Abstract

Nitrogenous nickel-based deposited metal was prepared by using the gas metal arc welding (GMAW) method, and it was further subjected to solid-solution and aging heat treatment. The influence of different solid-solution temperatures on the microstructure of the deposited metal was studied, and the complete heat treatment system for the nitrogenous nickel-based deposited metal was ultimately determined. The microstructure, mechanical properties, and deformation mechanism of the nitrogenous nickel-based deposited metal in two states (as-prepared state and complete heat-treated state) were finally investigated. The results show that the microstructure of the deposited metal mainly consisted of epitaxially grown columnar grains with large grains. Petal-like Laves phases formed between the dendrites. The main deformation mechanism was the unit dislocation a/2<110> cut precipitation phase. After a complete heat treatment, all the Laves phases were re-melted, and nanoscale M(C,N) phases precipitated in the grains, while M23C6 phases formed at the grain boundaries. The samples showed higher yield and ultimate tensile strengths than those of the as-prepared state metal, but with reduced ductility. The deformation mechanism involved not only a/2<110> matrix dislocations cutting the precipitated phase, but also two a/6<121> Shockley incomplete dislocations, together cutting the precipitated phase to form a stacking layer dislocation.

1. Introduction

Coal-fired power generation technology has been developed over the past century. It has gradually evolved from subcritical parameter units to ultra-(super-)critical thermal power units, which have effectively improved the operating parameters and thermal efficiency of thermal power units while significantly reducing greenhouse gas and pollutant emissions. In terms of optimizing the global electricity structure and developing the level of clean coal power generation technology, increasing steam temperature and pressure is the primary way to improve the efficiency of power plants. Once the operating temperature of a thermal power plant increases from subcritical to ultra-supercritical, reaching 600 °C, the energy consumption significantly decreases. At the same time, the highest temperature region of a component of a thermal power unit is subject to a stress of even 100 MPa, which requires good mechanical properties of the materials of the thermal power unit components [1]. In recent years, new austenitic heat-resistant types of steel with better high-temperature creep resistance and corrosion resistance have been developed, such as TP347HFG, Super304H, and HR3C. Among them, Super304H steel is widely used in thermal power units due to its excellent high-temperature performance during operation.

Nickel-based high-temperature alloys are considered to be the preferred material for welding ultra supercritical units owing to their excellent oxidation resistance and good high-temperature tensile and creep properties. From the perspective of technical safety and availability, nickel-based welding materials have been recognized for being able to weld new austenitic steels, especially Super304H steel. Currently, Inconel 625 alloy has excellent mechanical properties from room temperature to 980 °C. Inconel 625 filler wire can adapt to the chemical composition and thermal expansion differences of different metals, it is suitable for use as a dissimilar metal welding [2,3], and can significantly upgrade the high-temperature mechanical properties of welded joints [4,5]. Nevertheless, the price of nickel ore remains high, resulting in the cost of nickel-based welding consumables also rising. Therefore, the development of low-nickel thermal power unit welding consumables with excellent performance has become an urgent task.

This article is based on the composition of Inconel 625 welding material, but the proportion of the Ni element is significantly reduced. At the same time, a certain proportion of the N and Ti elements is added to the composition, as well as a certain amount of transition elements W and Co. The new welding material obtained is called nitrogenous nickel-based flux-cored wire. Because nitrogen has a powerful stabilizing effect on austenite [6], the presence of nitrogen leads to the formation of carbon nitrides in the alloy, and some studies have shown that carbon nitrides are more stable than carbides [7]. The presence of both the refractory alloying element tungsten and the boundary-strengthening element carbon can have a beneficial effect by providing high thermal fatigue resistance to the alloy [8]. The nanostructured W–Ti has a very significant high-temperature stability [9], and the transition group elements allow the alloys to obtain excellent mechanical properties at elevated temperatures, something which is beneficial to decrease the diffusion capacity of the other alloying elements and diminish the lamination fault energy of the alloy [10,11,12,13,14].

Nickel-based alloys are typical solid-solution strengthened high-temperature alloys. Therefore, different heat treatment methods have significant impacts on their properties. Mostafaei et al. [15] believe that the aging heat treatment improves the microhardness and tensile strength of nickel-based alloys but reduces plasticity. Safarzade et al. [16] found that the solution heat treatment resulted in the dissolution of Laves phases in Inconel 625, increasing hardness and yield strength, although it had little effect on tensile properties. Hu et al. [17] investigated the effect of different heat treatments on the microstructure evolution and tensile properties of Inconel 625 prepared by directed energy deposition (DED) and found that the yield and ultimate strength pairs of the alloy were large after the aging treatment, but the ductility of the specimens after the solid-solution aging treatment was the lowest. However, the steady work-hardening stage was shorter than that of other samples. Giulio Marchese et al. [18] investigated the mechanical behavior of laser-powder bed fusion (LPBF)-treated Inconel 625 samples and found that the high tensile properties of the 24 h aging treatment at 700 °C, either by direct aging or by post-solid-solution, were mainly dependent on the formation of the γ” phase and M23C6 carbides. Shujun Chen et al. [19] found that, by increasing the solid-solution treatment temperature of the GH4169 Ni-based superalloy from 950 °C to 1150 °C, the volume fraction of the Laves phase would be significantly reduced, and the tensile strength of the alloy was significantly increased at both room and elevated temperatures, with an increase in elongation of ~35%.

Although there have been many heat treatment protocols for nickel-based high-temperature alloys, and the associated microstructural and mechanical properties have been discussed [20,21,22,23,24], there are no articles that have investigated how nitrogenous nickel-based deposited metal could be heat treated. This paper focuses on the effect of heat treatment on the microstructure and tensile properties of the deposited metal of nitrogenous nickel-based flux-cored wires, demonstrating its excellent tensile properties. This study is expected to provide reliable data for the design of low-cost nickel-based welding materials for thermal power generation units.

