Research on the Microstructure and Properties of a Flux-Cored Wire Gas-Shielded Welded Joint of A710 Low-Alloy High-Strength Steel

Abstract

1. Introduction

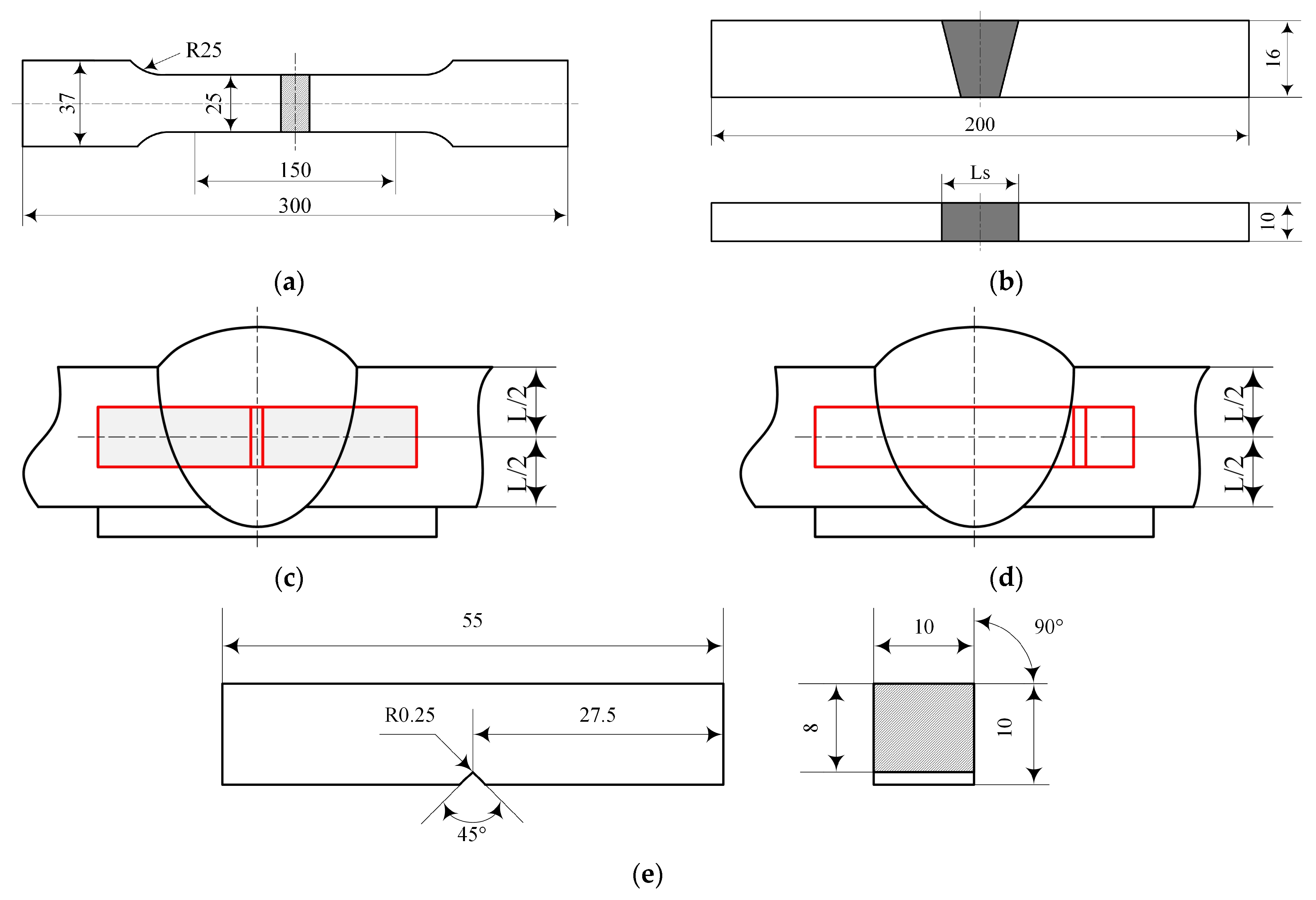

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results and Analysis

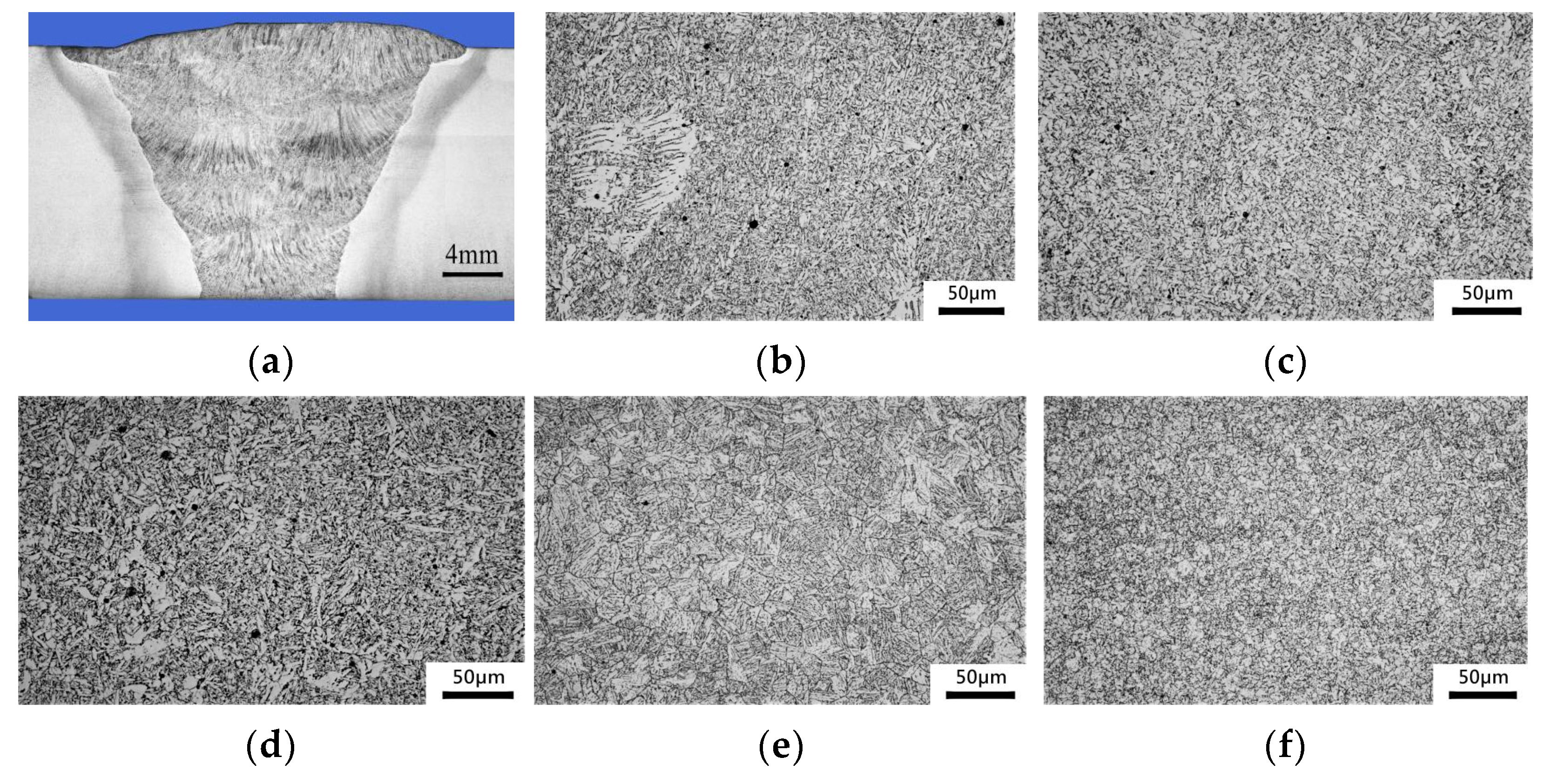

3.1. Macroscopic and Microstructure Morphology

3.2. Hardness Distribution

3.3. Mechanical Properties Analysis

3.3.1. Tensile Property

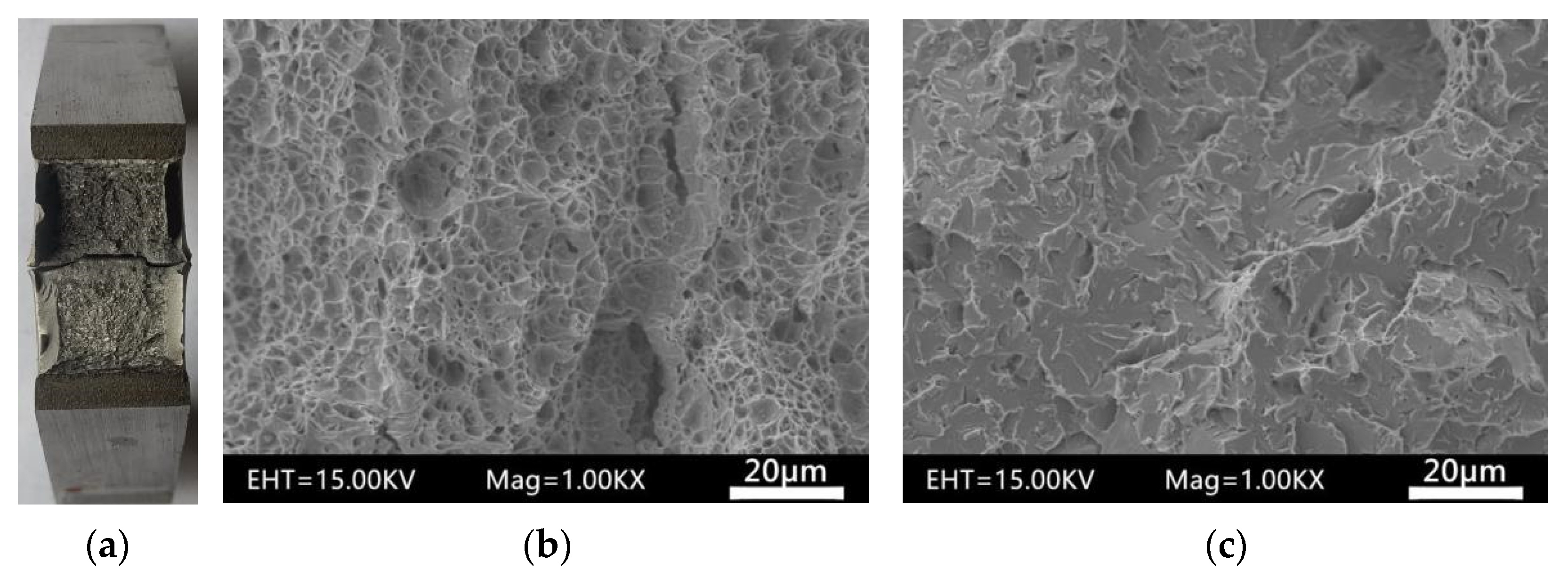

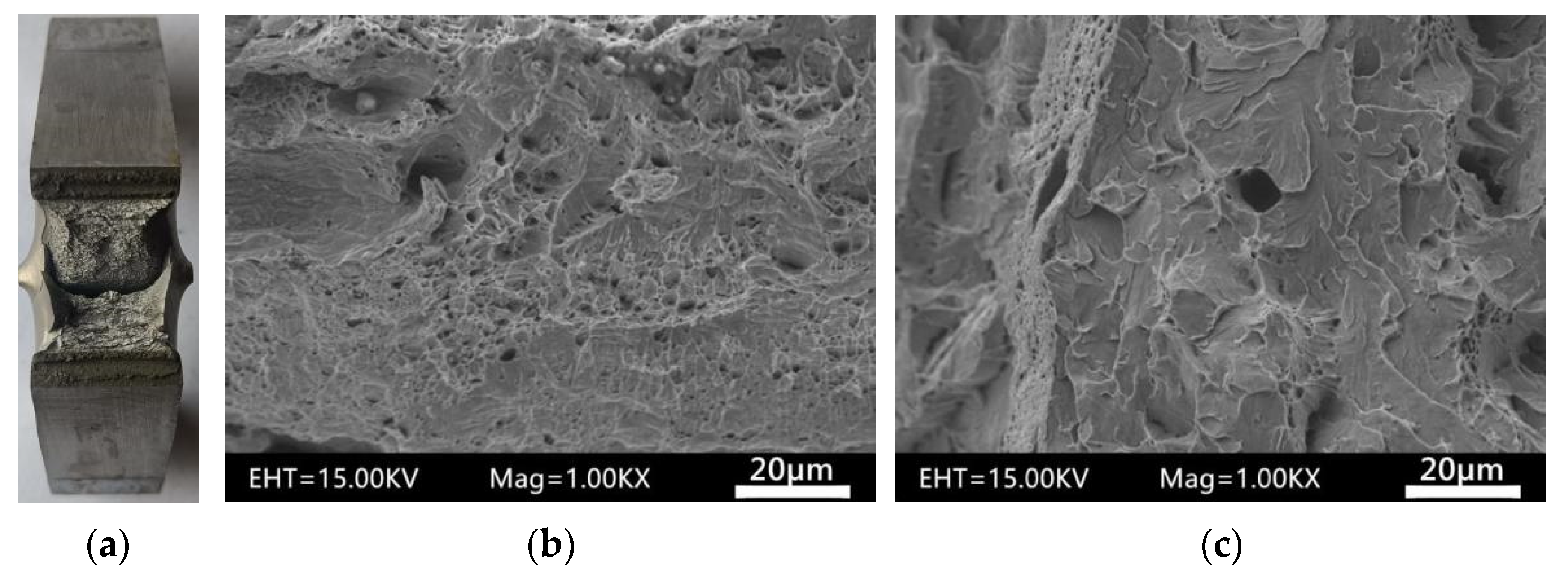

3.3.2. Low-Temperature Impact Properties

3.3.3. Bending Property

3.3.4. Fatigue Property

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rodrigues, T.A.; Duarte, V.; Avila, J.A.; Santos, T.G.; Miranda, R.M.; Oliveira, J.P. Wire and arc additive manufacturing of HSLA steel: Effect of thermal cycles on microstructure and mechanical properties. Addit. Manuf. 2019, 27, 440–450. [Google Scholar] [CrossRef]

