Thermal Expansion and Phase Transformation up to 1200 °C of Metastable Aluminas Produced by Flame Spraying

Abstract

1. Introduction

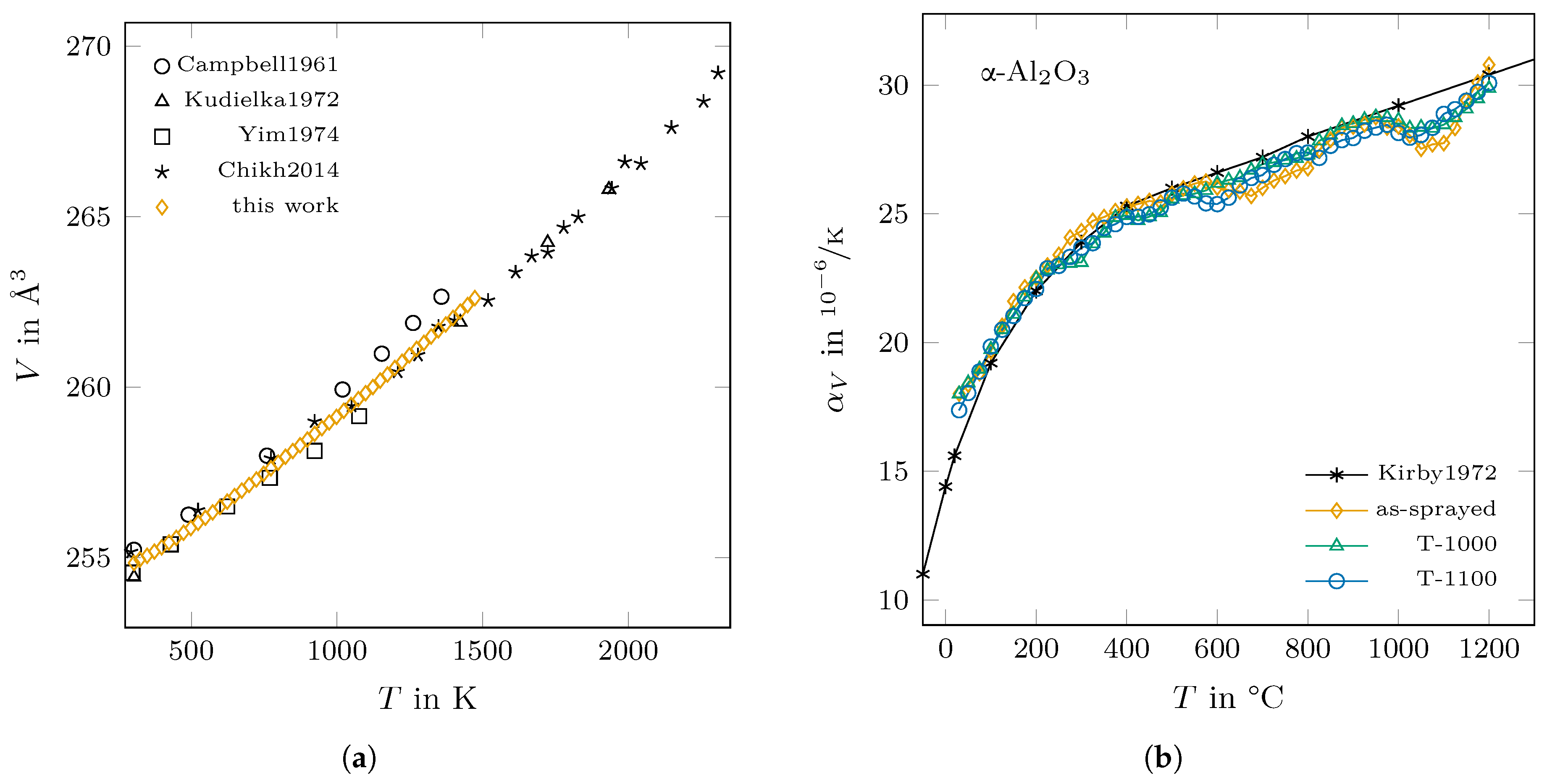

2. Materials and Methods

