Mechanical Characterization and Microstructural Analysis of Stir-Cast Aluminum Matrix Composites (LM5/ZrO2)

Abstract

1. Introduction

2. Materials Used

2.1. Aluminum Alloy (LM5)

2.2. Zirconium Dioxide (ZrO2)

3. Fabrication of LM5/ZrO2 Composites

4. Micro Structural Analysis

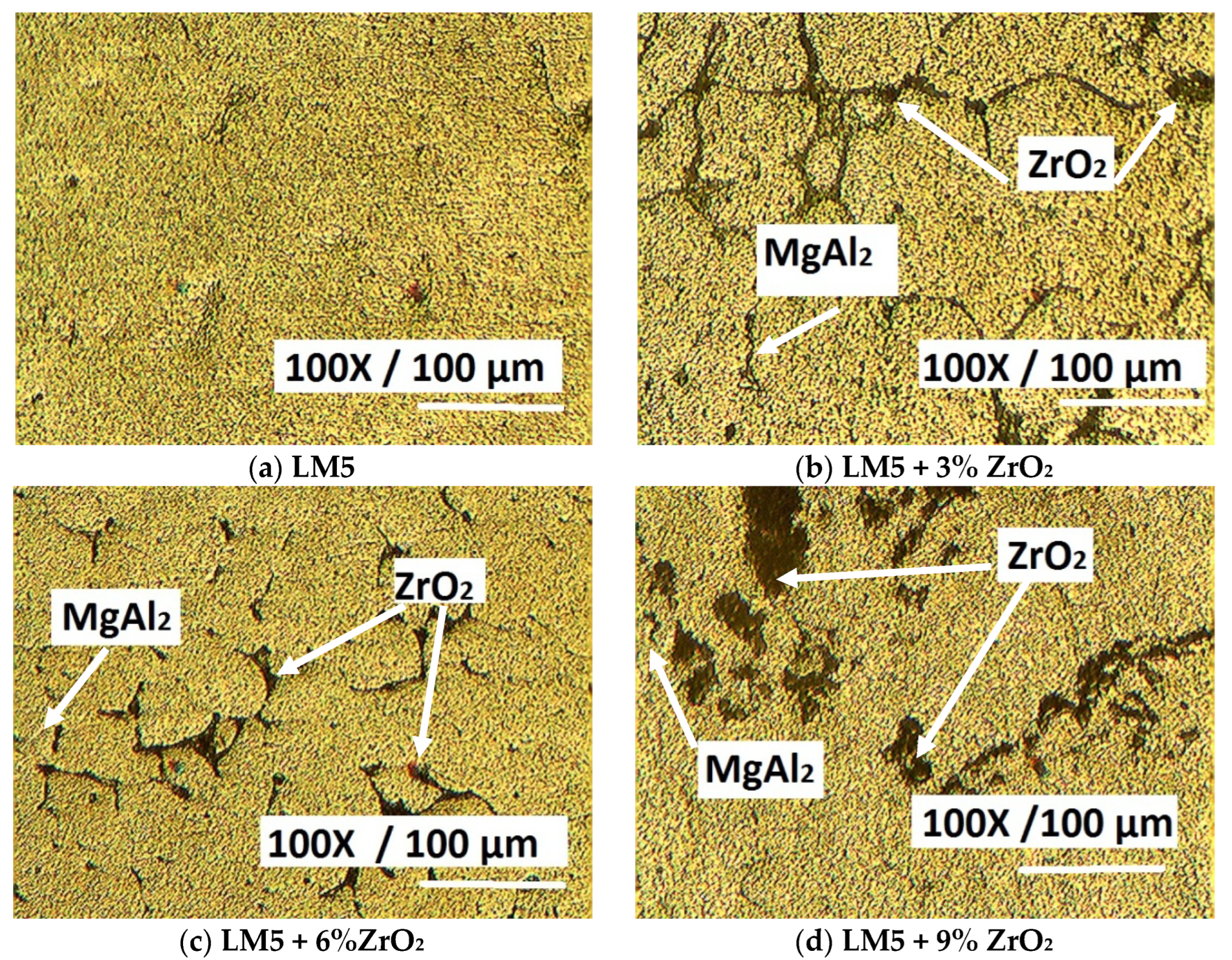

4.1. Optical Microscopy

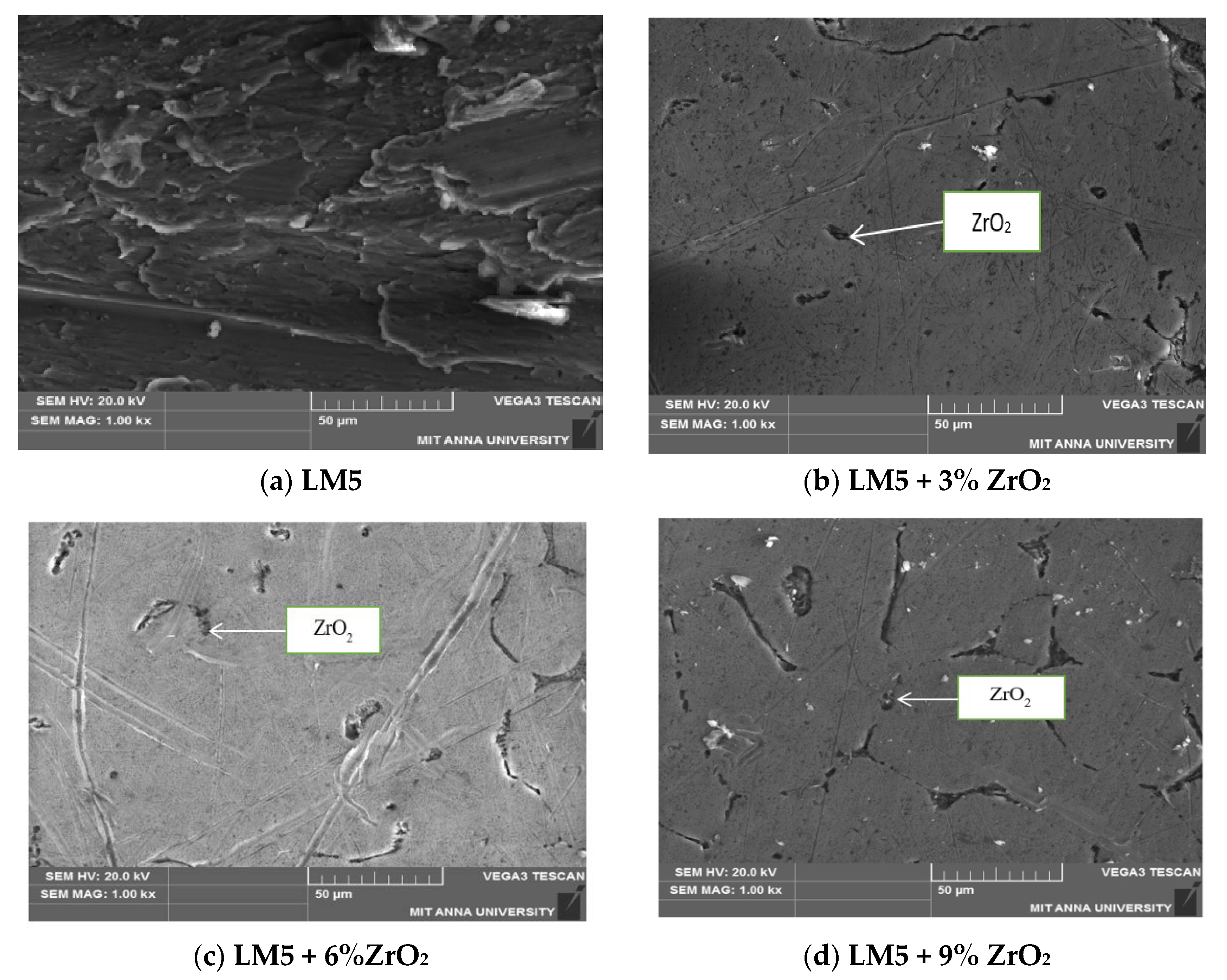

4.2. Scanning Electron Microscopy (SEM & EDAX)

5. Mechanical Characterization