- Wang, Z.L. Control of microstructure and properties of welded joints of heavy structures of low alloy high strength steels. Key Eng. Mater. 2019, 814, 171–175. [Google Scholar] [CrossRef]

- Berdnikova, O.; Pozniakov, V.; Bernatskyi, A.; Alekseienko, T.; Sydorets, V. Effect of the structure on the mechanical properties and cracking resistance of welded joints of low-alloyed high-strength steels. Procedia Struct. Integr. 2019, 16, 89–96. [Google Scholar] [CrossRef]

- Zeng, H.L.; Wang, C.J.; Yang, X.M.; Wang, X.S.; Liu, R. Automatic welding technologies for long-distance pipelines by use of all-position self-shielded flux cored wires. Nat. Gas Ind. B 2014, 1, 113–118. [Google Scholar]

- Bracarense, A.Q.; Souza, R.; Costa, M.C.M.; Faria, P.E.; Liu, S. Welding current effect on diffusible hydrogen content in flux cored arc weld metal. J. Braz. Soc. Mech. Sci. Eng. 2002, 24, 278–285. [Google Scholar] [CrossRef]

- Li, Z.; Srivatsan, T.S.; Wang, Y.; Zhang, W.; Li, Y. The spectral analysis of different flux-cored wires during arc welding of metals. Mater. Manuf. Process. 2012, 27, 664–669. [Google Scholar] [CrossRef]

- Hayat, F.; Uzun, H. Microstructural and mechanical properties of dual-phase steels welded using GMAW with solid and flux-cored welding wires. Int. J. Mater. Res. 2012, 103, 828–837. [Google Scholar] [CrossRef]

- Zou, Z.; Liu, Z.; Ai, X.; Wu, D. Effect of aluminum on microstructure and mechanical properties of weld metal of Q960 steel. Crystals 2022, 12, 26. [Google Scholar] [CrossRef]

- Ilić, A.; Miletić, I.; Nikolić, R.R.; Marjanović, V.; Ulewicz, R.; Stojanović, B.; Ivanović, L. Analysis of influence of the welding procedure on impact toughness of welded joints of the high-strength low-alloyed steels. Appl. Sci. 2020, 10, 2205. [Google Scholar] [CrossRef]

- Kornokar, K.; Nematzadeh, F.; Mostaan, H.; Sadeghian, A.; Moradi, M.; Waugh, D.G.; Bodaghi, M. Influence of heat input on microstructure and mechanical properties of gas tungsten arc welded HSLA S500MC steel joints. Metals 2022, 12, 565. [Google Scholar] [CrossRef]

- Oktadinata, H.; Winarto, W.; Siradj, E.S. Microstructure and impact toughness of flux-cored arc welded SM570-TMC steel at low and high heat input. Mater. Sci. Forum 2020, 991, 3–9. [Google Scholar] [CrossRef]

- Ni, Z.; Hu, F.; Li, Y.; Lin, S.; Cai, X. Microstructure and mechanical properties of the ternary gas shielded narrow-gap GMA welded joint of high-strength steel. Crystals 2022, 12, 1566. [Google Scholar] [CrossRef]

- Wen, C.; Wang, Z.; Deng, X.; Wang, G.; Misra, R.D.K. Effect of Heat Input on the Microstructure and Mechanical Properties of Low Alloy Ultra-High Strength Structural Steel Welded Joint. Steel Res. Int. 2018, 89, 1700500. [Google Scholar] [CrossRef]

