Evaluation of the Piezoresistivity of a Thin Film of ZnO Doped with Fluorine and Deposited via the Ultrasonic Spray Pyrolysis Technique for Applications in Micro/Nano-Electromechanical Sensors

Abstract

1. Introduction

2. Materials and Methods

2.1. Thin Film Deposition

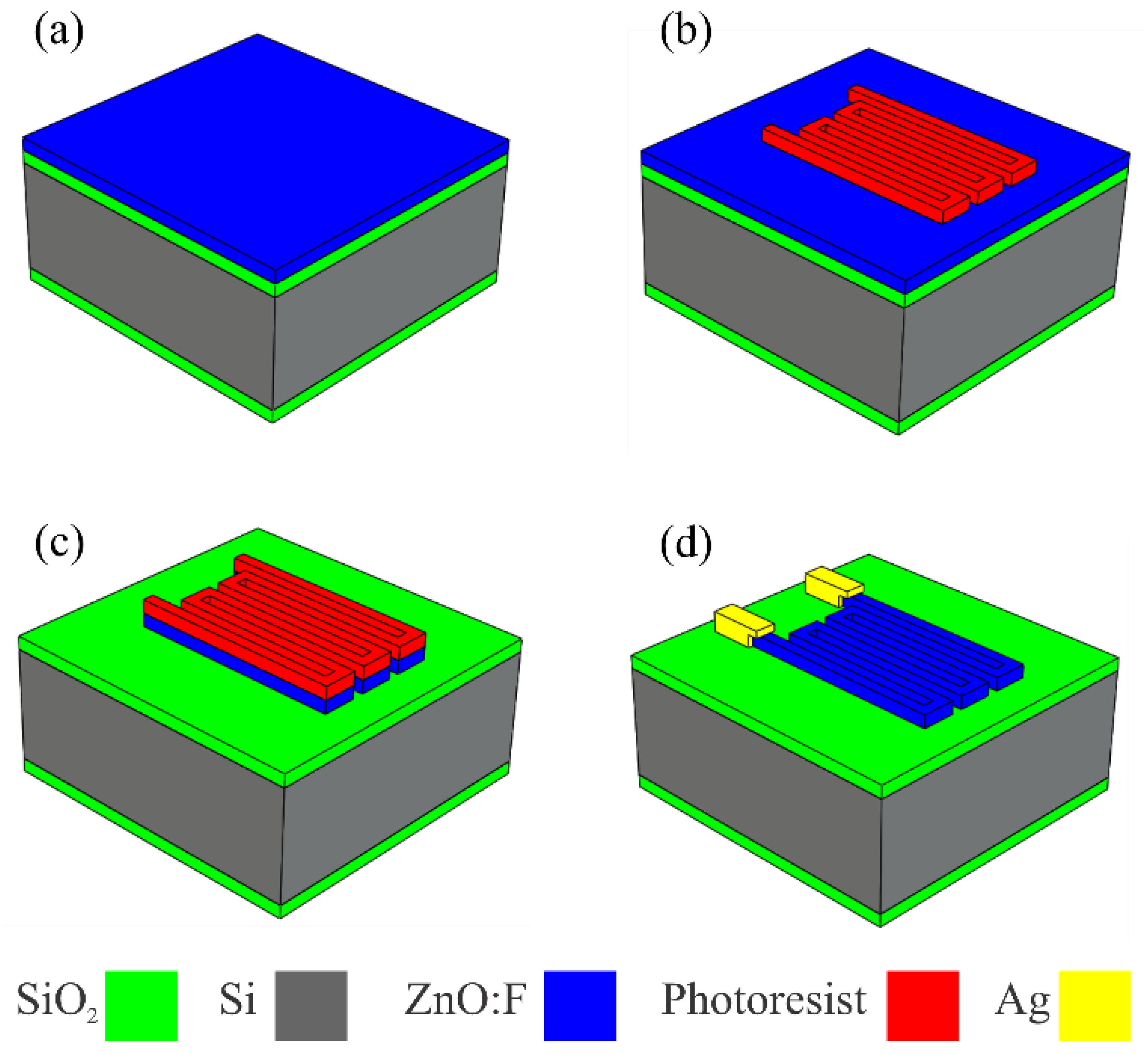

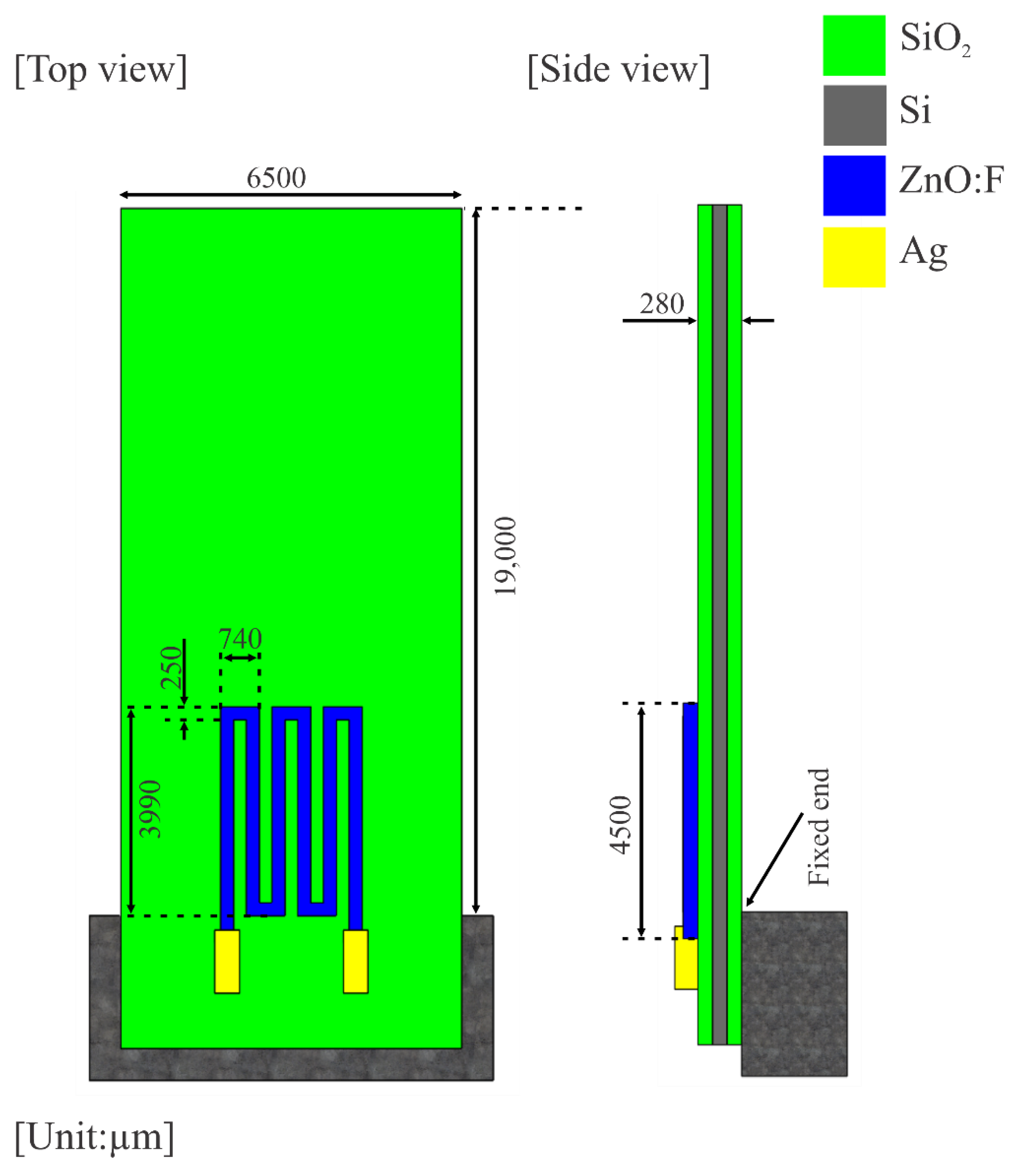

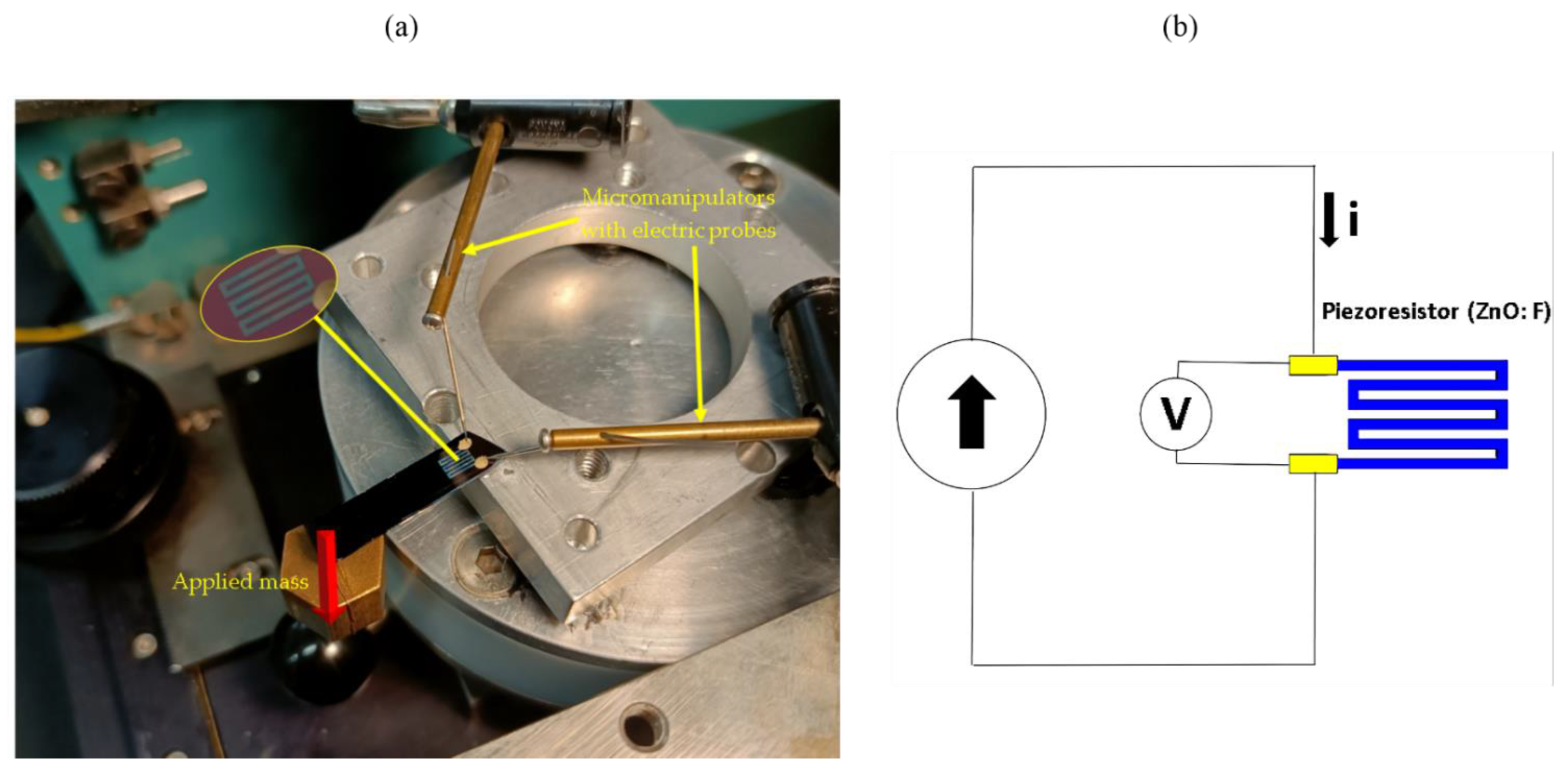

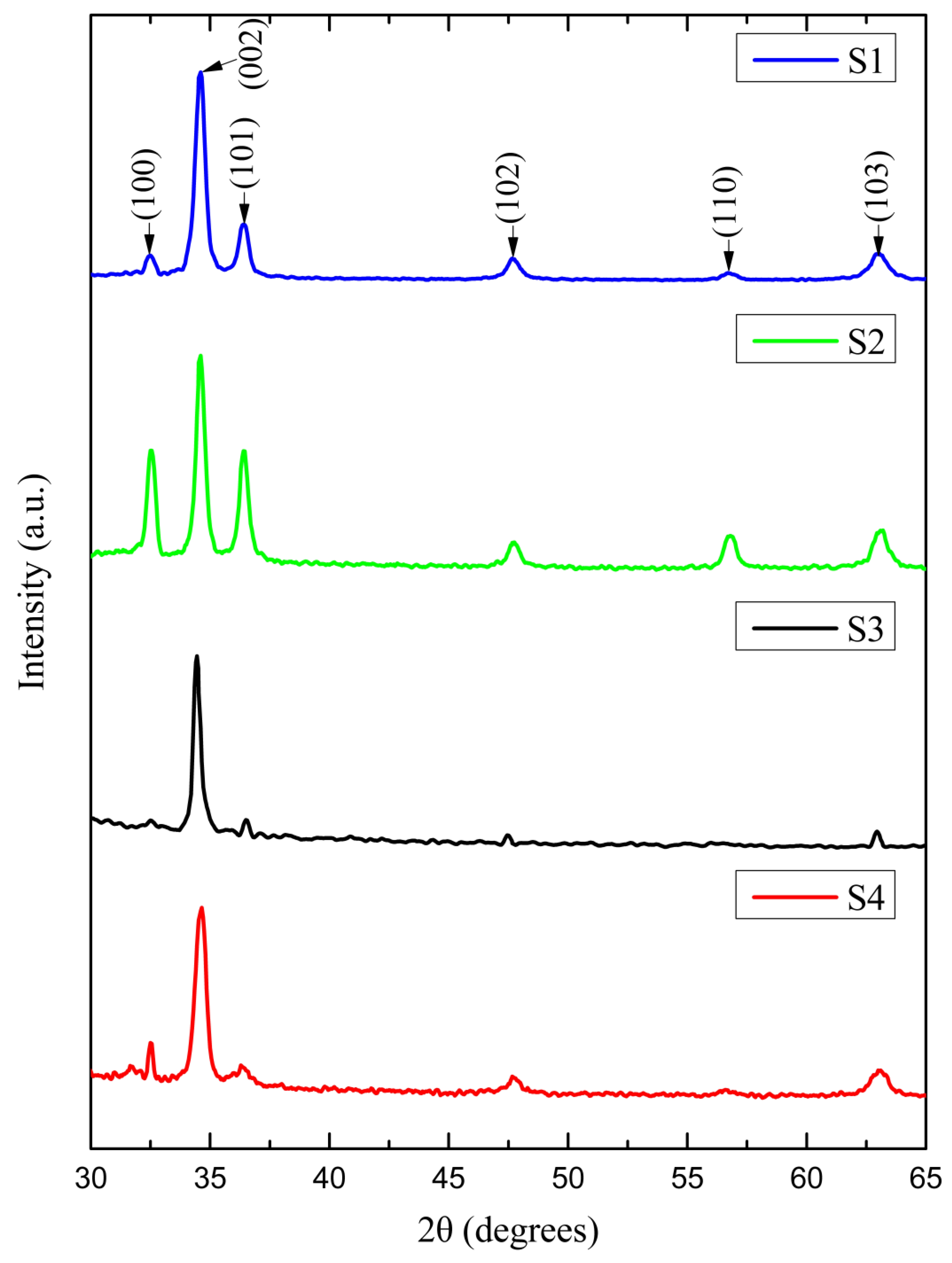

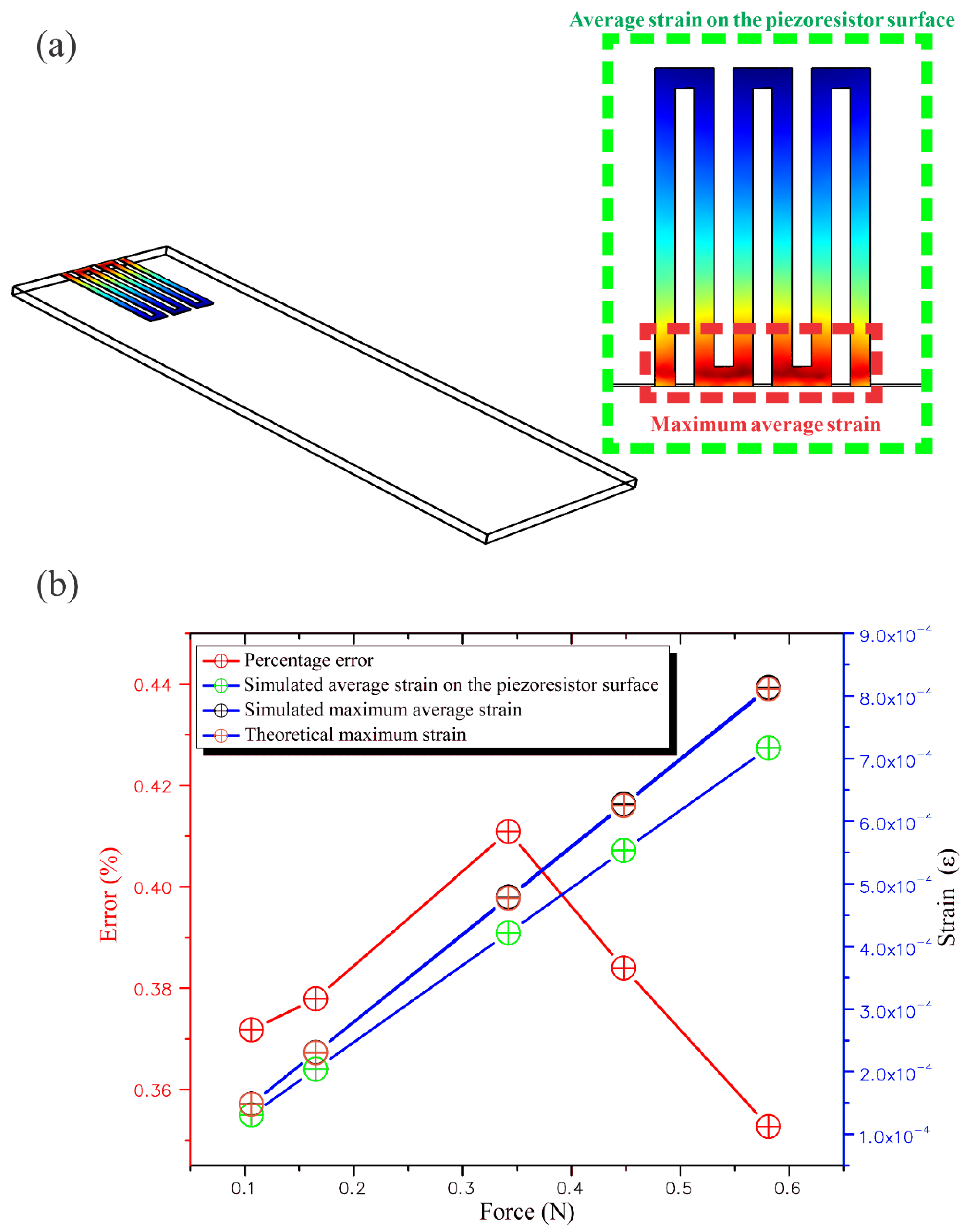

2.2. Characterization of Thin Films and Fabrication of the Cantilever Device

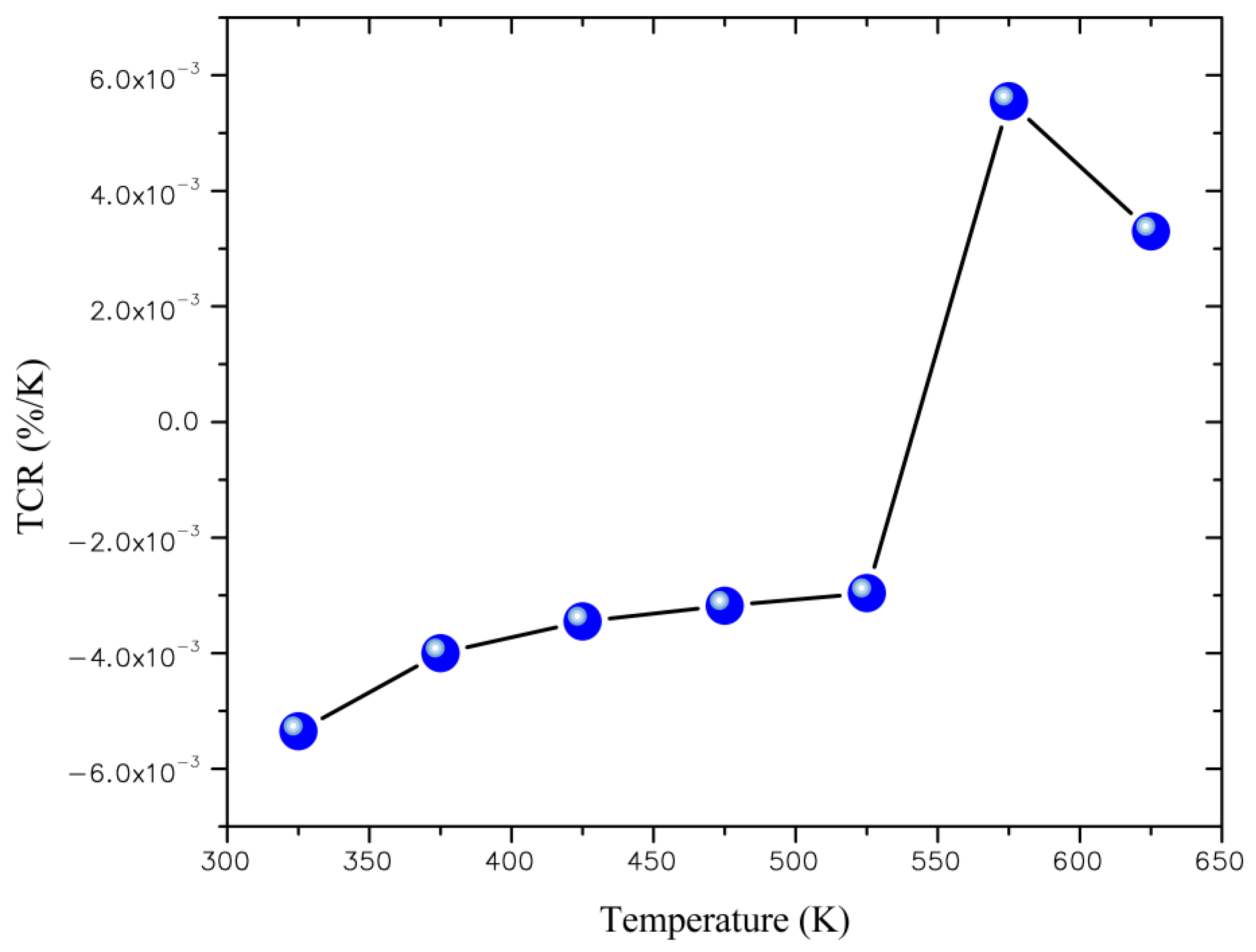

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, Y.; Wang, W.; Liao, K.; Hu, C.; Huang, Z.; Feng, Q. Piezoresistive effect in carbon nanotube films. Chin. Sci. Bull. 2003, 48, 125–127. [Google Scholar] [CrossRef]

- Fraga, M.A.; Furlan, H.; Pessoa, R.S.; Massi, M. Wide bandgap semiconductor thin films for piezoelectric and piezoresistive MEMS sensors applied at high temperatures: An overview. Microsyst. Technol. 2014, 20, 9–21. [Google Scholar] [CrossRef]

