Numerical Investigation of Heat/Flow Transfer and Thermal Stress in an Anode-Supported Planar SOFC

Abstract

:1. Introduction

2. Model Development

- (1)

- The SOFC is running in a steady state.

- (2)

- All gas species are deemed as ideal gases, and gas flow is assumed to be laminar flow.

- (3)

- The reaction active sites are uniformly distributed in the electrodes, and the ionic and electronic conductors are continuous and homogeneous.

- (4)

- Cells, frames, interconnectors, etc., are considered as isotropic materials and satisfy the isotropic Hooke’s law.

- (5)

- Ignoring the redox reaction of Ni-NiO.

2.1. Internal Reforming Reaction Mechanism

2.2. Transfer Process and Governing Equations

2.2.1. Mass Transfer

2.2.2. Momentum Transfer

2.2.3. Energy Transfer

2.2.4. Charge Transfer

2.3. Electrochemical Reaction Mechanism

2.4. Thermal Stress Model

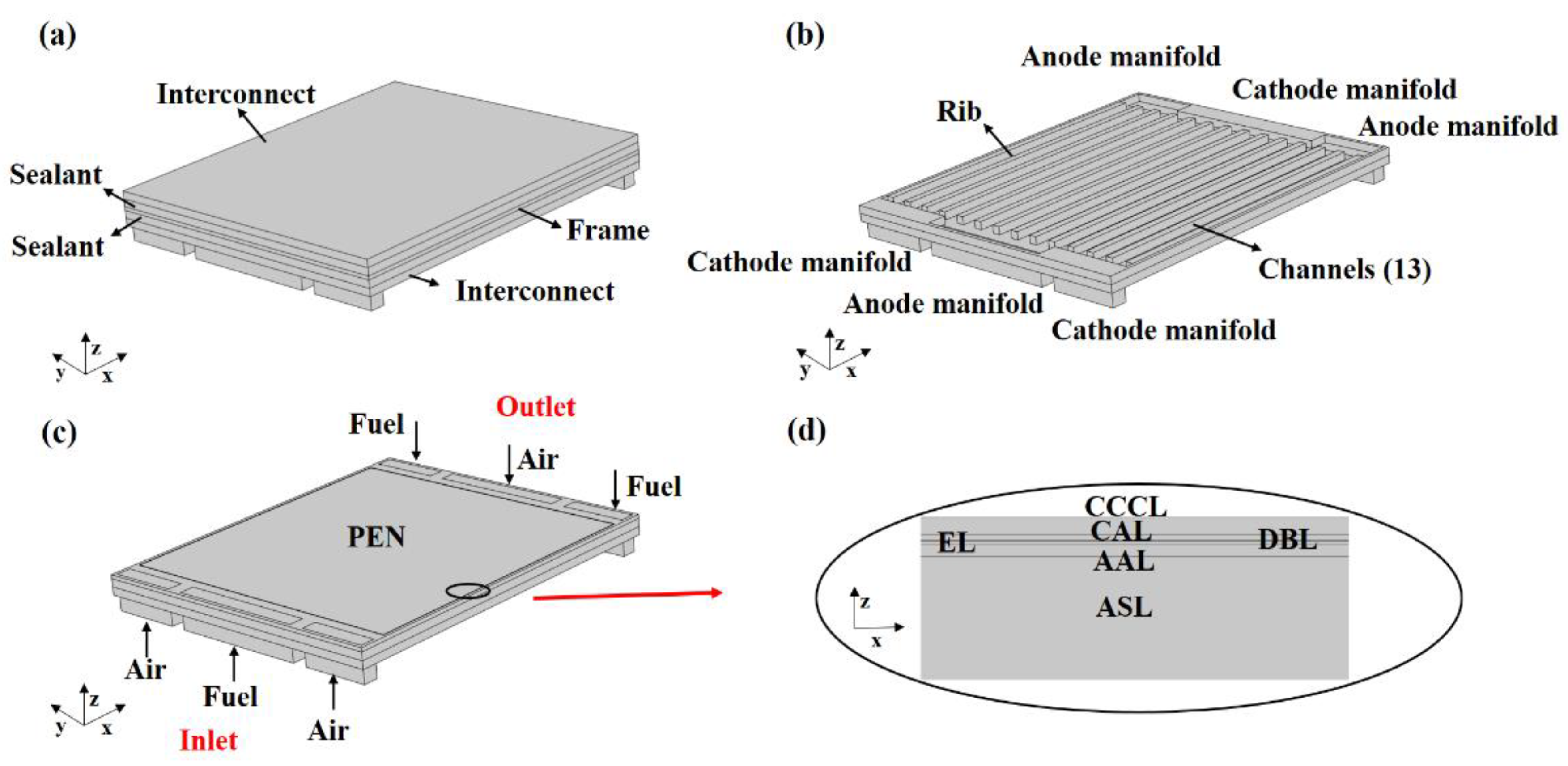

2.5. Geometric Model

2.6. Boundary Conditions and Physical Properties

3. Solution Methodology and Model Validation

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Guo, M.T.; Lin, Z.J. Long-term evolution of mechanical performance of solid oxide fuel cell stack and the underlying mechanism. Int. J. Hydrogen Energy 2021, 46, 23293–24304. [Google Scholar] [CrossRef]

