Development of Thermoelectric Half-Heusler Alloys over the Past 25 Years

Abstract

1. Introduction

2. Experimental Production Methods

3. Results and Discussion

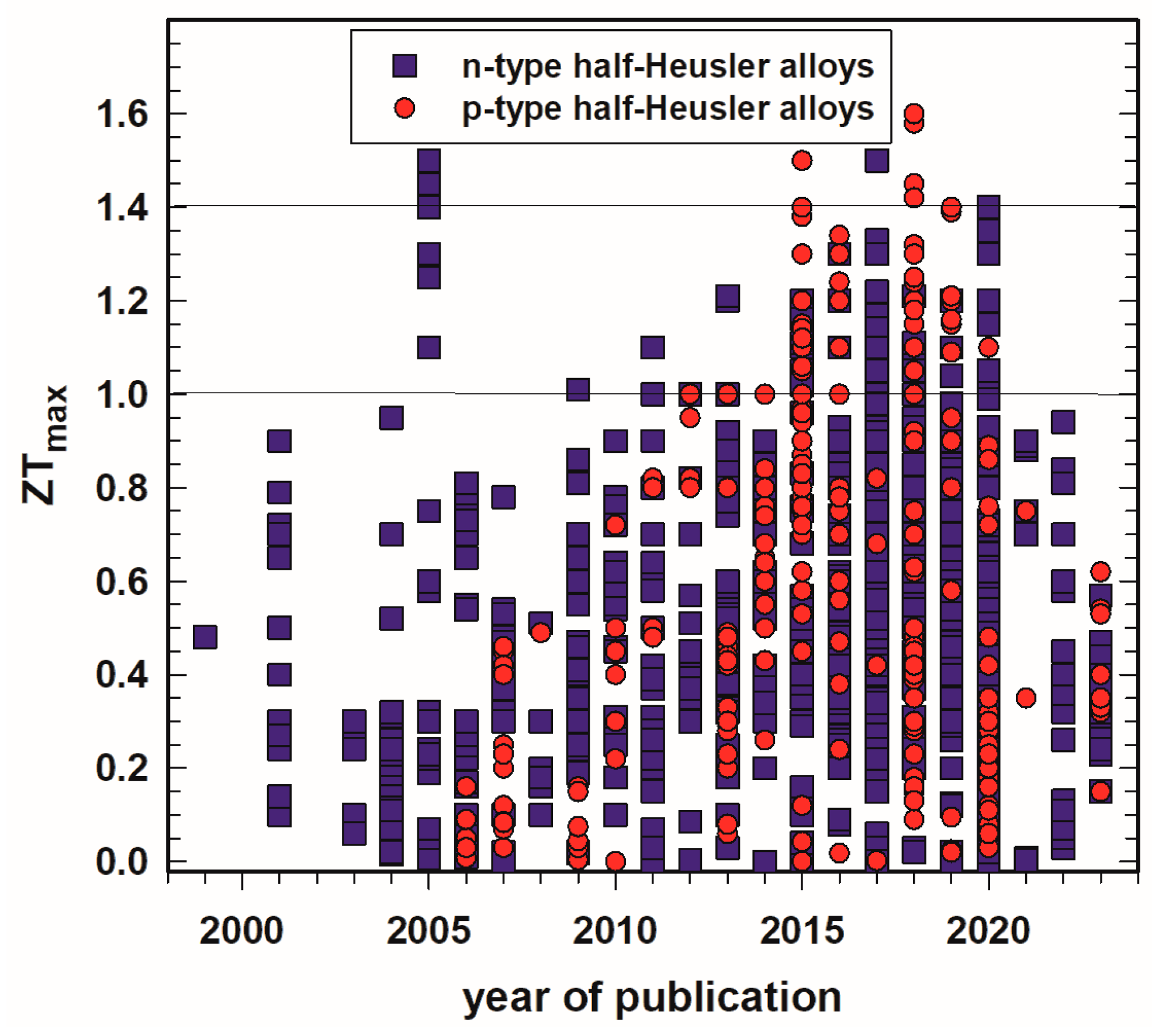

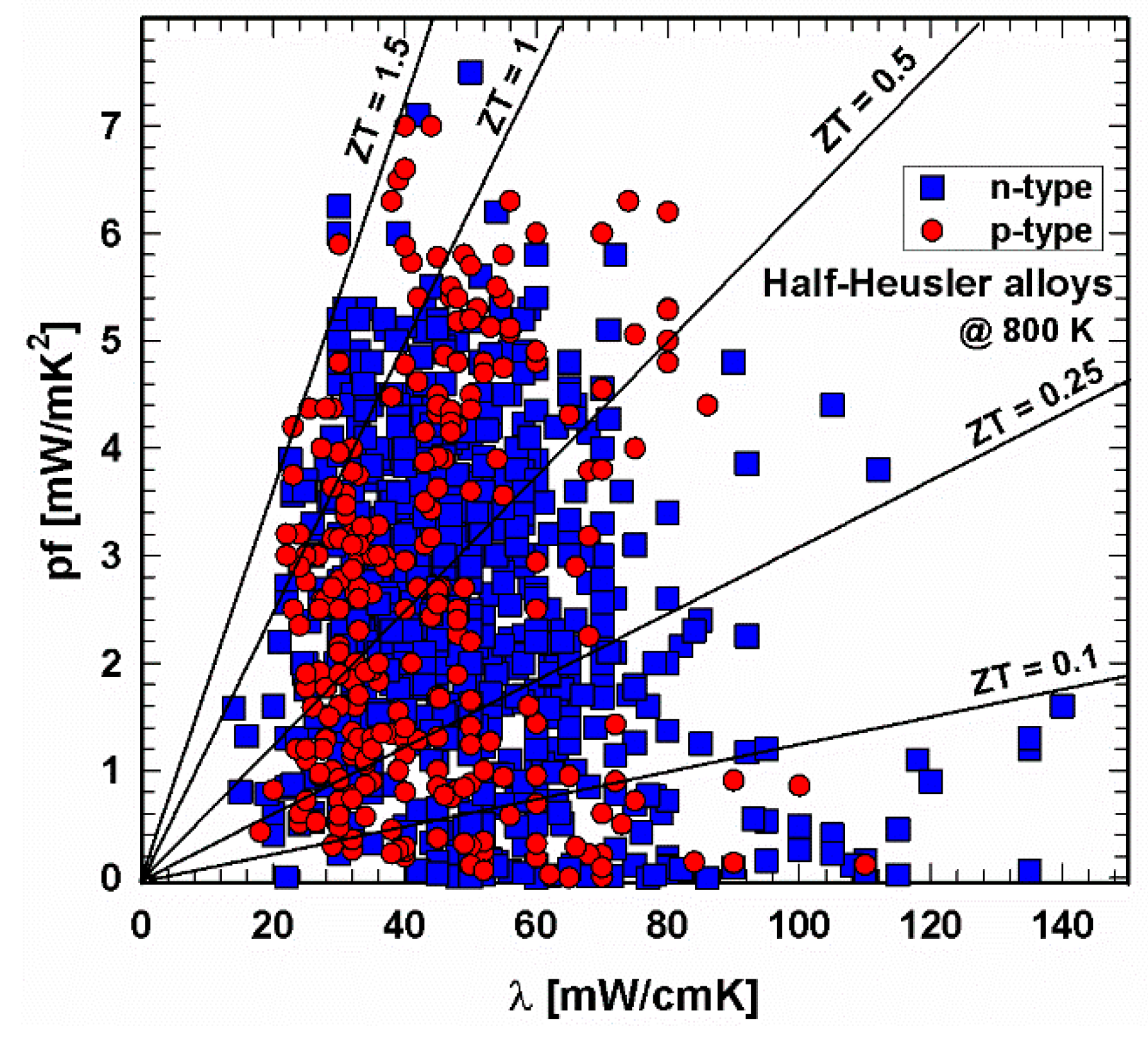

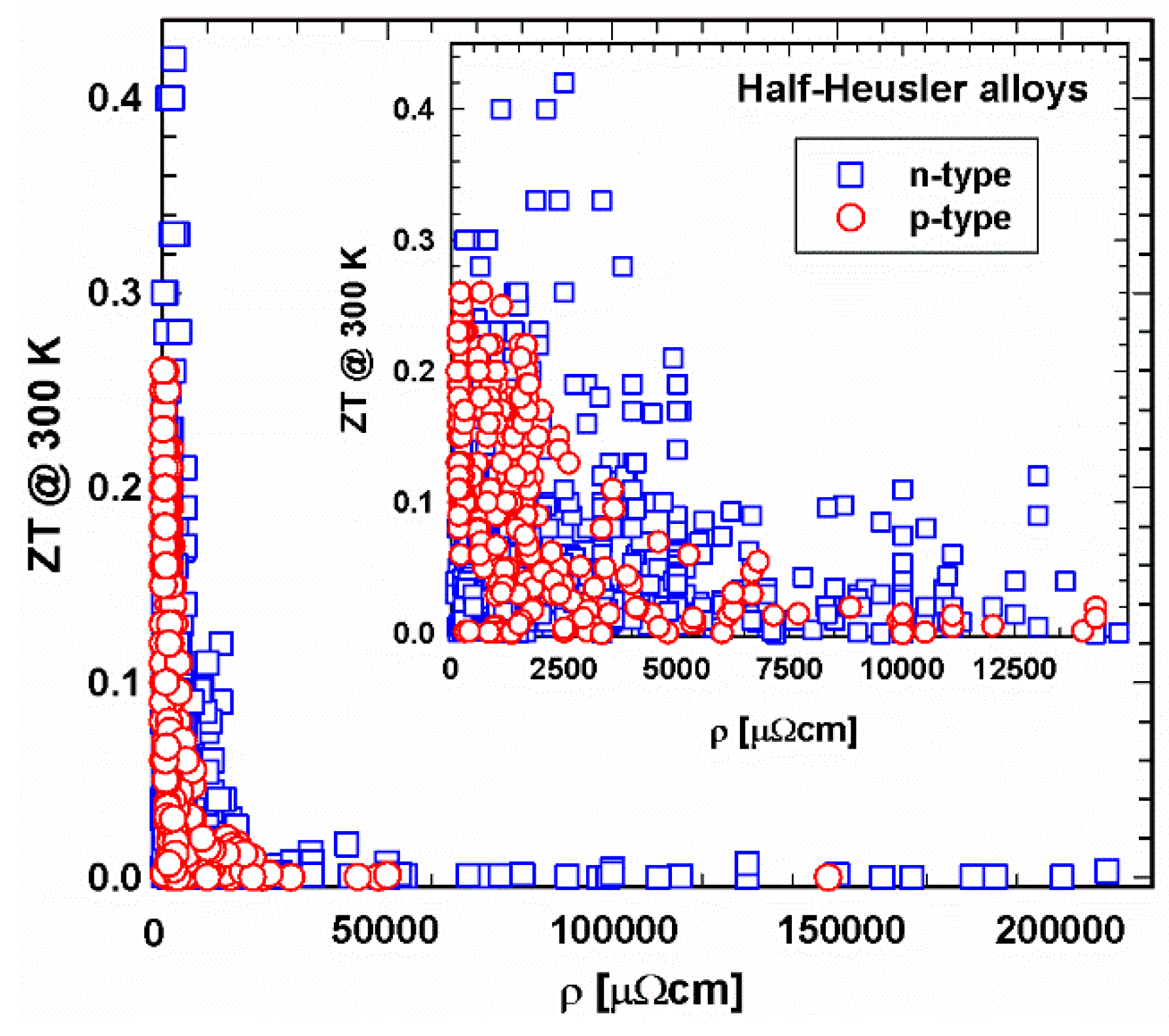

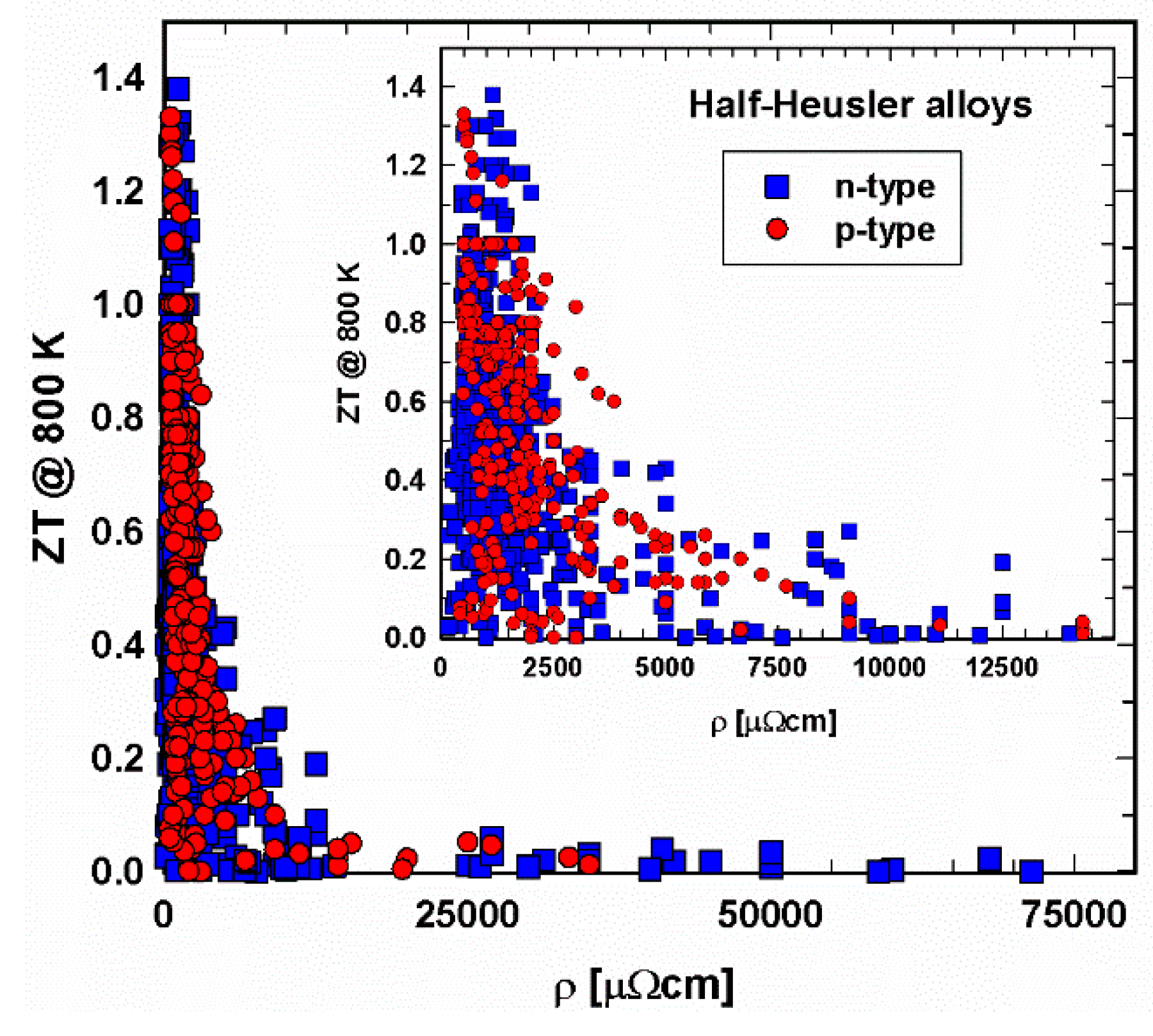

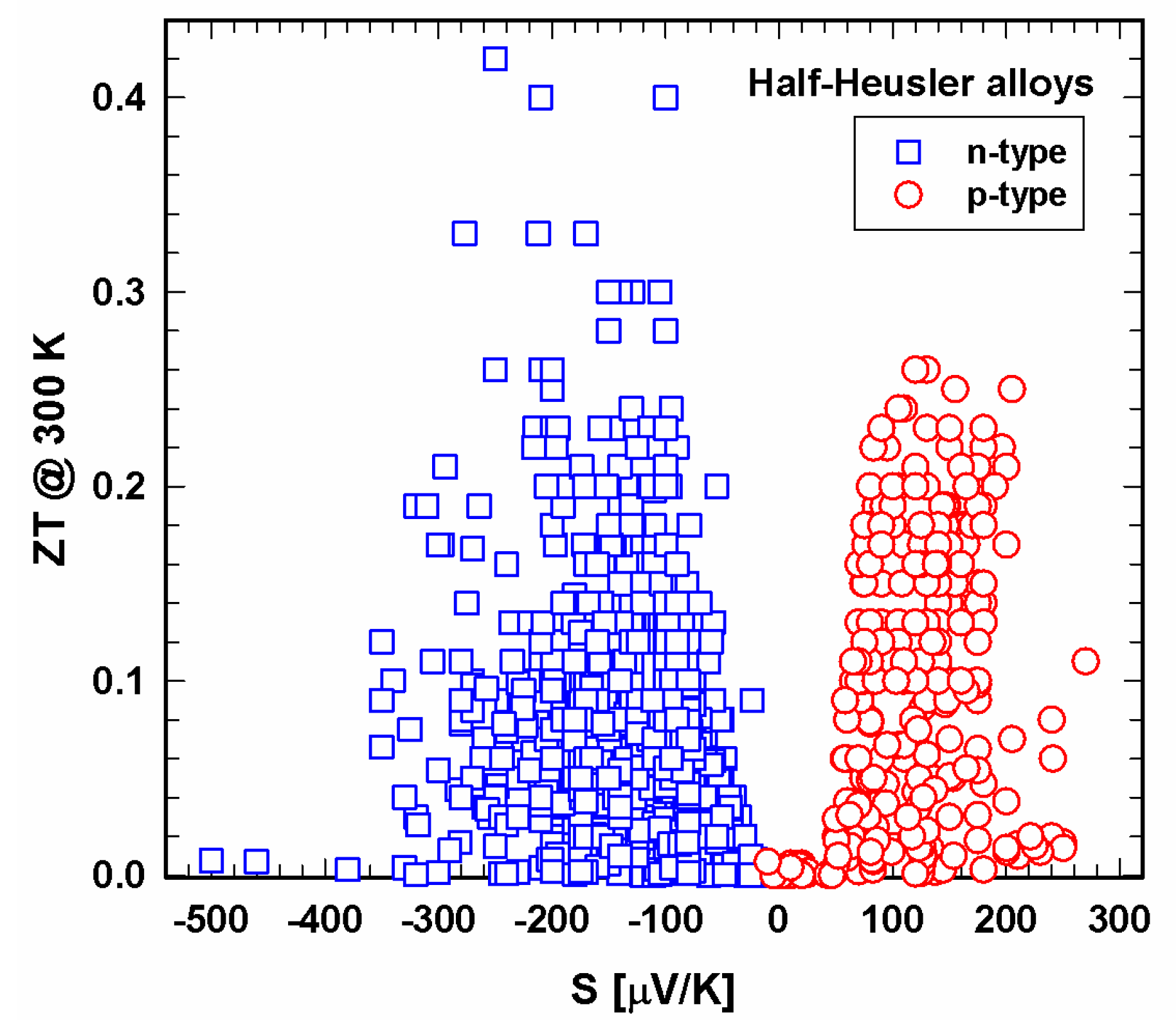

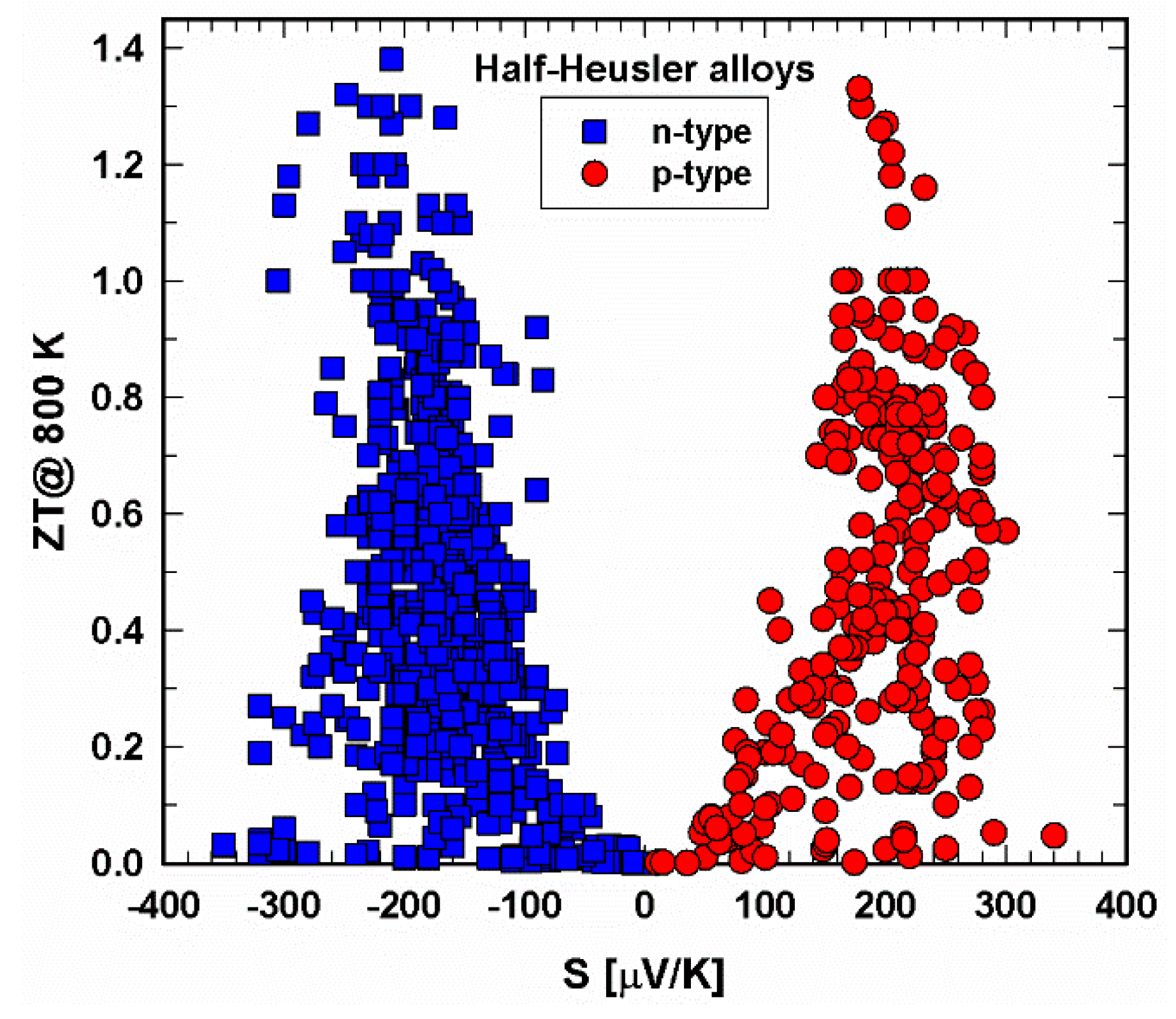

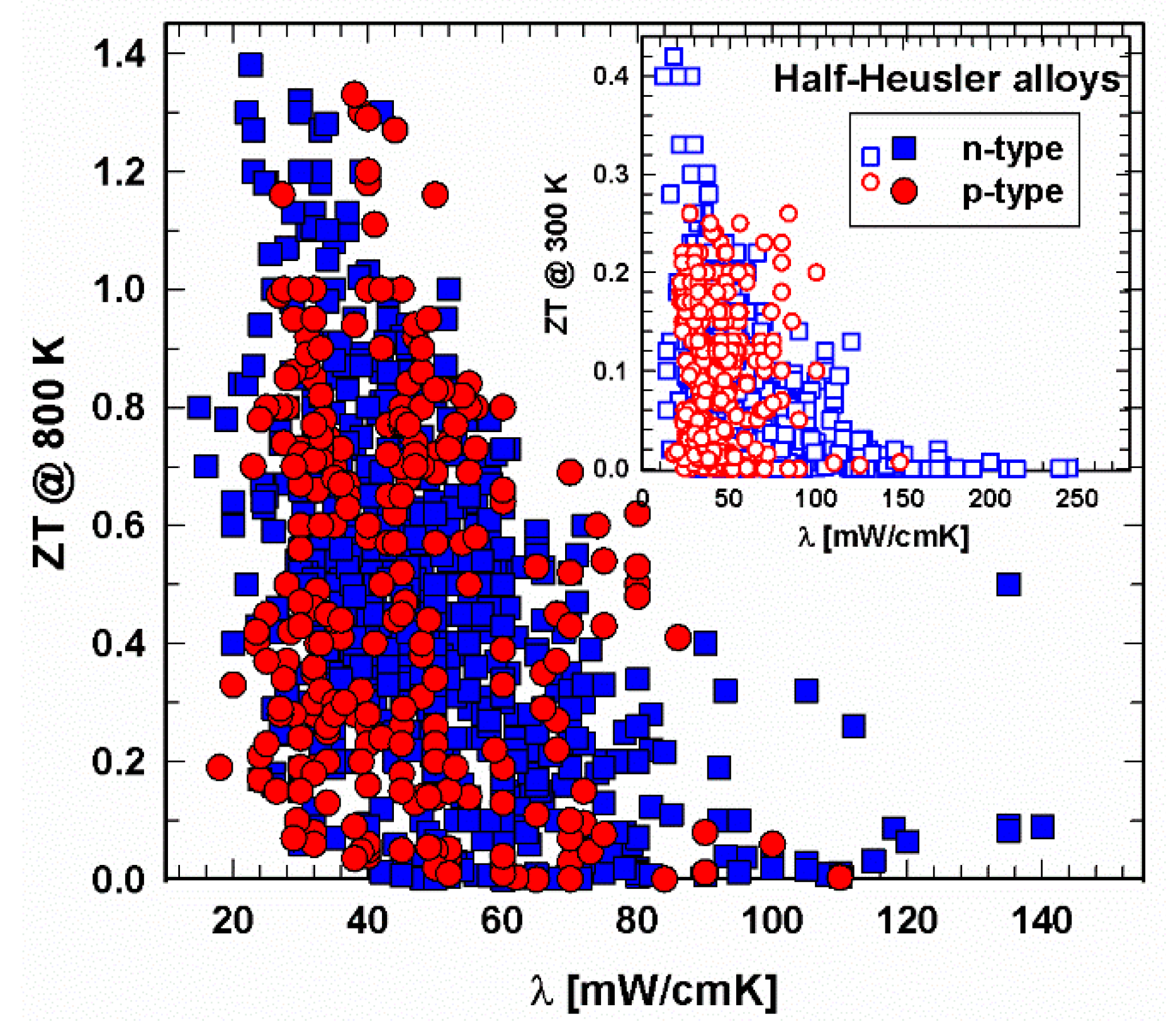

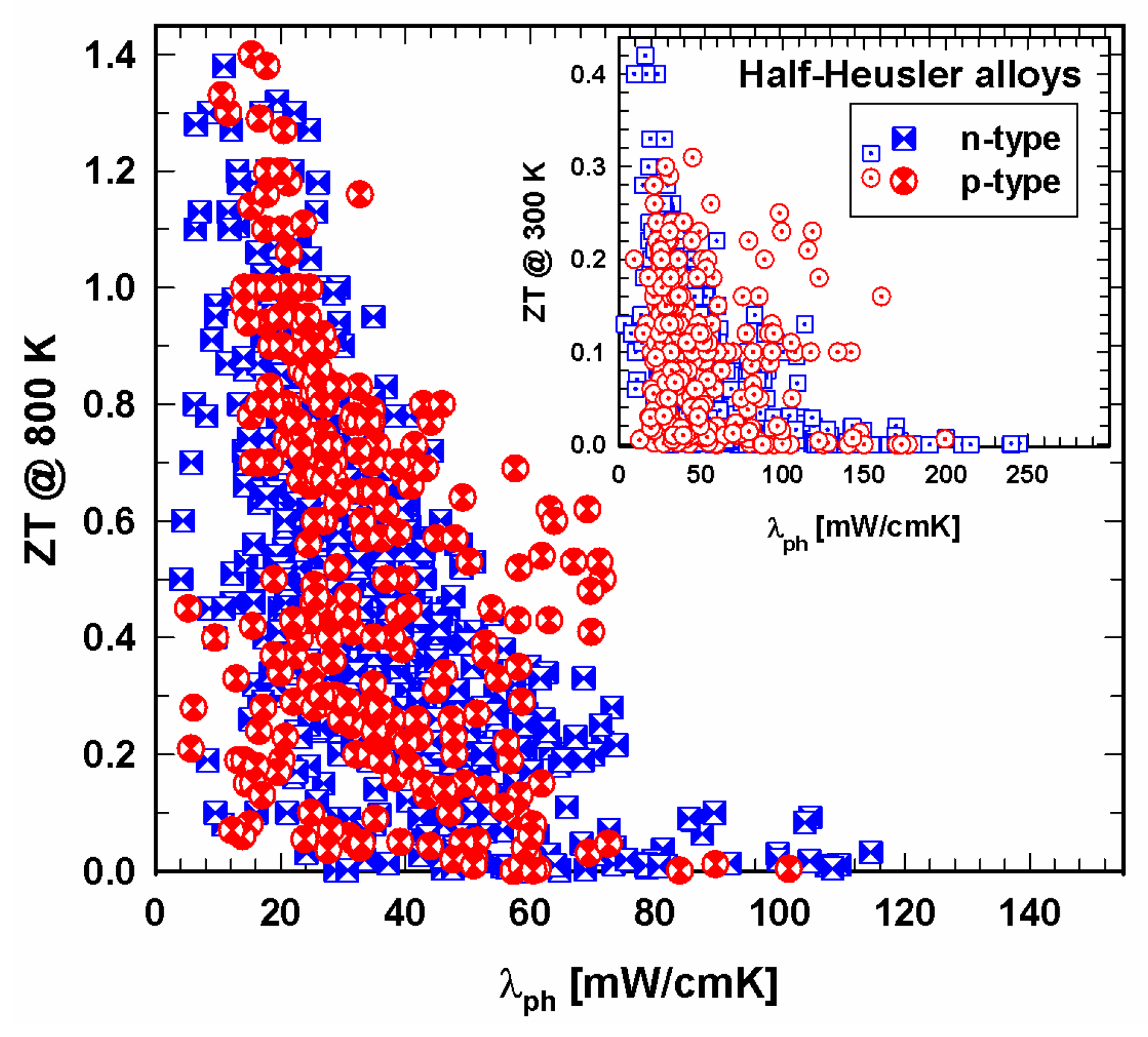

3.1. General Overview

3.2. N-Type Half-Heusler Alloys

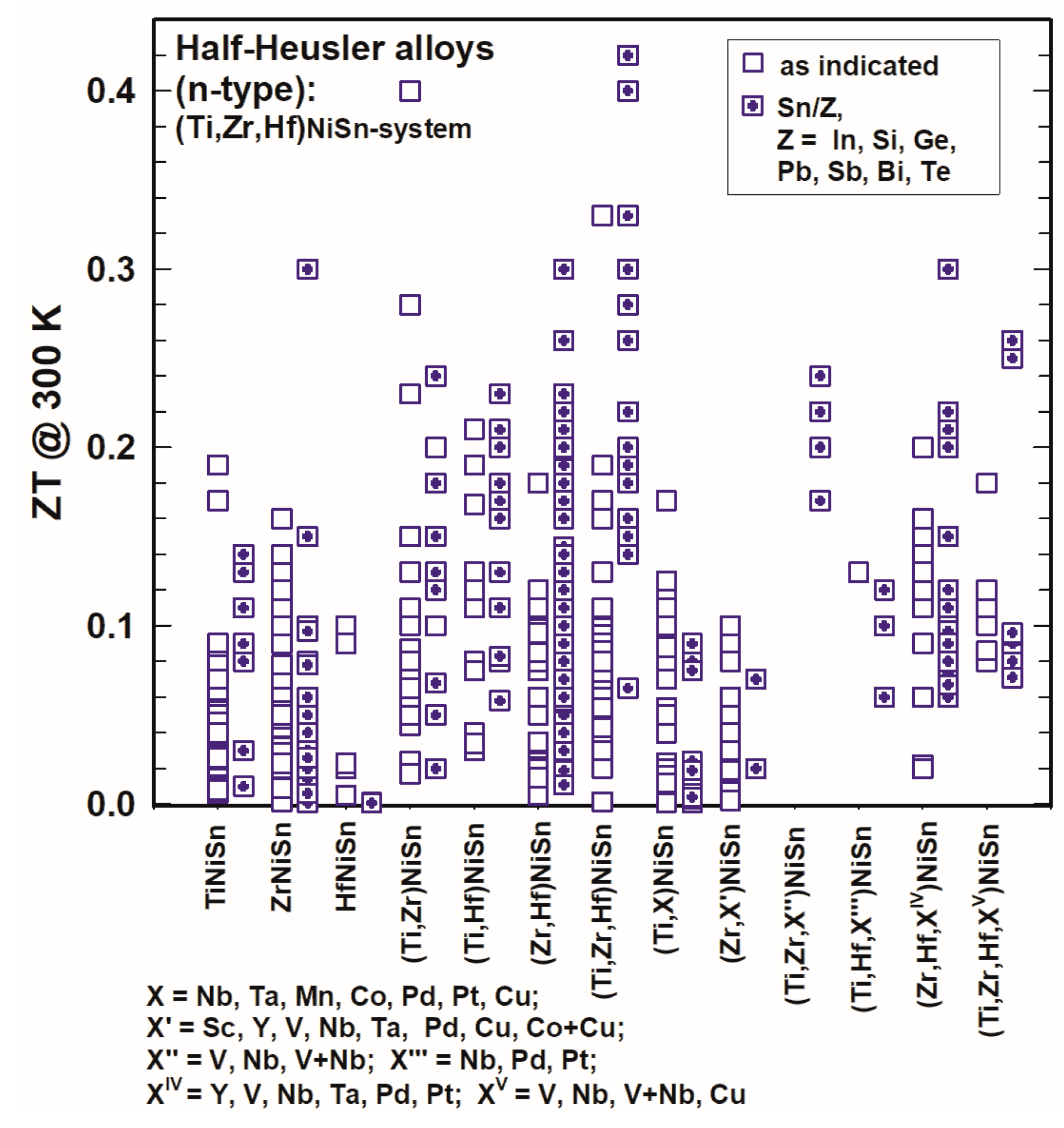

3.2.1. (Ti,Zr,Hf)NiSn-System

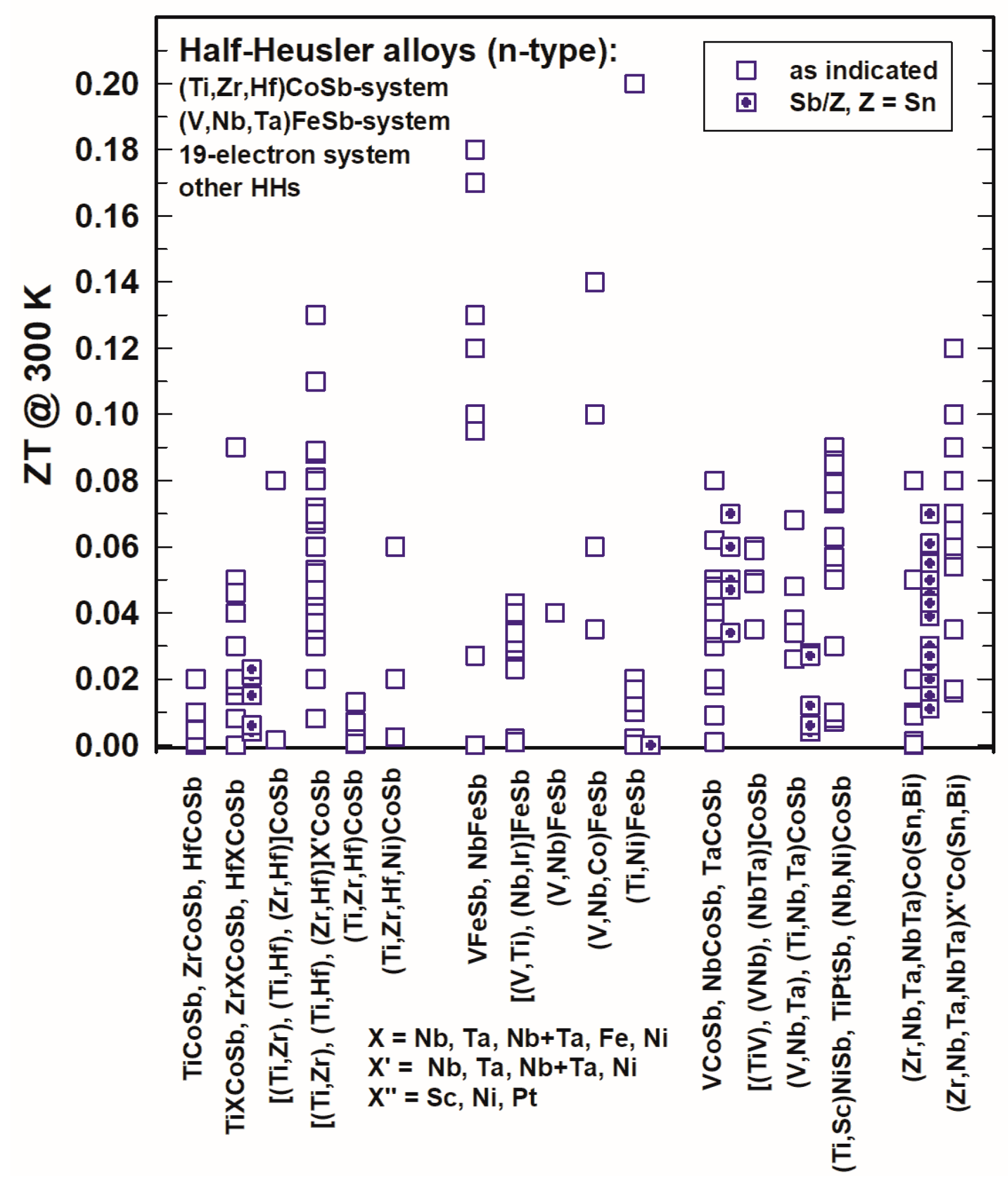

3.2.2. (Ti,Zr,Hf)CoSb-System, (V,Nb,Ta)FeSb-System, 19-Electron System and Other N-Type Half-Heusler Alloys

3.3. P-Type Half-Heusler Alloys

3.4. Miscellaneous

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Poon, S.J. Electronic and thermoelectric properties of half-Heusler alloys. In Semiconductors and Semimetals; Elsevier: Amsterdam, The Netherlands, 2001; Volume 70, pp. 37–72. [Google Scholar]

- Graf, T.; Felser, C.; Parker, S.S.P. Simple rules for the understanding of Heusler compounds. Prog. Solid State Chem. 2011, 39, 1–50. [Google Scholar] [CrossRef]

- Lee, M.-S.; Poudeu, F.P.; Mahanti, S.D. Electronic structure and thermoelectric properties of Sb-based semiconducting half-Heusler compounds. Phys. Rev. B 2011, 83, 085204. [Google Scholar] [CrossRef]

- Xie, W.; Weidenkaff, A.; Tang, X.; Zhang, Q.; Poon, J.; Tritt, T.M. Recent advances in nanostructured thermoelectric half-Heusler compounds. Nanomaterials 2012, 2, 379–412. [Google Scholar] [CrossRef] [PubMed]

- Felser, C.; Hirohata, A. Heusler Alloys: Properties, Growth, Applications. In Springer Series in Materials Science; Springer: Cham, Switzerland, 2016; Volume 222, p. 2015945328. [Google Scholar]

- Zhu, T.; Liu, Y.; Fu, C.; Heremans, J.P.; Snyder, J.G.; Zhao, X. Compromise and Synergy in High-Efficiency Thermoelectric Materials. Adv. Mater. 2017, 20, 1605884. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Zhu, H.; Liu, T.-H.; Song, Q.; He, R.; Mao, J.; Liu, Z.; Ren, W.; Liao, B.; Singh, D.J.; et al. Large thermoelectric power factor from crystal symmetry-protected non-bonding orbital in half-Heuslers. Nat. Commun. 2018, 9, 1721–1730. [Google Scholar] [CrossRef]

