1. Introduction

Cooling crystallization is a key unit operation in pharmaceutical and fine chemical industries. Tight control of product quality characteristics, such as median particle size and particle size distribution (PSD), is crucial in this product segment [

1]. At present, these small-scale crystallization processes with production rates below one ton per year are predominantly conducted batchwise due to challenging solid handling at small volume flow rates [

2,

3]. Nevertheless, continuous processes offer improved product consistency and the use of smaller equipment than conventional batch processes [

4].

Different crystallizer characteristics affect the feasibility of a continuous process and the product quality: An essential requirement for stable operation is sufficient suspension and transport of the particles avoiding sedimentation, agglomeration, and blockages. Ideally, the energy input is without high shear forces in order to minimize crystal attrition and breakage. The residence time distribution of the liquid phase (RTD

L) also influences the operation. It determines the concentration profile and hence the supersaturation profile and thus affects the kinetics and the attainable PSD. Moreover, the traceability of out-of-spec material depends in particular on knowledge of the RTD

L [

3,

5].

The two main concepts of continuous crystallizers are the mixed-suspension mixed-product removal (MSMPR) and tubular concepts [

6]. A significant benefit of the MSMPR concept is the decoupling of suspension degree and volume flow rate and, thus, residence time [

6]. On the other hand, high local shear intensities near the stirrer are disadvantageous, facilitating crystal attrition and breakage [

1]. The RTD

L is broad, whöich can be compensated by cascading multiple vessels, but the number is limited and usually ranges from two to four [

6]. Moreover, material transfer from one vessel to the other turns out to be challenging [

7]. For tubular configurations, a narrower RTD

L up to ideal plug flow can be achieved by different flow adaptions, e.g., segmentation of the mother liquor into slug flow [

4,

8]. Nevertheless, in most cases, the degree of suspension depends on volume flow rate and residence time [

6]. Additionally, due to the high surface-to-volume ratio, encrustations are more likely to cause blockages [

5].

The Taylor–Couette Crystallizer (TCC) is a promising alternative as it merges advantages of both configurations. It features homogeneous and gentle mixing without local shear peaks, decoupled from the net flow [

9,

10]. Moreover, the RTD

L is adjustable in a wide range by varying the operating and design parameters [

11]. However, it should be mentioned that the local mixing intensity and, thus, particle suspension and the RTD

L in a TCC cannot be adjusted independently [

12]. Concerning these characteristics, the TCC shows remarkable similarities to the continuous oscillatory flow baffled crystallizer [

13,

14].

A TCC, as shown in Figure 2, consists of two concentric cylinders placed inside each other, of which the inner one rotates (rotor) while the outer one is commonly held stationary (stator) for technical applications. By surpassing a critical rotation rate, a flow instability leads to a transition from pure azimuthal laminar Couette flow (LCF) to laminar Taylor vortex flow (LTVF) characterized by toroidal counter-rotating Taylor vortices (see Figure 3 and the related

Videos S1–S4 in the Supplementary Materials) [

10,

15].

An essential characteristic of the vortex structure is low intervortex mass transfer across vortex boundaries accompanied by improved local mixing described by the intravortex mass transfer. This behavior leads to the model representation that each vortex resembles a stirred tank. However, it could be shown that the mixing intensity in LTVF shows local differences, leading to a well-mixed outer “shell” and a weakly mixed vortex core [

16].

By increasing the rotation rate, local mixing and, thus, the degree of suspension improves. At the same time, another flow transition occurs, and azimuthal waves superimpose the vortex structure leading to the so-called wavy Taylor vortex flow (WTVF). Due to the vortex deformation, their boundaries decompose locally, increasing intervortex mass transfer [

17]. At even higher rotation rates, turbulent structures appear until, eventually, the wavy motion diminishes. The flow becomes purely turbulent while preserving its cellular character in the turbulent Taylor vortex flow (TTVF) [

10,

15].

