Plasma-Pulsed GMAW Hybrid Welding Process of 6061 Aluminum and Zinc-Coated Steel

Abstract

1. Introduction

2. Materials and Methods

2.1. Welding Test System and Test Material

2.2. Test Design

3. Results and Discussion

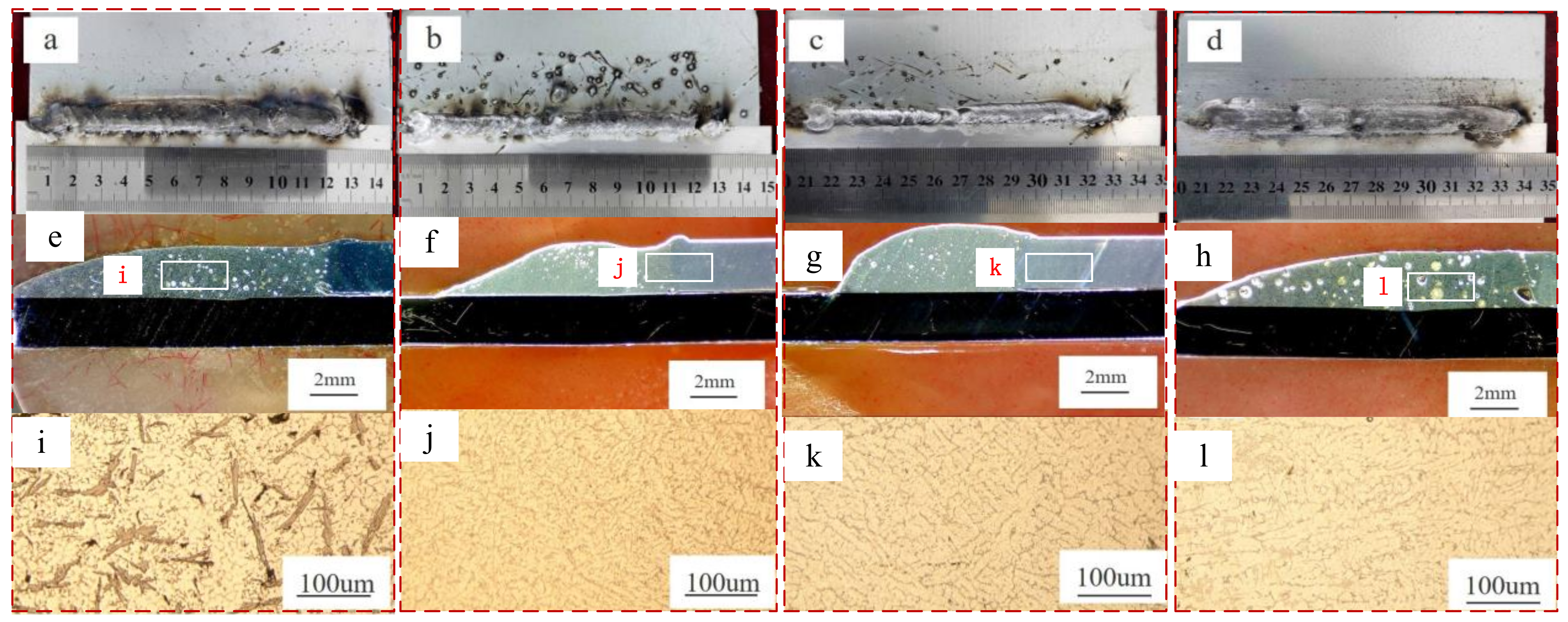

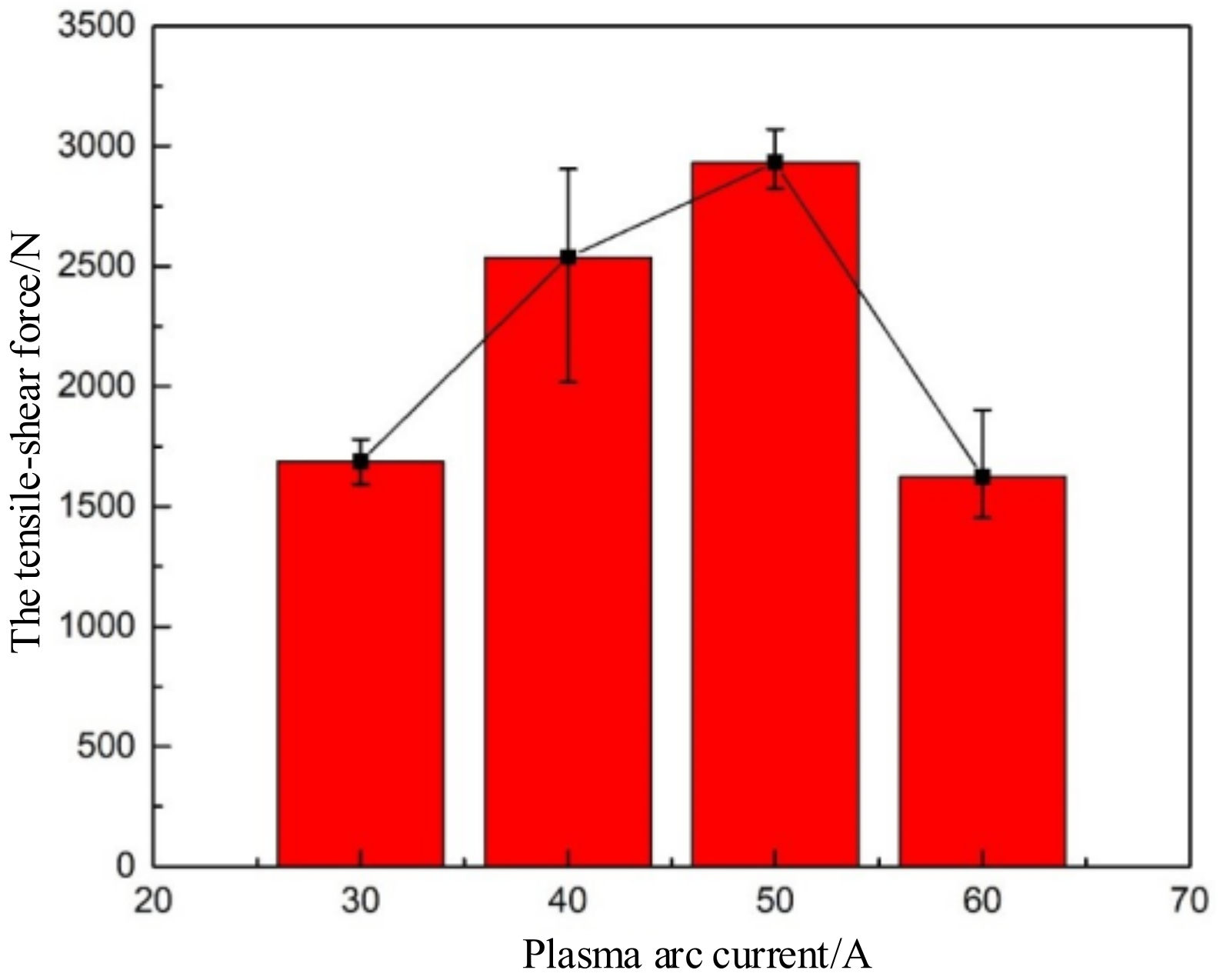

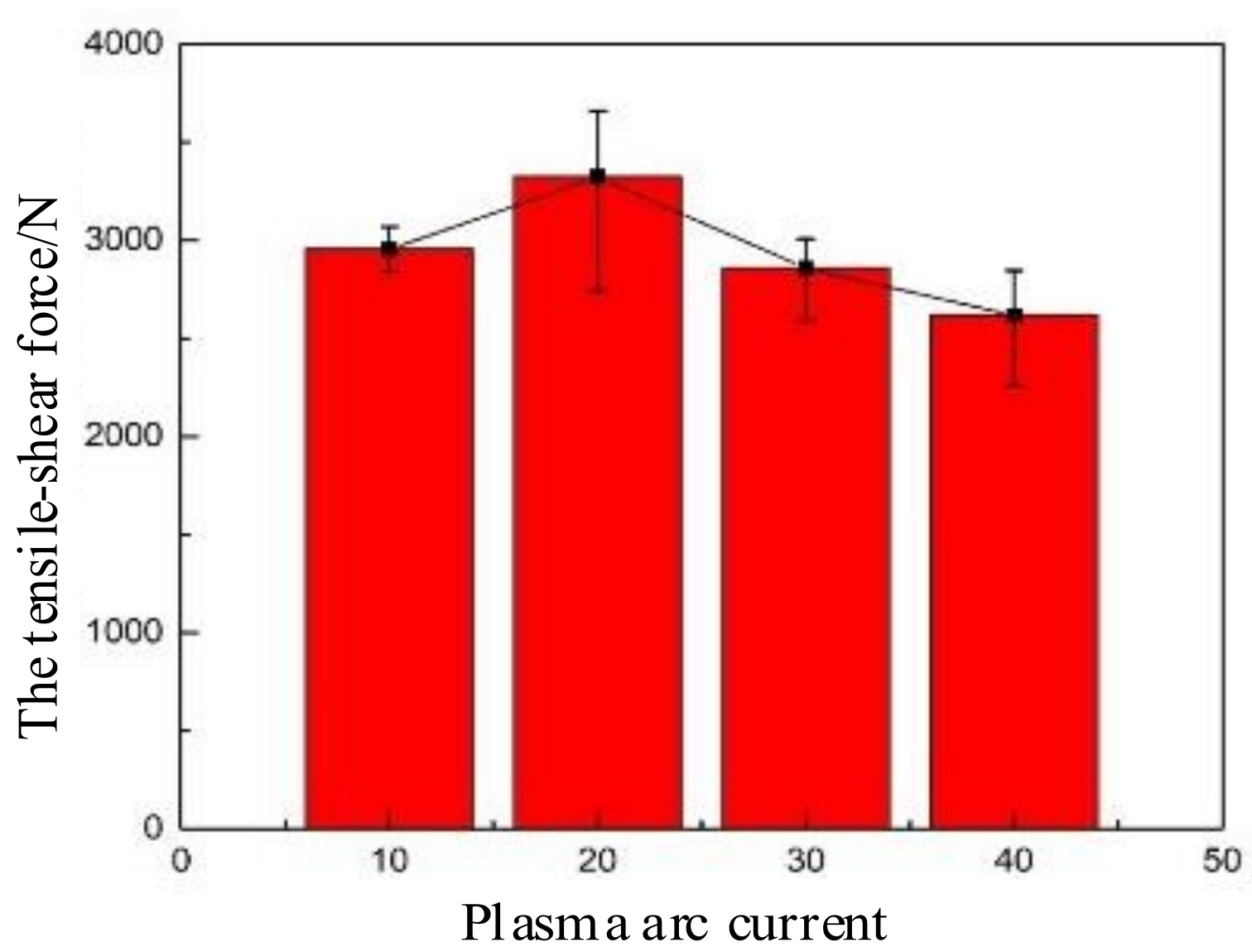

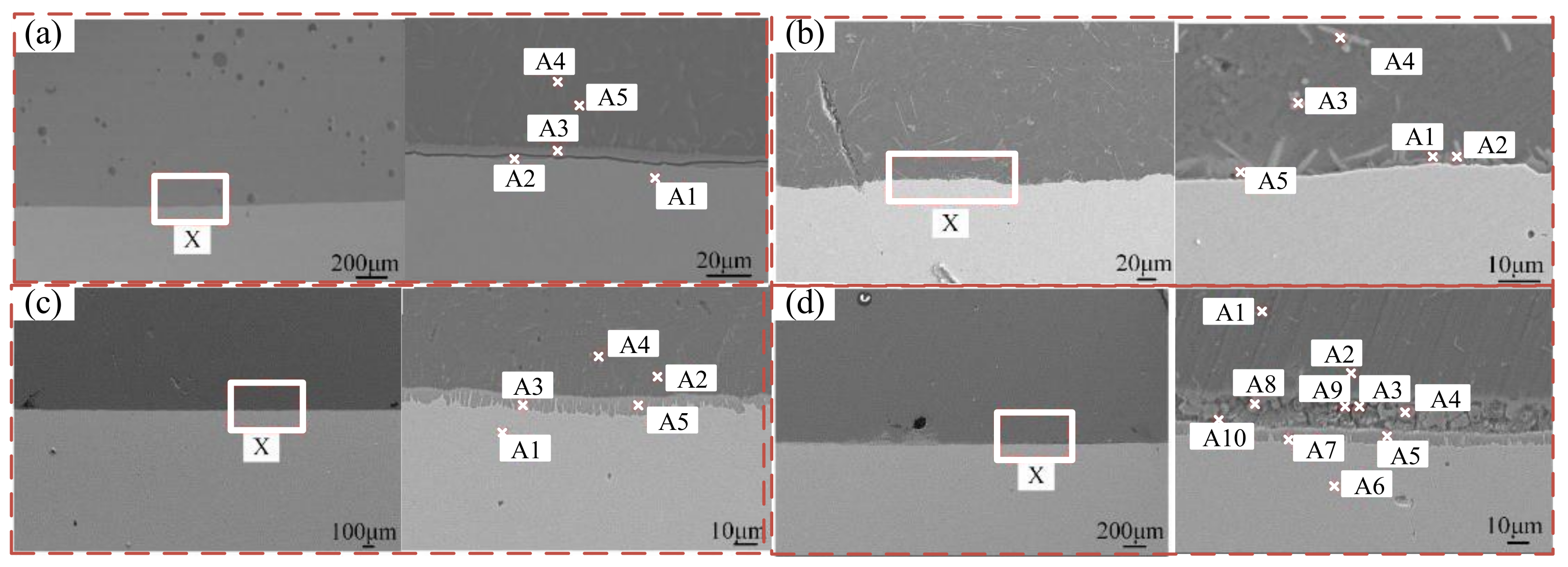

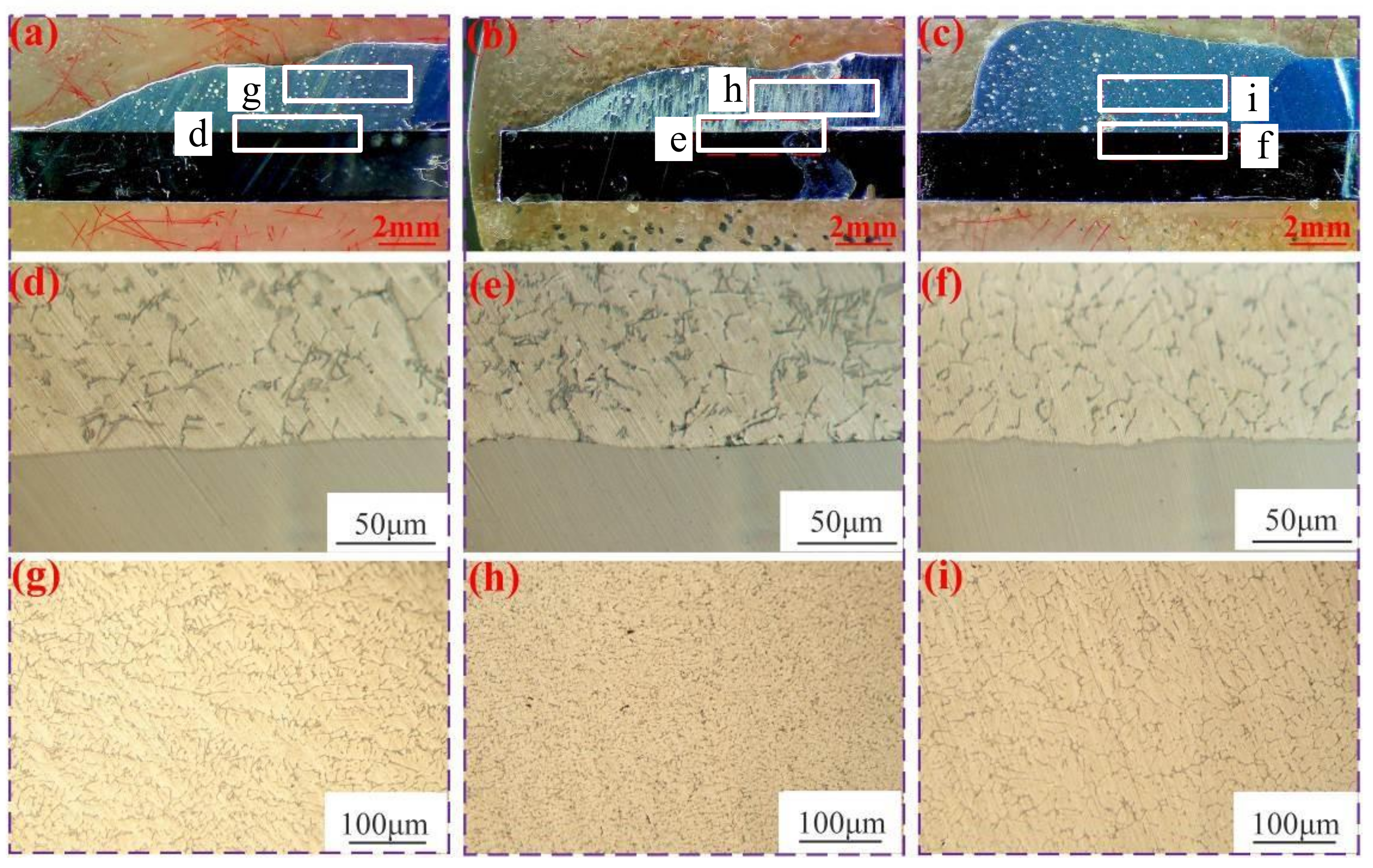

3.1. Effects of Plasma Arc Current and MIG Current on Microstructure and Mechanical Properties of Welded Joints

