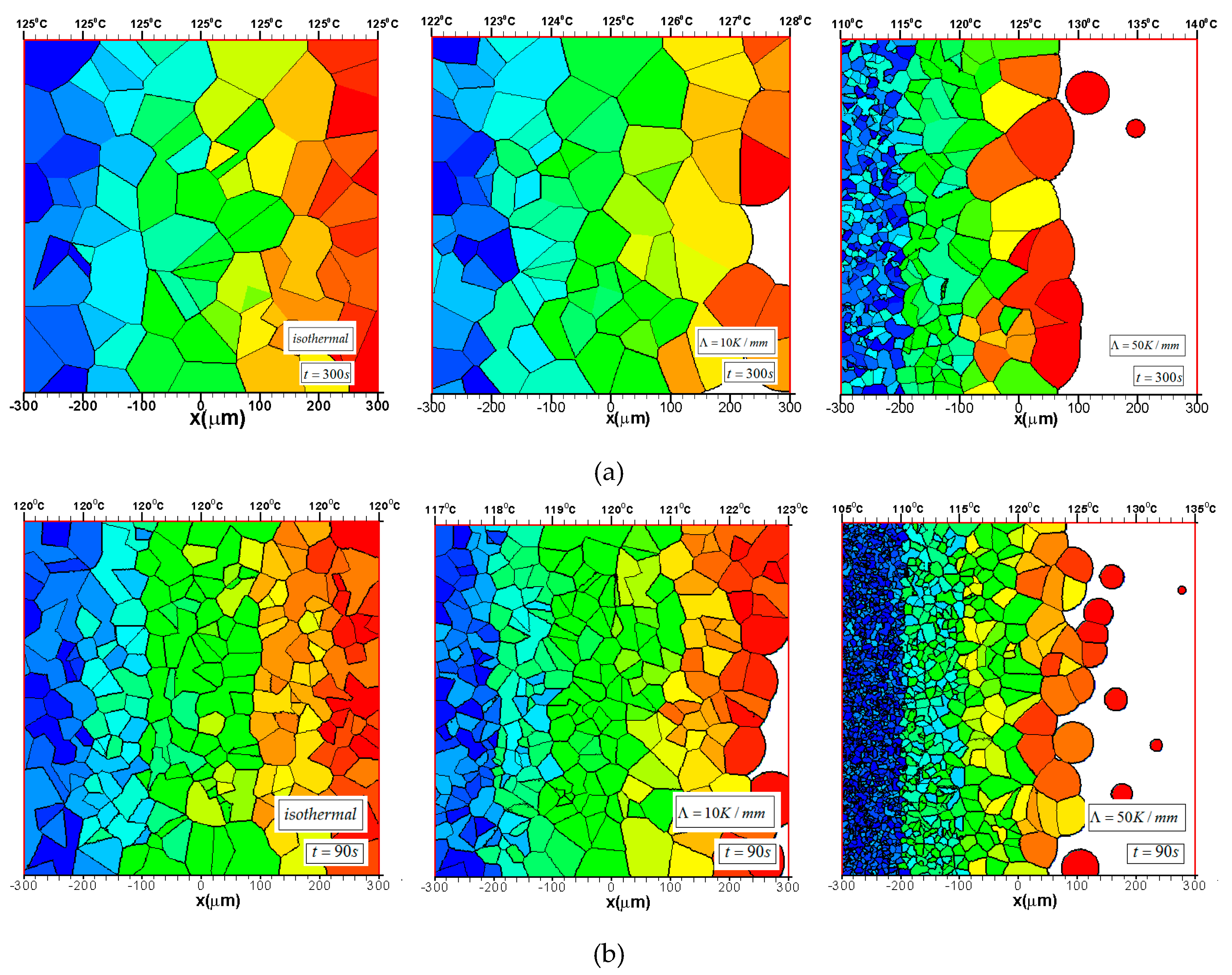

3.1. Performance of Probabilistic Model When Used Directly

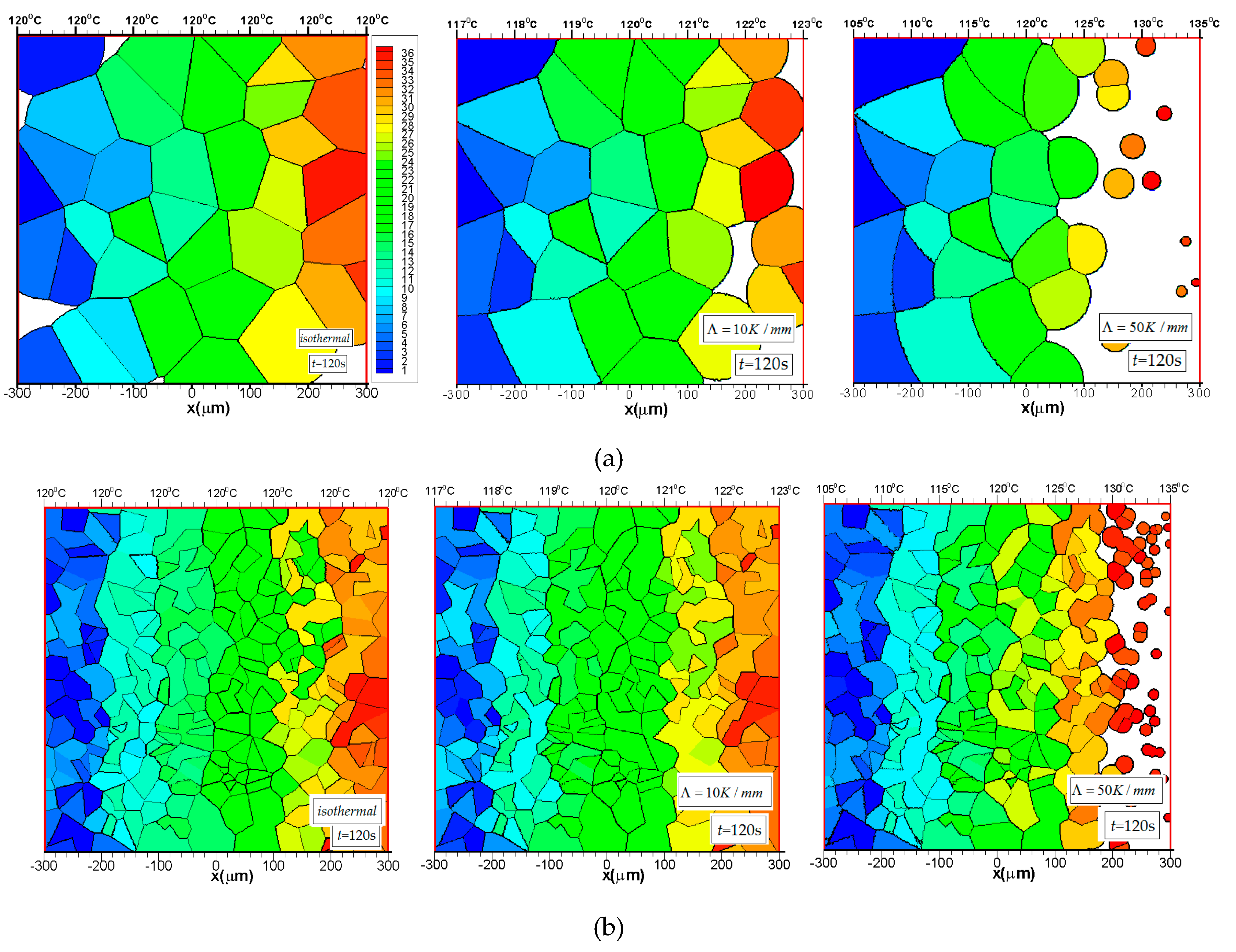

3.1.1. Nucleation Density Obeys Uniform Distribution

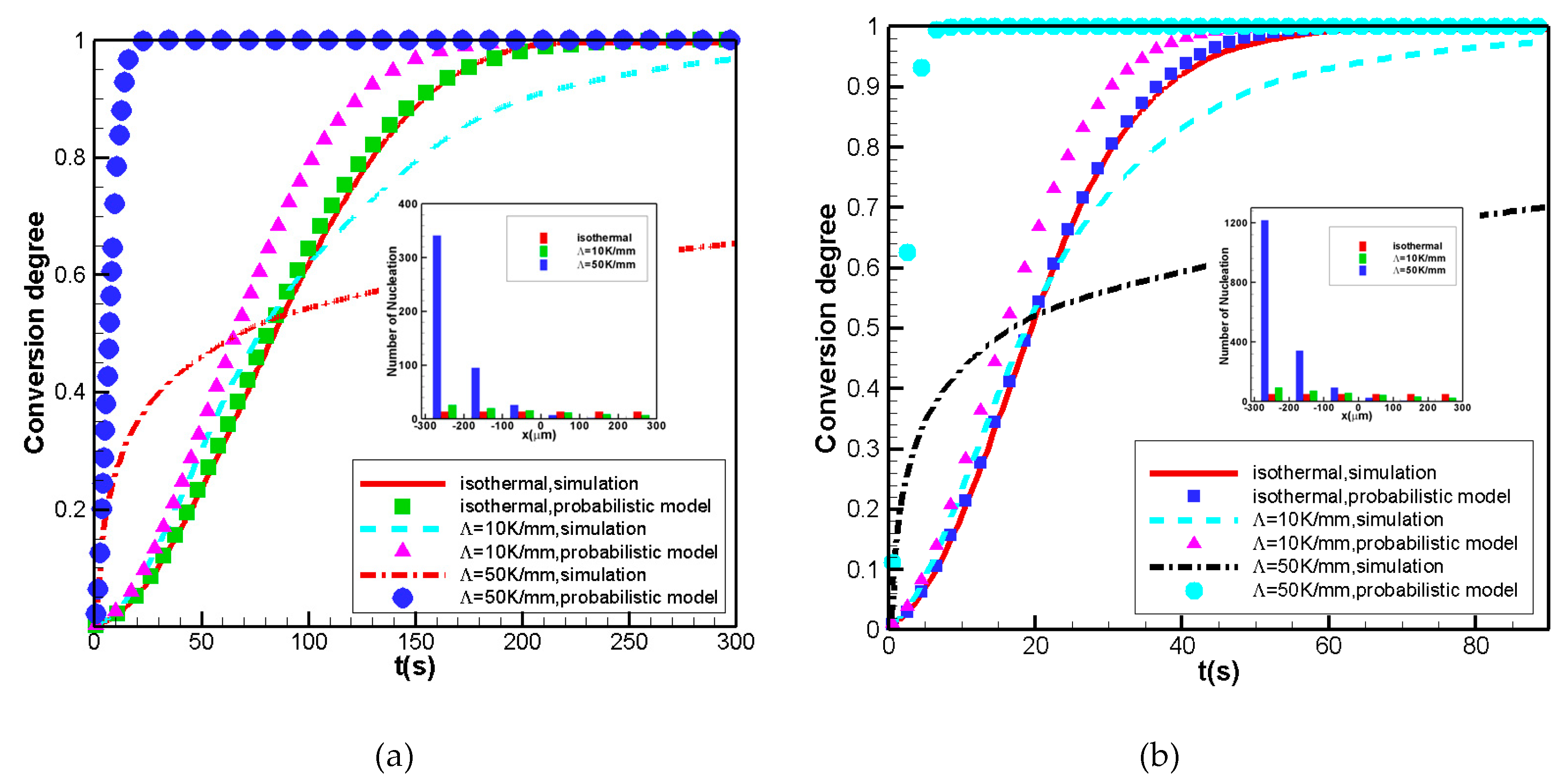

3.1.2. Nucleation Density Obeys a Linear Relationship with the Normal Growth Rate

3.1.3. Nucleation Density Obeys an Exponential Relationship between Temperatures

3.2. Discussion and Solution