2. Experimental

2.1. Materials

The nitrogenous nickel flux-cored wire used in this test had a diameter of 1.2 mm, and a chemical composition (mass fraction, %) of 0.1C, 2.5Mn, 0.45Si, 0.2Cu, 41Ni, 1.3Ti, 1.5Al, 22Cr, 4.5Mo, 5.00Nb, 4.0W, 0.55N, P < 0.001, S < 0.001, and rest Fe. The surface of the base material (304 L stainless steel plate) was washed, the surfacing layer was set to four layers in order to reduce the dilution rate during the surfacing, and the size of the as-prepared samples was 180 mm × 100 mm × 12 mm. The shielding gas was 97% Ar + 3% N2 to inhibit the oxidation of the weld metal during the welding process.

2.2. Fabrication Conditions

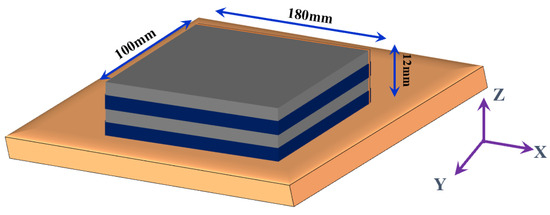

This test was used to deposit the metal layer by layer using a YD-500FR2 gas-shielded welding machine. A welding process with a torch fixed to the automatic travelling mechanism was used to weld the specimen, each pass in the opposite direction of the previous pass. To control the temperature of the middle layer, the welding process did not exceed 150 °C. The welding speed was 250 mm/min, the welding current was 180 A, the welding voltage was 25 V, and the shielding gas was 97% Ar + 3% N2 to inhibit the oxidation of the weld metal during the welding process. The prepared cladding test piece was a multipass four-layer deposited structure with the size of 180 mm × 100 mm × 12 mm. The macroscopic diagram is shown in Figure 1.

Figure 1.

Schematics of the deposition path (unit: mm).

2.3. Heat Treatment

In order to obtain a uniform microstructure, the solid-solution heat treatment of the specimens was carried out in an electric furnace with a precision of ±5 °C. The specimens were heat-treated at different solid-solution temperatures (950–1200 °C, water quenching) to study the effect of different solid-solution temperatures on the organization and properties of the specimens. The solid-solution heat treatment time was 4 h, and then the structure was quenched in water. One group of solid-solution-treated specimens was further subjected to a two-stage aging treatment at 750 °C/4 h + 650 °C/24 h (furnace cooling) to study the effect of aging on the alloy.

2.4. Characterization

The as-prepared and heat-treated samples were cut into pieces, subsequently ground, and polished down to 1 µm using SiC abrasive papers and diamond suspensions. They were then etched using aqua regia (HCl:HNO3 = 3:1) and the samples were immersed in the etchant for 30 s at room temperature. Afterward, the microstructures were investigated by means of optical microscope (OM-BX60M), field emission scanning electron microscope (FESEM-GeminiSEM-300), and by transmission electron microscope (TEM-JEM-2100) equipped with an energy dispersive X-ray spectroscopy (EDS) detector.

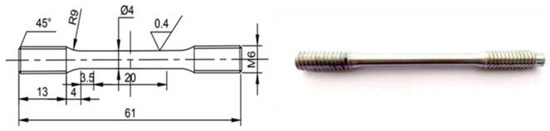

A differential scanning calorimetry (DSC) analysis of nitrogenous nickel-based deposited metal was carried out using a THEMYS integrated analyzer with a protective atmosphere of argon at a flow rate of 20 mL/min. Tensile samples with a diameter of 4 mm and a gauge length of 20 mm were obtained by machining, as shown in Figure 2. The tensile tests were carried out at 600 °C at a constant rate of 0.1 mm/min until the specimen broke. During the testing process, the temperature variation was kept within ±3 °C, and at least two parallel samples were used for each tensile condition. All tensile properties were measured under the same conditions and the average of the results was taken.

Figure 2.

Schematic of the tensile sample (unit: mm).

3. Results and Discussion

3.1. Evolution of the Microstructure

3.1.1. As-Prepared Sample

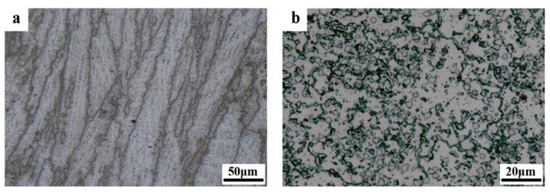

Figure 3 shows the microstructure of the nitrogenous nickel-based deposited metal alloy. The alloy organization in the as-prepared state consisted of columnar crystals and a few equiaxed grains (Figure 3a). The microstructure was dominated by columnar crystals, the alloy grains were relatively coarse, and the morphology of the grain boundaries and intracrystalline precipitates of the deposited metal is shown in Figure 3b. It can be seen that the intracrystalline precipitates were large-sized lumps, and the precipitates at the grain boundaries were large-sized in the shape of irregular bars and flaps (Figure 3b).

Figure 3.

Optical micrographs of the microstructure of nitrogenous nickel-based deposited metal. (a) Grain distribution in the deposited metal, (b) Morphology of precipitates distributed in dendrites and interdendrites.

