Abstract

It has been reported that the multiphase structure with martensite and a mixed structure obtained by the quenching and tempering of bearing steel shows high strength and ductility. However, there appears to be no study on the effects of very-high-cycle fatigue (VHCF) and ultrasonic nanocrystal surface modification (UNSM) of a new bearing steel required for the durability design of next-generation bearing steel. This study analyzed the characteristics of microstructure transformation associated with heat treatment cycles and studied and evaluated the fatigue strength characteristics by the UNSM. Fisheye cracks occur from small inclusions inside the specimen only in martensitic microstructure materials in the long-life range. And the characteristic of a double S-N curve in which the fatigue limit decreased in two stages appeared. However, fisheye cracks and double S-N curves did not appear in pearlite and mixed-structure materials.

1. Introduction

Bearing steel (STB2) (JIS: SUJ2) is called high-carbon chrome alloy steel and is widely used in roller bearings, ball bearings, and slim bearings. The use of bearings is increasing as a major part of high-speed rotating bodies such as aircraft, ships, industrial robots, the main bearings of wind turbines, and automobiles, and research is being conducted to obtain effective results on the long-life fatigue strength of bearing steels.

Bearing steel is a major component of all mechanical devices. However, inclusions such as TiN and Al2O3 are frequently observed as the origin of cracks in the VHCF (very-high-cycle fatigue) area, and the S-N curve falls again, making duplex S-N curves.

Therefore, manufacturers of bearing materials have increasingly attempted to reduce the size and amount of inclusions, such as TiN and Al2O3. The test material for this study adopted and used a new material obtained through the development of this series of bearing steels [1,2,3,4,5,6,7].

In this study, the new bearing steel is used as a specimen to study the physical properties of the new bearing steel with a martensitic structure tempered by Q/T (quenching and tempering) heat treatment and a mixed microstructure heat-treated by austempering [7,8,9].

In other words, the fatigue and microstructure characteristics of VHCF, according to the transformation of the microstructure of the new bearing steel, are quantitatively analyzed through EBSD (electron back scatter diffraction) analysis, and the fatigue and strength characteristics according to the effect of the UNSM (ultrasonic nanocrystal surface modification) treatment are analyzed. They were studied and analyzed using fracture mechanics techniques and fracture analysis.

2. Materials, Test Methods, and Results

2.1. Test Material and Heat Treatment Method

The chemical composition of the new bearing steel is mainly composed of C 1.0%, Si 0.25%, Mn 0.35%, and Cr 1.45%. The mechanical properties are summarized in Table 1, and this test material before heat treatment was called BAR (bearing, as received).

Table 1.

Mechanical properties.

The test piece that was subjected to quenching and tempering (Q/T) heat treatment was called BQT (bearing, quenching, and tempering) material, and the austempered material was called BAT (bearing, austempering) material. The etching solution for the microstructure observation was 5 mL HCl + 1 g picric acid + 100 mL ethanol (95%).

Heat treatment of BQT material is by austenitizing the material cut into 12 mm in diameter and 110 mm in length at 840 °C for 50 min in air, cooling with water at 70 °C for 15 min, quenching, and salt bathing at 180 °C for 90 min in air cooling. Additionally, the BAT material was austenitized in air at 840 °C for 50 min, treated with a salt bath at 220 °C for 45 min, and then cooled in air.

2.2. UNSM Processing Technology

UNSM processing technology applies ultrasonic vibration energy to apply more than 20,000 hits per second (about 1000 to 10,000 times/mm2) to the metal surface with a ball with very large static and dynamic loads, transforming the surface into a micronized structure. As a result, the microstructure of the surface layer is reformed into a nanocrystalline structure and at the same time, it is a technology that forms very large and deep compressive residual stresses.

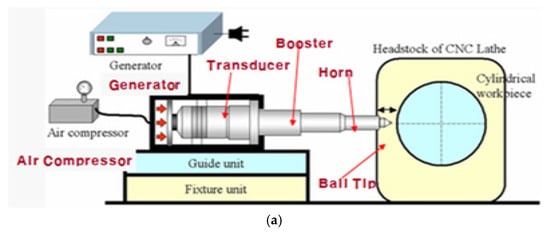

Figure 1a shows the processing system of UNSM, which consists of a generator that generates ultrasonic frequencies, an air compressor that applies a static load, a transducer that generates mechanical ultrasonic waves, a booster that amplifies the generated ultrasonic waves, a horn that transmits the amplified ultrasonic waves, and ultrasonic vibration energy. It consists of a ball tip that is ultimately delivered to the workpiece.

Figure 1.

(a) UNSM system, (b) micro forging traces by SEM photo, and (c) 3D image of atomic force microscope (AFM) after UNSM treatment.

Figure 1b is an example of micro forging traces that appeared on the surface after UNSM treatment observed at 3 K× magnification using an SEM (scanning electron microscope, FE-SEM, S-4300, Hitachi, Japan).

Also, Figure 1c shows the traces of 3D forging using an atomic force microscope (AFM, Scanning Probe Microscope, NX20, Canton, MA, USA). When UNSM technology is applied to the surface in this way, it has characteristics such as the formation of micro-dimples on the surface, improvement in surface roughness, increase in surface hardness, nanoization of crystals, and formation of deep and large compressive residual stress. Therefore, in fields such as VHCF (very-high-cycle fatigue) and SCC (stress corrosion cracking), the increase in durability and fatigue strength is very large, and the tribology characteristics are improved and wear resistance is greatly improved by reducing the coefficient of friction [10,11,12].

