Fabrication of Step−Index Fluorotellurite Fibers with High Numerical Aperture for Coherent Mid—Infrared Supercontinuum

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kibler, B.; Lemière, A.; Gomes, J.T.; Gaponov, D.; Lavoute, L.; Désévédavy, F.; Smektala, F. Octave−Spanning Coherent Supercontinuum Generation in a Step−Index Tellurite Fiber and towards Few−Cycle Pulse Compression at 2 μm. Opt. Commun. 2021, 488, 126853. [Google Scholar] [CrossRef]

- Heidt, A.M.; Rothhardt, J.; Hartung, A.; Bartelt, H.; Rohwer, E.G.; Limpert, J.; Tünnermann, A. High Quality Sub−Two Cycle Pulses from Compression of Supercontinuum Generated in All−Normal Dispersion Photonic Crystal Fiber. Opt. Express 2011, 19, 13873–13879. [Google Scholar] [CrossRef] [PubMed]

- Petersen, C.R.; Rajagopalan, N.; Markos, C.; Israelsen, N.M.; Rodrigo, P.J.; Woyessa, G.; Tidemand-Lichtenberg, P.; Pedersen, C.; Weinell, C.E.; Kiil, S.; et al. Non−Destructive Subsurface Inspection of Marine and Protective Coatings Using Near− and Mid−Infrared Optical Coherence Tomography. Coatings 2021, 11, 877. [Google Scholar] [CrossRef]

- Su, R.; Kirillin, M.; Chang, E.W.; Sergeeva, E.; Yun, S.H.; Mattsson, L. Perspectives of Mid−Infrared Optical Coherence Tomography for Inspection and Micrometrology of Industrial Ceramics. Opt. Express 2014, 22, 15804–15819. [Google Scholar] [CrossRef]

- Zorin, I.; Brouczek, D.; Geier, S.; Nohut, S.; Eichelseder, J.; Huss, G.; Schwentenwein, M.; Heise, B. Mid−Infrared Optical Coherence Tomography as a Method for Inspection and Quality Assurance in Ceramics Additive Manufacturing. Open Ceram. 2022, 12, 100311. [Google Scholar] [CrossRef]

- Jahromi, K.E.; Pan, Q.; Khodabakhsh, A.; Sikkens, C.; Assman, P.; Cristescu, S.M.; Moselund, P.M.; Janssens, M.; Verlinden, B.E.; Harren, F.J.M. A Broadband Mid−Infrared Trace Gas Sensor Using Supercontinuum Light Source: Applications for Real−Time Quality Control for Fruit Storage. Sensors 2019, 19, 2334. [Google Scholar] [CrossRef]

- Seddon, A.B.; Napier, B.; Lindsay, I.; Lamrini, S.; Moselund, P.M.; Stone, N.; Bang, O.; Farries, M. Prospective on Using Fibre Mid−Infrared Supercontinuum Laser Sources for in Vivo Spectral Discrimination of Disease. Analyst 2018, 143, 5874–5887. [Google Scholar] [CrossRef]

- Sotobayashi, H.; Chujo, W.; Konishi, A.; Ozeki, T. Wavelength−Band Generation and Transmission of 3.24−Tbit/s (81−Channel WDM × 40−Gbit/s) Carrier−Suppressed Return−to−Zero Format by Use of a Single Supercontinuum Source for Frequency Standardization. J. Opt. Soc. Am. B 2002, 19, 2803–2809. [Google Scholar] [CrossRef]

- Huang, C.; Liao, M.; Bi, W.; Li, X.; Hu, L.; Zhang, L.; Wang, L.; Qin, G.; Xue, T.; Chen, D.; et al. Ultraflat, Broadband, and Highly Coherent Supercontinuum Generation in All−Solid Microstructured Optical Fibers with All−Normal Dispersion. Photonics Res. 2018, 6, 601–608. [Google Scholar] [CrossRef]

- Sharma, U.; Chang, E.; Yun, S. Long−Wavelength Optical Coherence Tomography at 1.7 μm for Enhanced Imaging Depth. Opt. Express 2008, 16, 19712–19723. [Google Scholar] [CrossRef]

