Broadband Reflective Liquid Crystal Films Prepared by Rapid Inkjet Printing and Superposition Polymerization

Abstract

:1. Introduction

2. Experiments Methods

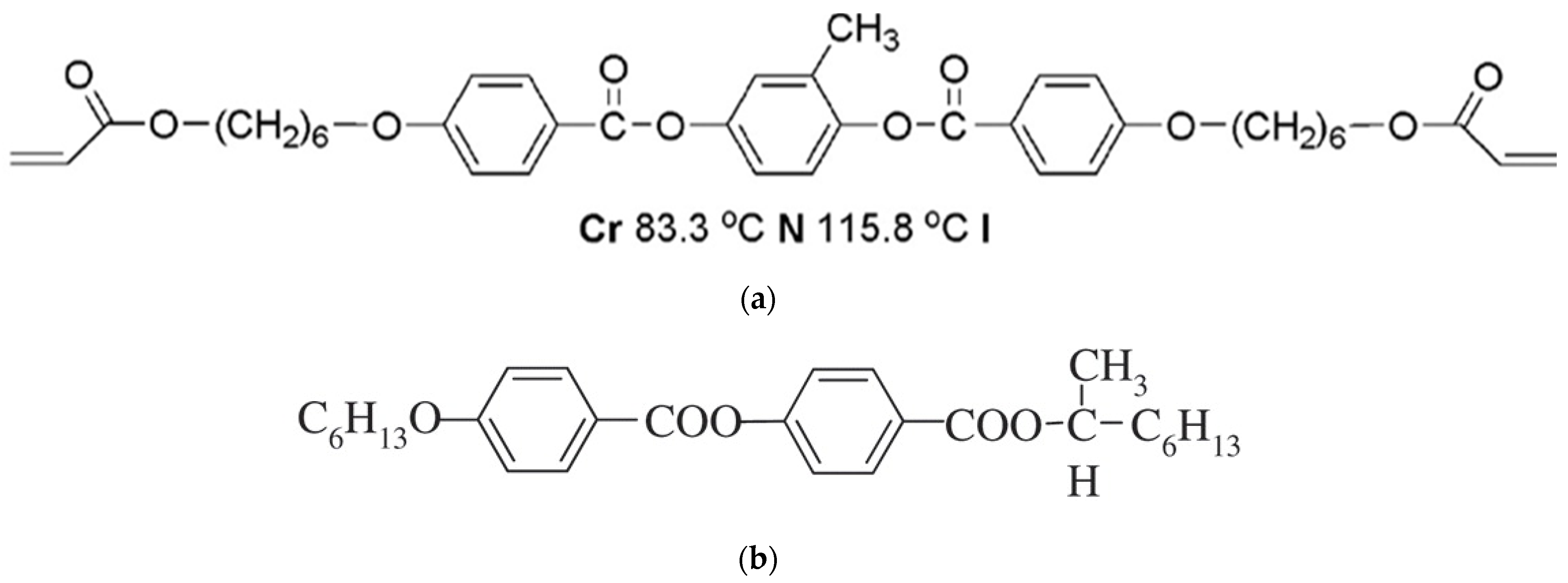

2.1. Materials

2.2. Measurements

2.3. Experimental Methods

2.3.1. Substrate Preparation

2.3.2. Ink Preparation