- Wu, Y.; Shi, Y.; Cai, N.; Ni, M. Thermal Modeling and Management of Solid Oxide Fuel Cells Operating with Internally Reformed Methane. J. Therm. Sci. 2018, 27, 203–212. [Google Scholar] [CrossRef]

- Serincan, M.F.; Pasaogullari, U.; Sammes, N.M. Thermal stresses in an operating micro-tubular solid oxide fuel cell. J. Power Sources 2010, 195, 4905–4914. [Google Scholar] [CrossRef]

- Zamudio-García, J.; Caizán-Juanarena, L.; Porras-Vázquez, J.M.; Losilla, E.R.; Marrero-López, D. A review on recent advances and trends in symmetrical electrodes for solid oxide cells. J. Power Sources 2022, 520, 230852. [Google Scholar] [CrossRef]

- Zhang, Z.G.; Yue, D.T.; Yang, G.G.; He, C.R.; Ye, S.; Wang, W.G.; Yuan, J.L. Three-dimensional CFD modeling of transport phenomena in multi-channel anode-supported planar SOFCs. Int. J. Heat Mass Transf. 2015, 84, 942–954. [Google Scholar] [CrossRef]

- Faheem, H.H.; Abbas, S.Z.; Tabish, A.N.; Fan, L.; Maqbool, F. A review on mathematical modelling of Direct Internal Reforming-Solid Oxide Fuel Cells. J. Power Sources 2022, 520, 230857. [Google Scholar] [CrossRef]

- Cai, W.; Zheng, Q.; Yu, W.; Yin, Z.; Yuan, J.; Zhang, Z.; Pei, Y. Effects of Methane Pre-Reforming Percentage and Flow Arrangement on the Distribution of Temperature and Thermal Stress in Solid Oxide Fuel Cell. Crystals 2022, 12, 953. [Google Scholar] [CrossRef]

- Lee, S.; Kim, H.; Yoon, K.J.; Son, J.-W.; Lee, J.-H.; Kim, B.-K.; Choi, W.; Hong, J. The effect of fuel utilization on heat and mass transfer within solid oxide fuel cells examined by three-dimensional numerical simulations. Int. J. Heat Mass Transf. 2016, 97, 77–93. [Google Scholar] [CrossRef]

- Zheng, J.; Xiao, L.; Wu, M.; Lang, S.; Zhang, Z.; Chen, M.; Yuan, J. Numerical Analysis of Thermal Stress for a Stack of Planar Solid Oxide Fuel Cells. Energies 2022, 15, 343. [Google Scholar] [CrossRef]

- Xie, J.M.; Wang, F.H. Thermal stress analysis of solid oxide fuel cell with anode functional layer. J. Inorg. Mater. 2017, 32, 400–406. [Google Scholar] [CrossRef]

- Frandsen, H.; Makowska, M.; Greco, F.; Chatzichristodoulou, C.; Ni, D.; Curran, D.; Strobl, M.; Kuhn, L.; Hendriksen, P. Accelerated creep in solid oxide fuel cell anode supports during reduction. J. Power Sources 2016, 323, 78–89. [Google Scholar] [CrossRef] [Green Version]

- Jiang, C.; Gu, Y.; Guan, W.; Zheng, J.; Ni, M.; Zhong, Z. 3D thermo-electro-chemo-mechanical coupled modeling of solid oxide fuel cell with double-sided cathodes. Int. J. Hydrogen Energy 2020, 45, 904–915. [Google Scholar]

- Xu, Q.; Xia, L.; He, Q.; Guo, Z.; Ni, M. Thermo-electrochemical modelling of high temperature methanol-fueled solid oxide fuel cells. Appl. Energy 2021, 291, 116832. [Google Scholar] [CrossRef]

- Luo, Y.; Liao, S.; Chen, S.; Fang, H.; Zhong, F.; Lin, L.; Zhou, C.; Chen, C.; Cai, G.; Au, C.-T.; et al. Optimized coupling of ammonia decomposition and electrochemical oxidation in a tubular direct ammonia solid oxide fuel cell for high-efficiency power generation. Appl. Energy 2022, 307, 118158. [Google Scholar] [CrossRef]