2.1. Sample Preparation

2.2. Sample Characterisation and Heat Treatment

2.3. Thermal Expansion Coefficient

3. Results

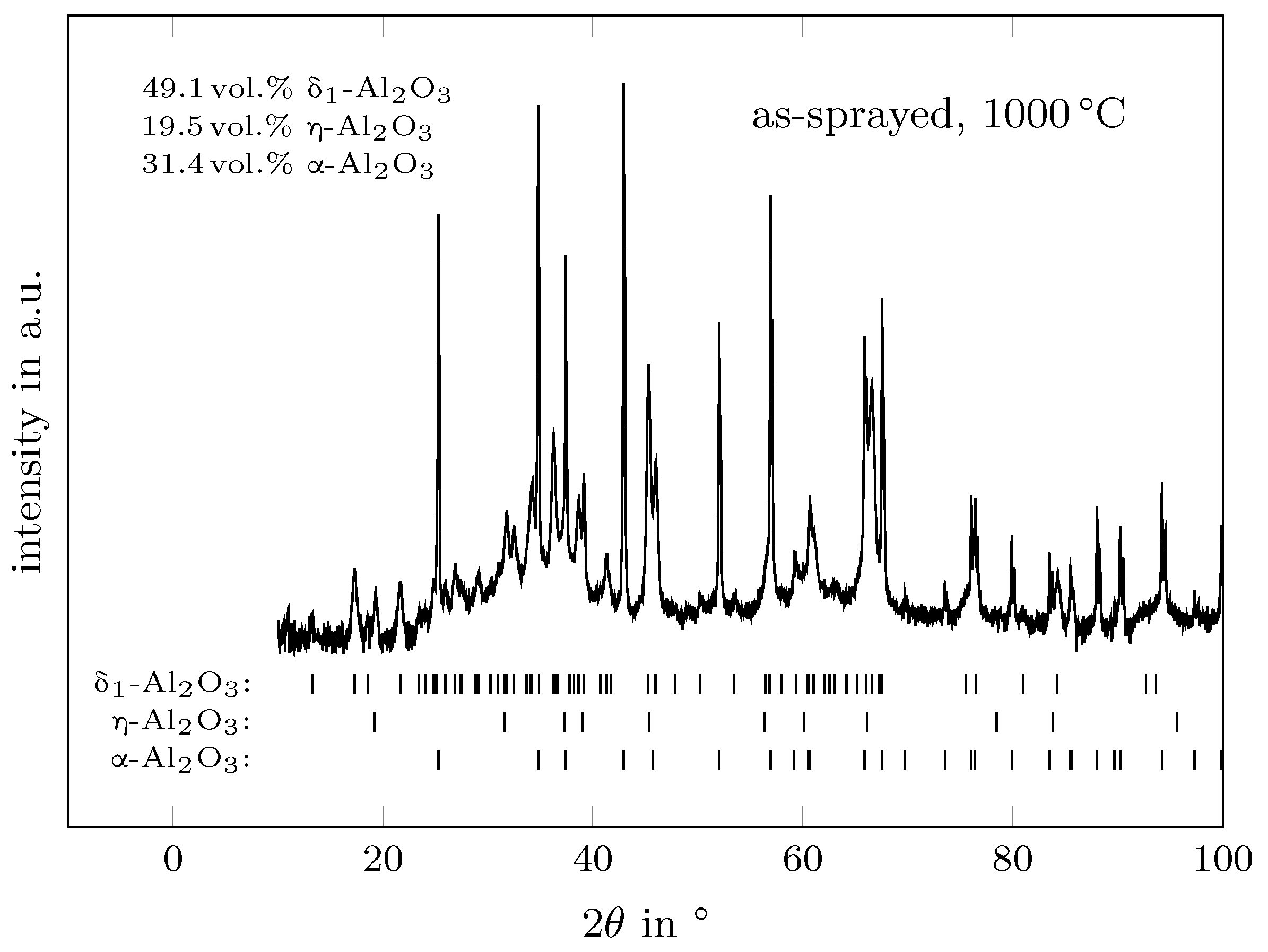

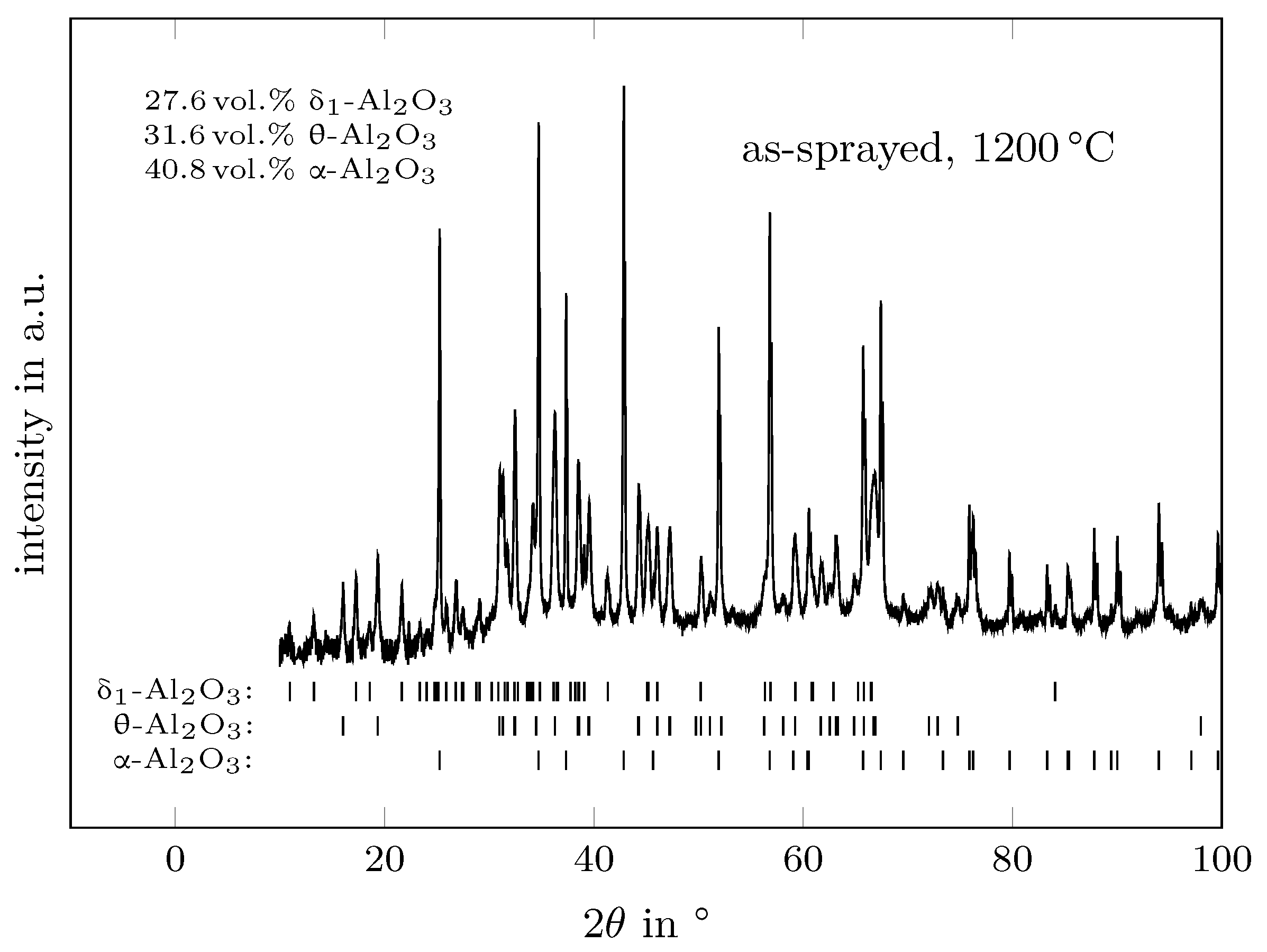

