Dielectric Behavior of Stretchable Silicone Rubber–Barium Titanate Composites

Abstract

1. Introduction

2. Materials and Methods

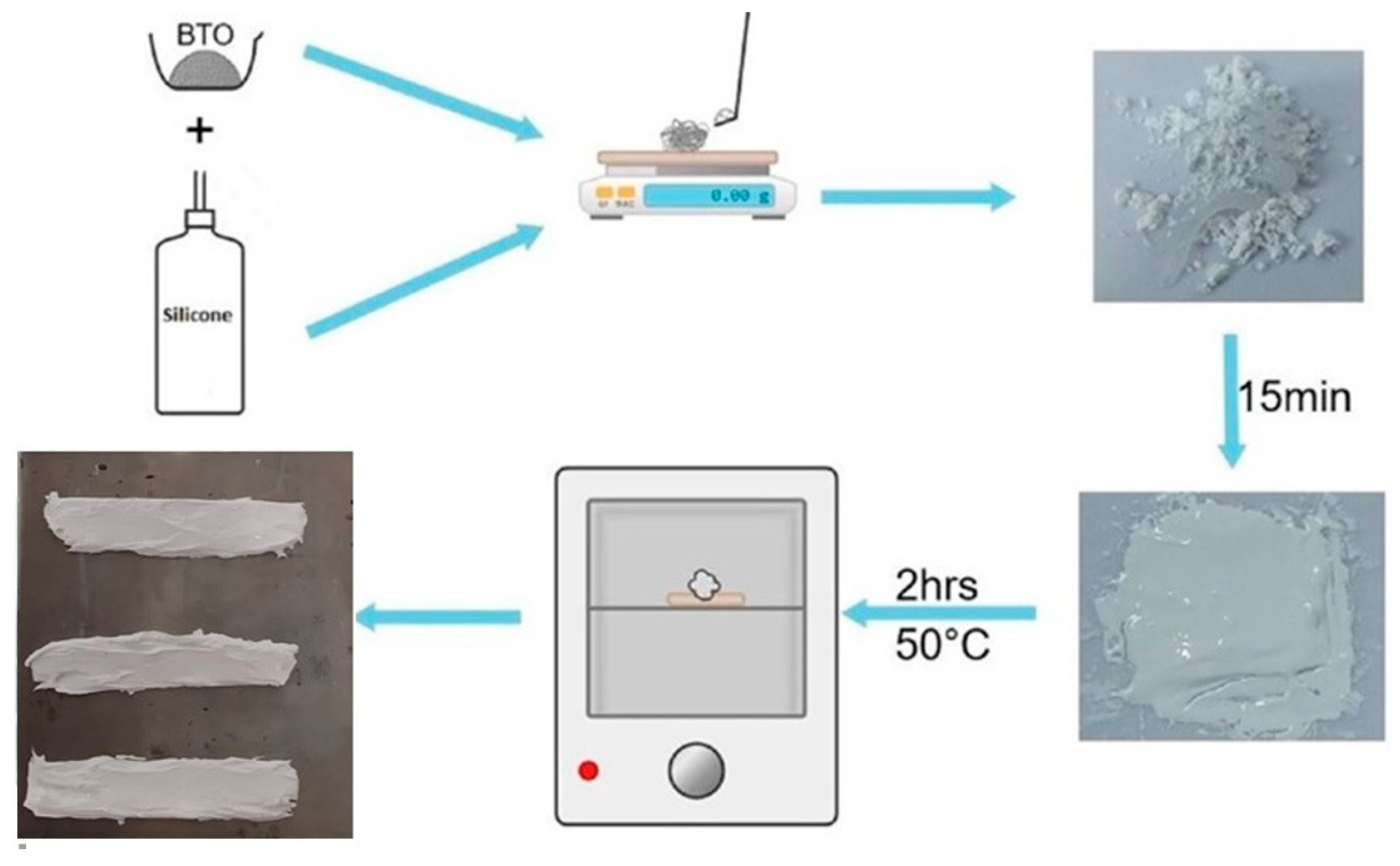

2.1. Sample Preparation

2.2. Characterization

2.2.1. Scanning Electron Microscopy Measurements

