Dielectric Temperature Stability and Enhanced Energy-Storage Performance of Sr0.4Ba0.6(Zr0.2Ti0.2Sn0.2Ta0.2Nb0.2)2O6 High-Entropy Ferroelectric Ceramics

Abstract

1. Introduction

2. Experimental Procedures

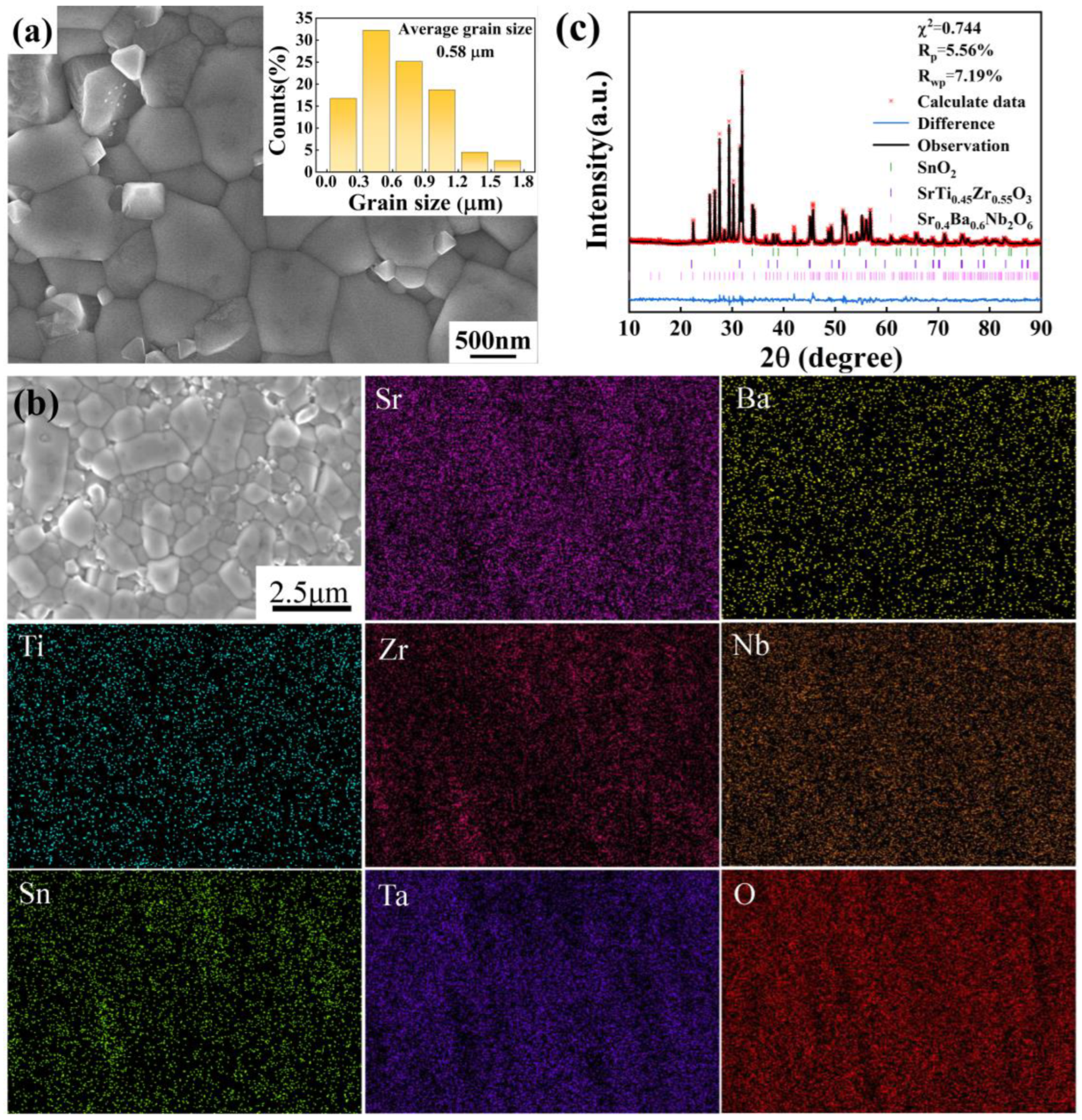

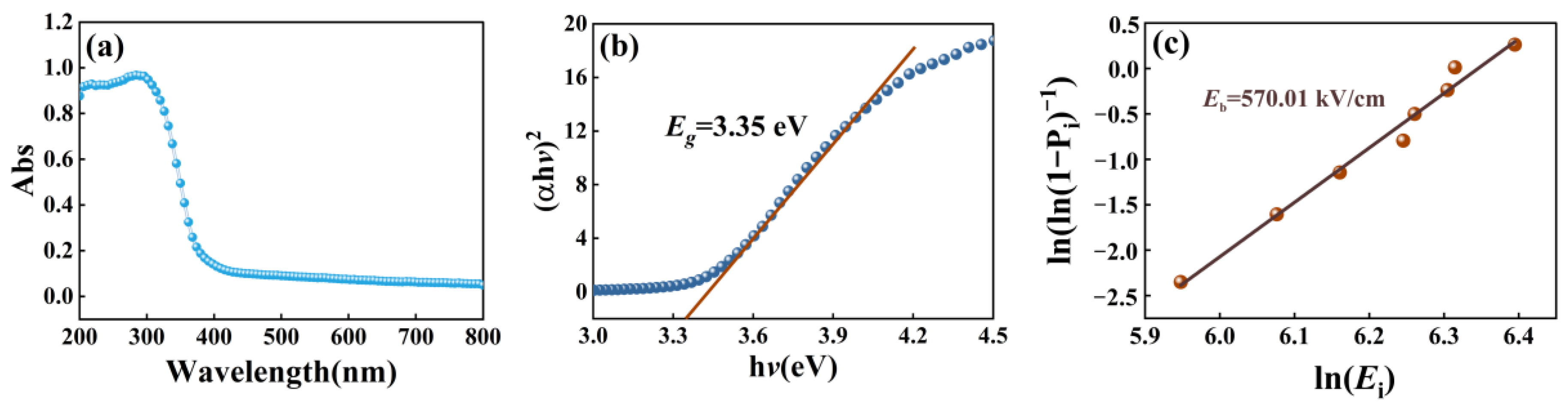

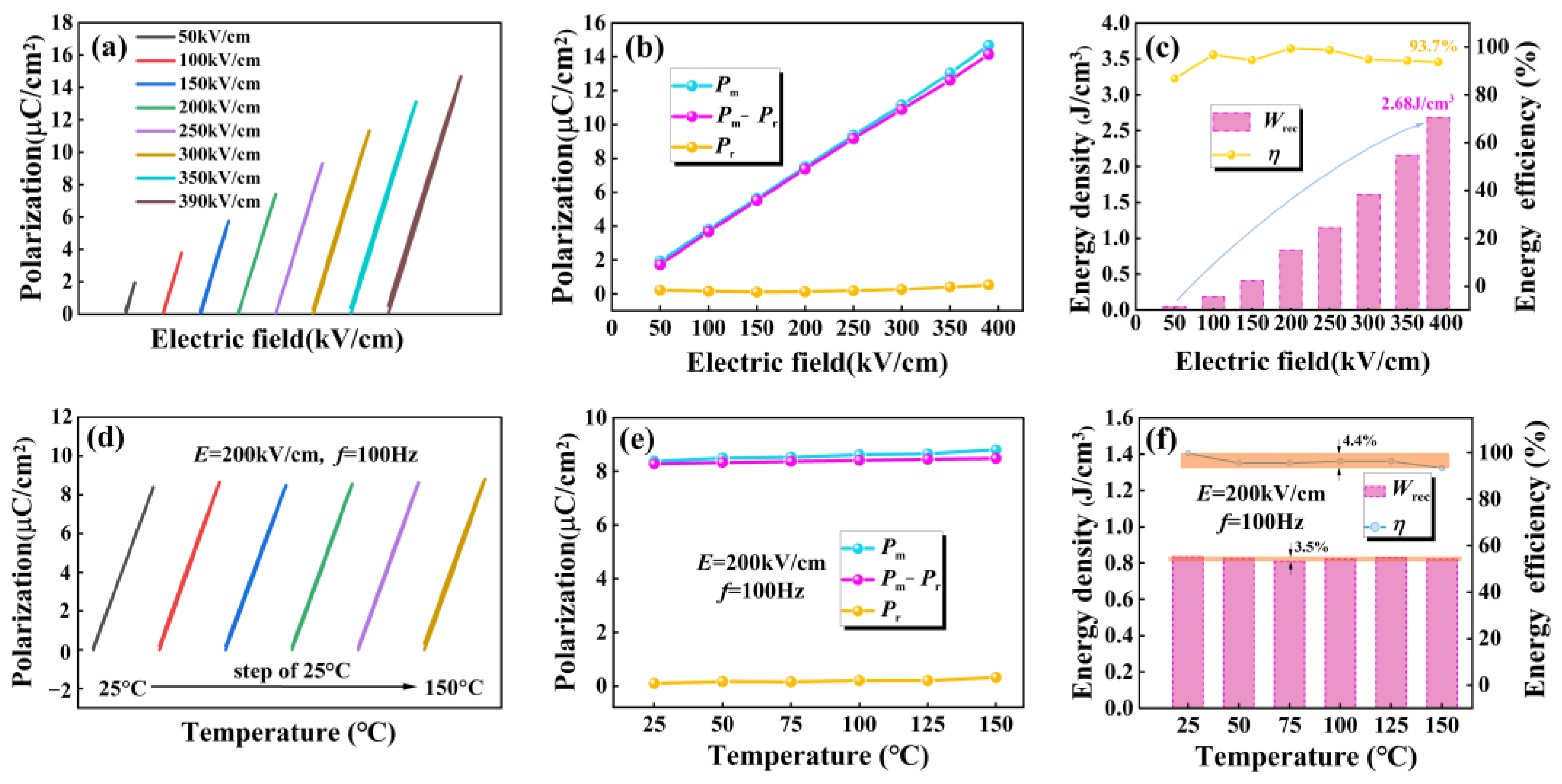

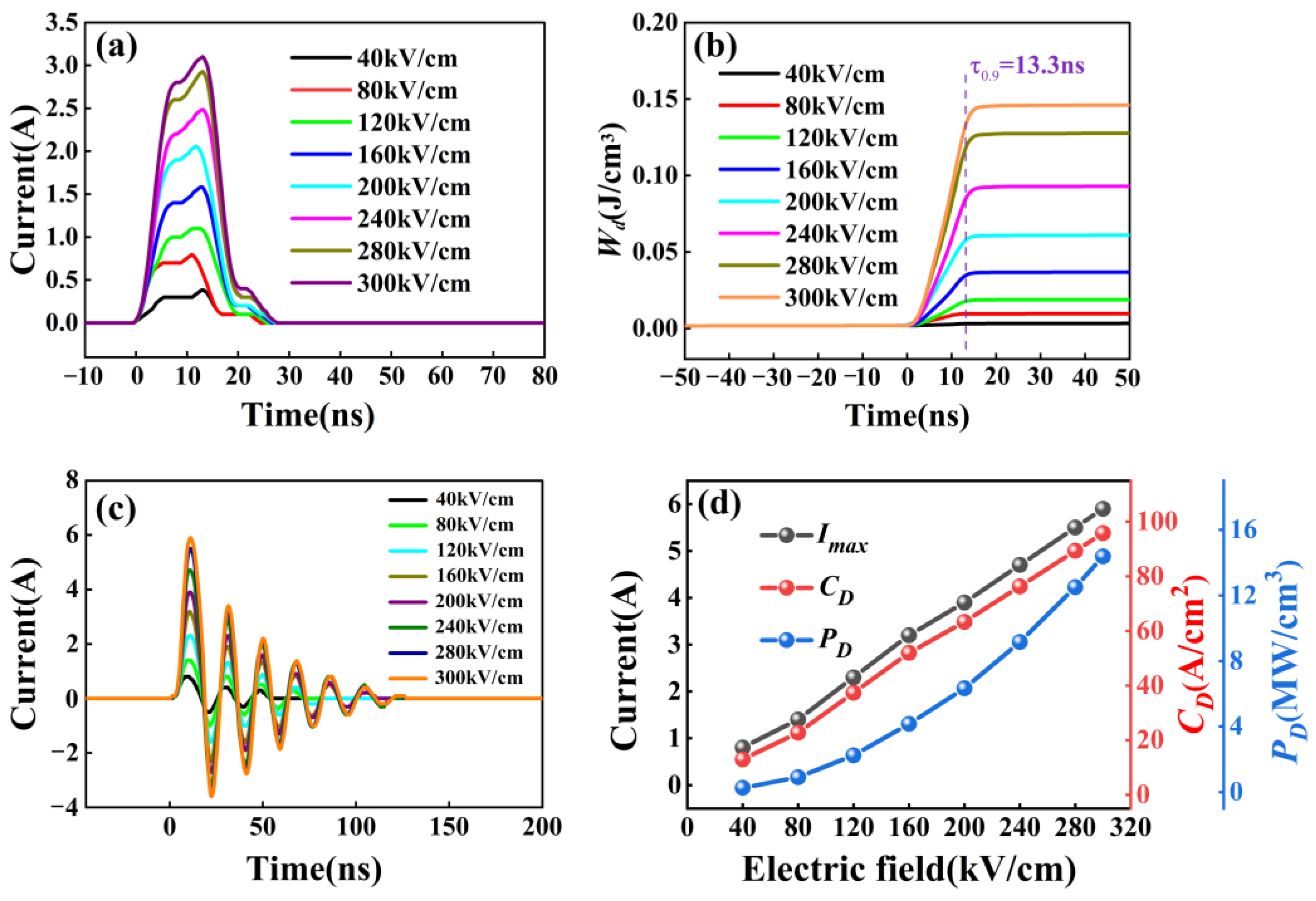

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhou, S.; Pu, Y.; Zhang, X.; Shi, Y.; Gao, Z.; Feng, Y.; Shen, G.; Wang, X.; Wang, D. High energy density, temperature stable lead-free ceramics by introducing high entropy perovskite oxide. Chem. Eng. J. 2022, 427, 131684. [Google Scholar] [CrossRef]

- Yang, L.; Kong, X.; Li, F.; Hao, H.; Cheng, Z.; Liu, H.; Li, J.-F.; Zhang, S. Perovskite lead-free dielectrics for energy storage applications. Prog. Mater. Sci. 2019, 102, 72–108. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, F.; Niu, Y.; Zhang, Z.; Lei, X.; Wang, Z.J. Excellent energy storage performance of perovskite high-entropy oxide-modified (Bi0.5Na0.5)TiO3-based ceramics. ACS Appl. Electron. Mater. 2024, 6, 4698–4708. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, H.; Cao, F.; Wang, G.; Dong, X.; Gu, Y.; He, H.; Liu, Y. Charge-discharge properties of lead zirconate stannate titanate ceramics. J. Appl. Phys. 2009, 106, 034105. [Google Scholar] [CrossRef]