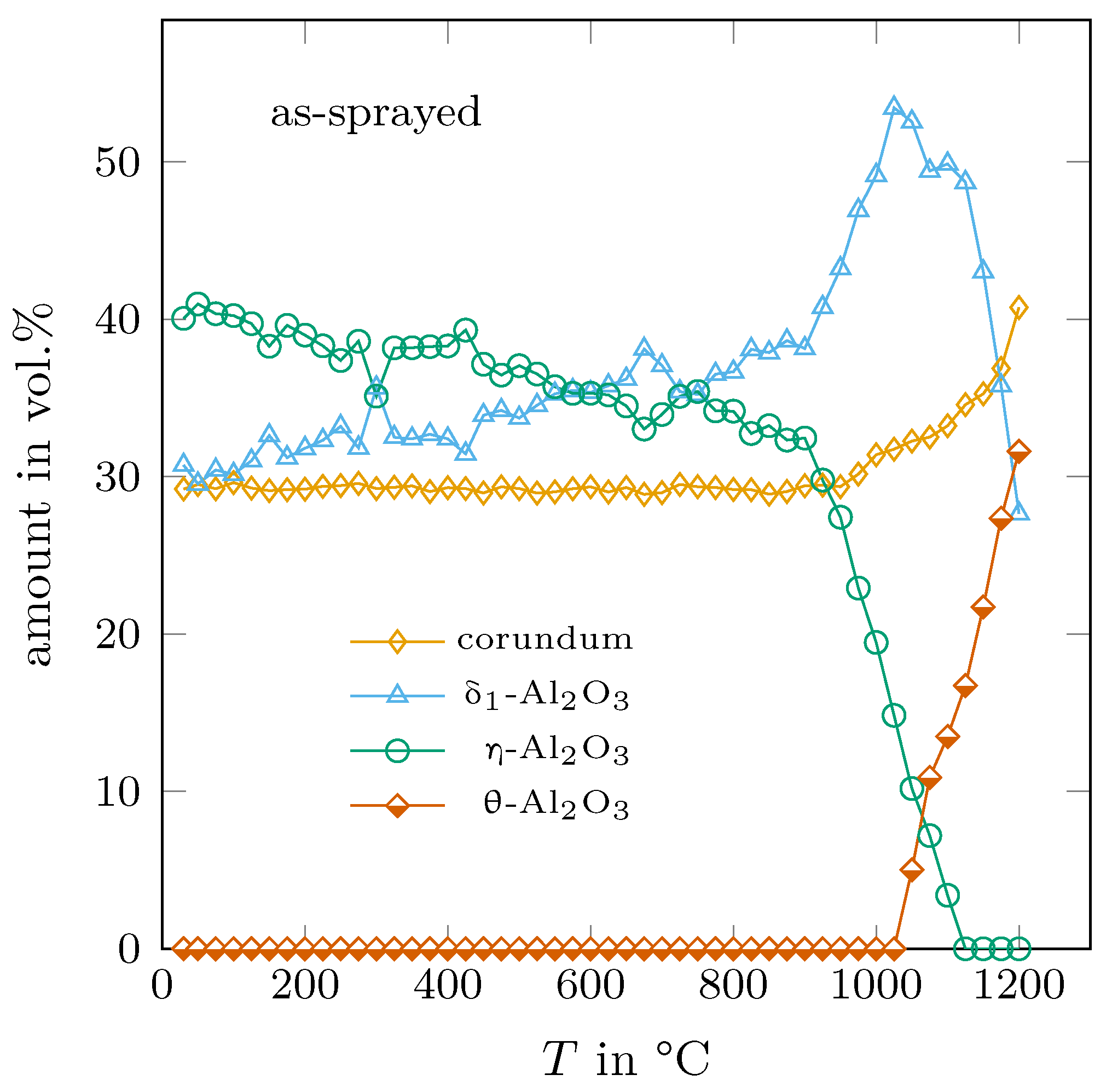

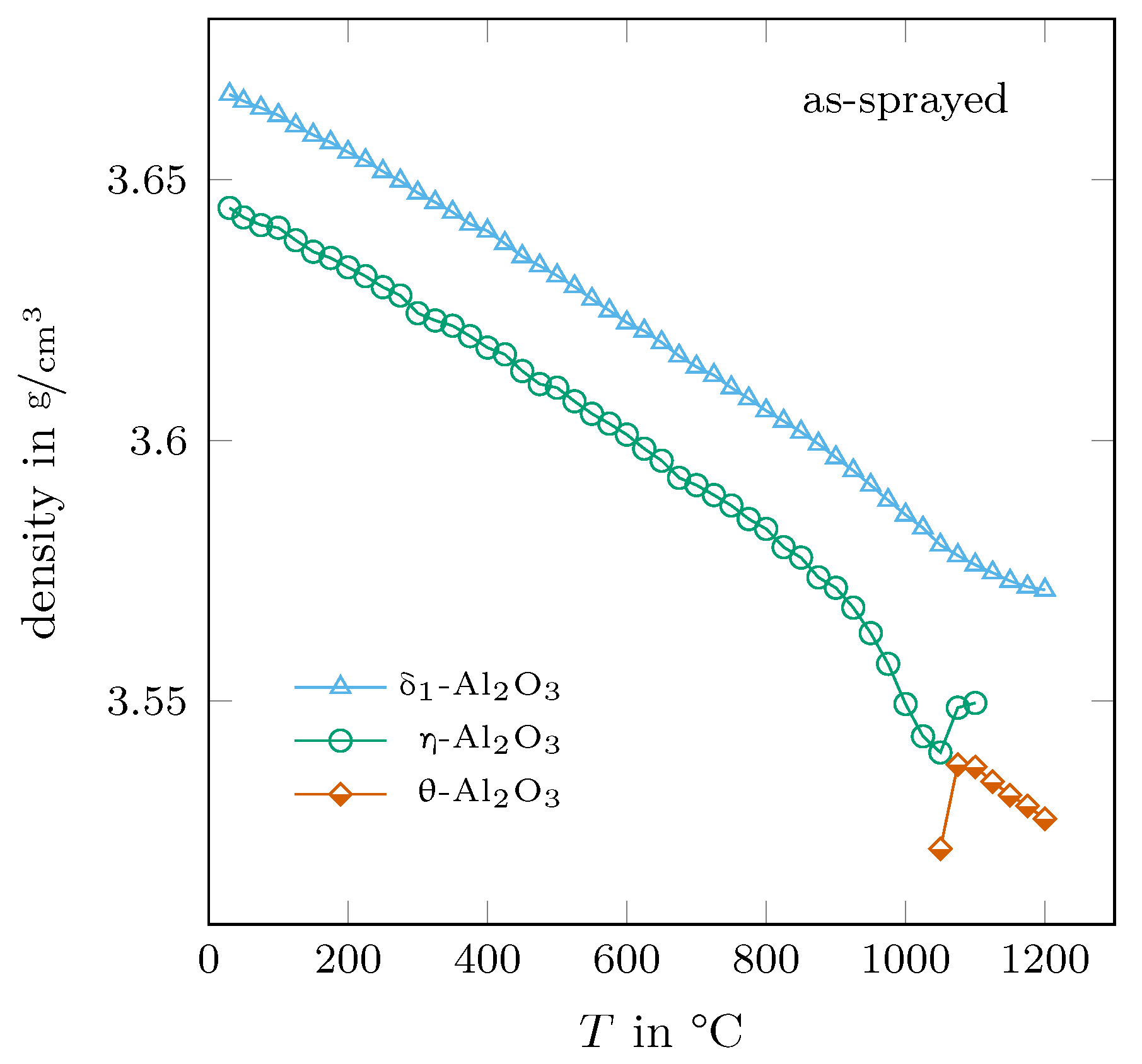

3.1. Phase Transformations of the Flame-Sprayed Sample

3.2. Structural Changes in -AlO and -AlO

