On the Peculiarities of Wire-Feed Electron Beam Additive Manufacturing (WEBAM) of Nickel Alloy–Copper Bimetal Nozzle Samples

Abstract

1. Introduction

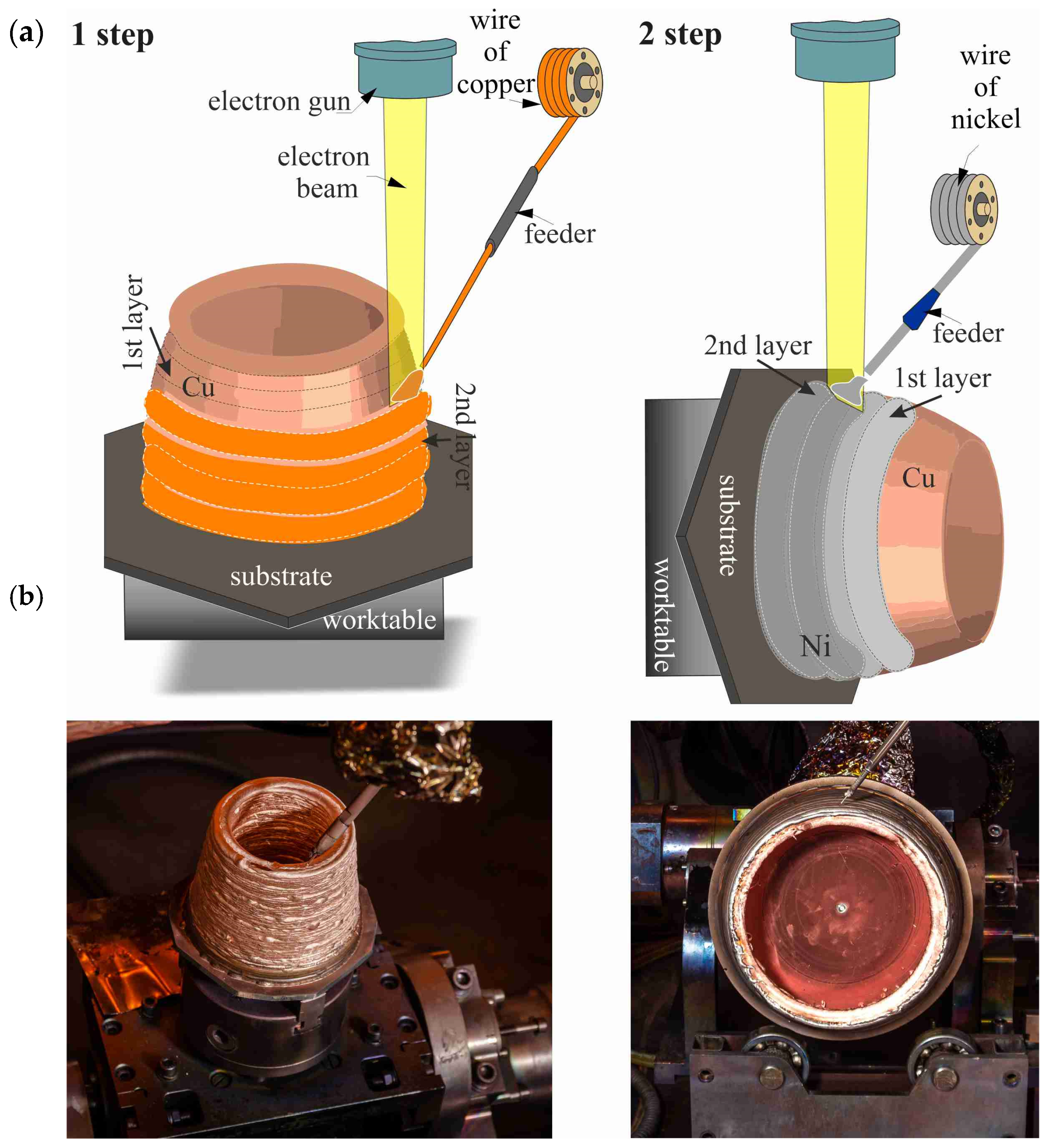

2. Materials and Methods

3. Results

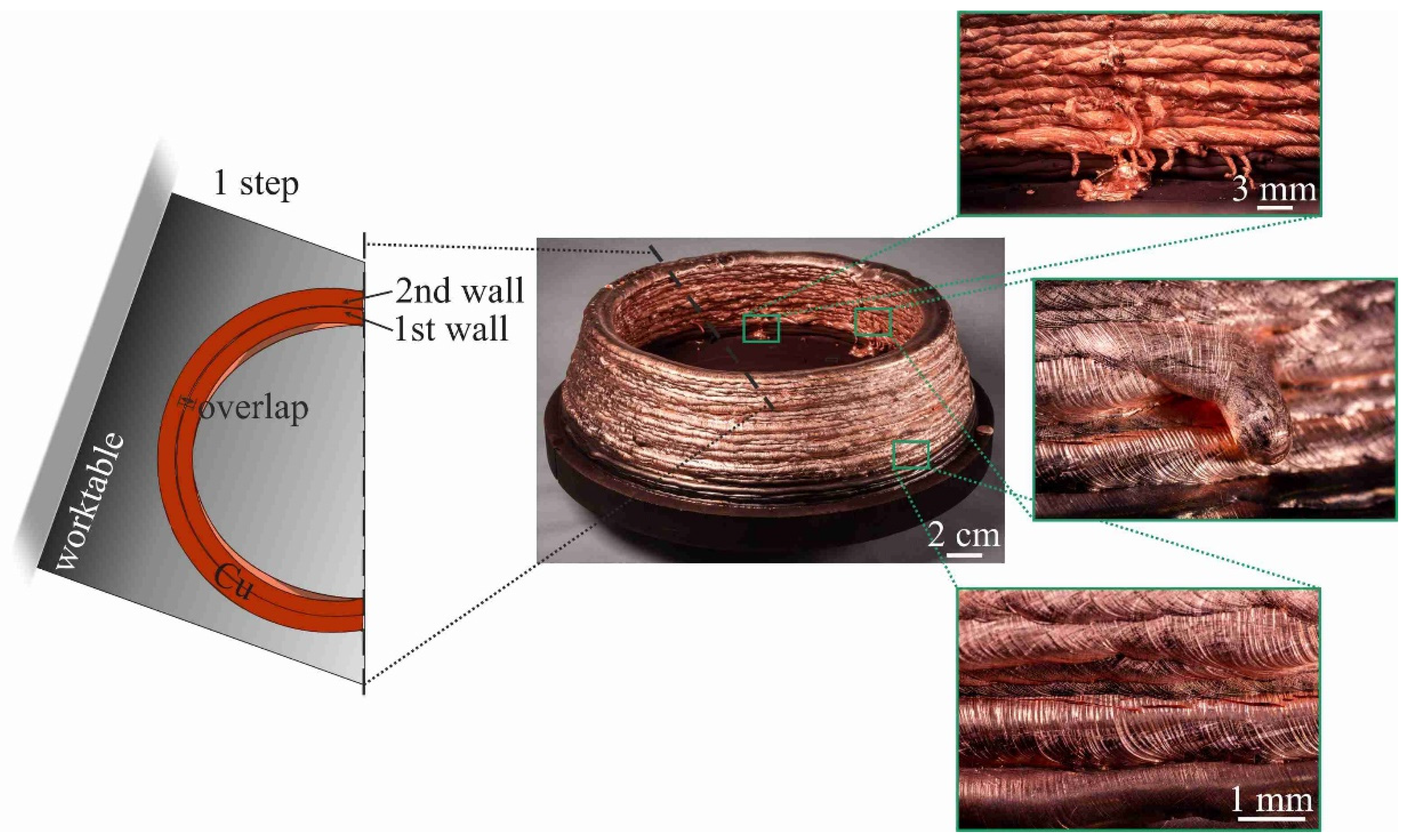

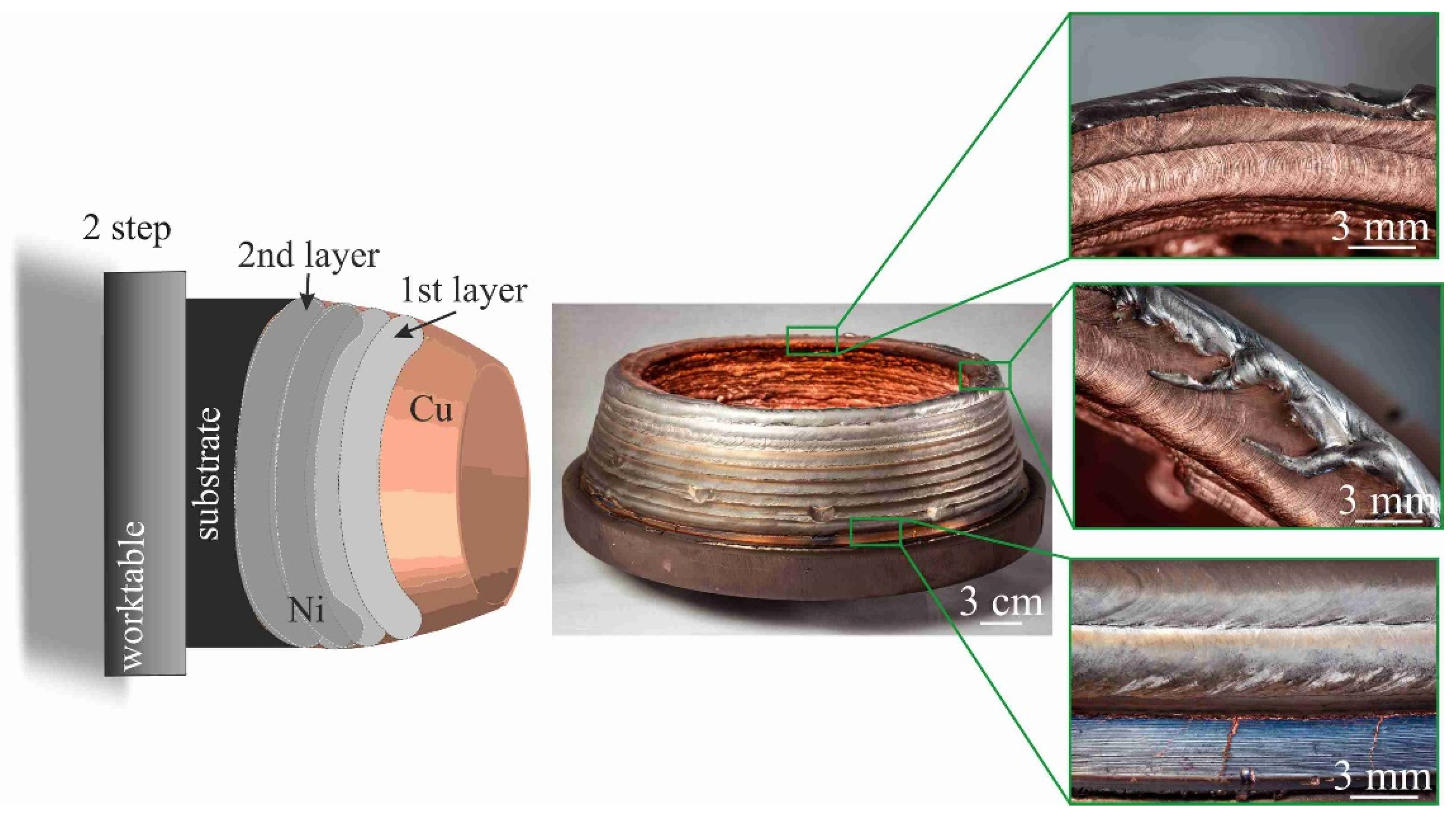

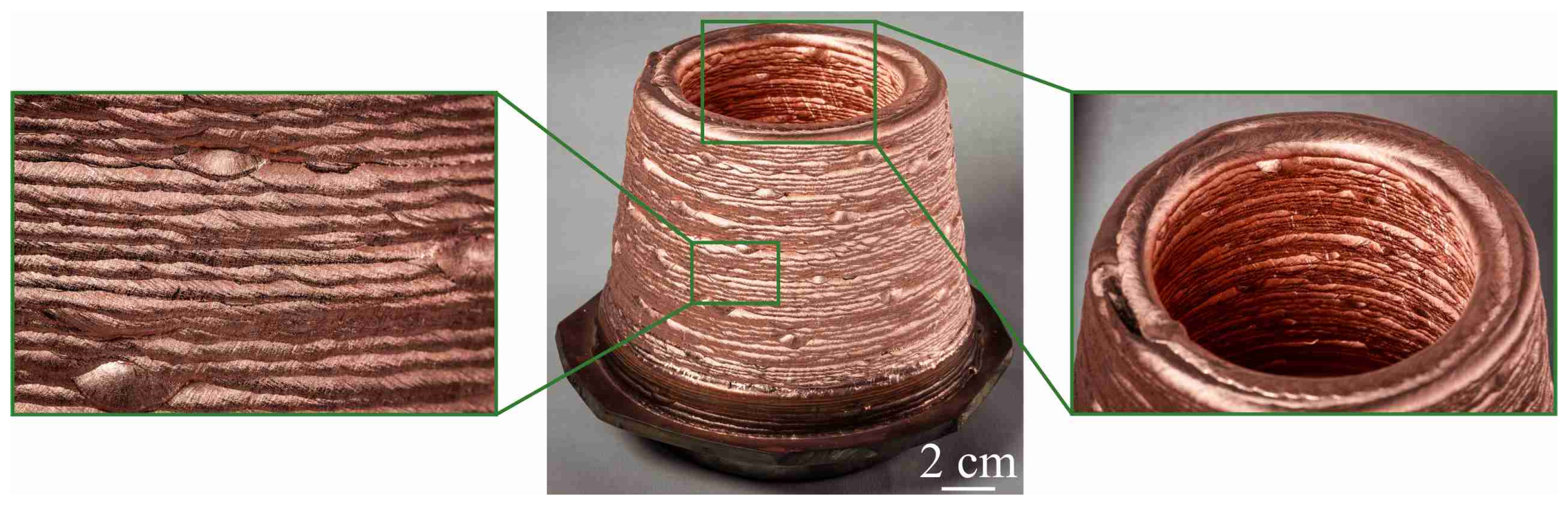

3.1. Macrostructure

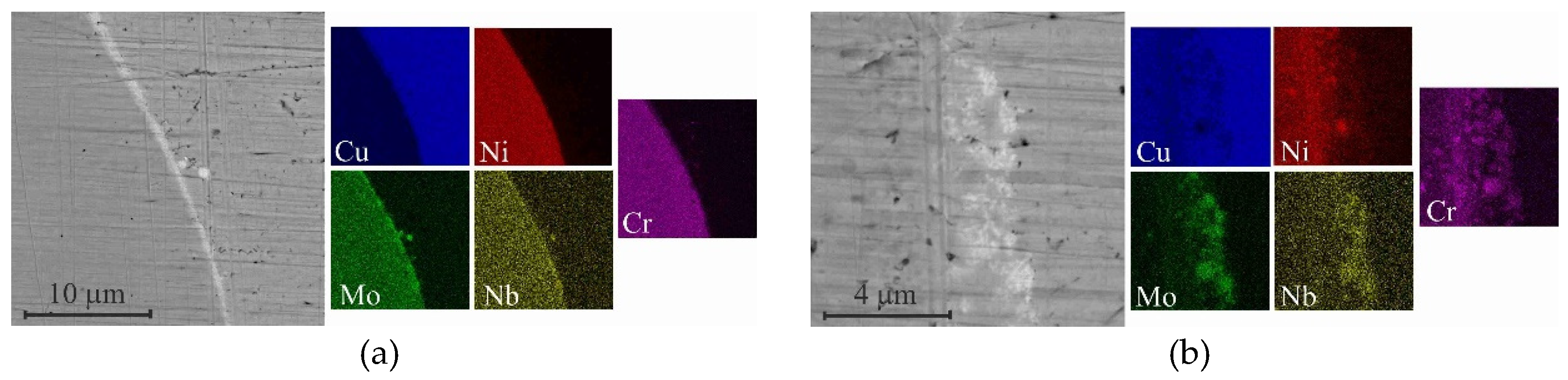