2.3.3. Composition Variations Design

2.3.4. Preparation of PSCLC Films by Ink Jet Printing

2.3.5. Verified Experiment

3. Results and Discussion

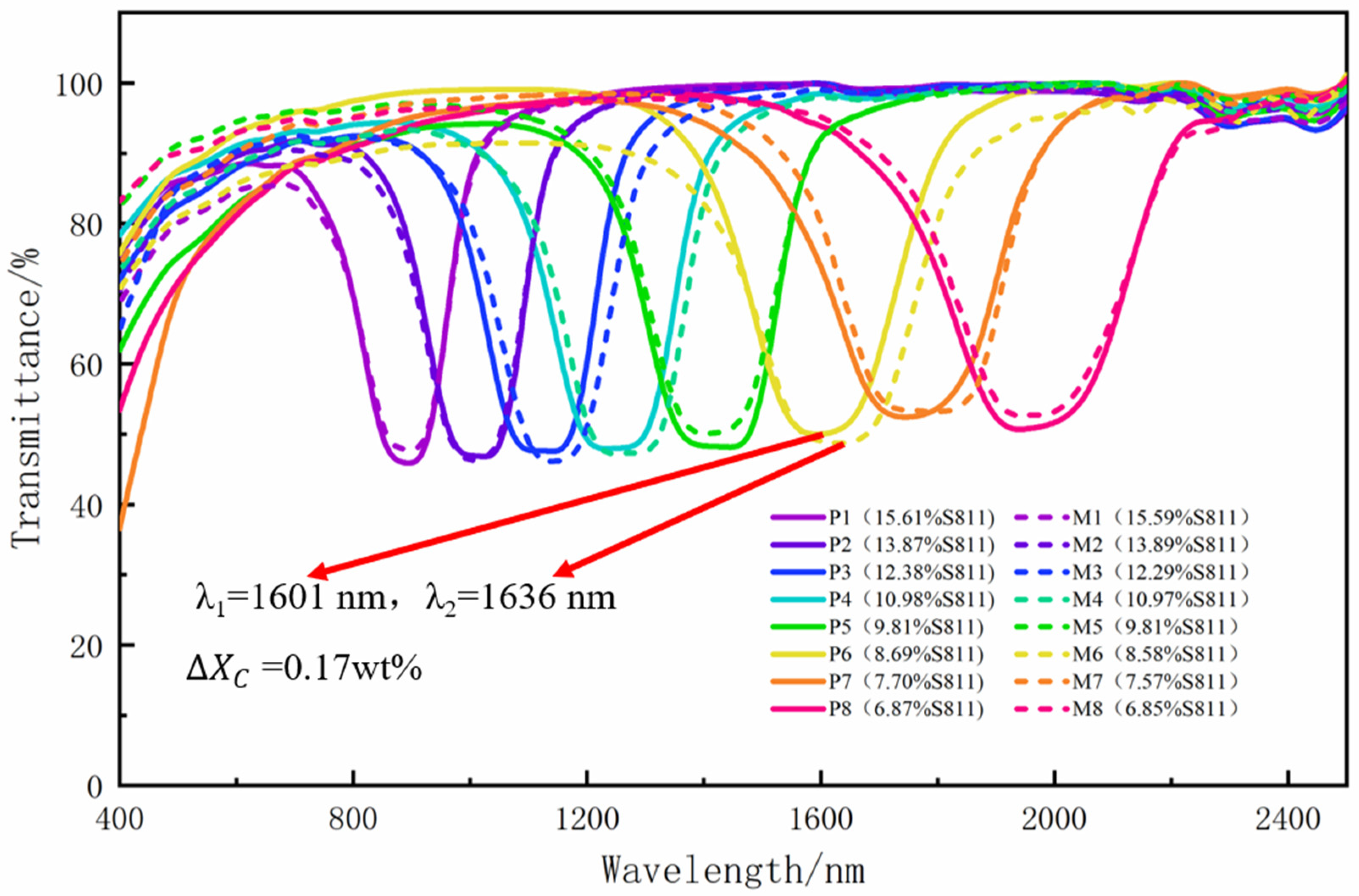

3.1. Establishment of a “Standard Curve”

3.2. Accuracy of Inkjet Printing

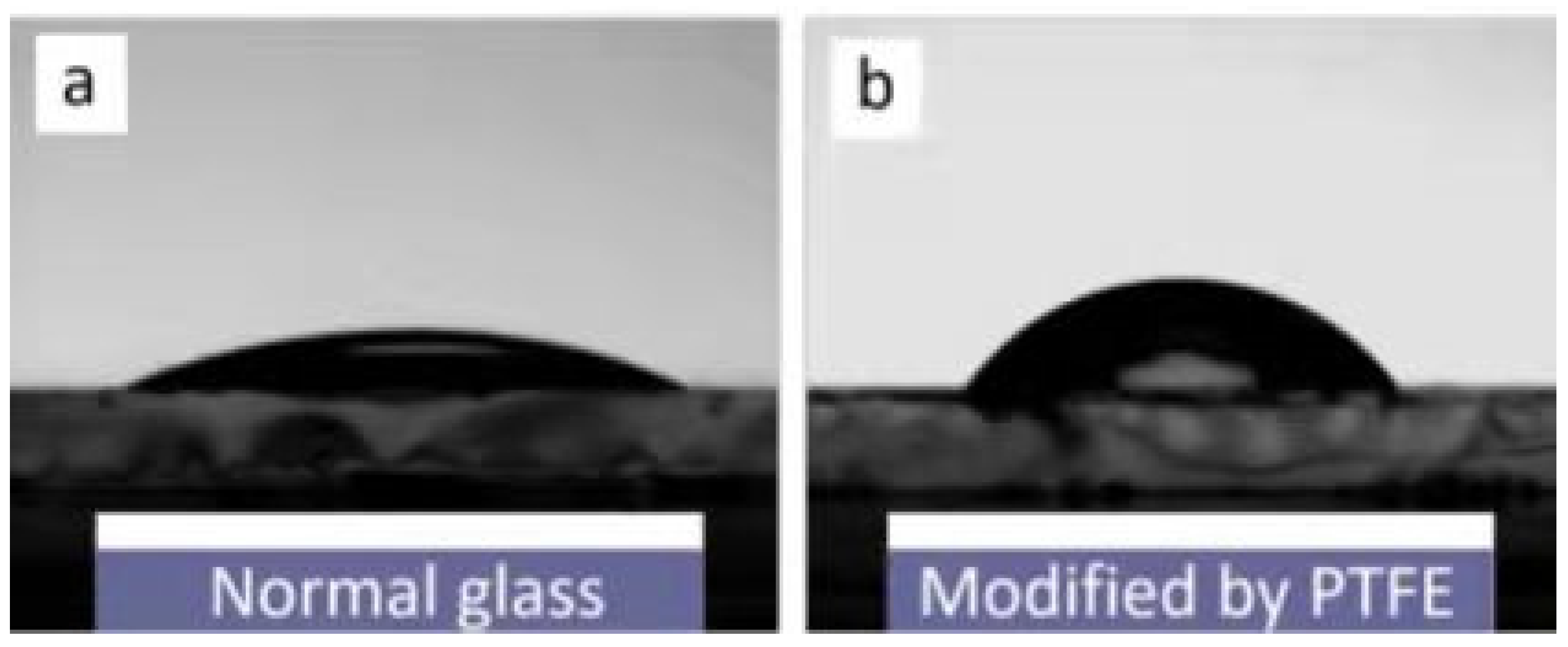

3.3. Principle of Unsticking Technology