- Quinn, R.J.; Bos, J.-W.G. Advances in half-Heusler alloys for thermoelectric power generation. Mater. Adv. 2021, 19, 6246–6266. [Google Scholar] [CrossRef]

- Freer, R.; Ekren, D.; Ghosh, T.; Biswas, K.; Qiu, P.; Wan, S.; Chen, L.; Han, S.; Fu, C.; Zhu, T.; et al. Key properties of inorganic thermoelectric materials—Tables. J. Phys. Energy 2022, 4, 022002. [Google Scholar] [CrossRef]

- Hu, T.; Yang, D.; Su, X.; Yan, Y.; You, Y.; Liu, W.; Uher, C.; Tang, X. Interpreting the combustion process for high-performance ZrNiSn thermoelectric materials. ACS Appl. Mater. Interfaces 2018, 10, 864–872. [Google Scholar] [CrossRef]

- Yu, C.; Zhu, T.-J.; Shi, R.-Z.; Zhang, Y.; Zhao, X.-B.; He, J. High-performance half-Heusler thermoelectric materials Hf1−x ZrxNiSn1−ySby prepared by levitation melting and spark plasma sintering. Acta Mater. 2009, 57, 2757–2764. [Google Scholar] [CrossRef]

- Yu, C.; Zhu, T.-J.; Xia, K.; Shen, J.J.; Yang, S.H.; Zhao, X. Reduced grain size and improved thermoelectric properties of melt spun (Hf, Zr) NiSn half-Heusler alloys. J. Electron. Mater. 2010, 39, 2008–2010. [Google Scholar] [CrossRef]

- Karati, A.; Ghosh, S.; Mallik, R.C.; Shabadi, R.; Murty, B.S.; Varadaraju, U.V. Effect of processing routes on the microstructure and thermoelectric properties of half-Heusler TiFe0.5Ni0.5Sb1−xSnx (x = 0, 0.05, 0.1, 0.2) alloys. J. Mater. Eng. Perform. 2022, 31, 305–317. [Google Scholar] [CrossRef]

- Bahrami, A.; Ying, P.; Wolff, U.; Perez-Rodriguez, N.; Schierning, G.; Nielsch, K.; He, R. Reduced lattice thermal conductivity for half-Heusler ZrNiSn through cryogenic mechanical alloying. ACS Appl. Mater. Interfaces 2021, 13, 38561–38568. [Google Scholar] [CrossRef] [PubMed]

- Hasan, R.; Ur, S.-C. Thermoelectric and transport Properties of V1−xTixFeSb half-Heusler system synthesized by controlled mechanical alloying process. Electron. Mater. Lett. 2018, 14, 725–732. [Google Scholar] [CrossRef]

- He, R.; Zhu, T.; Ying, P.; Chen, J.; Giebeler, L.; Kühn, U.; Grossman, J.C.; Wang, Y.; Nielsch, K. High-pressure-sintering-induced microstructural engineering for an ultimate phonon scattering of thermoelectric half-Heusler compounds. Small 2021, 17, 2102045. [Google Scholar] [CrossRef] [PubMed]

