A Carbon Black/Polyvinyl Alcohol-Based Composite Thin Film Sensor Integrating Strain and Humidity Sensing Using the Droplet Deposition Method

Abstract

:1. Introduction

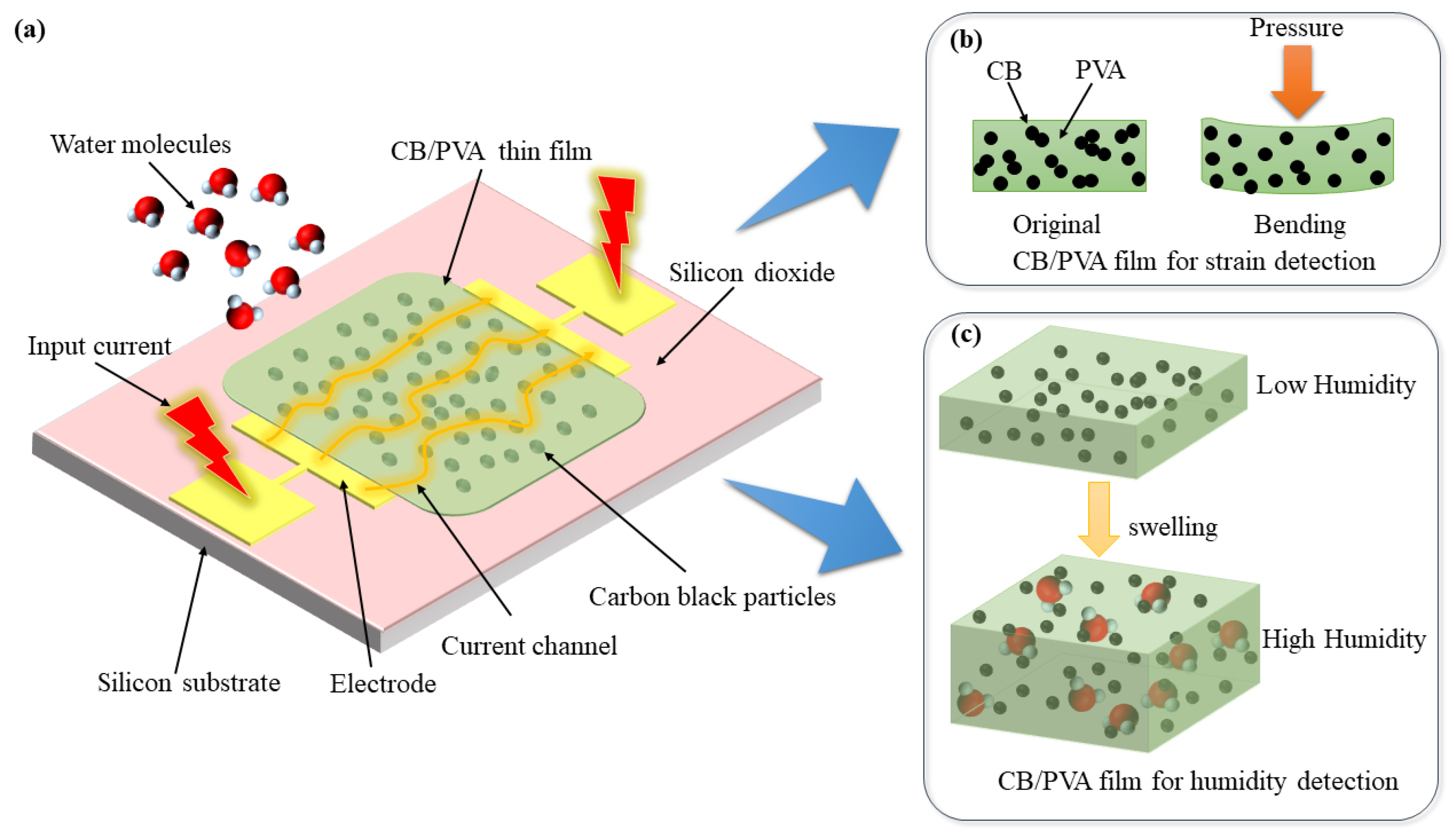

2. Design and Principle of Thin Film Sensor

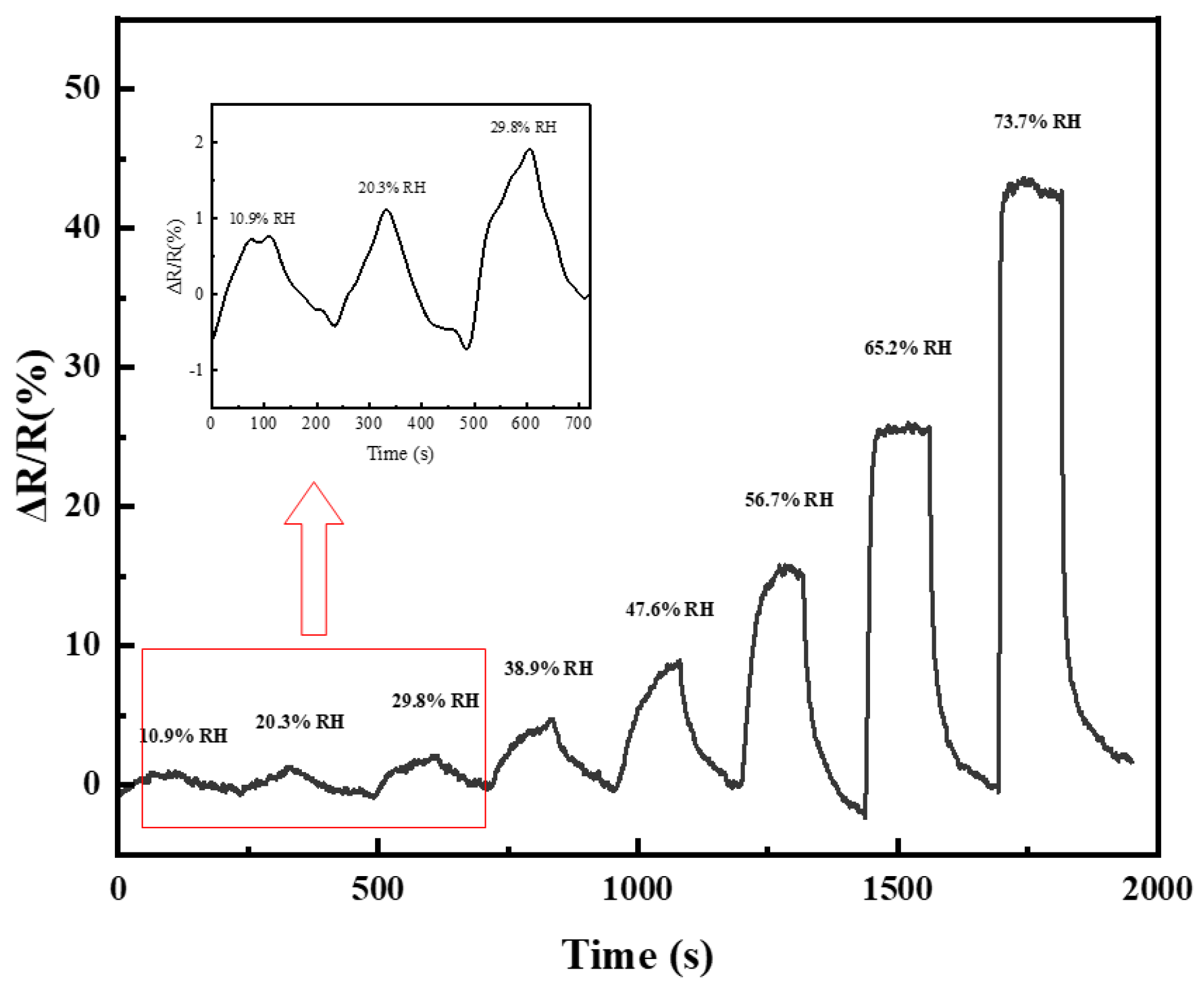