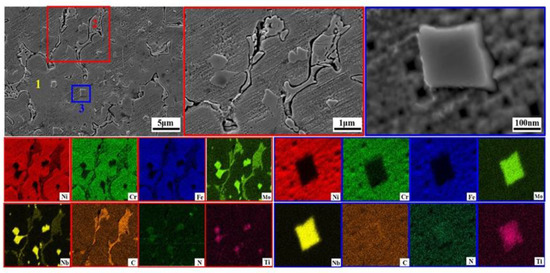

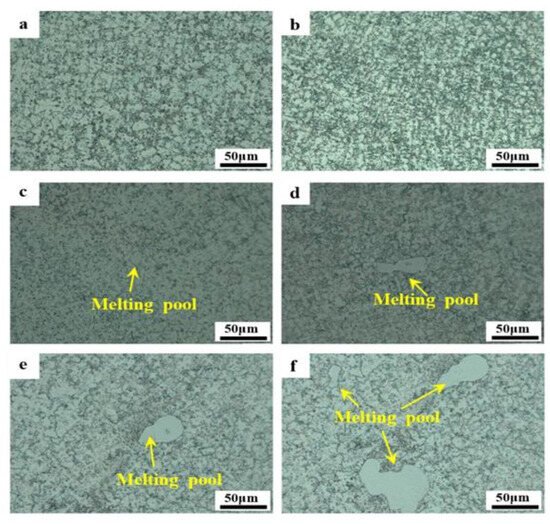

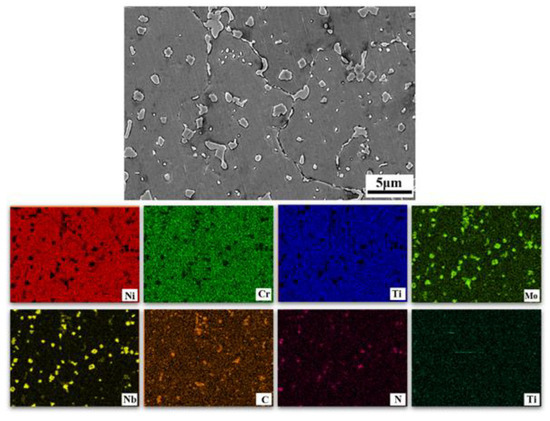

The type, distribution, amount, and morphology of the precipitated phases have an important influence on the high-temperature properties of alloys. FESEM and TEM were used to further examine and analyze the microstructure of the nitrogenous nickel-based deposited metal. In Figure 4, irregular petal-like precipitation phases with a size of about 5 μm can be observed at the grain boundaries, and blocky or streaky precipitation phases about 1 μm in size can also be observed at the grain boundaries. Some larger blocky and triangular precipitation phases can also be observed within the grains. This is consistent with the results shown by light microscopy (Figure 3b).

Figure 4.

Distribution of various elements in the alloy.

The results of the EDS spectral analysis of the matrix and the precipitated phase are listed in Table 1. It can be seen that the grey part of point 1 was a γ-Ni matrix, which mainly contained Ni, Cr, Fe elements, and other elements, albeit to a lesser extent. The scanning result of the irregular precipitated phase at point 2 was considered to be the Laves phase, which mainly included Ni, Cr, Mo, and Nb elements, with a significant increase in Mo and Nb content and a decrease in Ni and Cr content. In addition, some square and triangular precipitates were observed in the crystal, and the length of the square precipitation phase in the position of area 3 was about 1μm, such a precipitate containing mainly the elements of Nb, Mo, N, and C. The analysis of the scanning results shows that the intracrystalline precipitation phase was a composite carbon nitride M(C,N) with Mo and Nb as the main elements. This is consistent with other results reported in the literature [25,26].

Table 1.

Energy spectrum analysis of precipitates (atomic fraction, %).

Nitrogenous nickel-based deposition metals are highly alloyed with many elements. When an alloy is in the molten state, the elements within it are uniformly distributed in the melt. However, during solidification, differences in the solubility of the elements in the solid–liquid phase can lead to redistribution of the alloying elements, resulting in segregation behavior on the part of the elements. In the early stage of solidification, the γ-Ni phase with fewer solute elements crystallizes first, and the L → L + γ crystallization process occurs. It is generally believed that if the solubility of elements in the solid phase of an alloy is higher than their solubility in the liquid phase, then the elements are more likely to segregate at the dendrites after solidification of the alloy. On the contrary, if the solubility of the alloying elements in the liquid phase is higher than that in the solid phase, the elements are more likely to segregate between dendrites after solidification [27]. The results show that, as the solidification reaction proceeded, alloying elements such as Mo, Nb, and C accumulated in the interdendritic region, leading to the segregation behavior of the alloying elements. The occurrence of L → L + γ + M (C, N) was promoted, which, in turn, promoted the formation of carbon nitride. The Laves phase is a eutectic phase which is formed in the final stage of solidification. Based on the distribution of the elements, the content of Ti, Mo, and Nb in the residual liquid phase at the end of the solidification process increased rapidly, so the segregation was more serious than that of Ni, Cr, and Fe. The elements Cr, Fe, and Ni were depleted in the precipitation phase, with the intracrystalline precipitation phase consisting of a composite carbon nitride M(C,N) dominated by Mo and Nb. Carbon nitrides are more stable than carbides [7], a fact which is favorable to the strength of the alloy.

3.1.2. Heat-Treated Samples

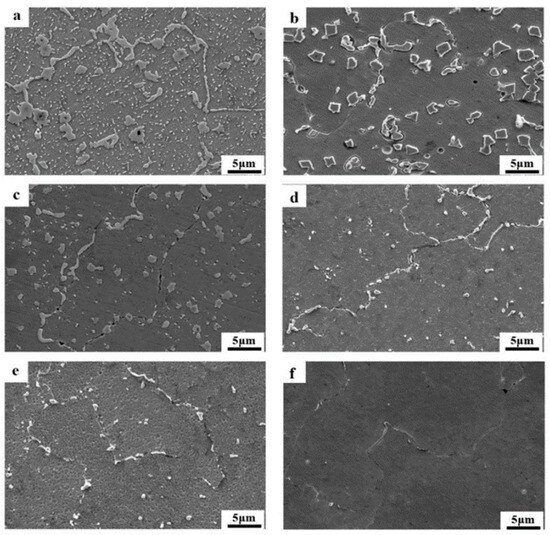

The mechanical properties of nickel-based alloys can be improved by solid-solution strengthening mechanisms [28]. However, severe segregation occurring during solidification leads to the formation of carbide precipitation phases in the interdendritic region of the as-prepared samples, as well as to the formation of some undesired phases such as the Laves phase and the δ phase. In order to obtain a more homogeneous organization and to study the effect of different solid-solution temperatures on nitrogenous nickel-based deposited metal, the specimens were subjected to solid-solution heat treatment for 4 h at 950 °C, 1000 °C, 1050 °C, 1100 °C, 1150 °C, and 1200 °C and then quenched in water. Figure 5a–f shows the FESEM images of different solid-solution-treated samples.

Figure 5.

FESEM images of heat-treated samples for 4 h at (a) 950 °C, (b) 1000 °C, (c) 1050 °C, (d) 1100 °C, (e) 1150 °C, (f) 1200 °C.