- Shen, Q.; Zhang, L.; Chen, L.; Goto, T.; Hirai, T. Thermoelectric properties of ZrNiSn-based half-Heusler compounds. J. Mater. Sci. Lett. 2001, 20, 2197–2199. [Google Scholar] [CrossRef]

- Xing, Y.; Liu, R.; Liao, J.; Zhang, Q.; Xia, X.; Wang, C.; Huang, H.; Chu, J.; Gu, M.; Zhu, T.; et al. High-efficiency half-Heusler thermoelectric modules enabled by self-propagating synthesis and topologic structure optimization. Energy Environ. Sci. 2019, 12, 3390–3399. [Google Scholar] [CrossRef]

- Xing, Y.F.; Liu, R.H.; Sun, Y.Y.; Chen, F.; Zhao, K.P.; Zhu, T.J.; Bai, S.Q.; Chen, L.D. Self-propagation high-temperature synthesis of half-Heusler thermoelectric materials: Reaction mechanism and applicability. J. Mater. Chem. A 2018, 6, 19470–19478. [Google Scholar] [CrossRef]

- Hu, T.; Cao, W.; Yang, D.; Yan, Y.; Cao, Y.; Zhang, T.; Su, X.; Liu, W.; Poudeu-Poudeu, P.; Tang, X. Ultra-fast fabrication of bulk ZrNiSn thermoelectric material through self-propagating high-temperature synthesis combined with in-situ quick pressing. Scripta Mater. 2019, 165, 140–144. [Google Scholar] [CrossRef]

- Birkel, C.S.; Zeier, W.G.; Douglas, J.E.; Lettiere, B.R.; Mills, C.E.; Seward, G.; Birkel, A.; Snedaker, M.L.; Zhang, Y.; Snyder, G.J.; et al. Rapid Microwave Preparation of Thermoelectric TiNiSn and TiCoSb half-Heusler Compounds. Chem. Mater. 2012, 24, 2558–2565. [Google Scholar] [CrossRef]

- Birkel, C.S.; Douglas, J.E.; Lettiere, B.R.; Seward, G.; Verma, N.; Zhang, Y.; Pollock, T.M.; Seshadri, R.; Stucky, G.D. Improving the thermoelectric properties of half-Heusler TiNiSn through inclusion of a second full Heusler phase: Microwave preparation and spark plasma sintering of TiNi1+xSn. Phys. Chem. Chem. Phys. 2013, 15, 6990–6997. [Google Scholar] [CrossRef] [PubMed]

- Lei, Y.; Li, Y.; Xu, L.; Yang, J.; Wan, R.; Long, H. Microwave synthesis and sintering of TiNiSn thermoelectric bulk. J. Alloys Compd. 2016, 660, 166–170. [Google Scholar] [CrossRef]

- Lei, Y.; Cheng, C.; Li, Y.; Wan, R.; Mang, M. Microwave synthesis and enhancement of thermoelectric figure of merit in half-Heusler TiNiSbxSn1−x. Ceram. Int. 2017, 43, 9343–9347. [Google Scholar] [CrossRef]