- Wang, C.; Lou, X. High energy storage properties of 0.94Bi0.5Na0.5TiO3-0.06BaTiO3 ceramics by incorporating Sr0.8Bi0.1γ0.1Ti0.8Zr0.2O2.95. Microstructures 2023, 3, 2023023. [Google Scholar]

- Kang, R.; Wang, Z.; Yang, W.; Zhao, Y.; Zhang, L.; Lou, X. Enhanced energy storage performance of Bi0.5Na0.5TiO3-based ceramics via grain tuning and relaxor construction. Chem. Eng. J. 2023, 455, 140924. [Google Scholar] [CrossRef]

- Xu, S.; Du, H.; Zhang, Y.; Hu, Y.; Tang, Z.; Liu, Y.; Du, X. Dielectric tunability of 0.94Na0.5Bi0.5TiO3-0.06BaTiO3 porous ceramics with oriented pore structure. J. Mater. Sci. Mater. Electron. 2024, 35, 284. [Google Scholar] [CrossRef]

- Zhou, S.; Pu, Y.; Zhao, X.; Ouyang, T.; Ji, J.; Zhang, Q.; Zhang, C.; Sun, S.; Sun, R.; Li, J.; et al. Dielectric temperature stability and energy storage performance of NBT-based ceramics by introducing high-entropy oxide. J. Am. Ceram. Soc. 2022, 105, 4796–4804. [Google Scholar] [CrossRef]

- Gordon, R. Energy Storage in Ceramic Dielectrics. J. Am. Ceram. Soc. 1990, 73, 323–328. [Google Scholar]

- Viola, G.; Ning, H.; Reece, M.J.; Wilson, R.; Correia, T.M.; Weaver, P.; Cain, M.G.; Yan, H. Reversibility in electric field-induced transitions and energy storage properties of bismuth-based perovskite ceramics. J. Phys. D Appl. Phys. 2012, 45, 355302. [Google Scholar] [CrossRef]

- Huang, Y.; Shang, K.; Yang, Y.; Shi, W.; Zhang, L.; Laletin, V.; Shur, V.; Jing, R.; Jin, L. Ultrahigh energy storage capacities in high-entropy relaxor ferroelectrics. J. Mater. Chem. A 2024, 12, 18224–18233. [Google Scholar] [CrossRef]

- Jiang, J.; Meng, X.; Li, L.; Guo, S.; Huang, M.; Zhang, J.; Wang, J.; Hao, X.; Zhu, H.; Zhang, S.-T. Ultrahigh energy storage density in lead-free relaxor antiferroelectric ceramics via domain engineering. Energy Storage Mater. 2021, 43, 383–390. [Google Scholar] [CrossRef]

- Hao, X. A Review on the dielectric materials for high energy-storage application. J. Adv. Dielectr. 2013, 3, 14. [Google Scholar] [CrossRef]

- Ning, Y.; Pu, Y.; Zhang, X.; Chen, Z.; Wu, C.; Zhang, L.; Wang, B.; Li, X. Remarkable energy-storage density together with efficiency of above 92% in high-entropy ferroelectric ceramics. Mater. Today Phys. 2024, 43, 101418. [Google Scholar] [CrossRef]

- Zhou, J.; Zheng, P.; Bai, W.; Fan, Q.; Zheng, L.; Zhang, Y. Breaking the mutual constraint between polarization and voltage resistance with nanograined high-entropy ceramic. ACS Appl. Mater. Interfaces 2024, 16, 2530–2538. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.-H.; Qi, J.-L.; Liu, Y.-Q.; Lan, S.; Luo, Z.-X.; Pan, H.; Lin, Y.-H. High energy storage capability of perovskite relaxor ferroelectrics via hierarchical optimization. Rare Met. 2021, 41, 730–744. [Google Scholar] [CrossRef]

- Wang, G.; Lu, Z.; Li, Y.; Li, L.; Ji, H.; Feteira, A.; Zhou, D.; Wang, D.; Zhang, S.; Reaney, I.M. Electroceramics for high-energy density capacitors: Current status and future perspectives. Chem. Rev. 2021, 121, 6124–6172. [Google Scholar] [CrossRef] [PubMed]

- Chauhan, A.; Patel, S.; Vaish, R.; Bowen, C. Anti-ferroelectric ceramics for high energy density capacitors. Materials 2015, 8, 8009–8031. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Chen, X.; Cao, F.; Wang, G.; Dong, X. Charge-discharge properties of an antiferroelectric ceramics capacitor under different electric fields. J. Am. Ceram. Soc. 2010, 93, 4015–4017. [Google Scholar] [CrossRef]

- Li, D.; Zeng, X.; Li, Z.; Shen, Z.-Y.; Hao, H.; Luo, W.; Wang, X.; Song, F.; Wang, Z.; Li, Y. Progress and perspectives in dielectric energy storage ceramics. J. Adv. Ceram. 2021, 10, 675–703. [Google Scholar] [CrossRef]