2.3. Tensile Test and Results

The new bearing steel was machined into a tensile test specimen (ASTM A370). Tensile tests were performed using an Instron universal testing machine at a strain rate of 0.02 mm/s according to the specifications of ASTM A370.

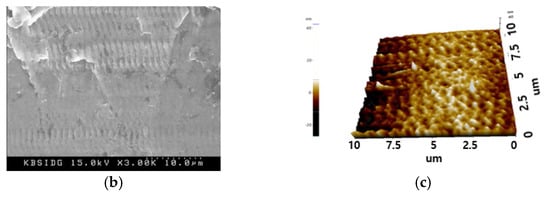

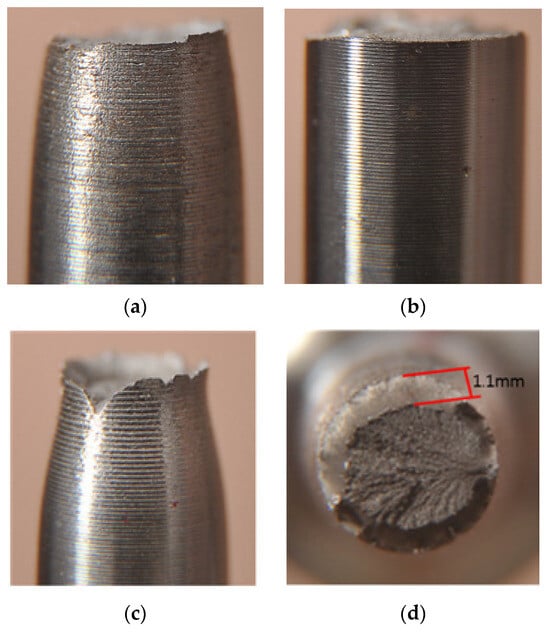

The tensile test results in Figure 2 were received as an Excel file and organized into stress and strain diagrams. Here, the BAR is shown as a dashed line in the stress–strain diagram in Figure 2, and the results were obtained with a tensile strength of 926 MPa, a yield strength of 577 MPa, an elongation rate of 17.2%, and a reduction in area rate of 40.5%.

Figure 2.

Stress–strain diagrams of a clean bearing steel.

The BQT material is indicated by a dotted line and has a tensile strength of 1993 MPa, a yield strength of 1100 MPa, an elongation of 1.2%, and a reduction in area rate of 2.5%. Additionally, the BAT is indicated by a solid line and has a tensile strength of 1302 MPa, a yield strength of 929 MPa, an elongation rate of 17%, and a reduction in area rate of 48.1%.

Here, the tensile strength of the BQT increased by 115.2% compared to the BAR, and the tensile strength of the BAT increased by 40.6% compared to the BAR. Additionally, the tensile strength of BQT increased by 53.1% compared to BAT. In this way, the tensile strength of BQT increases significantly compared to BAR and BAT materials, but the decrease in an elongation rate and cross-sectional shrinkage is due to the microstructure transformation of martensite by Q/T treatment.

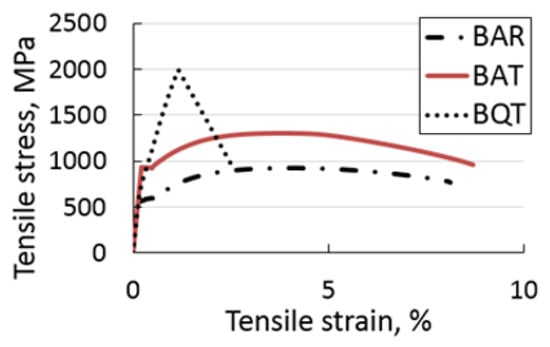

Figure 3a is a case where the side view of the tensile test piece of BAR was observed with an optical camera. In this picture, about 60% of the cup and cone shapes with a height of 0.25 mm were formed, and some local necking was formed.

Figure 3.

Visual observation of the side views of the tensile test specimens of the bearings: (a) BAR, (b) BQT, and (c) BAT. (c,d) is the fracture views of the BAT specimen, and the cup and cone are formed in a saw-tooth shape.

Figure 3b shows the results of the BQT material. There were no cups and cones observed in Figure 3a, and there was little change in the diameter of the smooth part and little local shrinkage. Therefore, in the diagram in Figure 2, it fractured with little deformation. However, as shown in Figure 3c,d, the BAT material has cups and cones with a height of about 1.1 mm and a large width in a saw-tooth shape, so it can be determined that the diameter change and local shrinkage of the smooth part are large.

2.4. Hardness Test and Test Results

Hardness was measured using a Vickers hardness meter (JP/HM-112, Mitutoyo, Japan). The first and second measurements were made 10 times, based on the center (origin) of the test piece, with a load of 5 N. In addition, because the structure formed of pearlite has a large deviation, the hardness was measured three times with a load of 10 N.

In other words, since the hardness value tends to vary greatly depending on the test piece and location, the surface hardness of the test piece was measured using a Rockwell hardness tester (Instron Wolpert Tester 2000, Santa Clara, CA, USA) and is summarized in Table 2. Here, the standard deviation (S.D.) of Rockwell hardness is 1.18 for BQT, 0.36 for BAR, and 5.35 for BAT material. The numbers in ( ) are the values converted from Rockwell hardness to Vickers hardness.

Table 2.

Hardness test results.

Here, when comparing the difference between the converted value of Rockwell hardness and the average value of Vickers hardness, the difference is small for BQT, but the difference is large for BAR and BAT. This is believed to be related to pearlite, the microstructure of the test piece.