2.2.2. X-ray Diffraction Experiments

2.2.3. Raman Spectroscopy Experiments

2.2.4. ATR Spectroscopy Experiments

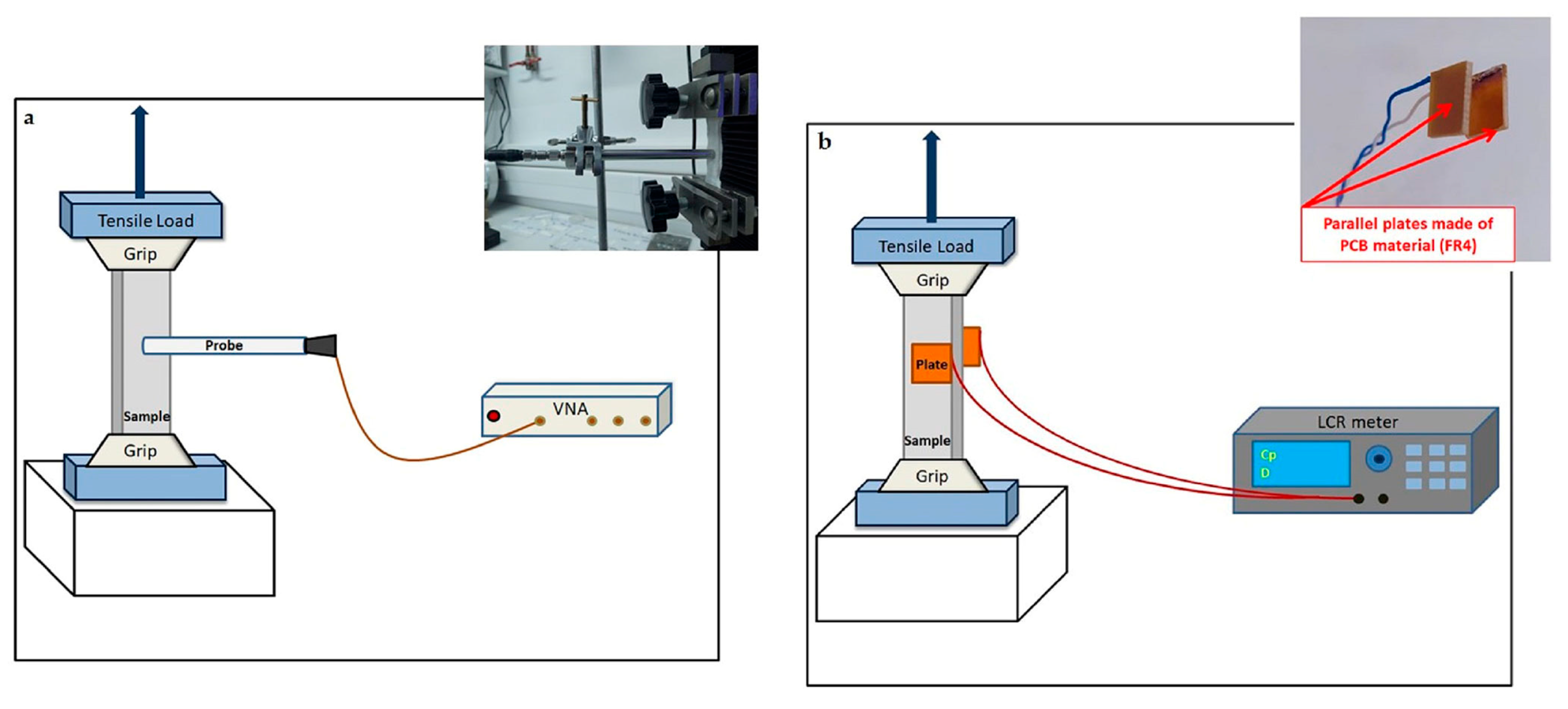

2.2.5. Dielectric Constant Measurements

2.2.6. Mechanical Testing