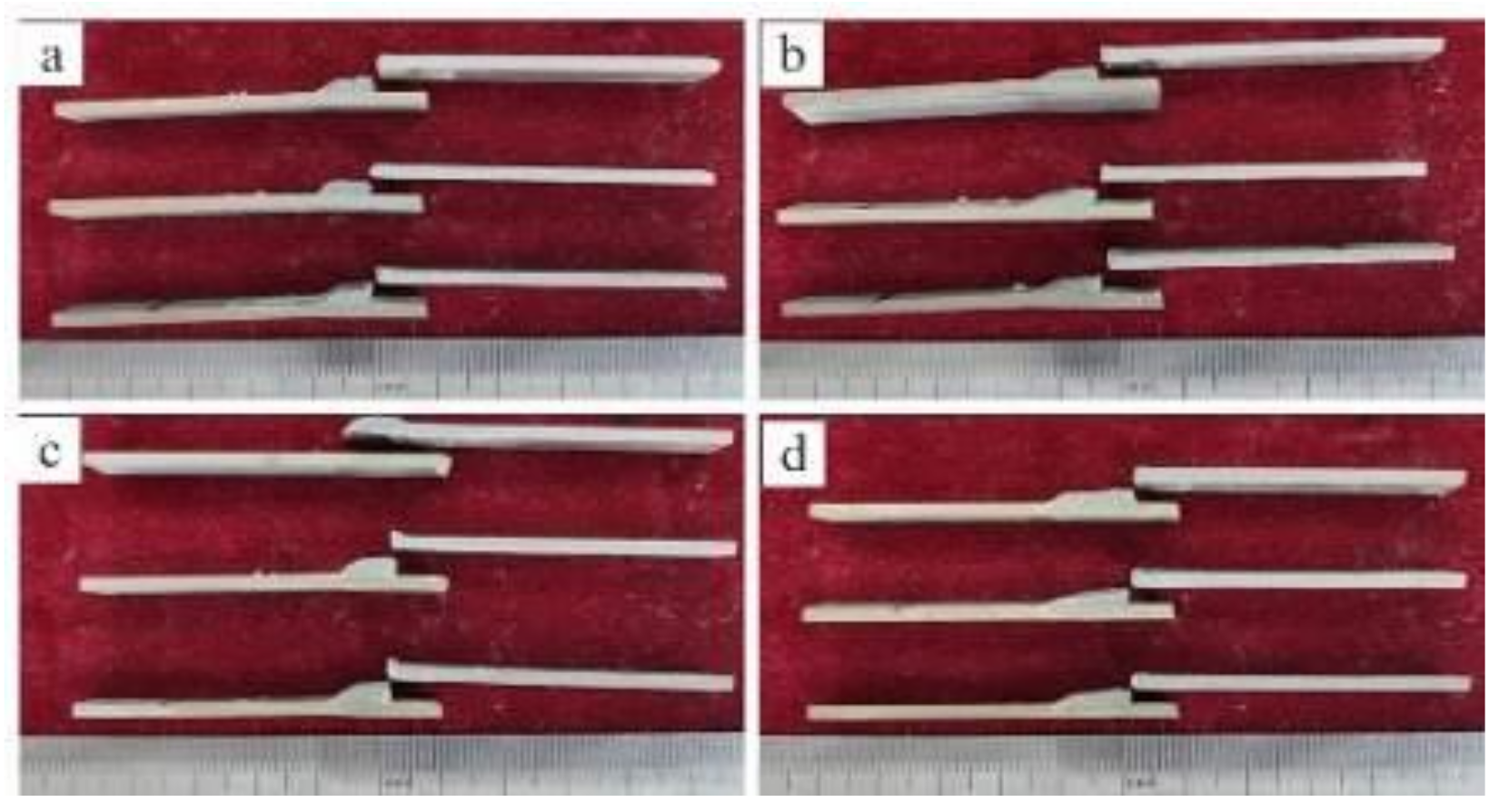

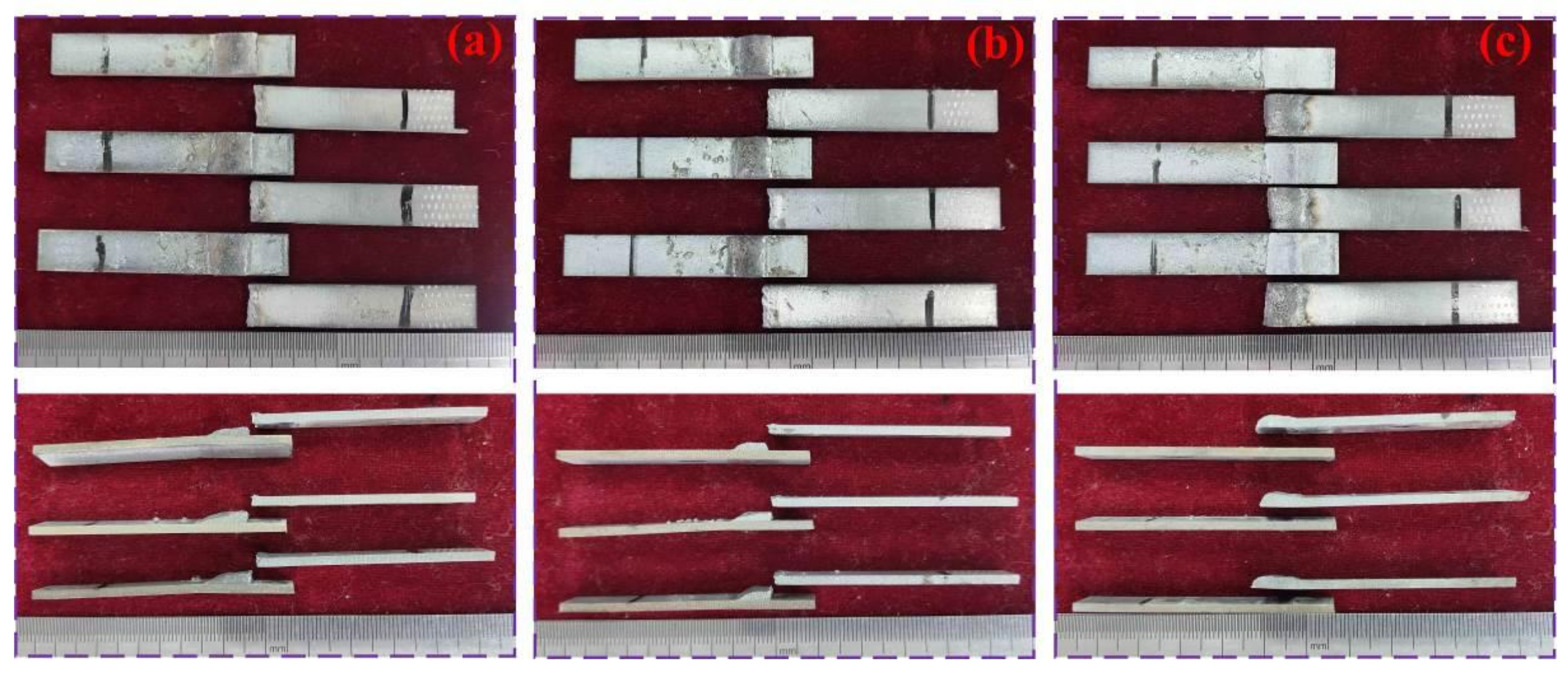

3.2. Effect of Filler Metal on Microstructure and Mechanical Properties of Welded Joints

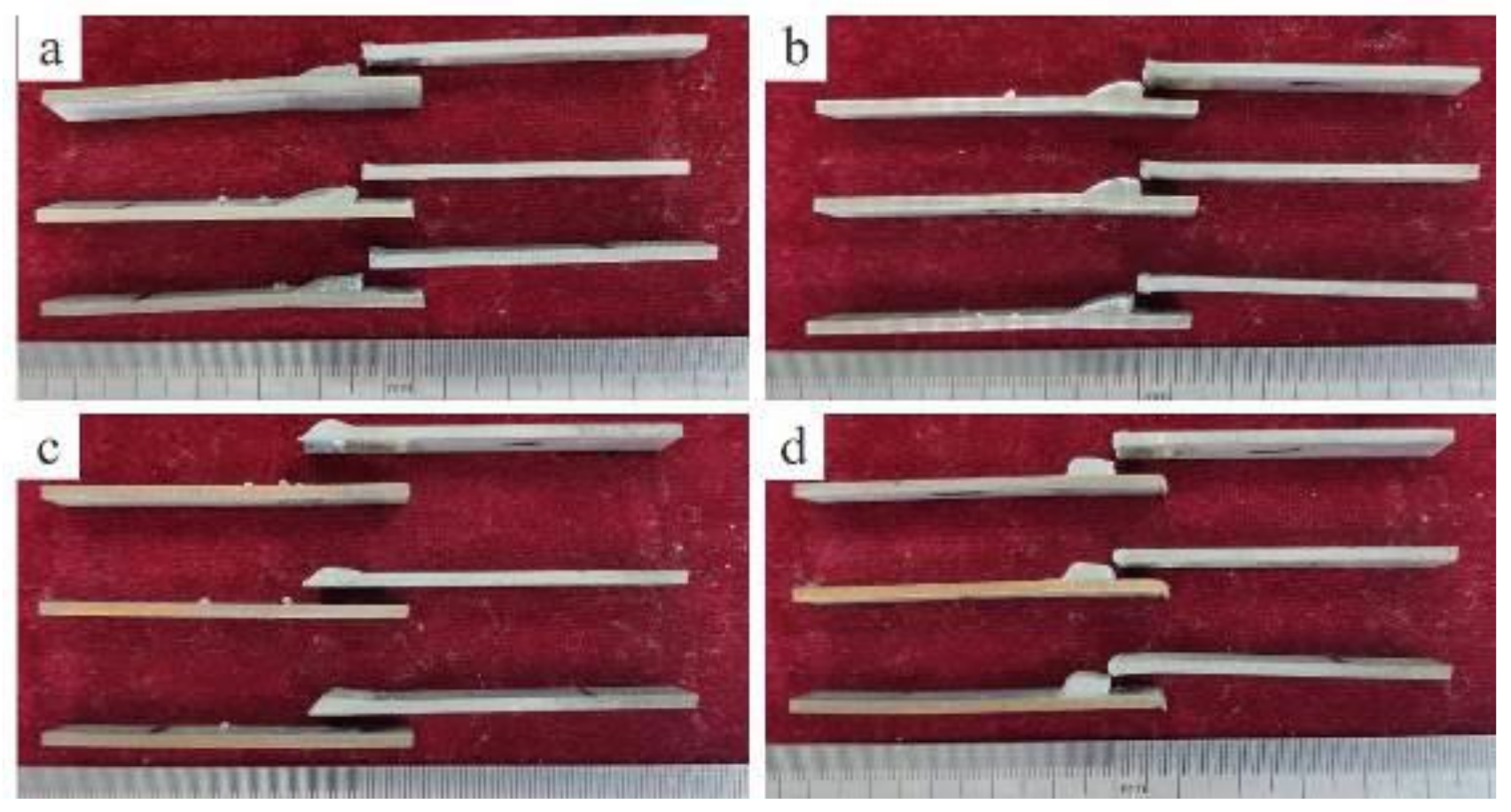

3.3. The Effect of the Plasma Welding Arc on the Joint

4. Conclusions

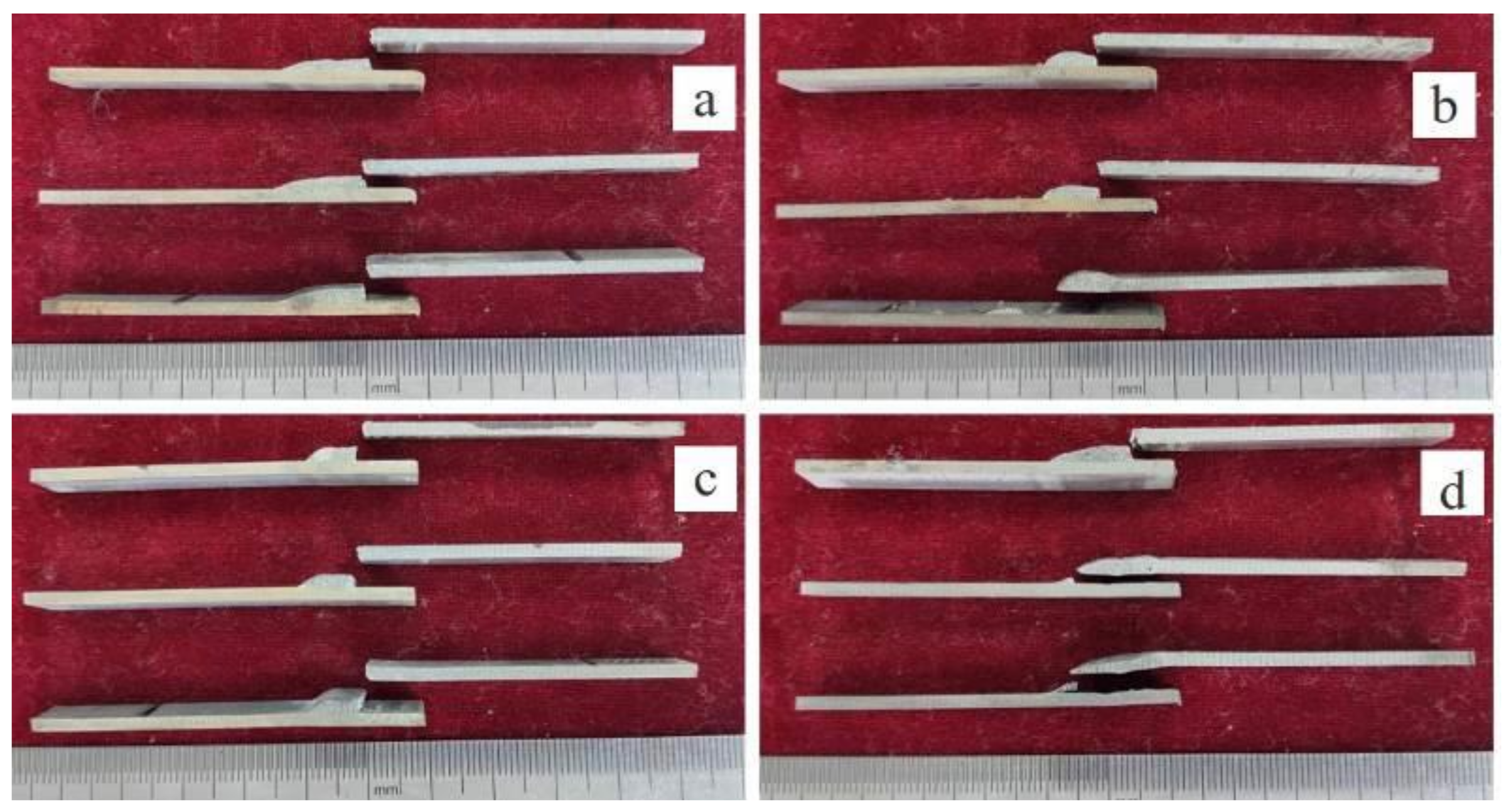

- According to the microstructure characteristics, the welded joint can be divided into a zinc-rich zone, an interface zone, and a weld zone. When the heat