Neutronographic Analysis of Load Partitioning and Micro Residual Stress Development in Duplex Stainless Steels

Abstract

1. Introduction

2. Materials and Methods

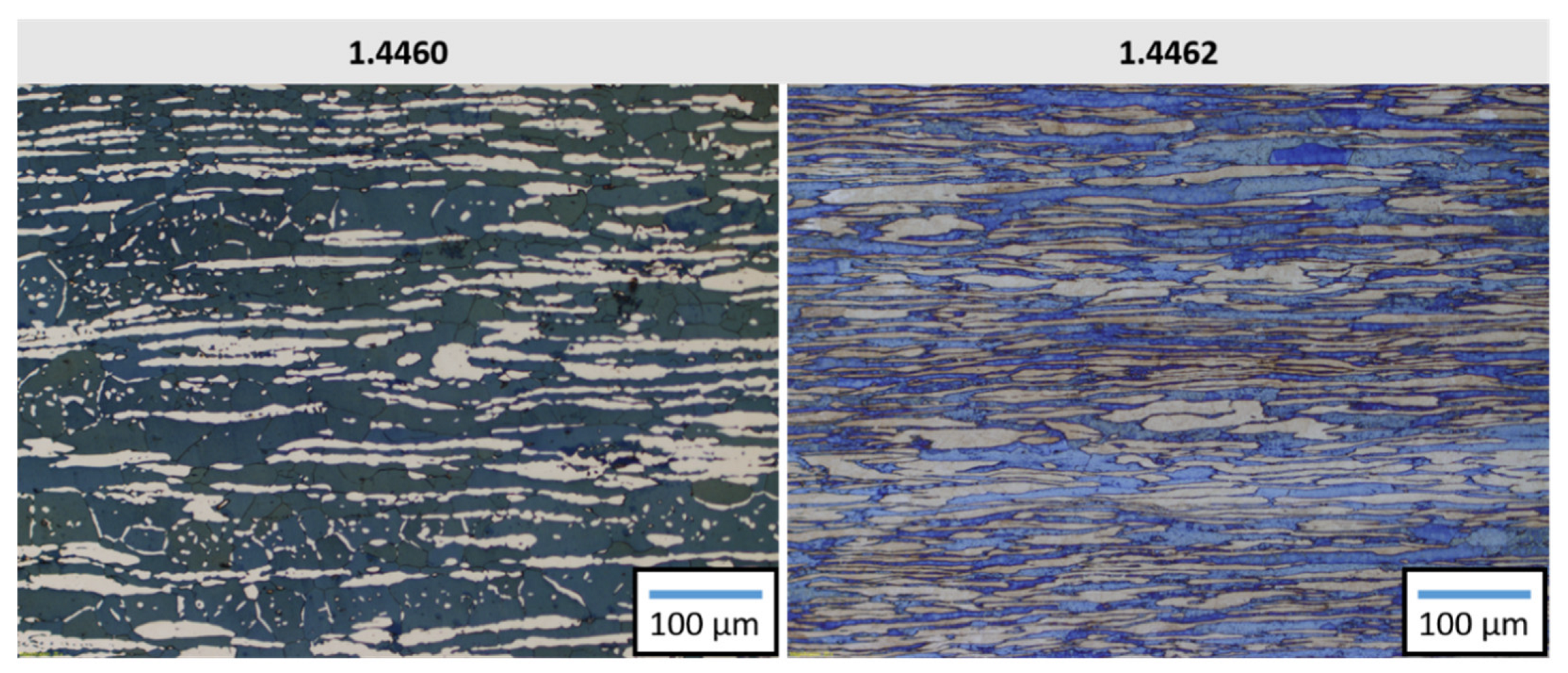