- Rogl, G.; Zehetbauer, M.J.; Rogl, P.F. The effect of severe plastic deformation on thermoelectric performance of skutterudites, half-Heuslers and Bi-tellurides. Mater. Trans. 2019, 60, 2071–2085. [Google Scholar] [CrossRef]

- Rogl, G.; Ghosh, S.; Wang, L.; Bursik, J.; Grytsiv, A.; Mallik, R.C.; Chen, X.-Q.; Zehetbauer, M.; Rogl, P. Half-Heusler alloys: Enhancement of ZT after severe plastic deformation (ultra-low thermal conductivity). Acta Mater. 2020, 183, 285–300. [Google Scholar] [CrossRef]

- Rogl, G.; Rogl, P.F. How severe plastic deformation changes the mechanical properties of thermoelectric skutterudites and half-Heusler alloys. Front. Mater. 2020, 7, 600261. [Google Scholar] [CrossRef]

- Kim, H.-S.; Gibbs, Z.M.; Tang, Y.; Wang, H.; Snyder, G.J. Characterization of Lorenz number with Seebeck coefficient measurement. APL Mater. 2015, 3, 041506. [Google Scholar] [CrossRef]

- Browning, V.M.; Poon, S.J.; Tritt, T.M.; Pope, A.L.; Bhattacharya, S. Thermoelectric properties of the half-Heusler compound (Zr, Hf)(Ni, Pd) Sn. Proc. MRS Fall 1998, 545, 403. [Google Scholar] [CrossRef]

- Cook, B.A.; Meisner, G.P.; Yang, J.; Uher, C. High temperature thermoelectric properties of MNiSn (M = Zr, Hf). In Proceedings of the Eighteenth International Conference on Thermoelectrics, Baltimore, MD, USA, 29 August 1999; pp. 64–67. [Google Scholar]

- Hohl, H.; Ramirez, A.P.; Goldmann, C.; Ernst, G.; Wölfing, B.; Bucher, E. Efficient dopants for ZrNiSn-based thermoelectric materials. J. Phys. Condens. Matter 1999, 11, 1697–1709. [Google Scholar] [CrossRef]

- Uher, C.; Yang, J.; Hu, S.; Morelli, D.T.; Meisner, G.P. Transport properties of pure and doped MNiSn, M = Zr, Hf. Phys. Rev. B 1999, 59, 8615–8621. [Google Scholar] [CrossRef]

- Shen, Q.; Chen, L.; Goto, T.; Hirai, T.; Yang, J.; Meisner, G.P.; Uher, C. Effects of partial substitution of Ni by Pd on the thermoelectric properties of ZrNiSn based half-Heusler compounds. Appl. Phys. Lett. 2001, 79, 4165–4172. [Google Scholar] [CrossRef]

- Katayama, T.; Kim, S.W.; Kimura, Y.; Mishima, Y. The effects of quaternary additions on thermoelectric properties of TiNiSn-based half-Heusler alloys. J. Electron. Mater. 2003, 32, 1160–1165. [Google Scholar] [CrossRef]

- Huang, X.Y.; Xu, Z.; Chen, L.D. The thermoelectric performance of ZrNiSn/ZrO2 composites. Solid State Commun. 2004, 130, 181–185. [Google Scholar] [CrossRef]

- Katsuyama, S.; Matsushima, H.; Ito, M. Effect of substitution for Ni by Co and/or thermoelectric properties of half-Heusler ZrNiSn. J. Alloys Compd. 2004, 385, 232–237. [Google Scholar] [CrossRef]

- Kawaharada, Y.; Uneda, H.; Muta, H.; Kurosaki, K.; Yamanaka, S. High temperature thermoelectric properties of NiZrSn half-Heusler compounds. J. Alloys Compd. 2004, 364, 59–63. [Google Scholar] [CrossRef]

- Kawaharada, Y.; Kurosaki, K.; Muta, H.; Uno, M.; Yamanaka, S. High temperature thermoelectric properties of TiCoSb half-Heusler compounds. J. Alloys Compd. 2004, 384, 308–311. [Google Scholar] [CrossRef]

- Kim, S.W.; Kimura, Y.; Mishima, Y. Enhancement of high temperature thermoelectric properties of intermetallic compounds based on a skutterudite IrSb3 and a half-Heusler TiNiSb. Sci. Technol. Adv. Mater. 2004, 5, 485–489. [Google Scholar] [CrossRef]

- Kurosaki, K.; Muta, H.; Yamanaka, S. Thermoelectric properties of titanium-based half-Heusler compounds. J. Alloys Compd. 2004, 384, 51–56. [Google Scholar] [CrossRef]

- Kurosaki, K.; Maekawa, T.; Muta, H.; Yamanaka, S. Effect of spark plasma sintering temperature on thermoelectric properties of (Ti, Zr, Hf)NiSn half-Heusler compounds. J. Alloys Compd. 2005, 397, 296–299. [Google Scholar] [CrossRef]

- Muta, H.; Yamaguchi, T.; Kurosaki, K.; Yamanaka, S. Thermoelectric properties of ZrNiSn based half-Heusler compounds. In Proceedings of the Twentyfourth International Conference on Thermoelectrics, Clemson, SC, USA, 19 August 2005; pp. 339–342. [Google Scholar]

- Sakurada, S.; Shutoh, N. Effect of Ti substitution on the thermoelectric properties of (Zr,Hf)NiSn half-Heusler compounds. Appl. Phys. Lett. 2005, 86, 082105. [Google Scholar] [CrossRef]

- Sekimoto, T.; Kurosaki, K.; Muta, H.; Yamanaka, S. Annealing effect on thermoelectric properties of TiCoSb half-Heusler compound. J. Alloys Compd. 2005, 394, 122–125. [Google Scholar] [CrossRef]

- Sekimoto, T.; Kurosaki, K.; Muta, H.; Yamanaka, S. Thermoelectric properties of (Ti,Zr,Hf)CoSb type half-Heusler compounds. Mater. Trans. 2005, 46, 1481–1484. [Google Scholar] [CrossRef]

- Sekimoto, T.; Kurosaki, K.; Muta, H.; Yamanaka, S. Thermoelectric and thermophysical properties of TiCoSb, ZrCoSb, HfCoSb prepared by SPS. In Proceedings of the Twentyfourth International Conference on Thermoelectrics, Clemson, SC, USA, 19 August 2005; pp. 335–339. [Google Scholar]

- Sakurada, S.; Shutoh, N. Thermoelectric properties of the Tix(Zr0.5Hf0.5)1−xNiSn half-Heusler compounds. J. Alloys Compd. 2005, 389, 204–208. [Google Scholar]

- Zhou, M.; Feng, C.; Chen, L.; Huang, X. Effects of partial substitution of Co by Ni on the high-temperature thermoelectric properties of TiCoSb-based half-Heusler compounds. J. Alloys Compd. 2005, 391, 194–197. [Google Scholar] [CrossRef]

- Chen, L.D.; Huang, X.Y.; Zhou, M.; Shi, X.; Zhang, W.B. The high temperature thermoelectric performances of Zr0.5Hf0.5Ni0.8Pd0.2Sn0.99Sb0.01 alloy with nanophase inclusions. J. Appl. Phys. 2006, 99, 064305. [Google Scholar] [CrossRef]

- Culp, S.R.; Poon, S.J.; Hickman, N.; Tritt, T.M.; Blumm, J. Effect of substitutions on the thermoelectric figure of merit of half-Heusler phases at 800 °C. Appl. Phys. Lett. 2006, 88, 042106. [Google Scholar] [CrossRef]

- Kimura, Y.; Zama, A.; Mishima, Y. Thermoelectric properties of p-type half-Heusler compounds HfPtSn and ZrPtSn. In Proceedings of the Twentyfifth International Conference on Thermoelectrics, Vienna, Austria, 6 August 2006; pp. 115–119. [Google Scholar]

- Ono, Y.; Inayama, S.; Adachi, H.; Kajitani, T. Thermoelectric properties of doped half-Heuslers NbCoSn1−xSbx and Nb0.99Ti0.01CoSn1−xSbx. JPN J. Appl. Phys. 2006, 45, 8740–8743. [Google Scholar] [CrossRef]

- Sekimoto, T.; Kurosaki, K.; Muta, H.; Yamanaka, S. Thermoelectric and thermophysical properties of ErPdX (X = Sb and Bi) half-Heusler compounds. J. Appl. Phys. 2006, 99, 103701. [Google Scholar] [CrossRef]

- Sekimoto, T.; Kurosaki, K.; Muta, H.; Yamanaka, S. Thermoelectric properties of (Ti,Zr)CoSnxSb1−x half-Heusler compounds. In Proceedings of the Twentyfifth International Conference on Thermoelectrics, Vienna, Austria, 6 August 2006; pp. 128–131. [Google Scholar]

- Sekimoto, T.; Kurosaki, K.; Muta, H.; Yamanaka, S. Thermoelectric properties of Sn-doped TiCoSb half-Heusler compounds. J. Alloys Compd. 2006, 407, 326–329. [Google Scholar] [CrossRef]

- Sekimoto, T.; Kurosaki, K.; Muta, H.; Yamanaka, S. Thermoelectric and thermophysical properties of TiCoSb-ZrCoSb-HfCoSb pseudo ternary system prepared by spark plasma sintering. Mater. Trans. 2006, 47, 1445–1448. [Google Scholar] [CrossRef]

- Katsuyama, S.; Matsuo, R.; Ito, M. Thermoelectric properties of half-Heusler alloys Zr1−xYxNiSn1−ySby. J. Alloys Compd. 2007, 428, 262–267. [Google Scholar] [CrossRef]

- Kim, S.-W.; Kimura, Y.; Mishima, Y. High temperature thermoelectric properties of TiNiSn-based half-Heusler compounds. Intermetallics 2007, 15, 349–356. [Google Scholar] [CrossRef]

- Sekimoto, T.; Kurosaki, K.; Muta, H.; Yamanaka, S. Thermoelectric properties of half-Heusler Type LaPdBi and GdPdBi. Mater. Trans. 2007, 48, 2079–2082. [Google Scholar] [CrossRef]

- Sekimoto, T.; Kurosaki, K.; Muta, H.; Yamanaka, S. High-thermoelectric figure of merit realized in p-type half-Heusler compounds: ZrCoSnxSb1−x. JPN J. Appl. Phys. 2007, 46, L673–L675. [Google Scholar] [CrossRef]

- Wu, T.; Jiang, W.; Li, X.; Zhou, Y.; Chen, L. Thermoelectric properties of p-type Fe-doped TiCoSb half-Heusler compounds. J. Appl. Phys. 2007, 102, 103705. [Google Scholar] [CrossRef]

- Culp, R.S.; Simson, J.W.; Poon, S.J.; Ponnambalan, V.; Edwards, J.; Tritt, T.M. (Zr,Hf)Co(Sb,Sn) half-Heusler phases as high-temperature (>700 °C) p-type thermoelectric materials. Appl. Phys. Lett. 2008, 93, 022105. [Google Scholar] [CrossRef]

- Kimura, Y.; Tamura, Y.; Kita, T. Thermoelectric properties of directionally solidified half-Heusler compound NbCoSn alloys. Appl. Phys. Lett. 2008, 92, 012105. [Google Scholar] [CrossRef]

- Xie, W.; Jin, Q.; Tang, X. The preparation and thermoelectric properties of Ti0.5Zr0.25Hf0.25Co1−xNixSb half-Heusler compounds. J. Appl. Phys. 2008, 103, 043711. [Google Scholar] [CrossRef]

- Kimura, Y.; Ueno, H.; Mishima, Y. Thermoelectric properties of directionally solidified half-Heusler (Ma0.5Mb0.5)NiSn (Ma, Mb = Hf, Zr, Ti) alloys. J. Electron. Mater. 2009, 38, 934–939. [Google Scholar] [CrossRef]

- Muta, H.; Kanemitsu, T.; Kurosaki, K.; Yamanaka, S. High-temperature thermoelectric properties of Nb-doped MNiSn (M = Ti, Zr) half-Heusler compound. J. Alloys Compd. 2009, 469, 50–55. [Google Scholar] [CrossRef]

- Qiu, P.; Huang, X.; Chen, X.; Chen, L. Enhanced thermoelectric performance by the combination of alloying and doping in TiCoSb-based half-Heusler compounds. J. Appl. Phys. 2009, 106, 103703. [Google Scholar] [CrossRef]

- Wu, T.; Jiang, W.; Li, X.; Bai, S.; Liufu, S.; Chen, L. Effects of Ge doping on the thermoelectric properties of TiCoSb-based p-type half-Heusler compounds. J. Alloys Compd. 2009, 467, 590–594. [Google Scholar] [CrossRef]

- Kenjo, T.; Kimura, Y.; Mishima, Y. Phase stability and thermoelectric properties of half-Heusler compounds (Ti,M)NiSn (M = Zr, Hf). Mater. Res. Soc. Symp. Proc. 2010, 1218, 43–48. [Google Scholar] [CrossRef]

- Kim, I.-H.; Kwon, J.-C.; Lee, Y.-G.; Yoon, M.-S.; Ryu, S.-L.; Kim, W.-G.; Ur, S.-C. Synthesis and thermoelectric properties of half-Heusler Zr-Ni-Sn alloy processed by mechanically alloying and hot-pressing. In Materials Science Forum; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2010; Volume 658, pp. 33–36. [Google Scholar]

- Kimura, Y.; Tanoguchi, T.; Kita, T. Vacancy site occupation by Co and Ir in half-Heusler ZrNiSn and conversion of the thermoelectric properties from n-type to p-type. Acta Mater. 2010, 58, 4354–4361. [Google Scholar] [CrossRef]

- Ouardi, S.; Fecher, G.H.; Balke, B.; Kozina, X.; Stryganyuk, G.; Felser, C. Electronic transport properties of electron- and hole-doped semiconducting C1bHeusler compounds: NiTi1-xMxSn (M = Sc, V). Phys. Rev. B 2010, 82, 085108. [Google Scholar] [CrossRef]

- Zhu, T.J.; Xiao, K.; Yu, C.; Shen, J.J.; Yang, S.H.; Zhou, A.J.; Zhao, X.B.; He, J. Effect of yttrium doping on the thermoelectric properties of Hf0.6Zr0.4NiSn0.98Sb0.02 half-Heusler alloys. J. Appl. Phys. 2010, 108, 044903. [Google Scholar] [CrossRef]

- Zou, M.; Li, J.F.; Guo, P.; Kita, T. Synthesis and thermoelectric properties of fine-grained VFeSb system half-Heusler compound polycrystals with high phase purity. J. Phys. D Appl. Phys. 2010, 43, 415403. [Google Scholar] [CrossRef]

- Gelbstein, Y.; Tal, N.; Yarmek, A.; Rosenberg, Y.; Dariel, M.P.; Ouardi, S.; Balke, B.; Felser, C.; Köhne, M. Thermoelectric properties of spark plasma sintered composites based on TiNiSn half-Heusler alloys. J. Mater. Res. 2011, 26, 1919–1924. [Google Scholar] [CrossRef]

- Joshi, G.; Yan, X.; Wang, H.; Liu, W.; Chen, G.; Ren, Z. Enhancement in thermoelectric figure-of-merit of an n-type half-Heusler compound by the nanocomposite approach. Adv. Energy Mater. 2011, 1, 643–647. [Google Scholar] [CrossRef]

- Makongo, J.P.A.; Misra, D.K.; Zhou, X.Y.; Pant, A.; Shabetai, M.R.; Su, X.L.; Uher, C.; Stokes, K.L.; Poudeu, P.F.P. Simultaneous large enhancements in thermopower and electrical conductivity of bulk nanostructured half-Heusler alloys. J. Am. Chem. Soc. 2011, 133, 18843–18852. [Google Scholar] [CrossRef]