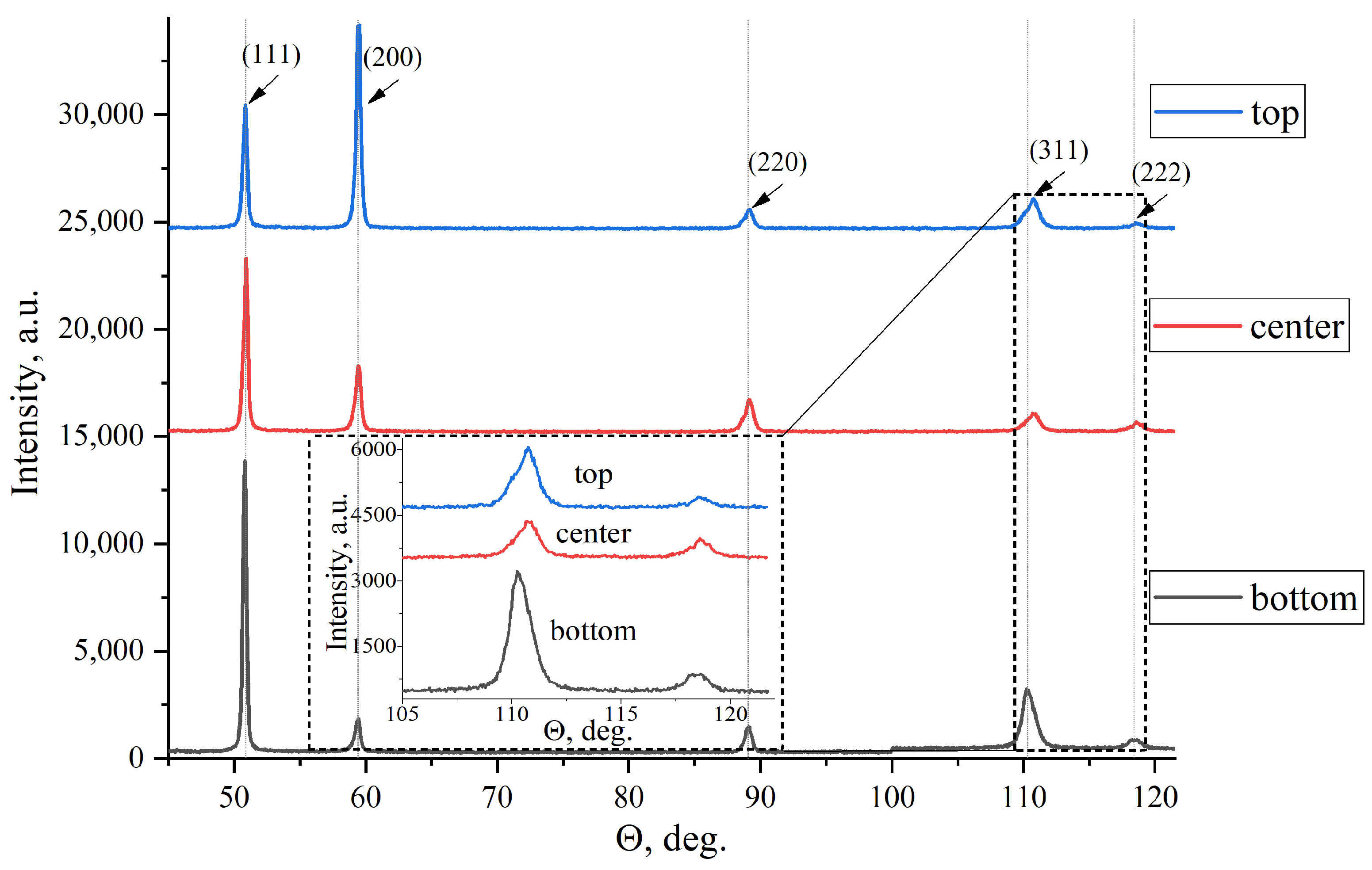

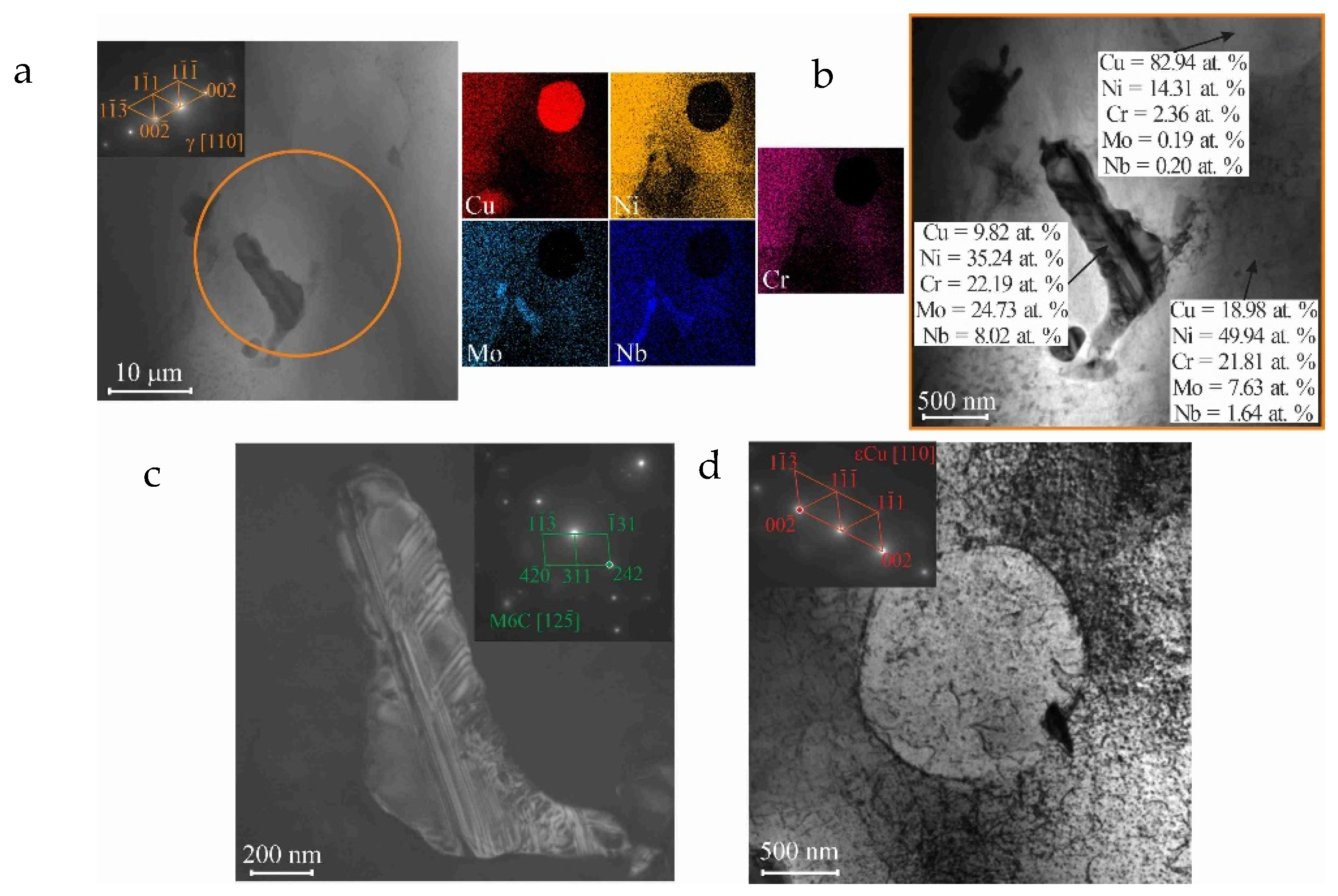

3.2. Microstructure

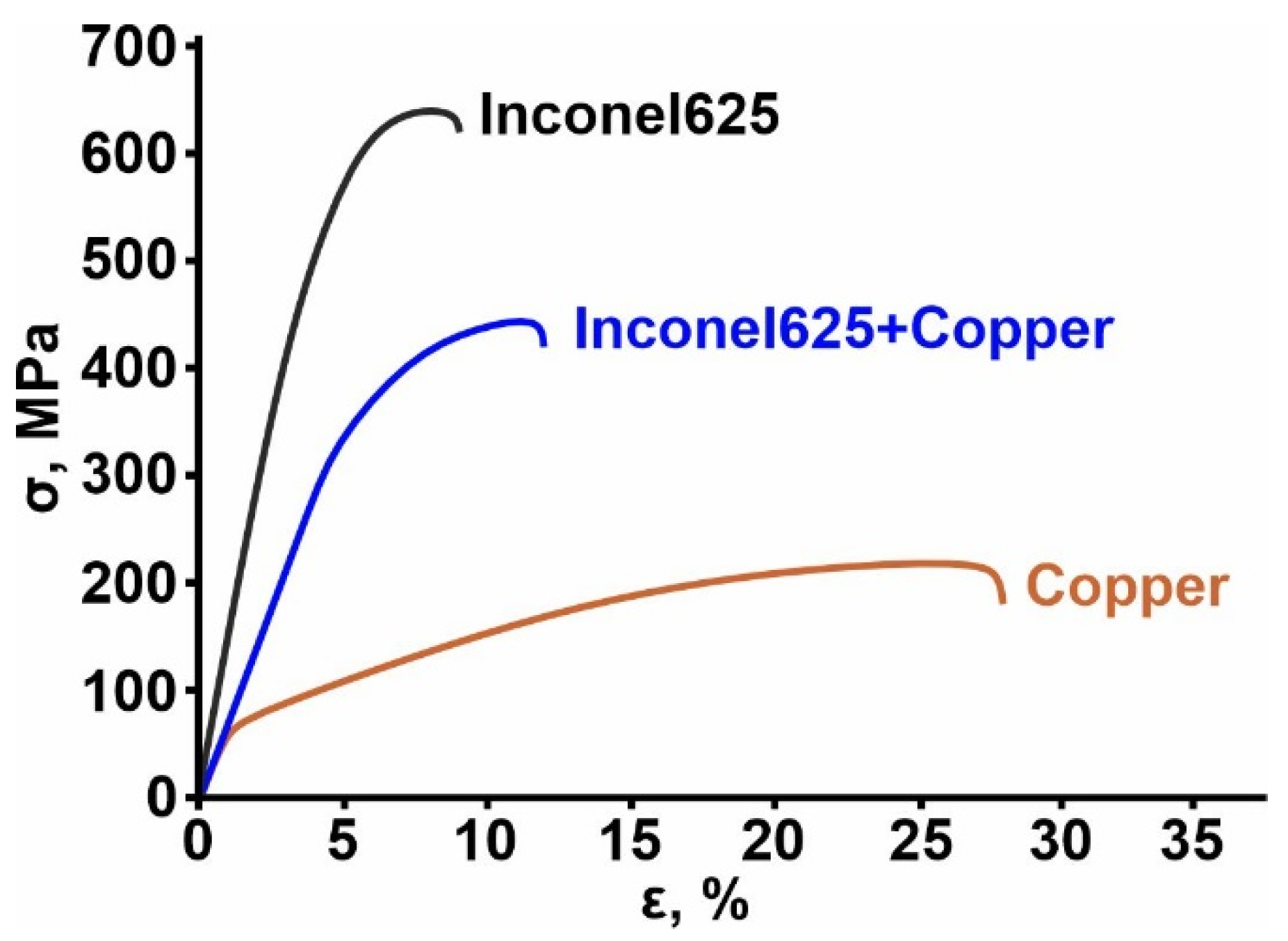

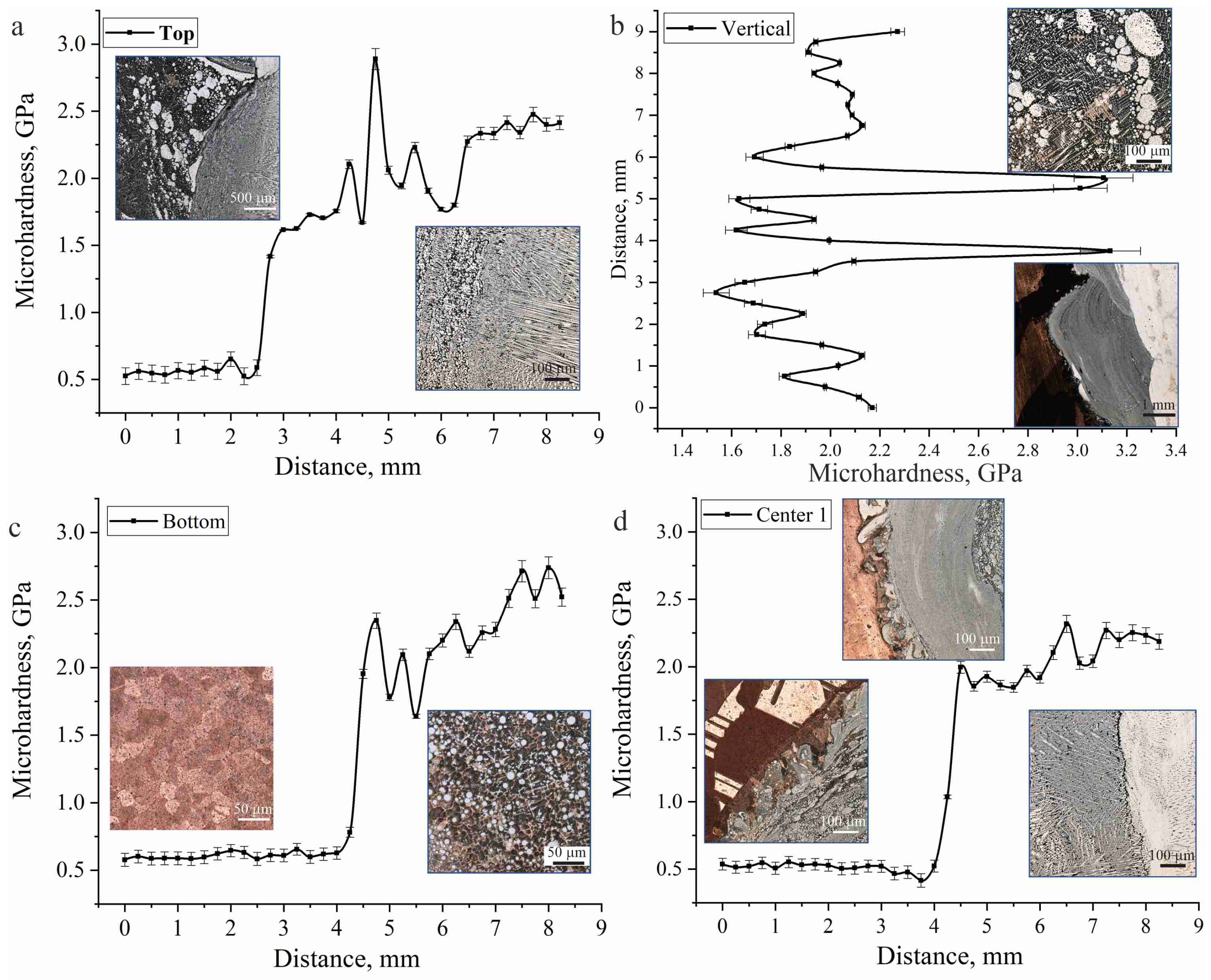

3.3. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Huang, S.H.; Liu, P.; Mokasdar, A.; Hou, L. Additive manufacturing and its societal impact: A literature review. Int. J. Adv. Manuf. Technol. 2013, 67, 1191–1203. [Google Scholar] [CrossRef]