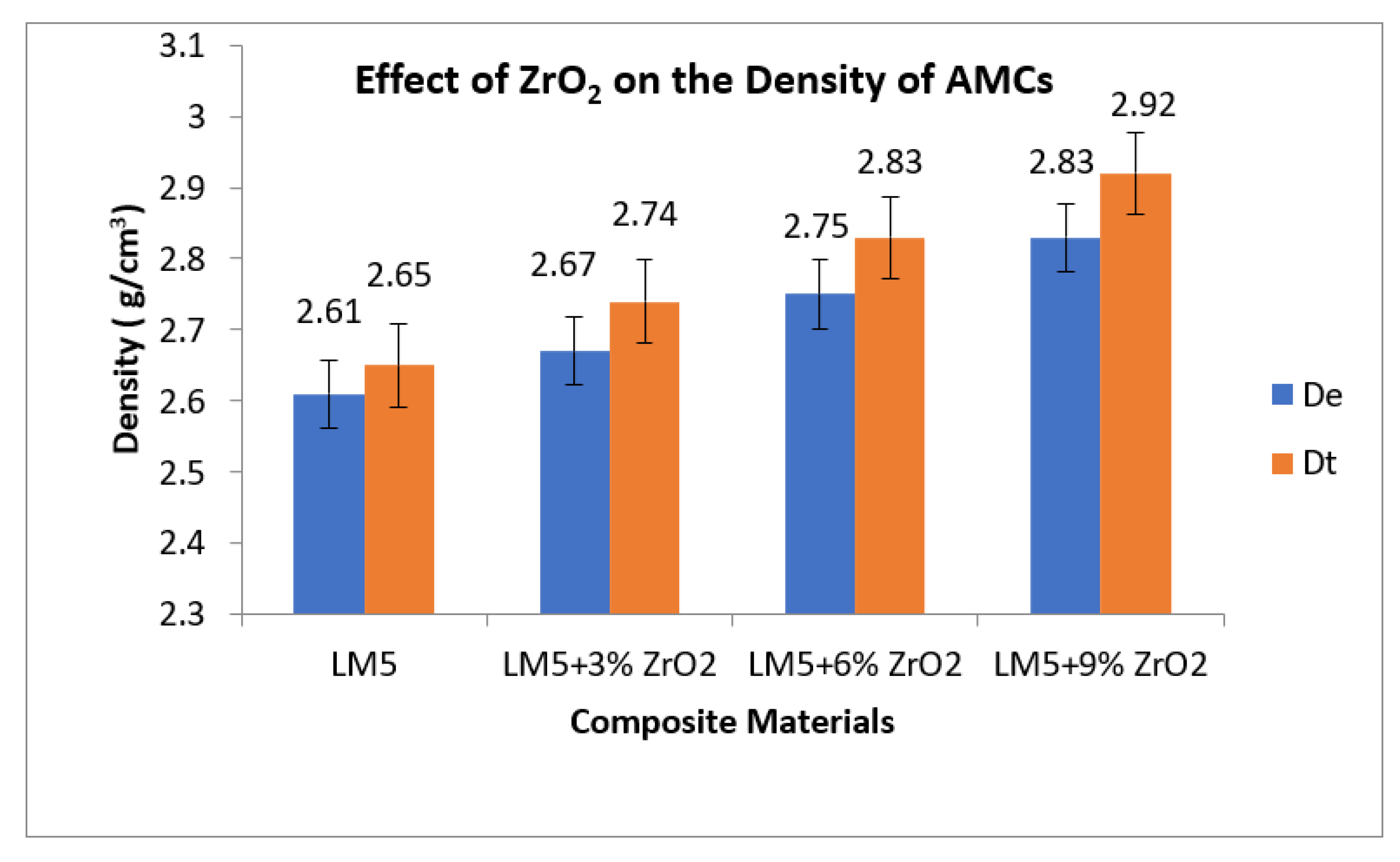

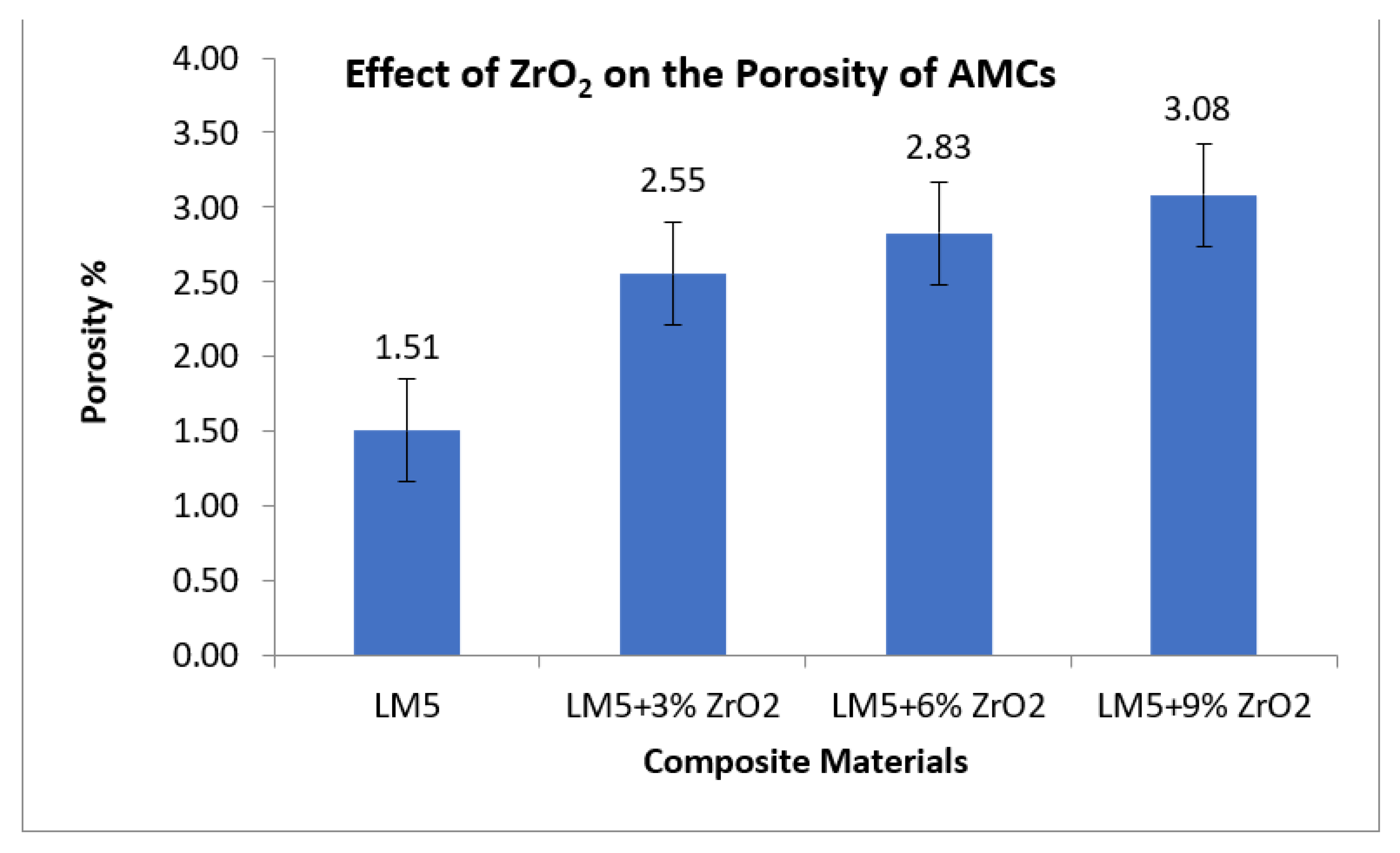

5.1. Density

5.2. Micro Hardness

5.3. Macro Hardness

5.4. Tensile Strength

5.5. Compressive Strength

5.6. Impact Strength

6. Results and Discussions