- Li, F.; Shen, T.; Wang, C.; Zhang, Y.; Qi, J.; Zhang, H. Recent Advances in Strain-Induced Piezoelectric and Piezoresistive Effect-Engineered 2D Semiconductors for Adaptive Electronics and Optoelectronics. Nano-Micro Lett. 2020, 12, 106. [Google Scholar] [CrossRef]

- Kumar, S.S.; Pant, B.D. Design principles and considerations for the “ideal” silicon piezoresistive pressure sensor: A focused review. Microsyst. Technol. 2014, 20, 1213–1247. [Google Scholar] [CrossRef]

- Li, C.; Cordovilla, F.; Jagdheesh, R.; Ocaña, J.L. Design Optimization and Fabrication of a Novel Structural SOI Piezoresistive Pressure Sensor with High Accuracy. Sensors 2018, 18, 439. [Google Scholar] [CrossRef]

- Li, X.; Liu, Q.; Pang, S.; Xu, K.; Tang, H.; Sun, C. High-temperature piezoresistive pressure sensor based on implantation of oxygen into silicon wafer. Sens. Actuators A Phys. 2012, 179, 277–282. [Google Scholar] [CrossRef]

- Sheeparamatti, B.G.; Balavalad, K.B. Fabrication and characterization of polysilicon-on-insulator (PolySOI) and a-SOI based micro piezoresistive pressure sensor for harsh environment applications. Microsyst. Technol. 2019, 25, 4119–4133. [Google Scholar] [CrossRef]

- Guo, S.; Eriksen, H.; Childress, K.; Fink, A.; Hoffman, M. High temperature high accuracy piezoresistive pressure sensor based on smart-cut soi. In Proceedings of the 2008 IEEE 21st International Conference on Micro Electro Mechanical Systems, Tucson, AZ, USA, 13–17 January 2008. [Google Scholar]

- Doll, J.C.; Pruitt, B.L. Alternative Materials and Transduction Methods. In Piezoresistor Design and Applications. Microsystems and Nanosystems; Springer: New York, NY, USA, 2013; Volume 1. [Google Scholar]

- Fiorillo, A.S.; Critello, C.D.; Pullano, A.S. Theory, Technology and Applications of Piezoresistive Sensors: A Review. Sens. Actuator A Phys. 2018, 281, 156–175. [Google Scholar] [CrossRef]