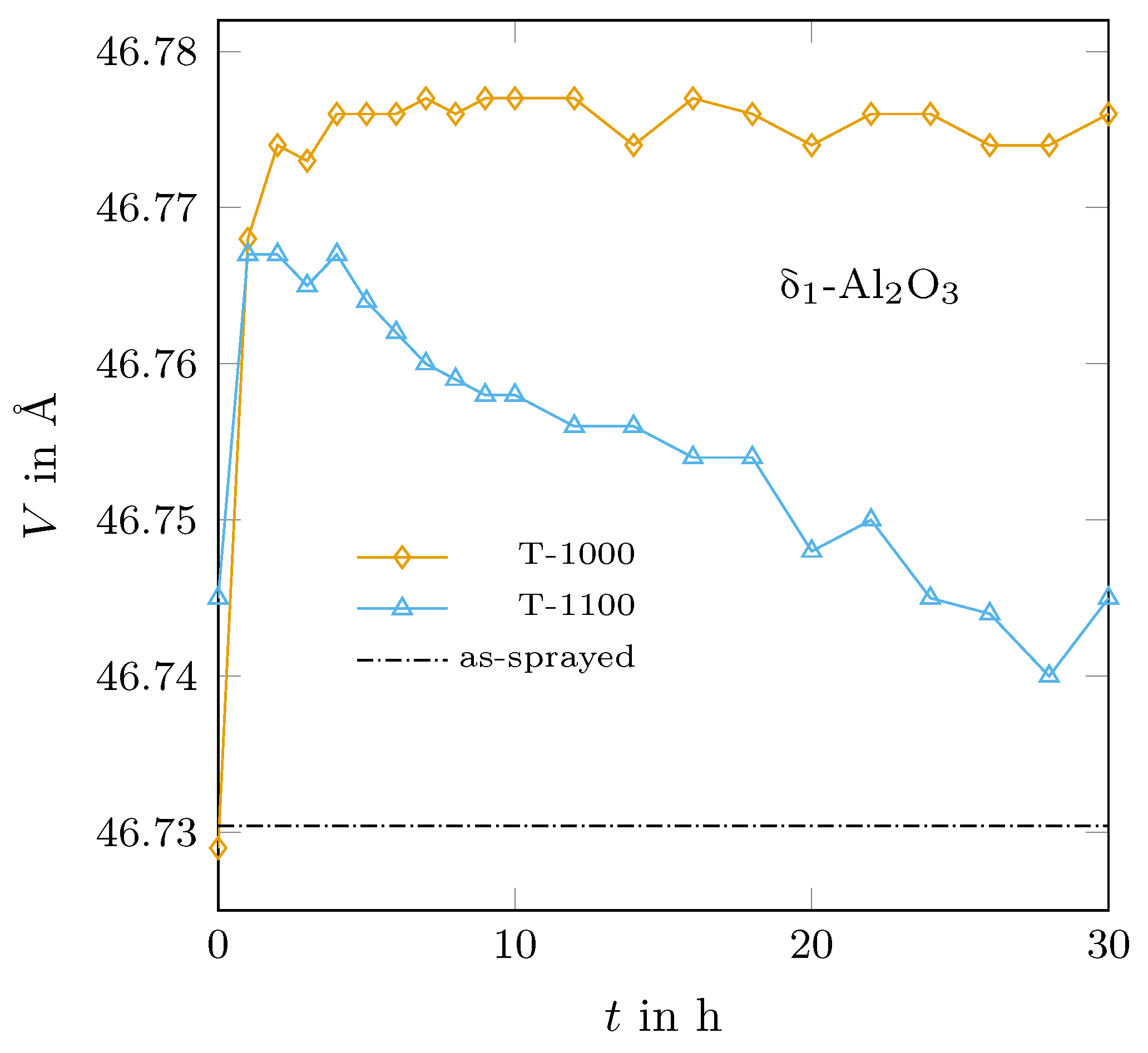

3.3. Structural Changes at a Constant Temperature

3.4. Thermal Expansion of Corundum and the Transition Aluminas

4. Discussion

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lee, J.; Jeon, H.; Oh, D.G.; Szanyi, J.; Kwak, J.H. Morphology-dependent phase transformation of γ-Al2O3. Appl. Catal. A Gen. 2015, 500, 58–68. [Google Scholar] [CrossRef]