2.1. The Design and Conductive Principle of the Sensor

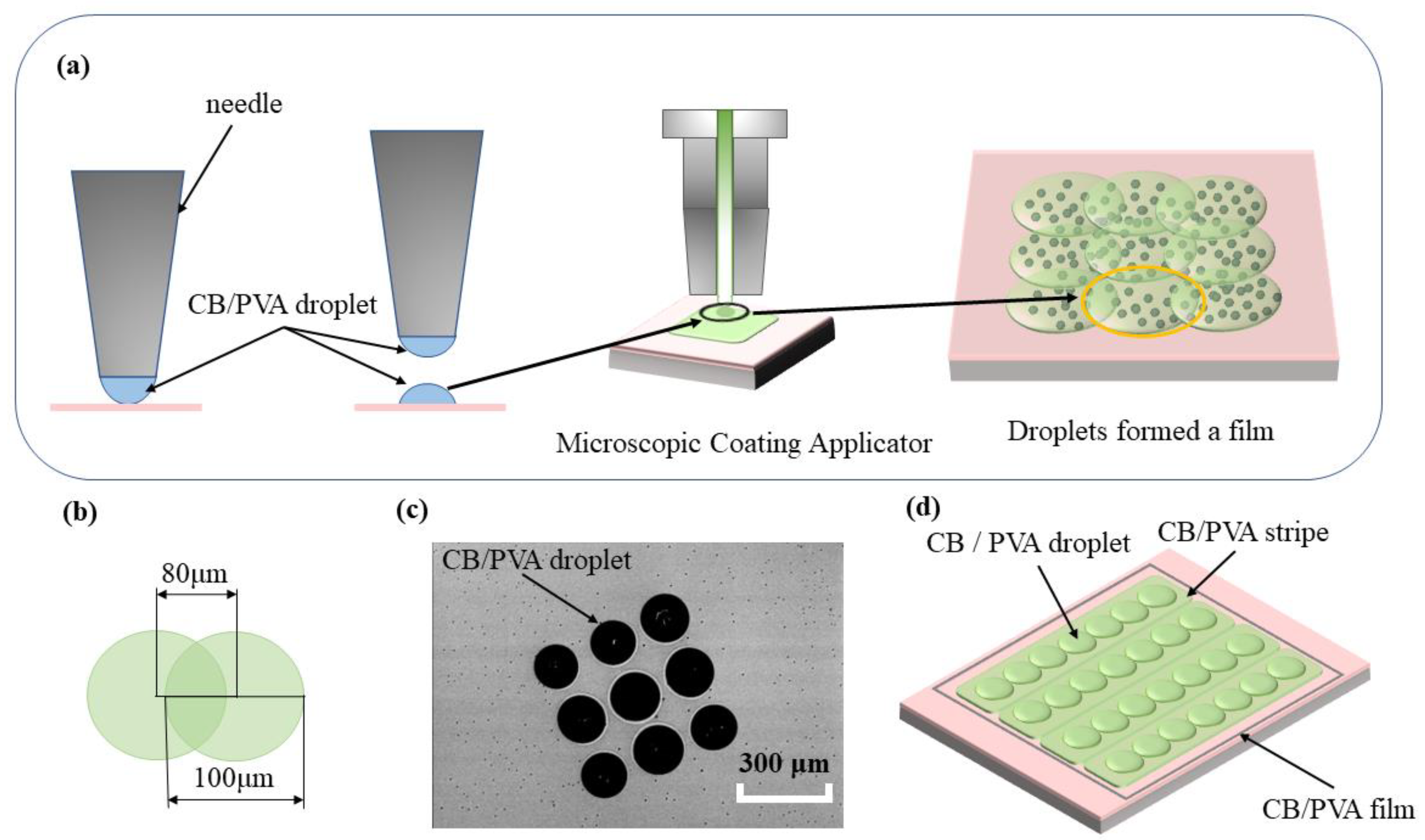

2.2. The Formation Mechanism of CB/PVA Film

3. Experimental

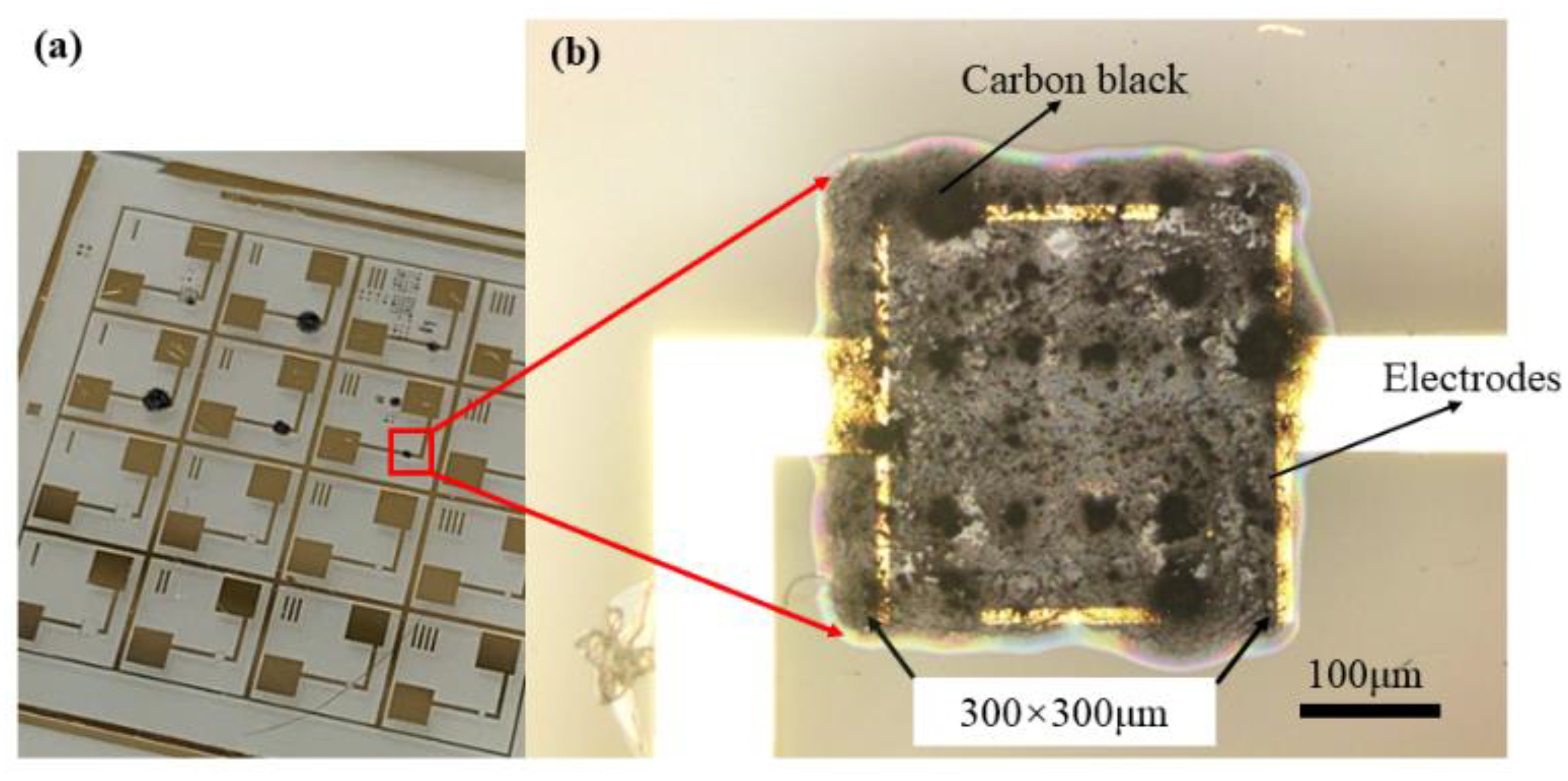

3.1. CB/PVA Composite Film Fabrication Process

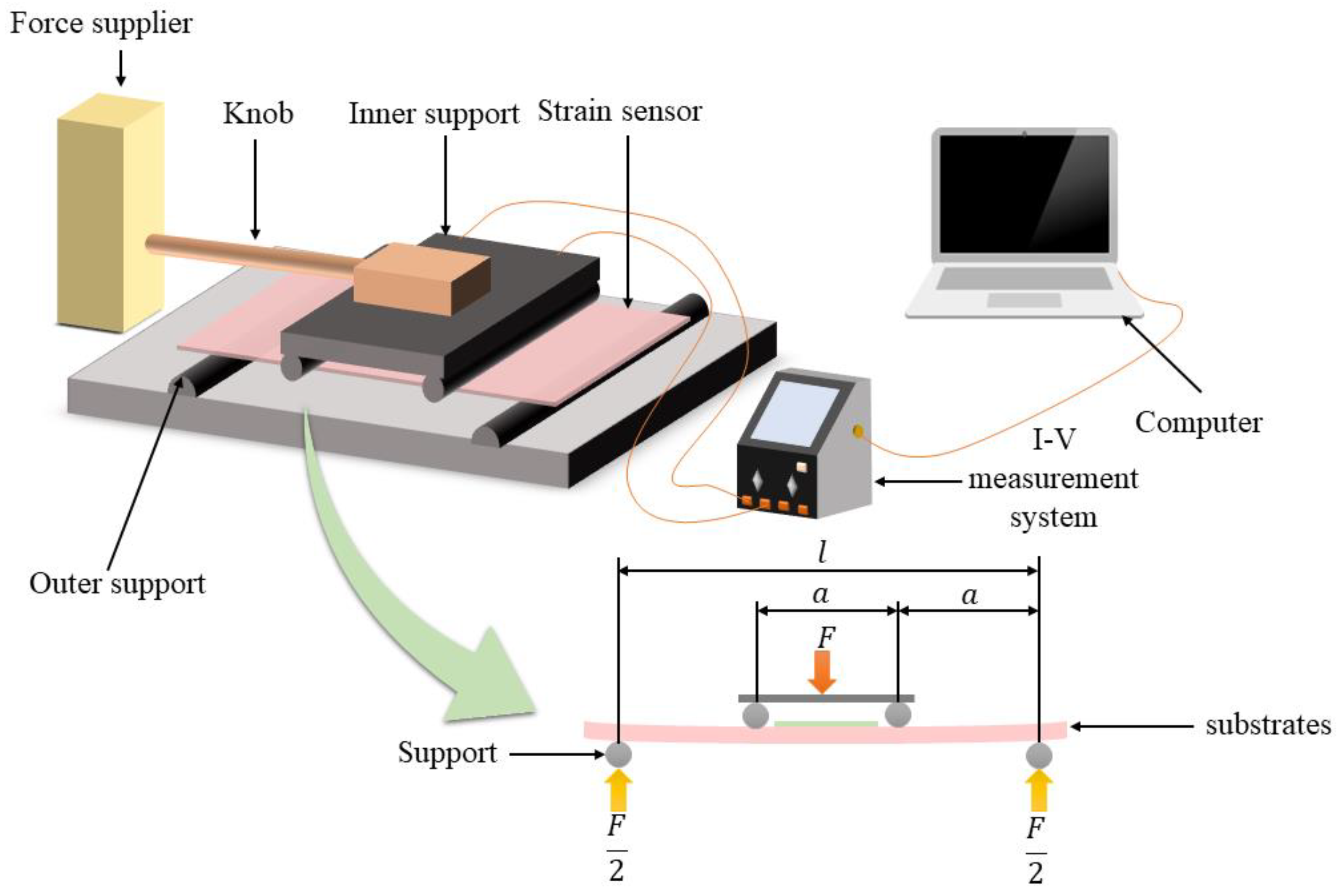

3.2. Four-Point Bending Method

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kenry; Yeo, J.C.; Lim, C.T. Emerging flexible and wearable physical sensing platforms for healthcare and biomedical applications. Microsyst. Nanoeng. 2016, 2. [Google Scholar] [CrossRef]

- Li, C.; Yang, S.; Guo, Y.; Huang, H.; Chen, H.; Zuo, X.; Fan, Z.; Liang, H.; Pan, L. Flexible, multi-functional sensor based on all-carbon sensing medium with low coupling for ultrahigh-performance strain, temperature and humidity sensing. Chem. Eng. J. 2021, 426, 130364. [Google Scholar] [CrossRef]

