Improvement of Heat Dissipation in Ag/Ni Substrates for Testing Cu-TiO2/TiO2-Modified Filters Using SERS Spectroscopy

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fabrication of SERS-Active Substrates

2.3. Filter Membrane Fabrication

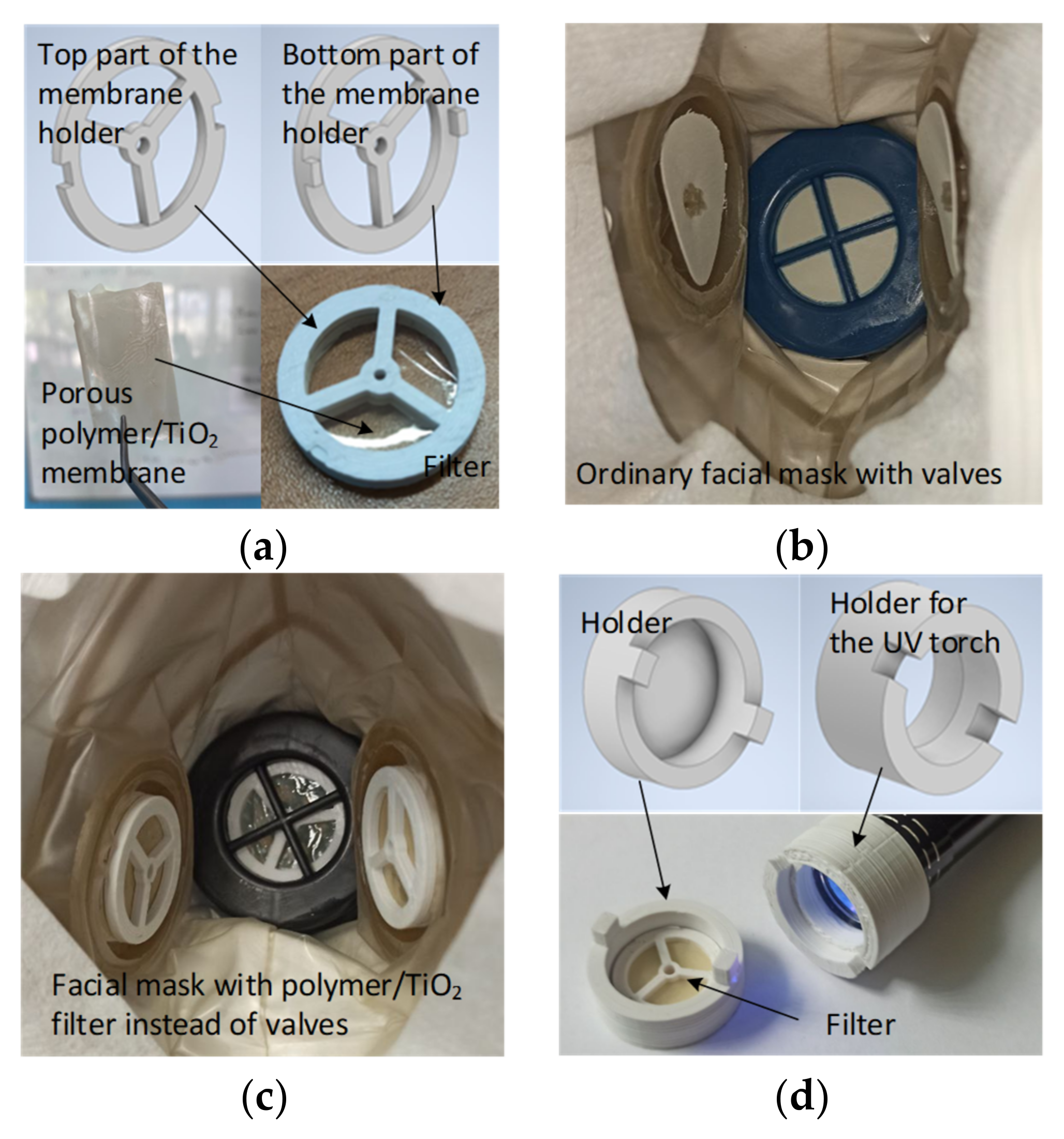

2.4. Embedding the Polymer Membrane in Facial Mask and Device for UV Cleaning