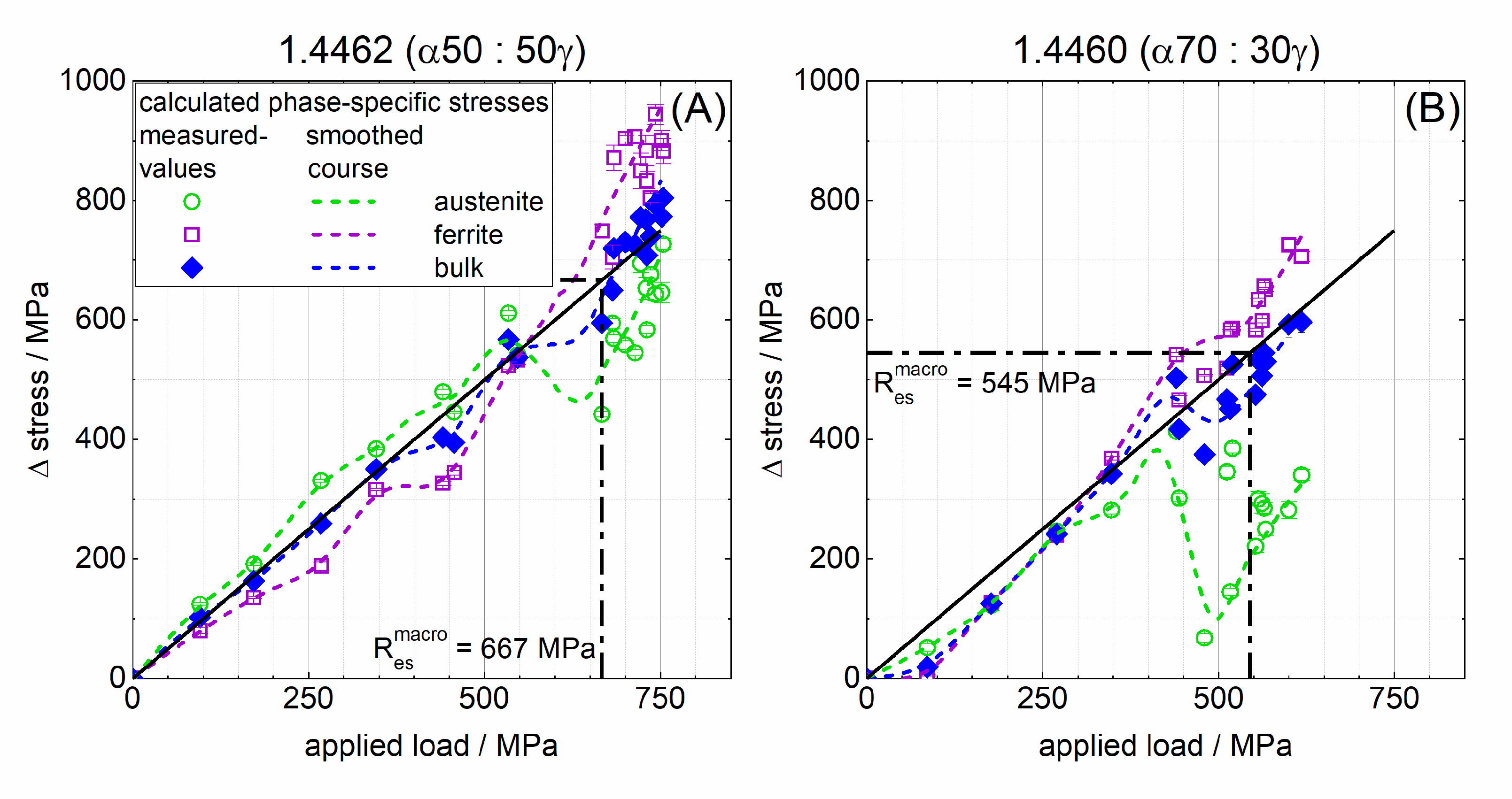

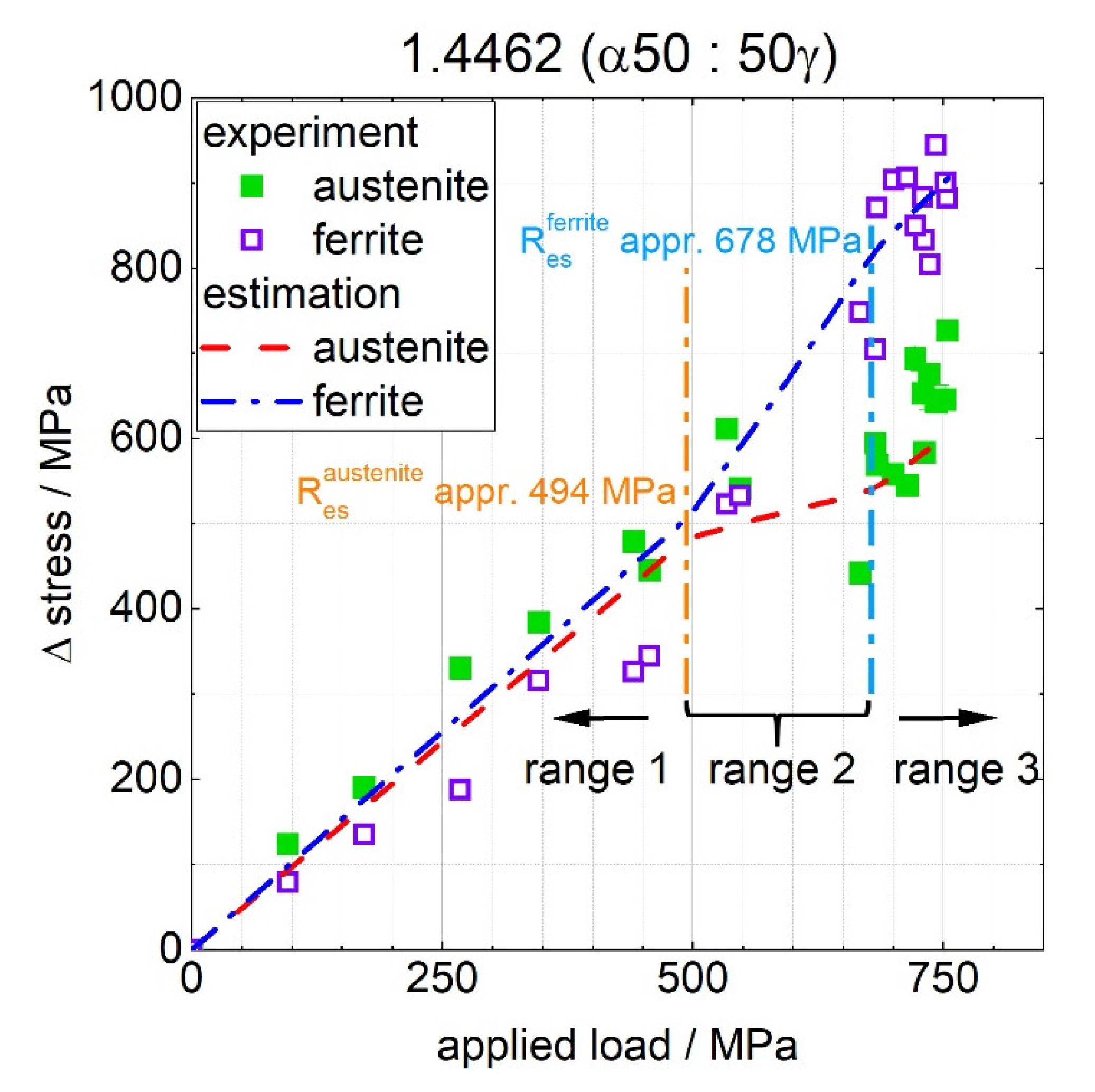