2.2.7. Combining Experiments

3. Results and Discussion

3.1. Characterization

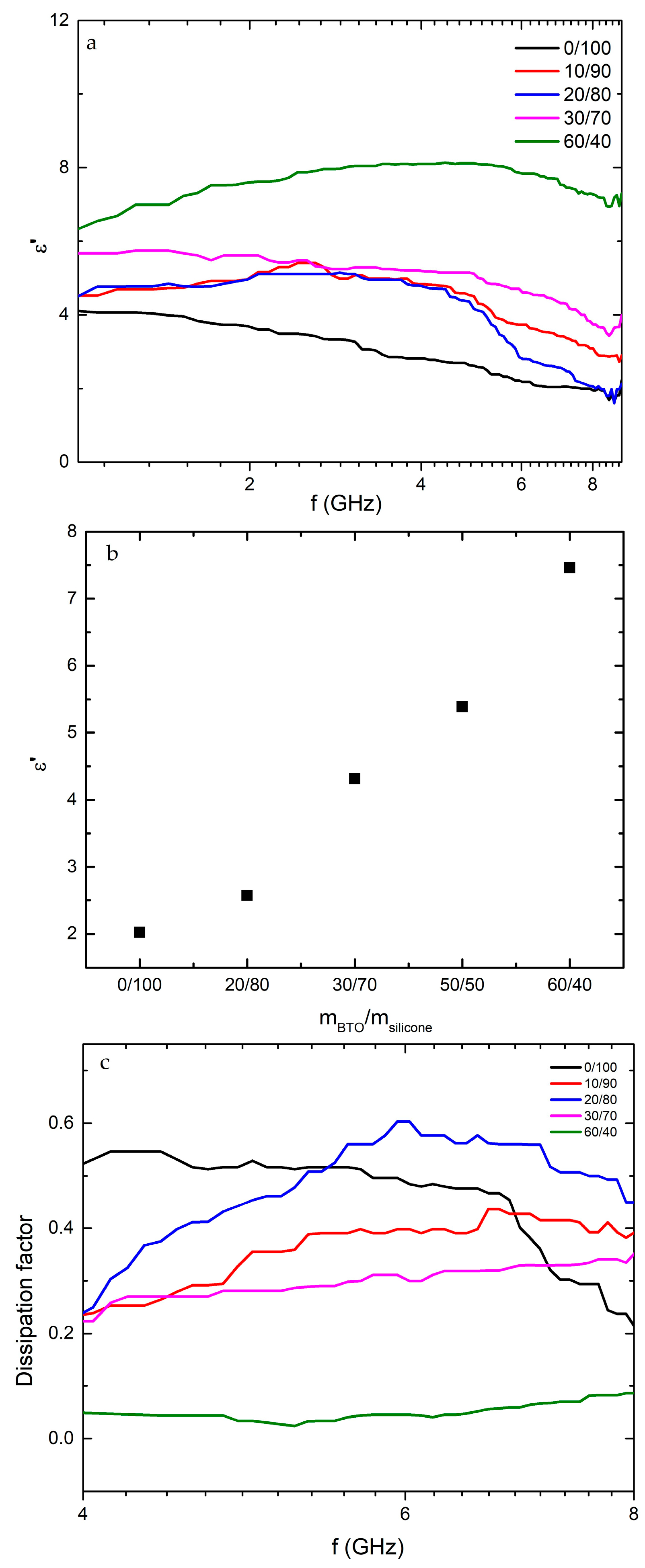

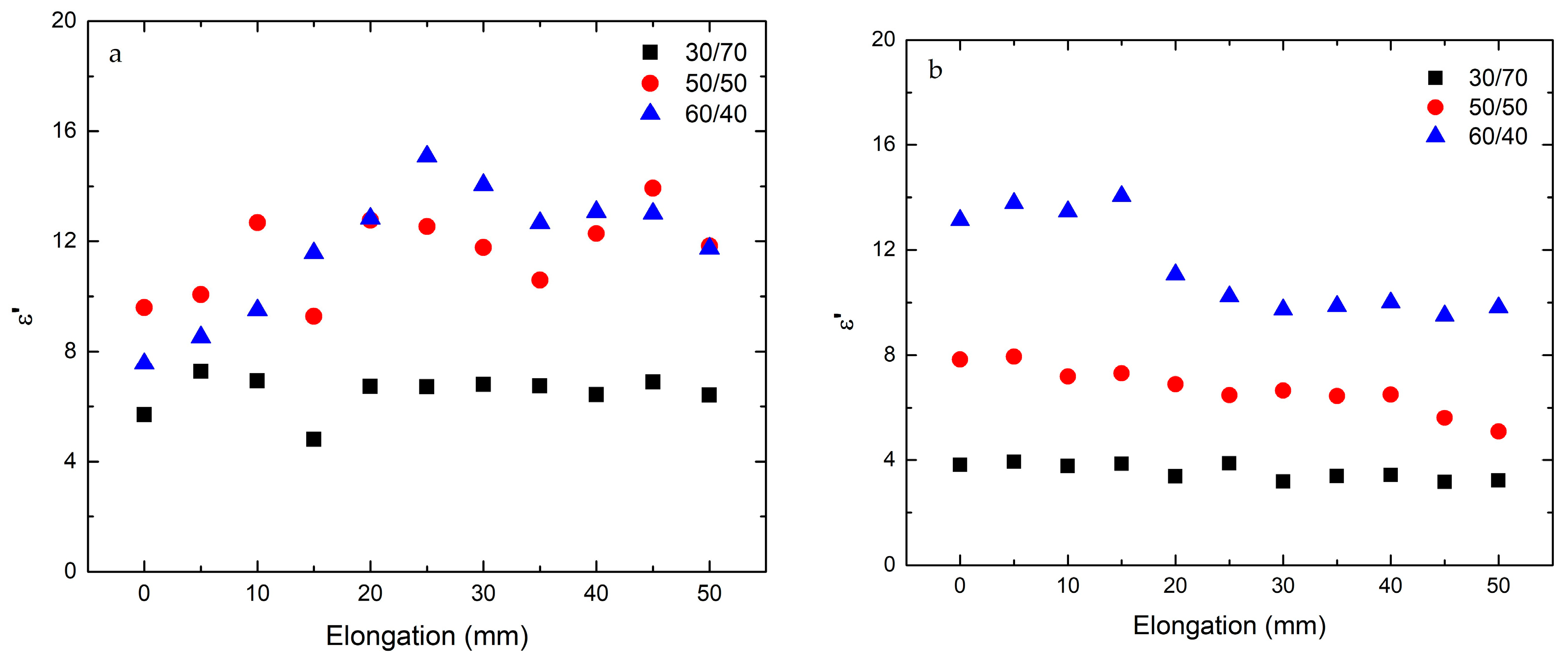

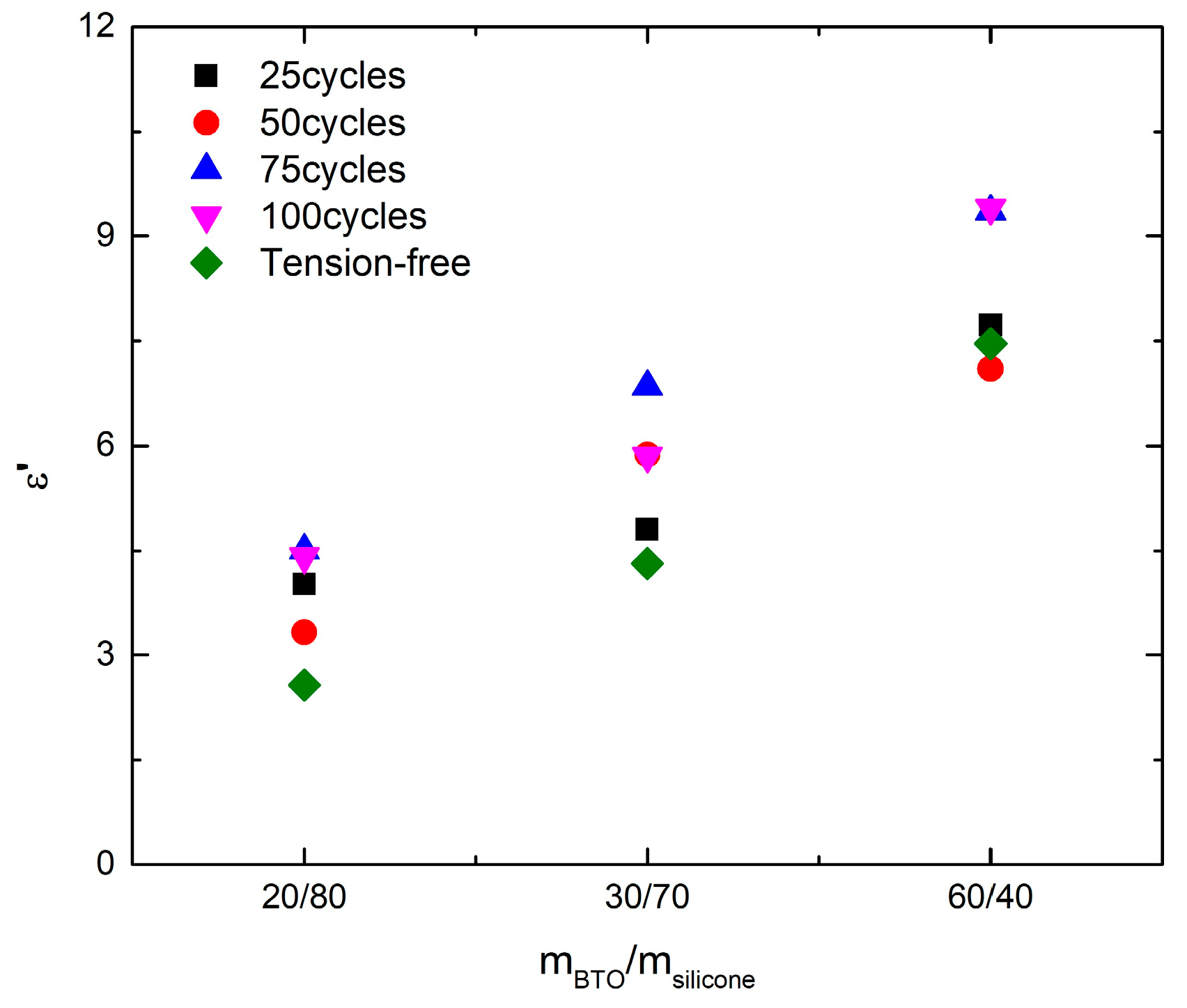

3.2. Dielectric Constant Measurements