- Luo, Y.; Shi, Y.X.; Liao, S.T.; Chen, C.Q.; Zhan, Y.Y.; Au, C.-T.; Jiang, L. Coupling ammonia catalytic decomposition and electrochemical oxidation for solid oxide fuel cells: A model based on elementary reaction kinetics. J. Power Sources 2019, 423, 125–136. [Google Scholar] [CrossRef]

- Ong, K.M.; Lee, W.Y.; Hanna, J.; Ghoniem, A.F. Isolating the impact of CO concentration in syngas mixtures on SOFC performance via internal reforming and direct oxidation. Int. J. Hydrogen Energy 2016, 41, 9035–9047. [Google Scholar] [CrossRef]

- Xie, Y.Y.; Ding, H.P.; Xue, X.J. Direct methane fueled solid oxide fuel cell model with detailed reforming reactions. Chem. Eng. J. 2013, 228, 917–924. [Google Scholar] [CrossRef]

- Tseronis, K.; Fragkopoulos, I.; Bonis, I.; Theodoropoulos, C. Detailed Multi-dimensional Modeling of Direct Internal Reforming Solid Oxide Fuel Cells. Fuel Cells 2016, 16, 294–312. [Google Scholar]

- Chiang, L.-K.; Liu, H.-C.; Shiu, Y.-H.; Lee, C.-H.; Lee, R.-Y. Thermal stress and thermo-electrochemical analysis of a planar anode-supported solid oxide fuel cell: Effects of anode porosity. J. Power Sources 2010, 195, 1895–1904. [Google Scholar] [CrossRef]

- Awrejcewicz, J.; Krysko, A.V.; Krylova, E.Y.; Yaroshenko, T.Y.; Zhigalov, M.; Krysko, V. Analysis of flexible elastic–plastic plates/shells behavior under coupled mechanical/thermal fields and one-sided corrosion wear. Int. J. Non-Linear Mech. 2020, 118, 103302. [Google Scholar] [CrossRef]

- Clague, R.; Marquis, A.J.; Brandon, N.P. Finite element and analytical stress analysis of a solid oxide fuel cell. J. Power Sources 2012, 210, 224–232. [Google Scholar] [CrossRef]

- Fang, X.; Lin, Z. Numerical study on the mechanical stress and mechanical failure of planar solid oxide fuel cell. Appl. Energy 2018, 229, 63–68. [Google Scholar] [CrossRef]

- Xu, M.; Li, T.; Yang, M.; Andersson, M. Solid oxide fuel cell interconnect design optimization considering the thermal stresses. Sci. Bull. 2016, 61, 1333–1344. [Google Scholar] [CrossRef] [Green Version]

- Thattai, A.T.; Van Biert, L.; Aravind, P.V. On direct internal methane steam reforming kinetics in operating solid oxide fuel cells with nickel-ceria anodes. J. Power Sources 2017, 370, 71–86. [Google Scholar] [CrossRef]

- Xu, H.R.; Chen, B.; Tan, P.; Zhang, Y.; He, Q.; Wu, Z.; Ni, M. The thermal effects of all porous solid oxide fuel cells. J. Power Sources 2019, 440, 227102. [Google Scholar] [CrossRef]

- Haberman, B.A.; Young, J.B. Three-dimensional simulation of chemically reacting gas flows in the porous support structure of an integrated-planar solid oxide fuel cell. Int. J. Heat Mass Transf. 2004, 47, 3617–3629. [Google Scholar] [CrossRef]

- Hsieh, C.L.; Tuan, W.H. Elastic and thermal expansion behavior of two-phase composites. Mater. Sci. Eng. A 2006, 425, 349–360. [Google Scholar] [CrossRef]

- Chiu, Y.-T.; Lin, C.-K. Effects of Nb and W additions on high-temperature creep properties of ferritic stainless steels for solid oxide fuel cell interconnect. J. Power Sources 2012, 198, 149–157. [Google Scholar] [CrossRef]

| Reaction Rate | Expression |

|---|---|

| Methane steam-reforming reaction rate | |

| Water–gas shift reaction rate |

| Parameters | Values (m) | Parameters | Values (m) |

|---|---|---|---|

| Length/width of anode-supported SOFC (x/y-axis) | 4 × 10−2/2 × 10−2 | Length/width of manifold cross section (x/y-axis) | 2 × 10−3/9 × 10−3 |

| Thickness of interconnect (z-axis) | 1 × 10−3 | Thickness of ASL (y-axis) | 3.65 × 10−4 |