- Sugavaneswaran, M.; Arumaikkannu, G. Modelling for randomly oriented multi material additive manufacturing component and its fabrication. Mater. Des. 2014, 54, 779–785. [Google Scholar] [CrossRef]

- Zheng, X.; Guo, X.; Watanabe, I. A mathematically defined 3D auxetic metamaterial with tunable mechanical and conduction properties. Mater. Des. 2021, 198, 109313. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Wang, Z.; Palmer, T.A.; Beese, A.M. Effect of processing parameters on microstructure and tensile properties of austenitic stainless steel 304L made by directed energy deposition additive manufacturing. Acta Mater. 2016, 110, 226–235. [Google Scholar] [CrossRef]

- Mehnen, J.; Ding, J.; Lockett, H.; Kazanas, P. Design study for wire and arc additive manufacture. Int. J. Prod. Dev. 2014, 19, 2–20. [Google Scholar] [CrossRef]

- Williams, S.W.; Martina, F.; Addison, A.C.; Ding, J.; Pardal, G.; Colegrove, P. Wire + arc additive manufacturing. Mater. Sci. Technol. 2016, 32, 641–647. [Google Scholar] [CrossRef]

- Li, J.L.Z.; Alkahari, M.R.; Rosli, N.A.B.; Hasan, R.; Sudin, M.N.; Ramli, F.R. Review of wire arc additive manufacturing for 3d metal printing. Int. J. Autom. Technol. 2019, 13, 346–353. [Google Scholar] [CrossRef]

- Gu, D.; Shi, X.; Poprawe, R.; Bourell, D.L.; Setchi, R.; Zhu, J. Material-structure-performance integrated laser-metal additive manufacturing. Science 2021, 80, 372. [Google Scholar] [CrossRef]

- Quintino, L.; Costa, A.; Miranda, R.; Yapp, D.; Kumar, V.; Kong, C.J. Welding with high power fiber lasers—A preliminary study. Mater. Des. 2007, 28, 1231–1237. [Google Scholar] [CrossRef]