- Makongo, J.P.A.; Misra, D.K.; Salvador, J.R.; Takas, N.J.; Wang, G.; Shabetai, M.R.; Pant, A.; Poudel, P.; Uher, C.; Stokes, K.L.; et al. Thermal and electronic charge transport in bulk nanostructured Zr0.25Hf0.75NiSn composites with full Heusler inclusions. J. Solid State Chem. 2011, 184, 2948–2960. [Google Scholar] [CrossRef]

- Poon, S.J.; Wu, D.; Zhu, S.; Xie, W.; Tritt, T.M.; Venkatasubramanian, P.T.; Venkatasubramanian, R. Half-Heusler phases and nanocomposites as emerging high-ZT thermoelectric materials. J. Mater. Res. 2011, 26, 2795–2802. [Google Scholar] [CrossRef]

- Schwall, M.; Balke, B. Niobium substitution in Zr0.5Hf0.5NiSn based Heusler compounds for high power factors. Appl. Phys. Lett. 2011, 98, 042106. [Google Scholar] [CrossRef]

- Simonson, J.W.; Wu, D.; Xie, W.J.; Tritt, T.M.; Poon, S.J. Introduction of resonant states and enhancement of thermoelectric properties in half-Heusler alloys. Phys. Rev. B 2011, 83, 235211. [Google Scholar] [CrossRef]

- Yan, X.; Joshi, G.; Liu, W.; Lan, Y.; Wang, H.; Lee, S.; Simonson, J.W.; Poon, S.J.; Tritt, T.M. Enhanced thermoelectric figure of merit of p-type half-Heuslers. Nano Lett. 2011, 11, 556–560. [Google Scholar] [CrossRef] [PubMed]

- Douglas, J.E.; Birkel, C.S.; Miao, M.-S.; Torbet, C.J.; Stucky, G.D.; Pollock, T.M.; Seshadri, R. Enhanced thermoelectric properties of bulk TiNiSn via formation of a TiNi2Sn second phase. Appl. Phys. Lett. 2012, 101, 183902. [Google Scholar] [CrossRef]

- Populoh, S.; Aguirre, M.H.; Brunko, O.C.; Galazka, K.; Lu, Y.; Weidenkaff, A. High figure of merit in (Ti,Zr,Hf)NiSn half-Heusler alloys. Scripta Mater. 2012, 66, 1073–1107. [Google Scholar] [CrossRef]

- Xie, H.-H.; Mi, J.-L.; Hu, L.-P.; Lock, N.; Chirstensen, M.; Fu, C.-G.; Brummerstedt Iversen, B.; Zhao, X.-B.; Zhu, T.-J. Interrelation between atomic switching disorder and thermoelectric properties of ZrNiSn half-Heusler compounds. CrystEngComm 2014, 14, 4467–4471. [Google Scholar] [CrossRef]

- Yan, X.; Liu, W.; Wang, H.; Chen, S.; Shiomi, J.; Esfarjani, K.; Wang, H.; Wang, D.; Chen, G.; Ren, Z. Stronger phonon scattering by larger differences in atomic mass and size in p-type half-Heuslers Hf1−xTixCoSb0.8Sn0.2. Energy Environ. Sci. 2012, 5, 7543–7548. [Google Scholar] [CrossRef]

- Appel, O.; Schwall, M.; Mogilyansky, D.; Köhne, M.; Balke, B.; Gelbstein, Y. Effects of microstructural evolution on the thermoelectric properties of spark-plasma-sintered Ti0.3Zr0.35Hf0.35NiSn half-Heusler compound. J. Electron. Mater. 2013, 42, 1340–1345. [Google Scholar] [CrossRef]

- Birkel, C.S.; Douglas, J.E.; Lettiere, B.R.; Seward, G.; Zhang, Y.; Pollock, T.M.; Seshadri, R.; Stucky, G.D. Influence of Ni nanoparticle addition and spark plasma sintering on the TiNiSn-Ni system: Structure, microstructure, and thermoelectric properties. Solid States Sci. 2013, 26, 16–22. [Google Scholar] [CrossRef]

- Chen, S.; Lukas, K.C.; Liu, W.; Opeil, C.P.; Chen, G.; Ren, Z. Effect of Hf concentration on thermoelectric properties of nanostructured n-type half-Heusler materials HfxZr1−xNiSn0.99Sb0.01. Adv. Energy Mater. 2013, 3, 1210–1214. [Google Scholar] [CrossRef]

- Downie, R.A.; MacLaren, D.A.; Smith, R.I.; Bos, J.W.G. Enhanced thermoelectric performance in TiNiSn-based half-Heuslers. Chem. Commun. 2013, 49, 4184–4186. [Google Scholar] [CrossRef] [PubMed]

- Fu, C.; Xie, H.; Liu, Y.; Zhu, T.; Xie, J.; Zhao, X.B. Thermoelectric properties of FeVSb half-Heusler compounds by levitation melting and spark plasma sintering. Intermetallics 2013, 32, 39–43. [Google Scholar] [CrossRef]

- Fu, C.; Liu, Y.; Xie, H.; Liu, X.; Zhao, X.; Snyder, J.G.; Xie, J.; Zhu, T. Electron and phonon transport in Co-doped FeV0.6Nb0.4Sb half-Heusler thermoelectric materials. J. Appl. Phys. 2013, 114, 134905. [Google Scholar] [CrossRef]

- Schwall, M.; Balke, B. Phase separation as a key to a thermoelectric high efficiency. Phys. Chem. Chem. Phys. 2013, 15, 1868–1872. [Google Scholar] [CrossRef]

- Xie, W.J.; Yan, Y.G.; Zhu, S.; Zhou, M.; Populoh, S.; Galazka, K.; Poon, S.J.; Weidenkaff, A.; He, J.; Tang, X.F.; et al. Significant ZT enhancement in p-type Ti(Co,Fe)Sb-InSb nanocomposites via a synergistic high-mobility electron injection, energy-filtering and boundary-scattering approach. Acta Mater. 2013, 61, 2087–2094. [Google Scholar] [CrossRef]

- Xie, W.J.; Wang, H.; Pei, Y.; Fu, C.; Liu, X.; Snyder, J.G.; Zhao, X.; Zhu, T. Beneficial contribution of alloy disorder to electron and phonon transport in half-Heusler thermoelectric materials. Adv. Funct. Mater. 2013, 23, 5123–5130. [Google Scholar] [CrossRef]

- Yan, X.; Liu, W.; Chen, S.; Wan, H.; Zhang, Q.; Chen, G.; Ren, Z. Thermoelectric property study of nanostructured p-type half-Heuslers (Hf,Zr,Ti)CoSb0.8Sn0.2. Adv. Energy Mater. 2013, 3, 1195–1200. [Google Scholar] [CrossRef]

- Zou, M.; Li, J.F.; Kita, T. Thermoelectric properties of fine-grained FeVSb half-Heusler alloys tuned to p-type by substituting vanadium with titanium. J. Solid State Chem. 2013, 198, 125–130. [Google Scholar] [CrossRef]

- Bartholome, K.; Balke, B.; Zuckermann, D.; Köhne, M.; Müller, M.; Tarantik, K.; König, J. Thermoelectric modules based on half-Heusler materials produced in large quantities. J. Electron. Mater. 2014, 43, 1775–1781. [Google Scholar] [CrossRef]

- Downie, R.A.; Mac Laren, D.A.; Bos, J.-W.G. Thermoelectric performance of multiphase XNiSn (X = Ti, Zr, Hf) half-Heusler alloys. J. Mater. Chem. A 2014, 2, 6107–6114. [Google Scholar] [CrossRef]

- Downie, R.A.; Popuri, S.R.; Ning, H.; Reece, M.J.; Bos, J.-W.G. Effect of spark plasma sintering on the structure and properties of Ti1−xZrxNiSn half-Heusler alloys. Materials 2014, 7, 7094–7104. [Google Scholar] [CrossRef] [PubMed]

- Fu, C.; Zhu, T.; Pei, Y.; Xie, H.; Wang, H.; Snyder, G.J.; Liu, Y.; Liu, Y.; Zhao, X. High band degeneracy contributes to high thermoelectric performance in p-type half-Heusler compounds. Adv. Energy Mater. 2014, 4, 1400600. [Google Scholar] [CrossRef]

- Gazka, K.; Populoh, S.; Xie, W.; Yoon, S.; Saucke, G.; Hulliger, J.; Weidenkaff, A. Improved thermoelectric performance of (Zr0.3Hf0.7)NiSn half-Heusler compounds by Ta substitution. J. Appl. Phys. 2014, 115, 183704. [Google Scholar] [CrossRef]

- Hsu, C.-C.; Liu, Y.-N.; Ma, H.-K. Effect of the Zr0.5Hf0.5CoSb1−xSnx/HfO2 half-Heusler nanocomposites on the ZT value. J. Alloys Compd. 2014, 597, 217–222. [Google Scholar] [CrossRef]

- Joshi, G.; He, R.; Engber, M.; Samsonidze, G.; Pantha, T.; Dahal, E.; Dahal, K.; Yang, J.; Lan, Y.; Kozinsky, B.; et al. NbFeSb-based p-type half-Heuslers for power generation applications. Energy Environ. Sci. 2014, 7, 4070–4076. [Google Scholar] [CrossRef]

- Krez, J.; Schmitt, J.; Snyder, G.J.; Felser, C.; Hermes, W.; Schwind, M. Optimization of the carrier concentration in phase-separated half-Heusler compounds. J. Mater. Chem. A 2014, 2, 13513–13518. [Google Scholar] [CrossRef]

- Misra, D.K.; Bhardwaj, A.; Singh, S. Enhanced thermoelectric performance of a new half-Heusler derivative Zr9Ni7Sn8 bulk nanocomposite: Enhanced electrical conductivity and low thermal conductivity. J. Mater. Chem. A 2014, 2, 11913–11921. [Google Scholar] [CrossRef]

- Rausch, E.; Balke, B.; Ouardi, S.; Felser, C. Enhanced thermoelectric performance in the p-type half-Heusler (Ti,Zr,Hf)CoSb0.8Sn0.2 system via phase separation. Phys. Chem. Chem. Phys. 2014, 16, 25258–25262. [Google Scholar] [CrossRef] [PubMed]

- Akram, R.; Zhang, Q.; Yang, D.; Zheng, Y.; Yan, Y.; Su, X.; Tang, X. Enhanced thermoelectric properties of La-doped ZrNiSn half-Heusler compound. J. Electron. Mater. 2015, 44, 3563–3570. [Google Scholar] [CrossRef]

- Appel, O.; Zilber, T.; Kalabukhov, S.; Beerib, O.; Gelbstein, Y. Morphological effects on the thermoelectric properties of Ti0.3Zr0.35Hf0.35Ni1+δSn alloys following phase separation. J. Mater. Chem. C 2015, 3, 11653–11659. [Google Scholar] [CrossRef]

- Chai, Y.W.; Oniki, T.; Kimura, Y. Microstructure and thermoelectric properties of a ZrNi1.1Sn half-Heusler alloy. Acta Mater. 2015, 85, 290–300. [Google Scholar] [CrossRef]

- Chen, L.; Gao, S.; Zeng, X.; Mehdizadeh Dehkordi, A.; Tritt, T.M.; Poon, S.J. Uncovering high thermoelectric figure of merit in (Hf,Zr)NiSn half-Heusler alloys. Appl. Phys. Lett. 2015, 107, 041902. [Google Scholar] [CrossRef]

- Fu, C.; Zhu, T.; Liu, Y.; Xie, H.; Zhao, X. Band engineering of high-performance p-type FeNbSb based half-Heusler thermoelectric materials for figure of merit ZT > 1. Energy Environ. Sci. 2015, 8, 216–220. [Google Scholar] [CrossRef]

- Fu, C.; Bai, S.; Liu, Y.; Tang, Y.; Chen, L.; Zhao, X.; Zhu, T. Realizing high figure of merit in heavy-band p-type half-Heusler thermoelectric materials. Nat. Commun. 2015, 6, 8144–8151. [Google Scholar] [CrossRef] [PubMed]

- Hattori, K.; Miyazaki, H.; Yoshida, K.; Inukai, M.; Nishino, Y. Direct observation of the electronic structure in thermoelectric half-Heusler alloys Zr1−xMxNiSn (M = Y and Nb). J. Appl. Phys. 2015, 117, 205102. [Google Scholar] [CrossRef]

- He, R.; Kim, H.S.; Lan, Y.; Wang, D.; Chen, S.; Ren, Z. Investigating the thermoelectric properties of p-type half-Heusler Hfx(Zr,Ti)1−xCoSb0.8Sn0.2 by reducing Hf concentration for power generation. RSC Adv. 2015, 4, 64711–64716. [Google Scholar] [CrossRef]

- Huang, L.; He, R.; Chen, S.; Zhang, H.; Dahal, K.; Zhou, H.; Wang, H.; Zhang, Q.; Ren, Z. A new n-type half-Heusler thermoelectric material NbCoSb. Mater. Res. Bull. 2015, 70, 773–778. [Google Scholar] [CrossRef]

- Huang, L.; Wang, Y.; Shuai, J.; Zhang, H.; Yang, S.; Zhang, Q.; Ren, Z. Thermal conductivity reduction by isoelectronic elements V and Ta for partial substitution of Nb in half-Heusler Nb(1−x)/2V(1−x)/2TaxCoSb. RSC Adv. 2015, 5, 102469–102476. [Google Scholar] [CrossRef]

- Li, S.; Zhao, H.; Li, D.; Jin, S.; Gu, L. Synthesis and thermoelectric properties of half-Heusler alloy YNiBi. J. Appl. Phys. 2015, 117, 205101–205108. [Google Scholar] [CrossRef]

- Liu, Y.; Xie, H.; Fu, C.; Snyder, G.J.; Zhao, X.; Zhu, T. Demonstration of a phonon-glass electron-crystal strategy in (Hf,Zr)NiSn half-Heusler thermoelectric materials by alloying. J. Mater. Chem. A 2015, 3, 22716–22722. [Google Scholar] [CrossRef]

- Rausch, E.; Balke, B.; Stahlhofen, J.M.; Ouardi, S.; Burkhardt, U.; Felser, C. Fine tuning of thermoelectric performance in phase-separated half-Heusler compounds. J. Mater. Chem. C 2015, 3, 10409. [Google Scholar] [CrossRef]

- Rausch, E.; Balke, B.; Ouardi, S.; Felser, C. Long-term stability of (Ti,Zr,Hf)CoSb1−xSnx thermoelectric p-type half-Heusler compounds upon thermal cycling. Energy Technol. 2015, 3, 1217–1224. [Google Scholar] [CrossRef]

- Schmitt, J.; Gibbs, Z.M.; Snyder, G.J.; Felser, C. Resolving the true band gap of ZrNiSn half-Heusler thermoelectric materials. Sci. Rep. 2015, 4, 6888. [Google Scholar] [CrossRef]

- Xie, H.; Wang, H.; Fu, C.; Liu, Y.; Snyder, G.J.; Zha, X.; Zhu, T. The intrinsic disorder related alloy scattering in ZrNiSn half-Heusler thermoelectric materials. Nature Commun. Sci. Rep. 2014, 4, 6888. [Google Scholar] [CrossRef]