In Table 2, the average Vickers hardness of BQT increased significantly by 103.1% compared to BAR and 105.9% compared to BAT. In other words, the BQT is analyzed to have a martensite structure depending on the heat treatment conditions, and the BAT is analyzed to be a mixture of pearlite structure and retained austenite structure (see Figure 4c), and it is believed and expected to be an effect of the transformation of the microstructure according to the set temperature and main ingredients.

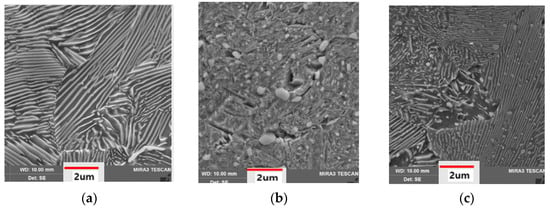

Figure 4.

Example of SEM observation at 20,000× BAR (a), (b) BQT, and (c) BAT specimens.

2.5. Fatigue Test and UNSM Processing Method

The diameter and radius of curvature of the fatigue test specimen are 3.0 mm and 7.0 mm, respectively, and the stress concentration coefficient Kt = 1.02. For the test pieces, abrasive paper from No. 100 to No. 2000 was used. The fatigue life of the new bearing steel at room temperature was tested in air under the conditions of a frequency of 53 Hz and a stress ratio R = −1 using a cantilever rotary bending fatigue tester (YRB200, Yamamoto, Japan) [2,3,4,5].

The UNSM processing technology used in this study causes the microstructure to become nano-structured, surface hardness is improved, and deep compressive residual stress is formed on the surface, as described in the literature [10,11,12].

3. Research Results and Discussions

3.1. Electron Microscope Observation of Microstructural Transformation Due to Heat Treatment

Figure 4 shows examples of observation using a scanning electron microscope (SEM, S4200, Hitachi, Japan). The microstructure of the BAR in Figure 4a showed layered pearlite at 20 K×. Figure 4b is a BQT material, and martensite and retained austenite structures were mainly observed at 20 K×. Figure 4c is of BAT material, and the pearlite structure and retained austenite structure are mixed.

3.2. Analysis by EBSD

The samples used for the EBSD of the new bearing steel were electro-polished in a mixed solution of 10% perchloric acid and 90% acetic acid and were set under the condition that the crystal size was 0.1 μm or more. The EBSD measurement device used in this study was DigiView EBSD Camera, EDAX (USA), and the measurement conditions were an acceleration voltage of 18 kV.

Figure 5a shows data for BAR, and the average particle size of the microstructure is about 3.53 μm (max. 19.53 μm, min. 1.31 μm). Figure 5a is an IQ (image quality) map showing the clarity of the electron beam diffraction pattern. The black area is the area where the IQ appears low and is due to increased crystal lattice distortion due to elastoplastic deformation.

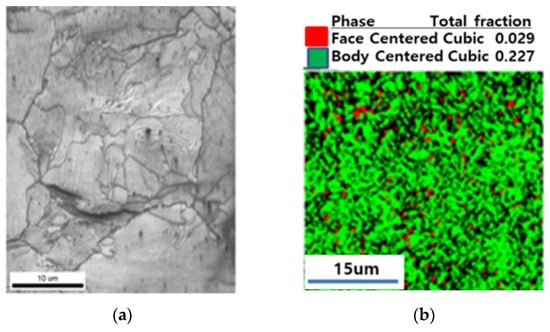

Figure 5.

(a) EBSD data of BAR specimen IQ. (b) EBSD data of BQT specimen, phase map. (c) Comparison of FCC IPF by EBSD data of the BQT specimen at 5 K×; (d) EBSD data for BAT specimens. phase map.

Figure 5b is the phase map of BQT, which is a martensitic structure. What appears in light green in this map is α-Fe (ferrite) with a body-centered cubic (BCC) crystal, with a ratio of 22.7%. Also, the small red dot is γ-Fe (austenite), which has a face-centered cubic (FCC) crystal structure and a ratio of 2.9%. Also, the part shown in black is the part that is not expressed during filtering because it does not meet the conditions.

In Figure 5b, lath-type martensite (BCT, body-centered tetragonal) has an average microstructure length of 1.67 μm (max. 2.87 μm, min. 0.31 μm) and an average width of 0.71 μm (max. 1.52 μm, min. 0.30 μm). For reference, the EBSD equipment used in this study recognizes all BCT images as BCC.

Figure 5c is the reverse pole map of the FCC phase and BCC phase of BQT material. There is almost no FCC phase (2.9%) of γ-Fe in the martensite structure, which means that the phase transformation of austenite to martensite has sufficiently progressed.

Figure 5d is a map of the inverse pole of BAT. The grains are isotropic, and the average grain size of the structure is 3.89 μm (max. 10.89 μm, min. 0.98 μm). In EBSD analysis, α-Fe was 77.3% and Fe3C was 22.7%, showing insufficient microstructure transformation. In other words, BAT material has a lot of retained austenite and has high strength as FCC.