2.5. Characterization of the Experimental Samples

2.6. Testing the Filters

2.7. SERS Measurements

3. Results and Discussion

3.1. Structural Properties of Filter Components

3.1.1. Pure and Cu-Doped Titanium Dioxide

3.1.2. Filtering Material

3.2. Characterization of the Ag/Ni/macroPSi Samples

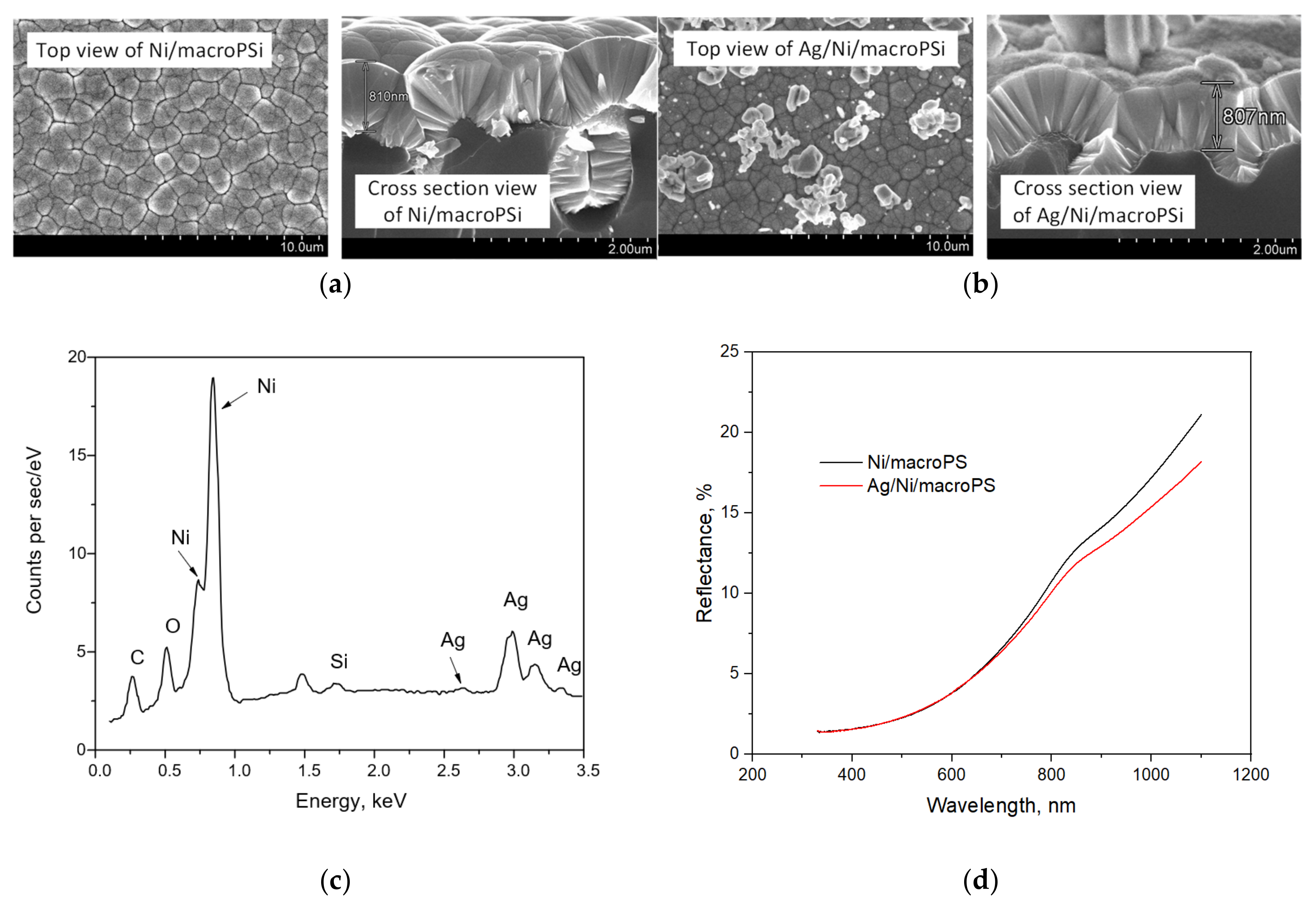