6.1. Microstructural Analysis

6.2. Density

6.3. Micro Hardness

6.4. Macro Hardness

6.5. Tensile Strength

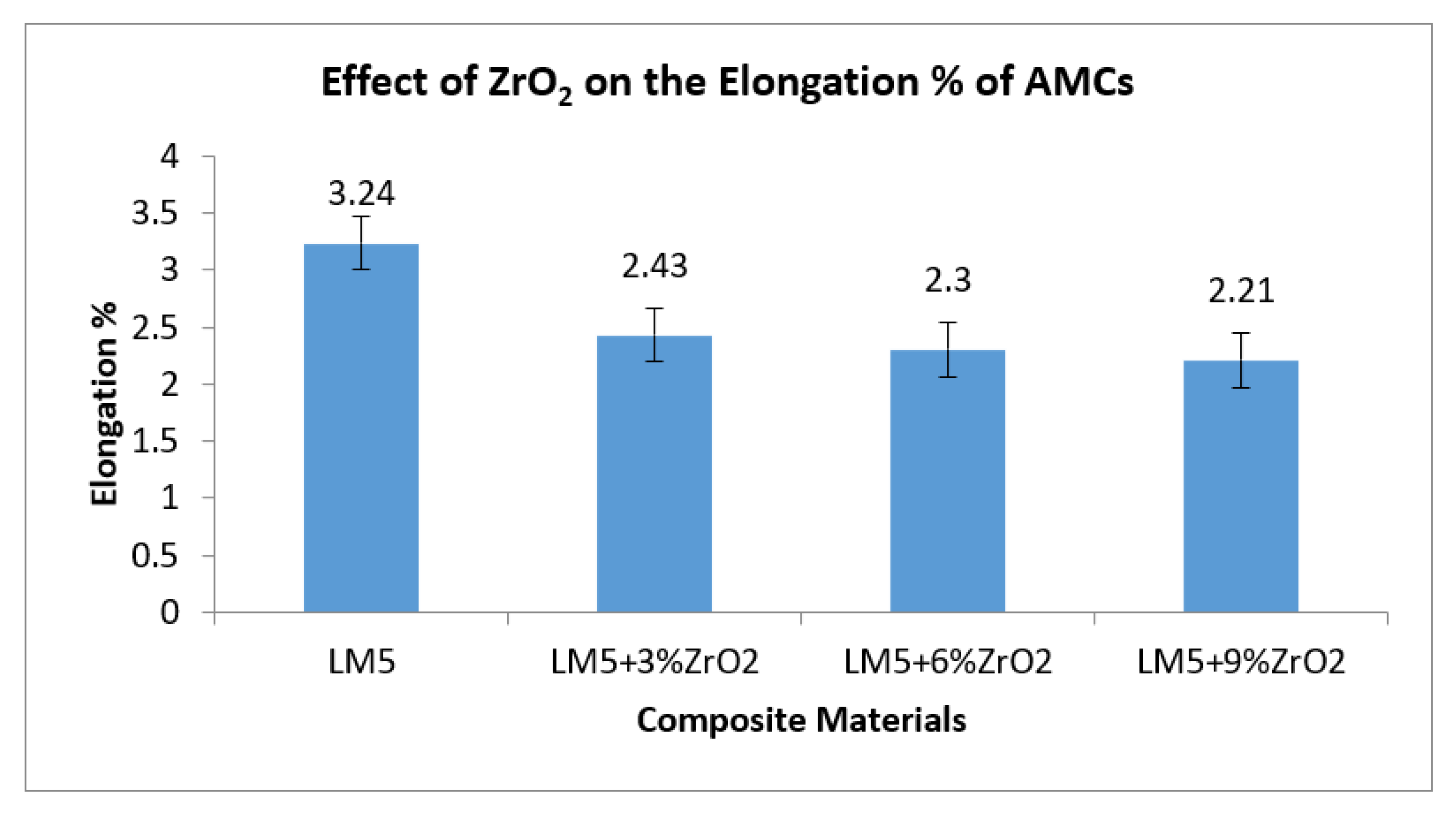

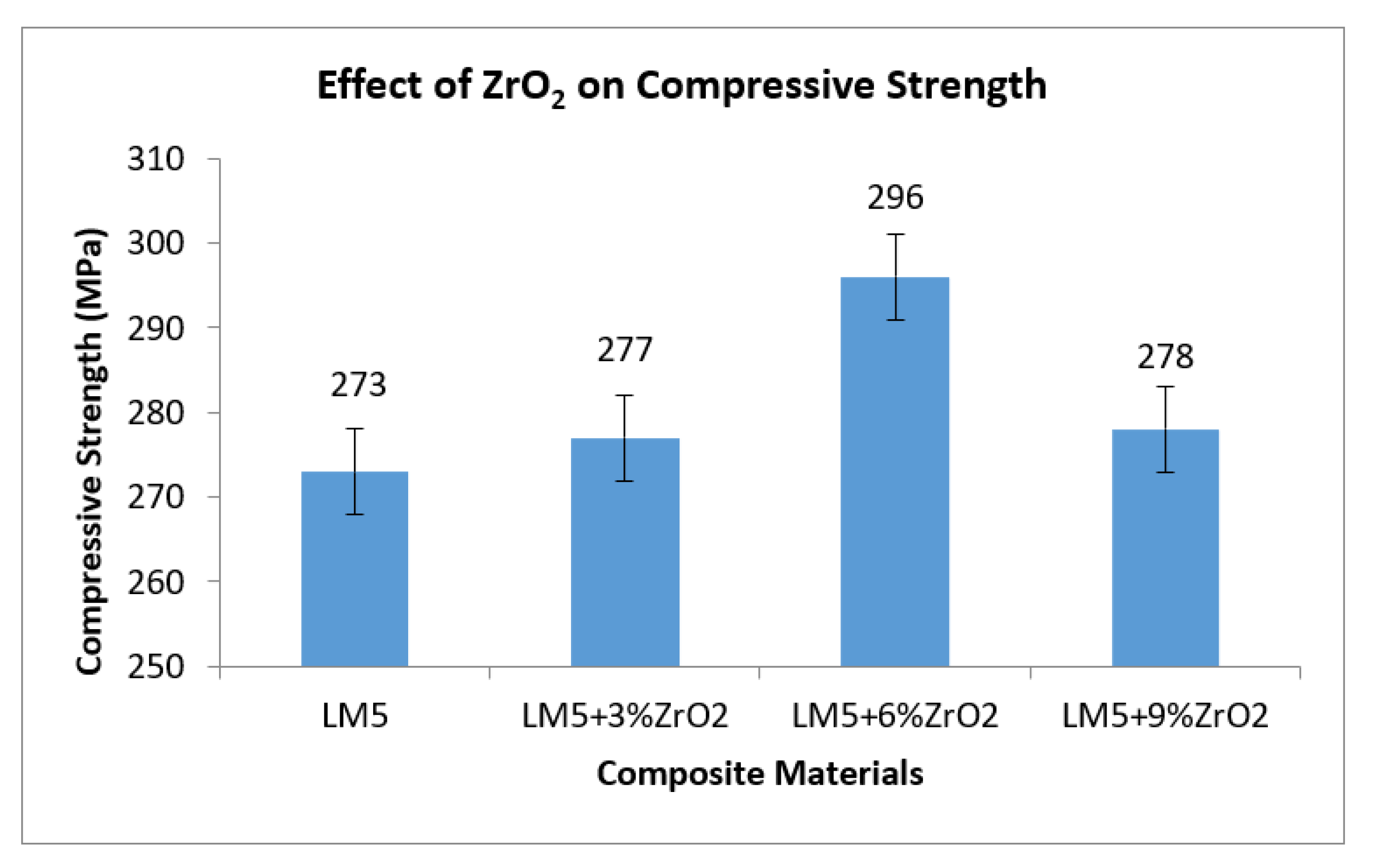

6.6. Compression Strength