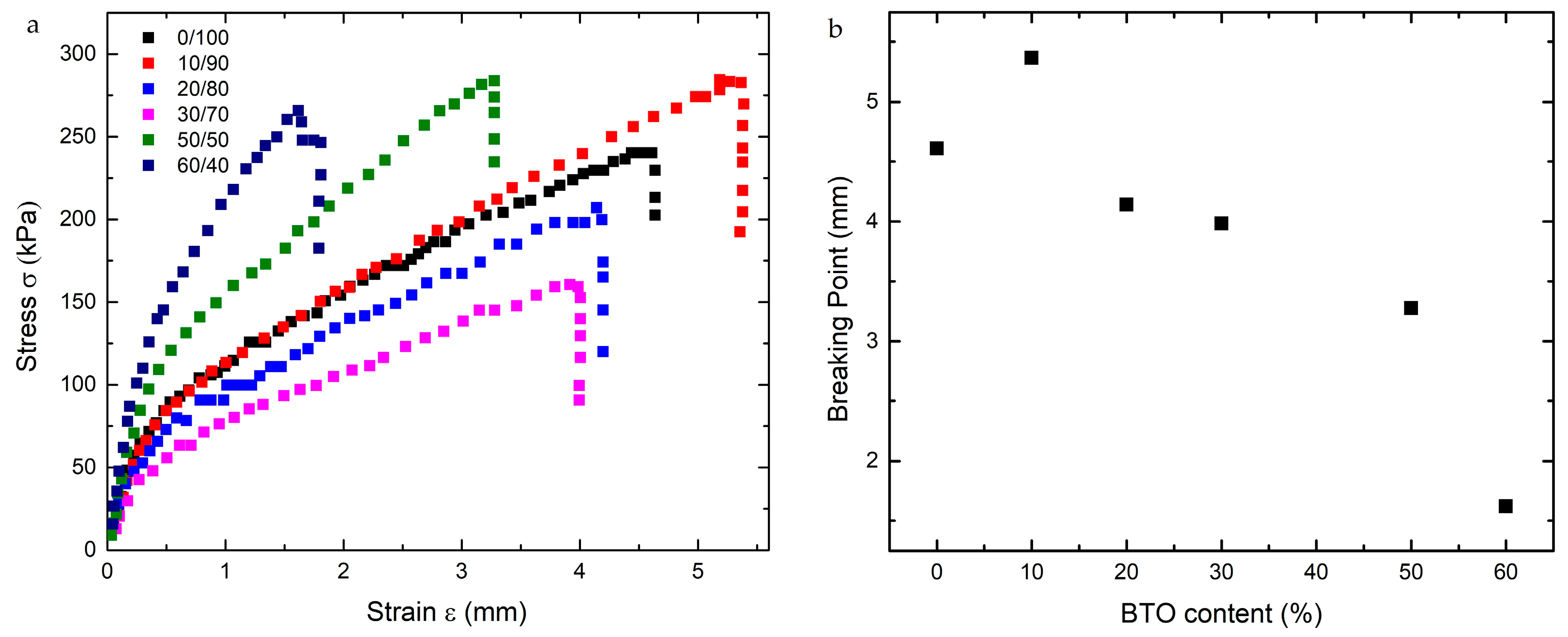

3.3. Mechanical Properties

4. Summary and Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nasiri, N. Wearable Devices—The Big Wave of Innovation; Intechopen: London, UK, 2019; ISBN 978-1-78984-497-9. [Google Scholar]