- Ilić, A.; Ivanović, L.; Josifović, D.; Lazić, V.; Živković, J. Effects of welding on mechanical and microstructural characteristics of high-strength low-alloy steel joints. IOP Conf. Ser. Mater. Sci. Eng. 2018, 393, 012020. [Google Scholar] [CrossRef]

- Song, F.; Yin, C.; Hu, F.; Wu, K. Effects of Mn-depleted zone formation on acicular ferrite transformation in weld metals under high heat input welding. Materials 2022, 15, 8477. [Google Scholar] [CrossRef] [PubMed]

- Atkinson, H.V.; Shi, G. Characterization of Inclusions in Clean Steels: A Review Including the Statistics of Extremes Methods. Prog. Mater. Sci. 2003, 48, 457–520. [Google Scholar] [CrossRef]

| Base Metal | C | Mn | Si | P | S | Nb | Ti | Ni | Cu | Cr | Mo | Ni | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A710 | ≤0.07 | 0.4~0.7 | ≤0.4 | ≤0.025 | ≤0.025 | 0.02~0.05 | ≤0.025 | 0.7~1.4 | 1.0~1.3 | 0.6~0.9 | 0.15~0.25 | 0.7~1.4 | ≤0.05 |

| Flux-Cored Wire | Mn | Si | Cr | Ni | Mo | V | Nb | Al | Cu |

|---|---|---|---|---|---|---|---|---|---|

| E81T1-Ni1M | ≤1.4 | ≤0.8 | ≤0.2 | 0.6~1.2 | ≤0.2 | ≤0.08 | ≤0.05 | ≤2.0 | ≤0.3 |

| Line | Current (A) | Voltage (V) | Welding Speed (cm/min) | Heat Input (kJ/cm) | Welding Sequence Diagram |

|---|---|---|---|---|---|

| 1 | 250–280 | 26–28 | 20 | 15 |  |

| 2 | 250–280 | 26–28 | 19 | 15 | |

| 3–4 | 250–280 | 26–28 | 35 | 8.6 | |

| 5–7 | 250–280 | 26–28 | 42 | 7.6 |

| Sample Number | Tensile Strength/MPa | Yield Strength/MPa | Break Elongation/% | Reduction in Area/% | ||||

|---|---|---|---|---|---|---|---|---|

| Single | Average | Single | Average | Single | Average | Single | Average | |

| LS-1# | 645 | 650 | 644 | 649 | 12 | 12 | 44 | 43 |

| LS-2# | 655 | 654 | 11 | 41 | ||||

| Sample Number | Test Temperature /°C | Location of Notch | Low Temperature Impact AKV/J | Average Low Temperature Impact AKV/J |

|---|---|---|---|---|

| CJ-1# | −40 | Weld | 74 | 71 |

| CJ-2# | 69 | |||

| CJ-3# | 69 | |||

| CJ-4# | HAZ | 257 | 253 | |

| CJ-5# | 253 | |||

| CJ-6# | 249 |

| Sample Number | Pressure Head Diameter | Bending Angle | Bending Results | |

|---|---|---|---|---|

| WQ-1# | 40 mm | 180° |  |  |

| WQ-2# | ||||

| WQ-3# | ||||

| WQ-4# | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Yang, Z.; Du, L. Research on the Microstructure and Properties of a Flux-Cored Wire Gas-Shielded Welded Joint of A710 Low-Alloy High-Strength Steel. Crystals 2023, 13, 484. https://doi.org/10.3390/cryst13030484

Wang X, Yang Z, Du L. Research on the Microstructure and Properties of a Flux-Cored Wire Gas-Shielded Welded Joint of A710 Low-Alloy High-Strength Steel. Crystals. 2023; 13(3):484. https://doi.org/10.3390/cryst13030484

Chicago/Turabian StyleWang, Xing, Zhibin Yang, and Lingzhi Du. 2023. "Research on the Microstructure and Properties of a Flux-Cored Wire Gas-Shielded Welded Joint of A710 Low-Alloy High-Strength Steel" Crystals 13, no. 3: 484. https://doi.org/10.3390/cryst13030484

APA StyleWang, X., Yang, Z., & Du, L. (2023). Research on the Microstructure and Properties of a Flux-Cored Wire Gas-Shielded Welded Joint of A710 Low-Alloy High-Strength Steel. Crystals, 13(3), 484. https://doi.org/10.3390/cryst13030484