input is approximately equal, the combination of the lower plasma arc current and the higher MIG current can achieve a higher tensile-shear force and a good weld microstructure. When the plasma arc current is 20 A and the MIG current is 80 A, the specimen with the highest tensile-shear force is obtained, reaching 65% of the 6061 aluminum base material.

- The welding test conducted with the optimal process parameters showed that the weld strength obtained by filling ER4043 welding wire was the highest, followed by that obtained with ER4047, ER1070, and ER5356, accounting for 65%, 56%, 46%, and 27% of the tensile-shear force of the base material, respectively. The joint samples obtained by filling only ER1070 welding wires were fractured at the boundary line, while the rest of the samples were fractured near the fusion line. According to the EDS results, there were high-C compounds near the interface region of the ER1070 welding wire sample, which was the reason for the fracture at the interface. In the ER4047 welding wire joint, excessive Si elements entered the weld pool, increasing the viscosity of the weld pool and the difficulty of gas escape and resulted in more porosity defects. This also led to a lower tensile-shear force of the joint with ER4047 than ER4043.

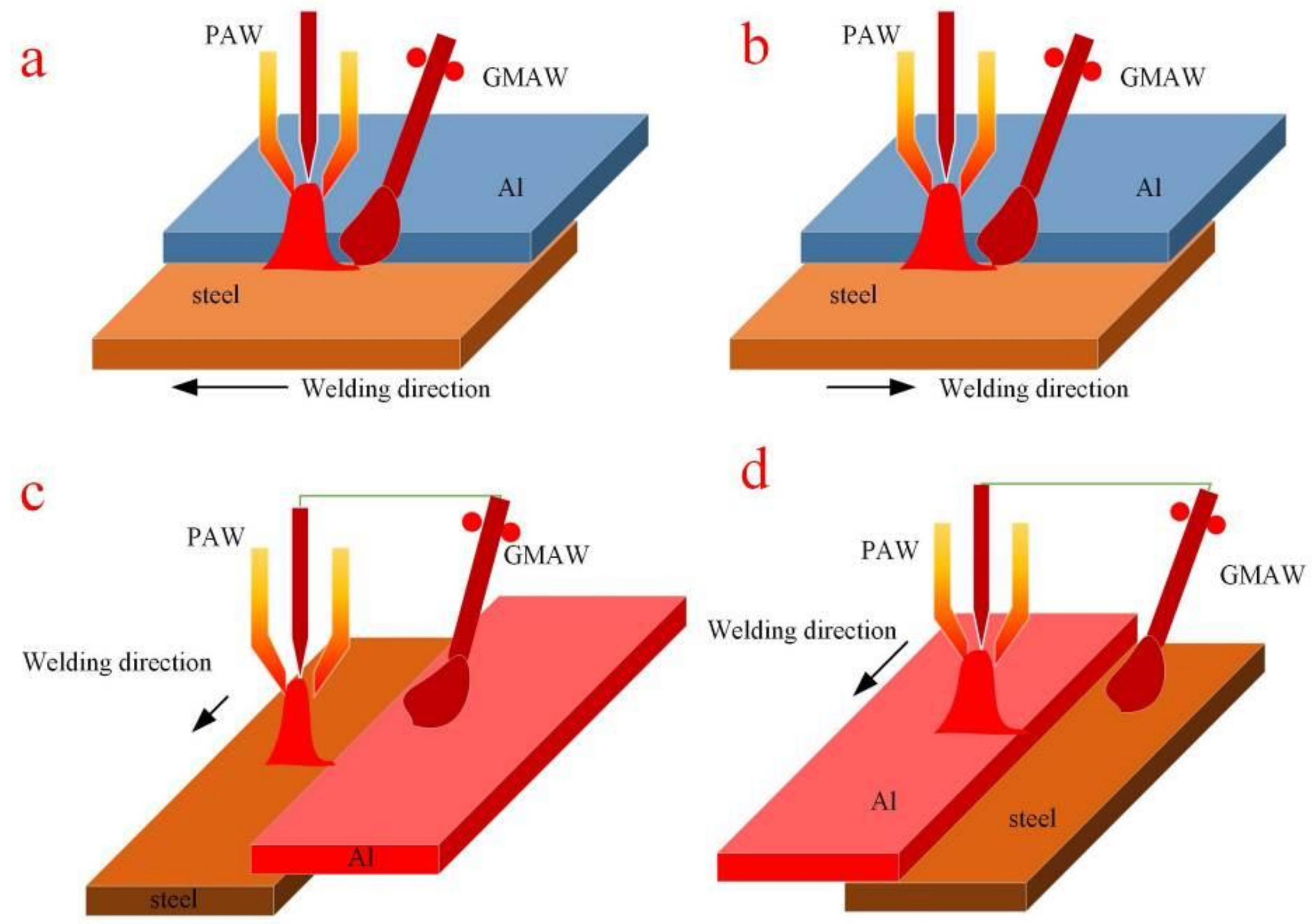

- The action position of the plasma arc played a significant role in the Al/steel interface, which directly influenced the strength of the welded joints. Regardless of the style of plasma-GMAW-P used to obtain the joints, Fe-Al IMCs appeared at the interface. When the plasma arc was in front of the welding direction and GMAW-P arc was in the rear, the tensile-shear force reached a maximum of 3322 N.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhou, L.; Luo, L.Y.; Tan, C.W.; Li, Z.Y.; Song, X.G.; Zhao, H.Y.; Huang, Y.X.; Feng, J.C. Effect of Welding Speed on Microstructural Evolution and Mechanical Properties of Laser Welded-Brazed Al/Brass Dissimilar Joints. Opt. Laser Technol. 2018, 98, 234–246. [Google Scholar] [CrossRef]