- Rampur, A.; Spangenberg, D.M.; Sierro, B.; Hänzi, P.; Klimczak, M.; Heidt, A.M. Perspective on the next Generation of Ultra−Low Noise Fiber Supercontinuum Sources and Their Emerging Applications in Spectroscopy, Imaging, and Ultrafast Photonics. Appl. Phys. Lett. 2021, 118, 240504. [Google Scholar] [CrossRef]

- Møller, U.; Bang, O. Intensity Noise in Normal−Pumped Picosecond Supercontinuum Generation, Where Higher−Order Raman Lines Cross into Anomalous Dispersion Regime. Electron. Lett. 2013, 49, 63–65. [Google Scholar] [CrossRef]

- Heidt, A.M.; Hartung, A.; Bosman, G.W.; Krok, P.; Rohwer, E.G.; Schwoerer, H.; Bartelt, H. Coherent Octave Spanning Near−Infrared and Visible Supercontinuum Generation in All−Normal Dispersion Photonic Crystal Fibers. Opt. Express 2011, 19, 3775–3787. [Google Scholar] [CrossRef] [PubMed]

- Huang, C.; Liao, M.; Bi, W.; Hu, L.; Bi, W.; Li, X.; Chen, D.; Zhang, L.; Huang, C.; Gao, W.; et al. Asterisk−Shaped Microstructured Fiber for an Octave Coherent Supercontinuum in a Sub−Picosecond Region. Opt. Lett. 2018, 43, 486–489. [Google Scholar] [CrossRef] [PubMed]

- Corwin, K.L.; Newbury, N.R.; Dudley, J.M.; Coen, S.; Diddams, S.A.; Weber, K.; Windeler, R.S. Fundamental Noise Limitations to Supercontinuum Generation in Microstructure Fiber. Phys. Rev. Lett. 2003, 90, 113904. [Google Scholar] [CrossRef]

- Han, F.; Wei, L.; Hu, J.; Shi, J.; Feng, X. Highly Coherent Visible Supercontinuum Generation in a Micrometer−Core Borosilicate Glass Photonic Crystal Fiber. J. Opt. Soc. Am. B 2021, 38, 145–151. [Google Scholar] [CrossRef]

- Xiao, K.; Ye, Y.; Min, R. Broadband Coherent Mid−Infrared Supercontinuum Generation in All−Chalcogenide Microstructured Fiber with All−Normal Dispersion. Front. Phys. 2022, 10, 557. [Google Scholar] [CrossRef]

- Zhang, N.; Peng, X.; Wang, Y.; Dai, S.; Yuan, Y.; Su, J.; Li, G.; Zhang, P.; Yang, P.; Wang, X. Ultrabroadband and Coherent Mid−Infrared Supercontinuum Generation in Te−Based Chalcogenide Tapered Fiber with All−Normal Dispersion. Opt. Express 2019, 27, 10311–10319. [Google Scholar] [CrossRef]

- Jiang, X.; Joly, N.; Finger, M.; Babic, F.; Pang, M.; Sopalla, R.; Frosz, M.H.; Poulain, S.; Poulain, M.; Cardin, V.; et al. Supercontinuum Generation in ZBLAN Glass Photonic Crystal Fiber with Six Nanobore Cores. Opt. Lett. 2016, 41, 4245–4248. [Google Scholar] [CrossRef]

- Li, Y.; Wang, L.; Liao, M.; Liu, Y.; Li, X.; Bi, W.; Yu, F.; Zhang, L.; Jiang, Y.; Wang, Z.; et al. Step−Index Fluoride Fibers with All−Normal Dispersion for Coherent Mid−Infrared Supercontinuum Generation. J. Opt. Soc. Am. B 2019, 36, 2972–2980. [Google Scholar] [CrossRef]

- Strutynski, C.; Froidevaux, P.; Désévédavy, F.; Jules, J.-C.; Gadret, G.; Bendahmane, A.; Tarnowski, K.; Kibler, B.; Smektala, F. Tailoring Supercontinuum Generation beyond 2 μm in Step−Index Tellurite Fibers. Opt. Lett. 2017, 42, 247–250. [Google Scholar] [CrossRef] [PubMed]