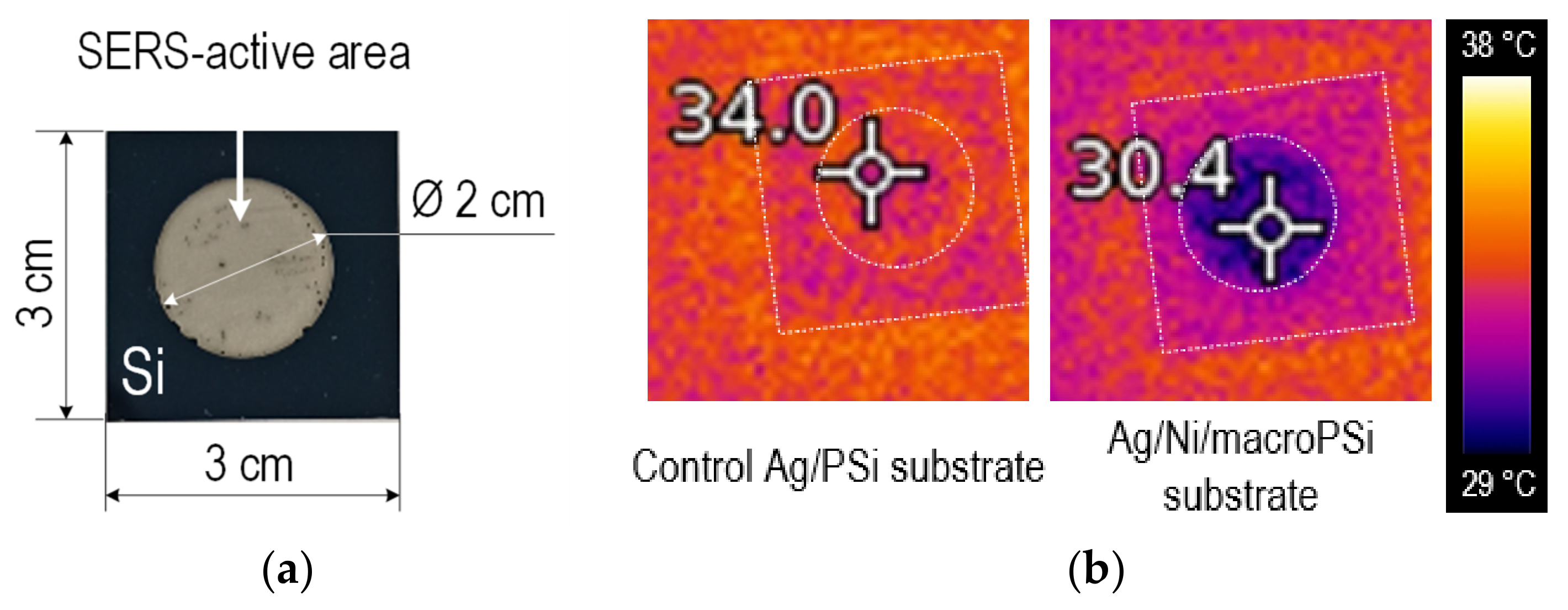

3.2.1. Structure, Optical and Thermal Properties of Ag/Ni/macroPSi Samples

3.2.2. SERS-Activity Study of Ag/Ni Samples

3.3. SERS Study of the Filters

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hirota, K. Air Contamination with SARS-CoV-2 in the Operating Room. J. Anesth. 2021, 35, 333–336. [Google Scholar] [CrossRef]