- Kovarik, L.; Bowden, M.; Szanyi, J. High temperature transition aluminas in δ-Al2O3/θ-Al2O3 stability range: Review. J. Catal. 2021, 393, 357–368. [Google Scholar] [CrossRef]

- Dauger, A.; Fargeot, D. T.E.M. study of Al2O3 metastable phases. Radiat. Eff. 1983, 74, 279–289. [Google Scholar] [CrossRef]

- Nordahl, C.S.; Messing, G.L. Thermal analysis of phase transformation kinetics in α-Al2O3 seeded boehmite and γ-Al2O3. Thermochim. Acta 1998, 318, 187–199. [Google Scholar] [CrossRef]

- Fargeot, D.; Mercurio, D.; Dauger, A. Structural characterization of alumina metastable phases in plasma sprayed deposits. Mater. Chem. Phys. 1990, 24, 299–314. [Google Scholar] [CrossRef]

- Damani, R.; Makroczy, P. Heat treatment induced phase and microstructural development in bulk plasma sprayed alumina. J. Eur. Ceram. Soc. 2000, 20, 867–888. [Google Scholar] [CrossRef]

- Di Girolamo, G.; Brentari, A.; Blasi, C.; Serra, E. Microstructure and mechanical properties of plasma sprayed alumina-based coatings. Ceram. Int. 2014, 40, 12861–12867. [Google Scholar] [CrossRef]

- Rudolph, M.; Motylenko, M.; Rafaja, D. Structure model of γ-Al2O3 based on planar defects. IUCrJ 2019, 6, 116–127. [Google Scholar] [CrossRef]

- Levin, I.; Brandon, D. Metastable Alumina Polymorphs: Crystal Structures and Transition Sequences. J. Am. Ceram. Soc. 1998, 81, 1995–2012. [Google Scholar] [CrossRef]

- Paglia, G.; Božin, E.S.; Billinge, S.J. Fine-Scale Nanostructure in γ-Al2O3. Chem. Mater. 2006, 18, 3242–3248. [Google Scholar] [CrossRef]

- Pardo, P.; Alarcón, J. Thermal stability of transition alumina nanocrystals with different microstructures. Ceram. Int. 2018, 44, 11486–11496. [Google Scholar] [CrossRef]

- Deng, L.; Han, S.; Zhou, D.; Li, Y.; Shen, W. Morphology dependent effect of γ-Al2O3 for ethanol dehydration: Nanorods and nanosheets. CrystEngComm 2022, 24, 796–804. [Google Scholar] [CrossRef]

- Feng, H.; Wang, H.; Ma, Z.; Wang, S.; Li, P. Quantification of surface orientation effect on the thermal stability of γ-Al2O3 with different morphologies. Appl. Surf. Sci. 2022, 594, 153509. [Google Scholar] [CrossRef]

- Bolelli, G.; Cannillo, V.; Gadow, R.; Killinger, A.; Lusvarghi, L.; Manfredini, T.; Müller, P. Properties of Al2O3 coatings by High Velocity Suspension Flame Spraying (HVSFS): Effects of injection systems and torch design. Surf. Coat. Technol. 2015, 270, 175–189. [Google Scholar] [CrossRef]

- Rudolph, M.; Salomon, A.; Schmidt, A.; Motylenko, M.; Zienert, T.; Stöcker, H.; Himcinschi, C.; Amirkhanyan, L.; Kortus, J.; Aneziris, C.G.; et al. Thermally Induced Formation of Transition Aluminas from Boehmite. Adv. Eng. Mater. 2017, 19, 1700141. [Google Scholar] [CrossRef]

- Wilson, S.; Mc Connell, J. A kinetic study of the system γ-AlOOH/Al2O3. J. Solid State Chem. 1980, 34, 315–322. [Google Scholar] [CrossRef]

- Kovarik, L.; Bowden, M.; Shi, D.; Washton, N.M.; Andersen, A.; Hu, J.Z.; Lee, J.; Szanyi, J.; Kwak, J.h.; Peden, C.H. Unraveling the Origin of Structural Disorder in High Temperature Transition Al2O3: Structure of θ-Al2O3. Chem. Mater. 2015, 27, 7042–7049. [Google Scholar] [CrossRef]