- Campagnoli, M.R.; Galati, M.; Saboori, A. On the processability of copper components via powder-based additive manufacturing processes: Potentials, challenges and feasible solutions. J. Manuf. Process. 2021, 72, 320–337. [Google Scholar] [CrossRef]

- Jadhav, S.D.; Dadbakhsh, S.; Goossens, L.; Kruth, J.-P.; Van Humbeeck, J.; Vanmeensel, K. Influence of selective laser melting process parameters on texture evolution in pure copper. J. Mater. Process Technol. 2019, 270, 47–58. [Google Scholar] [CrossRef]

- Chen, Y.; Ren, S.; Zhao, Y.; Qu, X. Microstructure and properties of CuCr alloy manufactured by selective laser melting. J. Alloys Compd. 2019, 786, 189–197. [Google Scholar] [CrossRef]

- Zhou, Z.; Wang, Y.; Gao, J.; Kolbe, M. Microstructure of rapidly solidified Cu–25wt.% Cr alloys. Mater. Sci. Eng. A 2005, 398, 318–322. [Google Scholar] [CrossRef]

- Hauf, U.; Kauffmann, A.; Kauffmann-Weiss, S.; Feilbach, A.; Boening, M.; Mueller, F.E.; Hinrichsen, V.; Heilmaier, M. Microstructure formation and resistivity change in CuCr during rapid solidification. Metals 2017, 7, 478. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, S.; Yang, H.; Peng, D.; Wang, Y.; Zhu, H. Investigating the influence of the scanning rotation angle on the microstructure and properties of LPBFed CuCr0.8 alloy. J. Manuf. Process. 2022, 84, 1150–1161. [Google Scholar] [CrossRef]

- Onuike, B.; Heer, B.; Bandyopadhyay, A. Additive manufacturing of Inconel 718—Copper alloy bimetallic structure using laser engineered net shaping (LENSTM). Addit. Manuf. 2018, 21, 133–140. [Google Scholar] [CrossRef]

- Pan, T.; Zhang, X.; Yamazaki, T.; Sutton, A.; Cui, W.; Li, L.; Liou, F. Characteristics of Inconel 625—Copper bimetallic structure fabricated by directed energy deposition. Int. J. Adv. Manuf. Technol. 2020, 109, 1261–1274. [Google Scholar] [CrossRef]

- Velu, M.; Bhat, S. Metallurgical and mechanical examinations of steel–copper joints arc welded using bronze and nickel-base superalloy filler materials. Mater. Des. 2013, 47, 793–809. [Google Scholar] [CrossRef]

- Zhang, Y.-Z.; Tu, Y.; Xi, M.-Z.; Shi, L.-K. Characterization on laser clad nickel based alloy coating on pure copper. Surf. Coat. Technol. 2008, 202, 5924–5928. [Google Scholar] [CrossRef]

- Kim, S.H.; Shin, G.-H.; Kim, B.-K.; Kim, K.T.; Yang, D.-Y.; Aranas, C.; Choi, J.-P.; Yu, J.-H. Thermo-mechanical improvement of Inconel 718 using ex situ boron nitride-reinforced composites processed by laser powder bed fusion. Sci. Rep. 2017, 7, 14359. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Liu, J.; Chen, C.; Zhu, Y.; Liu, N.; Zhou, Y.; Chen, S. High catalytic performance non-enzymatic H2O2 sensor based on Cu2O@Cu9S5 yolk-shell nanospheres. Appl. Surf. Sci. 2022, 587, 152766. [Google Scholar] [CrossRef]

- Cao, W.; Guo, T.; Wang, J.; Xu, G.; Jiang, J.; Liu, D. Cu-based materials: Design strategies (hollow, core-shell, and LDH), sensing performance optimization, and applications in small molecule detection. Coord. Chem. Rev. 2023, 497, 215450. [Google Scholar] [CrossRef]

- Billah, K.M.M.; Coronel, J.L., Jr.; Chavez, L.; Lin, Y.; Espalin, D. Additive manufacturing of multimaterial and multifunctional structures via ultrasonic embedding of continuous carbon fiber. Compos. Part C Open Access 2021, 5, 100149. [Google Scholar] [CrossRef]

- Ng, K.; Man, H.C.; Cheng, F.; Yue, T.M. Laser cladding of copper with molybdenum for wear resistance enhancement in electrical contacts. Appl. Surf. Sci. 2007, 253, 6236–6241. [Google Scholar] [CrossRef]

- Majumdar, J.D.; Manna, I. Laser surface alloying of copper with chromium: I. microstructural evolution. Mater. Sci. Eng. A 1999, 268, 216–226. [Google Scholar] [CrossRef]

- Liu, F.; Liu, C.; Tao, X.; Chen, S. Laser cladding of Ni-based alloy on copper substrate. J. Univ. Sci. Technol. Beijing Miner. Metall. Mater. 2006, 13, 329–332. [Google Scholar] [CrossRef]

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Martukanitz, R.; Michaleris, P.; Palmer, T.; DebRoy, T.; Liu, Z.-K.; Otis, R.; Heo, T.W.; Chen, L.-Q. Toward an integrated computational system for describing the additive manufacturing process for metallic materials. Addit. Manuf. 2014, 1, 52–63. [Google Scholar] [CrossRef]

- Kushnarev, Y.V.; Semenchuk, V.M.; Chumaevskii, A.V.; Osipovich, K.S.; Rubtsov, V.E.; Kolubaev, E.A. Production of experimental samples of nickel-based alloy and copper nozzles by electron beam additive manufacturing. Russ. Phys. J. 2024, 67, 419–426. [Google Scholar] [CrossRef]