- Werner, M.; Gluche, P.; Adamschik, M.; Kohn, E.; Fecht, H.-J. Review on diamond based piezoresistive sensors. In Proceedings of the IEEE International Symposium on Industrial Electronics, Pretoria, South Africa, 7–10 July 1998. [Google Scholar]

- Li, C.; Cordovilla, F.; Ocaña, J.L. The design and analysis of a novel structural piezoresistive pressure sensor for low pressure measurement. Microsyst. Technol. 2017, 23, 5677–5687. [Google Scholar] [CrossRef]

- Azhari, F.; Banthia, N. Cement-based sensors with carbon fibers and carbon nanotubes for piezoresistive sensing. Cem. Concr. Compos. 2012, 34, 866–873. [Google Scholar] [CrossRef]

- French, P.J.; Evans, A.G.R. Piezoresistance in polysilicon and its applications to strain gauges. Solid-State Electron. 1989, 32, 1–10. [Google Scholar] [CrossRef]

- Cardoso, G.W.A.; Leal, G.; Massi, M.; da Silva Sobrinho, A.S.; Libardi, J. The influence of aluminum incorporation on the structural and electrical properties of ZnO thin films for applications in piezoresistive sensors. In Proceedings of the 2017 32nd Symposium on Microelectronics Technology and Devices (SBMicro), Fortaleza, Brazil, 28 August–1 September 2017. [Google Scholar]

- Samoei, V.K.; Jayatissa, A.H. Aluminum doped zinc oxide (AZO)-based pressure sensor. Sens. Actuators A Phys. 2020, 303, 111816. [Google Scholar] [CrossRef]

- Zeng, Q.; Lei, D.; Zhang, Y.; Huang, H. Transferable self-supporting ZnO porous films for low-cost piezoresistive sensors. Semicond. Sci. Technol. 2014, 29, 045009. [Google Scholar] [CrossRef]

- Inomata, N.; Van Toan, N.; Ono, T. Piezoresistive property of an aluminum-doped zinc oxide thin film deposited via atomic-layer deposition for microelectromechanical system/nanoelectromenchanical system applications. IEEE J. Trans. Electr. Electron. Eng. 2017, 12, 120–124. [Google Scholar] [CrossRef]