- Therkorn, J.; Drewry, D.; Andonian, J.; Benishek, L.; Billman, C.; Forsyth, E.R.; Garibaldi, B.T.; Nowakowski, E.; Rainwater-Lovett, K.; Sauer, L.; et al. Development and Comparison of Complementary Methods to Study Potential Skin and Inhalational Exposure to Pathogens during Personal Protective Equipment Doffing. Clin. Infect. Dis. 2019, 69, S231–S240. [Google Scholar] [CrossRef] [PubMed]

- Berry, M.E.; Kearns, H.; Graham, D.; Faulds, K. Surface Enhanced Raman Scattering for the Multiplexed Detection of Pathogenic Microorganisms: Towards Point-of-Use Applications. Analyst 2021, 146, 6084–6101. [Google Scholar] [CrossRef] [PubMed]

- Shapel, U.A.; Shapel, A.; Sharstniou, A.; Bandarenka, H. Plasmonic Nanovoids for Monitoring Sanitary Conditions of a Public Place by Surface-Enhanced Raman Spectroscopy. In Proceedings of the Frontiers in Biological Detection: From Nanosensors to Systems XIII; SPIE: Bellingham, WA, USA, 2021; Volume 11662, p. 116620L. [Google Scholar]

- Azzaya, D.; Gantuya, B.; Oyuntsetseg, K.; Davaadorj, D.; Matsumoto, T.; Akada, J.; Yamaoka, Y. High Antibiotic Resistance of Helicobacter Pylori and Its Associated Novel Gene Mutations among the Mongolian Population. Microorganisms 2020, 8, 1062. [Google Scholar] [CrossRef] [PubMed]

- Cherian, S.; Potdar, V.; Jadhav, S.; Yadav, P.; Gupta, N.; Das, M.; Rakshit, P.; Singh, S.; Abraham, P.; Panda, S.; et al. SARS-CoV-2 Spike Mutations, L452R, T478K, E484Q and P681R, in the Second Wave of COVID-19 in Maharashtra, India. Microorganisms 2021, 9, 1542. [Google Scholar] [CrossRef]

- Doron, S.; Gorbach, S.L. Bacterial Infections: Overview. In International Encyclopedia of Public Health; (Kris) Heggenhougen, H.K., Ed.; Academic Press: Oxford, UK, 2008; pp. 273–282. ISBN 978-0-12-373960-5. [Google Scholar]

- Dalstrom, D.J.; Venkatarayappa, I.; Manternach, A.L.; Palcic, M.S.; Heyse, B.A.; Prayson, M.J. Time-Dependent Contamination of Opened Sterile Operating-Room Trays. JBJS 2008, 90, 1022. [Google Scholar] [CrossRef]

- Zhiqing, L.; Yongyun, C.; Wenxiang, C.; Mengning, Y.; Yuanqing, M.; Zhenan, Z.; Haishan, W.; Jie, Z.; Kerong, D.; Huiwu, L.; et al. Surgical Masks as Source of Bacterial Contamination during Operative Procedures. J. Orthop. Transl. 2018, 14, 57–62. [Google Scholar] [CrossRef]

- Otter, J.A.; Donskey, C.; Yezli, S.; Douthwaite, S.; Goldenberg, S.D.; Weber, D.J. Transmission of SARS and MERS Coronaviruses and Influenza Virus in Healthcare Settings: The Possible Role of Dry Surface Contamination. J. Hosp. Infect. 2016, 92, 235–250. [Google Scholar] [CrossRef]

- Kumar, S.; Karmacharya, M.; Joshi, S.R.; Gulenko, O.; Park, J.; Kim, G.-H.; Cho, Y.-K. Photoactive Antiviral Face Mask with Self-Sterilization and Reusability. Nano Lett. 2021, 21, 337–343. [Google Scholar] [CrossRef]