When an axial flow is added, the vortices move and carry the liquid trapped inside from the inlet to the outlet (see

Video S1 in the Supplementary Materials) [

18]. Depending on the operating point, the axial displacement velocity of the vortices may decrease up to complete stagnation [

18]. In this case, an additional bypass stream accounts for the superimposed net flow. While the displacement velocity depends on the rotation and volume flow rates, no clear trend is discernible in the literature, as the observed velocities show significant variation [

12,

19].

Across the different flow regimes, RTD

Ls range from nearly ideal plug flow in LTVF with low rotation rates to almost complete backmixing in TTVF with high rotation rates [

11]. Several studies used different modeling approaches to address the RTD

L. A broad review can be found, e.g., in [

20]. For example, Moore and Cooney [

11] developed an empirical correlation based on the classical 1D dispersion model, incorporating various flow regimes for different design parameters. Richter et al. [

21] developed a phenomenological model based on the cellular nature of Taylor–Couette flow. They discretized the apparatus volume into the individual vortices and solved a mass balance for each vortex. The further models address, with increasing complexity, additional phenomena such as bypass flow and inhomogeneous mixing inside the vortices [

16,

22].

Solid–liquid flows have also been the subject of several investigations. It is noticeable in the literature is that most of the studies of Taylor–Couette applications have a vertical set-up with a flow from bottom to top: Ma and Cooney [

23] investigated a Taylor–Couette system for adsorption using chitin resin particles (

= 40–100 µm;

= 1500 kg

m

−3) in disrupted cell suspensions with water-like properties. They showed that the particles concentrated at the bottom of the apparatus despite complete particle suspension.

Similar behavior was described by Resende et al. [

24]. They investigated the suspension of porous agarose gel particles (volume fraction: 10%;

= 214 µm;

= 1080–1230 kg

m

−3 depending on the liquid used) and the RTD

L, as well as the residence time distribution of the solid phase (RTD

S) in a Taylor–Couette reactor. By using water with different proportions of glycerol, they were able to determine the effect of viscosity on solids suspension. They found that at high viscosity (

= 10.7 mPas), complete suspension was already possible in the LTVF regime, whereas with pure water, the particles were fluidized only in the turbulent regime. In the LTVF regime, the mean residence time of the liquid phase was significantly reduced by the presence of the particles, while the mean residence time of the particles was significantly larger than that of the liquid. This also showed a concentration of the particles in the apparatus despite complete suspension. With another study using similar particles, Resende et al. [

25] found that particles (volume fraction: 2%) in the TTVF did not affect the RTD

L and, moreover, that there was no measurable difference between RTD

S and RTD

L.

Ibáñez-González et al. [

26] used a Taylor–Couette apparatus as an expanded bed adsorber. Agarose gel particles with quartz core (volume fraction: 21–31%;

= 100–300 µm;

= 1200 kg

m

−3) were used as the adsorbent. Complete suspension of the particles was already able to be achieved in the LTVF regime. They were also able to show that the particles accumulated in the lower part of the apparatus when the volume flow rate was appropriately adjusted. Thus, a stable expanded bed was able to be generated and a mesh for retention at the outlet was able to be omitted. In addition, they showed that—compared to the correlation established by Moore and Cooney [

11]—no deviations of the RTD

L to pure liquid transport were able to be detected up to bed heights of 20 cm (apparatus length

= 95 cm), but the results scattered up to 25%.

Contradictory results were obtained by Rida et al. [

27] and Dherbécourt et al. [

20]. In their studies, they investigated the influence of neutrally buoyant particles (volume fraction: 0–8%;

= 800–1500 µm) on local micromixing and axial dispersion in LTVF and WTVF regimes without axial flow. The particles led to a significant intensification of local mixing inside the vortices as well as macroscopically between the vortices for both regimes, with a more pronounced effect in the LTVF regime. They attributed this behavior, among other things, to the perturbation of the flow and the drag between particles and fluid. Furthermore, it was visually confirmed that particles did not optimally follow streamlines and broke vortex boundaries, increasing material transport between adjacent vortices.