- Cardoso, G.W.A.; Leal, G.; da Silva Sobrinho, A.S.; Fraga, M.A.; Massi, M. Evaluation of piezoresistivity properties of sputtered ZnO thin films. Mater. Res. 2014, 17, 588–592. [Google Scholar] [CrossRef]

- Gregory, O.J.; Slot, A.B.; Amons, P.S.; Crisman, E.E. High temperature strain gages based on reactively sputtered AlNx thin films. Surf. Coat. Technol. 1997, 88, 79–89. [Google Scholar] [CrossRef]

- Yan, W.; Fuh, H.R.; Lv, Y.; Chen, K.Q.; Tsai, T.Y.; Wu, Y.R.; Shieh, T.H.; Hung, K.M.; Li, J.; Zhang, D.; et al. Giant gauge factor of Van der Waals material based strain sensors. Nat. Commun. 2021, 12, 2018. [Google Scholar] [CrossRef]

- Erskine, J.C. Polycrystalline silicon-on-metal strain gauge transducers. IEEE Trans. Electron. Dev. 1983, 30, 796–801. [Google Scholar] [CrossRef]

- Onuma, Y.; Kamimura, K.; Homma, Y. Piezoresistive elements of polycrystalline semiconductor thin films. Sens. Actuators 1988, 13, 71–77. [Google Scholar] [CrossRef]

- Obieta, I.; Gracia, F.J. Sputtered silicon thin films for piezoresistive pressure microsensors. Sens. Actuators A Phys. 1994, 42, 685–688. [Google Scholar] [CrossRef]

- Fraga, M.A.; Furlan, H.; Pessoa, R.S.; Rasia, L.A.; Mateus, C.F.R. Studies on SiC, DLC and TiO2 thin films as piezoresistive sensor materials for high temperature application. Microsyst. Technol. 2012, 18, 1027–1033. [Google Scholar] [CrossRef]

- Phan, H.-P.; Viet Dao, D.; Tanner, P.; Wang, L.; Nguyen, N.-T.; Zhu, Y.; Dimitrijev, S. Fundamental piezoresistive coefficients of p-type single crystalline 3C-SiC. Appl. Phys. Lett. 2014, 104, 111905. [Google Scholar] [CrossRef]

- Ferreira, A.; Silva, J.P.; Rodrigues, R.; Martin, N.; Lanceros-Méndez, S.; Vaz, F. High performance piezoresistive response of nanostructured ZnO/Ag thin films for pressure sensing applications. Thin Solid Film. 2019, 691, 137587. [Google Scholar] [CrossRef]

- Luka, G.; Wachnicki, L.; Witkowski, B.S.; Jakiela, R.; Virt, I.S. Structure-property relationships in ZnO:Al-hydroquinone films grown on flexible substrates by atomic and molecular layer deposition. Mater. Des. 2017, 119, 297–302. [Google Scholar] [CrossRef]

- Tuyaerts, R.; Poncelet, O.; Raskin, J.-P.; Proost, J. Internal stress and opto-electronic properties of ZnO thin films deposited by reactive sputtering in various oxygen partial pressures. J. Appl. Phys. 2017, 122, 155306. [Google Scholar] [CrossRef]

- Lakhmi, R.; Debeda, H.; Dufour, I.; Lucat, C. Force Sensors Based on Screen-Printed Cantilevers. IEEE Sens. J. 2010, 10, 1133–1137. [Google Scholar] [CrossRef]

- Pérez, R.; Chaillet, N.; Domanski, K.; Janus, P.; Grabiec, P. Fabrication, modeling and integration of a silicon technology force sensor in a piezoelectric micro-manipulator. Sens. Actuators A Phys. 2006, 128, 367–375. [Google Scholar] [CrossRef]

- Lee, C.; Thillaigovindan, J.; Chen, C.-C.; Chen, X.T.; Chao, Y.-T.; Tao, S.; Xiang, W.; Yu, A.; Feng, H.; Lo, G.Q. Si nanophotonics based cantilever sensor. Appl. Phys. Lett. 2008, 93, 113113. [Google Scholar] [CrossRef]

- Bao, M.-H. Micro Mechanical Transducers: Pressure Sensors, Accelerometers and Gyroscopes, 1st ed.; Elsevier Science: Amsterdam, The Netherlands, 2000. [Google Scholar]

- Hindrichsen, C.G.; Lou-Møller, R.; Hansen, K.; Thomsen, E.V. Advantages of PZT thick film for MEMS sensors. Sens. Actuators A Phys. 2010, 163, 9–14. [Google Scholar] [CrossRef]

- Liu, C. Foundations of MEMS, 2nd ed.; Pearson Education: Upper Saddle River, NJ, USA, 2006. [Google Scholar]

- Cheng, Y.; Liao, Y.; Li, J.; Guo, Z.-S. Mechanical characterization of zinc oxide thin films on glass substrates by nanoindentation. In Proceedings of the Second International Conference on Smart Materials and Nanotechnology in Engineering, Weihai, China, 20 October 2009. [Google Scholar]

- Fang, T.-H.; Chang, W.-J.; Lin, C.-M. Nanoindentation characterization of ZnO thin films. Mater. Sci. Eng. A 2007, 452–453, 715–720. [Google Scholar] [CrossRef]

- Tapily, K.; Gu, D.; Baumgart, H.; Namkoong, G.; Stegall, D.; Elmustafa, A.A. Mechanical and structural characterization of atomic layer deposition-based ZnO films. Semicond. Sci. Technol. 2011, 26, 115005. [Google Scholar] [CrossRef]