- Yang, D.; Ge, F.; Tian, M.; Ning, N.; Zhang, L.; Zhao, C.; Ito, K.; Nishi, T.; Wang, H.; Luan, Y. Dielectric Elastomer Actuator with Excellent Electromechanical Performance Using Slide-Ring Materials/Barium Titanate Composites. J. Mater. Chem. A 2015, 3, 9468–9479. [Google Scholar] [CrossRef]

- Kofod, G.; Stoyanov, H.; Kollosche, M.; Risse, S.; Ragusch, H.; McCarthy, D.N.; Waché, R.; Rychkov, D.; Dansachmüller, M. Molecular Level Materials Design for Improvements of Actuation Properties of Dielectric Elastomer Actuators. In Proceedings of the Electroactive Polymer Actuators and Devices (EAPAD) 2011, San Diego, CA, USA, 28 March 2011; Volume 7976, pp. 160–171. [Google Scholar] [CrossRef]

- Cholleti, E.R.; Stringer, J.; Kelly, P.; Bowen, C.; Aw, K. Mechanical Behaviour of Large Strain Capacitive Sensor with Barium Titanate Ecoflex Composite Used to Detect Human Motion. Robotics 2021, 10, 69. [Google Scholar] [CrossRef]

- Kim, K.; Hyun, B.G.; Jang, J.; Cho, E.; Park, Y.G.; Park, J.U. Nanomaterial-Based Stretchable and Transparent Electrodes. J. Inf. Disp. 2016, 17, 131–141. [Google Scholar] [CrossRef]

- An, B.W.; Shin, J.H.; Kim, S.Y.; Kim, J.; Ji, S.; Park, J.; Lee, Y.; Jang, J.; Park, Y.G.; Cho, E.; et al. Smart Sensor Systems for Wearable Electronic Devices. Polymers 2017, 9, 303. [Google Scholar] [CrossRef] [PubMed]

- Hwang, B.U.; Lee, J.H.; Trung, T.Q.; Roh, E.; Kim, D.I.; Kim, S.W.; Lee, N.E. Transparent Stretchable Self-Powered Patchable Sensor Platform with Ultrasensitive Recognition of Human Activities. ACS Nano 2015, 9, 8801–8810. [Google Scholar] [CrossRef] [PubMed]

- Dagdeviren, C.; Su, Y.; Joe, P.; Yona, R.; Liu, Y.; Kim, Y.S.; Huang, Y.; Damadoran, A.R.; Xia, J.; Martin, L.W.; et al. Conformable Amplified Lead Zirconate Titanate Sensors with Enhanced Piezoelectric Response for Cutaneous Pressure Monitoring. Nat. Commun. 2014, 5, 4496. [Google Scholar] [CrossRef] [PubMed]

- Bonato, P. Wearable Sensors/Systems and Their Impact on Biomedical Engineering. IEEE Eng. Med. Biol. Mag. 2003, 22, 18–20. [Google Scholar] [CrossRef] [PubMed]

- Qin, R.; Hu, M.; Li, X.; Liang, T.; Tan, H.; Liu, J.; Shan, G. A New Strategy for the Fabrication of a Flexible and Highly Sensitive Capacitive Pressure Sensor. Microsyst. Nanoeng. 2021, 7, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Gayler, M.L.V. Melting Point of High-Purity Silicon. Nature 1938, 142, 589–590. [Google Scholar] [CrossRef]

- Cholleti, E.R.; Stringer, J.; Assadian, M.; Battmann, V.; Bowen, C.; Aw, K. Highly Stretchable Capacitive Sensor with Printed Carbon Black Electrodes on Barium Titanate Elastomer Composite. Sensors 2019, 19, 42. [Google Scholar] [CrossRef]

- Wongwilawan, S.; Ishida, H.; Manuspiya, H. Dielectric Properties at Microwave Frequency in Barium Strontium Titanate/Poly(Benzoxazine/Urethane) Composite Films. Ferroelectrics 2013, 452, 84–90. [Google Scholar] [CrossRef]

- Kasgoz, A. Quantifying Dielectric and Microwave Absorption Properties of Barium Titanate and Strontium Ferrite Filled Polymer Composites. Polym. Polym. Compos. 2021, 29, 1377–1389. [Google Scholar] [CrossRef]

- Ratheesh, R.; Sebastian, M.T. Polymer-Ceramic Composites for Microwave Applications. Microw. Mater. Appl. 2017, 2, 481–535. [Google Scholar] [CrossRef]

- Fenske, K.; Misra, D. Dielectric Materials at Microwave Frequencies. Appl. Microw. Wirel. 2000, 12, 92–100. [Google Scholar]

- Schadler, L.S.; Nelson, J.K. Polymer Nanodielectrics–Short History and Future Perspective. J. Appl. Phys. 2020, 128, 120902. [Google Scholar] [CrossRef]

- Fréchette, M.F. What Are Nanodielectrics? IEEE Electr. Insul. Mag. 2013, 29, 8–11. [Google Scholar] [CrossRef]

- Du, F.Y.; Chen, R.C.; Che, J.; Xu, W.D.; Liu, X.; Li, Y.T.; Zhou, Y.L.; Yuan, J.; Zhang, Q.P. High Loading BaTiO3 nanoparticles Chemically Bonded with Fluorinated Silicone Rubber for Largely Enhanced Dielectric Properties of Polymer Nanocomposites. Phys. Chem. Chem. Phys. 2021, 23, 26219–26226. [Google Scholar] [CrossRef] [PubMed]