- Lu, Y.; Sage, D.D.; Fink, C.; Zhang, W. Dissimilar Metal Joining of Aluminium to Zinc-Coated Steel by Ultrasonic plus Resistance Spot Welding–Microstructure and Mechanical Properties. Sci. Technol. Weld. Join. 2020, 25, 218–227. [Google Scholar] [CrossRef]

- Lu, Y.; Walker, L.; Kimchi, M.; Zhang, W. Microstructure and Strength of Ultrasonic Plus Resistance Spot Welded Aluminum Alloy to Coated Press Hardened Boron Steel. Met. Mater. Trans. A 2020, 51, 93–98. [Google Scholar] [CrossRef]

- Li, Y.; Geng, S.; Zhu, Z.; Wang, Y.; Mi, G.; Jiang, P. Effects of Heat Source Configuration on the Welding Process and Joint Formation in Ultra-High Power Laser-MAG Hybrid Welding. J. Manuf. Process. 2022, 77, 40–53. [Google Scholar] [CrossRef]

- Kaushik, P.; Dwivedi, D.K. Effect of Tool Geometry in Dissimilar Al-Steel Friction Stir Welding. J. Manuf. Process. 2021, 68, 198–208. [Google Scholar] [CrossRef]

- Zhang, G.; Su, W.; Zhang, J.; Wei, Z. Friction Stir Brazing: A Novel Process for Fabricating Al/Steel Layered Composite and for Dissimilar Joining of Al to Steel. Met. Mater Trans. A 2011, 42, 2850–2861. [Google Scholar] [CrossRef]

- Ge, Y.; Xia, Y. Mechanical Characterization of a Steel-Aluminum Clinched Joint under Impact Loading. Thin-Walled Struct. 2020, 151, 106759. [Google Scholar] [CrossRef]

- Su, Y.; Hua, X.; Wu, Y. Effect of Input Current Modes on Intermetallic Layer and Mechanical Property of Aluminum–Steel Lap Joint Obtained by Gas Metal Arc Welding. Mater. Sci. Eng. A 2013, 578, 340–345. [Google Scholar] [CrossRef]

- Lu, Y.; Mayton, E.; Song, H.; Kimchi, M.; Zhang, W. Dissimilar Metal Joining of Aluminum to Steel by Ultrasonic plus Resistance Spot Welding—Microstructure and Mechanical Properties. Mater. Des. 2019, 165, 107585. [Google Scholar] [CrossRef]

- Yazdipour, A.; Heidarzadeh, A. Dissimilar Butt Friction Stir Welding of Al 5083-H321 and 316L Stainless Steel Alloys. Int. J. Adv. Manuf. Technol. 2016, 87, 3105–3112. [Google Scholar] [CrossRef]

- Su, Y.; Hua, X.; Wu, Y. Influence of Alloy Elements on Microstructure and Mechanical Property of Aluminum–Steel Lap Joint Made by Gas Metal Arc Welding. J. Mater. Process. Technol. 2014, 214, 750–755. [Google Scholar] [CrossRef]

- Wan, L.; Huang, Y. Microstructure and Mechanical Properties of Al/Steel Friction Stir Lap Weld. Metals 2017, 7, 542. [Google Scholar] [CrossRef]

- Xia, H.; Tao, W.; Li, L.; Tan, C.; Zhang, K.; Ma, N. Effect of Laser Beam Models on Laser Welding–Brazing Al to Steel. Opt. Laser Technol. 2020, 122, 105845. [Google Scholar] [CrossRef]

- Zhang, G.; Chen, M.; Shi, Y.; Huang, J.; Yang, F. Analysis and Modeling of the Growth of Intermetallic Compounds in Aluminum–Steel Joints. RSC Adv. 2017, 7, 37797–37805. [Google Scholar] [CrossRef]

- Das, A.; Shome, M.; Goecke, S.-F.; De, A. Numerical Modelling of Gas Metal Arc Joining of Aluminium Alloy and Galvanised Steels in Lap Joint Configuration. Sci. Technol. Weld. Join. 2016, 21, 303–309. [Google Scholar] [CrossRef]

- Yu, F.; Wei, Y.; Ji, Y.; Chen, L.-Q. Phase Field Modeling of Solidification Microstructure Evolution during Welding. J. Mater. Process. Technol. 2018, 255, 285–293. [Google Scholar] [CrossRef]

- Miranda-Pérez, A.F.; Rodríguez-Vargas, B.R.; Calliari, I.; Pezzato, L. Corrosion Resistance of GMAW Duplex Stainless Steels Welds. Materials 2023, 16, 1847. [Google Scholar] [CrossRef]

- Figner, G.; Vallant, R.; Weinberger, T.; Enzinger, N.; Schröttner, H.; Paśič, H. Friction Stir Spot Welds between Aluminium and Steel Automotive Sheets: Influence of Welding Parameters on Mechanical Properties and Microstructure. Weld World 2009, 53, R13–R23. [Google Scholar] [CrossRef]

- Yang, M.; Ma, H.; Shen, Z.; Chen, D.; Deng, Y. Microstructure and Mechanical Properties of Al-Fe Meshing Bonding Interfaces Manufactured by Explosive Welding. Trans. Nonferrous Met. Soc. China 2019, 29, 680–691. [Google Scholar] [CrossRef]

- Fujii, H.T.; Goto, Y.; Sato, Y.S.; Kokawa, H. Microstructure and Lap Shear Strength of the Weld Interface in Ultrasonic Welding of Al Alloy to Stainless Steel. Scr. Mater. 2016, 116, 135–138. [Google Scholar] [CrossRef]

- Kanemaru, S.; Sasaki, T.; Sato, T.; Era, T.; Tanaka, M. Study for the Mechanism of TIG-MIG Hybrid Welding Process. Weld World 2015, 59, 261–268. [Google Scholar] [CrossRef]

- Chen, J.; Wu, C.S.; Chen, M.A. Improvement of Welding Heat Source Models for TIG-MIG Hybrid Welding Process. J. Manuf. Process. 2014, 16, 485–493. [Google Scholar] [CrossRef]