These studies have in common the fact that vertical bottom-up operation involves the risk of particles accumulating in the apparatus, which increases the risk of blockage during a crystallization process with accompanying particle growth. Although this effect can be counteracted by a suitable rotation rate or volumetric flow rate selection, the possible operating window is restricted in this way. In contrast, vertical top-down operation circumvents this challenge. However, the effect of gravity can reduce the particle residence time since the particles can “fall through” the vortices, as shown in [

28]. Accordingly, the horizontal operation mode shows potential for a crystallization process, although no investigations are yet available regarding the rotation rate required for the suspension of particles.

It becomes clear that the lowest possible rotation rate must be used to achieve a narrow RTDL. At the same time, complete suspension of the particles must always be ensured, which accordingly limits the operating window as a fundamental prerequisite for stable operation in crystallization applications.

Therefore, this paper aimed to understand the interplay between suspension and RTD

L in the TCC to be able to choose the optimal design parameters for defined requirements or predict optimal operating parameters for a given TCC configuration. For this purpose, the necessary rotation rate and flow regime for complete particle suspension was first determined for different rotor and stator radius ratios, particle sizes, and mass fractions. On this basis, a correlation was established, which calculated this just-suspended rotation rate. Furthermore, the effect of particles on the RTD

L in an operating window relevant for cooling crystallization was investigated on the basis of tracer experiments and was compared to the correlation established by Moore and Cooney [

11]. Finally, the results were combined so that a prediction was possible.

3. Results and Discussion

In this section, the flow transitions are first presented. Subsequently, the suspension experiments’ results are presented to discuss the RTDL for operating regions with complete suspension. Subsequently, a combination of the correlation of the just-suspended rotational Reynolds number developed here with a correlation of the RTDL known from literature is presented. The aim was to find a design that allows suspension at the lowest possible rotational Reynolds number in order to obtain the largest possible operating window and to be able to set the RTDL most flexibly.

3.1. Flow Regime Transitions

The flow regime transitions were considered for the radius ratios

= 0.5, 0.7, and 0.84 (cf.

Table 2) with varying rotor radii and one constant stator radius to obtain an overview of the range investigated in the suspension experiments. Qualitative observations are first described; then, the respective flow transitions are discussed.

Due to the superimposed inlet flow, a region of undirected flow occured at the inlet. The width of this area corresponded approximately to the width of a vortex pair. It was minimized by the fact that the inlet was attached tangentially to the stator and pointed in the rotor’s rotation direction. Accordingly, the inlet flow should correspond to the direction of the Taylor–Couette flow to generate as many vortices as possible and maximize their benefits on suspension and RTD

L. Consistent with literature [

18], new vortices periodically formed from the inlet region, migrated through the apparatus, and collapsed at the outlet. If the change in rotation rate resulted in a change in the flow regime, this did not directly affect the entire apparatus but only the newly formed vortices. These moved through the apparatus and thus displaced the prevailing flow regime. This behavior can be seen in

Figure 3a for the radius ratio

= 0.7, where the different flow regimes were separated at the vertical line: The newly forming wavy vortices showed turbulences, while the present vortices retained their laminar wavy nature. Accordingly, the complete formation of a new flow regime took at least one residence time.

Exemplary images of the three observed flow regimes are shown in

Figure 3b, and the flow regime transitions are presented in

Figure 4, while the respective data are listed in

Table S1 in the Supplementary Materials. The onset of LTVF shifted towards higher rotational Reynolds numbers as the radius ratio increased. This relationship is given by the linear stability theory of the Taylor–Couette flow and was also validated experimentally [

44]. The LTVF region became larger for smaller radius ratios, which also agrees with the findings of Nemri et al. [

45] and DiPrima et al. [

46].