| Thickness of sealant (z-axis) | 1 × 10−3 | Thickness of AAL (z-axis) | 3.5 × 10−5 |

| Thickness of frame (z-axis) | 4.8 × 10−4 | Thickness of EL (z-axis) | 1 × 10−5 |

| Height/width of channel (z/y-axis) | 1 × 10−3/2 × 10−3 | Thickness of DBL (z-axis) | 3 × 10−6 m |

| Height/width of rib (z/y-axis) | 1 × 10−3/1 × 10−3 | Thickness of CAL (z-axis) | 1.7 × 10−5 m |

| Height of manifold (z-axis) | 2 × 10−3 | Thickness of CCCL (z-axis) | 5 × 10−5 m |

| Fe | C | Cr | Mn | Si | Ti | Cu | S | P | Al | La | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Crofer 22 APU | Bal. | 0.003 | 22.71 | 0.44 | 0.02 | 0.07 | 0.01 | <0.002 | 0.004 | 0.01 | 0.09 |

| ASL | AAL | EL | DBL | CAL | CCCL | Interconnect | Seal | |

|---|---|---|---|---|---|---|---|---|

| Thermal conductivity k (W·m−1·K−1) | 6 | 6 | 2 | 2 | 2 | 2 | 44.5 | 0.064 |

| Porosity ε | 0.38 | 0.2 | 0.27 | 0.27 | ||||

| Volume fraction of electronic conductor in the composite θ | 0.4 | 0.4 | 0.5 | |||||

| Tortuosity τ | 5 | 13.3 | 3.5 | 3.5 | ||||

| Permeability β (m2) | 5.4 × 10−15 | 3 × 10−16 | 9 × 10−16 | 9 × 10−16 | ||||

| Active surface area-to-volume ratio Ave (m−1) | 1.08 × 105 | 1.3 × 105 | 2.44 × 106 | 2.44 × 106 |

| T | Ni | NiO | YSZ | LSCF | GDC | Interconnect | Seal | |

|---|---|---|---|---|---|---|---|---|

| Young’s modulus E (GPa) | 1073 K | 0.25 | 90 | 185 | 10 | 90 | 60 | 0.019 |

| Poisson’s ratio v | 1073 K | 0.3 | 0.34 | 0.313 | 0.32 | 0.32 | 0.3 | 0 |

| Coefficient of thermal expansion α (10−6K−1) | 1073 K | 16.2 | 13.0 | 10.5 | 26 | 12.63 | 15.5 | 15.5 |

| Boundary Conditions | Temperature/K | Species | Ions | Electrons | |

|---|---|---|---|---|---|

| Anode manifold inlet | Sccm: 400 | 1073 | Fuel | None | None |

| Cathode manifold inlet | Sccm: 1000 | 1073 | YO2 = 0.233, YN2 = 0.727 | None | None |

| Top of upper interconnect | Wall | Adiabatic | None | None | 0 V |

| Bottom of lower interconnect | Wall | Adiabatic | None | None | 0.7 V |

| Both sides of the cell | Wall | Adiabatic | None | None | None |

| Anode channel outlet | Pout = Patm = 1 atm | Convection | Convection | None | None |

| Cathode channel outlet | Pout = Patm = 1 atm | Convection | Convection | None | None |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, W.; Yuan, J.; Zheng, Q.; Yu, W.; Yin, Z.; Zhang, Z.; Pei, Y.; Li, S. Numerical Investigation of Heat/Flow Transfer and Thermal Stress in an Anode-Supported Planar SOFC. Crystals 2022, 12, 1697. https://doi.org/10.3390/cryst12121697

Cai W, Yuan J, Zheng Q, Yu W, Yin Z, Zhang Z, Pei Y, Li S. Numerical Investigation of Heat/Flow Transfer and Thermal Stress in an Anode-Supported Planar SOFC. Crystals. 2022; 12(12):1697. https://doi.org/10.3390/cryst12121697

Chicago/Turabian StyleCai, Weiqiang, Jinliang Yuan, Qingrong Zheng, Wanneng Yu, Zibin Yin, Zhonggang Zhang, Yuyao Pei, and Shian Li. 2022. "Numerical Investigation of Heat/Flow Transfer and Thermal Stress in an Anode-Supported Planar SOFC" Crystals 12, no. 12: 1697. https://doi.org/10.3390/cryst12121697

APA StyleCai, W., Yuan, J., Zheng, Q., Yu, W., Yin, Z., Zhang, Z., Pei, Y., & Li, S. (2022). Numerical Investigation of Heat/Flow Transfer and Thermal Stress in an Anode-Supported Planar SOFC. Crystals, 12(12), 1697. https://doi.org/10.3390/cryst12121697