When the solid-solution temperature was 950 °C, a large number of short rod-like precipitates could be observed in the crystal (Figure 5a), and a large number of continuous inhomogeneous precipitates appeared to be enriched at the grain boundaries. With the increase in solid-solution temperature, the rod-like precipitates inside the alloy gradually disappeared.

Figure 6 shows the results of the compositional analysis of the precipitated phase in the form of a short bar, which was inferred to be the δ phase based on the morphological and compositional characteristics of this precipitated phase [29,30]. It was also found that the δ phase contained not only Nb and Ni elements, but also more elements such as Cr and Ti. This is due to the fact that Ti can replace part of Nb, Fe can replace part of Ni, and Cr can replace both Ni and Nb in the formation of the δ phase [31,32]. This also explains the reason for the occurrence of a large number of δ precipitates from the perspective of elemental composition. When the temperature increased to 1050 °C (Figure 5b), the short rod-like precipitates inside the grain completely disappeared, the precipitates at the grain boundaries were greatly reduced, and the shape of the precipitates inside the grain started to become gentle from having sharp angles, a phenomenon which reduces the concentration of stress, and, at the same time, some fine precipitated phases appeared inside the grain.

Figure 6.

EDS analysis results of the short rod-shaped δ phase.

When the solid-solution temperature continued to rise, the shape and size of the carbonitrides in the alloy crystal also changed, the weld specimens in the precipitates became mostly solidified into the matrix, in the grain boundaries, and within the territory of a small amount of precipitates, the diameter of the precipitates within the crystal size became much smaller, and the corners became rounded. When the solid-solution temperature reached 1200 °C (Figure 5f), it can be seen that the precipitates at the grain boundaries almost remelted back, and the precipitates within the grain also returned to the matrix.

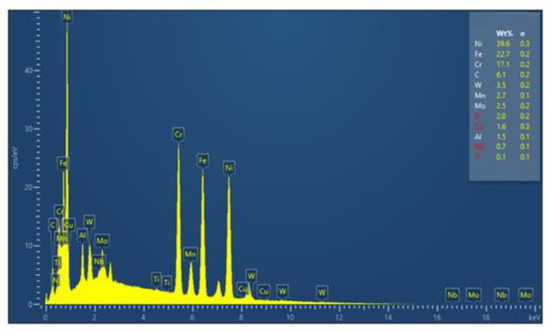

3.2. Phase Transition Temperature

In order to study the precipitation temperature and solidification sequence of the phases in the nitrogenous nickel-based deposited metal alloy, the nitrogenous nickel-based deposited metal alloy was analyzed using differential scanning calorimetry (DSC). The differential thermal analysis curve of the alloy at elevated temperatures is shown in Figure 7, in which four distinct thermal reaction zones are visible. The first reaction region corresponds to a lower temperature and a smaller area. The first reaction zone corresponds to a lower temperature and a smaller area. According to the location and intensity of the thermal reaction zone, this zone corresponds to the generation zone of carbides, and the temperature is represented by Tp. The second thermal reaction region on the curve is more pronounced in intensity and corresponds to the temperature at which the solid phase in the nitrogenous nickel-based deposited metal begins to transform into the liquid phase, i.e., the alloy becomes a supersaturated solid solution after the γʹ phase is completely solidified, and melting begins to take place in eutectic positions between the dendrites as the temperature continues to rise, i.e., the initial melting temperature of nitrogenous nickel-based deposited metals (1120 °C), denoted by Tl. The third obvious thermal reaction zone is the heat absorption reaction during the solid solution of carbon and nitrides (1242 °C), and the temperature of this reaction zone is denoted by Tc. The intensity of the heat absorption peak corresponding to the fourth heat absorption reaction is the most obvious, and it is the most dominant heat absorption reaction in the whole temperature-raising process, corresponding to the melting of the γ phase (TL, 1264 °C).

Figure 7.

Heating curve of DSC results of nitrogenous nickel-based deposited metal.

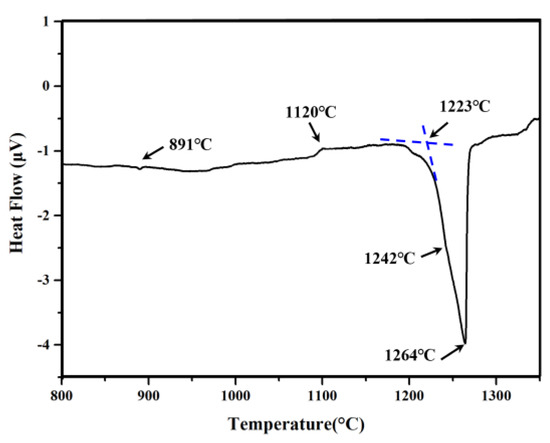

According to the heating curve obtained by DSC, it can be noticed that the initial melting temperature of the nitrogenous nickel-based deposited metal was around 1120 °C. Since the DSC test must be detected when the phase variable reaches a certain level, the initial melting temperature determined by DSC may be high. Therefore, the initial melting temperature of the nitrogenous nickel-based deposited metal alloy was determined using a metallographic method, and the experimental results are shown in Figure 8. It can be seen from the figure that there was no melt pool in the microstructure of nitrogenous nickel-based deposited metal at 1100 °C (Figure 8a) and 1105 °C (Figure 8b). However, when the temperature was increased to 1110 °C (Figure 8c), the eutectic in the alloy started to undergo initial melting; when the temperature was higher than 1120 °C (Figure 8e,f), a large amount of initial melting of the eutectic in the alloy started to occur. Thus, by reference to the DSC curves and metallographic organization, the initial melting temperature of the nitrogenous nickel-based deposited metal alloy can be determined to have been in the range of 1105 °C−1110 °C.

Figure 8.

Metallographic determination of the initial melting temperature of the nitrogenous nickel-based alloy: (a) 1100 °C/1 h, (b) 1105 °C/1 h, (c) 1110 °C/1 h, (d) 1115 °C/1 h, (e) 1120 °C/1 h, (f) 1130 °C/1 h.