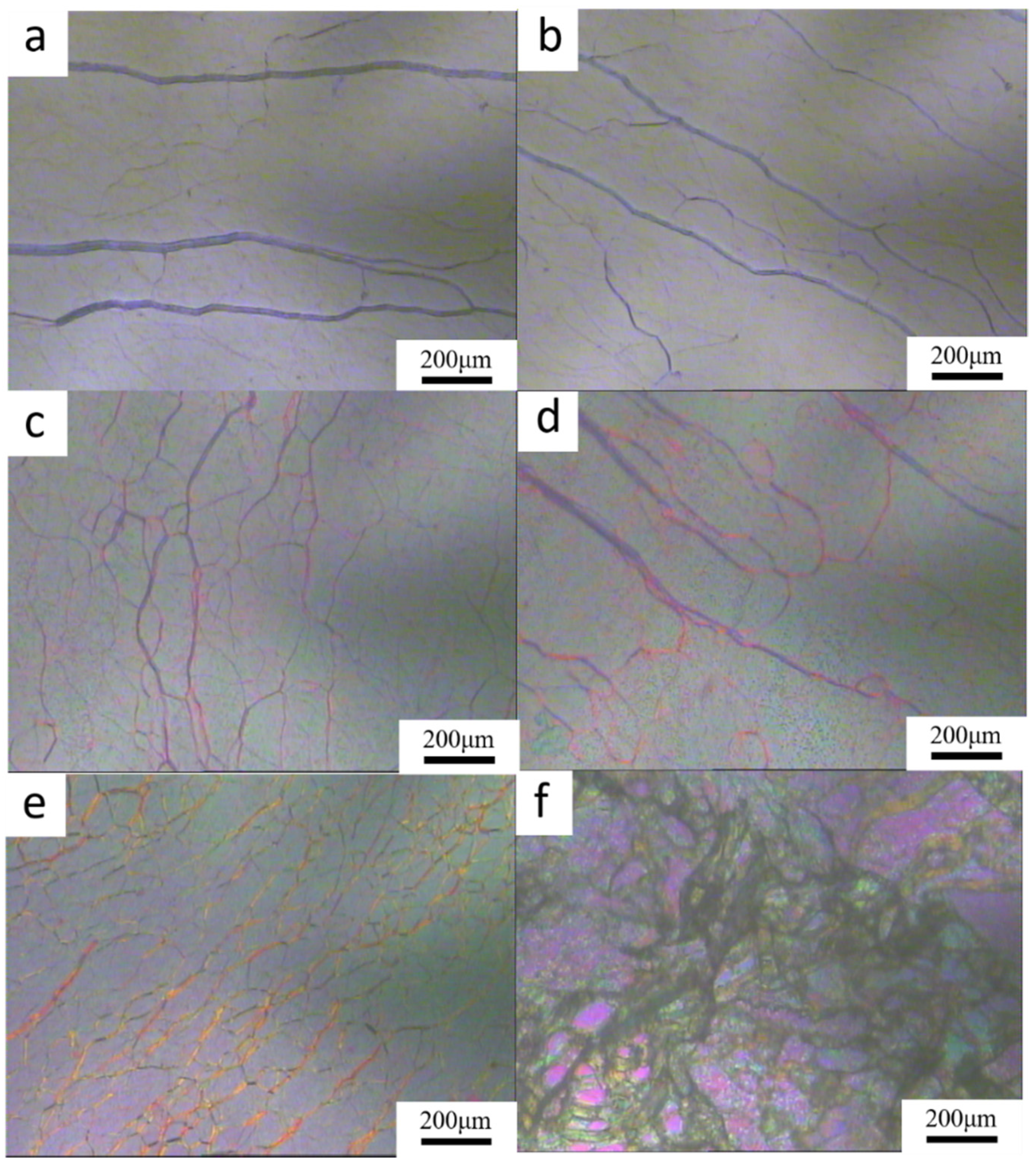

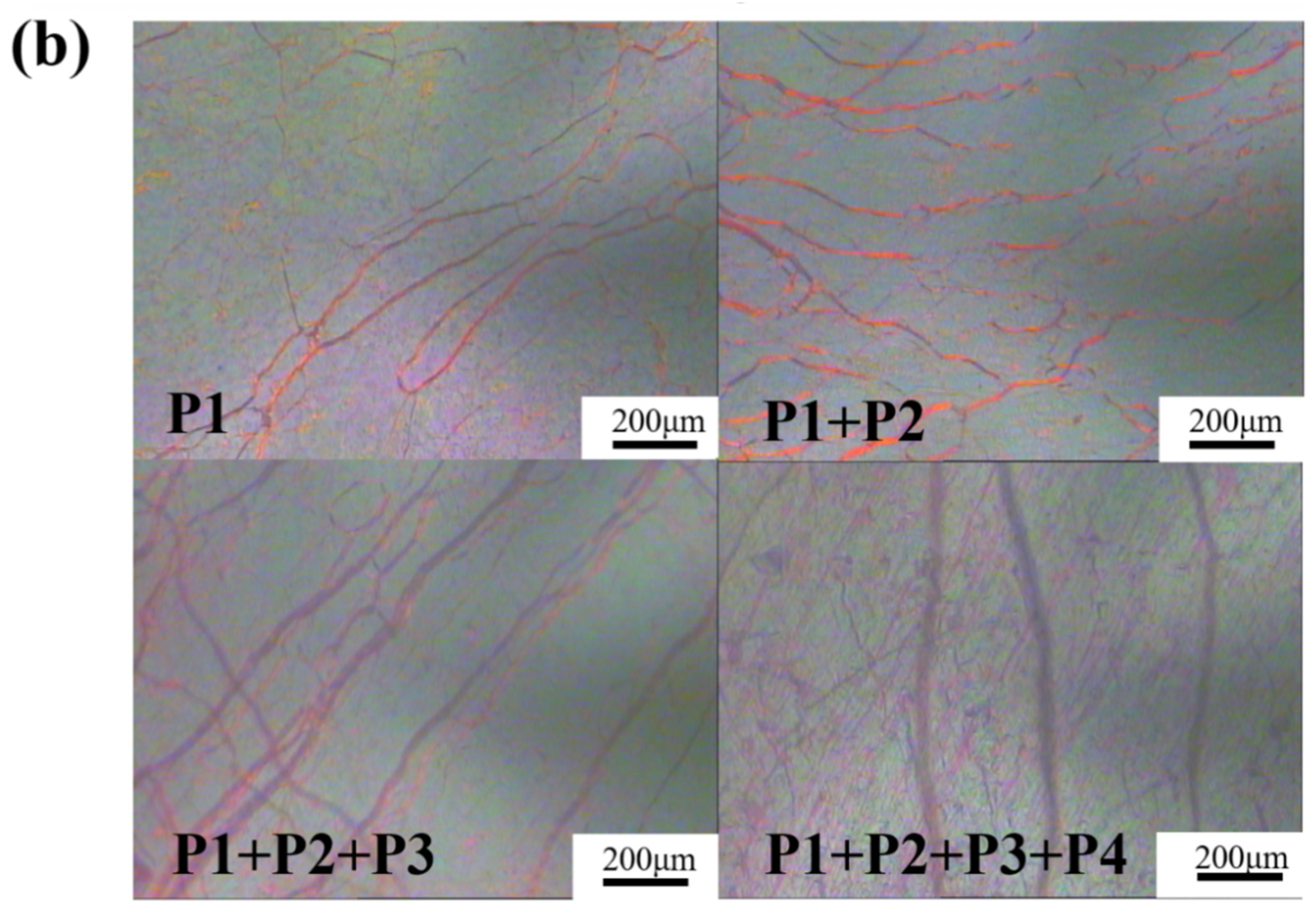

3.4. Morphology of the PSCLC Layer on the Substrate

3.5. Method to Prepare the PSCLC Film with Wide-Band Reflection by IJP Technology

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Acknowledgments

Conflicts of Interest

References

- Liu, S.; Li, Y.; Zhou, P.; Huang, S.; Chen, Q.; Su, Y. 51-3: A Multi-plane Optical See-through Head Mounted Display with Reverse Mode PSLC. SID Symp. Dig. Tech. Pap. 2017, 48, 763–766. [Google Scholar] [CrossRef]

- Fuh, A.Y.G.; Chih, S.Y.; Wu, S.T. Advanced electro-optical smart window based on PSLC using a photoconductive TiOPc electrode. Liq. Cryst. 2018, 45, 864–871. [Google Scholar] [CrossRef]

- Sun, H.; Xie, Z.; Ju, C.; Hu, X.; Yuan, D.; Zhao, W.; Shui, L.; Zhou, G. Dye-Doped Electrically Smart Windows Based on Polymer-Stabilized Liquid Crystal. Polymers 2019, 11, 694. [Google Scholar] [CrossRef] [Green Version]

