Simultaneously Improve White LED Omni-Directional Package Efficacy and Spatial Color Uniformity on Scattered Photon Extraction Technology

Abstract

:1. Introduction

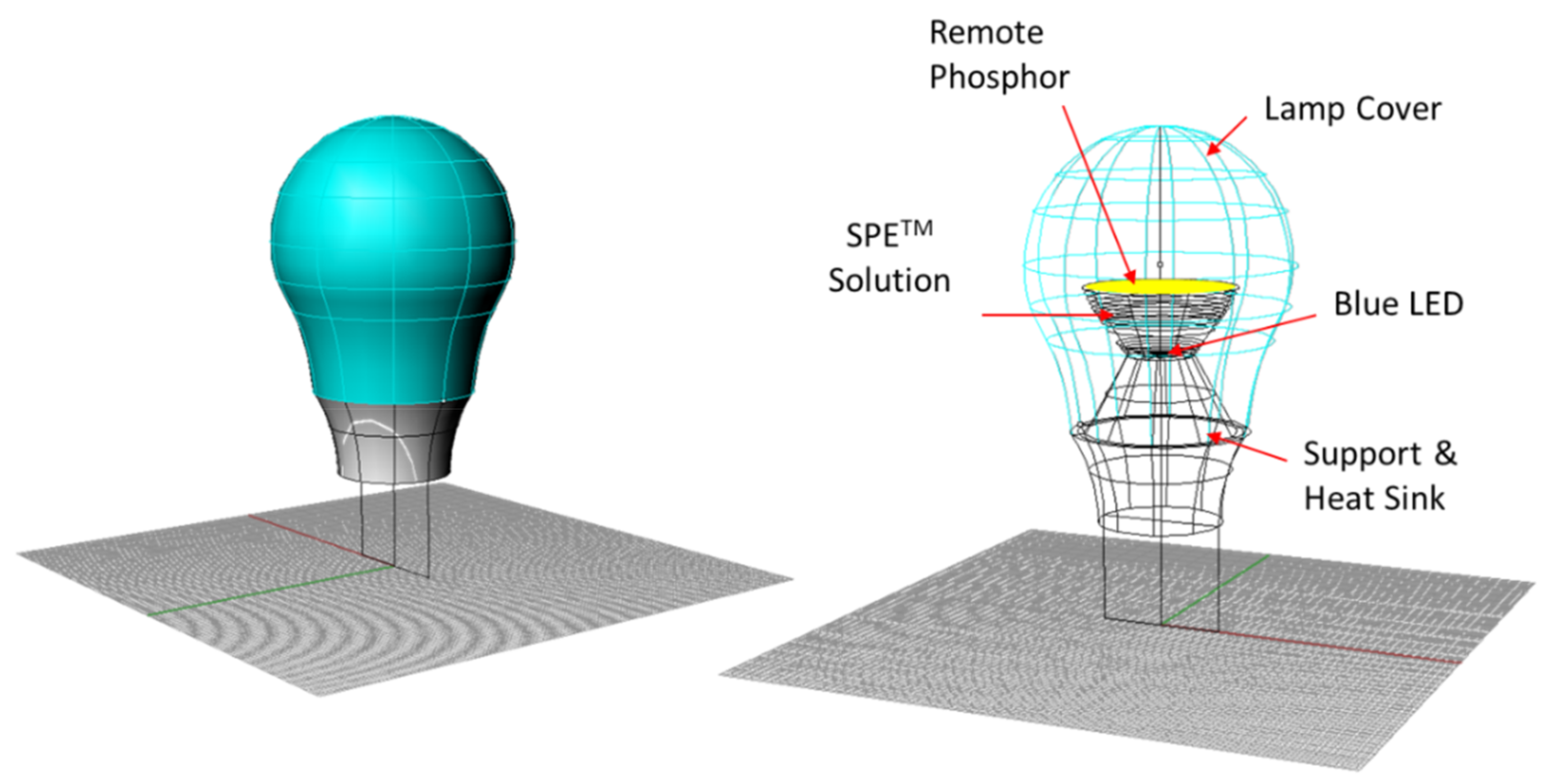

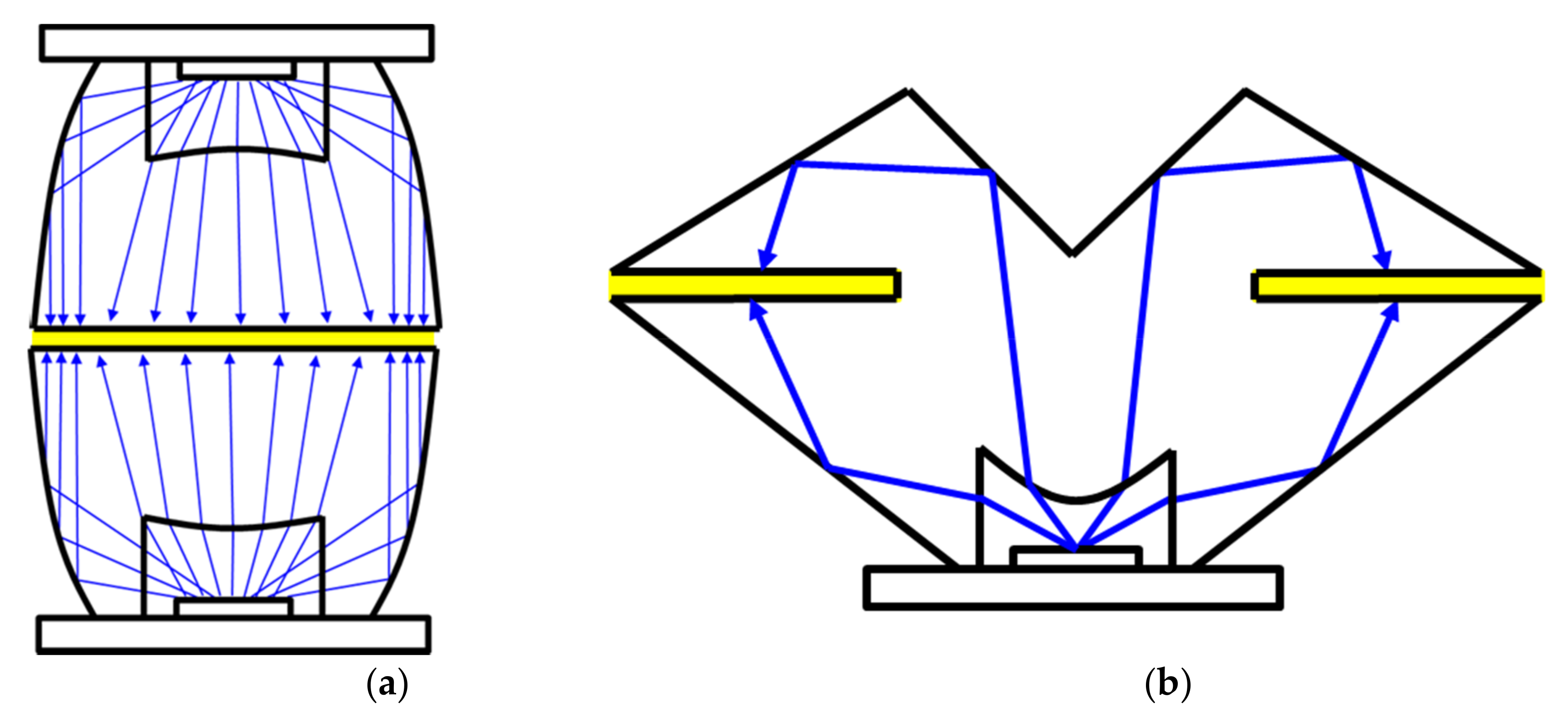

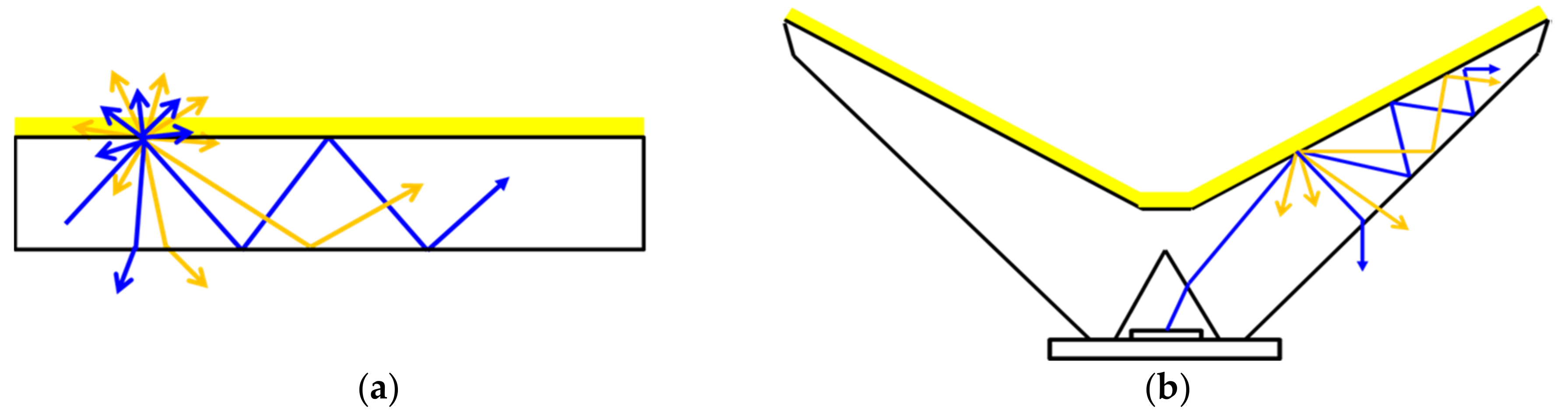

2. Omnidirectional ACCTD of Existing SPE™ Solution

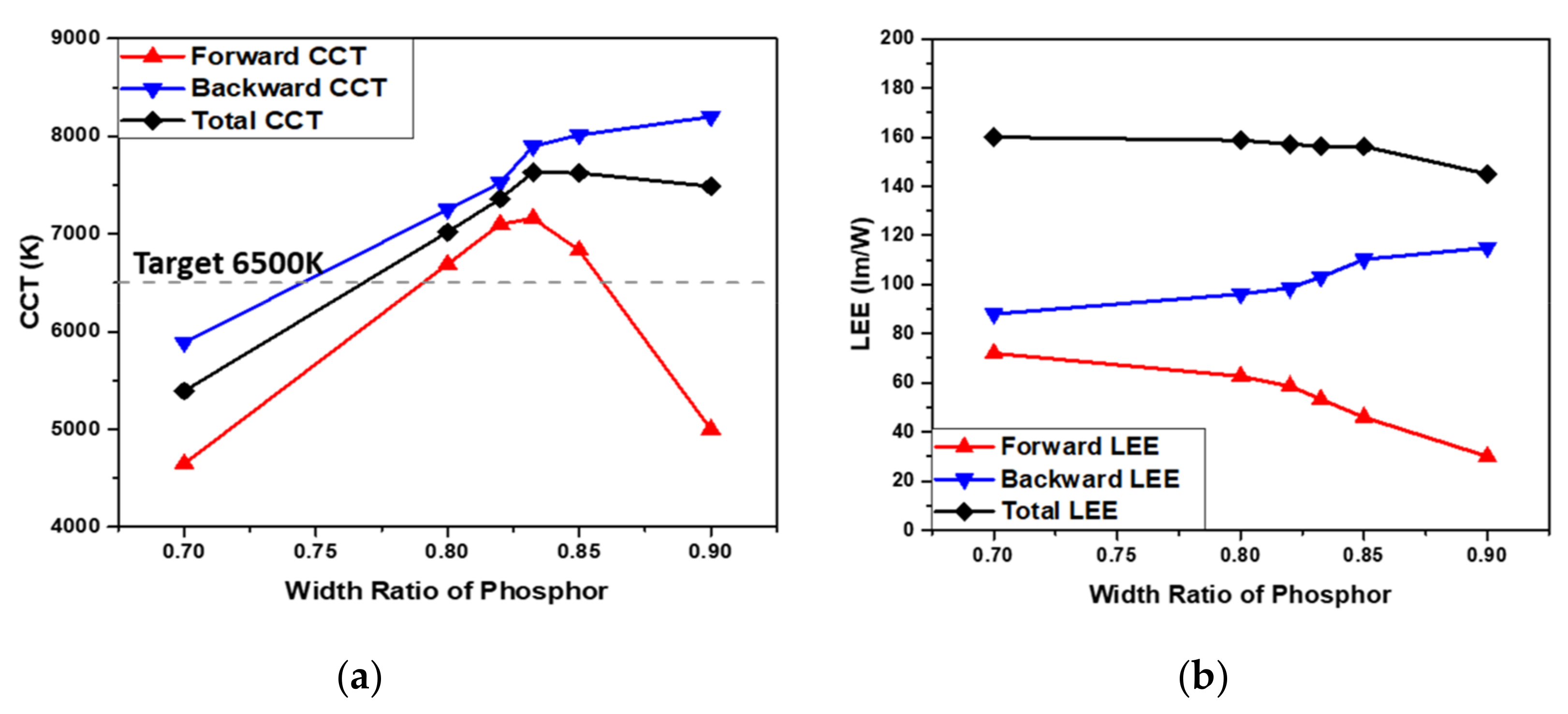

2.1. Optical Model and Simulation

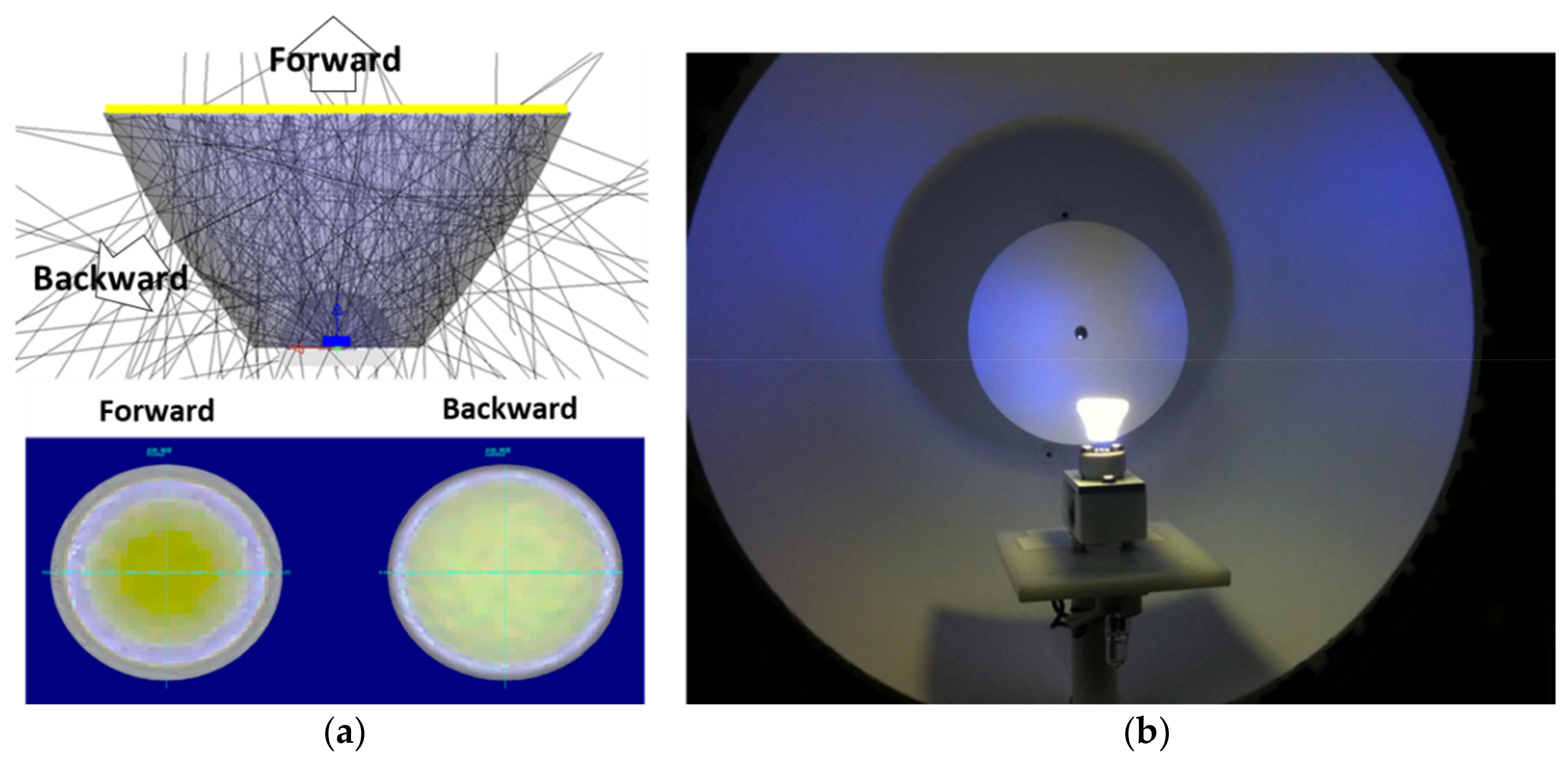

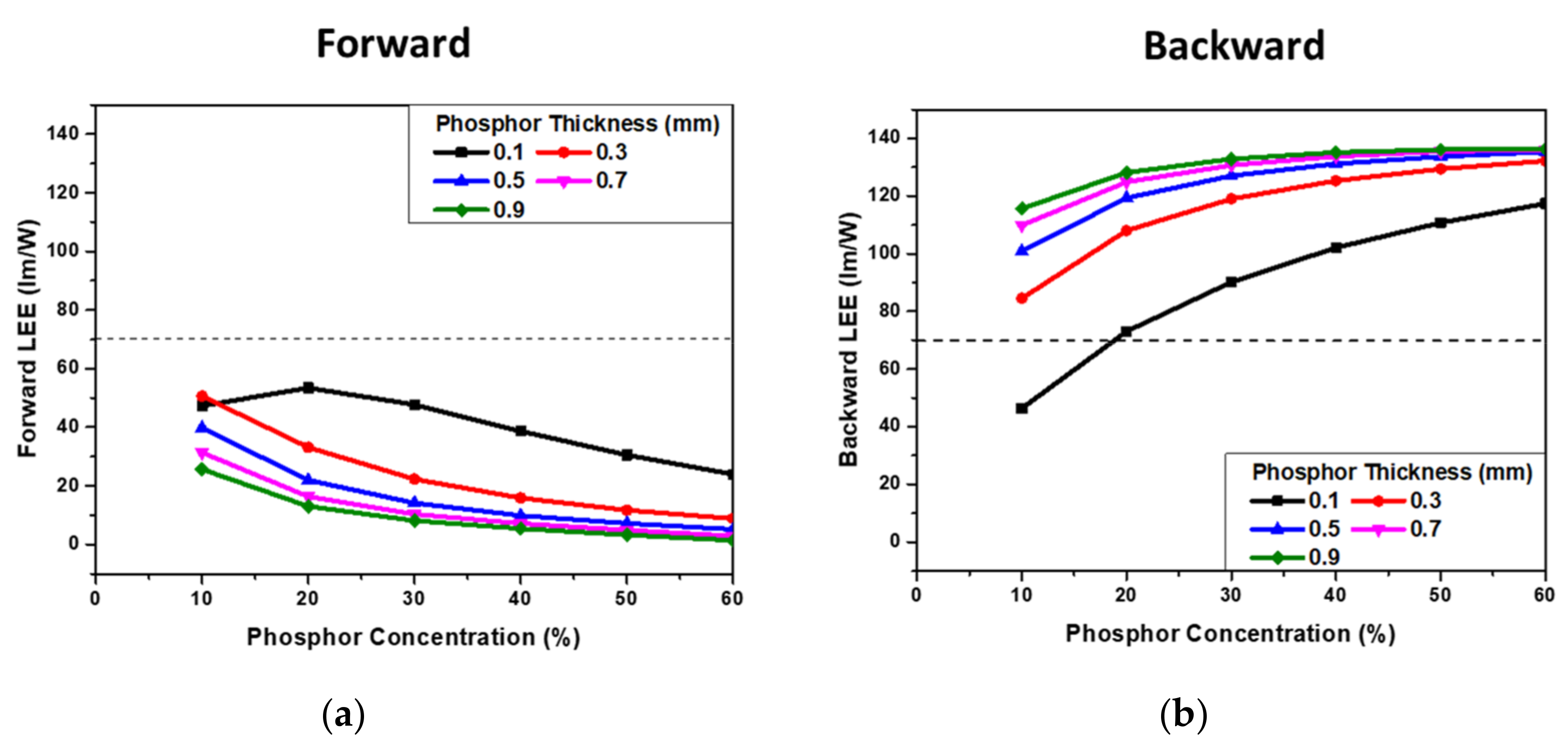