In order to maximize the efficiency of the solid-solution treatment and prevent the initial melting of nitrogenous nickel-based deposited metals, and taking into account the temperature fluctuations inside the heat treatment furnace, the final solid-solution treatment temperature for nitrogenous nickel-based deposited metals was set to 1100 °C. By adopting previous heat treatment regimes for similar alloys [33,34,35,36,37], the final treatment was a one-stage solid-solution treatment and a two-stage aging treatment, and the specific complete heat treatment regimes are shown in Table 2.

Table 2.

Heat treatment scheme of nitrogenous nickel-based deposited metal in the present study.

3.3. Completely Heat-Treated Organization

The microstructure of nickel-based high-temperature alloys is influenced by many factors, such as the quantity, morphology, and size of carbides in the alloy, the morphology, volume fraction, and size of the γʹ phase, and the quantity of TPC phases (such as Laves phase, μ phase, etc.) [38]. Due to the low plasticity of the Laves phase, the crack propagation speed will be very fast, which seriously affects the service life of the alloy under high-temperature load conditions. If the carbides in the alloy are small-sized lumps, the high-temperature alloys have relatively good mechanical properties. However, the mechanical properties of nickel-based high-temperature alloys can be particularly affected by factors such as whether the distribution of the γʹ phase is uniform and whether the arrangement is regular or not [38,39].

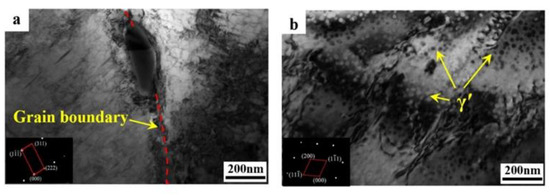

The typical microstructure of nitrogenous nickel-based deposited metal after the complete heat treatment (sample treated by solution and aging, hereinafter referred to as SA sample) is shown in Figure 9. From the figure, it can be seen that the precipitates inside the crystal were more uniform, and there were also many small particles precipitated in the grain. From the element mapping diagram, it can be seen that these small particles were very small carbonitrides. It is worth noting that the shape of the precipitates in the aged sample became more rounded, without the very obvious edges and corners that were present in the preparation pattern (Figure 4). This change can reduce the stress concentration inside the grains, thereby improving the strength of the alloy. In addition, some fine precipitates were visible at the grain boundaries of the SA sample. Meanwhile, many nanoscale phases were precipitated from the SA sample. To accurately analyze the types of these fine precipitates, TEM was used for further examination. Based on the bright field image and electron diffraction pattern, it can be determined that the precipitated phase at the grain boundary position was M23C6 carbide (Figure 10a). Furthermore, as shown in Figure 10b, the diffusely distributed precipitation phase with less than 1μm in intracrystalline size can be identified as the γʹ phase.

Figure 9.

Microstructure of nitrogenous nickel-based deposited metal after the complete heat treatment.

Figure 10.

TEM bright field images and electron selective diffraction pattern photos of the sample: (a) grain boundary, (b) intragranular.

There are many factors that affect the mechanical properties of nickel-based high-temperature alloys, among which the evolution of carbides plays a very important role [40,41]. The addition of nitrogen to the alloy leads to the generation of intracrystalline carbon nitrides, which are more stable than carbides and benefit from enhanced intracrystalline strengthening [7]. The as-prepared state of the nitrogenous nickel-based deposited metal contained eutectic and carbon nitride compounds mainly distributed between the dendrites, and the size of the precipitates at the grain boundaries was also larger than the size of the intracrystalline precipitates (Figure 4). In addition, the element W added to the alloy was enriched in the precipitation phase and in the matrix, and the element W was a solid-solution strengthening element, so it can make the alloy have a stronger solid-solution strengthening effect, which is one of the reasons leading to the nitrogenous nickel-based alloys with high-yield strength.

After SA, most of the precipitated phases on the grain boundaries of the sample melted back into the matrix (Figure 9). The size of the intragranular precipitates was smaller, and the shape changed from a block with sharp edges in the as-prepared state to an ellipsoid, weakening the stress concentration. Most of the carbon nitrides on the grain boundaries were re-dissolved into the matrix, and the re-melting of the deleterious Laves phase had a solid-solution strengthening effect. The precipitation of M23C6 at the grain boundaries can prevent grain boundary sliding and improve the durability of the alloy [42,43]. The large amount of carbon nitride generated inside the grain can also increase its strength. At the same time, the presence of a large number of strengthening phases γʹ also plays a reinforcing role. Therefore, it can be inferred that the SA state had high-yield strength.

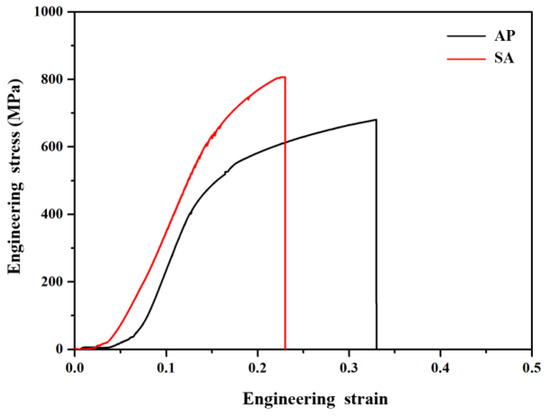

3.4. Tensile Behaviors

Figure 11 shows the engineering stress–strain curves of the nitrogenous nickel-based deposited metal in the as-prepared and SA state, and the corresponding tensile performance results are shown in Table 3. The tensile stress remained constant until the samples fractured, and, as it can be seen from the figure, the specimens in both states showed a significant work-hardening behavior after yielding until the alloy fracture occurred. The results show that the yield strength of the as-prepared state sample was 415 MPa, the ultimate tensile stress was 681 MPa, and the elongation was 26.81%. Tensile strength of the SA sample was about 120 MPa higher than that of the as-prepared state sample, while the elongation decreased by 11%.

Figure 11.

Tensile engineering stress–strain curves of different samples at 600 °C (AP: as-prepared state, SA: solution and aging state).

Table 3.

Tensile performance at 600 °C (AP: as-prepared state, SA: solution and aging state).