The wavy flow was not present for the radius ratio

= 0.5. Here, the laminar flow transitioned directly into the turbulent flow. This absence of the WTVF was described by Coles [

15] for radius ratios smaller than around

= 0.714. Nevertheless, in our investigations, WTVF also occurred for the radius ratio

= 0.7. This could have been due to the slight difference between the values and manufacturing tolerances of the glass stator used, which was also observed by Nemri et al. [

45] for

= 0.687.

Increasing rotational Reynolds numbers within the WTVF showed an increasing occurrence of local turbulence (cf.

Figure 2a). While further subdivisions of this regime into complementary subcategories can be found in the literature (e.g., [

47,

48]), the entire rotational Reynolds number range in which wavy flows occur is referred to here as WTVF for simplicity.

It can be seen that the WTVF region was more pronounced for the radius ratio = 0.84, and the TTVF started at much higher rotational Reynolds numbers than for the radius ratio = 0.7. Accordingly, the operating window for achieving minimum dispersion became larger for larger radius ratios.

3.2. Particle Suspension

At first, the general flow behavior of the particles in the TCC is discussed exemplarily for the geometry

= 0.7. Since the volumetric flow did not influence the suspension in the range we investigated, all experiments were carried out at the constant axial Reynolds number

= 15.67. Different states of suspension were observable in the TCC, exemplarily depicted in

Figure 5. If the rotor’s energy input was insufficient to suspend all particles, sediment would periodically form between the vortex pairs (a). This phenomenon occurred due to the velocity distribution in the annular gap: Caused by the Taylor vortices, the azimuthal direction of motion generated by the rotor is superimposed by velocity components in radial and axial directions [

49]. At the boundaries between two vortices, the axial component becomes zero. The flow is either directed towards the rotor—also called inflow boundary—or towards the stator—also called outflow boundary [

49,

50].

It is known from the literature that the azimuthal velocity component is minimal at the inflow boundary [

51]. Accordingly, particles forced against the stator by centrifugal force settled as soon as they reached the inflow boundary (see

Figure 5a and the corresponding

Video S5 in the Supplementary Materials).

Although the particles in the center of the sediment did not move, macroscopically, the sediment migrated with the vortices through the apparatus. This was because the particles at the edge of the sediment reached areas of higher azimuthal and axial velocities as a result of the movement of the vortices and could eventually be resuspended.

When the rotation rate was increased, the velocities in the area of the inflow boundary also increased. As a result, the sediment became narrower until a point was reached at which the particles no longer remained settled but were pushed along with the flow in the azimuthal direction (see

Figure 5b).

Regarding the statistical evaluation of the acquired experimental data listed in

Table S2 in the Supplementary Materials, the regression coefficients

of Equation (6) were calculated. The result was obtained according to Equation (18).

With a degree of freedom of 29, the coefficient of determination was

= 0.991, which—like the parity plot in

Figure 6—showed that the model describes the suspension criterion well. Since the coefficient of determination can only improve by adding independent variables, the adjusted coefficient of determination

was also considered [

38]. It avoids distortion due to examining several independent variables [

38]. With

= 0.99, the good fit was still validated.

The statistical significance of the regression was examined by observing the regression as a whole and the individual regression coefficients. For the overall function, the

-value of the

-statistic was considered. This parameter describes the probability with which the tabulated F-value of the random variable is greater than the empirical F-value; thus, the probability that the relationship is not statistically significant. In other words, if

is smaller than the required significance level

—here:

= 0.05—the correlation is statistically significant. In deviation, the

-value of Student’s

-statistic was used for the individual regression coefficients. However, the evaluation scheme remained the same here [

38].

The

-values in

Table 3 show that the model correlation and all influencing variables are to be considered statistically significant since they are substantially smaller than the required significance level

= 0.05.