- El-Atab, N.; Qaiser, N.; Badghaish, H.; Shaikh, S.F.; Hussain, M.M. Flexible Nanoporous Template for the Design and Development of Reusable Anti-COVID-19 Hydrophobic Face Masks. ACS Nano 2020, 14, 7659–7665. [Google Scholar] [CrossRef]

- Aïssa, B.; Isaifan, R.J.; Madhavan, V.E.; Abdallah, A.A. Structural and Physical Properties of the Dust Particles in Qatar and Their Influence on the PV Panel Performance. Sci. Rep. 2016, 6, 31467. [Google Scholar] [CrossRef]

- Trestsova, M.A.; Utepova, I.A.; Chupakhin, O.N.; Semenov, M.V.; Pevtsov, D.N.; Nikolenko, L.M.; Tovstun, S.A.; Gadomska, A.V.; Shchepochkin, A.V.; Kim, G.A.; et al. Oxidative C-H/C-H Coupling of Dipyrromethanes with Azines by TiO2-Based Photocatalytic System. Synthesis of New BODIPY Dyes and Their Photophysical and Electrochemical Properties. Molecules 2021, 26, 5549. [Google Scholar] [CrossRef]

- Shtyka, O.; Shatsila, V.; Ciesielski, R.; Kedziora, A.; Maniukiewicz, W.; Dubkov, S.; Gromov, D.; Tarasov, A.; Rogowski, J.; Stadnichenko, A.; et al. Adsorption and Photocatalytic Reduction of Carbon Dioxide on TiO2. Catalysts 2021, 11, 47. [Google Scholar] [CrossRef]

- Kamalov, R.; Vokhmintsev, A.; Dorosheva, I.; Kravets, N.; Weinstein, I. Synthesis of Composite Based on Carbon Nanotubes and Anodic Titania. Adv. Sci. Lett. 2016, 22, 688–690. [Google Scholar] [CrossRef]

- Dorosheva, I.B.; Petrova, S.A.; Weinstein, I.A.; Rempel, A.A. Synthesis, Modification and Characterization of Titania Nanostructures. AIP Conf. Proc. 2022, 2466, 030021. [Google Scholar] [CrossRef]

- Gaponenko, N.V.; Sergeev, O.V.; Misiewicz, J.; Gnaser, H.; Heiderhoff, R.; Cramer, R.M.; Balk, L.J.; Dunbar, A.; Hamilton, B. Erbium Photoluminescence in Sol-Gel-Derived Titanium Dioxide Films. In Proceedings of the International Conference on Solid State Crystals ’98: Epilayers and Heterostructures in Optoelectronics and Semiconductor Technology, Zakopane, Poland, 12–16 October 1998; SPIE: Bellingham, WA, USA, 1999; Volume 3725, pp. 239–242. [Google Scholar] [CrossRef]

- Volkova, L.S.; Tarasov, A.M.; Dubkov, S.V.; Gromov, D.G.; Ryazanov, R.M. Facile fabrication of a TiO2 NW-based glucose sensor by direct ink writing. St. Petersburg Polytech. Univ. J. Phys. Math. 2022, 58, 125–130. [Google Scholar] [CrossRef]

- Serga, V.; Burve, R.; Krumina, A.; Pankratova, V.; Popov, A.I.; Pankratov, V. Study of Phase Composition, Photocatalytic Activity, and Photoluminescence of TiO2 with Eu Additive Produced by the Extraction-Pyrolytic Method. J. Mater. Res. Technol. 2021, 13, 2350–2360. [Google Scholar] [CrossRef]

- Margarucci, L.M.; Gianfranceschi, G.; Romano Spica, V.; D’Ermo, G.; Refi, C.; Podico, M.; Vitali, M.; Romano, F.; Valeriani, F. Photocatalytic Treatments for Personal Protective Equipment: Experimental Microbiological Investigations and Perspectives for the Enhancement of Antimicrobial Activity by Micrometric TiO2. Int. J. Environ. Res. Public Health 2021, 18, 8662. [Google Scholar] [CrossRef]