2.1. Basic Characterization of the Two Duplex Steels

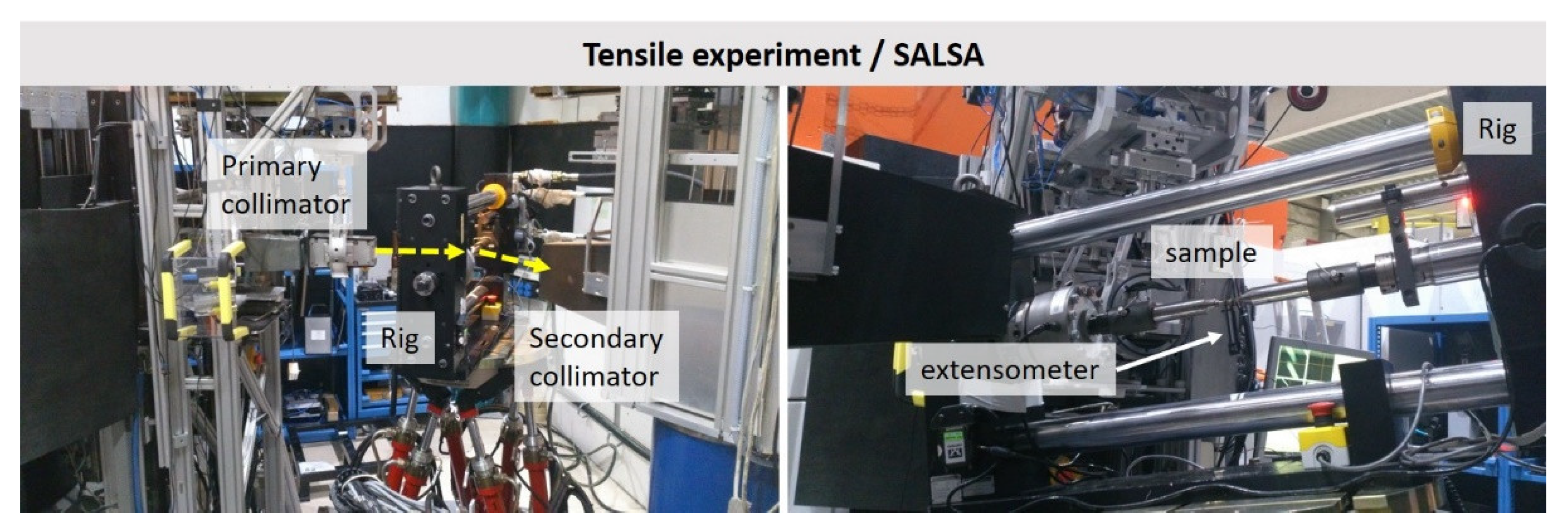