- Chen, D.; Zhu, X.; Yang, X.; Yan, N.; Cui, Y.; Lei, X.; Liu, L.; Khaliq, J.; Li, C. A review on structure–property relationships in dielectric ceramics using high-entropy compositional strategies. J. Am. Ceram. Soc. 2023, 106, 6602–6616. [Google Scholar] [CrossRef]

- Xie, A.; Fu, J.; Zuo, R.; Jiang, X.; Li, T.; Fu, Z.; Yin, Y.; Li, X.; Zhang, S. Supercritical relaxor nanograined ferroelectrics for ultrahigh-energy-storage capacitors. Adv. Mater. 2022, 34, 2204356. [Google Scholar] [CrossRef]

- Yang, H.; Yan, F.; Lin, Y.; Wang, T.; Wang, F.; Wang, Y.; Guo, L.; Tai, W.; Wei, H. Lead-free BaTiO3-Bi0.5Na0.5TiO3-Na0.73Bi0.09NbO3 relaxor ferroelectric ceramics for high energy storage. J. Eur. Ceram. Soc. 2017, 37, 3303–3311. [Google Scholar] [CrossRef]

- Abdelmoula, N.; Chaabane, H.; Khemakhem, H.; Von der Mühll, R.; Simon, A. Relaxor or classical ferroelectric behavior in A site substituted perovskite type Ba1−x(Sm0.5Na0.5)xTiO3. Phys. Status Solidi 2006, 203, 987–996. [Google Scholar] [CrossRef]

- Yang, H.; Lu, Z.; Li, L.; Bao, W.; Ji, H.; Li, J.; Feteira, A.; Xu, F.; Zhang, Y.; Sun, H.; et al. Novel BaTiO3-Based, Ag/Pd-compatible lead-free relaxors with superior energy storage performance. ACS Appl. Mater. Interfaces 2020, 12, 43942–43949. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.; Yu, H.; Ren, Y.; Qi, H.; Yang, X.; Deng, Y.; Zhang, S.-T.; Chen, J. Multi-symmetry high-entropy relaxor ferroelectric with giant capacitive energy storage. Nano Energy 2023, 112, 108458. [Google Scholar] [CrossRef]

- Xiong, W.; Zhang, H.; Cao, S.; Gao, F.; Svec, P.; Dusza, J.; Reece, M.J.; Yan, H. Low-loss high entropy relaxor-like ferroelectrics with A-site disorder. J. Eur. Ceram. Soc. 2021, 41, 2979–2985. [Google Scholar] [CrossRef]

- Qiao, W.; Xu, Z.; Yuan, W.; Xu, J.; Gao, Y.; Bai, M.; Zhu, X.; Hu, Y.; Lou, X. High-performance energy storage in BNST-based lead-free ferroelectric ceramics achieved through high-entropy engineering. Chem. Eng. J. 2023, 477, 147167. [Google Scholar] [CrossRef]

- Tian, Z.; Zhang, Y.; Zhang, J.; Shi, P. Facile Preparation, Microstructure and dielectric properties of La(Cr0.2Mn0.2Fe0.2Co0.2Ni0.2)O3 perovskite high-entropy ceramics. Crystals 2022, 12, 1756. [Google Scholar] [CrossRef]

- Ning, Y.; Pu, Y.; Zhang, Q.; Zhou, S.; Wu, C.; Zhang, L.; Shi, Y.; Sun, Z. Achieving high energy storage properties in perovskite oxide via high-entropy design. Ceram. Int. 2023, 49, 12214–12223. [Google Scholar] [CrossRef]

- Zhang, R.-Z.; Reece, M.J. Review of high entropy ceramics: Design, synthesis, structure and properties. J. Mater. Chem. A 2019, 7, 22148–22162. [Google Scholar] [CrossRef]

- Liu, Z.; Xu, S.; Li, T.; Xie, B.; Guo, K.; Lu, J. Microstructure and ferroelectric properties of high-entropy perovskite oxides with A-site disorder. Ceram. Int. 2021, 47, 33039–33046. [Google Scholar] [CrossRef]

- Fang, J.; Wang, T.; Li, K.; Li, Y.; Gong, W. Energy storage properties of Mn-modified (Na0.2Bi0.2Ca0.2Sr0.2Ba0.2)TiO3 high-entropy relaxor-ferroelectric ceramics. Results Phys. 2022, 38, 105617. [Google Scholar] [CrossRef]

- Ning, Y.; Pu, Y.; Wu, C.; Chen, Z.; Zhang, X.; Zhang, L.; Wang, B. Design strategy of high-entropy perovskite energy-storage ceramics: A review. J. Eur. Ceram. Soc. 2024, 44, 4831–4843. [Google Scholar] [CrossRef]

- Ding, Y.; Ren, K.; Chen, C.; Huan, L.; Gao, R.; Deng, X.; Chen, G.; Cai, W.; Fu, C.; Wang, Z.; et al. High-entropy perovskite ceramics: Advances in structure and properties. Process. Appl. Ceram. 2024, 18, 1–11. [Google Scholar] [CrossRef]