- Burko, A.; Zavatski, S.; Baturova, A.; Kholiboeva, M.; Kozina, J.; Kravtsunova, K.; Popov, V.; Gudok, A.; Dubkov, S.; Khartov, S.; et al. Polymer Membrane Modified with Photocatalytic and Plasmonic Nanoparticles for Self-Cleaning Filters. Polymers 2023, 15, 726. [Google Scholar] [CrossRef]

- Girel, K.; Yantcevich, E.; Arzumanyan, G.; Doroshkevich, N.; Bandarenka, H. Detection of DNA Molecules by SERS Spectroscopy with Silvered Porous Silicon as an Active Substrate. Phys. Status Solidi 2016, 213, 2911–2915. [Google Scholar] [CrossRef]

- Leyland, N.S.; Podporska-Carroll, J.; Browne, J.; Hinder, S.J.; Quilty, B.; Pillai, S.C. Highly Efficient F, Cu Doped TiO2 Anti-Bacterial Visible Light Active Photocatalytic Coatings to Combat Hospital-Acquired Infections. Sci. Rep. 2016, 6, 24770. [Google Scholar] [CrossRef] [PubMed]

- Ouyang, K.; Dai, K.; Walker, S.L.; Huang, Q.; Yin, X.; Cai, P. Efficient Photocatalytic Disinfection of Escherichia Coli O157:H7 Using C70-TiO2 Hybrid under Visible Light Irradiation. Sci. Rep. 2016, 6, 25702. [Google Scholar] [CrossRef] [PubMed]

- Girel, K.; Burko, A.; Barysiuk, A.; Dubkov, S.; Gromov, D.; Bandarenka, H. Correlation of Surface Potential and SERS-Activity of Ag Particles Formed by Electroless Deposition on Si-Based Substrate. Curr. Appl. Phys. 2023, 49, 18–24. [Google Scholar] [CrossRef]

- Karachevtseva, L.A.; Lytvynenko, O.A.; Malovichko, E.A.; Sobolev, V.D.; Stronska, O.J. Electrical Properties of Macroporous Silicon Structures. Semicond. Phys. Quantum Electron. Optoelectron. 2001, 4, 40–43. [Google Scholar] [CrossRef]

- Bardyshev, N.I.; Mokrushin, A.D.; Puryaeva, T.P.; Serebryakova, N.V.; Starkov, V.V. Nanopores in Macroporous Silicon. Inorg. Mater. 2004, 40, 1127–1132. [Google Scholar] [CrossRef]

- Girel, K.; Burko, A.; Zavatski, S.; Barysiuk, A.; Litvinova, K.; Eganova, E.; Tarasov, A.; Novikov, D.; Dubkov, S.; Bandarenka, H. Atomic Layer Deposition of Hafnium Oxide on Porous Silicon to Form a Template for Athermal SERS-Active Substrates. Appl. Phys. A 2023, 129, 294. [Google Scholar] [CrossRef]

- Thuy, N.M.; Van, D.Q.; Hai, L.T.H. The Visible Light Activity of the TiO2 and TiO2:V4+ Photocatalyst. Nanomater. Nanotechnol. 2012, 2, 14. [Google Scholar] [CrossRef]

- Challagulla, S.; Tarafder, K.; Ganesan, R.; Roy, S. Structure Sensitive Photocatalytic Reduction of Nitroarenes over TiO2. Sci. Rep. 2017, 7, 8783. [Google Scholar] [CrossRef]

- Liu, B.; Wang, X.; Cai, G.; Wen, L.; Song, Y.; Zhao, X. Low Temperature Fabrication of V-Doped TiO2 Nanoparticles, Structure and Photocatalytic Studies. J. Hazard. Mater. 2009, 169, 1112–1118. [Google Scholar] [CrossRef]