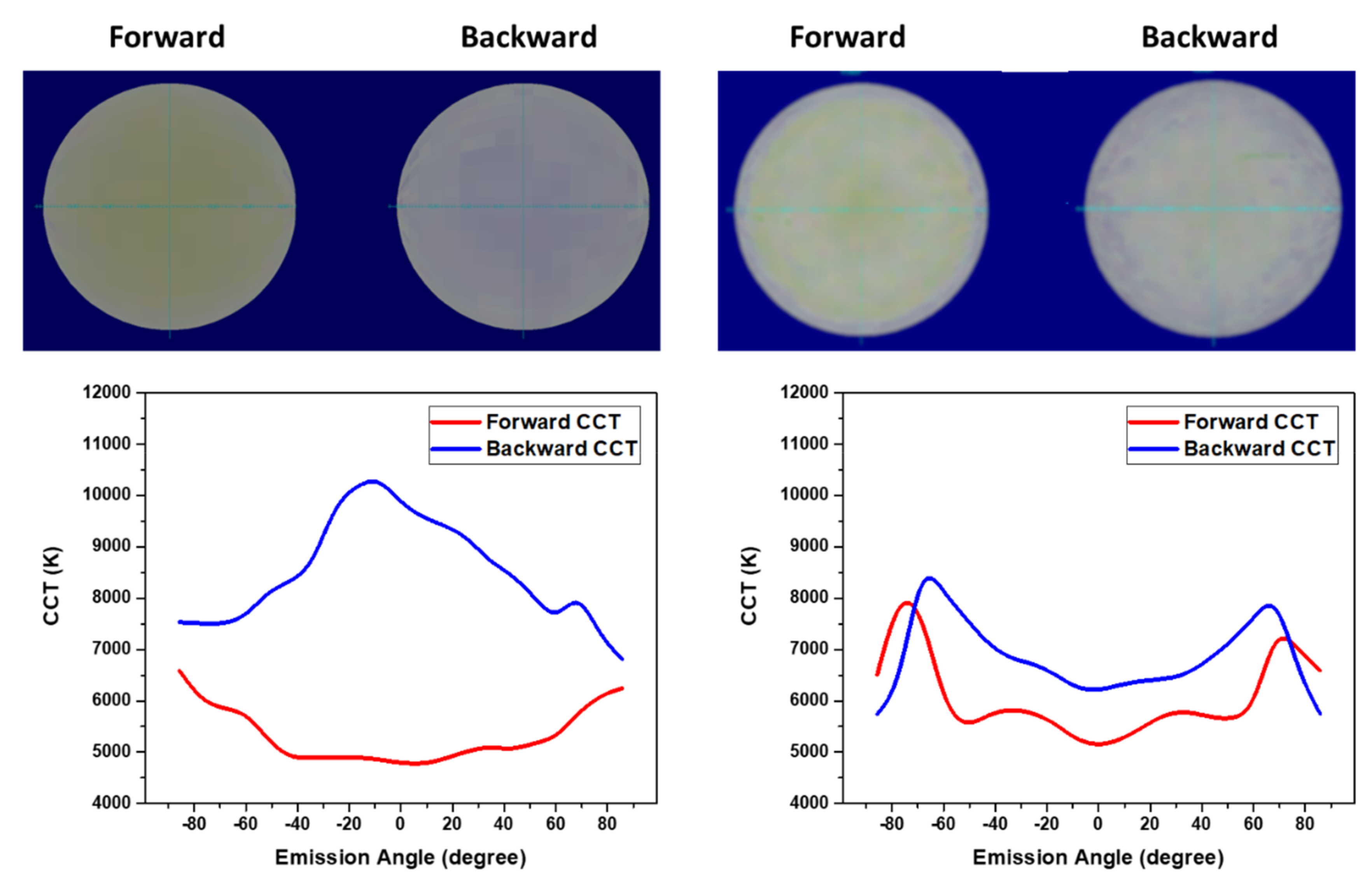

2.2. Simulation Results

3. Design Strategy for SPE™ Technology

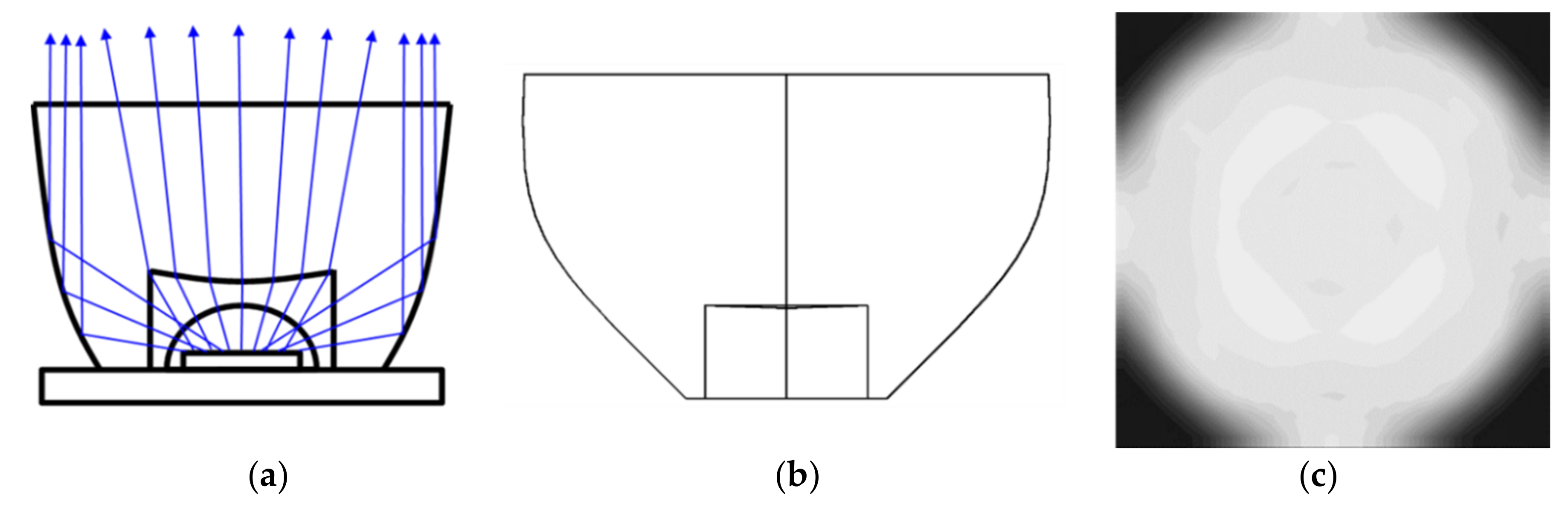

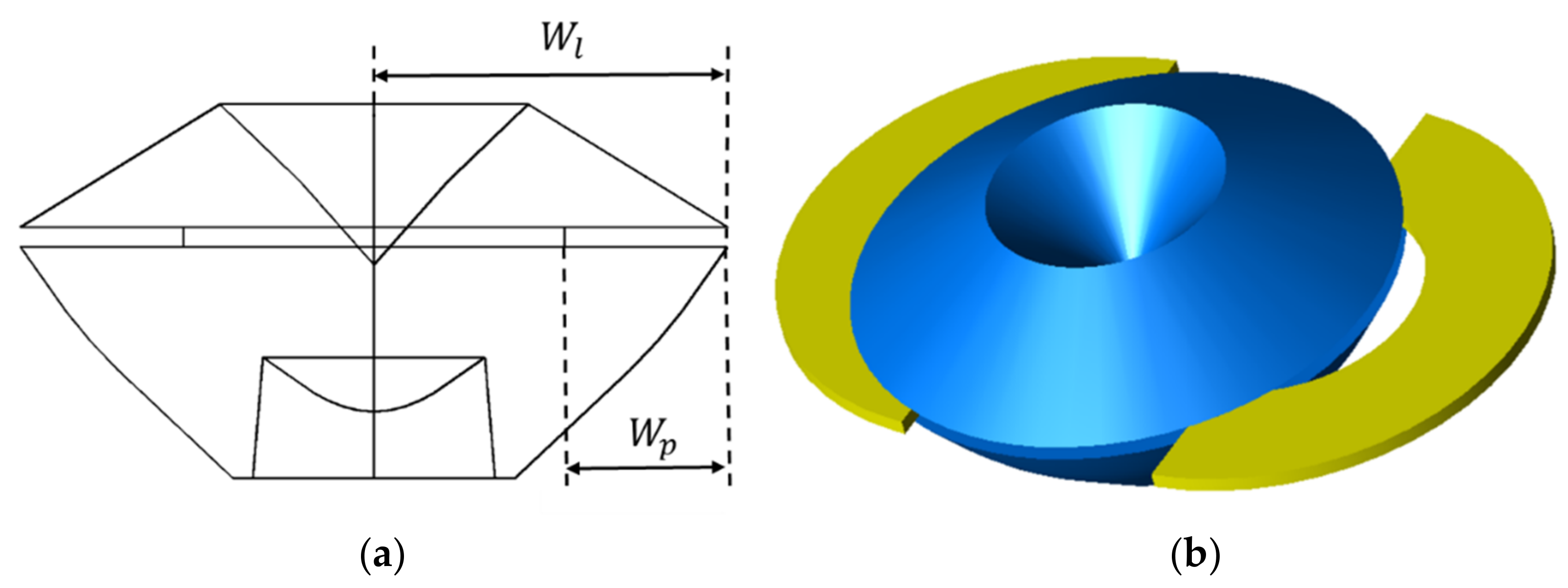

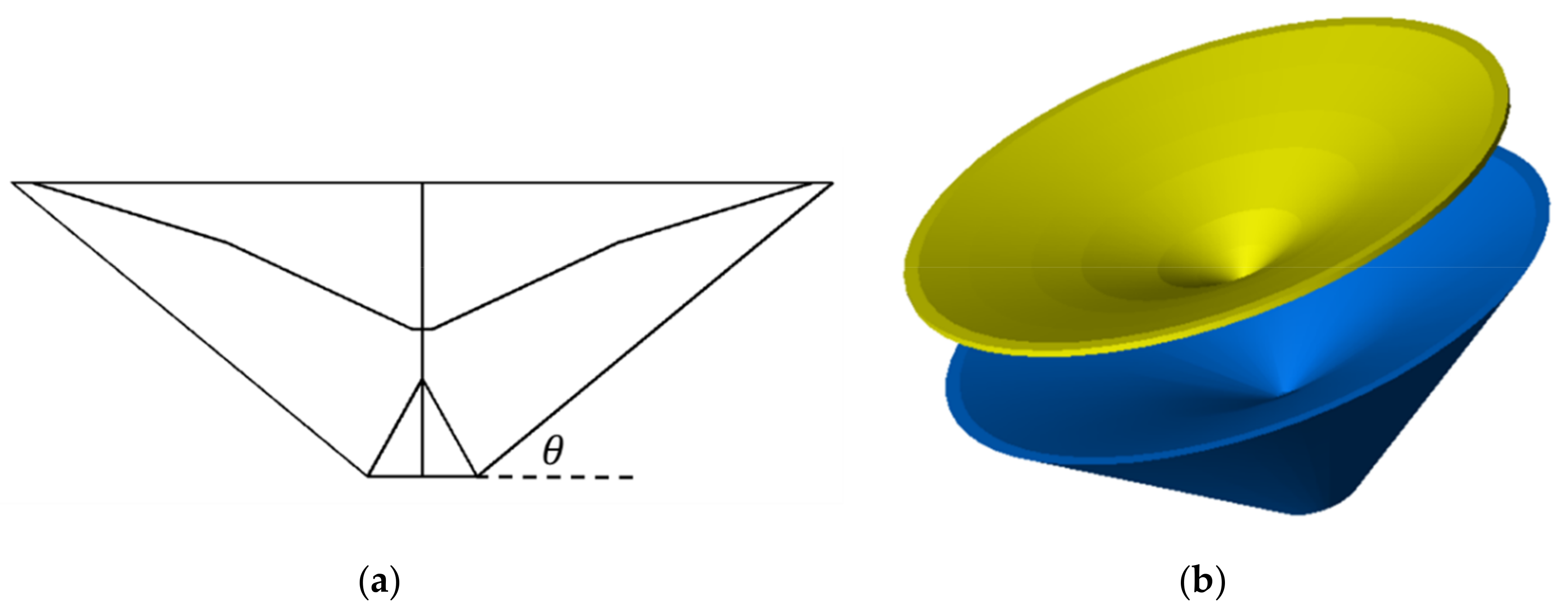

3.1. Two-Way Structure Lens Design

3.2. Light-Guide Structure Lens Design

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Narendran, N. Improved performance white LED. Proc. SPIE 2015, 5941, 594108. [Google Scholar]