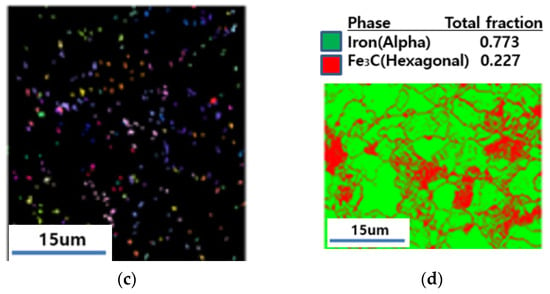

Figure 6a is the phase transformation diagram of the Fe-Fe3C system, which analyzes the structure formed by temperature and carbon content according to the Cr content [13]. Here, the new bearing steel has 1.0 C and 1.45 Cr as its main components, and its austenitization temperature is 840 °C (1113 K), so it corresponds to the red dot in the picture. This point is not austenite but an area where cementite and austenite are mixed. Therefore, layered cementite and retained austenite can be observed in Figure 4c.

Figure 6.

(a) The cementite spheroidization process in high-carbon steels with different chromium contents. (b) Data on retained austenite by tempering temperature and austenitizing temperature.

Figure 6b shows data on the retained austenite ratio according to tempering temperature and austenitization temperature [13]. In these data, when analyzing the BQT material at a tempering temperature of 840 °C and 180 °C, the austenite ratio is in the range of about 0.057. When analyzing the BAT material at tempering temperatures of 840 °C and 220 °C, the austenite ratio is in the range of about 0.025. Therefore, it matches well with the observation of a large number of layered pearlite and small grains of retained austenite in the 20k times magnified photograph of the BAT material in Figure 4c.

Table 3 quantitatively compares the differences in the components of BCC, FCC, and HCP in Figure 5 among the EBSD analysis data. The BAT material of new bearing steel is characterized by a high ratio of BCC and HCP. It was proven that the heat treatment conditions were unsuitable due to the high HCP ratio, which is not present in BQT material.

Table 3.

Comparison of BCC, FCC, and HCP of phase map using EBSD data.

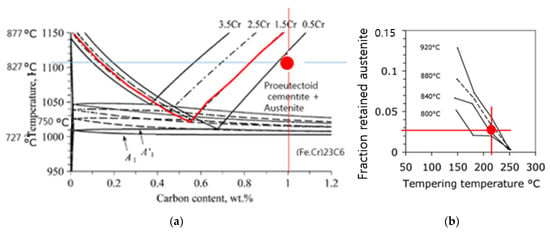

3.3. S-N Curve and Fatigue Characteristics

3.3.1. S-N Curve of BQT Material and UNSM Treatment Effect

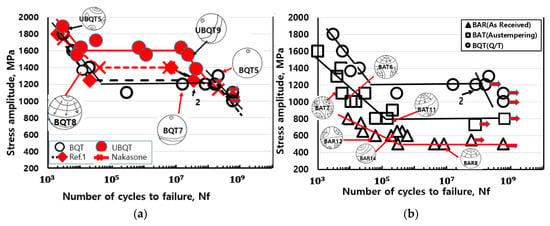

Figure 7a shows the S-N curve of BQT, a martensitic structure of new bearing steel, in the shape of ‘○’, along with the results of ordinary bearing research (indicated by ‘◆’ and a long dotted line) and Nakasone’s data (indicated by ‘X’ and a dotted line) compared with [4].

Figure 7.

(a) Comparison of S-N curves of BQT-bearing specimen before and after UNSM treatment and other reference data [1,2,3,4]. (b) Comparison of S-N curves before heat treatment (BAR) and after heat treatment (BQT and BAT) of a new bearing specimen.

In this figure, the fatigue limit of the BQT was shown at 1200 MPa, and the fatigue limit in the VHVF region showed a double S-N curve, which is a common feature in bearing steel [2,3,4,5]. In addition, in BQT material, all fisheye cracks occurred in the VHCF region after 106.

In Figure 7a, the macroscopic fracture characteristics were sketched and compared to the S-N data of the BQT at three stress levels. The BQT8 at 1390 MPa developed and grew one surface crack and fractured at 1.42 × 104. In the BQT5 at 1300 MPa, one fisheye crack occurred, grew, and fractured at 2.1 × 108. In addition, one fisheye crack occurred and grew in the BQT7 at 1200 MPa and fractured at 1.62 × 107.

In addition, in Figure 7a, the macroscopic fracture characteristics were sketched on the S-N data of the UBQT material. UBQT5 material at 1900 MPa developed and grew three surface cracks and fractured at 2.7 × 103. UBQT9 material at 1550 MPa developed and grew one fisheye crack and fractured at 2.2 × 107.

The characteristic of the above three stress levels of BQT is that fisheye cracks occurred in all VHCF areas after 106. The characteristics of UBQT are similar to those of BQT. However, due to the UNSM effect, both the fatigue life and fatigue limit increased compared to BQT material.

3.3.2. S-N Curve and Fatigue Characteristics of New Bearing Steel

Figure 7b shows a comparison of the S-N curves of the new bearing steel BAR used in this study, the BQT with a martensitic structure through Q/T treatment, and the austempered BAT material.

In Figure 7b, the macroscopic fracture characteristics of the S-N data of the BAR material were sketched at three stress levels. In the BAR8 at 500 MPa, one surface crack occurred, grew, and fractured at a life of 8.2 × 106. The BAR12 at 600 MPa fractured at 6.2 × 104 due to the occurrence, growth, and coalescence of five surface cracks. In addition, the BAR14 at 650 MPa developed and grew one surface crack and fractured at 2.9 × 105.

In Figure 7b, the macroscopic fracture characteristics were sketched and compared to the S-N data of the BAT material at three stress levels. The BAT7 at 1100 MPa developed, grew, and coalesced four surface cracks and fractured at a lifespan of 5.8 × 103. The BAT6 at 1000 MPa fractured at 1.1 × 104 due to the occurrence, growth, and coalescence of three small surface cracks. Additionally, in the BAT11 at 800 MPa, one surface crack occurred, grew, and fractured at 1.47 × 105.