- Akram, R.; Yan, Y.; Yang, D.W.; She, X.Y.; Zheng, G.; Su, X.L.; Tang, X.F. Microstructure and thermoelectric properties of Sb doped Hf0.25Zr0.75NiSn half-Heusler compounds with improved carrier mobility. Intermetallics 2016, 74, 1–7. [Google Scholar] [CrossRef]

- Chai, Y.W.; Oniki, T.; Kenjo, T.; Kimura, Y. The effect of an isoelectronic Ti-Zr substitution on Heusler nanoprecipitation and the thermoelectric properties of a (Ti0.2Zr0.8)Ni1.1Sn half-Heusler alloy. J. Alloys Compd. 2016, 662, 566–577. [Google Scholar] [CrossRef]

- Chauhan, N.S.; Bhardwaj, A.; Senguttuvan, T.D.; Pant, R.P.; Mallik, R.C.; Misra, D.K. A synergistic combination of atomic scale structural engineering and panoscopic approach in p-type ZrCoSb-based half-Heusler thermoelectric materials for achieving high ZT. J. Mater. Chem. C 2016, 4, 5766–5778. [Google Scholar] [CrossRef]

- Chen, L.; Zeng, X.; Tritt, T.M.; Poon, S.J. Half-Heusler alloys for efficient thermoelectric power conversion. J. Electron. Mater. 2016, 45, 5554–5556. [Google Scholar] [CrossRef]

- Fu, C.; Wu, H.; Liu, Y.; He, J.; Zhao, X.; Zhu, T. Enhancing the figure of merit of heavy-band thermoelectric materials through hierarchical phonon scattering. Adv. Sci. 2016, 3, 1600035. [Google Scholar] [CrossRef]

- Gürth, M.; Rogl, G.; Romaka, V.V.; Grytsiv, A.; Bauer, E.; Rogl, P. Thermoelectric high ZT half-Heusler alloys Ti1−x−yZrxHfyNiSn. Acta Mater. 2016, 104, 210–222. [Google Scholar] [CrossRef]

- He, R.; Huang, L.; Wang, Y.; Samsonidze, G.; Kozinsky, B.; Zhang, Q.; Ren, Z. Enhanced thermoelectric properties of n-type NbCoSn half-Heusler by improving phase purity. Appl. Mater. 2016, 4, 104804. [Google Scholar] [CrossRef]

- He, R.; Kraemer, D.; Mao, J.; Zeng, L.; Jie, Q.; Lan, Y.; Li, C.; Shuai, J.; Kim, H.S.; Liu, Y.; et al. Achieving high power factor and output power density in p-type half-Heuslers Nb1−xTixFeSb. Proc. Natl. Acad. Soc. USA 2016, 113, 13576–13581. [Google Scholar] [CrossRef]

- Huang, L.; Zhang, Q.; Yuan, B.; Lai, X.; Yan, X.; Ren, Z. Recent progress in half-Heusler thermoelectric materials. Mater. Res. Bull. 2016, 76, 107–112. [Google Scholar] [CrossRef]

- Liu, Y.; Makongo, J.P.A.; Page, A.; Sahoo, P.; Uher, C.; Stokes, K.; Poudeu, P.F.P. Distribution of impurity states and charge transport in Zr0.25Hf0.75Ni1+xSn1−ySby nanocomposites. J. Solid State Chem. 2016, 234, 72–86. [Google Scholar] [CrossRef]

- Rogl, G.; Grytsiv, A.; Gürth, M.; Tavassoli, A.; Ebner, C.; Wünschek, A.; Puchegger, S.; Soprunyuk, V.; Schranz, W.; Bauer, E.; et al. Mechanical properties of half-Heusler alloys. Acta Mater. 2016, 107, 178–195. [Google Scholar] [CrossRef]

- Visconti, A.; Bernard-Granger, G.; Navone, C.; Leforestier, J.; Mingo, N. Microstructure investigations and thermoelectric properties of an n-type half-Heusler alloy sintered by spark plasma sintering. Scripta Mater. 2016, 123, 100–104. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Y.; Huang, L.; Chen, S.; Dahal, H.; Wang, D.; Ren, Z. Synthesis and thermoelectric properties of n-type half-Heusler compound VCoSb with valence electron count of 19. J. Alloys Compd. 2016, 654, 321–326. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Y.; Dahal, H.; Mao, J.; Huang, L.; Zhang, Q.; Ren, Z. Thermoelectric properties of n-type half-Heusler compounds (Hf0.25Zr0.75)1−xNbxNiSn. Acta Mater. 2016, 113, 41–47. [Google Scholar] [CrossRef]

- Berry, T.; Ouardi, S.; Fecher, G.H.; Balke, B.; Kreiner, G.; Auffermann, G.; Schnelle, W.; Felser, C. Improving thermoelectric performance of TiNiSn by mixing MnNiSb in the half-Heusler structure. Phys. Chem. Chem. Phys. 2017, 19, 1543–1550. [Google Scholar] [CrossRef]

- Berry, T.; Fu, C.; Auffermann, G.; Fecher, G.H.; Schnelle, W.; Serrano-Sanchez, F.; Yue, Y.; Liang, H.; Felser, C. Enhancing thermoelectric performance of TiNiSn half-Heusler compounds via modulation doping. Chem. Mater. 2017, 29, 7042–7048. [Google Scholar] [CrossRef]

- Chen, L.; Liu, Y.; He, J.; Tritt, T.M.; Poon, S.J. High thermoelectric figure of merit by resonant dopant in half-Heusler alloys. AIP Adv. 2017, 7, 065208. [Google Scholar] [CrossRef]

- He, R.; Zhu, H.; Sun, J.; Mao, J.; Reith, H.; Chen, S.; Schierning, G.; Nielsch, K.; Ren, Z. Improved thermoelectric performance of n-type half-Heusler MCo1−xNixSb (M = Hf, Zr). Mater. Today Phys. 2017, 1, 24–30. [Google Scholar] [CrossRef]

- Huang, L.; Zhang, Q.; Wang, Y.; He, R.; Shuai, J.; Zhang, J.; Wang, C.; Ren, Z. The effect of Sn doping on thermoelectric performance of n-type half-Heusler NbCoSb. Phys. Chem. Chem. Phys. 2017, 19, 25683–25690. [Google Scholar] [CrossRef]

- Kim, K.S.; Kim, Y.M.; Mun, H.; Kim, J.; Park, J.; Borisevich, A.Y.; Lee, K.H.; Kim, S.W. Direct observation of inherent atomic-scale defect disorders responsible for high performance Ti1−xHfxNiSn1−ySby half-Heusler thermoelectric alloys. Adv. Mater. 2017, 29, 170209. [Google Scholar]

- Lkhagvasuren, E.; Ouardi, S.; Fecher, G.H.; Auffermann, G.; Kreiner, G.; Schnelle, W.; Felser, C. Optimized thermoelectric performance of the n-type half-Heusler material TiNiSn by substitution and addition of Mn. AIP Adv. 2017, 7, 045010. [Google Scholar] [CrossRef]

- Mao, J.; Zhou, J.; Zhu, H.; Liu, Z.; Zhang, H.; He, R.; Chen, G.; Ren, Z. Thermoelectric properties of n type ZrNiPb-based half-Heuslers. Chem. Mater. 2017, 29, 867–872. [Google Scholar] [CrossRef]

- Rogl, G.; Sauerschnig, P.; Rykavets, Z.; Romaka, V.V.; Heinrich, P.; Hinterleitner, B.; Grytsiv, A.; Bauer, E.; Rogl, P. (V,Nb)-doped half Heusler alloys based on {Ti,Zr,Hf}NiSn with high ZT. Acta Mater. 2017, 131, 336–348. [Google Scholar] [CrossRef]

- Silpawilawan, W.; Kurosaki, K.; Ohishi, Y.; Muta, H.; Yamanaka, S. FeNbSb p-type half-Heusler compound: Beneficial thermomechanical properties and high temperature stability for thermoelectrics. J. Mater. Chem. C 2017, 5, 6677–6681. [Google Scholar] [CrossRef]

- Tavassoli, A.; Failamani, F.; Grytsiv, A.; Rogl, G.; Heinrich, P.; Müller, H.; Bauer, E.; Zehetbauer, M.; Rogl, P. On the half-Heusler compounds Nb1−x{Ti,Zr,Hf}xFeSb: Phase relations, thermoelectric properties at low and high temperature, and mechanical properties. Acta Mater. 2017, 135, 263–276. [Google Scholar] [CrossRef]

- Visconti, A.; Navone, C.; Leforestier, J.; Mingo, N.; Bernard-Grange, G. Influence of the addition of HfO2 particles on the thermoelectric properties of an n-type half-Heusler alloy sintered by spark plasma sintering. J. Alloys Compds. 2017, 709, 36–41. [Google Scholar] [CrossRef]

- Yu, J.; Fu, C.; Liu, Y.; Xia, K.; Aydemir, U.; Chasapis, T.C.; Snyder, G.J.; Zhao, X.; Zhu, T. Unique role of refractory Ta alloying in enhancing the figure of merit of NbFeSb thermoelectric materials. Adv. Energy Mater. 2017, 8, 1701313. [Google Scholar] [CrossRef]

- Zeier, W.G.; Anand, S.; Huang, L.; He, R.; Zhang, H.; Ren, Z.; Wolverton, C.; Snyder, G.J. Using the 18-electron rule to understand the nominal 19-electron half-Heusler NbCoSb with Nb vacancies. Chem. Mater. 2017, 29, 1210–1217. [Google Scholar] [CrossRef]

- Barczak, S.A.; Halpin, J.E.; Buckman, J.; Decourt, R.; Pollet, M.; Smith, R.I.; MacLaren, D.A.; Bos, J.-W.G. Grain-by-grain compositional variations and interstitial metals—A new route toward achieving high performance in half-Heusler thermoelectrics. ACS Appl. Mater. Interfaces 2018, 10, 4786–4793. [Google Scholar] [CrossRef]

- Chauhan, N.S.; Bathula, S.; Vishwakarma, A.; Bhardwaj, R.; Gahtori, B.; Srivastava, A.K.; Saravanan, M.; Dhar, A. A nanocomposite approach for enhancement of thermoelectric performance in hafnium-free half-Heuslers. Materialia 2018, 1, 168–174. [Google Scholar] [CrossRef]

- Chauhan, N.S.; Bathula, S.; Vishwakarma, A.; Bhardwaj, R.; Johari, K.K.; Gahtori, B.; Saravanan, M.; Dhar, A. Compositional tuning of ZrNiSn half-Heusler alloys: Thermoelectric characteristics and performance analysis. J. Phys. Chem. Solids 2018, 123, 105–112. [Google Scholar] [CrossRef]

- Chauhan, N.S.; Bathula, S.; Vishwakarma, A.; Bhardwaj, R.; Gahtori, B.; Kumar, A.; Dhar, A. Vanadium-doping-induced resonant energy levels for the enhancement of thermoelectric performance in Hf-free ZrNiSn half-Heusler alloys. ACS Appl. Energy Mater. 2018, 1, 757–764. [Google Scholar] [CrossRef]

- Chauhan, N.S.; Bathula, S.; Vishwakarma, A.; Bhardwaj, R.; Johari, K.K.; Gahtori, B.; Dhar, A. Facile fabrication of p- and n-type half-Heusler alloys with enhanced thermoelectric performance and low specific contact resistance employing spark plasma sintering. Mater. Lett. 2018, 228, 250–253. [Google Scholar] [CrossRef]

- Hu, C.; Xia, K.; Chen, X.; Zhao, X.; Zhu, T. Transport mechanisms and property optimization of p-type (Zr,Hf)CoSb half-Heusler thermoelectric materials. Mater. Today Phys. 2018, 7, 69–76. [Google Scholar] [CrossRef]

- Liu, Y.; Fu, C.; Xia, K.; Chen, X.; Zhao, X.; Zhu, T. Lanthanide contraction as a design factor for high-performance half-Heusler thermoelectric materials. Adv. Mater. 2018, 30, 1800881. [Google Scholar] [CrossRef]

- Mallick, M.M.; Vitt, S. Enhancing the thermoelectric performance of a p-type half-Heusler alloy, HfCoSb by incorporation of a band-matched chalcogenide, Cu2Te. J. Mater. Chem. A 2018, 6, 14709–14716. [Google Scholar] [CrossRef]

- Ren, W.; Zhu, H.; Zhu, Q.; Saparamadu, U.; He, R.; Liu, Z.; Mao, J.; Wang, C.; Nielsch, K.; Wang, Z.; et al. Ultrahigh power factor in thermoelectric system Nb0.95M0.05FeSb (M = Hf, Zr, and Ti). Adv. Sci. 2018, 5, 1800278. [Google Scholar] [CrossRef]

- Rogl, G.; Yubuta, K.; Romaka, V.V.; Michor, H.; Schafler, E.; Grytsiv, A.; Bauer, E.; Rogl, P. High-ZT half-Heusler thermoelectrics, Ti0.5Zr0.5NiSn and Ti0.5Zr0.5NiSn0.98Sb0.02: Physical properties at low temperatures. Acta Mater. 2018, 166, 466–483. [Google Scholar] [CrossRef]

- Shen, J.; Fu, C.; Liu, Y.; Zhao, X.; Zhu, T. Enhancing thermoelectric performance of FeNbSb half-Heusler compound by Hf-Ti dual doping. Energy Storage Mater. 2018, 10, 69–74. [Google Scholar] [CrossRef]

- Silpawilawan, W.; Ohishi, Y.; Muta, H.; Yamanaka, S.; Kurosaki, K. Thermoelectric properties of p-type half-Heusler compounds FeNb0.9M0.1Sb (M = Ti, Zr, Hf). Mater. Trans. 2018, 59, 1030–1034. [Google Scholar] [CrossRef]

- Tavassoli, A.; Grytsiv, A.; Rogl, G.; Romaka, V.V.; Michor, H.; Reissner, M.; Bauer, E.; Zehetbauer, M.; Rogl, P. The half- Heusler system Ti1+xFe1.33−xSb—TiCoSb with Sb/Sn substitution: Phase relations, crystal structures and thermoelectric properties. Dalton Trans. 2018, 47, 879–897. [Google Scholar] [CrossRef] [PubMed]

- Xia, K.; Liu, Y.; Anand, S.; Snyder, G.J.; Xin, J.; Yu, J.; Zhao, X.; Zhu, T. Enhanced thermoelectric performance in 18-electron Nb0.8CoSb half-Heusler compound with intrinsic Nb vacancies. Adv. Funct. Mater. 2018, 28, 1705845. [Google Scholar] [CrossRef]

- Yan, Y.; Geng, W.; Qiu, J.; Ke, H.; Luo, C.; Yang, J.; Uher, C.; Tang, X. Thermoelectric properties of n-type ZrNiSn prepared by rapid non-equilibrium laser processing. RSC Adv. 2018, 8, 15796–15803. [Google Scholar] [CrossRef]

- Zhao, D.; Zou, M.; Bo, L.; Wang, Y. Synthesis and thermoelectric properties of Pd-doped ZrCoBi half-Heusler compounds. Materials 2018, 11, 728–737. [Google Scholar] [CrossRef]

- Zhu, T.; Fu, C.; Zhao, X. High figure of merit p-type FeNbHfSb thermoelectric material and the preparation method thereof. United States Patent US2018/0331268A1, 15 November 2018. [Google Scholar]

- Zhu, H.; He, R.; Mao, J.; Zhu, Q.; Li, C.; Sun, J.; Ren, W.; Wang, Y.; Liu, Z.; Tang, Z.; et al. Discovery of ZrCoBi based half-Heuslers with high thermoelectric conversion efficiency. Nat. Commun. 2018, 9, 2497. [Google Scholar] [CrossRef]