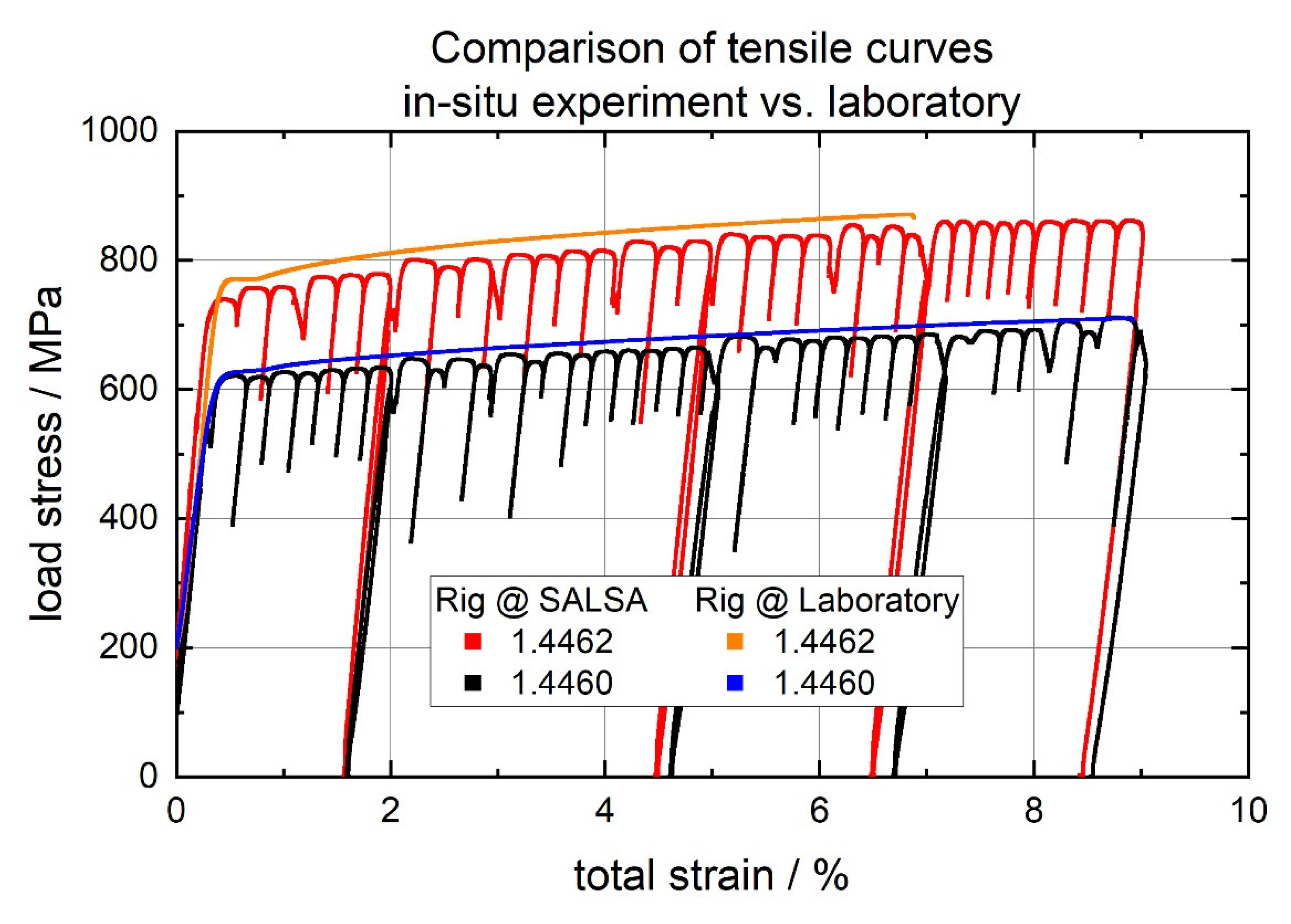

2.2. Neutronographic In Situ Load–Unload Test