- Tan, D.Q. The Search for Enhanced Dielectric Strength of Polymer-Based Dielectrics: A Focused Review on Polymer Nanocomposites. J. Appl. Polym. Sci. 2020, 137, 1–32. [Google Scholar] [CrossRef]

- Luo, H.; Zhang, D.; Jiang, C.; Yuan, X.; Chen, C.; Zhou, K. Improved Dielectric Properties and Energy Storage Density of Poly(Vinylidene Fluoride-Co-Hexafluoropropylene) Nanocomposite with Hydantoin Epoxy Resin Coated BaTiO3. ACS Appl. Mater. Interfaces 2015, 7, 8061–8069. [Google Scholar] [CrossRef]

- Tang, H.; Ma, Z.; Zhong, J.; Yang, J.; Zhao, R.; Liu, X. Effect of Surface Modification on the Dielectric Properties of PEN Nanocomposites Based on Double-Layer Core/Shell-Structured BaTiO3 Nanoparticles. Colloids Surf. A Physicochem. Eng. Asp. 2011, 384, 311–317. [Google Scholar] [CrossRef]

- Li, R.; Zhao, Z.; Chen, Z.; Pei, J. Novel BaTiO3/PVDF Composites with Enhanced Electrical Properties Modified by Calcined BaTiO3 Ceramic Powders. Mater. Express 2017, 7, 536–540. [Google Scholar] [CrossRef]

- Nayak, S.; Chaki, T.K.; Khastgir, D. Development of Flexible Piezoelectric Poly(Dimethylsiloxane)-BaTiO3 Nanocomposites for Electrical Energy Harvesting. Ind. Eng. Chem. Res. 2014, 53, 14982–14992. [Google Scholar] [CrossRef]

- Namitha, L.K.; Sebastian, M.T. High Permittivity Ceramics Loaded Silicone Elastomer Composites for Flexible Electronics Applications. Ceram. Int. 2017, 43, 2994–3003. [Google Scholar] [CrossRef]

- Yaqoob, U.; Chung, G.S. Effect of Surface Treated MWCNTs and BaTiO3 nanoparticles on the Dielectric Properties of a P(VDF-TrFE) Matrix. J. Alloys Compd. 2017, 695, 1231–1236. [Google Scholar] [CrossRef]

- Sharma, P.; Kumar, P.; Kundu, R.S.; Juneja, J.K.; Ahlawat, N.; Punia, R. Structural and Dielectric Properties of Substituted Barium Titanate Ceramics for Capacitor Applications. Ceram. Int. 2015, 41, 13425–13432. [Google Scholar] [CrossRef]

- Choudhury, A. Dielectric and Piezoelectric Properties of Polyetherimide/BaTiO3 Nanocomposites. Mater. Chem. Phys. 2010, 121, 280–285. [Google Scholar] [CrossRef]

- Stefanescu, E.A.; Tan, X.; Lin, Z.; Bowler, N.; Kessler, M.R. Multifunctional Fiberglass-Reinforced PMMA-BaTiO3 Structural/Dielectric Composites. Polymer 2011, 52, 2016–2024. [Google Scholar] [CrossRef]

- Choi, W.; Choi, K.; Yang, G.; Kim, J.C.; Yu, C. Improving Piezoelectric Performance of Lead-Free Polymer Composites with High Aspect Ratio BaTiO3 Nanowires. Polym. Test. 2016, 53, 143–148. [Google Scholar] [CrossRef]

- Kumar, A.; Patra, K.; Hossain, M. Silicone Composites Cured under a High Electric Field: An Electromechanical Experimental Study. Polym. Compos. 2021, 42, 914–930. [Google Scholar] [CrossRef]

- Jiang, L.; Betts, A.; Kennedy, D.; Jerrams, S. The Fabrication of Dielectric Elastomers from Silicone Rubber and Barium Titanate: Employing Equi-Biaxial Pre-Stretch to Achieve Large Deformations. J. Mater. Sci. 2015, 50, 7930–7938. [Google Scholar] [CrossRef]

- Yao, H.Y.; Lin, Y.W.; Chang, T.H. Dielectric Properties of Batio3-Epoxy Nanocomposites in the Microwave Regime. Polymers 2021, 13, 1391. [Google Scholar] [CrossRef] [PubMed]

- Cheng, K.C.; Lin, C.M.; Wang, S.F.; Lin, S.T.; Yang, C.F. Dielectric Properties of Epoxy Resin-Barium Titanate Composites at High Frequency. Mater. Lett. 2007, 61, 757–760. [Google Scholar] [CrossRef]

- Hasan, N.; Noordin, N.H.; Karim, M.S.A.; Rejab, M.R.M.; Ma, Q.J. Dielectric Properties of Epoxy–Barium Titanate Composite for 5 GHz Microstrip Antenna Design. SN Appl. Sci. 2020, 2, 62. [Google Scholar] [CrossRef]

- Akinay, Y.; Hayat, F. Synthesis and Microwave Absorption Enhancement of BaTiO3 Nanoparticle/Polyvinylbutyral Composites. J. Compos. Mater. 2019, 53, 593–601. [Google Scholar] [CrossRef]