- Dorosheva, I.B.; Adiyak, E.V.; Valeeva, A.A.; Rempel, A.A. Synthesis of Nonstoichiometric Titanium Dioxide in the Hydrogen Flow. AIP Conf. Proc. 2019, 2174, 020019. [Google Scholar] [CrossRef]

- Pottier, A.; Chanéac, C.; Tronc, E.; Mazerolles, L.; Jolivet, J.-P. Synthesis of Brookite TiO2 Nanoparticlesby Thermolysis of TiCl4 in Strongly Acidic Aqueous Media. J. Mater. Chem. 2001, 11, 1116–1121. [Google Scholar] [CrossRef]

- Chen, J.; Li, J.; Xu, L.; Hong, W.; Yang, Y.; Chen, X. The Glass-Transition Temperature of Supported PMMA Thin Films with Hydrogen Bond/Plasmonic Interface. Polymers 2019, 11, 601. [Google Scholar] [CrossRef]

- Thomas, K.J.; Sheeba, M.; Nampoori, V.P.N.; Vallabhan, C.P.G.; Radhakrishnan, P. Raman Spectra of Polymethyl Methacrylate Optical Fibres Excited by a 532 Nm Diode Pumped Solid State Laser. J. Opt. A: Pure Appl. Opt. 2008, 10, 055303. [Google Scholar] [CrossRef]

- Thakur, V.K.; Vennerberg, D.; Madbouly, S.A.; Kessler, M.R. Bio-Inspired Green Surface Functionalization of PMMA for Multifunctional Capacitors. RSC Adv. 2014, 4, 6677–6684. [Google Scholar] [CrossRef]

- Kumar, V.; Maheshwari, N.; Sharma, N.N. Self Assembled Monolayer Modified SU8 Surface for Electrowetting Application. Macromol. Symp. 2015, 357, 18–22. [Google Scholar] [CrossRef]

- Chen, Z.; Yao, J.; Xu, Q.; Wang, Z. Two-Photon Polymerization Fabrication and Raman Spectroscopy Research of SU-8 Photoresist Using the Femtosecond Laser. Optoelectron. Lett. 2017, 13, 210–213. [Google Scholar] [CrossRef]

- Tfaili, S.; Gobinet, C.; Angiboust, J.-F.; Manfait, M.; Piot, O. Raman Microimaging Using a Novel Multifiber-Based Device: A Feasibility Study on Pharmaceutical Tablets. Int. J. Spectrosc. 2012, 2012, e959235. [Google Scholar] [CrossRef]

- Khinevich, N.; Bandarenka, H.; Zavatski, S.; Girel, K.; Tamulevičienė, A.; Tamulevičius, T.; Tamulevičius, S. Porous Silicon—A Versatile Platform for Mass-Production of Ultrasensitive SERS-Active Substrates. Microporous Mesoporous Mater. 2021, 323, 111204. [Google Scholar] [CrossRef]

- Giorgis, F.; Descrovi, E.; Chiodoni, A.; Froner, E.; Scarpa, M.; Venturello, A.; Geobaldo, F. Porous Silicon as Efficient Surface Enhanced Raman Scattering (SERS) Substrate. Appl. Surf. Sci. 2008, 254, 7494–7497. [Google Scholar] [CrossRef]

- Zeiri, L.; Rechav, K.; Porat, Z.; Zeiri, Y. Silver Nanoparticles Deposited on Porous Silicon as a Surface-Enhanced Raman Scattering (SERS) Active Substrate. Appl. Spectrosc. 2012, 66, 294–299. [Google Scholar] [CrossRef]

- Mikac, L.; Ivanda, M.; Đerek, V.; Gotić, M. Influence of Mesoporous Silicon Preparation Condition on Silver Clustering and SERS Enhancement. J. Raman Spectrosc. 2016, 47, 1036–1041. [Google Scholar] [CrossRef]