- Saini, T.S.; Tuan, T.H.; Xing, L.; Phuoc, N.; Hoa, T.; Suzuki, T.; Ohishi, Y. Coherent Mid−Infrared Supercontinuum Spectrum Using a Step−Index Tellurite Fiber with All−Normal Dispersion. Appl. Phys. Express 2018, 11, 102501. [Google Scholar] [CrossRef]

- Feng, S.; Liu, C.; Cui, J.; Xu, Y.; Li, M.; Xiao, X.; Ma, W.; Guo, H. Intense 2.71−μm Fluorescence Emission in Low Hydroxyl Heavily Er3+−Doped Fluorotellurite Glass for Mid−Infrared Fiber Laser. J. Non. Cryst. Solids 2022, 586, 121569. [Google Scholar] [CrossRef]

- Guo, X.; Jia, Z.; Jiao, Y.; Li, Z.; Yao, C.; Hu, M. 25.8 W All−Fiber Mid−Infrared Supercontinuum Light Sources Based on Fluorotellurite Fibers. IEEE Photonics Technol. Lett. 2022, 34, 367–370. [Google Scholar] [CrossRef]

- Strutynski, C.; Picot−Clémente, J.; Lemiere, A.; Froidevaux, P.; Désévédavy, F.; Gadret, G.; Jules, J.C.; Kibler, B.; Smektala, F. Fabrication and Characterization of Step−Index Tellurite Fibers with Varying Numerical Aperture for near− and Mid−Infrared Nonlinear Optics. J. Opt. Soc. Am. B 2016, 33, 12–18. [Google Scholar] [CrossRef]

- Huang, F.; Guo, Y.; Ma, Y.; Zhang, L.; Zhang, J. Highly Er3+−Doped ZrF4−Based Fluoride Glasses for 2.7 μm Laser Materials. Appl. Opt. 2013, 52, 1399–1403. [Google Scholar] [CrossRef]

- Li, X.; Chen, W.; Xue, T.; Gao, J.; Gao, W.; Hu, L.; Liao, M. Low Threshold Mid−Infrared Supercontinuum Generation in Short Fluoride−Chalcogenide Multimaterial Fibers. Opt. Express 2014, 22, 24179–24191. [Google Scholar] [CrossRef]

- Yan, X.; Qin, G.; Liao, M.; Suzuki, T.; Ohishi, Y. Transient Raman Response and Soliton Self−Frequency Shift in Tellurite Microstructured Fiber. J. Appl. Phys. 2010, 108, 123110. [Google Scholar] [CrossRef]