- Weng, C.H.; Yang, Y.; Jia, J.; Liu, C.; Mao, D.; Weerasinghe, R.; Wu, J. Decoupling and decomposition analysis on the CO2 emissions of tourism industry: A case study of Hainan. E3S Web Conf. 2019, 118, 04042. [Google Scholar] [CrossRef]

- Hossain, M.M.; Toda, M.; Hokama, T.; Yamazaki, M.; Moorthi, K.; Ono, T. Piezoresistive Nanomechanical Humidity Sensors Using Internal Stress In-Plane of Si-Polymer Composite Membranes. IEEE Sens. Lett. 2019, 3, 2500404. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, Y.; Wei, Y.; Xu, W.; Fang, D.; Zhai, L.; Lin, K.-C.; An, L. A Silicon Carbonitride Ceramic with Anomalously High Piezoresistivity. J. Am. Ceram. Soc. 2008, 91, 1346–1349. [Google Scholar] [CrossRef]

- Ruhhammer, J.; Zens, M.; Goldschmidtboeing, F.; Seifert, A.; Woias, P. Highly elastic conductive polymeric MEMS. Sci. Technol. Adv. Mater. 2015, 16, 015003. [Google Scholar] [CrossRef] [PubMed]

- Mannsfeld, S.C.; Tee, B.C.; Stoltenberg, R.M.; Chen, C.V.; Barman, S.; Muir, B.V.; Sokolov, A.N.; Reese, C.; Bao, Z. Highly sensitive flexible pressure sensors with microstructured rubber dielectric layers. Nat. Mater. 2010, 9, 859–864. [Google Scholar] [CrossRef] [PubMed]

- Latessa, G.; Brunetti, F.; Reale, A.; Saggio, G.; Di Carlo, A. Piezoresistive behaviour of flexible PEDOT:PSS based sensors. Sens. Actuators B Chem. 2009, 139, 304–309. [Google Scholar] [CrossRef]

- Wang, C.; Xia, K.; Wang, H.; Liang, X.; Yin, Z.; Zhang, Y. Advanced Carbon for Flexible and Wearable Electronics. Adv. Mater. 2019, 31, e1801072. [Google Scholar] [CrossRef] [PubMed]

- Nag, A.; Mitra, A.; Mukhopadhyay, S.C. Graphene and its sensor-based applications: A review. Sens. Actuators A Phys. 2018, 270, 177–194. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Fal’ko, V.I.; Colombo, L.; Gellert, P.R.; Schwab, M.G.; Kim, K. A roadmap for graphene. Nature 2012, 490, 192–200. [Google Scholar] [CrossRef]

- Lee, S.; Reuveny, A.; Reeder, J.; Lee, S.; Jin, H.; Liu, Q.; Yokota, T.; Sekitani, T.; Isoyama, T.; Abe, Y.; et al. A transparent bending-insensitive pressure sensor. Nat. Nanotechnol. 2016, 11, 472–478. [Google Scholar] [CrossRef]

- Tran, L.; Kim, J. A Comparative Study of the Thermoplastic Polyurethane/Carbon Nanotube and Natural Rubber/Carbon Nanotube Composites According to Their Mechanical and Electrical Properties. Fibers Polym. 2018, 19, 1948–1955. [Google Scholar] [CrossRef]

- Stampfer, C.; Jungen, A.; Linderman, R.; Obergfell, D.; Roth, S.; Hierold, C. Nano-electromechanical displacement sensing based on single-walled carbon nanotubes. Nano Lett. 2006, 6, 1449–1453. [Google Scholar] [CrossRef] [PubMed]

- Amjadi, M.; Yoon, Y.J.; Park, I. Ultra-stretchable and skin-mountable strain sensors using carbon nanotubes-Ecoflex nanocomposites. Nanotechnology 2015, 26, 375501. [Google Scholar] [CrossRef] [PubMed]

- Zhu, S.-E.; Krishna Ghatkesar, M.; Zhang, C.; Janssen, G.C.A.M. Graphene based piezoresistive pressure sensor. Appl. Phys. Lett. 2013, 102, 161904. [Google Scholar] [CrossRef]

- Tian, H.; Shu, Y.; Wang, X.F.; Mohammad, M.A.; Bie, Z.; Xie, Q.Y.; Li, C.; Mi, W.T.; Yang, Y.; Ren, T.L. A graphene-based resistive pressure sensor with record-high sensitivity in a wide pressure range. Sci. Rep. 2015, 5, 8603. [Google Scholar] [CrossRef]

- Watthanawisuth, N.; Maturos, T.; Sappat, A.; Tuantranont, A.; Ieee. The IoT Wearable Stretch Sensor Using 3D-Graphene Foam. In 2015 IEEE Sensors; IEEE: New York, NY, USA, 2015; pp. 426–429. [Google Scholar]