- Chen, H. LED Structure with Ultraviolet-Light Emission Chip and Multilayered Resins to Generate Various Colored Lights. U.S. Patent 5,962,971, 5 October 1999. [Google Scholar]

- -Narendran, N.; Gu, Y.; Freyssinier, J.P.; Zhu, Y. Extracting phosphor-scattered photons to improve white LED efficiency. Phys. Stat. Sol. 2005, 202, R60–R62. [Google Scholar] [CrossRef]

- Zhu, Y.; Narendran, N. Optimizing the performance of remote phosphor LEDs. J. Light Vis. Environ. 2008, 32, 115–119. [Google Scholar] [CrossRef]

- Zhu, Y.; Narendran, N. Investigation of remote-phosphor white light-emitting diodes with multi-phosphor layers. J. Appl. Phys. 2010, 49, 100203. [Google Scholar] [CrossRef]

- Li, B.; Zhang, D.; Huang, Y.; Ni, Z.; Zhuang, S. A new structure of multi-layer phosphor package of white LED with high efficiency. Chin. Opt. Lett. 2010, 8, 221–223. [Google Scholar]

- Liu, Z.; Liu, S.; Wang, K.; Luo, X. Measurement and numerical studies of optical properties of YAG: Ce phosphor for white light-emitting diode packaging. Appl. Opt. 2010, 49, 247–257. [Google Scholar] [CrossRef] [PubMed]