- Chen, L.; Yu, H.; Wu, J.; Deng, S.; Liu, H.; Zhu, L.; Qi, H.; Chen, J. Large energy capacitive high-entropy lead-free ferroelectrics. Nano-Micro Lett. 2023, 15, 65. [Google Scholar] [CrossRef]

- Ning, Y.; Pu, Y.; Chen, Z.; Zhang, L.; Wu, C.; Zhang, X.; Wang, B.; Zhang, J. Novel high-entropy relaxors with ultrahigh energy-storage efficiency and density. Chem. Eng. J. 2023, 476, 146673. [Google Scholar] [CrossRef]

- Duan, J.; Wei, K.; Du, Q.; Ma, L.; Qi, H.; Li, H. High-entropy tungsten bronze ceramics for large capacitive energy storage with near-zero Losses. Adv. Funct. Mater. 2024, 34, 2409446. [Google Scholar] [CrossRef]

- Sarkar, A.; Wang, Q.; Schiele, A.; Chellali, M.R.; Bhattacharya, S.S.; Wang, D.; Brezesinski, T.; Hahn, H.; Velasco, L.; Breitung, B. High-entropy oxides: Fundamental aspects and electrochemical properties. Adv. Mater. 2019, 31, 1806236. [Google Scholar] [CrossRef] [PubMed]

- Wright, A.J.; Luo, J. A step forward from high-entropy ceramics to compositionally complex ceramics: A new perspective. J. Mater. Sci. 2020, 55, 9812–9827. [Google Scholar] [CrossRef]

- Wright, A.J.; Wang, Q.; Huang, C.; Nieto, A.; Chen, R.; Luo, J. From high-entropy ceramics to compositionally-complex ceramics: A case study of fluorite oxides. J. Eur. Ceram. Soc. 2020, 40, 2120–2129. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, J.; Zhang, L.; Liu, S.; Zhang, D.; Wang, X. Large activation energy in aged Mn-doped Sr0.4Ba0.6Nb2O6 ferroelectric ceramics. RSC Adv. 2017, 7, 26894–26902. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, Z.; Du, H.; Liu, X.; Liu, J.; Kang, R.; Mao, P.; Zhang, L. Enhanced energy storage properties promoted by the synergistic effects of aging effects and relaxor behavior in Ce-Mn co-doped Sr0.4Ba0.6Nb2O6 ferroelectric ceramics. Ceram. Int. 2024, 50, 38462–38470. [Google Scholar] [CrossRef]

- Yan, F.; Bai, H.; Ge, G.; Lin, J.; Shi, C.; Zhu, K.; Shen, B.; Zhai, J.; Zhang, S. Composition and Structure Optimized BiFeO3-SrTiO3 Lead-Free Ceramics with Ultrahigh Energy Storage Performance. Small 2022, 18, 2106515. [Google Scholar] [CrossRef]

- Lin, J.; Ge, G.; Zhu, K.; Bai, H.; Sa, B.; Yan, F.; Li, G.; Shi, C.; Zhai, J.; Wu, X.; et al. Simultaneously achieving high performance of energy storage and transparency via A-site non-stoichiometric defect engineering in KNN-based ceramics. Chem. Eng. J. 2022, 444, 136538. [Google Scholar] [CrossRef]

- Venet, M.; Guerra, J.d.L.S.; Santos, I.A.; Eiras, J.A.; Garcia, D. Diffuse phase transition and relaxor behaviour of textured Sr0.63Ba0.37Nb2O6 ceramics. J. Phys. Condens. Matter 2007, 19, 026207. [Google Scholar] [CrossRef]

- Sun, E.; Qi, X.; Yuan, Z.; Sang, S.; Zhang, R.; Yang, B.; Cao, W.; Zhao, L. Relaxation behavior in 0.24Pb(In1/2Nb1/2)O3-0.49Pb(Mg1/3Nb2/3)O3-0.27PbTiO3 ferroelectric single crystal. Ceram. Int. 2016, 42, 4893–4898. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, J.; Zhang, L.; Shi, X.; Liu, S.; Zhang, D. Relaxor transition and properties of Mn-doped SrxBa1−xNb2O6 ferroelectric ceramics. Ceram. Int. 2016, 42, 16697–16702. [Google Scholar] [CrossRef]

- Ogihara, H.; Randall, C.A.; Trolier-McKinstry, S. Weakly coupled relaxor behavior of BaTiO3-BiScO3 ceramics. J. Am. Ceram. Soc. 2009, 92, 110–118. [Google Scholar] [CrossRef]

- Choi, D.H.; Baker, A.; Lanagan, M.; Trolier-McKinstry, S.; Randall, C.; Johnson, D. Structural and dielectric properties in (1 − x)BaTiO3-xBi(Mg1/2Ti1/2)O3 ceramics (0.1 ≤ x ≤ 0.5) and potential for high-voltage multilayer capacitors. J. Am. Ceram. Soc. 2013, 96, 2197–2202. [Google Scholar] [CrossRef]

- Raengthon, N.; Sebastian, T.; Cumming, D.; Reaney, I.M.; Cann, D.P.; Roedel, J. BaTiO3-Bi(Zn1/2Ti1/2)O3-BiScO3 ceramics for high-temperature capacitor applications. J. Am. Ceram. Soc. 2012, 95, 3554–3561. [Google Scholar] [CrossRef]