- An, Z.; Li, J.; Kikuchi, A.; Wang, Z.; Jiang, Y.; Ono, T. Mechanically strengthened graphene-Cu composite with reduced thermal expansion towards interconnect applications. Microsyst. Nanoeng. 2019, 5, 20. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Zhang, R.; Yu, W.; Wang, K.; Wei, J.; Wu, D.; Cao, A.; Li, Z.; Cheng, Y.; Zheng, Q.; et al. Stretchable and highly sensitive graphene-on-polymer strain sensors. Sci. Rep. 2012, 2, 870. [Google Scholar] [CrossRef]

- Huang, J.-C. Carbon black filled conducting polymers and polymer blends. Adv. Polym. Technol. 2002, 21, 299–313. [Google Scholar] [CrossRef]

- Xiao, H.; Li, H.; Ou, J. Modeling of piezoresistivity of carbon black filled cement-based composites under multi-axial strain. Sens. Actuators A Phys. 2010, 160, 87–93. [Google Scholar] [CrossRef]

- Nan, N.; DeVallance, D.B. Development of poly(vinyl alcohol)/wood-derived biochar composites for use in pressure sensor applications. J. Mater. Sci. 2017, 52, 8247–8257. [Google Scholar] [CrossRef]

- Das, M.; Sarkar, D. Development of room temperature ethanol sensor from polypyrrole (PPy) embedded in polyvinyl alcohol (PVA) matrix. Polym. Bull. 2017, 75, 3109–3125. [Google Scholar] [CrossRef]

- Jiang, K.; Fei, T.; Jiang, F.; Wang, G.; Zhang, T. A dew sensor based on modified carbon black and polyvinyl alcohol composites. Sens. Actuator B-Chem. 2014, 192, 658–663. [Google Scholar] [CrossRef]

- Krishna, A.; Kumar, A.; Singh, R.K. Effect of Polyvinyl Alcohol on the Growth, Structure, Morphology, and Electrical Conductivity of Polypyrrole Nanoparticles Synthesized via Microemulsion Polymerization. ISRN Nanomater. 2012, 2012, 809063. [Google Scholar] [CrossRef]

- Maity, D.; Rajavel, K.; Kumar, R.T.R. Polyvinyl alcohol wrapped multiwall carbon nanotube (MWCNTs) network on fabrics for wearable room temperature ethanol sensor. Sens. Actuators B Chem. 2018, 261, 297–306. [Google Scholar] [CrossRef]

- Mbam, S.O.; Nwonu, S.E.; Orelaja, O.A.; Nwigwe, U.S.; Gou, X.-F. Thin-film coating; historical evolution, conventional deposition technologies, stress-state micro/nano-level measurement/models and prospects projection: A critical review. Mater. Res. Express 2019, 6, 122001. [Google Scholar] [CrossRef]

- Zhang, S.; Li, S.; Xia, Z.; Cai, K. A review of electronic skin: Soft electronics and sensors for human health. J. Mater. Chem. B 2020, 8, 852–862. [Google Scholar] [CrossRef]

- Krebs, F.C. Fabrication and processing of polymer solar cells: A review of printing and coating techniques. Sol. Energy Mater. Sol. Cells 2009, 93, 394–412. [Google Scholar] [CrossRef]

- Zhou, X.; Zhu, L.; Fan, L.; Deng, H.; Fu, Q. Fabrication of Highly Stretchable, Washable, Wearable, Water-Repellent Strain Sensors with Multi-Stimuli Sensing Ability. ACS Appl. Mater. Interfaces 2018, 10, 31655–31663. [Google Scholar] [CrossRef]

- Qi, X.; Li, X.L.; Jo, H.; Bhat, K.S.; Kim, S.; An, J.; Kang, J.W.; Lim, S. Mulberry paper-based graphene strain sensor for wearable electronics with high mechanical strength. Sens. Actuator A-Phys. 2020, 301, 8. [Google Scholar] [CrossRef]

- Yu, Z.; Zhang, Q.; Li, L.; Chen, Q.; Niu, X.; Liu, J.; Pei, Q. Highly flexible silver nanowire electrodes for shape-memory polymer light-emitting diodes. Adv. Mater. 2011, 23, 664–668. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.H.; Kim, S.R.; Kil, H.J.; Kim, Y.C.; Park, J.W. Highly Conformable, Transparent Electrodes for Epidermal Electronics. Nano Lett. 2018, 18, 4531–4540. [Google Scholar] [CrossRef]

- Ke, K.; McMaster, M.; Christopherson, W.; Singer, K.D.; Manas-Zloczower, I. Highly sensitive capacitive pressure sensors based on elastomer composites with carbon filler hybrids. Compos. Part A Appl. Sci. Manuf. 2019, 126, 105614. [Google Scholar] [CrossRef]

- Liu, H.; Jiang, H.; Du, F.; Zhang, D.; Li, Z.; Zhou, H. Flexible and Degradable Paper-Based Strain Sensor with Low Cost. ACS Sustain. Chem. Eng. 2017, 5, 10538–10543. [Google Scholar] [CrossRef]

- Shintake, J.; Piskarev, Y.; Jeong, S.H.; Floreano, D. Ultrastretchable Strain Sensors Using Carbon Black-Filled Elastomer Composites and Comparison of Capacitive Versus Resistive Sensors. Adv. Mater. Technol. 2017, 3, 1700284. [Google Scholar] [CrossRef]