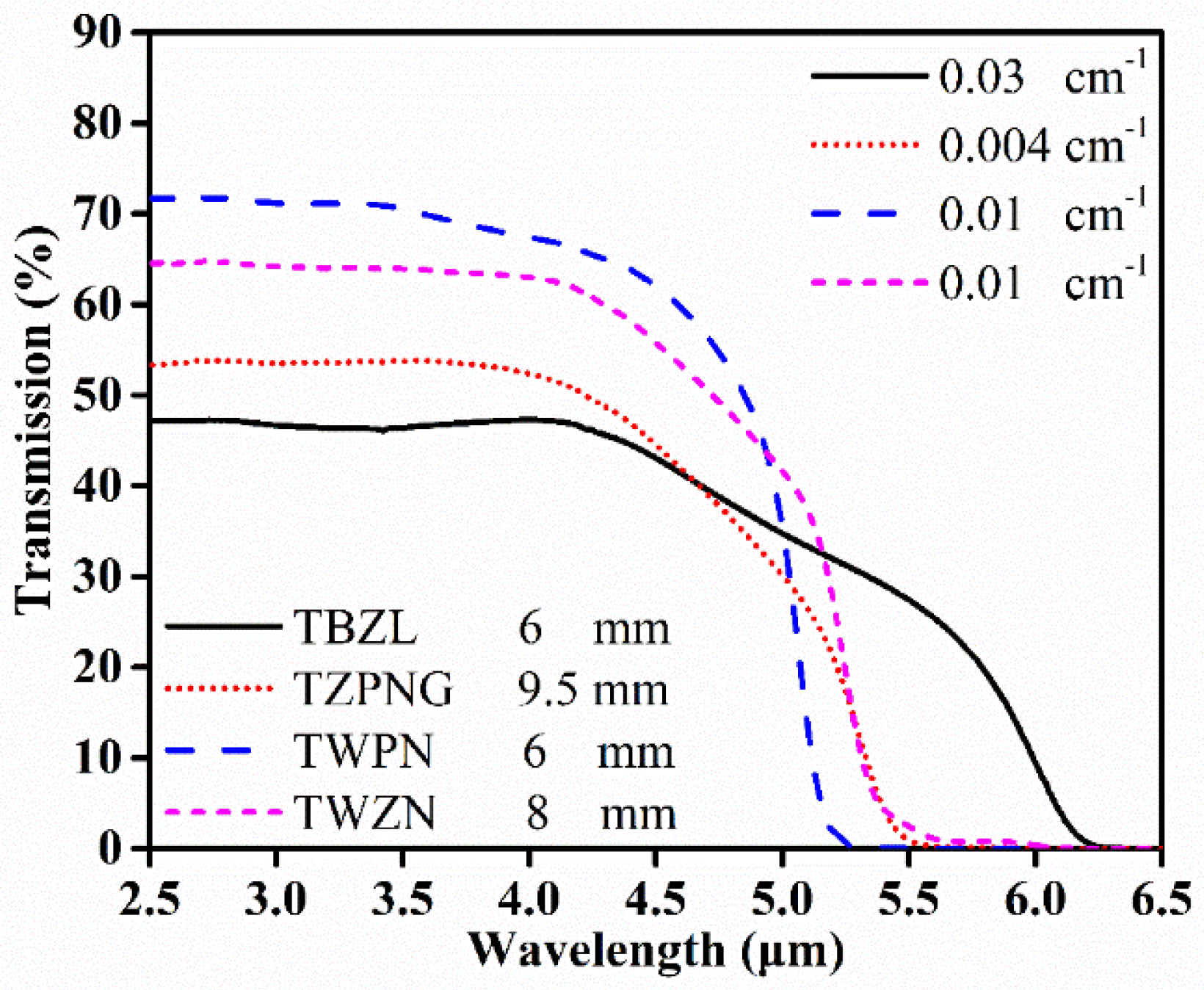

| Glass Compositions (mol%) | Notation |

|---|---|

| 78TeO2−5Bi2O5−10.5ZnO−1.5ZnF2−5Li2O | TBZL |

| 69TeO2−6WO3−15ZnO−5ZnF2−5Na2O | TWZN |

| 60TeO2−30WO3−10PbO−3NaF | TWPN |

| 65TeO2−13ZnO−5ZnF2−5PbF2−8Nb2O5−4GeO2 | TZPNG |

| Glass | Tg (°C) | Tx (°C) | ∆T (°C) | TEC (×10−6 K−1) | n (1552 nm) |

|---|---|---|---|---|---|

| TBZL | 301 | 440 | 139 | 17.4 | 2.078 |

| TWZN | 301 | 445 | 144 | 17.3 | 2.002 |

| TWPN | 370 | >500 | >130 | 14.0 | 2.128 |

| TZPNG | 350 | >500 | >150 | 13.5 | 2.029 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Liao, M.; Han, J.; Luo, J. Fabrication of Step−Index Fluorotellurite Fibers with High Numerical Aperture for Coherent Mid—Infrared Supercontinuum. Crystals 2022, 12, 1649. https://doi.org/10.3390/cryst12111649

Li Y, Liao M, Han J, Luo J. Fabrication of Step−Index Fluorotellurite Fibers with High Numerical Aperture for Coherent Mid—Infrared Supercontinuum. Crystals. 2022; 12(11):1649. https://doi.org/10.3390/cryst12111649

Chicago/Turabian StyleLi, Yu, Meisong Liao, Jianjun Han, and Jie Luo. 2022. "Fabrication of Step−Index Fluorotellurite Fibers with High Numerical Aperture for Coherent Mid—Infrared Supercontinuum" Crystals 12, no. 11: 1649. https://doi.org/10.3390/cryst12111649

APA StyleLi, Y., Liao, M., Han, J., & Luo, J. (2022). Fabrication of Step−Index Fluorotellurite Fibers with High Numerical Aperture for Coherent Mid—Infrared Supercontinuum. Crystals, 12(11), 1649. https://doi.org/10.3390/cryst12111649