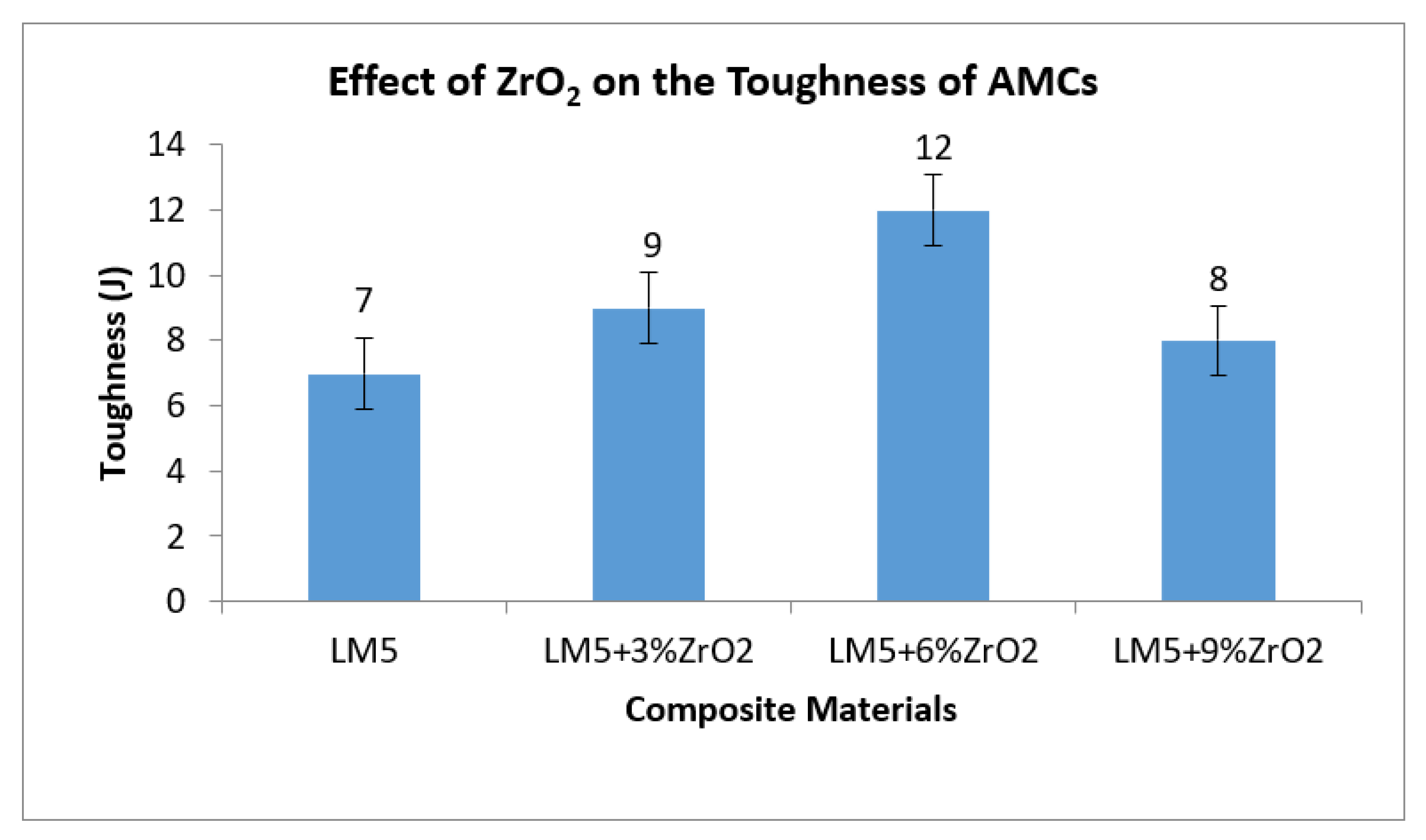

6.7. Impact Strength

7. Conclusions

- (i)

- The optical micrograph and SEM of the AMCs show a uniform distribution of reinforcement particles in the matrix. EDAX shows the presence of constituents.