3. Results

4. Discussion

4.1. Data Evaluation

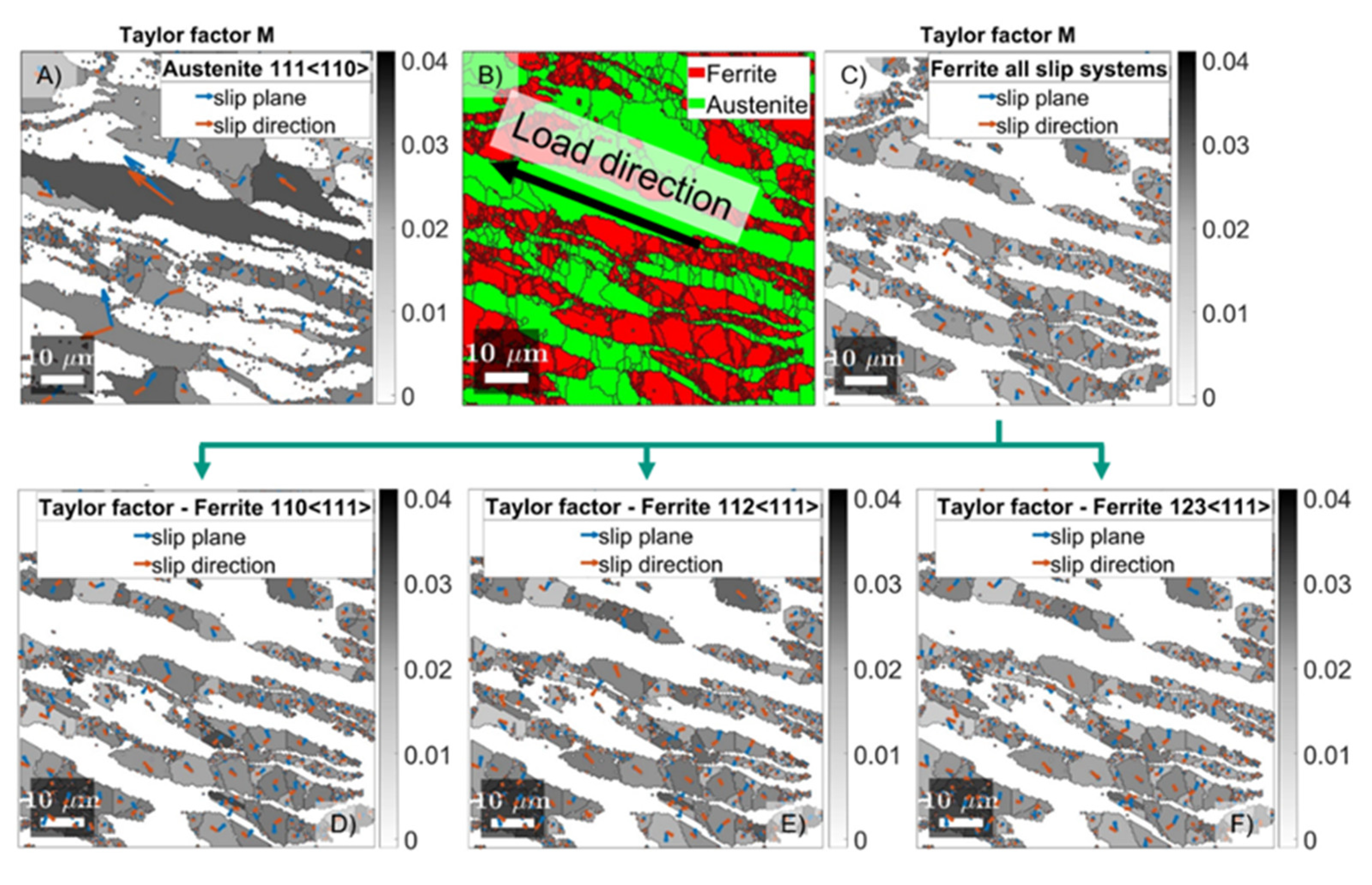