- Pecharromán, C.; Sobrados, I.; Iglesias, J.; González-Carreño, T.; Sanz, J. Thermal Evolution of Transitional Aluminas Followed by NMR and IR Spectroscopies. J. Phys. Chem. B 1999, 103, 6160–6170. [Google Scholar] [CrossRef]

- Xu, S.; Jaegers, N.R.; Hu, W.; Kwak, J.H.; Bao, X.; Sun, J.; Wang, Y.; Hu, J.Z. High-Field One-Dimensional and Two-Dimensional 27Al Magic-Angle Spinning Nuclear Magnetic Resonance Study of θ-, δ-, and γ-Al2O3 Dominated Aluminum Oxides: Toward Understanding the Al Sites in γ-Al2O3. ACS Omega 2021, 6, 4090–4099. [Google Scholar] [CrossRef]

- Shirasuka, K.; Yanagida, H.; Yamaguchi, G. The Preparation of η Alumina and its Structure. J. Ceram. Assoc. 1976, 84, 610–613. [Google Scholar] [CrossRef]

- Paglia, G.; Rohl, A.L.; Buckley, C.E.; Gale, J.D. Determination of the structure of γ-Alumina from interatomic potential and first-principles calculations: The requirement of significant numbers of nonspinel positions to achieve an accurate structural model. Phys. Rev. B 2005, 71, 224115. [Google Scholar] [CrossRef]

- Samain, L.; Jaworski, A.; Edén, M.; Ladd, D.M.; Seo, D.K.; Javier Garcia-Garcia, F.; Häussermann, U. Structural analysis of highly porous γ-Al2O3. J. Solid State Chem. 2014, 217, 1–8. [Google Scholar] [CrossRef]

- Paglia, G.; Buckley, C.E.; Rohl, A.L.; Hart, R.D.; Winter, K.; Studer, A.J.; Hunter, B.A.; Hanna, J.V. Boehmite Derived γ-Alumina System. 1. Structural Evolution with Temperature, with the Identification and Structural Determination of a New Transition Phase, γ‘-Alumina. Chem. Mater. 2004, 16, 220–236. [Google Scholar] [CrossRef]

- Luo, Z. Structure of boehmite-derived γ-Alumina and its transformation mechanism revealed by electron crystallography. Acta Crystallogr. Sect. B 2021, 77, 772–784. [Google Scholar] [CrossRef]

- Kovarik, L.; Bowden, M.; Genc, A.; Szanyi, J.; Peden, C.H.; Kwak, J.H. Structure of δ-Alumina: Toward the Atomic Level Understanding of Transition Alumina Phases. J. Phys. Chem. C 2014, 118, 18051–18058. [Google Scholar] [CrossRef]

- Kovarik, L.; Bowden, M.; Shi, D.; Szanyi, J.; Peden, C.H. Structural Intergrowth in θ-Al2O3. J. Phys. Chem. C 2019, 123, 9454–9460. [Google Scholar] [CrossRef]

- Kovarik, L.; Bowden, M.; Andersen, A.; Jaegers, N.R.; Washton, N.; Szanyi, J. Quantification of High-Temperature Transition Al2O3 and Their Phase Transformations. Angew. Chem. Int. Ed. 2020, 59, 21719–21727. [Google Scholar] [CrossRef] [PubMed]

- Zienert, T.; Endler, D.; Hubálková, J.; Eusterholz, M.; Boll, T.; Heilmaier, M.; Günay, G.; Weidner, A.; Biermann, H.; Kraft, B.; et al. Coarse-grained refractory composite castables based on alumina and niobium. Adv. Eng. Mater. 2022, 24, 2200296. [Google Scholar] [CrossRef]

- Günay, G.; Zienert, T.; Endler, D.; Aneziris, C.G.; Biermann, H.; Weidner, A. High-temperature compressive behavior of refractory alumina-niobium composite material. Adv. Eng. Mater. 2022, 24, 2200292. [Google Scholar] [CrossRef]

- Kraft, B.; Wagner, S.; Hoffmann, M.J. Field Assisted Sintering of Nb-Al2O3 Composite Materials and Investigation of Electrical Conductivity. Adv. Eng. Mater. 2022, 24, 202200063. [Google Scholar] [CrossRef]

- Zienert, T.; Farhani, M.; Dudczig, S.; Aneziris, C.G. Coarse-grained refractory composites based on Nb-Al2O3 and Ta-Al2O3 castables. Ceram. Int. 2018, 44, 16809–16818. [Google Scholar] [CrossRef]