- Shuai, Y.; He, Y.; Tran, N.T.; Shi, F.G. Angular CCT uniformity of phosphor converted white LEDs: Effects of phosphor materials and packaging structures. IEEE Photonics Technol. Lett. 2011, 23, 137–139. [Google Scholar] [CrossRef]

- Wang, K.; Wu, D.; Chen, F.; Liu, Z.; Luo, X.; Liu, S. Angular color uniformity enhancement of white light-emitting diodes integrated with freeform lenses. Opt. Lett. 2010, 35, 1860–1862. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Liu, S.; Wang, K.; Luo, X. Analysis of factors affecting color distribution of white LEDs. In Proceedings of the 2008 International Conference on Electronic Packaging Technology & High Density Packaging, Shanghai, China, 28–31 July 2008; pp. 1–8. [Google Scholar]

- Li, S.; Chen, F.; Wang, K.; Zhao, S.; Zhao, Z.; Liu, S. Design of a compact modified total internal reflection lens for high angular color uniformity. Appl. Opt. 2012, 51, 8557–8562. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.Y.; Li, C.; Yu, B.H.; Wang, Y.H.; Niu, H.B. Effects of YAG: Ce phosphor particle size on luminous flux and angular color uniformity of phosphor-converted white LEDs. J. Disp. Technol. 2012, 8, 329–335. [Google Scholar] [CrossRef]

- Sun, C.C.; Chen, C.Y.; Chen, C.C.; Chiu, C.Y.; Peng, Y.N.; Wang, Y.H.; Yang, T.H.; Chung, C.Y. High uniformity in angular correlated-color-temperature distribution of white LEDs from 2800 K to 6500 K. Opt. Express 2012, 20, 6622–6630. [Google Scholar] [CrossRef] [PubMed]