- Tuyaerts, R.; Raskin, J.-P.; Proost, J. Electromechanical testing of ZnO thin films under high uniaxial strain. In Proceedings of the 2017 International Conference of Microelectronic Test Structures (ICMTS), Grenoble, France, 28–30 March 2017. [Google Scholar]

- Farhath, M.; Samad, M.F. Design and simulation of a high sensitive stripped-shaped piezoresistive pressure sensor. J. Comput. Electron. 2020, 19, 310–320. [Google Scholar] [CrossRef]

- Senturia, S.D. Microsystem Design; Springer: Boston MA, USA, 2002. [Google Scholar]

- Bannikoppa, S.; Katageri, A.C.; Balavalad, K.B.; Sheeparamatti, B.G. Design of piezoresistive pressure sensor for enhanced sensitivity. In Proceedings of the 2016 International Conference on Energy Efficient Technologies for Sustainability, Nagercoil, India, 7–8 April 2016. [Google Scholar]

- Rao, P.T.; Santhoshkumar, M.C. Highly oriented (100) ZnO thin films by spray pyrolysis. Appl. Surf. Sci. 2009, 255, 7212–7215. [Google Scholar]

- Guillén-Santiago, A.; Olvera, M.d.l.L.; Maldonado, A.; Asomoza, R.; Acosta, D.R. Electrical, structural and morphological properties of chemically sprayed F-doped ZnO films: Effect of the ageing-time of the starting solution, solvent and substrate temperature. Phys. Stat. Sol. A 2004, 201, 952–959. [Google Scholar] [CrossRef]

- Rodríguez-Báez, J.; Maldonado, A.; Castañeda, L.; Delgado, G.T.; Castanedo-Pérez, R.; Olvera, M.d.l.L. On the effect of acetic acid on physical properties of chemically sprayed fluorine-doped ZnO thin films. Thin Solid Film. 2007, 515, 8689–8694. [Google Scholar] [CrossRef]

- Anandhi, R.; Mohan, R.; Swaminathan, K.; Ravichandran, K. Influence of aging time of the starting solution on the physical properties of fluorine doped zinc oxide films deposited by a simplified spray pyrolysis technique. Superlattices Microstruct. 2012, 51, 680–689. [Google Scholar] [CrossRef]

- Rodríguez-Báez, J.; Maldonado, A.; Torres-Delgado, G.; Castanedo-Pérez, R.; Olvera, M.d.l.L. Influence of the molar concentration and substrate temperature on fluorine-doped zinc oxide thin films chemically sprayed. Mater. Lett. 2006, 60, 1594–1598. [Google Scholar] [CrossRef]

- Biswal, R.R.; Velumani, S.; Babu, B.J.; Maldonado, A.; Tirado-Guerra, S.; Castañeda, L.; Olvera, M.d.l.L. Fluorine doped zinc oxide thin films deposited by chemical spray, starting from zinc pentanedionate and hydrofluoric acid: Effect of the aging time of the solution. Mater. Sci. Eng. B 2010, 174, 46–49. [Google Scholar] [CrossRef]

- Pawar, B.N.; Ham, D.-H.; Mane, R.S.; Ganesh, T.; Cho, B.-W.; Han, S.-H. Fluorine-doped zinc oxide transparent and conducting electrode by chemical spray synthesis. Appl. Surf. Sci. 2008, 254, 6294–6297. [Google Scholar] [CrossRef]

- Gunasekaran, E.; Ezhilan, M.; Mani, G.K.; Shankar, P.; Kulandaisamy, A.J.; Rayappan, J.B.B.; Babu, K.J. Fluorine doped ZnO thin film as acetaldehyde sensor. Semicond. Sci. Technol. 2018, 33, 095005. [Google Scholar] [CrossRef]

- Shinde, S.S.; Shinde, P.S.; Pawar, S.M.; Moholkar, A.V.; Bhosale, C.H.; Rajpure, K.Y. Physical properties of transparent and conducting sprayed fluorine doped zinc oxide thin films. Solid State Sci. 2008, 10, 1209–1214. [Google Scholar] [CrossRef]

- Alkhayatt, A.H.O.; Hussian, S.K. Fluorine dopant concentration effect on the structural and optical properties of spray deposited nanocrystalline ZnO thin films. Surf. Interfaces 2017, 8, 176–181. [Google Scholar] [CrossRef]

- Nakrela, A.; Benramdane, N.; Bouzidi, A.; Kebbab, Z.; Medles, M.; Mathieu, C. Site location of Al-dopant in ZnO lattice by exploiting the structural and optical characterisation of ZnO:Al thin films. Results Phys. 2016, 6, 133–138. [Google Scholar] [CrossRef]

- Pearson, G.L.; Bardeen, J. Electrical Properties of Pure Silicon and Silicon Alloys Containing Boron and Phosphorus. Phys. Rev. 1949, 75, 865–883. [Google Scholar] [CrossRef]

- Sanchez-Juarez, A.; Tiburcio-Silver, A.; Ortiz, A.; Zironi, E.P.; Rickards, J. Electrical and optical properties of fluorine-doped ZnO thin films prepared by spray pyrolysis. Thin Solid Film. 1998, 333, 196–202. [Google Scholar] [CrossRef]

- Douayar, A.; Diaz, R.; Cherkaoui El Moursli, F.; Schmerber, G.; Dinia, A.; Abd-Lefdil, M. Fluorine-doped ZnO thin films deposited by spray pyrolysis technique. Eur. Phys. J. Appl. Phys. 2011, 53. [Google Scholar] [CrossRef]

- Sanchez-Juarez, A.; Tiburcio-Silver, A.; Ortiz, A. Properties of fluorine-doped ZnO deposited onto glass by spray pyrolysis. Sol. Energy Mater. Sol. Cells 1998, 52, 301–311. [Google Scholar] [CrossRef]