3.5. Microstructure Evolution

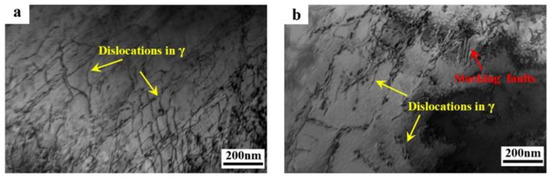

From Figure 12a, it can be seen that there were many dislocations entangled in the microstructure of the nitrogenous nickel-based deposited metal after the tensile fracture. Meanwhile, it can also be observed that many dislocations accumulated and entangled at the grain boundaries, leading to a rapid increase in dislocation density and to the formation of cellular structures. As the tensile deformation proceeded, the dislocations forming the cell wall gradually aligned themselves to form subgrain boundaries. The subgrain boundaries can play the role of hindering the dislocation slip and improve the tensile strength of the sample; therefore, our sample had a high tensile strength. After the heat treatment, not only unit dislocations and dislocation entanglements at the grain boundaries, but also stacking dislocations were observed in the matrix (Figure 12b). Stacking dislocations reduce the density of dislocations accumulated at the grain boundaries and improve the inhomogeneity of dislocation distributions, thus reducing the possibility of localized deformation of the sample. Hence, it can be inferred that the tensile strength of the SA sample improved after the heat treatment, a phenomenon which is consistent with the results in Figure 11.

Figure 12.

TEM images showing deformation microstructures at 600 °C. (a) As-prepared, (b) SA.

There have been many studies on the generation of dislocations and stacking dislocations. The lowest energy of the total dislocation in face-centered cubic crystals is the unit dislocation with a Burgers vector of a/2<110> located on the {111} plane. If the unit dislocation slips along the <110> direction of the {111} crystal plane under shear stress, it will slip in the direction of the lower energy a/6 <112>, and this slip will form a laminar dislocation; two incomplete dislocations between the laminar dislocations and the normal zone will inevitably form. This dislocation reaction can be obtained by decomposition as follows:

The dislocation configuration in which two dislocations a/6<112> are sandwiched between two dislocations after decomposition is called an extended dislocation. This dislocation reaction is feasible when judged from both geometrical and energetic conditions [44]. Rea [45] suggests that, first, the a/2<101> dislocation breaks down at the interface between the matrix and the precipitated phase into the a/6<121> Shockley incomplete dislocation and the a/3<112> leading dislocation; these then cut into the precipitated phase to form a laminar dislocation. Viswanathan [46] believes that it is a stacking fault formed by the joint cutting and precipitation of two a/6<121> Shockley incomplete dislocations. According to the reaction energies of the dislocations, the two Shockley incomplete dislocations decomposed from the matrix dislocation have lower energies and are, therefore, also more reactive. However, regardless of the dislocation theory, the stacking fault is generated by the cutting and precipitation of the leading incomplete dislocation. At this point, if the leading dislocation continues to slip, a continuous layer fault will be formed [44]. Therefore, the formation mechanism of the stacking dislocations in this article is more aligned with Viswanathan’s research. In addition, the nitrogenous nickel-based alloy had a large number of transition group elements added, among which the elements Co and W which can significantly reduce the lamination energy of the alloy [8,47]. It has been shown that increasing the W content of the GH4586 alloy from 2% to 5% increases the yield strength of the alloy at 800 °C by about 50 MPa [8]. The stacking dislocations in Figure 12b in this paper may have been formed in this way as well.

4. Conclusions

In this paper, the effect of different solid-solution temperatures on nitrogenous nickel-based deposited metal was investigated and the final heat treatment was determined, while the tensile strength and strengthening mechanisms of the alloys in the as-prepared state and after the heat treatment were analyzed. The following conclusions can be drawn:

(1) The microstructure of the nitrogenous nickel-based deposited metal is dominated by columnar crystals. The formation of dendrites leads to a large amount of interdendritic segregation of the elements Nb, Mo, and Ti, resulting in the formation of petal-like Laves phases at the grain boundaries. Due to the addition of N to the alloy, Many blocky M(C,N)-type carbonitrides are precipitated. The initial melting temperature of the alloy is in the range of 1105–1110 °C.

(2) After the solid-solution treatment and the two-stage aging treatment, M23C6 carbides form at the grain boundaries, and a large number of nano γʹ precipitation phases appear in the microstructure. At this point, the Laves phase is basically re-dissolved in the matrix, and the edges of the M(C, N)-type carbides become rounded, a phenomenon which plays a positive role in the determination of the mechanical properties of the alloy.

(3) The solution and aging heat treatments increase the yield and tensile strength of the nitrogenous nickel-based deposited metal, but it decreases the elongation. The main deformation mechanism of the deposited metal is a/2<110> matrix dislocations cutting the precipitated phase, while the main deformation mechanism of the solid solution and aging heat-treated sample is not only a/2<110> matrix dislocations cutting the precipitated phase, but also stacking layer dislocations formed by the joint cutting of precipitated phases by the two a/6<121> Shockley incomplete dislocations.

Author Contributions

All authors contributed to the study conception and design. Material preparation, data curation, and analysis, Y.W. and Z.D.; writing—original draft preparation, Y.W.; writing—review and editing, Y.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Bhiogade, D.S. Ultra supercritical thermal power plant material advancements: A review. J. Alloys Metall. Syst. 2023, 3, 100024. [Google Scholar] [CrossRef]

- Jang, C.; Lee, J.; Kim, J.S.; Jin, T.E. Mechanical property variation within Inconel 82/182 dissimilar metal weld between low alloy steel and 316 stainless steel. Int. J. Press. Vessel. Piping 2008, 85, 635–646. [Google Scholar] [CrossRef]

- Kumar, N.P.; Shanmugam, N.S.; Sreedhar, G. High cycle fatigue behaviour of Inconel 625 weld overlay on AISI 316L plate. Surface Coat. Technol. 2021, 415, 127138. [Google Scholar] [CrossRef]

- Ahmad, G.N.; Raza, M.S.; Singh, N.K.; Kumar, H. Experimental investigation on ytterbium fiber laser butt welding of Inconel 625 and duplex stainless steel 2205 thin sheets. Opt. Laser Technol. 2020, 126, 106117. [Google Scholar] [CrossRef]