- Kanemaru, S.K.; Sasaki, T.; Sato, T.; Mishima, H.; Tashiro, S.; Tanaka, M. Study for the Arc Phenomena of TIG-MIG Hybrid Welding Process by 3D Numerical Analysis Model. Querterly J. Jpn. Weld. Soc. 2012, 30, 323–330. [Google Scholar] [CrossRef]

- Cai, D.T.; Han, S.G.; Zheng, S.D.; Yan, D.J.; Luo, J.Q.; Liu, X.L.; Luo, Z.Y. Plasma-MIG Hybrid Welding Process of 5083 Marine Aluminum Alloy. In Proceedings of the Materials Science Forum, Salt Lake City, UT, USA, 23–27 October 2016. [Google Scholar]

- Ding, M.; Liu, S.S.; Zheng, Y.; Wang, Y.C.; Li, H.; Xing, W.Q.; Yu, X.Y.; Dong, P. TIG–MIG Hybrid Welding of Ferritic Stainless Steels and Magnesium Alloys with Cu Interlayer of Different Thickness. Mater. Des. 2015, 88, 375–383. [Google Scholar] [CrossRef]

- Jiang, H.; Liao, Y.; Gao, S.; Li, G.; Cui, J. Comparative Study on Joining Quality of Electromagnetic Driven Self-Piecing Riveting, Adhesive and Hybrid Joints for Al/Steel Structure. Thin-Walled Struct. 2021, 164, 107903. [Google Scholar] [CrossRef]

| Parameter Set | Plasma Arc Current | MIG Current | Filler Metal |

|---|---|---|---|

| #1 | 40, 50, 60 | 60 | ER4043 |

| #2 | 30, 40, 50, 60 | 70 | ER4043 |

| #3 | 10, 20, 30, 40 | 80 | ER4043 |

| #4 | 20 | 80 | ER4047, ER1070, ER5356 |

| Welding Wire | Si | Cu | Fe | Mn | Ti | Zn | Mg | Al |

|---|---|---|---|---|---|---|---|---|

| ER4043 | 4.50–6.00 | 0.30 | 0.80 | 0.05 | 0.20 | 0.10 | 0.05 | Bal. |

| ER4047 | 11.0–13.0 | 0.30 | 0.80 | 0.15 | - | 0.20 | 0.10 | Bal. |

| ER1070 | 0.3 | - | 0.3 | - | - | - | - | Bal. |

| ER5356 | 0.25 | 0.10 | 0.40 | 0.05–0.20 | 0.06–0.20 | 0.10 | 4.50–5.50 | Bal. |

| Elements (at.%) | Fe | Al | Si. | Cu | O |

|---|---|---|---|---|---|

| A1 | 98.48 | 0.20 | 0.26 | 1.06 | - |

| A2 | 38.90 | 57.91 | 2.37 | 0.82 | - |

| A3 | 23.65 | 71.31 | 4.40 | 0.64 | - |

| A4 | 3.57 | 88.94 | 6.28 | 0.28 | - |

| A5 | 0.32 | 98.10 | - | 0.24 | 0.24 |

| Elements (at.%) | Fe | Al | Si. | Cu | Zn |

|---|---|---|---|---|---|

| A1 | 10.95 | 72.87 | 15.89 | 0.29 | - |

| A2 | 9.72 | 66.60 | 23.41 | 0.27 | - |

| A3 | 9.89 | 66.60 | 22.95 | 7.33 | - |

| A4 | 8.98 | 78.24 | 11.43 | - | 1.35 |

| A5 | 13.26 | 63.86 | 21.36 | - | 1.52 |

| Elements (at.%) | Fe | Al | C | Au | O | Mg |

|---|---|---|---|---|---|---|

| A1 | 76.95 | - | 20.86 | 1.16 | - | - |

| A2 | 1.97 | 97.48 | - | - | - | - |

| A3 | 78.02 | - | 20.49 | 0.70 | - | - |

| A4 | 0.82 | 89.75 | 6.95 | - | 0.75 | 0.98 |

| A5 | 77.63 | - | 21.37 | - | - | - |

| Elements (at.%) | Fe | Al | C | Mg | O | Zn |

|---|---|---|---|---|---|---|

| A1 | 2.13 | 71.04 | 20.64 | 3.84 | 1.24 | - |

| A2 | - | 76.37 | 17.41 | 3.85 | 1.71 | - |

| A3 | - | 29.93 | 8.29 | 1.20 | 51.95 | 6.23 |

| A4 | 0.68 | 64.36 | 16.86 | 1.36 | 6.45 | 10.28 |

| A5 | 67.17 | 11.93 | 20.23 | - | - | - |

| A6 | 74.49 | - | 24.62 | - | - | - |

| A7 | 74.30 | - | 23.41 | - | - | - |

| A8 | 0.51 | 33.41 | 18.86 | 2.84 | 37.05 | 6.04 |

| A9 | 0.71 | 36.88 | 10.43 | 2.44 | 38.97 | 8.75 |

| A10 | 22.31 | 57.95 | 19.74 | - | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; He, W.; Zheng, H.; Yu, J.; Zhang, H.; Li, Y.; Gao, J.; Su, Z. Plasma-Pulsed GMAW Hybrid Welding Process of 6061 Aluminum and Zinc-Coated Steel. Crystals 2023, 13, 723. https://doi.org/10.3390/cryst13050723

Zhang H, He W, Zheng H, Yu J, Zhang H, Li Y, Gao J, Su Z. Plasma-Pulsed GMAW Hybrid Welding Process of 6061 Aluminum and Zinc-Coated Steel. Crystals. 2023; 13(5):723. https://doi.org/10.3390/cryst13050723

Chicago/Turabian StyleZhang, Hongchang, Wenhu He, Huaibei Zheng, Jiang Yu, Hongtao Zhang, Yinan Li, Jianguo Gao, and Zhaofang Su. 2023. "Plasma-Pulsed GMAW Hybrid Welding Process of 6061 Aluminum and Zinc-Coated Steel" Crystals 13, no. 5: 723. https://doi.org/10.3390/cryst13050723

APA StyleZhang, H., He, W., Zheng, H., Yu, J., Zhang, H., Li, Y., Gao, J., & Su, Z. (2023). Plasma-Pulsed GMAW Hybrid Welding Process of 6061 Aluminum and Zinc-Coated Steel. Crystals, 13(5), 723. https://doi.org/10.3390/cryst13050723