- Aneziris, C.G.; Gehre, P.; Kratschmer, T.; Berek, H. Thermal Shock Behavior of Flame-Sprayed Free-Standing Coatings Based on Al2O3 with TiO2- and ZrO2-Additions. Int. J. Appl. Ceram. Technol. 2011, 8, 953–964. [Google Scholar] [CrossRef]

- Maslen, E.; Streltsov, V.; Streltsova, N.; Ishizawa, N.; Satow, Y. Synchrotron X-ray study of the electron density in α-Al2O3. Acta Crystallogr. Sect. B 1993, 49, 973–980. [Google Scholar] [CrossRef]

- Husson, E. Structural studies of transition aluminas. Theta alumina. Eur. J. Solid State Inorg. Chem. 1996, 33, 1223–1231. [Google Scholar]

- Gutiérrez, G.; Taga, A.; Johansson, B. Theoretical structure determination of γ-Al2O3. Phys. Rev. B 2001, 65, 012101. [Google Scholar] [CrossRef]

- Kirby, R.K.; Hahn, T.A.; Rothrock, B.D. American Institute of Physics Handbook—4f: Thermal Expansion, 3rd ed.; McGraw-Hill Book Company: New York, NY, USA, 1972. [Google Scholar]

- Campbell, W.J.; Grain, C. Thermal Expansion of Alpha-Alumina. Adv. X-ray Anal. 1961, 5, 244–256. [Google Scholar] [CrossRef]

- Kudielka, H. Die thermische Ausdehnung der isotypen Mischreihen-Endglieder Cr2O3 und α-Al2O3, ermittelt mit einer neuen, lichtstarken Seemann-Bohlin-Kammer. Monatshefte Chem. 1972, 103, 72–80. [Google Scholar] [CrossRef]

- Yim, W.; Paff, R. Thermal expansion of AlN, sapphire, and silicon. J. Appl. Phys. 1974, 45, 1456–1457. [Google Scholar] [CrossRef]

- Chikh, H.; Si-Ahmed, F.; Afir, A.; Pialoux, A. In-situ X-ray Diffraction Study of Alumina α-Al2O3 Thermal Behavior. Int. J. Recent Dev. Eng. Technol. 2014, 3, 137–143. [Google Scholar]

- Tonejc, A.; Kosanović, C.; Stubićar, M.; Tonejc, A.; Subotić, B.; Smit, I. Equivalence of ball milling and thermal treatment for phase transitions in the Al2O3 system. J. Alloys Compd. 1994, 204, L1–L3. [Google Scholar] [CrossRef]

- Bodaghi, M.; Mirhabibi, A.; Zolfonun, H.; Tahriri, M.; Karimi, M. Investigation of phase transition of γ-Alumina to α-Alumina via mechanical milling method. Phase Transit. 2008, 81, 571–580. [Google Scholar] [CrossRef]

- Kozawa, T.; Naito, M. Mechanically induced formation of metastable χ- and κ-Al2O3 from boehmite. Adv. Powder Technol. 2016, 27, 935–939. [Google Scholar] [CrossRef]

- Daraio, D.; Villoria, J.; Ingram, A.; Alexiadis, A.; Stitt, E.H.; Munnoch, A.L.; Marigo, M. Using Discrete Element method (DEM) simulations to reveal the differences in the γ-Al2O3 α-Al2O3 mechanically induced phase transformation between a planetary ball mill and an attritor mill. Miner. Eng. 2020, 155, 106374. [Google Scholar] [CrossRef]

| Phase | Temperature Range: Transition Rate in vol.%/K | ||

|---|---|---|---|

| -AlO | 30–900 °C: −0.0089 | 900–1125 °C: −0.1505 | |

| -AlO | 30–900 °C: 0.0091 | 900–1025 °C: 0.1204 | 1125–1200 °C: −0.2817 |

| -AlO | 1025–1200 °C: 0.1756 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zienert, T.; Aneziris, C.G. Thermal Expansion and Phase Transformation up to 1200 °C of Metastable Aluminas Produced by Flame Spraying. Crystals 2023, 13, 743. https://doi.org/10.3390/cryst13050743

Zienert T, Aneziris CG. Thermal Expansion and Phase Transformation up to 1200 °C of Metastable Aluminas Produced by Flame Spraying. Crystals. 2023; 13(5):743. https://doi.org/10.3390/cryst13050743

Chicago/Turabian StyleZienert, Tilo, and Christos Georgios Aneziris. 2023. "Thermal Expansion and Phase Transformation up to 1200 °C of Metastable Aluminas Produced by Flame Spraying" Crystals 13, no. 5: 743. https://doi.org/10.3390/cryst13050743

APA StyleZienert, T., & Aneziris, C. G. (2023). Thermal Expansion and Phase Transformation up to 1200 °C of Metastable Aluminas Produced by Flame Spraying. Crystals, 13(5), 743. https://doi.org/10.3390/cryst13050743