- Wu, L.; Wang, X.; Li, L. Lead-free BaTiO3-Bi(Zn2/3Nb1/3)O3 weakly coupled relaxor ferroelectric materials for energy storage. RSC Adv. 2016, 6, 14273–14282. [Google Scholar] [CrossRef]

- Luo, J.; Du, J.; Tang, Q.; Mao, C. Lead sodium niobate glass-ceramic dielectrics and internal electrode structure for high energy storage density capacitors. IEEE Trans. Electron Devices 2008, 12, 3549. [Google Scholar] [CrossRef]

- Li, M.; Fan, P.; Ma, W.; Liu, K.; Zang, J.; Samart, C.; Zhang, T.; Tan, H.; Salamon, D.; Zhang, H. Constructing layered structures to enhance the breakdown strength and energy density of Na0.5Bi0.5TiO3-based lead-free dielectric ceramics. J. Mater. Chem. C 2019, 7, 15292–15300. [Google Scholar] [CrossRef]

- Jin, L.; Pang, J.; Luo, W.; Huang, Y.; Jing, R.; Xu, J.; Guo, D.; Hu, Q.; Tian, Y.; Lu, X.; et al. Enhanced breakdown strength and improved ferroelectric properties in lead-containing relaxor ferroelectric ceramics with addition of glass. Mater. Res. Express 2019, 6, 116310. [Google Scholar] [CrossRef]

- Abdullahi Hassan, Y.; Hu, H. Current status of polymer nanocomposite dielectrics for high-temperature applications. Compos. Part A Appl. Sci. Manuf. 2020, 138, 106064. [Google Scholar] [CrossRef]

- Liu, G.; Li, Y.; Guo, B.; Tang, M.; Li, Q.; Dong, J.; Yu, L.; Yu, K.; Yan, Y.; Wang, D.; et al. Ultrahigh dielectric breakdown strength and excellent energy storage performance in lead-free barium titanate-based relaxor ferroelectric ceramics via a combined strategy of composition modification, viscous polymer processing, and liquid-phase sintering. Chem. Eng. J. 2020, 398, 125625. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, Y.; Zhou, M.; Li, X.; Wang, L.; Xia, L.; Shen, Y.; Dong, X. Achieving ultrahigh dielectric breakdown strength in MgO-based ceramics by composite structure design. J. Mater. Chem. C 2019, 7, 8120–8130. [Google Scholar] [CrossRef]

- Yang, H.; Yan, F.; Lin, Y.; Wang, T. Novel strontium titanate-based lead-free ceramics for high-energy storage applications. ACS Sustain. Chem. Eng. 2017, 5, 10215–10222. [Google Scholar] [CrossRef]

- Li, C.; Liu, J.; Bai, W.; Wu, S.; Zheng, P.; Zhang, J.; Pan, Z.; Zhai, J. Superior energy storage performance in (Bi0.5Na0.5)TiO3-based lead-free relaxor ferroelectrics for dielectric capacitor application via multiscale optimization design. J. Mater. Chem. A 2022, 10, 9535–9546. [Google Scholar] [CrossRef]

- Zuo, C.; Yang, S.; Cao, Z.; Jie, W.; Wei, X. Combustion synthesis of high-performance high-entropy dielectric ceramics for energy storage applications. Ceram. Int. 2023, 49, 25486–25494. [Google Scholar] [CrossRef]

- Xu, S.; Hao, R.; Yan, Z.; Hou, S.; Peng, Z.; Wu, D.; Liang, P.; Chao, X.; Wei, L.; Yang, Z. Enhanced energy storage properties and superior thermal stability in SNN-based tungsten bronze ceramics through substitution strategy. J. Eur. Ceram. Soc. 2022, 42, 2781–2788. [Google Scholar] [CrossRef]

- Xu, S.; Shen, S.; Huang, C.; He, Y.; Chao, X.; Wu, D.; Liang, P.; Yang, Z.; Lu, J.; Wei, L. Enhancing energy storage performance in lead-free bismuth sodium niobate-based tungsten bronze ceramics through relaxor tuning. ACS Appl. Mater. Interfaces 2023, 15, 11642–11651. [Google Scholar] [CrossRef]

- Lv, J.; Song, S.; Jiao, Y.; Yang, Z.; Zhang, Y.; Fan, Y.; Song, C.; Liu, G. Enhancing the dielectric and energy storage properties of lead-free Na0.5Bi0.5TiO3–BaTiO3 ceramics by adding K0.5Na0.5NbO3 ferroelectric. Ceram. Int. 2022, 48, 22–31. [Google Scholar] [CrossRef]

- Pu, Y.; Yao, M.; Liu, H.; Frömling, T. Phase transition behavior, dielectric and ferroelectric properties of (1 − x)(Bi0.5Na0.5)TiO3-xBa0.85Ca0.15Ti0.9Zr0.1O3 ceramics. J. Eur. Ceram. Soc. 2016, 36, 2461–2468. [Google Scholar] [CrossRef]