For assessing the impacts on the just-suspended rotational Reynolds number, the effect of each influencing parameter was calculated using Equation (18). This was done by determining the change in

when each influencing factor is changed from its smallest to its largest value, with the other factors averaged. The radius ratio’s effect with a change of

= −6635 thereby exceeds that of the Archimedes number and the particle mass fraction with

= 352 and 571, respectively. This finding is underlined in

Figure 7, showing the dependence of

on the radius ratio, particle size, and mass fraction. Regarding the crystallization process, this result is favorable since the Archimedes number and the particle mass fraction are target values predetermined by the material system and process conditions. In the following, these influences are discussed individually.

The rotational Reynolds number to achieve the just-suspended state decreased following a linear trend for the increasing radius ratio. Accordingly, the degree of turbulence also decreased with the increasing radius ratio, which could have reduced axial dispersion. It is noteworthy that the geometry = 0.84 enabled complete suspension already in the WTVF regime, while for all other geometries investigated, TTVF was necessary.

As the mass fraction of particles increased,

also increased. This behavior is to be expected and is explained by the fact that an increased number of particles represents an additional force input into the fluid, which must be compensated by an increased momentum [

52]. Moreover, the higher number of particles also increases the friction between the fluid and the particles, resulting in an raised apparent suspension viscosity (cf.

Section 2.3.1), and thus the dissipated power increased [

40]. Accordingly, the energy input needed to be increased by increasing the rotation rate and hence the rotational Reynolds number. The dependence appeared to be approximately linear, which can be seen in more detail in

Figures S2–S7 in the Supplementary Materials. In conventional stirred tanks, on the other side, a dependence

is assumed [

40]. However, this cannot be directly applied to the Taylor–Couette system. If the apparent suspension viscosity was used in the calculation of

, the increase in the just-suspended rotation rate would be counteracted by the increase in the viscosity (cf. Equation (3)), resulting in lower just-suspended rotational Reynolds numbers.

For increasing particle sizes,

also increases. Since the particle mass increases faster than the surface, the force for particle fluidization must increase [

40]. The influence of the particle size, however, was found to be less pronounced than the mass fraction’s influence (cf.

Figures S2–S7 in the Supplementary Materials).

In summary, both particle size and mass fraction had a minor influence on the just-suspended rotational Reynolds number only. This fact is advantageous because these parameters are non-adjustable quantities in a crystallization process but are predetermined by the specifications and the material system. Thus, the increase in

and

in the TCC’s axial direction during a crystallization process does not pose the risk of excessive sedimentation, encrustation, and eventually blockage. Nevertheless, the rotation rate should be chosen high enough for complete suspension of the final particle size and mass fraction, which might broaden the RTD

L. On the other hand, minor changes to the rotor and stator radii can significantly affect the suspended state. Thus, the intensity of the local and the axial mixing can be precisely adjusted since these depend particularly on the rotational Reynolds number [

47]. In the following, we examine how the impacts of the influencing parameters on the just-suspended rotational Reynolds number affected the RTD

L and whether the achievable residence time distribution in the completely suspended state can be predicted using the regression Equation (18) established here.

3.3. Liquid Phase Residence Time Distribution

First, we checked whether the presence of particles influenced the mean residence time of the liquid phase. For this purpose, the mean values and standard deviations of the normalized arithmetic mean residence times

(Equation (12)) were calculated for both the experiments performed with particle-free solution and suspension. The comparison of the values with

= 1.04 ± 0.05 and

= 1.07 ± 0.07 made it clear that the particles had no influence on the mean residence time of the fluid within the scope of the measurement accuracy achieved here. All results of the RTD

L experiments can be found in

Table S3 in the Supplementary Materials.