- Barczak, S.A.; Quinn, R.J.; Halpin, J.E.; Domosud, K.; Smith, R.I.; Baker, A.R.; Don, E.; Forbes, I.; Refson, K.; MacLaren, D.A.; et al. Suppression of thermal conductivity without impeding electron mobility in n-type XNiSn half-Heusler thermoelectrics. J. Mater. Chem. A 2019, 7, 27124–27134. [Google Scholar] [CrossRef]

- Chauhan, N.S.; Bathula, S.; Gahtori, B.; Mahanti, S.D.; Bhattacharya, A.; Vishwakarma, A.; Bhardwaj, R.; Singh, V.N.; Dhar, A. Compositional tailoring for realizing high thermoelectric performance in hafnium-free n type ZrNiSn half-Heusler alloys. ACS Appl. Mater. Interfaces 2019, 11, 47830–47836. [Google Scholar] [CrossRef]

- Du, N.V.; Rahman, J.U.; Meang, E.-J.; Lim, C.-H.; Shin, W.H.; Seo, W.-S.; Huy, P.T.; Kim, M.H.; Lee, S. Synthesis and thermoelectric properties of Ti-substituted (Hf0.5Zr0.5)1−xTixNiSn0.998Sb0.002 half-Heusler compounds. J. Alloys Compd. 2019, 773, 1141–1145. [Google Scholar]

- Ferluccio, D.A.; Halpin, J.E.; MacIntosh, K.L.; Quinn, R.J.; Don, E.; Smith, R.I.; MacLaren, D.A.; Bos, J.-W.G. Low thermal conductivity and promising thermoelectric performance in AxCoSb (A = V, Nb or Ta) half-Heuslers with inherent vacancies. J. Mater. Chem. C 2019, 7, 6539–6547. [Google Scholar] [CrossRef]

- Gong, B.; Li, Y.; Liu, F.; Zhu, J.; Wang, X.; Ao, W.; Zhang, C.; Li, J.; Xie, H.; Zhu, T. Continuously enhanced structural disorder to suppress the lattice thermal conductivity of ZrNiSn-based half-Heusler alloys by multielement and multisite alloying with very low Hf content. ACS Appl. Mater. Interfaces 2019, 11, 13397–13404. [Google Scholar] [CrossRef] [PubMed]

- Grytsiv, A.; Romaka, V.V.; Watson, N.; Rogl, G.; Michor, H.; Hinterleitner, B.; Puchegger, S.; Bauer, E.; Rogl, P. Thermoelectric half-Heusler compounds TaFeSb and Ta1−xTixFeSb (0 ≤ x ≤ 0.11): Formation and physical properties. Intermetallics 2019, 111, 106468. [Google Scholar] [CrossRef]

- Huang, L.; Wang, J.; Mo, X.; Lei, X.; Ma, S.; Wang, C.; Zhang, Q. Improving the thermoelectric properties of the half-Heusler compound VCoSb by vanadium vacancy. Materials 2019, 12, 1637. [Google Scholar] [CrossRef]

- Joshi, H.; Rai, D.P.; Hnamte, L.; Laref, A.; Thapa, R.K. A theoretical analysis of elastic and optical properties of half-Heusler MCoSb (M = Ti, Zr and Hf). Heliyon 2019, 5, e01155. [Google Scholar] [CrossRef]

- Karati, A.; Mukherjee, S.; Mallik, R.C.; Shabadi, R.; Murty, B.S.; Varadaraju, U.V. Simultaneous increase in thermopower and electrical conductivity through Ta-doping and nanostructuring in half-Heusler TiNiSn alloys. Materialia 2019, 7, 100410. [Google Scholar] [CrossRef]

- Karati, A.; Nagini, M.; Ghosh, S.; Shabadi, R.; Pradeep, K.G.; Mallik, R.C.; Murty, B.S.; Varadaraju, U.V. Ti2NiCoSnSb—A new half-Heusler type high-entropy alloy showing simultaneous increase in Seebeck coefficient and electrical conductivity for thermoelectric applications. Sci. Rep. 2019, 9, 5331–5343. [Google Scholar] [CrossRef]

- Li, S.; Zhu, H.; Mao, J.; Feng, Z.; Li, X.; Chen, C.; Cao, F.; Liu, X.; Singh, D.J.; Ren, Z.; et al. N-type TaCoSn-based half-Heuslers as promising thermoelectric materials. ACS Appl. Mater. Interfaces 2019, 11, 41321–41329. [Google Scholar] [CrossRef]

- Mallik, M.M.; Rajput, K.; Vitta, S. Increasing figure-of-merit of ZrNiSn half-Heusler alloy by minimal substitution and thermal conductivity reduction. J. Mater. Sci. Mater. Electron. 2019, 30, 6139–6147. [Google Scholar] [CrossRef]

- Qiu, Q.; Liu, Y.; Xia, K.; Fang, T.; Yu, J.; Zhao, X.; Zhu, T. Grain boundary scattering of charge transport in n-type (Hf,Zr)CoSb half-Heusler thermoelectric materials. Adv. Energy Mater. 2019, 9, 1803447. [Google Scholar] [CrossRef]

- Shen, J.; Wang, Z.; Chu, J.; Bai, S.; Zha, X.; Chen, L.; Zhu, T. Low contact resistivity and interfacial behavior of p-type NbFeSb/Mo thermoelectric junction. ACS Appl. Mater. Interfaces 2019, 11, 14182–14190. [Google Scholar] [CrossRef] [PubMed]

- Shen, J.; Fan, L.; Hu, C.; Zhu, T.; Xin, J.; Fu, T.; Zhao, D.; Zhao, X. Enhanced thermoelectric performance in the n-type NbFeSb half-Heusler compound with heavy element Ir doping. Mater. Today Phys. 2019, 8, 62–70. [Google Scholar] [CrossRef]

- Synoradzki, K.; Ciesielski, K.; Veremchuk, I.; Borrmann, H.; Skokowski, P.; Szymanski, D.; Grin, Y.; Kaczorowski, D. Thermal and electronic transport properties of the half-Heusler phase ScNiSb. Materials 2019, 12, 1723–1734. [Google Scholar] [CrossRef] [PubMed]

- Xia, K.; Nan, P.; Tan, S.; Wang, Y.; Ge, B.; Zhang, W.; Anand, S.; Zhao, X.; Snyder, G.J.; Zhu, T. Short-range order in defective half-Heusler thermoelectric crystals. Energy Environ. Sci. 2019, 12, 1568–1574. [Google Scholar] [CrossRef]

- Zhu, H.; Mao, J.; Feng, Z.; Sun, J.; Zhu, Q.; Liu, Z.; Singh, D.J.; Wang, Y.; Ren, Z. Understanding the asymmetrical thermoelectric performance for discovering promising thermoelectric materials. Sci. Adv. 2019, 5, eaav5813. [Google Scholar] [CrossRef] [PubMed]

- Zhu, H.; Mao, J.; Li, Y.; Sun, J.; Wang, Y.; Zhu, Q.; Li, G.; Song, Q.; Zhou, J.; Fu, Y.; et al. Discovery of TaFeSb-based half-Heuslers with high thermoelectric performance. Nat. Commun. 2019, 10, 270–278. [Google Scholar] [CrossRef]

- Bae, W.; Hwang, J.Y.; Kim, S.-I.; Jeong, H.M.; Kim, S.; Lim, J.-H.; Kim, H.S.; Lee, K.H. Thermoelectric transport properties of n-Type Sb-doped (Hf,Zr,Ti)NiSn half-Heusler alloys prepared by temperature-regulated melt spinning and spark plasma sintering. Appl. Sci. 2020, 10, 4963–4970. [Google Scholar] [CrossRef]

- Chauhan, N.S.; Raghuvanshi, P.R.; Tyagi, K.; Johari, K.K.; Tyagi, L.; Gahtori, B.; Bathula, S.; Bhattacharya, A.; Mahanti, S.D.; Singh, V.N.; et al. Defect engineering for enhancement of thermoelectric performance of (Zr,Hf)NiSn-based n-type half-Heusler alloys. J. Phys. Chem. C 2020, 124, 8584–8593. [Google Scholar] [CrossRef]

- Ciesielski, K.; Synoradzki, K.; Veremchuk, I.; Skokowski, P.; Szymański, D.; Grin, Y.; Kaczorowski, D. Thermoelectric performance of the half-Heusler phases RNiSb (R = Sc, Dy, Er, Tm, Lu): High mobility ratio between majority and minority charge carriers. Phys. Rev. Appl. 2020, 14, 054046. [Google Scholar] [CrossRef]

- El-Khouly, A.; Novitskii, A.; Adam, A.M.; Sedegov, A.; Kalugina, A.; Pankratova, D.; Karpenkov, D.; Khovaylo, V. Transport and thermoelectric properties of Hf-doped FeVSb half-Heusler alloys. J. Alloys Compd. 2020, 820, 153413. [Google Scholar] [CrossRef]

- El-Khouly, A.; Novitskii, A.; Serhiienko, I.; Kalugina, A.; Sedegov, A.; Karpenkov, D.; Voronin, A.; Khovaylo, V.; Adam, A.M. Optimizing the thermoelectric performance of FeVSb half-Heusler compound via Hf-Ti double doping. J. Power Sources 2020, 477, 228768. [Google Scholar] [CrossRef]

- Fang, T.; Xia, K.; Nan, P.; Ge, B.; Zhao, X.; Zhu, T. A new defective 19-electron TiPtSb half-Heusler thermoelectric compound with heavy band and low lattice thermal conductivity. Mater. Today Phys. 2020, 13, 100200. [Google Scholar] [CrossRef]

- Graziosi, P.; Kumarasinghe, C.; Neophytou, N. Material descriptors for the discovery of efficient thermoelectrics. ACS Appl. Energy Mater. 2020, 3, 5913–5926. [Google Scholar] [CrossRef]

- Johari, K.K.; Bhardwaj, R.; Chauhan, N.S.; Gahtori, B.; Bathula, S.; Auluck, S.; Dhakate, S.R. Band structure modification and mass fluctuation effects of isoelectronic germanium-doping on thermoelectric properties of ZrNiSn. ACS Appl. Mater. 2020, 3, 1349–1357. [Google Scholar] [CrossRef]

- Kang, H.B.; Poudel, B.; Li, W.; Lee, H.; Saparamadu, U.; Nozariasbmarz, A.; Kang, M.G.; Gupta, A.; Heremans, J.; Priy, S. Decoupled phononic-electronic transport in multi-phase n-type half-Heusler nanocomposites enabling efficient high temperature power generation. Mater. Today 2020, 36, 63–72. [Google Scholar] [CrossRef]

- Karati, A.; Hariharan, V.S.; Ghosh, S.; Prasad, A.; Nagini, M.; Guruvidyathri, K.; Mallik, R.C.; Shabadi, R.; Bichler, L.; Murty, B.S.; et al. Thermoelectric properties of half-Heusler high-entropy Ti2NiCoSn1−xSb1+x (x = 0.5, 1) alloys with VEC > 18. Scripta Mater. 2020, 186, 375–380. [Google Scholar] [CrossRef]

- Li, S.; Bai, F.; Wang, R.; Chen, C.; Li, X.; Cao, F.; Sui, J.; Liu, X.; Ren, Z.; Zhang, Q. Titanium doping to enhance thermoelectric performance of 19-electron VCoSb half-Heusler compounds with vanadium vacancies. Ann. Phys. 2020, 525, 1900440. [Google Scholar] [CrossRef]

- Li, N.; Zhu, H.; He, W.; Zhang, B.; Cui, W.; Hu, Z.-Y.; Sang, X.; Lu, X.; Wang, G.; Zhou, X. Realizing both n- and p-types of high thermoelectric performance in Fe1-xNixTiSb half-Heusler compounds. J. Mater. Chem. C 2020, 8, 3156–3164. [Google Scholar] [CrossRef]

- Pedersen, S.V.; Croteau, J.R.; Kempf, N.; Zhang, Y.; Butt, D.P.; Jaques, B.J. Novel synthesis and processing effects on the figure of merit for NbCoSn, NbFeSb, and ZrNiSn based half-Heusler thermoelectrics. J. Solid State Chem. 2020, 285, 121203. [Google Scholar] [CrossRef]

- Serrano-Sanchez, F.; Luo, T.; Yu, J.; Xie, W.; Le, C.; Auffermann, G.; Weidenkaff, A.; Zhu, T.; Zhao, X.; Alonso, J.A.; et al. Thermoelectric properties of n-type half-Heusler NbCoSn with heavy-element Pt substitution. J. Mater. Chem. A 2020, 8, 14822–14828. [Google Scholar] [CrossRef]

- Yang, X.; Jiang, Z.; Kang, H.; Chen, Z.; Guo, E.; Liu, D.; Yang, F.; Li, R.; Jiang, X.; Wang, T. Enhanced thermoelectric performance of Zr1−xTaxNiSn half-Heusler alloys by diagonal-rule doping. ACS Appl. Mater. Interfaces 2020, 12, 3773–3783. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.; Xing, Y.; Hu, C.; Huang, Z.; Qiu, Q.; Wang, C.; Xia, K.; Wang, Z.; Bai, S.; Zhao, X.; et al. Half-Heusler thermoelectric module with high conversion efficiency and high-power density. Adv. Energy Mater. 2020, 10, 2000888. [Google Scholar] [CrossRef]

- Wang, R.-F.; Li, S.; Xue, W.-H.; Chen, C.; Wang, Y.-M.; Liu, X.-J.; Zhang, Q. Enhanced thermoelectric performance of n-type TiCoSb half- Heusler by Ta doping and Hf alloying. Rare Met. 2021, 40, 40–47. [Google Scholar] [CrossRef]

- Zelenka, F.; Brož, P.; Vrestal, J.; Bursik, J.; Zemanova, A.; Rogl, G.; Rogl, P. Study of thermal stability of half-Heusler alloys TiFe1.33Sb and TixNb1−xFeSb (x = 0, 0.15) by differential thermal analysis and Knudsen effusion method. Calphad 2021, 74, 102292. [Google Scholar] [CrossRef]

- Guo, S.; Anad, S.; Brod, M.K.; Zhang, Y.; Snyder, G.J. Conduction band engineering of half-Heusler thermoelectrics using orbital chemistry. J. Mater. Chem. A 2022, 10, 3051. [Google Scholar] [CrossRef]

- Karati, A.; Ghosh, S.; Nagini, M.; Mallik, R.C.; Shabadi, R.; Murty, B.S.; Varadaraju, U.V. Thermoelectric properties of nanocrystalline half-Heusler high-entropy Ti2NiCoSn1−xSb1+x(x = 0.3, 0.5, 0.7, 1) alloys with VEC > 18. J. Alloys Compds. 2022, 927, 166578. [Google Scholar] [CrossRef]

- Karati, A.; Mishra, S.R.; Ghosh, S.; Mallik, R.C.; Shabadi, R.; Murty, B.S.; Ramanujan, R.V.; Yadav, S.K.; Murty, B.S.; Varadaraju, U.V. Thermoelectric properties of a high entropy half-Heusler alloy processed by a fast powder metallurgy route. J. Alloys Compd. 2022, 924, 166108. [Google Scholar] [CrossRef]

- Mesaritis, G.; Ioannou, I.; Delimitis, A.; Hatzikraniotis, E.; Gelbstein, Y.; Kyratsi, T. n-type (Zr,Ti)NiSn half-Heusler materials via mechanical alloying: Structure, Sb-doping and thermoelectric properties. J. Phys. Chem. Solids 2022, 167, 110735. [Google Scholar] [CrossRef]