- Phan, H.-P.; Dinh, T.; Kozeki, T.; Qamar, A.; Namazu, T.; Dimitrijev, S.; Nguyen, N.-T.; Dao, D.V. Piezoresistive effect in p-type 3C-SiC at high temperatures characterized using Joule heating. Sci. Rep. 2016, 6, 28499. [Google Scholar] [CrossRef]

- Dao, D.V.; Phan, H.-P.; Qamar, A.; Dinh, T. Piezoresistive effect of p-type single crystalline 3C–SiC on (111) plane. RSC Adv. 2016, 6, 21302–21307. [Google Scholar] [CrossRef]

- Sahay, P.P.; Nath, R.K. Al-doped ZnO thin films as methanol sensors. Sens. Actuators B Chem. 2008, 134, 654–659. [Google Scholar] [CrossRef]

| Samples | Thickness (nm) | × 10−2 (Ω.cm) | Rsheet × 103 (Ω) |

|---|---|---|---|

| S1 | 295 ± 26 | 5.21 | 1.76 |

| S2 | 273 ± 22 | 16.32 | 5.97 |

| S3 | 247 ± 27 | 7.38 | 2.98 |

| S4 | 234 ± 25 | 8.79 | 3.75 |

| Samples | a (Å) | c (Å) | TC (100) | TC (002) | TC (101) |

|---|---|---|---|---|---|

| S1 | 3.233 | 5.201 | 0.227 | 2.476 | 0.275 |

| S2 | 3.222 | 5.200 | 0.767 | 1.893 | 0.439 |

| S3 | 3.233 | 5.205 | 0.314 | 2.501 | 0.184 |

| S4 | 3.233 | 5.201 | 0.419 | 2.303 | 0.177 |

| Thin Film | Structure | Deposit Method and Temperature | GF | πl (Pa−1) | Bending Method | Substrate | Ref. |

|---|---|---|---|---|---|---|---|

| Al-doped ZnO (AZO) | Polycrystalline: hexagonal wurtzite Preferential orientation: (002) C-axis perpendicular to the surface | DC magnetron Co-sputtering 200 °C | Not reported | Not reported | Cantilever beam | SiO2/Si | [15] |

| ZnO with 23 at. % Ag doping | A mixture between hexagonal ZnO (002) and (101) with the phase fcc-Ag (111) | Glancing angle deposition (GLAD) room temperature | 19 (Low strain) 122 (Medium strain) | Not reported | System (Shimadzu-AG-IS universal testing machine) | Biaxial-oriented PET | [27] |

| ZnO with 5% Al doping | Not reported | Atomic layer deposition (ALD) 200 °C. | 8.5 | Not reported | Cantilever beam | SiO2/Si | [18] |

| AZO with 1 vol % organic content | Polycrystalline with predominant (10-10) plane and presence of the (0002) plane (indicating that some crystallites were oriented with the c-axis perpendicular to the plane and others had the c-axis parallel to the plane) | Atomic layer deposition (ALD) 140 °C | −9.5 | −6.6 × 10−11 | Film bending radius | Al2O3-coated PET | [28] |

| ZnO | Polycrystalline: hexagonal wurtzite Preferential orientation: (002) C-axis perpendicular to the surface | RF reactive magnetron sputtering annealed at 600 °C | 2.6 | Not reported | Cantilever beam | SiO2/Si | [19] |

| ZnO | Polycrystalline: hexagonal wurtzite Preferential orientation: (002) C-axis perpendicular to the surface | DC reactive magnetron sputtering | −8.5 | Not reported | Bent substrate | SiO2 | [29] |

| ZnO with 15 at. % F doping | Polycrystalline: hexagonal wurtzite Preferential orientation: (002) C-axis perpendicular to the surface | Ultrasonic spray pyrolysis (homemade system) 450 °C | 12.7 | 9.13 × 10−11 | Cantilever beam | SiO2/Si | Our work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petlacalco Ramírez, H.E.; Alcántara Iniesta, S.; Soto Cruz, B.S.; Mejía Silva, J.I. Evaluation of the Piezoresistivity of a Thin Film of ZnO Doped with Fluorine and Deposited via the Ultrasonic Spray Pyrolysis Technique for Applications in Micro/Nano-Electromechanical Sensors. Crystals 2022, 12, 1607. https://doi.org/10.3390/cryst12111607

Petlacalco Ramírez HE, Alcántara Iniesta S, Soto Cruz BS, Mejía Silva JI. Evaluation of the Piezoresistivity of a Thin Film of ZnO Doped with Fluorine and Deposited via the Ultrasonic Spray Pyrolysis Technique for Applications in Micro/Nano-Electromechanical Sensors. Crystals. 2022; 12(11):1607. https://doi.org/10.3390/cryst12111607

Chicago/Turabian StylePetlacalco Ramírez, Héctor Eduardo, Salvador Alcántara Iniesta, Blanca Susana Soto Cruz, and Jesús Israel Mejía Silva. 2022. "Evaluation of the Piezoresistivity of a Thin Film of ZnO Doped with Fluorine and Deposited via the Ultrasonic Spray Pyrolysis Technique for Applications in Micro/Nano-Electromechanical Sensors" Crystals 12, no. 11: 1607. https://doi.org/10.3390/cryst12111607

APA StylePetlacalco Ramírez, H. E., Alcántara Iniesta, S., Soto Cruz, B. S., & Mejía Silva, J. I. (2022). Evaluation of the Piezoresistivity of a Thin Film of ZnO Doped with Fluorine and Deposited via the Ultrasonic Spray Pyrolysis Technique for Applications in Micro/Nano-Electromechanical Sensors. Crystals, 12(11), 1607. https://doi.org/10.3390/cryst12111607