- Tarasov, S.Y.; Filippov, A.V.; Savchenko, N.L.; Fortuna, S.V.; Rubtsov, V.E.; Kolubaev, E.A.; Psakhie, S.G. Effect of heat input on phase content crystalline lattice parameter residual strain in wire-feed electron beam additive manufactured 304 stainless steel. Int. J. Adv. Manuf. Technol. 2018, 99, 2353–2363. [Google Scholar] [CrossRef]

- Osipovich, K.S.; Chumaevskii, A.V.; Gusarova, A.V.; Kalashnikov, K.N.; Kolubaev, E.A. Mechanical Properties of Steel– Copper Polymetal Manufactured by the Wire-Feed Electron-Beam Additive Technology. High Temp. Mater. Process. 2020, 24, 91–98. [Google Scholar] [CrossRef]

- Utyaganova, V.; Filippov, A.; Tarasov, S.; Shamarin, N.; Gurianov, D.; Vorontsov, A.; Chumaevskii, A.; Fortuna, S.; Savchenko, N.; Rubtsov, V.; et al. Characterization of AA7075/AA5356 gradient transition zone in an electron beam wire-feed additive manufactured sample. Mater. Charact. 2021, 172, 110867. [Google Scholar] [CrossRef]

- Stavroulakis, P.; Toulfatzis, A.; Vazdirvanidis, A.; Pantazopoulos, G.S. Papaefthymiou Mechanical behaviour and microstructure of heat-treated Cu–Ni–Si alloy. Mater. Sci. Technol. 2020, 36, 939–948. [Google Scholar] [CrossRef]

- Yin, J.; Yang, L.; Yang, X.; Zhu, H.; Wang, D.; Ke, L.; Wang, Z.; Wang, G.; Zeng, X. High-power laser-matter interaction during laser powder bed fusion. Addit. Manuf. 2019, 29, 100778. [Google Scholar] [CrossRef]

- Hebert, R.J. Viewpoint: Metallurgical aspects of powder bed metal additive manufacturing. J. Mater. Sci. 2016, 51, 1165–1175. [Google Scholar] [CrossRef]

- Song, B.; Zhao, X.; Li, S.; Han, C.; Wei, Q.; Wen, S.; Liu, J.; Shi, Y. Differences in microstructure and properties between selective laser melting and traditional manufacturing for fabrication of metal parts: A review. Front. Mech. Eng. 2015, 10, 111–125. [Google Scholar] [CrossRef]

- Wu, A.S.; Brown, D.W.; Kumar, M.; Gallegos, G.F.; King, W.E. An Experimental Investigation into Additive Manufacturing-Induced Residual Stresses in 316L Stainless Steel. Metall. Mater. Trans. A 2014, 45, 6260–6270. [Google Scholar] [CrossRef]

- Mukherjee, T.; Zuback, J.S.; De, A.; DebRoy, T. Printability of alloys for additive manufacturing. Sci. Rep. 2016, 6, 19717. [Google Scholar] [CrossRef]

- Puebla, K.; Murr, L.E.; Gaytan, S.M.; Martinez, E.; Medina, F.; Wicker, R.B. Effect of Melt Scan Rate on Microstructure and Macrostructure for Electron Beam Melting of Ti-6Al-4V. Mater. Sci. Appl. 2012, 3, 259–264. [Google Scholar] [CrossRef]

- Kainuma, R.; Liu, X.J.; Ohnuma, I.; Hao, S.M.; Ishida, K. Miscibility gap of B2 phase in NiAl to Cu3Al section of the Cu–Al–Ni system. Intermetallics 2005, 13, 655–661. [Google Scholar] [CrossRef]

| Parameters | Beam Sweep | Liner Speed, mm/min | I, A (1st Layer) | I, A (last Layer) | |

|---|---|---|---|---|---|

| Mode I | C11000 | Spiral | 400 | 80 | 60 |

| Inconel 625 | Ellipse | 300 | 70 | 50 | |

| Mode II | C11000 | Spiral | 400 | 68 | 67 |

| Inconel 625 | Ellipse | 300 | 70 | 50 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Osipovich, K.; Semenchuk, V.; Chumaevskii, A.; Gurianov, D.; Korsunsky, A.M.; Rubtsov, V.; Kolubaev, E. On the Peculiarities of Wire-Feed Electron Beam Additive Manufacturing (WEBAM) of Nickel Alloy–Copper Bimetal Nozzle Samples. Crystals 2024, 14, 976. https://doi.org/10.3390/cryst14110976

Osipovich K, Semenchuk V, Chumaevskii A, Gurianov D, Korsunsky AM, Rubtsov V, Kolubaev E. On the Peculiarities of Wire-Feed Electron Beam Additive Manufacturing (WEBAM) of Nickel Alloy–Copper Bimetal Nozzle Samples. Crystals. 2024; 14(11):976. https://doi.org/10.3390/cryst14110976

Chicago/Turabian StyleOsipovich, Kseniya, Vyacheslav Semenchuk, Andrey Chumaevskii, Denis Gurianov, Alexander M. Korsunsky, Valery Rubtsov, and Evgeny Kolubaev. 2024. "On the Peculiarities of Wire-Feed Electron Beam Additive Manufacturing (WEBAM) of Nickel Alloy–Copper Bimetal Nozzle Samples" Crystals 14, no. 11: 976. https://doi.org/10.3390/cryst14110976

APA StyleOsipovich, K., Semenchuk, V., Chumaevskii, A., Gurianov, D., Korsunsky, A. M., Rubtsov, V., & Kolubaev, E. (2024). On the Peculiarities of Wire-Feed Electron Beam Additive Manufacturing (WEBAM) of Nickel Alloy–Copper Bimetal Nozzle Samples. Crystals, 14(11), 976. https://doi.org/10.3390/cryst14110976