- Koulouridis, S.; Kiziltas, G.; Zhou, Y.; Hansford, D.J.; Volakis, J.L. Polymer-Ceramic Composites for Microwave Applications: Fabrication and Performance Assessment. IEEE Trans. Microw. Theory Tech. 2006, 54, 4202–4208. [Google Scholar] [CrossRef]

- Liu, C.; Liu, L.; Yang, D.; Zhang, L. A Dipolar Silicone Dielectric Elastomer and Its Composite with Barium Titanate Nanoparticles. J. Mater. Sci. Mater. Electron. 2020, 31, 11411–11424. [Google Scholar] [CrossRef]

- Guo, C.; Fuji, M. Effect of Silicone Coupling Agent on Dielectric Properties of Barium Titanate/Silicone Elastomer Composites. Adv. Powder Technol. 2016, 27, 1162–1172. [Google Scholar] [CrossRef]

- Bele, A.; Cazacu, M.; Stiubianu, G.; Vlad, S. Silicone-Barium Titanate Composites with Increased Electromechanical Sensitivity. the Effects of the Filler Morphology. RSC Adv. 2014, 4, 58522–58529. [Google Scholar] [CrossRef]

- Jiang, L.; Kennedy, D.; Jerrams, S.; Betts, A. Enhancement of Dielectric Properties with the Addition of Bromine and Dopamine Modified Barium Titanate Particles to Silicone Rubber. MRS Commun. 2016, 6, 437–441. [Google Scholar] [CrossRef]

- Mustafa, N.; Azman, A.N.; Mohd Shah, A.S.; Hasan, N.; Abdul Karim, M.S. Study on Effect of Barium Titanate Concentration in Epoxy-Based Composite towards Dielectric Material Properties. Mater. Today Proc. 2023, 2–6. [Google Scholar] [CrossRef]

- Pant, H.C.; Patra, M.K.; Verma, A.; Vadera, S.R.; Kumar, N. Study of the Dielectric Properties of Barium Titanate-Polymer Composites. Acta Mater. 2006, 54, 3163–3169. [Google Scholar] [CrossRef]

- Jain, R.; Dubey, A.; Soni, A.; Gupta, S.; Shami, T. Barium Titanate Flakes Based Composites for Microwave Absorbing Applications. Process. Appl. Ceram. 2013, 7, 189–193. [Google Scholar] [CrossRef]

- Popielarz, R.; Chiang, C.K.; Nozaki, R.; Obrzut, J. Dielectric Properties of Polymer/Ferroelectric Ceramic Composites from 100 Hz to 10 GHz. Macromolecules 2001, 34, 5910–5915. [Google Scholar] [CrossRef]

- Biglar, M.; Gromada, M.; Stachowicz, F.; Trzepieciński, T. Synthesis of Barium Titanate Piezoelectric Ceramics for Multilayer Actuators (MLAs). Acta Mech. Autom. 2017, 11, 275–279. [Google Scholar] [CrossRef]

- Singh, M.; Yadav, B.C.; Ranjan, A.; Kaur, M.; Gupta, S.K. Synthesis and Characterization of Perovskite Barium Titanate Thin Film and Its Application as LPG Sensor. Sens. Actuators B Chem. 2017, 241, 1170–1178. [Google Scholar] [CrossRef]

- Wang, Q. Preparation and Surface Modification of Mg(OH)2/Siloxane Nanocomposite Flame Retardant. J. Polym. Eng. 2015, 35, 113–117. [Google Scholar] [CrossRef]

- Dwij, V.; De, B.K.; Sharma, G.; Shukla, D.K.; Gupta, M.K.; Mittal, R.; Sathe, V. Revisiting 70 Years of Lattice Dynamics of BaTiO3: Combined First Principle and Experimental Investigation. arXiv 2012, arXiv:2012.12669. [Google Scholar]

- Sá, P.; Bdikin, I.; Almeida, B.; Rolo, A.G.; Isakov, D. Production and PFM Characterization of Barium Titanate Nanofibers. Ferroelectrics 2012, 429, 48–55. [Google Scholar] [CrossRef]

- Chauhan, R.; Srivastava, R.C. Various Properties of the 0.6BaTiO3-0.4Ni0.5Zn0.5Fe2O4 Multiferroic Nanocomposite. Pramana J. Phys. 2016, 87, 2–7. [Google Scholar] [CrossRef]

- Pino-Ramos, V.H.; Alvarez-Lorenzo, C.; Concheiro, A.; Bucio, E. One-Step Grafting of Temperature-and PH-Sensitive (N-Vinylcaprolactam-Co-4-Vinylpyridine) onto Silicone Rubber for Drug Delivery. Des. Monomers Polym. 2017, 20, 33–41. [Google Scholar] [CrossRef]

- Sun, D.; Jin, X.; Liu, H.; Zhu, J.; Zhu, Y.; Zhu, Y. Investigation on FTIR Spectrum of Barium Titanate Ceramics Doped with Alkali Ions. Ferroelectrics 2007, 355, 145–148. [Google Scholar] [CrossRef]

- Ashiri, R. Detailed FT-IR Spectroscopy Characterization and Thermal Analysis of Synthesis of Barium Titanate Nanoscale Particles through a Newly Developed Process. Vib. Spectrosc. 2013, 66, 24–29. [Google Scholar] [CrossRef]

- Shen, L.; Qiu, W.; Liu, B.; Guo, Q. Stable Superhydrophobic Surface Based on Silicone Combustion Product. RSC Adv. 2014, 4, 56259–56262. [Google Scholar] [CrossRef]