The characteristics of the BAR stress levels above are that when the fatigue life is long, the number of surface cracks generated decreases, and when the fatigue life is short, the number of surface cracks increases, and cracks occur, grow, coalesce, and fracture. The characteristic at each stress level above is that in the VHCF area after 106 in BAT and UBAT materials, the double S-N curve, which is a characteristic of the occurrence of fisheye cracks and a two-stage change in fatigue strength in bearing steel, did not appear.

In this figure, the fatigue limit of the BAR appeared at about 500 MPa, and the fatigue limit of the BAT appeared at 800 MPa, an increase of about 60% compared to the BAR. In addition, the fatigue limit of BQT was found at 1200 MPa, which was a significant increase of about 140% compared to BAR. In particular, the fatigue strength of BQT, which has a martensitic structure, increased significantly compared to BAR, and fisheye cracks occurred in the VHCF area. In addition, the characteristic of a double S-N curve, in which the fatigue limit that occurs in general bearing steels decreases in two stages, appeared.

In this way, it is analyzed that the fatigue strength of BQT with a martensite phase structure is higher than that of the test material with pearlite structure. This phenomenon is consistent with the organizational observations, quantitative analysis, and previous research results reviewed previously [2,3].

In other words, the S-N curve in Figure 7b and Table 4 confirmed that the fatigue limit tended to increase in the order of BAR material < BAT material < BQT material. This is in good agreement with the observation of microstructure characteristics in Figure 4 and Figure 5, high-magnification SEM analysis, and the results of microstructure formation in the phase diagram.

Table 4.

Comparison of fatigue limit.

The fatigue limits of three types of new bearing steel (BAR, BQT, and BAT) and three UNSM-treated materials (UBAR, UBQT, and UBAT) according to the heat treatment conducted in this study were compared, as shown in Table 4. The fatigue limit of UBAR increased by 44% compared to BAR, and the fatigue limit of UBQT increased by 122% compared to UBAR, confirming that the UNSM treatment effect is useful, as shown in other research results [10,11,12].

In this way, the UNSM treatment increases the fatigue limit due to the treatment effect on the surface of the test specimen. This UNSM effect can reduce the production process, and the tendency to improve fatigue life and durability is due to nanoization of the surface structure, increase in surface hardness, decrease in surface roughness, and compressive residual stress, which are similar characteristics in other bearing steel materials.

3.3.3. Observation of Fatigue Fracture Surfaces of Surface Cracks and Fisheye Cracks

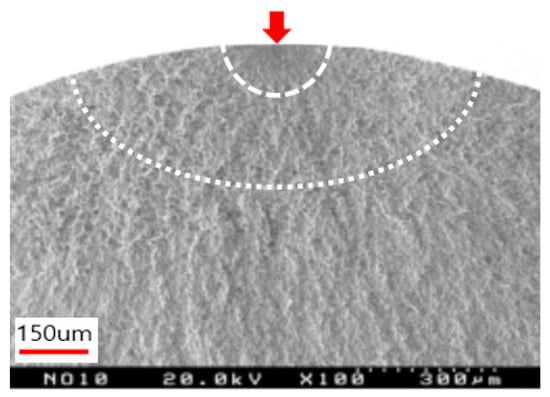

Figure 8 shows the SEM observation of the fracture surface of BQT8 (1390 MPa, Nf = 1.42 × 104), a martensitic structure of new bearing steel, at a magnification of 100×. In other words, the area indicated by the arrow is the origin of the major crack that induced fatigue fracture and occurs on the surface. The dotted lines of the circle and oval in the picture show the form in which the surface crack occurred and progressed, initially forming a semicircle and gradually growing into an oval [1,2,3,4,5,6,7,14,15,16,17,18,19,20,21]. This SEM fracture image is similar to the fatigue fracture surface of a strong metal, and the fracture surface has few curves and is flat.

Figure 8.

Fracture photo of a small surface crack that occurred and grew on the BQT8 specimen under 1390 MPa, Nf = 1.42 × 104.

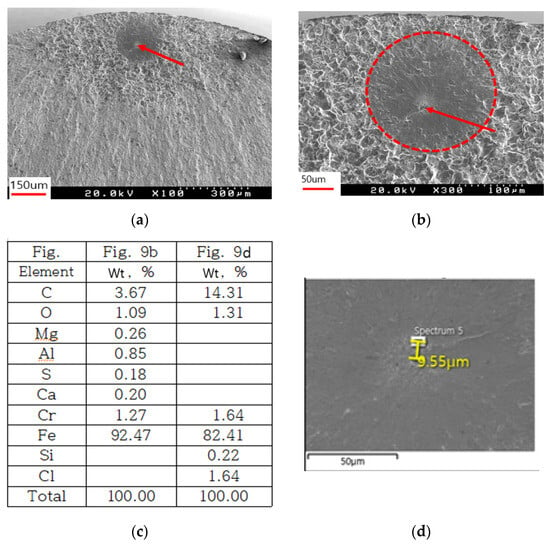

Figure 9a is observed at 100×, and Figure 9b is observed at 300× on BQT7 material (1150 MPa, Nf = 1.76 × 107). In this case, the internal originating fracture type that occurred inside the test specimen, indicated by a circle, is a fisheye crack with a fine granular area (FGA). Additionally, arrows indicate the location of cracks, such as inclusions that caused fisheye cracks. The occurrence and growth process of these fisheye cracks are similar to other research results [1,2,3,4,5,6,7,8,9,10,14,15,16,17,18,19,20,21].