- Keppens, A.; Denijs, S.; Wouters, S.; Ryckaert, W.R.; Deconinck, G.; Hanselaer, P. Modelling the spatial colour distribution of phosphor-white high power light-emitting diodes. Proc. SPIE 2010, 7717, 77170J. [Google Scholar]

- Sommer, C.; Krenn, J.R.; Hartmann, P.; Pachler, P.; Schweighart, M.; Tasch, S.; Wenzl, F.P. The effect of the phosphor particle sizes on the angular homogeneity of phosphor-converted high-power white LED light sources. IEEE J. Sel. Top. Quant. 2009, 15, 1181–1188. [Google Scholar] [CrossRef]

- Sommer, C.; Reil, F.; Krenn, J.R.; Hartmann, P.; Pachler, P.; Tasch, S.; Wenzl, F.P. The impact of inhomogeneities in the phosphor distribution on the device performance of phosphor-converted high-power white LED light sources. J. Light. Technol. 2010, 28, 3226–3232. [Google Scholar] [CrossRef]

- Kan, D.; Wu, E.; Wang, D. Design optimization and experimental verification of white-light-emitting diodes using multiple phosphor films. Proc. SPIE 2006, 6669, 63370. [Google Scholar]

- Yu, R.; Jin, S.; Cen, S.; Liang, P. Effect of the phosphor geometry on the luminous flux of phosphor-converted light-emitting diodes. IEEE Photonics Technol. Lett. 2010, 22, 1765–1767. [Google Scholar]

- Zhu, Y.; Narendran, N.; Gu, Y. Investigation of the optical properties of YAG: Ce phosphor. Proc. SPIE 2006, 6637, 63370S. [Google Scholar]

- Kuo, H.C.; Hung, C.W.; Chen, H.C.; Chen, K.J.; Wang, C.H.; Sher, C.W.; Yeh, C.C.; Lin, C.C.; Chen, C.H.; Cheng, Y.J. Patterned structure of remote phosphor for phosphor-converted white LEDs. Opt. Express 2011, 19, A930–A936. [Google Scholar] [CrossRef]

- Lin, M.T.; Ying, S.P.; Lin, M.Y.; Tai, K.Y.; Tai, S.C.; Liu, C.H.; Chen, J.C.; Sun, C.C. Ring remote phosphor structure for phosphor-converted white LEDs. IEEE Photonics Technol. Lett. 2010, 22, 574–576. [Google Scholar] [CrossRef]

- Allen, S.C.; Steckl, A.J. ELiXIR-solid-state luminaire with enhanced light extraction by internal reflection. J. Display Technol. 2007, 3, 155–159. [Google Scholar] [CrossRef]

- Allen, S.C.; Steckl, A.J. A nearly ideal phosphor-converted white light-emitting diode. Appl. Phys. Lett. 2008, 92, 143309. [Google Scholar] [CrossRef]

- Lee, T.X.; Chou, C.F. Ideal luminous efficacy and color spatial uniformity of package-free LED based on a packaging phosphor-coated geometry. Appl. Opt. 2016, 55, 7688–7693. [Google Scholar] [CrossRef] [PubMed]

| Traditional | Two-Way | Light-Guide | |

|---|---|---|---|

| Phosphor Thickness (mm) | 0.5 mm | 0.5 mm | 0.5 mm |

| Phosphor Concentration (%) | 30% | 30% | 4% |

| Forward CCT (K) | 3932 K | 6691 K | 6342 K |

| Backward CCT (K) | 7521 K | 7251 K | 6717 K |

| ΔCCT (K) | 3589 K | 560 K | 375 K |

| SDCCT (K) | 1954 K | 548 K | 190 K |

| Forward LEE (Lm/W) | 14.2 Lm/W | 62.7 Lm/W | 77.5 Lm/W |

| Backward LEE (Lm/W) | 127.0 Lm/W | 96.1 Lm/W | 80.9 Lm/W |

| ΔLEE (Lm/W) | 112.8 Lm/W | 33.4 Lm/W | 3.4 Lm/W |

| Total LEE (Lm/W) | 141.2 Lm/W | 158.7 Lm/W | 158.4 Lm/W |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, T.-X.; Huang, Y.-C. Simultaneously Improve White LED Omni-Directional Package Efficacy and Spatial Color Uniformity on Scattered Photon Extraction Technology. Crystals 2019, 9, 21. https://doi.org/10.3390/cryst9010021

Lee T-X, Huang Y-C. Simultaneously Improve White LED Omni-Directional Package Efficacy and Spatial Color Uniformity on Scattered Photon Extraction Technology. Crystals. 2019; 9(1):21. https://doi.org/10.3390/cryst9010021

Chicago/Turabian StyleLee, Tsung-Xian, and Yun-Chieh Huang. 2019. "Simultaneously Improve White LED Omni-Directional Package Efficacy and Spatial Color Uniformity on Scattered Photon Extraction Technology" Crystals 9, no. 1: 21. https://doi.org/10.3390/cryst9010021

APA StyleLee, T.-X., & Huang, Y.-C. (2019). Simultaneously Improve White LED Omni-Directional Package Efficacy and Spatial Color Uniformity on Scattered Photon Extraction Technology. Crystals, 9(1), 21. https://doi.org/10.3390/cryst9010021