- (ii)

- The LM5/9%ZrO2 AMC has the highest density value of 2.83 g/cm3. The LM5/3%ZrO2 AMC has a porosity of 2.55%.

- (iii)

- The LM5/9% ZrO2 AMC has the highest micro hardness value of 78 VHN and macro hardness of 72 HRE.

- (iv)

- The LM5/6% ZrO2 AMC has the highest tensile strength of 220 MPa, highest compressive strength of 296 MPa, and hardest toughness of 12 J.

- (v)

- The LM5/6% ZrO2 AMCs may be used for many structural applications due to their excellent mechanical properties.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shi, Q.; Zhou, J.; Ullah, S.; Yang, X.; Tokarska, K.; Trzebicka, B.; Ta, H.Q.; Rümmeli, M.H. A review of recent developments in Si/C composite materials for Li-ion batteries. Energy Storage Mater. 2021, 34, 735–754. [Google Scholar] [CrossRef]

- Nturanabo, F.; Masu, L.; Kirabira, J.B. Novel Applications of Aluminium Metal Matrix Composites. Aluminum Alloys and Composites; IntechOpen: London, UK, 2020. [Google Scholar] [CrossRef]

- Blanco, D.; Rubio, E.M.; Lorente-Pedreille, R.M.; Sáenz-Nuño, M.A. Lightweight Structural Materials in Open Access: Latest Trends. Materials 2021, 14, 6577. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Zhu, J.; Ji, C.; Guo, Y.; Fang, R.; Mei, S.; Liu, S. Laser powder bed fusion of high-entropy alloy particle-reinforced stainless steel with enhanced strength, ductility, and corrosion resistance. Mater. Des. 2021, 209, 109950. [Google Scholar] [CrossRef]

- Prakash, J.U.; Moorthy, T.; Ananth, S. Fabrication and Sliding Wear Behaviour of Metal Matrix Composites. Appl. Mech. Mater. 2014, 612, 157–162. [Google Scholar] [CrossRef]

- Sadhana, A.D.; Prakash, J.U.; Sivaprakasam, P.; Ananth, S. Wear behaviour of aluminium matrix composites (LM25/Fly ash)–A Taguchi approach. Mater. Today Proc. 2020, 33, 3093–3096. [Google Scholar] [CrossRef]

- Srikanth, M.; Annamalai, A.R.; Muthuchamy, A.; Jen, C.-P. A Review of the Latest Developments in the Field of Refractory High-Entropy Alloys. Crystals 2021, 11, 612. [Google Scholar] [CrossRef]

- Ravi, B.; Naik, B.B.; Prakash, J.U. Characterization of Aluminium Matrix Composites (AA6061/B4C) Fabricated by Stir Casting Technique. Mater. Today Proc. 2015, 2, 2984–2990. [Google Scholar] [CrossRef]

- Danninger, H.; Calderon, R.D.O.; Gierl-Mayer, C. Powder metallurgy and sintered materials. Addit. Manuf. 2017, 19, 1–57. [Google Scholar]

- Meena, K.; Manna, A.; Banwait, S. An Analysis of Mechanical Properties of the Developed Al/SiC-MMC’s. Am. J. Mech. Eng. 2013, 1, 14–19. [Google Scholar] [CrossRef]

- Ravikumar, M.; Reddappa, H.N.; Suresh, R. Study on mechanical and Tribological characterization of Al2O3/SiCp reinforced aluminum metal matrix composite. Silicon 2018, 10, 2535–2545. [Google Scholar] [CrossRef]

- Rino, J.; Sivalingappa, D.; Koti, H.; Jebin, D.V. Properties of Al6063 MMC Reinforced with Zircon Sand and Alumina. IOSR J. Mech. Civ. Eng. 2013, 5, 72–77. [Google Scholar] [CrossRef]

- Girisha, K.B.; Chittappa, H.C. Preparation, Characterization and Wear Study of Aluminum Alloy (Al 356.1) Reinforced with Zirconium Nano Particles. Int. J. Innov. Res. Sci. Eng. Technol. 2013, 2, 3627–3637. [Google Scholar]

- Nathan, V.B.; Soundararajan, R.; Abraham, C.B.; Vinoth, E.; Narayanan, J. Study of mechanical and metallurgical characterization of correlated aluminium hybrid metal matrix composites. Mater. Today Proc. 2021, 45, 1237–1242. [Google Scholar] [CrossRef]

- Malhotra, S.; Narayan, R.; Gupta, R.D. Synthesis and Characterization of Aluminum 6061 Alloy-Fly ash& Zir-conia Metal Matrix Composite. Int. J. Curr. Eng. Technol. 2013, 3, 1716–1719. [Google Scholar]

- Madhusudhan, M.; Naveen, G.; Mahesha, K. Mechanical Characterization of AA7068-ZrO2 reinforced Metal Matrix Composites. Mater. Today Proc. 2017, 4, 3122–3130. [Google Scholar] [CrossRef]

- Jebarose Juliyana, S.; Udaya Prakash, J.; Čep, R.; Karthik, K. Multi-Objective Optimization of Machining Parameters for Drilling LM5/ZrO2 Composites Using Grey Relational Analysis. Materials 2023, 16, 3615. [Google Scholar] [CrossRef]