- Guo, Y.; Ono, Y.; Nagao, Y. Modification for Uniform Surface of Nafion Ultrathin Film Deposited by Inkjet Printing. Langmuir 2015, 31, 10137–10144. [Google Scholar] [CrossRef]

- Costa, P.; Ferreira, A.; Sencadas, V.; Viana, J.C.; Lanceros-Méndez, S. Electro-mechanical properties of triblock copolymer styrene–butadiene–styrene/carbon nanotube composites for large deformation sensor applications. Sens. Actuators A Phys. 2013, 201, 458–467. [Google Scholar] [CrossRef]

- Huang, Y.-T.; Inomata, N.; Wang, Z.; Lin, Y.-C.; Ono, T. Flexible Porous Carbon Black-Polymer Composites with a High Gauge Factor. Sens. Mater. 2020, 32, 2527–2538. [Google Scholar] [CrossRef]

- Zhu, M.; Sakamoto, K.; Li, J.; Inomata, N.; Toda, M.; Ono, T. Piezoresistive strain sensor based on monolayer molybdenum disulfide continuous film deposited by chemical vapor deposition. J. Micromech. Microeng. 2019, 29, 055002. [Google Scholar] [CrossRef]

- Zhu, M.; Li, J.; Inomata, N.; Toda, M.; Ono, T. Vanadium-doped molybdenum disulfide film-based strain sensors with high gauge factor. Appl. Phys. Express 2019, 12, 015003. [Google Scholar] [CrossRef]

- Salvatori, S.; Pettinato, S.; Piccardi, A.; Sedov, V.; Voronin, A.; Ralchenko, V. Thin Diamond Film on Silicon Substrates for Pressure Sensor Fabrication. Materials 2020, 13, 3697. [Google Scholar] [CrossRef] [PubMed]

- Pedersen, T.; Fragiacomo, G.; Hansen, O.; Thomsen, E.V. Highly sensitive micromachined capacitive pressure sensor with reduced hysteresis and low parasitic capacitance. Sens. Actuators A Phys. 2009, 154, 35–41. [Google Scholar] [CrossRef]

- Bae, B.; Flachsbart, B.R.; Park, K.; Shannon, M.A. Design optimization of a piezoresistive pressure sensor considering the output signal-to-noise ratio. J. Micromech. Microeng. 2004, 14, 1597–1607. [Google Scholar] [CrossRef]

- Barlian, A.A.; Park, W.T.; Mallon, J.R., Jr.; Rastegar, A.J.; Pruitt, B.L. Review: Semiconductor Piezoresistance for Microsystems. Proc. IEEE Inst. Electr. Electron. Eng. 2009, 97, 513–552. [Google Scholar] [CrossRef] [PubMed]

- Fiorillo, A.S.; Critello, C.D.; Pullano, S.A. Theory, technology and applications of piezoresistive sensors: A review. Sens. Actuators A Phys. 2018, 281, 156–175. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, Q.; Chen, P. Flexible Strain Sensor Based on Carbon Black/Silver Nanoparticles Composite for Human Motion Detection. Materials 2018, 11, 1836. [Google Scholar] [CrossRef]

- Li, M.; Li, H.; Zhong, W.; Zhao, Q.; Wang, D. Stretchable conductive polypyrrole/polyurethane (PPy/PU) strain sensor with netlike microcracks for human breath detection. ACS Appl. Mater. Interfaces 2014, 6, 1313–1319. [Google Scholar] [CrossRef]

- Sekertekin, Y.; Bozyel, I.; Gokcen, D. A Flexible and Low-Cost Tactile Sensor Produced by Screen Printing of Carbon Black/PVA Composite on Cellulose Paper. Sensors 2020, 20, 2908. [Google Scholar] [CrossRef] [PubMed]

- Li, K.; Yang, W.; Yi, M.; Shen, Z. Graphene-based pressure sensor and strain sensor for detecting human activities. Smart Mater. Struct. 2021, 30, 085027. [Google Scholar] [CrossRef]