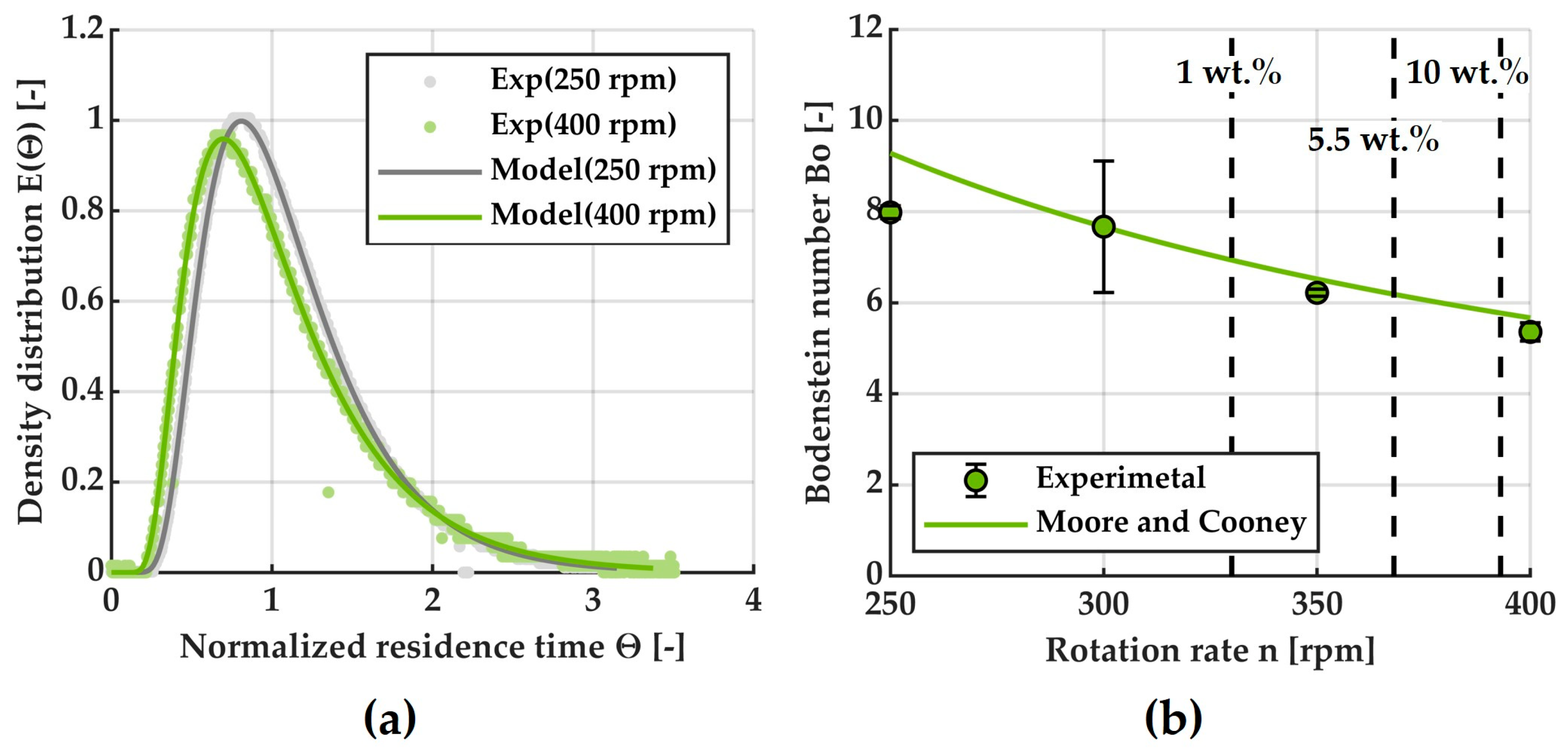

The suitability of the one-zone cell model (cf.

Section 2.3.2) to reproduce the measured RTD

Ls is exemplarily depicted for the radius ratio

= 0.7 and particle-free solution in

Figure 8a. It shows the impulse responses for two operating points that covered the just-suspended rotation rates in a broad range. As can be seen, the model reproduced the experimental data very well. Accordingly, the assumption of perfect mixing of the liquid phase inside the vortices was valid. Furthermore, the rotation rate increase showed a slight increase in the axial dispersion only.

Figure 8b shows this effect in more detail on the basis of the Bodenstein numbers within this range of rotation rates. In addition, the results were compared with an empirical correlation for the Bodenstein number in the Taylor–Couette system of Moore and Cooney [

11] described by Equation (19).