3.2.1. Discussion

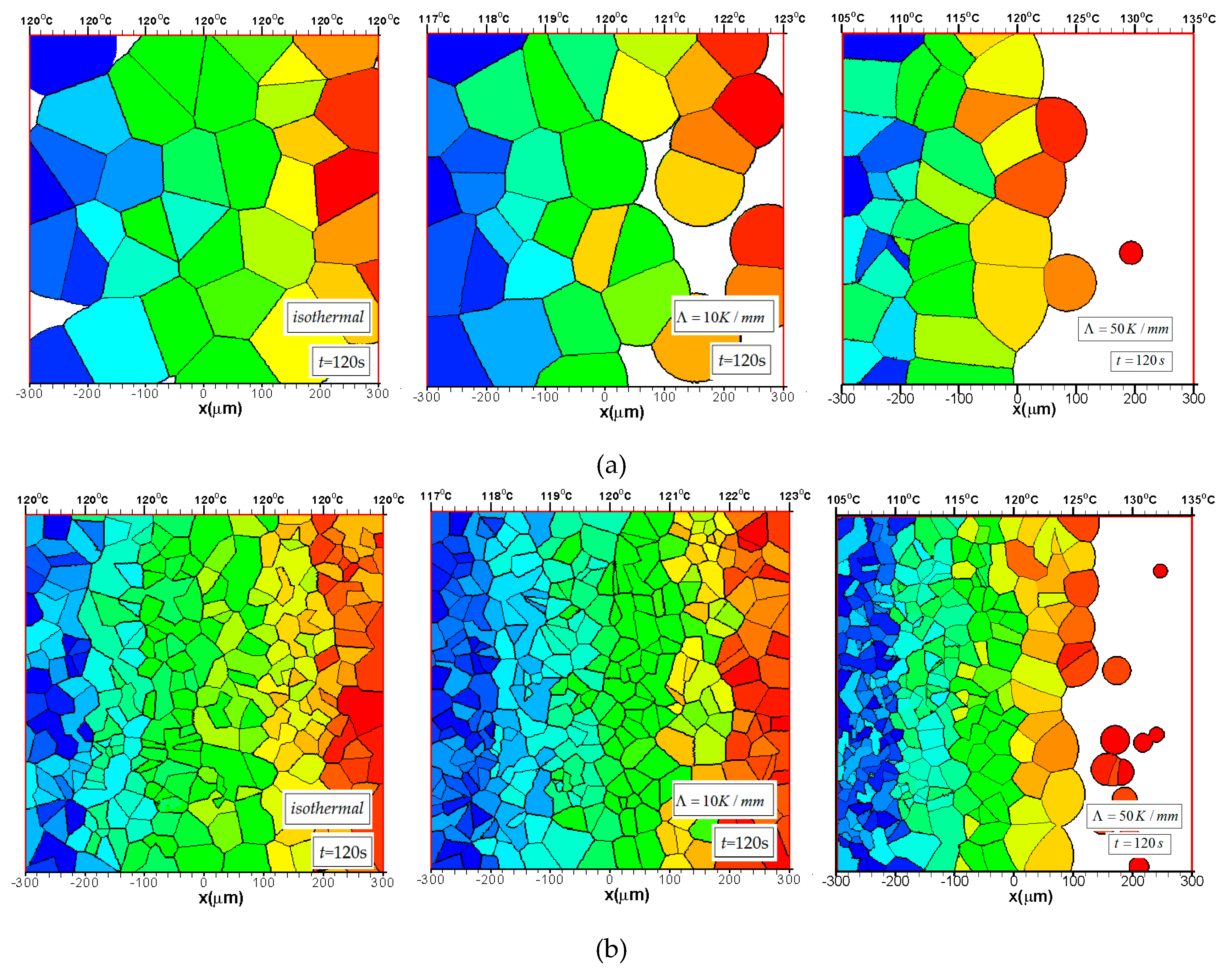

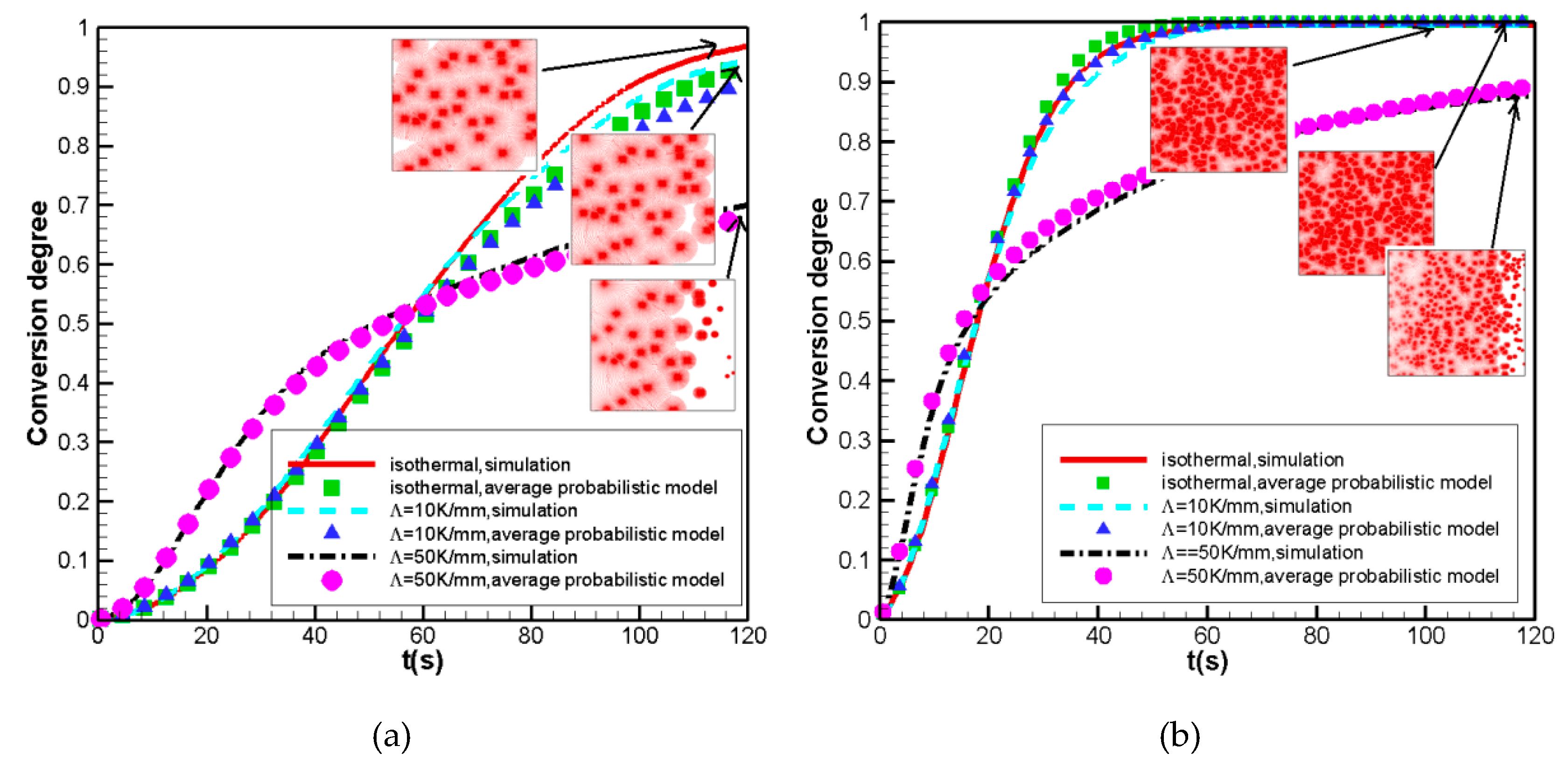

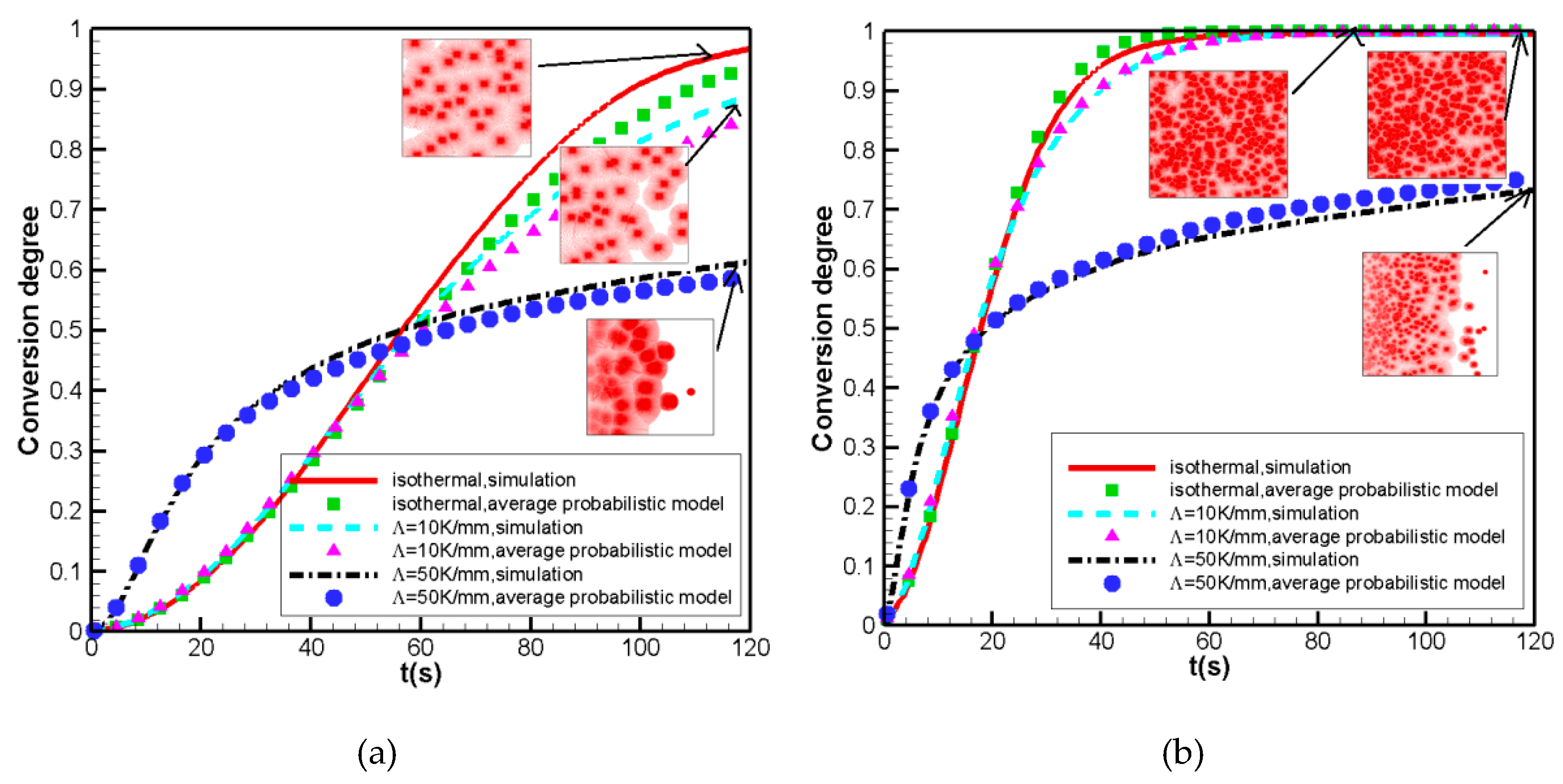

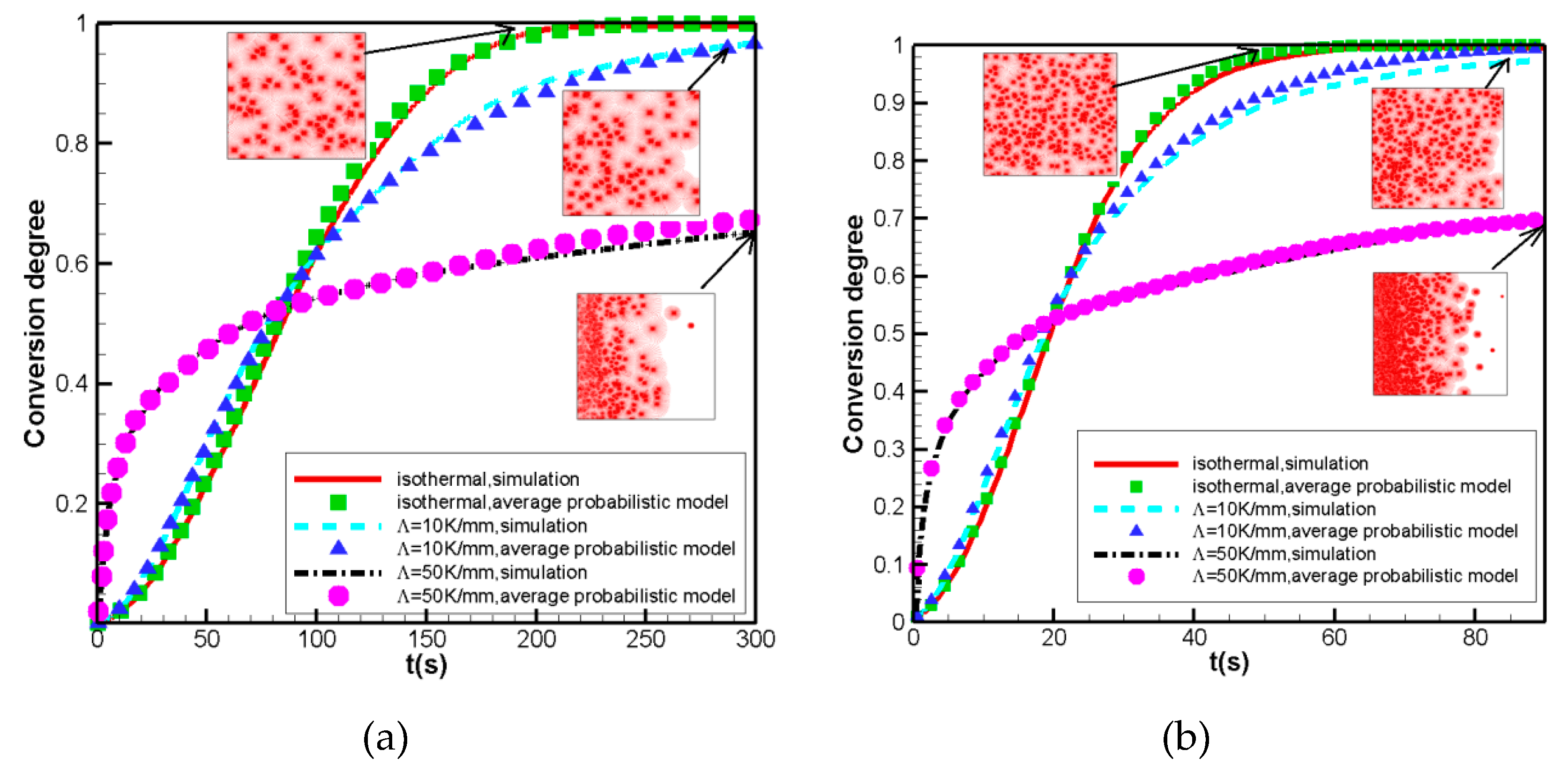

3.2.2. Performance of the Average Probabilistic Model

Nucleation Density Obeys Uniform Distribution

Nucleation Density Obeys a Linear Relationship with the Normal Growth Rate

Nucleation Density Obeys an Exponential Relationship between Temperatures