- Silva, F.A.B. Poly(Dimethylsiloxane) and Poly[Vinyltrimethoxysilane-Co-2-(Dimethylamino) Ethyl Methacrylate] Based Cross-Linked Organic-Inorganic Hybrid Adsorbent for Copper(II) Removal from Aqueous Solutions. J. Brazilian Chem. Soc. 2016, 27, 2181–2191. [Google Scholar] [CrossRef]

- Su, J.; Zhang, J. Recent Development on Modification of Synthesized Barium Titanate (BaTiO3) and Polymer/BaTiO 3 Dielectric Composites. J. Mater. Sci. Mater. Electron. 2019, 30, 1957–1975. [Google Scholar] [CrossRef]

- Curecheriu, L.; Balmus, S.B.; Buscaglia, M.T.; Buscaglia, V.; Ianculescu, A.; Mitoseriu, L. Grain Size-Dependent Properties of Dense Nanocrystalline Barium Titanate Ceramics. J. Am. Ceram. Soc. 2012, 95, 3912–3921. [Google Scholar] [CrossRef]

- Sebastian, M.T. Dielectric Materials for Wireless Communication; Elsevier: Amsterdam, The Netherlands, 2010; ISBN 0080560504. [Google Scholar]

- Konishi, Y. Novel Dielectric Waveguide Components—Microwave Applications of New Ceramic Materials. Proc. IEEE 1991, 79, 726–740. [Google Scholar] [CrossRef]

- Narang, S.B.; Bahel, S. Low Loss Dielectric Ceramics for Microwave Applications: A Review. J. Ceram. Process. Res. 2010, 11, 316–321. [Google Scholar]

- Mirkhani, S.A.; Shayesteh Zeraati, A.; Aliabadian, E.; Naguib, M.; Sundararaj, U. High Dielectric Constant and Low Dielectric Loss via Poly(Vinyl Alcohol)/Ti3C2Tx MXene Nanocomposites. ACS Appl. Mater. Interfaces 2019, 11, 18599–18608. [Google Scholar] [CrossRef]

- Bele, A.; Cazacu, M.; Stiubianu, G.; Vlad, S.; Ignat, M. Polydimethylsiloxane-Barium Titanate Composites: Preparation and Evaluation of the Morphology, Moisture, Thermal, Mechanical and Dielectric Behavior. Compos. Part B Eng. 2015, 68, 237–245. [Google Scholar] [CrossRef]

- Kumar, A.; Ahmad, D.; Patra, K. Barium Titanate Particle Filled Silicone Elastomer Composite: Preparation and Evaluation of Morphology and Mechanical Behaviour. J. Phys. Conf. Ser. 2019, 1240, 12049. [Google Scholar] [CrossRef]

- Vrejoiu, I.; Pedarnig, J.D.; Dinescu, M.; Bauer-Gogonea, S.; Bäuerle, D. Flexible Ceramic-Polymer Composite Films with Temperature-Insensitive and Tunable Dielectric Permittivity. Appl. Phys. A Mater. Sci. Process. 2002, 74, 407–409. [Google Scholar] [CrossRef]

- Tomar, R.; Pandey, R.; Singh, N.B.; Gupta, M.K.; Gupta, P. Electrical Properties of Barium Titanate in Presence of Sn2+ Dopant. SN Appl. Sci. 2020, 2, 1–7. [Google Scholar] [CrossRef]

- Sheima, Y.; Yuts, Y.; Frauenrath, H.; Opris, D.M. Polysiloxanes Modified with Different Types and Contents of Polar Groups: Synthesis, Structure, and Thermal and Dielectric Properties. Macromolecules 2021, 54, 5737–5749. [Google Scholar] [CrossRef]

- Jian, G.; Jiao, Y.; Meng, Q.; Wei, Z.; Zhang, J.; Yan, C.; Moon, K.S.; Wong, C.P. Enhanced Dielectric Constant and Energy Density in a BaTiO3/Polymer-Matrix Composite Sponge. Commun. Mater. 2020, 1, 1–12. [Google Scholar] [CrossRef]

- Raza, M.H.; Butt, S.U.; Khattak, A.; Alahmadi, A.A. Investigation of Ramped Compression Effect on the Dielectric Properties of Silicone Rubber Composites for the Coating of High-Voltage Insulation. Materials 2022, 15, 2343. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Drymiskianaki, A.; Katsara, K.; Manousaki, A.; Viskadourakis, Z.; Kenanakis, G. Dielectric Behavior of Stretchable Silicone Rubber–Barium Titanate Composites. Crystals 2024, 14, 160. https://doi.org/10.3390/cryst14020160

Drymiskianaki A, Katsara K, Manousaki A, Viskadourakis Z, Kenanakis G. Dielectric Behavior of Stretchable Silicone Rubber–Barium Titanate Composites. Crystals. 2024; 14(2):160. https://doi.org/10.3390/cryst14020160

Chicago/Turabian StyleDrymiskianaki, Argyri, Klytaimnistra Katsara, Alexandra Manousaki, Zacharias Viskadourakis, and George Kenanakis. 2024. "Dielectric Behavior of Stretchable Silicone Rubber–Barium Titanate Composites" Crystals 14, no. 2: 160. https://doi.org/10.3390/cryst14020160

APA StyleDrymiskianaki, A., Katsara, K., Manousaki, A., Viskadourakis, Z., & Kenanakis, G. (2024). Dielectric Behavior of Stretchable Silicone Rubber–Barium Titanate Composites. Crystals, 14(2), 160. https://doi.org/10.3390/cryst14020160