- Khandelwal, H.; Schenning, A.P.; Debije, M.G. Infrared Regulating Smart Window Based on Organic Materials. Adv. Energy Mater. 2017, 7, 1602209. [Google Scholar] [CrossRef]

- Guo, J.; Wu, H.; Chen, F.; Zhang, L.; He, W.; Yang, H.; Wei, J. Fabrication of multi-pitched photonic structure in cholesteric liquid crystals based on a polymer template with helical structure. J. Mater. Chem. 2010, 20, 4094–4102. [Google Scholar] [CrossRef]

- Khandelwal, H.; Timmermans, G.H.; Debije, M.G.; Schenning, A.P. Dual electrically and thermally responsive broadband reflectors based on polymer network stabilized chiral nematic liquid crystals: The role of crosslink density. Chem. Commun. 2016, 52, 10109–10112. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Zhou, Y.; Wu, S.-T. Broadband circular polarizer using stacked chiral polymer films. Opt. Express 2007, 15, 6414–6419. [Google Scholar] [CrossRef]

- Kang, Y.J.; Bail, R.; Lee, C.W.; Chin, B.D. Inkjet Printing of Mixed-Host Emitting Layer for Electrophosphorescent Organic Light-Emitting Diodes. ACS Appl. Mater. Interfaces 2019, 11, 21784–21794. [Google Scholar] [CrossRef]

- Olivier, S.; Ishow, E.; Della-Gatta, S.M.; Maindron, T. Inkjet deposition of a hole-transporting small molecule to realize a hybrid solution-evaporation green top-emitting OLED. Org. Electron. 2017, 49, 24–32. [Google Scholar] [CrossRef]

- Kang, J.-G.; Koo, Y.; Ha, J.; Lee, C. Invited Paper: Recent Developments in Inkjet-printed OLEDs for High Resolution, Large Area Applications. SID Symp. Dig. Tech. Pap. 2020, 51, 591–594. [Google Scholar] [CrossRef]

- Marin, V.; Holder, E.; Wienk, M.M.; Tekin, E.; Kozodaev, D.; Schubert, U.S. Ink-jet printing of electron donor/acceptor blends: Towards bulk heterojunction solar cells. Macromol. Rapid Commun. 2005, 26, 319–324. [Google Scholar] [CrossRef]

- Holder, E.; Langeveld BM, W.; Schubert, U.S. New trends in the use of transition metal-ligand complexes for applications in electroluminescent devices. Adv. Mater. 2005, 17, 1109–1121. [Google Scholar] [CrossRef]

- Hoth, C.N.; Schilinsky, P.; Choulis, S.A.; Brabec, C.J. Printing Highly Efficient Organic Solar Cells. Nano Lett. 2008, 8, 2806–2813. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alamán, J.; Alicante, R.; Peña, J.I.; Sánchez-Somolinos, C. Inkjet Printing of Functional Materials for Optical and Photonic Applications. Materials 2016, 9, 910. [Google Scholar] [CrossRef] [Green Version]

- Crowley, K.; O’Malley, E.; Morrin, A.; Smyth, M.R.; Killard, A.J. An aqueous ammonia sensor based on an inkjet-printed polyaniline nanoparticle-modified electrode. Analyst 2008, 133, 391–399. [Google Scholar] [CrossRef]

- Ma ZL, S.; Wang, H.T. Advanced electronic skin devices for healthcare applications. J. Mater. Chem. B 2019, 7, 173–197. [Google Scholar]

- Cull, T.; Goulding, M.; Bradley, M. A parallel high-throughput approach to liquid crystal screening. Rev. Sci. Instrum. 2005, 76, 062216. [Google Scholar] [CrossRef] [Green Version]

- Cull, T.R.; Goulding, M.J.; Bradley, M. Liquid Crystal Libraries—Ink-jet Formulation and High-Throughput Analysis. Adv. Mater. 2007, 19, 2355–2359. [Google Scholar] [CrossRef]