The correlation can describe the Bodenstein numbers with sufficient accuracy. The RTD

L is quite broad and far from plug flow conditions for these operating points. With the Bodenstein numbers achieved, the residence time behavior is comparable to an MSMPR cascade of two to four vessels, which matches the amount commonly employed in crystallization processes [

4]. In this respect, the TCC is convincing because the particles are suspended more gently than with conventional stirrers [

12], and only one apparatus is required. Accordingly, the effort required for operation is reduced, and the challenging transfer of the suspension from vessel to vessel is omitted [

7].

Considering the just-suspended rotation rates for the different mass fractions (dashed lines in

Figure 8b) confirmed the assumption that the RTD

L changes only slightly due to the change in the required rotation rate caused by the expected increase in the mass fraction in a crystallization process. Therefore, at a fixed radius ratio, it is possible to operate the apparatus “on the safe side” with respect to the suspension without significant broadening in the RTD

L.

3.4. Prediction of Liquid Phase Residence Time Distribution in a Just-Suspended State

The results so far show that the requirement of complete particle suspension decisively determines the achievable RTD

L in the TCC. Depending on the apparatus geometry, operation in TTVF or WTVF is required, characterized by high axial dispersion. For design purposes, it is, therefore, useful to be able to predict the attainable RTD

L in the just-suspended state. For this purpose, the calculation procedure depicted in

Figure 9, which links the just-suspended correlation established in this study (Equation (18)) to the correlation of Moore and Cooney [

11] (Equation (19)), is proposed.

The procedure is as follows: As a first step, the target variables resulting from the crystallization process, i.e., volume flow rate , mass fraction , and median particle size , are defined as inputs. Depending on the material system and its crystallization kinetics, the residence time , necessary to achieve the defined particle properties, can be estimated. In combination with the volume flow rate, the required volume of the TCC is then calculable. The degrees of freedom that can be varied for this purpose are, e.g., the apparatus’s length and the radius ratio as inputs—making the radii of stator and rotor dependent variables. With this, the just-suspended rotational Reynolds number and, eventually, the Bodenstein number can be calculated. Then, as the final step, it is to be decided whether the TCC is a proper choice regarding its RTDL. to achieve the targeted PSD. For this, the effect of on the PSD has to be quantified in another study.

To verify this method, we applied it in a slightly modified way along the apparatus at hand in this study. The available parameter space was limited by the constant apparatus length so that the residence time was not fixed. The particle size and mass fraction were set constant to

= 348.82 µm (

= 80.75) and

= 5.5 wt.%, respectively. This seemed to be reasonable since the influences on

were minor. The radius ratio was varied in the range

= 0.5–0.84 by changing the rotor radius while keeping the stator radius set constant at

= 26.8 mm. The volume flow rates were calculated from the two axial Reynolds numbers

= 3.92 and

= 15.67. The results of the prediction are shown in

Figure 10. The experiments with the radius ratios and rotation rates listed in

Table 4 were used for validation.

As expected, the Bodenstein number in the just-suspended state increased for increasing radius ratios since, as described in the previous section, the rotational Reynolds number decreased, displayed by the additional x-axis on top. While at a radius ratio of = 0.5, the residence time behavior of a continuous stirred tank was almost achieved, the backmixing could be significantly reduced when was increased.

Furthermore, the RTD

L also became narrower by increasing the volume flow

or the axial Reynolds number

since the convective mass transport increased significantly more than the dispersive component, which was already evident from the model of Moore and Cooney [

11]. However, it must be taken into account that the increase in the axial Reynolds number also reduced the residence time

; in the case of quadrupling of

investigated here,

was reduced to a quarter. To meet this challenge, the crystallizer length and the radii of both the rotor and stator could be increased while maintaining a high radius ratio.