Figure 9.

(a) is the observed case at 100× and (b) is 300× for BQT7 (1150 MPa, Nf = 1.76 × 107). The EDS analysis results of the fish eye crack (b) are summarized in (c). TiN and Al2O3, which are commonly contained in bearing steel, were not detected. (d) shows a position 9.55 μm away from the point indicated by the arrow in Figure (b), and the component analysis here is summarized in (c).

The results of the EDS analysis of the center of this fisheye crack (Figure 9b) are shown in Figure 9c. Here, TiN and Al2O3, which are common inclusions in bearing steel, were not detected.

Figure 9d shows a position 9.55 μm away from the point indicated by the arrow in Figure 9b, and the component analysis here is summarized in Figure 9c. Here too, Cr was detected at a slightly higher level, and C was detected at 14.31%. In addition, most of the samples were analyzed as Fe, and beyond the inclusions, 1.0% of C, 0.25% of Si, 0.35% of Mn, and 1.45% of Cr, which are the main components of the sample, appeared.

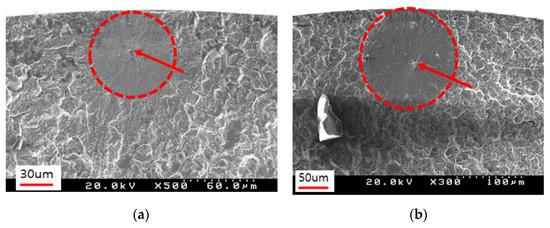

Figure 10a shows the fatigue fracture surface of the UBQT9 observed at 500× (1550 MPa, Nf = 2.2 × 107). The fracture type that occurred inside the test specimen is a fisheye crack (FGA), indicated by a circle, and the arrow indicates the origin. Figure 10b shows the fatigue fracture surface of UBQT6 observed at 300× (1400 MPa, Nf = 3.75 × 107). The two data were also similar to those of BQT material.

Figure 10.

(a) shows the fracture surface of UBQT9 at 500× (1550 MPa, Nf = 2.2 × 107) and is an FGA type. (b) is an observed example of 300× (1400 MPa, Nf = 3.75 × 107) for UBQT6 material.

The occurrence and growth process of fisheye cracks in BQT and UBQT materials are similar to other research results. In conclusion, the fisheye crack of the new bearing steel used in this study is a fracture form of a fisheye crack in which fatigue cracks occur and grow in very small inclusions, some of which are mainly composed of Al2O3. TiN inclusions, which are commonly observed in bearing steel, were not observed in this study, confirming that it is a relatively clean new bearing steel.

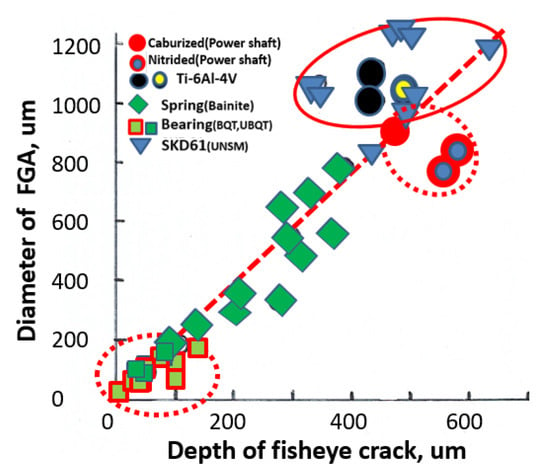

3.3.4. Relationship Between the Depth of Fisheye Crack Occurrence and the Diameter of FGA

Figure 11 simultaneously shows other research results on the relationship between the depth at which the fisheye crack occurred on the surface of the test specimen and the diameter of the FGA. That is, the data for bearing steels, SNCM420, SKD61 material, Ti-6Al-4V material, and bainite spring steel, are summarized in the figure and show good correlation with each other [3,4,5,6,8,9,10,11,12,22,23,24].

Figure 11.

The relationship between fisheye crack depth and FGA diameter is compared with reference data.

In the bearing steel that was the subject of this study, small fisheye cracks occurred close to the surface, as shown in the data indicated by the oval-shaped dotted line. That is, data on 10 fisheye cracks were compiled within a range of 19 to 150 µm of the specimen surface and a diameter of the FGA within a range of 32 to 200 um. Similar to SKD61 material, the carburizing material, nitriding material, and Ti-6Al-4V material of SNCM420 summarized in this figure have data collected within the range of 350–600 µm deep from the surface and 750–1100 µm in terms of FGA diameter.

In other words, the location of fisheye cracks is where the influence of surface-hardening layers such as carburizing, nitriding, and surface treatments such as UNSM disappears. In addition, bainitic spring steel had a predominant tendency for fisheye cracks to occur close to the surface (approximately 100 to 400 um).

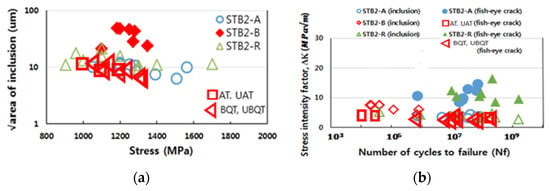

3.3.5. Fracture Mechanical Analysis of Inclusions

Figure 12a compares the relationship between bending stress and which is widely used in parameter analysis of inclusions and matrices, using the results of other bearing materials [2,3]. In this figure, it can be seen that the bearing material is widely distributed from a minimum of 7.6 to a maximum of 75.