- Serrano-Sanchez, F.; Yao, M.; He, B.; Chen, D.; Gloskovskii, A.; Fedorov, A.; Auffermann, G.; Liu, E.; Burkhardt, U.; Fecher, G.H.; et al. Electronic structure and low-temperature thermoelectric transport of TiCoSb single crystals. Nanoscale 2022, 14, 10067. [Google Scholar] [CrossRef]

- Yang, X.; Wang, Y.; Min, R.; Chen, Z.; Guo, E.; Kang, H.; Li, L.; Jiang, X.; Wang, T. Enhancement in thermoelectric properties of ZrNiSn-based alloys by Ta-Hf Co-doping. Acta Mater. 2022, 233, 117976. [Google Scholar] [CrossRef]

- Barczak, S.A.; Kennedy, B.F.; da Silva, I.; Bos, J.-W.G. Mechanistic insights into the formation of thermoelectric TiNiSn from in situ neutron powder diffraction. Chem. Mater. 2023, 35, 3694. [Google Scholar] [CrossRef] [PubMed]

- Chen, R.; Yan, Y.; Zhang, W.; Liu, F.; Kang, H.; Guo, E.; Chen, Z.; Wang, T. Enhanced thermoelectric properties of Zr0.85−xHfxNb0.15−yTayCoSb medium-entropy alloys: Tradeoff between “What to Alloy” and “How Much to Alloy”. Chem. Mater. 2023, 35, 2202. [Google Scholar] [CrossRef]

- Ciesielski, K.; Synoradzki, K.; Szymański, D.; Tobita, K.; Berent, K.; Obstarczyk, P.; Kimura, K.; Kaczorowski, D. Half- Heusler phase TmNiSb under pressure: Intrinsic phase separation, thermoelectric performance and structural transition. Sci. Rep. 2023, 13, 1592. [Google Scholar] [CrossRef]

- Liu, R.; Wang, C.; Huang, J.; Luo, P.; Liu, X.; Ye, S.; Dong, Z.; Zhang, J.; Luo, J. Preparation and thermoelectric properties of Sc-doped Ti1−xNiSb half-Heusler alloys. Acta Phys. Sin. 2013, 72, 20230035. [Google Scholar]

- Min, R.; Gao, Y.; Jiang, X.; Yang, X.; Li, L.; Kang, H.; Guo, E.; Chen, Z.; Wang, T. Enhancement in the thermoelectric performance of ZrNiSn-based alloys through extra Zr-rich nanoprecipitates with superstructures. Chem. Eng. J. 2023, 464, 142531. [Google Scholar] [CrossRef]

- Verma, A.K.; Johari, K.K.; Dubey, P.; Candolfi, C.; Lenoir, B.; Walia, S.; Dhakate, S.R.; Gahtori, B. Coupling of electronic transport and defect engineering substantially enhances the thermoelectric performance of p-type TiCoSb HH alloy. J. Alloys Compds. 2023, 947, 169416. [Google Scholar] [CrossRef]

- Vikram, B.S.; Barman, C.K.; Alam, A. Accelerated discovery of new 8-electron half-Heusler compound as promising energy and topological quantum materials. J. Phys. Chem. C 2019, 123, 12. [Google Scholar] [CrossRef]

- Vikram, B.S.; Kangsabanik, J.; Alam, A. Accurate high-throughput screening of I-II-V 8-electron half-Heusler compounds for renewable-energy application. arXiv 2019, arXiv:1910.02984v1. [Google Scholar]

- Hoat, D.M.; Naseri, M. Electronic and thermoelectric properties of RbYSn half-Heusler compound with a 8 valence electrons: Spin-orbit coupling effect. Chem. Phys. 2020, 528, 110510. [Google Scholar] [CrossRef]

| N-Type Half-Heusler Alloys (Ti,Zr,Hf)NiSn-System | X | Z | References (Marked with *: Not Measured above RT) |

|---|---|---|---|

| TiNiSn | [19,21,22,23], [31] *, [30,34,39,58,75,83,88,90,99,139,143,144,152,178,210,213] | ||

| TiNiSn/Z | Sb | [24,39,58] | |

| Si | [34] | ||

| (Ti,X)NiSn | Nb | [66] | |

| Ta | [178,212] | ||

| Ti(Ni,X)Sn | Mn | [138,139,144] | |

| Pd | [17] | ||

| Pt | [34] | ||

| Cu | [152] | ||

| Ti(Ni,X)Sn/Z | Co | Sb | [48,67,179,198,207,208] |

| ZrNiSn | [6,7,10,12,14,17], [29,31,32] *, [33,35,36,37,42,57,66,70,71,85,99,106,108,110,119,122,123,129,153,154,155,166,171,174,196,203,210,212] | ||

| ZrNiSn/Z | In | [32] * | |

| Si | [181] | ||

| Ge | [181,196] | ||

| Sb | [10,17,19], [32] *, [37,123,195] | ||

| Bi | [145] | ||

| (Zr,X)NiSn | Sc | [122] | |

| Y | [57,114] | ||

| V | [155] | ||

| Nb | [66] | ||

| Ta | [203,212] | ||

| Zr(Ni,X)Sn | Pd | [33,34] | |

| Cu | [36] | ||

| Co + Cu | [36] | ||

| Zr(Ni,X)Sn/Z | Pd | Sb | [33] |

| HfNiSn | [12], [31] *, [99,119,129,195] | ||

| HfNiSn/Z | Sb | [129] | |

| (Ti,Zr)NiSn | [25,26,27,31,34,65,69,90,99,100,129,161] | ||

| (Ti,Zr)NiSn/Z | Sb | [25,26,27,90,99,100,149,161,201,210] | |

| (Ti,Zr,X)NiSn/Z | V | Sb | [146] |

| Nb | Sb | [146] | |

| (Ti,Hf)NiSn | [31] *, [34,58,65,69,90,102,124,129,134,143] | ||

| (Ti,Hf)NiSn/Z | Sb | [58,143] | |

| (Ti,Hf,X)NiSn | Nb | [31] * | |

| (Ti,Hf)(Ni,X)Sn | Pd | [58] | |

| (Zr,Hf)NiSn | [11], [31,32] *, [65,77,78,80,81,84,87,90,93,99,109,137,154,156,190] | ||

| (Zr,Hf)NiSn/Z | Sb | [11,12,18,43,49,50,73,76,77,79,89,93,95,98,111,119,124,127,129,132,133,135,138,140,146,172,187,201,204] | |

| (Zr,Hf,X)NiSn | V | [81] | |

| Nb | [31] * | ||

| Ta | [203,212] | ||

| (Zr,Hf)(Ni,X)Sn | Pd | [17], [29] *, [33,49,50] | |

| Pt | [95] | ||

| (Zr,Hf,X)NiSn/Z | Y | Sb | [73] |

| V | Sb | [140] | |

| Nb | Sb | [137,140] | |

| Ta | Sb | [140] | |

| (Zr,Hf)(Ni,X)Sn/Z | Pd | Sb | [33] |

| (Ti,Zr,Hf)NiSn | [40,41,43,47], [49] *, [105,129,146,170,183] | ||

| (Ti,Zr,Hf)NiSn/Z | Sb | [43,127,189] | |

| Bi | [77,93] | ||

| Te | [93] | ||

| (Ti,Zr,Hf,X)NiSn | Nb | [105] | |

| (Ti,Zr,Hf)(Ni,X)Sn | Cu | [170] | |

| (Ti,Zr,Hf,X)NiSn/Z | V + Nb | Sb | [174] |

| (Ti,Zr)Ni1±xSn | [22,110,171] | ||

| (Ti,Zr)Ni1±xSn | [138] | ||

| (Zr,Hf)Ni1±xSn | [77] | ||

| TiNiSn+full Heusler | [83] | ||

| TiNiSn+HfO2 | [149] | ||

| ZrNiSn+B | [29] * | ||

| ZrNiSn+La | [108] | ||

| ZrNiSn+ZrO2 | [35] | ||

| ZrNiSn+ZnO | [153] | ||

| (Zr,Hf)NiSn+W | [197] | ||

| (Zr,Hf)NiSn+ZrO2 | [95] | ||

| (Zr,Hf)NiSn/Z+Nb | Sb | [80] * | |

| (Zr,Hf)NiSn/Z+full Heusler | Sb | [77,78] | |

| (Zr,Hf)(Ni,X)Sn/Z+ZrO2 | Pd | Sb | [49] |

| (Ti,Zr,Hf)NiSn/Z+ZrO2 | Sb | [17] | |

| (Ti,Zr,Hf)CoSb-System | |||

| TiCoSb | [38,44,46,48,55,56,61,68,177] | ||

| (Ti,X)CoSb | Ta | [204] | |

| Ti(Co,X)Sb | Fe | [61] | |

| Ni | [48] | ||

| (Ti,X)CoSb/Z | Nb + Ta | Sn | [38] |

| ZrCoSb | [3,45,46,56,60,141,147,177] | ||

| (Zr,X)CoSb | Nb | [156] | |

| Zr(Co,X)Sb | Ni | [141] | |

| HfCoSb | [45,46,56,177,195] | ||

| (Hf,X)CoSb | Nb | [182] | |

| (Ti,Zr)CoSb | [67] | ||

| (Ti,Zr)(Co,X)Sb | Ni | [67] | |

| (Ti,Hf,X)CoSb | Ta | [204] | |

| (Zr,Hf,X)CoSb | Nb | [158,182] | |

| Nb + Ta | [214] | ||

| (Ti,Zr,Hf)CoSb | [56,64] | ||

| (Ti,Zr,Hf)(Co,X)Sb | Ni | [64] | |

| (V,Nb,Ta)FeSb-System | |||

| VFeSb | [74,91,192] | ||

| (V,X)FeSb | Ti | [15] | |

| NbFeSb | [26,148] | ||

| Nb(Fe,X)Sb | Ir | [184] | |

| (V,Nb)FeSb | [92] | ||

| (V,Nb)(Fe,X)Sb | Co | [92] | |

| Ti(Fe,X)Sb | Ni | [200] | |

| Ti(Fe,X)Sb/Z | Ni | Sn | [13] |

| 19-Electron System | |||

| VCoSb | [136,173,176,199] | ||

| VCoSb/Z | Sn | [136] | |

| NbCoSb | [116,117,142,151,165,173] | ||

| Nb(Co,X)Sb | Ni | [186] | |

| NbCoSb/Z | Sn | [142] | |

| TaCoSb | [173] | ||

| (Ti,V)CoSb | [136,199] | ||

| (V,Nb)CoSb | [117] | ||

| (Nb,Ta)CoSb | [117] | ||

| (V,Nb,Ta)CoSb | [117] | ||

| (Ti,Nb,Ta)CoSb/Z | Sn | [38] | |

| TiNiSb | [212] | ||

| (Ti,X)NiSb | Sc | [212] | |

| TiPtSn | [194] | ||

| Other N-type Half-Heusler Material | |||

| TiCoSn | [21] | ||

| TiPtSn | [51] | ||

| VCoSn | [207] | ||

| NbCoSn | [130,180,202] | ||

| NbCoSn/Z | Sb | [52,63] | |

| Nb(Co,X)Sn | Pt | [202] | |

| (Nb,Ti)Sn/Z | Sb | [52] | |

| TaCoSn | [180] | ||

| (Ta,X)CoSn | Nb | [180] | |

| (Ta,X)CoSn/Z | Nb | Sb | [180] |

| ZrCoBi | [167,187] |

| P-Type Half-Heusler Alloys (Ti,Zr,Hf)NiSn-System | X | Z | References |

|---|---|---|---|

| (Zr,X)NiSn | Sc | [122] | |

| Y | [114] | ||

| ZrNiSn + Co | [71] | ||

| ZrNiSn + Ir | [71] | ||

| (Ti,Zr,Hf)CoSb-System | |||

| TiCoSb | [54,211] | ||

| TiCoSb/Z | Ge | [68] | |

| TiCoSb/Z | Sn | [55,107,120,164] | |

| ZrCoSb/Z | Sn | [16,19,60,107,126] | |

| HfCoSb/Z | Sn | [107,120] | |

| (Ti.Zr)CoSb/Z | Sn | [107] | |

| (Ti,Hf)CoSb/Z | Sn | [18,86,107,120,121,132,159] | |

| (Zr,Hf)CoSb/Z | Sn | [62,76,82,98,107,115,132,156,157] | |

| (Ti,Zr,Hf)CoSb/Z | Sn | [96,107,121] | |

| (Ti,Hf)CoSb/Z+Cu1.96Ni0.04Te0.97Se0.03 | Sn | [159] | |

| (Zr,Hf)CoSb/Z+HfO2 | Sn | [103] | |

| (Ti,Zr)[Fe,(Fe,Co), (Fe,Ni)]Sb-System | |||

| TiFeSb | [164] | ||

| Ti(Fe,Co)Sb | [61,94,164,206,218] | ||

| Ti(Fe,Co)Sb/Z | Sn | [164] | |

| (Ti,Zr)(Co,Fe)Sb | [218] | ||

| (Ti,Zr)(Co,Fe)Sb/Z | Sn | [218] | |

| Ti(Fe,Ni)Sb | [200] | ||

| Ti(Co,Fe)Sb+InSb | [94] | ||

| (V,Nb,Ta)FeSb-System | |||

| (V,X)FeSb | Ti | [15,97] | |

| Hf | [192] | ||

| Ti + Hf | [193] | ||

| NbFeSb | [27,112,131,147,195,206] | ||

| (Nb,X)FeSb | Ti | [104,112,128,131,148,160,163,183,201,206] | |

| Zr | [113,148,160,163] | ||

| Hf | [113,148,160,163,168] | ||

| Ti + Hf | [26,162] | ||

| Ti + Ta | [150,204] | ||

| (V,Nb,X)FeSb | Ti | [101,112] | |

| TaFeSb | [175,188] | ||

| (Ta,X)FeSb | Ti | [175,188] | |

| Other P-Type Half-Heusler Material | |||

| NbCoSb/Z | Sn | [201] | |

| ZrCoBi/Z | Sn | [169] | |

| ZrPtSn | [51] | ||

| HfPtSn | [51] | ||

| ScNiSb | [185,191] | ||

| DyNiSb | [191] | ||

| ErNiSb | [191] | ||

| TmNiSb | [191,212] | ||

| LuNiSb | [191] | ||

| YNiBi | [118] | ||

| ErPdSb | [53] | ||

| ErPdBi | [53] | ||

| LaPdBi | [59] | ||

| GdPdBi | [59] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rogl, G.; Rogl, P.F. Development of Thermoelectric Half-Heusler Alloys over the Past 25 Years. Crystals 2023, 13, 1152. https://doi.org/10.3390/cryst13071152

Rogl G, Rogl PF. Development of Thermoelectric Half-Heusler Alloys over the Past 25 Years. Crystals. 2023; 13(7):1152. https://doi.org/10.3390/cryst13071152

Chicago/Turabian StyleRogl, Gerda, and Peter Franz Rogl. 2023. "Development of Thermoelectric Half-Heusler Alloys over the Past 25 Years" Crystals 13, no. 7: 1152. https://doi.org/10.3390/cryst13071152

APA StyleRogl, G., & Rogl, P. F. (2023). Development of Thermoelectric Half-Heusler Alloys over the Past 25 Years. Crystals, 13(7), 1152. https://doi.org/10.3390/cryst13071152