3.2.3. Effects of Division Number m on the Conversion Degree When Using the Average Probabilistic Model

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kennedy, P.; Zheng, R. Flow Analysis of Injection Molds, 2nd ed.; Hanser: Munich, Germany, 2013. [Google Scholar]

- Pantanin, R.; Coccorullo, I.; Speranza, V. Modeling of morphology evolution in the injection molding process of thermoplastic polymers. Prog. Polym. Sci. 2005, 30, 1185–1222. [Google Scholar] [CrossRef]

- Liu, Z.; Ouyang, J.; Ruan, C.; Liu, Q. Simulation of polymer crystallization under isothermal and temperature gradient condtions using praticle level set method. Crystals 2016, 6, 90. [Google Scholar] [CrossRef]

- Piorkowska, E.; Galeski, A. Overall crystallization kinetics. In Handbook of Polymer Crystallization; Piorkowska, E., Rutledge, G.C., Eds.; Jonn Wiley & Sons Inc.: Hoboken, NJ, USA, 2013; pp. 215–234. [Google Scholar]

- Piorkowska, E. Modeling of polymer crystallization in temperature gradient. J. Appl. Polym. Sci. 2002, 86, 1351–1362. [Google Scholar] [CrossRef]

- Avrami, M. Kinetics of phase change. I. General theory. J. Chem. Phys. 1939, 7, 1103–1112. [Google Scholar]

- Pawlak, A.; Piorkowska, E. Crystallization of isotactic polypropylene in a temperature gradient. Colloid. Polym. Sci. 2001, 279, 939–946. [Google Scholar] [CrossRef]

- Ruan, C. Morphological monte carlo simulation for crystallzation of isotactic polypropylene in a temperature gradient. Crystals 2019, 9, 213. [Google Scholar] [CrossRef]

- Liu, P.; Hu, A.; Wang, S.; Shi, M.; Ye, G.; Xu, J. Evaluation of nonisothermal crystallization kinetics models for linear poly(phenylene sulfide). J. Appl. Polym. Sci. 2011, 121, 14–20. [Google Scholar] [CrossRef]

- Yang, J.; McCoy, B.; Madras, G. Distribution kinetics of polymer crystallization and the Avrami equation. J. Chem. Phys. 2005, 122, 064901. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Wu, W.; Lu, G.; Zou, J. Isothermal and non-isothermal crystallization kinetics and predictive modeling in the solidification of poly(cyclohexylene dimethylene cyclohexanedicarboxylate) melt. J. Elast. Plast. 2016, 49, 132–156. [Google Scholar] [CrossRef]