- Corigliano, P.; Crupi, V. Fatigue analysis of TI6AL4V/INCONEL 625 dissimilar welded joints. Ocean Eng. 2021, 221, 108582. [Google Scholar] [CrossRef]

- Kermanpur, A.; Behjati, P.; Han, J.; Najafizadeh, A.; Lee, Y.K. A microstructural investigation on deformation mechanisms of Fe-18Cr-12Mn-0.05C metastable austenitic steels containing different amounts of nitrogen. Mater. Des. 2015, 82, 273–280. [Google Scholar] [CrossRef]

- Fox, S.; Brooks, J.W.; Loretto, M.H.; Smallman, R.E. Strength of Metals and Alloys. ICSMA J. 1985, 1, 399–401. [Google Scholar]

- Sengupta, A.; Putatunda, S.K.; Bartosiewicz, L.; Hangas, J.; Nailos, P.J.; Peputapeck, M.; Alberts, F.E. Tensile behavior of a new single-crystal nickel-based superalloy (CMSX-4) at room and elevated temperatures. J. Mater. Eng. Perform. 1994, 3, 73–81. [Google Scholar] [CrossRef]

- Chookajorn, T.; Murdoc, H.A.; Schuh, C.A. Design of Stable Nanocrystalline Alloys. Science 2012, 337, 951–954. [Google Scholar] [CrossRef]

- Shang, S.L.; Kim, D.E.; Zacherl, C.L.; Wang, Y.; Du, Y.; Liu, Z.K. Effects of alloying elements and temperature on the elastic properties of dilute Ni-base superalloys from first-principles calculations. J. Appl. Phys. 2012, 112, 053515. [Google Scholar] [CrossRef]

- Eriş, R.; Akdeniz, M.V.; Mekhrabov, A.O. On the optimization of the microstructural and mechanical properties of model Ni-based superalloys through the alloying effects of refractory Mo and W elements. Metall. Mater. Trans. A 2022, 53A, 1859–1872. [Google Scholar] [CrossRef]

- Eriş, R.; Akdeniz, M.V.; Mekhrabov, A.O. Atomic size effect of alloying elements on the formation, evolution and strengthening of γ’-Ni3Al precipitates in Ni-based superalloys. Intermetallics 2019, 109, 37–47. [Google Scholar] [CrossRef]

- Duhl, D.N.; Sullivan, C.P. Some effects of hafnium additions on mechanical properties of a columnar-grained nickel-base superalloy. J. Met. 1971, 23, 38–40. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Wang, C.-Y. Transition metal solutes in Ni-based ternary model superalloys: Partitioning and effects on elastic properties from first-principles calculations. Comput. Mater. Sci. 2021, 195, 110447. [Google Scholar] [CrossRef]

- Mostafaei, A.; Behnamian, Y.; Krimer, Y.L.; Stevens, E.L.; Luo, J.L.; Chmielus, M. Effect of solutionizing and aging on the microstructure and mechanical properties of powder bed binder jet printed nickel-based superalloy 625. Mater Des. 2016, 111, 482–491. [Google Scholar] [CrossRef]

- Safarzade, A.; Sharifitabar, M.; Afarani, M.S.H.F.E. effects of heat treatment on microstructure and mechanical properties of inconel 625 alloy fabricated by wire arc additive manufacturing process. Trans. Nonferrous Met. Soc. China 2020, 30, 3016–3030. [Google Scholar] [CrossRef]

- Hu, Y.L.; Li, Y.L.; Zhang, S.Y.; Lin, X.; Wang, Z.H.; Huang, W.D. Effect of solution temperature on static recrystallization and ductility of Inconel 625 superalloy fabricated by directed energy deposition. Mater. Sci. Eng. A 2020, 772, 138711. [Google Scholar] [CrossRef]

- Marchese, G.; Lorusso, M.; Parizia, S.; Bassini, E.; Lee, J.W.; Calignano, F.; Manfredi, D.; Terner, M.; Hong, H.U.; Ugues, D.; et al. Influence of heat treatments on microstructure evolution and mechanical properties of Inconel 625 processed by laser powder bed fusion. Mater. Sci. Eng. A 2018, 729, 64–75. [Google Scholar] [CrossRef]

- Chen, S. Modified heat treatment and related microstructure-mechanical property evolution of arc melting additively manufactured GH4169 Ni-based superalloy. J. Alloys Compd. 2023, 947, 169449. [Google Scholar] [CrossRef]

- Zhao, Z.; Li, L.; Yang, W.; Zeng, Y.; Lian, Y.; Yue, Z. A comprehensive study of theanisotropic tensile properties of laser additive manufactured Ni-based superalloy after heat treatment. Int. J. Plast. 2022, 148, 103147. [Google Scholar] [CrossRef]

- Tucho, W.M.; Cuvillier, P.; Sjolyst-Kvemeland, A.; Hansen, V. Microstructure andhardness studies of Inconel 718 manufactured by selective laser melting beforeand after solution heat treatment. Mater. Sci. Eng. A 2017, 689, 220–232. [Google Scholar] [CrossRef]

- Zhang, D.; Niu, W.; Cao, X.; Liu, Z. Effect of standard heat treatment on the microstructure and mechanical properties of selective laser melting manufacturedInconel 718 superalloy. Mater. Sci. Eng. A 2015, 644, 32–40. [Google Scholar] [CrossRef]

- Chlebus, E.; Gruber, K.; Kuznicka, B.; Kurzac, J.; Kurzynowski, T. Effect of heattreatment on the microstructure and mechanical properties of Inconel 718processed by selective laser melting. Mater. Sci. Eng. A 2015, 639, 647–655. [Google Scholar] [CrossRef]

- Qi, H.; Azer, M.; Ritter, A. Studies of standard heat treatment effects on microstructure and mechanical properties of laser net shape manufactured INCONEL718. Mater. Sci. Eng. A 2009, 40A, 2410–2422. [Google Scholar]

- Hong, S.G.; Kang, K.B.; Park, C.G. Strain-induced precipitation of NbC in Nb-Ti microalloyed HSLA steels. Scr. Mater. 2002, 46, 163–168. [Google Scholar] [CrossRef]