| Material | Fabrication Methods | Gauge Factor | Reference |

|---|---|---|---|

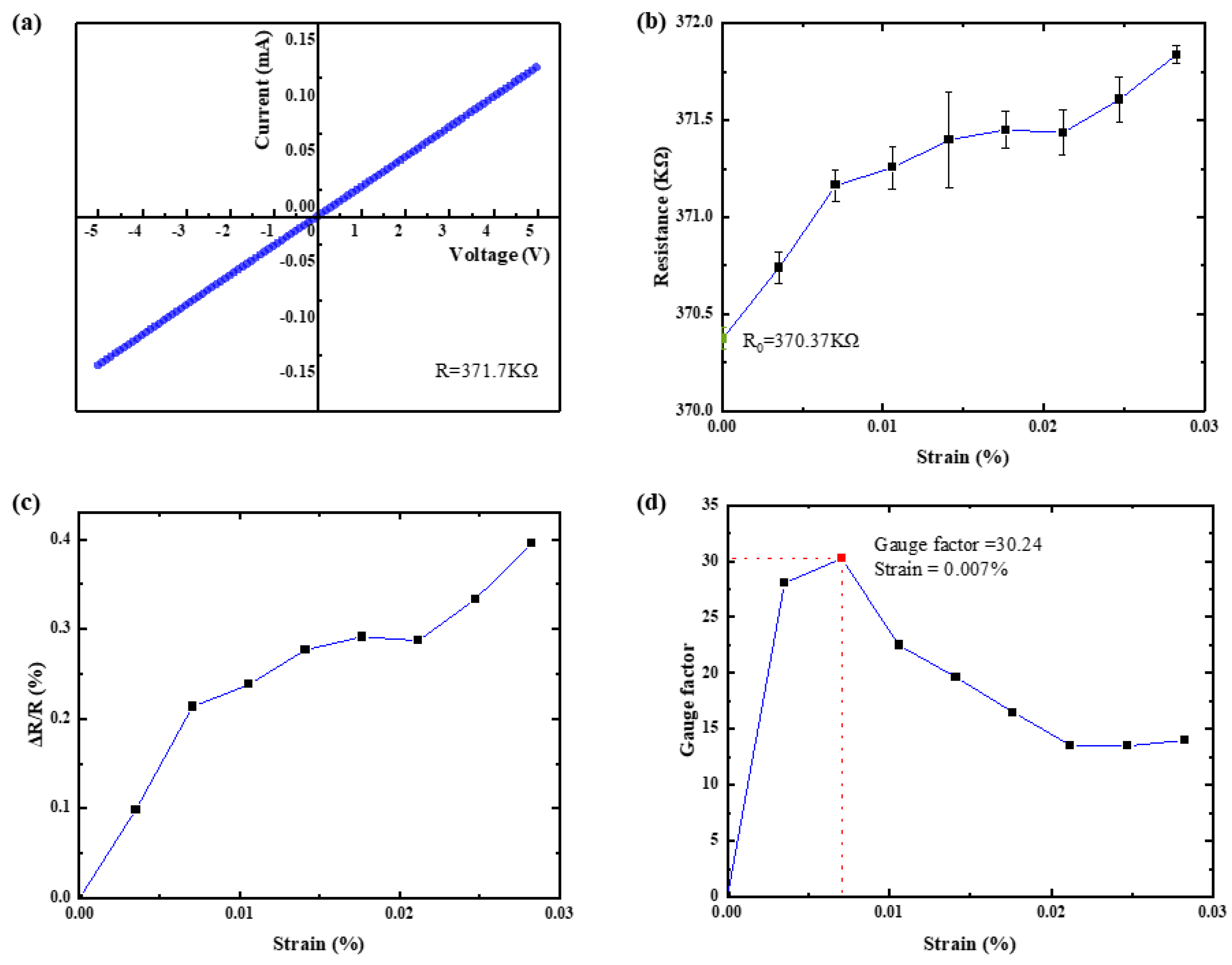

| CB/PVA | Droplet deposition | 30 at 0.007% strain | This work |

| CB/PVA | Spin coating | 150 | [40] |

| CB/PHOTONEECE | Spin coating | 3.3 | [40] |

| CB/AgNPs/TPU | Deposit via surface grafting | 21.12 at 100% strain | [48] |

| PPy/PU | In situ polymerization | 2.32 at 50% strain | [49] |

| SBS/CNT | Solution casting | 120 at 20% | [39] |

| CB/ecoflex | Drop casting | 1.62–3.37 | [37] |

| CNT/NR | Knife coating | 7.08 at 100% | [13] |

| CB/PVA | Screen Printing | 10.68 at 3.21% | [50] |

| Graphene/cotton | Soaking | 83.7 at 27% | [51] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Liu, X.; Wu, X.; Liu, Q.; Wang, Z. A Carbon Black/Polyvinyl Alcohol-Based Composite Thin Film Sensor Integrating Strain and Humidity Sensing Using the Droplet Deposition Method. Crystals 2022, 12, 1316. https://doi.org/10.3390/cryst12091316

Zhang Y, Liu X, Wu X, Liu Q, Wang Z. A Carbon Black/Polyvinyl Alcohol-Based Composite Thin Film Sensor Integrating Strain and Humidity Sensing Using the Droplet Deposition Method. Crystals. 2022; 12(9):1316. https://doi.org/10.3390/cryst12091316

Chicago/Turabian StyleZhang, Yiqun, Xiaoyu Liu, Xiaodong Wu, Qi Liu, and Zhuqing Wang. 2022. "A Carbon Black/Polyvinyl Alcohol-Based Composite Thin Film Sensor Integrating Strain and Humidity Sensing Using the Droplet Deposition Method" Crystals 12, no. 9: 1316. https://doi.org/10.3390/cryst12091316

APA StyleZhang, Y., Liu, X., Wu, X., Liu, Q., & Wang, Z. (2022). A Carbon Black/Polyvinyl Alcohol-Based Composite Thin Film Sensor Integrating Strain and Humidity Sensing Using the Droplet Deposition Method. Crystals, 12(9), 1316. https://doi.org/10.3390/cryst12091316