- Bandarenka, H.V.; Khinevich, N.V.; Burko, A.A.; Redko, S.V.; Zavatski, S.A.; Shapel, U.A.; Mamatkulov, K.Z.; Vorobyeva, M.Y.; Arzumanyan, G.M. 3D Silver Dendrites for Single-Molecule Imaging by Surface-Enhanced Raman Spectroscopy. ChemNanoMat 2021, 7, 141–149. [Google Scholar] [CrossRef]

- Shrestha, Y.K.; Yan, F. Determination of Critical Micelle Concentration of Cationic Surfactants by Surface-Enhanced Raman Scattering. RSC Adv. 2014, 4, 37274–37277. [Google Scholar] [CrossRef]

- Smets, W.; Moretti, S.; Denys, S.; Lebeer, S. Airborne Bacteria in the Atmosphere: Presence, Purpose, and Potential. Atmos. Environ. 2016, 139, 214–221. [Google Scholar] [CrossRef]

- Dahms, M.; Eiserloh, S.; Rödel, J.; Makarewicz, O.; Bocklitz, T.; Popp, J.; Neugebauer, U. Raman Spectroscopic Differentiation of Streptococcus Pneumoniae From Other Streptococci Using Laboratory Strains and Clinical Isolates. Front. Cell. Infect. Microbiol. 2022, 12, 930011. [Google Scholar] [CrossRef]

- Wesełucha-Birczyńska, A.; Kozicki, M.; Czepiel, J.; Birczyńska, M. Raman Micro-spectroscopy Tracing Human Lymphocyte Activation. Analyst 2013, 138, 7157–7163. [Google Scholar] [CrossRef]

- Kurouski, D.; Washington, J.; Ozbil, M.; Prabhakar, R.; Shekhtman, A.; Lednev, I.K. Disulfide Bridges Remain Intact while Native Insulin Converts into Amyloid Fibrils. PLoS ONE 2012, 7, e36989. [Google Scholar] [CrossRef]

- Kurouski, D.; Lednev, I.K. The Impact of Protein Disulfide Bonds on the Amyloid Fibril Morphology. Int. J. Biomed. Nanosci. Nanotechnol. 2011, 2, 167–176. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bandarenka, H.; Burko, A.; Girel, K.; Laputsko, D.; Orel, E.; Mizgailo, A.; Sharopov, U.; Podelinska, A.; Shapel, U.; Pankratov, V.; et al. Improvement of Heat Dissipation in Ag/Ni Substrates for Testing Cu-TiO2/TiO2-Modified Filters Using SERS Spectroscopy. Crystals 2023, 13, 749. https://doi.org/10.3390/cryst13050749

Bandarenka H, Burko A, Girel K, Laputsko D, Orel E, Mizgailo A, Sharopov U, Podelinska A, Shapel U, Pankratov V, et al. Improvement of Heat Dissipation in Ag/Ni Substrates for Testing Cu-TiO2/TiO2-Modified Filters Using SERS Spectroscopy. Crystals. 2023; 13(5):749. https://doi.org/10.3390/cryst13050749

Chicago/Turabian StyleBandarenka, Hanna, Aliaksandr Burko, Kseniya Girel, Diana Laputsko, Elizaveta Orel, Anna Mizgailo, Utkirjon Sharopov, Alise Podelinska, Uladzislau Shapel, Vladimir Pankratov, and et al. 2023. "Improvement of Heat Dissipation in Ag/Ni Substrates for Testing Cu-TiO2/TiO2-Modified Filters Using SERS Spectroscopy" Crystals 13, no. 5: 749. https://doi.org/10.3390/cryst13050749

APA StyleBandarenka, H., Burko, A., Girel, K., Laputsko, D., Orel, E., Mizgailo, A., Sharopov, U., Podelinska, A., Shapel, U., Pankratov, V., Piskunov, S., & Bocharov, D. (2023). Improvement of Heat Dissipation in Ag/Ni Substrates for Testing Cu-TiO2/TiO2-Modified Filters Using SERS Spectroscopy. Crystals, 13(5), 749. https://doi.org/10.3390/cryst13050749