- Goff, R.; Poutot, G.; Delaunay, D.; Fulchiron, R.; Koscher, E. Study and modeling of heat transfer during the solidification of semi-crystalline polymers. Int. J. Heat Mass Transf. 2005, 48, 5417–5430. [Google Scholar] [CrossRef]

- Yan, D.; Jiang, H.; Li, H. FEM simulation of nonisothermal crystallization, 1 crystallinity distribution on 2D space. Macromol. Theory Simul. 2000, 9, 166–175. [Google Scholar] [CrossRef]

- Zhou, Y.; Turng, L.; Shen, C. Modeling and prediction of morphology and crystallinity for cylindrical-shaped crystals during polymer processing. Polym. Eng. Sci. 2010, 50, 1226–1235. [Google Scholar] [CrossRef]

- Lamberti, G.; Santis, F. Heat transfer and crystallization kinetics during fast cooling o of thin polymer films. Heat Mass Transf. 2007, 43, 1143–1150. [Google Scholar] [CrossRef]

- Hoffman, J.; Miller, R. Kinetics of crystallization from the melt and chain folding in polyethylene fractions revisited: Theory and experiment. Polymer 1997, 38, 3151–3212. [Google Scholar] [CrossRef]

- Swaminarayan, S.; Charbon, C. A multiscale model for polymer crystallization. I. Growth of individual spherulites. Polym. Eng. Sci. 1998, 38, 634–643. [Google Scholar]

- Thananchai, L. Mathematical modeling of solidification of semi-crystallization polymers under quiescent non-isothermal crystallization: Determination of crystallite’s size. Sci. Asia. 2001, 27, 127–132. [Google Scholar]

- Ruan, C. Kinetics and morphology of flow indueced polymer crystallization in 3D shear flow investigated by Monte Carlo simulation. Crystals 2017, 7, 51. [Google Scholar] [CrossRef]

- Ruan, C.; Liu, C.; Zheng, G. Monte Carlo simulation for the morphology and kinetics of spherulites and shish-kebabs in isothermal polymer crystallization. Math. Prob. Eng. 2015, 50624, 1–10. [Google Scholar] [CrossRef]

| Λ\m | ||||

|---|---|---|---|---|

| 8.17749 × 10−2 | 3.41766 × 10−2 | 2.34258 × 10−2 | 1.72930 × 10−2 | |

| 1.99437 × 10−1 | 6.19496 × 10−2 | 2.60574 × 10−2 | 5.49196 × 10−3 | |

| 2.94745 × 10−1 | 6.96178 × 10−2 | 1.84072 × 10−2 | 8.83252 × 10−3 | |

| 3.61451 × 10−1 | 9.02186 × 10−2 | 3.16783 × 10−2 | 3.04310 × 10−3 | |

| 3.99903 × 10−1 | 7.89859 × 10−2 | 4.75056 × 10−2 | 5.82306 × 10−3 |

| Λ\T0 | °C | °C | °C | °C |

|---|---|---|---|---|

| 7.24991 × 10−3 | 1.72930 × 10−2 | 6.03332 × 10−3 | 2.89613 × 10−3 | |

| 1.21956 × 10−2 | 5.49196 × 10−3 | 6.49543 × 10−3 | 2.42921 × 10−3 | |

| 1.05234 × 10−2 | 8.83252 × 10−3 | 7.60522 × 10−3 | 4.33847 × 10−3 | |

| 6.36686 × 10−3 | 3.04310 × 10−3 | 9.75746 × 10−3 | 8.50667 × 10−3 | |

| 9.21316 × 10−3 | 5.82306 × 10−3 | 9.06534 × 10−3 | 3.86348 × 10−3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruan, C.; Lv, Y. A Note for Probabilistic Model of Polymer Crystallization in Temperature Gradients. Crystals 2019, 9, 538. https://doi.org/10.3390/cryst9100538

Ruan C, Lv Y. A Note for Probabilistic Model of Polymer Crystallization in Temperature Gradients. Crystals. 2019; 9(10):538. https://doi.org/10.3390/cryst9100538

Chicago/Turabian StyleRuan, Chunlei, and Yunlong Lv. 2019. "A Note for Probabilistic Model of Polymer Crystallization in Temperature Gradients" Crystals 9, no. 10: 538. https://doi.org/10.3390/cryst9100538

APA StyleRuan, C., & Lv, Y. (2019). A Note for Probabilistic Model of Polymer Crystallization in Temperature Gradients. Crystals, 9(10), 538. https://doi.org/10.3390/cryst9100538