Figure 12.

Comparison of bearing data of (a) and ΔK (b) of the matrix where the fisheye crack occurred with BQT and UBQT specimens.

However, BQT and UBQT materials are distributed from a minimum of 7.6 to a maximum of 14.3 and are marked with ‘◁’. In other words, the diameter of the inclusions is on the smaller side, and as shown in the data, it tends to converge to a certain value. Other bearing result values also tended to converge around 10 and were in good agreement with the results of this study [2,3,14,17].

Figure 12b shows the ΔK (stress intensity factor range) of the fisheye crack inclusions and matrix, respectively, and compares them with the data of four types of bearing steel and spring steel.

At this time, ΔK (MPa) used Equation (1).

Here, σ is the bending stress (MPa), and (μm) is the area of the fisheye crack, inclusion, and matrix.

In Figure 12b, ΔK of BQT and UBQT was obtained as 3.1 to 3.9 MPa. However, STB2-A and STB2-R materials approached 10 MPa and were similar to the value of ΔKth (lower limit stress intensity factor range) of steel materials.

In particular, thanks to the efforts of the developers of this new bearing, there were no TiN inclusions in the BQT and UBQT materials. In particular, fisheye cracks occurred where small materials such as Al2O3 were present, so the ΔKth value tended to be much lower than that of ordinary bearing steel.

4. Conclusions

In this study, SEM and EBSD analyzed the characteristics of microstructure transformation and inclusions caused by the heat treatment cycle of new bearing steel and studied VHCF characteristics and UNSM treatment effects to obtain the following results.

The fatigue limit of BQT, which has a martensitic structure, was 1200 MPa, which was approximately 140% higher than that of BAR. Only in the long life range of a martensitic structure (BQT, UBQT) did fisheye cracks occur from small inclusions inside the specimen, and the characteristic of a double S-N curve in which the fatigue limit decreased in two stages appeared. However, fisheye cracks and double S-N curves did not appear in pearlite and mixed-structure materials (BAR, UBAR, BAT, and UBAT).

In bearing steel, unlike other metal materials, fisheye cracks occurred close to the surface. That is, a fisheye crack with FGA diameters of 32 to 203 µm occurred within 19 to 150 µm of the specimen surface. As fisheye cracks in bearing steel occurred near the surface of the test specimen, the diameter of the FGA tended to decrease.

In the new bearing steel of martensitic structure (BQT and UBQT) materials, TiN and Cr matrices were not observed, and fisheye cracks occurred in the VHCF area due to small inclusions. However, in general bearing steel, fisheye cracks occurred at a rate of 80% TiN and 20% Al2O3, but in this bearing steel, TiN was eliminated through the developer’s efforts, and fisheye cracks occurred in small inclusions, which determined the fatigue life.

ΔK for BQT and UBQT was calculated to be 3.1 to 3.9. There are no TiN inclusions in BQT and UBQT materials, and fisheye cracks occur where small Al2O3 was present, so they are lower than the ΔKth (lower limit the stress intensity factor range) than ordinary bearing steels (STB2-A material and STB2-R material). It showed a tendency to become much lower than the stress intensity factor range value. However, ordinary bearing steels approached 10 and were similar to the ΔKth value of steel materials.

Author Contributions

Conceptualization, S.-H.N. and C.-M.S.; methodology, S.-K.J.; investigation, S.-H.N. and D.-K.K.; data curation, S.-K.J. and C.-M.S.; writing-original draft preparation, M.-S.S.; writing—review and editing, S.-H.N. and C.-M.S.; visualization, D.-K.K., and M.-S.S.; supervision, S.-H.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by Development of Reliability Measurement Technology for Hydrogen Refueling Station funded by Korea Research Institute of Standards and Science (KRISS–2024–GP2024-0010).

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

Dong-Kyun Kim was employed by the LG Innotek. The remaining author declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Chakraborty, J.; Bhattacharjeeb, D.; Mannaa, I. Development of Ultrafine Bainite + Martensite Duplex Microstructure in SAE 52100 Bearing Steel by Prior Cold Deformation. Scr. Mater. 2009, 61, 604–607. [Google Scholar] [CrossRef]

- Nahm, S.H.; Suh, M.S.; Suh, C.M.; Pyun, Y.S. Characteristics of Inclusions of Bearing Steels and Fish-eye Crack Mechanism. Trans. Korean Soc. Mech. Eng. A 2018, 42, 419–427. [Google Scholar] [CrossRef]

- Nahm, S.H.; Suh, M.S.; Suh, C.M.; Pyun, Y.S. A Study on the Very High Cycle Fatigue and Fracture Behavior of Bearing Steel by Ultrasonic Nanocrystal Surface Modification. Trans. Korean Soc. Mech. Eng. A 2018, 42, 513–521. [Google Scholar] [CrossRef]

- Nakasone, Y.; Hara, H. FEM Simulation of Growth of Fish-Eye Cracks in the Very High Cycle Fatigue of a High Strength Steel SUJ2. In Proceedings of the 3rd International Conference on Very High Cycle Fatigue (VHCF-3), Kusatsu, Japan, 16–19 September 2004; pp. 40–47. [Google Scholar]

- Sakai, T.; Sato, Y.; Oguam, N. Characteristic S-N properties of high-carbon-chromium-bearing steel under axial loading in long-life fatigue. Fatigue Fract. Eng. Mater. Struct. 2002, 25, 765–773. [Google Scholar] [CrossRef]