- Feng, W.; Li, L.; Du, X.; Welle, A.; Levkin, P.A. Single-Step Fabrication of High-Density Microdroplet Arrays of Low-Surface-Tension Liquids. Adv. Mater. 2016, 28, 3202–3208. [Google Scholar] [CrossRef] [Green Version]

- Dhanumalayan, E.; Joshi, G.M. Performance properties and applications of polytetrafluoroethylene (PTFE)—A review. Adv. Compos. Hybrid Mater. 2018, 1, 247–268. [Google Scholar] [CrossRef]

- Broer, D.J.; Lub, J.; Mol, G.N. Wide-band reflective polarizers from cholesteric polymer networks with a pitch gradient. Nature 1995, 378, 467–469. [Google Scholar] [CrossRef]

| Sample No. | Print Formulation (wt%) | |||

|---|---|---|---|---|

| S811 | SLC-1717 | C6M | IRG 651 | |

| P1 | 15.61 | 68.37 | 15.03 | 0.99 |

| P2 | 13.87 | 70.09 | 15.03 | 1.01 |

| P3 | 12.38 | 71.59 | 14.99 | 1.04 |

| P4 | 10.98 | 72.95 | 15.02 | 1.05 |

| P5 | 9.81 | 74.12 | 15.00 | 1.07 |

| P6 | 8.69 | 75.27 | 14.95 | 1.09 |

| P7 | 7.70 | 76.18 | 15.01 | 1.11 |

| P8 | 6.87 | 77.02 | 14.99 | 1.12 |

| Sample No. | Manual Formulation (wt%) | |||

|---|---|---|---|---|

| S811 | SLC-1717 | C6M | IRG651 | |

| M1 | 15.59 | 68.37 | 15.06 | 0.99 |

| M2 | 13.89 | 70.05 | 15.05 | 1.02 |

| M3 | 12.29 | 71.76 | 14.92 | 1.03 |

| M4 | 10.97 | 73.00 | 14.96 | 1.08 |

| M5 | 9.81 | 74.13 | 14.97 | 1.10 |

| M6 | 8.58 | 75.45 | 14.84 | 1.14 |

| M7 | 7.57 | 76.53 | 14.78 | 1.12 |

| M8 | 6.85 | 77.24 | 14.82 | 1.09 |

| Sample No. | Print Formulation (wt%) | |||

|---|---|---|---|---|

| S811 | SLC-1717 | C6M | IRG 651 | |

| P1 | 10.98 | 72.95 | 15.02 | 1.05 |

| P2 | 8.69 | 75.27 | 14.95 | 1.09 |

| P3 | 6.87 | 77.02 | 14.99 | 1.12 |

| P4 | 6.12 | 77.75 | 15.00 | 1.13 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, W.; Yao, D.; Luo, S.; Xiong, R.; Yuan, X. Broadband Reflective Liquid Crystal Films Prepared by Rapid Inkjet Printing and Superposition Polymerization. Crystals 2022, 12, 473. https://doi.org/10.3390/cryst12040473

He W, Yao D, Luo S, Xiong R, Yuan X. Broadband Reflective Liquid Crystal Films Prepared by Rapid Inkjet Printing and Superposition Polymerization. Crystals. 2022; 12(4):473. https://doi.org/10.3390/cryst12040473

Chicago/Turabian StyleHe, Wanli, Daipeng Yao, Shiguang Luo, Ruijuan Xiong, and Xiaotao Yuan. 2022. "Broadband Reflective Liquid Crystal Films Prepared by Rapid Inkjet Printing and Superposition Polymerization" Crystals 12, no. 4: 473. https://doi.org/10.3390/cryst12040473

APA StyleHe, W., Yao, D., Luo, S., Xiong, R., & Yuan, X. (2022). Broadband Reflective Liquid Crystal Films Prepared by Rapid Inkjet Printing and Superposition Polymerization. Crystals, 12(4), 473. https://doi.org/10.3390/cryst12040473