Comparing the prediction with the experimental data showed that both correlations used for this purpose had sufficient accuracy and described the system well. Therefore, the simplification of using the solution viscosity rather than the apparent suspension viscosity in the calculations seemed to be valid from a viewpoint of design optimization.

At the radius ratios

= 0.5 and 0.7, no effect of the particles on the RTD

L was discernible. This can be explained by the fact that the vortex boundaries were already locally strongly disrupted by the turbulence in the TTVF present here, which agrees with the results of Resende et al. [

25]. However, the significant difference between the Bodenstein numbers for the radius ratio

= 0.84 is remarkable, showing an increase in axial dispersion due to the presence of particles. The WTVF regime was present at this operating point, and the vortex boundaries allowed significantly less mass transport between two adjacent vortices. In this condition, particles that do not follow the streamlines and break the vortex boundaries can consequently increase the intervortex mass transfer [

20].

In an actual continuous crystallization, an axial gradient will occur in the particle mass fraction and size. This might reduce the broadening of the RTD

L by the particles since smaller particles can follow the streamlines better and the vortex breakthrough would be less pronounced [

20]. Interestingly, for

= 0.84, the experimentally determined Bodenstein number for the particle-free flow significantly exceeded the predicted value, while

of the particle-laden flow agreed with the prediction. Giordano et al. [

18] reported similar results. They concluded that for decreasing turbulence outside the TTVF, the bypass flow increasingly affects the RTD

L since the intensity of local mixing decreases. Thereby, the bypass current depends on the drift velocity ratio (see

Section 2.3.2), which can show significant differences between different Taylor–Couette apparatuses [

12,

19]. Therefore, it is possible that in the experiments of Moore and Cooney [

11], a more intense bypass current increased dispersion compared to the data presented here. However, since the drift velocity ratio was not part of these two studies, this hypothesis cannot be verified.

4. Conclusions and Outlook

In this study, we investigated the relationship between particle suspension and achievable liquid phase residence time distribution (RTDL) in a Taylor–Couette crystallizer (TCC). The system was characterized by flexibility in terms of local and global mixing, which were, however, coupled for a given geometry. An improvement of the local mixing or the suspension by the rotational Reynolds number is always accompanied by a broadening of the RTDL. Accordingly, the effects on the just-suspended rotational Reynolds number were determined as the lower limit of the operating window.

It was demonstrated that this Reynolds number was mainly influenced by the radius ratio between the rotor and stator and therewith design of the TCC. This resulted in just-suspended states achieved in the flow regimes of turbulent Taylor vortex flow up to wavy Taylor vortex flow. With this, it was shown that a TCC for cooling crystallization allowed a flexible application. Depending on the geometry selected, the axial dispersion is adjustable from almost complete back-mixing to a narrow RTDL by adjusting the process parameter rotation rate and volume flow rate. Furthermore, it was demonstrated that the achievable RTDL in the just-suspended state in terms of the Bodenstein number was predictable. For this, a correlation for the just-suspended rotational Reynolds number was established and connected with another correlation for the Bodenstein number already known from the literature. A calculation sequence was then proposed for a design optimization towards a maximized Bodenstein number in a just-suspended state.

In future work, the applicability to a different material system should be determined. Therefore, the effect of the substance-specific parameter viscosity and density difference between solution and particles, postulated in the correlation by the Archimedes number, should be validated. Furthermore, a correction factor could be integrated for varying particle shapes, whereby it can be expected that with increasing deviation from spherical shape, the degree of suspension will be enhanced [

40].

The solid phase residence time distribution should be investigated since it describes the variability in the growth times of the crystals. In addition, a cooling concept has to be developed that takes into account the variability of the RTDL, allowing an optimal setting of the supersaturation for the cooling crystallization. With the help of this knowledge, the influencing variables for crystallization can then be precisely adjusted.

The study presented here demonstrated that a TCC shows potential for use in cooling crystallization. While the achievable RTDL cannot match the plug flow conditions of other crystallizers, the TCC stands out for its combination of intense and uniform suspension and adjustable RTDL.