- Miyamoto, G.; Iwata, N.; Takayama, N.; Furuhara, T. Quantitative Analysis of Variant Selection in Ausformed Lath Martensite. Acta Mater. 2012, 60, 1139–1148. [Google Scholar] [CrossRef]

- Miyamoto, G.; Takayama, N.; Furuhara, T. Accurate Measurement of the Orientation Relationship of Lath Martensite and Bainite by Electron Backscatter Diffraction Analysis. Scrita Mater. 2009, 60, 1113–1116. [Google Scholar] [CrossRef]

- Roland, T.; Retraint, D.; Lu, K.; Lu, J. Fatigue Life Improvement through Surface Nanostructuring of Stainless Steel by Means of Surface Mechanical Attrition Treatment. Scr. Mater. 2006, 54, 1949–1954. [Google Scholar] [CrossRef]

- Dai, K.; Shaw, L. Analysis of Fatigue Resistance Improvements via Surface Severe Plastic Deformation. Int. J. Fatigue 2008, 30, 1398–1402. [Google Scholar] [CrossRef]

- Gill, A.; Telang, A.; Mannava, S.R.; Qian, D.; Pyun, Y.S.; Soyama, H.; Vasudevan, V.K. Comparison of Mechanisms of Advanced Mechanical Surface treatments in Nickel-Based Superalloy. Mater. Sci. Eng. A 2013, 576, 346–355. [Google Scholar] [CrossRef]

- Pyun, Y.S.; Kim, J.H.; Suh, C.M.; Cho, I.S.; Oh, J.Y.; Wang, Q.; Khan, M.K. The Rotary Bending Fatigue and Ultrasonic Fatigue Performance of Ti-6Al-4V ELI and STA Alloys after Ultrasonic Nanocrystal Surface Modification Treatment. In Proceedings of the 6th International Conference on VHCF, Chengdu, China, 5–18 October 2014. [Google Scholar]

- Nahm, S.H.; Shim, H.B.; Baek, U.B.; Suh, C.M. Very High Cycle Fatigue Behaviors and Surface Crack Growth Mechanism of Hydrogen-Embrittled AISI 304 Stainless Steels. Mater. Sci. Appl. 2018, 9, 393–411. [Google Scholar] [CrossRef][Green Version]

- Luzginova, N.V.; Zhao, L.; Sietsma, J. The Cementite Spheroidization Process in High-Carbon Steels with Different Chromium Contents. Metall. Mater. Trans. A 2008, 39, 513. [Google Scholar] [CrossRef]

- Gu, C.; Liu, W.-Q.; Lian, J.-H.; Bao, Y.-P. In-depth analysis of the fatigue mechanism induced by inclusions for high-strength bearing steels. Int. J. Miner. Metall. Mater. 2021, 28, 826–834. [Google Scholar] [CrossRef]

- Bomas, H.; Linkewitz, T.; Mayr, P. Application of a weakest-link concept to the fatigue limit of the bearing steel SAE 52100 in a bainitic condition. Fatigue Fract. Eng. Mater. Struct. 1999, 22, 733–742. [Google Scholar]

- Laia, J.; Rydénb, K.; Gabellia, A.; Strandell, I. The fatigue limit of bearing steels—Part I: A pragmatic approach to predict very high cycle fatigue strength. Int. J. Fatigue 2012, 37, 155–168. [Google Scholar] [CrossRef]

- Cerullo, M. Sub-Surface Fatigue Crack Growth at Alumina Inclusions in AISI 52100 Roller Bearings. Procedia Eng. 2014, 74, 333–338. [Google Scholar] [CrossRef]

- Spriestersbach, D.; Brodyanski, A.; Lösch, J.; Kopnarski, M.; Kerscher, E. Very high cycle fatigue of bearing steels with artificial defects in vacuum. Mater. Sci. Technol. 2016, 32, 1111–1118. [Google Scholar] [CrossRef]

- Mayer, H. Fatigue crack growth and threshold measurements at very high frequencies. Int. Mater. Rev. 2013, 44, 1–34. [Google Scholar] [CrossRef]

- Mayer, H.; Haydn, W.; Schuller, R.; Issler, S.; Furtner, B.; Bacher-Höchst, M. Very high cycle fatigue properties of bainitic high carbon–chromium steel. Int. J. Fatigue 2009, 31, 242–249. [Google Scholar] [CrossRef]

- Darisuren, S.; Park, J.H.; Pyun, Y.S.; Amanov, A. A Study on the Improvement of the Fatigue Life of Bearings by Ultrasonic Nanocrystal Surface Modification Technology. Metals 2019, 9, 1114. [Google Scholar] [CrossRef]

- Suh, C.M.; Nahm, S.H.; Kim, J.H.; Pyun, Y.S. A Study on the VHCF Fatigue Behaviors of Hydrogen Attacked Inconel 718 Alloy. Trans. Korean Soc. Mech. Eng. A 2016, 40, 637–646. [Google Scholar] [CrossRef]

- Suh, C.M.; Pyun, Y.S.; Suh, M.S. Variation of Rotating Bending Fatigue Characteristics by UNSM on Ti-6Al-4V. J. Ocean Eng. Technol. 2011, 25, 49–55. [Google Scholar] [CrossRef]

- Suh, C.M.; Song, G.H.; Suh, M.S.; Pyun, Y.S. Fatigue and Mechanical Characteristics of Nanostructured Tool Steel by Ultrasonic Cold Forging Technology. Mater. Sci. Eng. A 2007, 443, 101–106. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).