- Jebarose Juliyana, S.; Udaya Prakash, J.; Salunkhe, S. Optimisation of wire EDM process parameters using Taguchi technique for machining of hybrid composites. Int. J. Mater. Eng. Innov. 2022, 13, 257–271. [Google Scholar] [CrossRef]

- Rubi, C.S.; Prakash, J.U. Drilling of Hybrid Aluminum Matrix Composites using Grey-Taguchi Method. INCAS Bull. 2020, 12, 167–174. [Google Scholar] [CrossRef]

- Jebarose Juliyana, S.; Udaya Prakash, J. Optimization of Machining Parameters for Wire EDM of AMCs (LM5/ZrO2) using Taguchi Technique. INCAS Bullein 2022, 14, 57–68. [Google Scholar] [CrossRef]

- Zhang, W.Y.; Du, Y.H.; Zhang, P.; Wang, Y.J. Air-isolated stir casting of homogeneous Al-SiC composite with no air entrapment and Al4C3. J. Mater. Process. Technol. 2019, 271, 226–236. [Google Scholar] [CrossRef]

- Sozhamannan, G.G.; Prabu, S.B.; Venkatagalapathy, V.S.K. Effect of Processing Paramters on Metal Matrix Composites: Stir Casting Process. J. Surf. Eng. Mater. Adv. Technol. 2012, 2, 11–15. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Essa, A.R.S.; Ataya, S.; Seleman, M.M.E.-S.; El-Aty, A.A.; Alzahrani, B.; Touileb, K.; Bakkar, A.; Ponnore, J.J.; Mohamed, A.Y.A. Friction Stir Welding of AA5754-H24: Impact of Tool Pin Eccentricity and Welding Speed on Grain Structure, Crystallographic Texture, and Mechanical Properties. Materials 2023, 16, 2031. [Google Scholar] [CrossRef]

- Ghiasvand, A.; Ranjbarnodeh, E.; Mirsalehi, S.E. The microstructure and mechanical properties of single-pass and double-pass lap joint of Al 5754H-11 and Mg AZ31-O alloys by friction stir welding. J. Mater. Res. Technol. 2023, 23, 6023–6038. [Google Scholar] [CrossRef]

- Bhandare, R.G.; Sonawane, P.M. Preparation of aluminium matrix composite by using stir casting method. Int. J. Eng. Adv. Technol. 2013, 3, 61–65. [Google Scholar]

- Jebarose Juliyana, S.; Udaya Prakash, J. Optimisation of drilling process parameters of aluminium matrix composites (LM5/ZrO2). Int. J. Enterp. Netw. Manag. 2023, 14, 193–204. [Google Scholar]

- Juliyana, S.J.; Prakash, J.U. Optimization of burr height in drilling of aluminium matrix composites (LM5/ZrO2) using Taguchi technique. Adv. Mater. Process. Technol. 2022, 8, 417–426. [Google Scholar] [CrossRef]

- Juliyana, S.J.; Prakash, J.U. Drilling parameter optimization of metal matrix composites (LM5/ZrO2) using Taguchi Technique. Mater. Today Proc. 2020, 33, 3046–3050. [Google Scholar] [CrossRef]

- Gigan, S. Optical microscopy aims deep. Nat. Photon. 2017, 11, 14–16. [Google Scholar] [CrossRef]

- Mertz, J. Introduction to Optical Microscopy, 2nd ed.; Cambridge University Press: Cambridge, UK, 2019. [Google Scholar] [CrossRef]

- Azad, M.; Avin, A. Scanning Electron Microscopy (SEM): A Review. In Proceedings of the 2018 International Conference on Hydraulics and Pneumatics—HERVEX, Baile Govora, Romania, 7–9 November 2018; pp. 1–9. [Google Scholar]

- Ouakki, M.; Galai, M.; Benzekri, Z.; Verma, C.; Ech-Chihbi, E.; Kaya, S.; Boukhris, S.; Ebenso, E.E.; Touhami, M.E.; Cherkaoui, M. Insights into corrosion inhibition mechanism of mild steel in 1 M HCl solution by quinoxaline derivatives: Electrochemical, SEM/EDAX, UV-visible, FT-IR and theoretical approaches. Colloids Surfaces A Physicochem. Eng. Asp. 2021, 611, 125810. [Google Scholar] [CrossRef]

- Li, Y.; Kim, H.N.; Wu, H.; Kim, M.J.; Ko, J.W.; Park, Y.J.; Huang, Z.; Kim, H.D. Microstructure and thermal con-ductivity of gas-pressure-sintered Si3N4 ceramic: The effects of Y2O3 additive content. J. Eur. Ceram. Soc. 2021, 41, 274–283. [Google Scholar] [CrossRef]

- Broitman, E. Indentation Hardness Measurements at Macro-, Micro-, and Nanoscale: A Critical Overview. Tribol. Lett. 2017, 65, 23. [Google Scholar] [CrossRef]

- Rezayat, M.; Yazdi, M.S.; Zandi, M.D.; Azami, A. Tribological and corrosion performance of electrodeposited Ni–Fe/Al2O3 coating. Results Surf. Interfaces 2022, 9, 100083. [Google Scholar] [CrossRef]

- Ashkani, O.; Tavighi, M.R.; Karamimoghadam, M.; Moradi, M.; Bodaghi, M.; Rezayat, M. Influence of Aluminum and Copper on Mechanical Properties of Biocompatible Ti-Mo Alloys: A Simulation-Based Investigation. Micromachines 2023, 14, 1081. [Google Scholar] [CrossRef]

- Idrisi, A.H.; Mourad, A.-H.I. Conventional stir casting versus ultrasonic assisted stir casting process: Mechanical and physical characteristics of AMCs. J. Alloys Compd. 2019, 805, 502–508. [Google Scholar] [CrossRef]