- Ren, P.; He, J.; Yan, F.; Wang, X. Temperature stable dielectric and energy storage properties of (1 − x)(0.94Bi0.5Na0.5TiO3-0.09BiAlO3)-xSrTiO3 ceramics. J. Alloys Compd. 2019, 807, 151676. [Google Scholar] [CrossRef]

- Zhang, L.; Pu, Y.; Chen, M.; Wei, T.; Peng, X. Novel Na0.5Bi0.5TiO3 based, lead-free energy storage ceramics with high power and energy density and excellent high-temperature stability. Chem. Eng. J. 2020, 383, 123154. [Google Scholar] [CrossRef]

- Li, Q.; Li, M.; Wang, C.; Zhang, M.; Fan, H. Enhanced temperature stable dielectric properties and energy-storage density of BaSnO3-modified (Bi0.5Na0.5)0.94Ba0.06TiO3 lead-free ceramics. Ceram. Int. 2019, 45, 19822–19828. [Google Scholar] [CrossRef]

- Li, D.; Lin, Y.; Zhang, M.; Yang, H. Achieved ultrahigh energy storage properties and outstanding charge–discharge performances in (Na0.5Bi0.5)0.7Sr0.3TiO3-based ceramics by introducing a linear additive. Chem. Eng. J. 2020, 392, 123729. [Google Scholar] [CrossRef]

- Cao, L.; Yuan, Y.; Li, E.; Zhang, S. Relaxor regulation and improvement of energy storage properties of Sr2NaNb5O15-based tungsten bronze ceramics through B-site substitution. Chem. Eng. J. 2021, 421, 127846. [Google Scholar] [CrossRef]

| Compositions | Wrec (J/cm3) | H (%) | BDS (kV/cm) | Temperature Range (°C) | Article |

|---|---|---|---|---|---|

| Sr0.4Ba0.6(Zr0.2Ti0.2Sn0.2Ta0.2Nb0.2)2 | 2.68 | 93.7 | 570.1 | ±5%, 111–317 °C | This work |

| Sr2Ag0.2Na0.8Nb5−xTaxO15 | 1.44 | 82 | 175 | −9.6–232.7 °C | [62] |

| Sr2Na0.85Bi0.05Nb5−xTaxO15 | 1.6 | 80 | 200 | −97.3–165.2 °C | [63] |

| NBT–BT–KNN | 2.81 | 94.4 | 180 | -- | [64] |

| (1−x)BNT-xBCZT | 0.665 | 83.2 | 70 | ±15%, 81–330 °C | [65] |

| (1−x)BNT-0.09BA-xST | 0.84 | 48.3 | 90 | ±5%, 132.8–391.8 °C | [66] |

| 0.93Na0.5Bi0.5TiO3-0.07LiTaO3 | 2.3 | 74.2 | 200 | ±15%, 15–600 °C | [67] |

| (1−x)BNBT-xBS | 1.2 | 86.7 | 115 | ±15%, 45–338 °C | [68] |

| (Na0.5Bi0.5)0.7Sr0.3TiO3 | 3.13 | 91.14 | 262 | -- | [69] |

| Sr1.88La0.12NaNb4.88−xTaxTi0.12O15 | 2.03 | 94 | 35 | -- | [70] |

| Sr(Zr0.2Sn0.2Hf0.2Ti0.2Nb0.2)O3 | 3.52 | 86.5 | 283 | ±5%, 52.4–362 °C | [8] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Li, Z.; Yang, S.; Mao, P.; Kang, R. Dielectric Temperature Stability and Enhanced Energy-Storage Performance of Sr0.4Ba0.6(Zr0.2Ti0.2Sn0.2Ta0.2Nb0.2)2O6 High-Entropy Ferroelectric Ceramics. Crystals 2025, 15, 26. https://doi.org/10.3390/cryst15010026

Zhao Y, Li Z, Yang S, Mao P, Kang R. Dielectric Temperature Stability and Enhanced Energy-Storage Performance of Sr0.4Ba0.6(Zr0.2Ti0.2Sn0.2Ta0.2Nb0.2)2O6 High-Entropy Ferroelectric Ceramics. Crystals. 2025; 15(1):26. https://doi.org/10.3390/cryst15010026

Chicago/Turabian StyleZhao, Yingying, Ziao Li, Shiqiang Yang, Pu Mao, and Ruirui Kang. 2025. "Dielectric Temperature Stability and Enhanced Energy-Storage Performance of Sr0.4Ba0.6(Zr0.2Ti0.2Sn0.2Ta0.2Nb0.2)2O6 High-Entropy Ferroelectric Ceramics" Crystals 15, no. 1: 26. https://doi.org/10.3390/cryst15010026

APA StyleZhao, Y., Li, Z., Yang, S., Mao, P., & Kang, R. (2025). Dielectric Temperature Stability and Enhanced Energy-Storage Performance of Sr0.4Ba0.6(Zr0.2Ti0.2Sn0.2Ta0.2Nb0.2)2O6 High-Entropy Ferroelectric Ceramics. Crystals, 15(1), 26. https://doi.org/10.3390/cryst15010026