- Misra, R.D.K.; Nathani, H.; Hartmann, J.E.; Siciliano, F.J.M.S. Microstructural evolution in a new 770MPa hot rolled Nb-Ti. Mater. Sci. Eng. A 2005, 394, 339–352. [Google Scholar] [CrossRef]

- Xu, H.C.; Shi, C.B.; Zhu, X.; Wang, S.J.; Li, J.; Wang, S.Z. Eutectic precipitates and microstructure of electroslag remelted 15Cr-22Ni austenitic heat-resistant steel with varying Nb contents. J. Iron Steel Res. Int. 2022, 29, 1823–1835. [Google Scholar] [CrossRef]

- Wangy, F.; Chenx, Z.; Su, C. Microstructure and mechanical properties of Inconel 625 fabricated by wire-arc additive manufacturing. Surf. Coat. Technol. 2019, 374, 116–123. [Google Scholar]

- Xu, F.; Lv, Y.; Liu, Y.; Xu, B.; He, P. Effect of heat treatment on micro structure and mechanical properties of Inconel 625 alloy fabricated by pulsed plasma arc deposition. Phys. Procedia 2013, 50, 48–54. [Google Scholar] [CrossRef]

- Xing, X.; Di, X.; Wang, B. The effect of post-weld heat treatment temperature on the micro structure of Inconel 625 deposited metal. J. Alloys Compd. 2014, 593, 110–116. [Google Scholar] [CrossRef]

- Cozar, R.; Pineau, A. Influence of the Co/Ni ratio on the γ and γ’’ precipitation in Fe-Ni-Co-Ta alloys. Metall. Trans. 1974, 5, 2471–2472. [Google Scholar] [CrossRef]

- Sundararaman, M.; Mukhopadhyay, P.; Banerjee, S. Some aspects of the precipitation of metastable inter metallic phases in Inconel 718. Metall. Trans. A 1992, 23, 2015–2028. [Google Scholar] [CrossRef]

- Kreitcberg, A.; Brailovski, V.; Turenne, S. Effect of heat treatment and hot isostatic pressing on the microstructure and mechanical properties of Inconel 625 alloy processed by laser powder bed fusion. Mater. Sci. Eng. A 2017, 689, 1–10. [Google Scholar] [CrossRef]

- Chu, Z.; Yu, J.; Sun, X.; Guan, H.; Hu, Z. Tensile property and deformation behavior of a direction ally solidified Ni-base super alloy. Mater. Sci. Eng. A 2010, 527, 3010–3014. [Google Scholar] [CrossRef]

- Yang, X.H.; Yu, J.J.; Sun, X.F.; Jin, T.; Guan, H.R.; Hu, Z.O. Investigation of impact toughness of a Ni-based super alloy at elevated temperature. Mater. Des. (1980–2015) 2012, 36, 699–704. [Google Scholar] [CrossRef]

- Li, C.; White, R.; Fang, X.Y.; Weaver, M.; Guo, Y.B. Microstructure Evolution Characteristics of Inconel625 Alloy from Selective Laser Melting to Heat Treatment. Mater. Sci. Eng. A 2017, 705, 20–31. [Google Scholar] [CrossRef]

- Tian, Y.; Gontcharov, A.; Gauvin, R.; Lowden, P.; Brochu, M. Effect of heat treatment on microstructure evolution and mechanical properties of Inconel 625 with 0.4 wt% boron modification fabricated by gas tungsten arc deposition. Mater. Sci. Eng. A 2017, 684, 275–283. [Google Scholar] [CrossRef]

- Ro, Y.; Koizumi, Y.; Harada, H. High temperature tensile properties of a series of nickel-base superalloys on a γ/γʹ tie line. Mater. Sci. Eng. A 1997, 223, 59–63. [Google Scholar] [CrossRef]

- Murakumo, T.; Kobayashi, T.; Koizumi, Y.; Harada, H. Creep behaviour of Ni-base single-crystal superalloys with various y’ volume fraction. Acta Mater. IA 2004, 52, 3737–3744. [Google Scholar] [CrossRef]

- Heo, N.H.; Chang, J.C.; Kim, S.J. Elevated temperature intergranular cracking in heat-resistant steels. Mater. Sci. Eng. A 2013, 559, 665–677. [Google Scholar] [CrossRef]

- Roy, A.K.; Pal, J.; Mukhopadhyay, C. Dynamic strain ageing of an austenitic superalloy- temperature and strain rate effects. Mater. Sci. Eng. A 2008, 474, 363–370. [Google Scholar] [CrossRef]

- He, L.Z.; Zheng, Q.; Sun, X.F.; Hou, G.C.; Guan, H.R.; Hu, Z.Q. M23C6 precipitation behavior in a Ni-base superalloy M963. J. Mater. Sci. 2005, 40, 2959–2964. [Google Scholar] [CrossRef]

- Huang, X.; Kang, Y.; Zhou, H.; Zhang, Y.; Hu, Z. Influence of heat treatment on the microstructure of a unidirectional Ni-base superalloy. Mater. Lett. 1998, 36, 210–213. [Google Scholar] [CrossRef]

- Dai, Z.; Su, Y.; Wang, Y.; Yang, T.; Liang, X. Study on the tensile properties and deformation mechanism of high-temperature resistant nitrogen-containing nickel-based welding material deposited metal. Mater. Sci. Eng. A 2024, 903, 146671. [Google Scholar] [CrossRef]

- Rae, C.M.F.; Reed, R.C. Primary creep in single crystal superalloys: Origins, mechanisms and effects. Acta Mater. 2007, 55, 1067–1081. [Google Scholar] [CrossRef]

- Viswanathan, G.B.; Sarosi, P.M.; Henry, M.F.; Whitis, D.D.; Milligan, W.W.; Mills, M.J. Investigation of creep deformation mechanisms at intermediate temperatures in Rene 88 DT. Acta Mater. 2005, 53, 3041–3057. [Google Scholar] [CrossRef]

- Nanseng, Y.; Yuhuan, W.; Hongzheng, F.; Wengao, L.; Rongde, T. Influence of W and Co on high temperature creep behavior of Ni-20Cr base alloys. Acta Metall. Sin. 1981, 17, 44–49. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).