- Jiang, B.; Zhenglong, L.; Xi, C.; Peng, L.; Nannan, L.; Yanbin, C. Microstructure and mechanical properties of TiB2-reinforced 7075 aluminum matrix composites fabricated by laser melting deposition. Ceram. Int. 2019, 45, 5680–5692. [Google Scholar] [CrossRef]

- Sharma, D.K.; Sharma, M.; Upadhyay, G. Services, Boron Carbide (B4C) Reinforced Aluminum Matrix Composites (AMCs). Int. J. Innov. Technol. Explor. Eng. 2019, 9, 2194–2203. [Google Scholar] [CrossRef]

- Abdel Hakam, R.; Abdel Aziz Taha, M. Study of mechanical properties and wear behavior of nano-ZrO2-hardened Al2024 matrix composites prepared by stir cast method. Egypt. J. Chem. 2022, 65, 307–313. [Google Scholar]

- Udayashankar, S.; Ramamurthy, V.S. Development and Characterization of Al 6061-ZrO2 Reinforced Metal Matrix Composites. Int. J. Eng. Technol. 2018, 7, 128–132. [Google Scholar]

- Pai, B.C.; Ramani, G.; Pillai, R.M.; Satyanarayana, K.G. Role of magnesium in cast aluminium alloy matrix compo-sites. J. Mater. Sci. 1995, 30, 1903–1911. [Google Scholar] [CrossRef]

- Yar, A.A.; Montazerian, M.; Abdizadeh, H.; Baharvandi, H. Microstructure and mechanical properties of aluminum alloy matrix composite reinforced with nano-particle MgO. J. Alloy Compd. 2010, 484, 400–404. [Google Scholar] [CrossRef]

- Prakash, J.U.; Juliyana, S.J.; Pallavi, P.; Moorthy, T. Optimization of Wire EDM Process Parameters for Machining Hybrid Composites (356/B4C/Fly Ash) using Taguchi Technique. Mater. Today Proc. 2018, 5, 7275–7283. [Google Scholar] [CrossRef]

- Biswas, P.; Mandal, D.; Mondal, M.K. Failures analysis of in-situ Al–Mg2Si composites using actual microstructure based model. Mater. Sci. Eng. A 2020, 797, 140155. [Google Scholar] [CrossRef]

- Samal, P.; Vundavilli, P.R.; Meher, A.; Mahapatra, M.M. Recent progress in aluminum metal matrix composites: A review on processing, mechanical and wear properties. J. Manuf. Process. 2020, 59, 131–152. [Google Scholar] [CrossRef]

- Abdizadeh, H.; Baghchesara, M.A. Investigation on mechanical properties and fracture behavior of A356 aluminum alloy based ZrO2 particle reinforced metal-matrix composites. Ceram. Int. 2013, 39, 2045–2050. [Google Scholar] [CrossRef]

- Al-Jaafari, M.A. A comparative study using silicon carbide and zirconium dioxide nano material’s to improve the me-chanical properties of 6261AA. Period. Eng. Nat. Sci. 2022, 10, 323–333. [Google Scholar]

- Juliyana, S.J.; Prakash, J.U.; Salunkhe, S.; Hussein, H.M.A.; Gawade, S.R. Mechanical Characterization and Microstructural Analysis of Hybrid Composites (LM5/ZrO2/Gr). Crystals 2022, 12, 1207. [Google Scholar] [CrossRef]

- Vatin, N.I.; Murali, G.; Abid, S.R.; de Azevedo, A.R.G.; Tayeh, B.A.; Dixit, S. Enhancing the Impact Strength of Prepacked Aggregate Fibrous Concrete Using Asphalt-Coated Aggregates. Materials 2022, 15, 2598. [Google Scholar] [CrossRef]

| Cu | Mg | Si | Mn | Fe | Pb | Zn | Al |

|---|---|---|---|---|---|---|---|

| 0.032 | 3.299 | 0.212 | 0.022 | 0.268 | 0.02 | 0.01 | Balance |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prakash, J.U.; Jebarose Juliyana, S.; Salunkhe, S.; Gawade, S.R.; Nasr, E.S.A.; Kamrani, A.K. Mechanical Characterization and Microstructural Analysis of Stir-Cast Aluminum Matrix Composites (LM5/ZrO2). Crystals 2023, 13, 1220. https://doi.org/10.3390/cryst13081220

Prakash JU, Jebarose Juliyana S, Salunkhe S, Gawade SR, Nasr ESA, Kamrani AK. Mechanical Characterization and Microstructural Analysis of Stir-Cast Aluminum Matrix Composites (LM5/ZrO2). Crystals. 2023; 13(8):1220. https://doi.org/10.3390/cryst13081220

Chicago/Turabian StylePrakash, Jayavelu Udaya, Sunder Jebarose Juliyana, Sachin Salunkhe, Sharad Ramdas Gawade, Emad S. Abouel Nasr, and Ali K. Kamrani. 2023. "Mechanical Characterization and Microstructural Analysis of Stir-Cast Aluminum Matrix Composites (LM5/ZrO2)" Crystals 13, no. 8: 1220. https://doi.org/10.3390/cryst13081220

APA StylePrakash, J. U., Jebarose Juliyana, S., Salunkhe, S., Gawade, S. R., Nasr, E. S. A., & Kamrani, A. K. (2023). Mechanical Characterization and Microstructural Analysis of Stir-Cast Aluminum Matrix Composites (LM5/ZrO2). Crystals, 13(8), 1220. https://doi.org/10.3390/cryst13081220