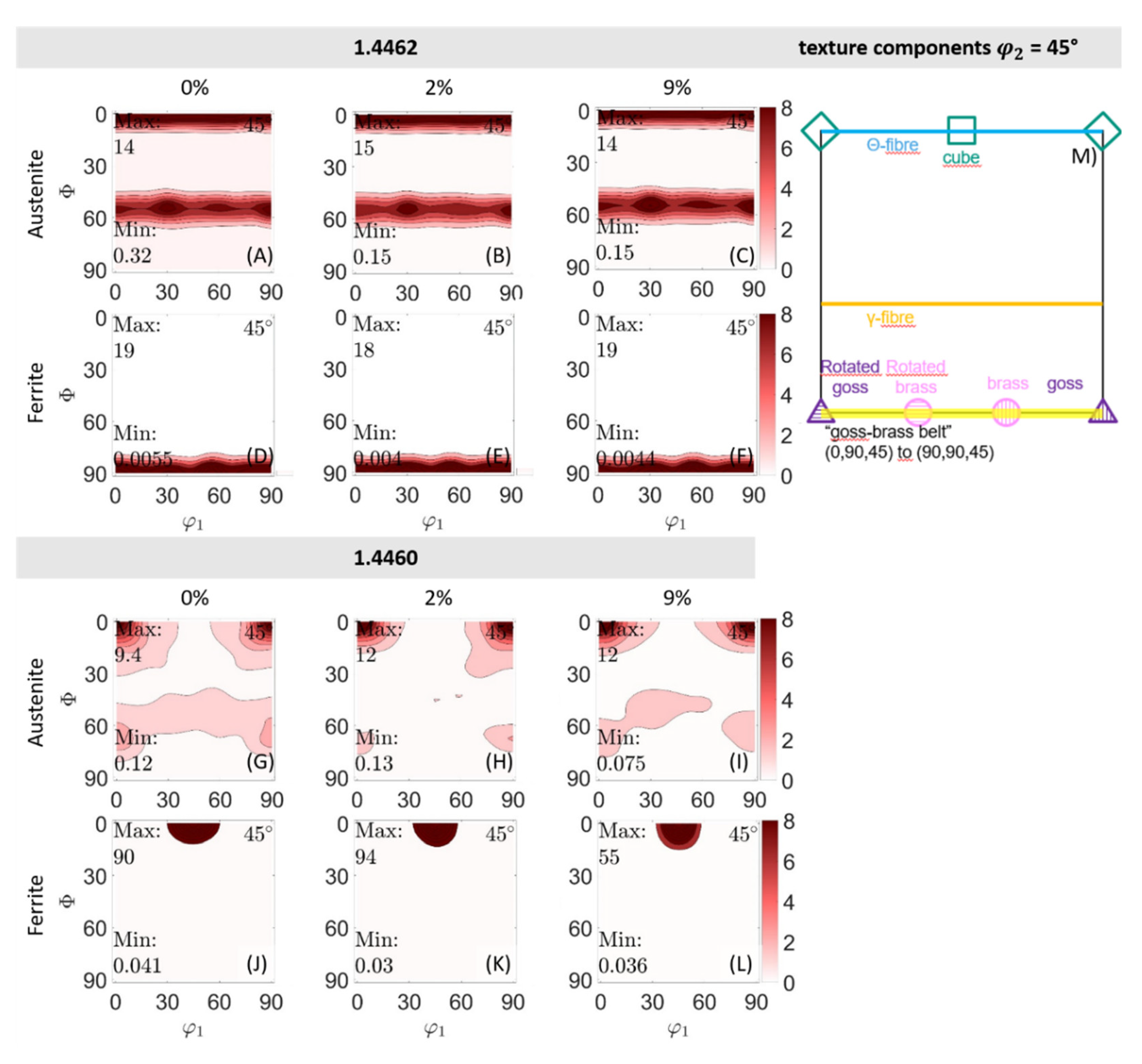

4.2. Texture

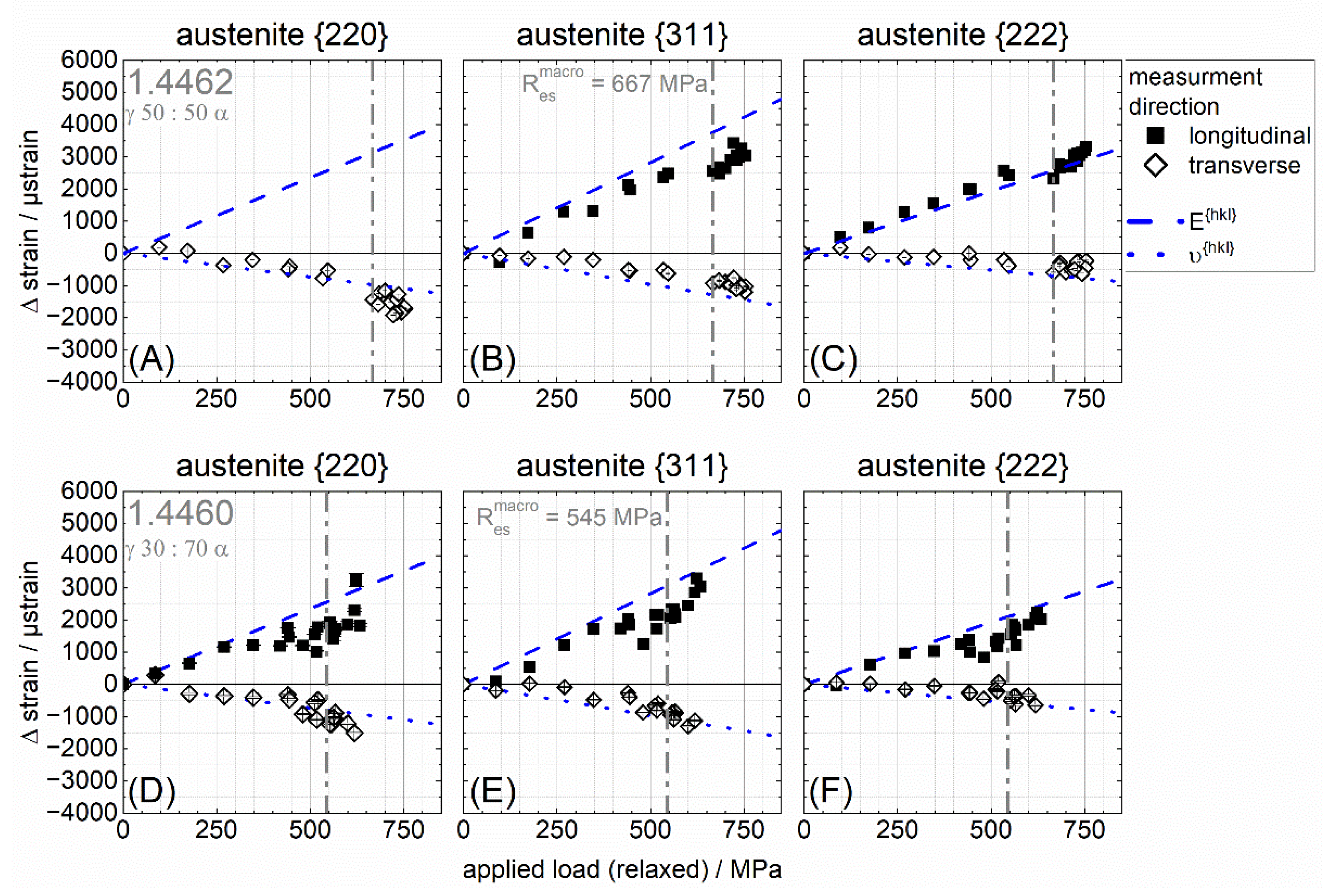

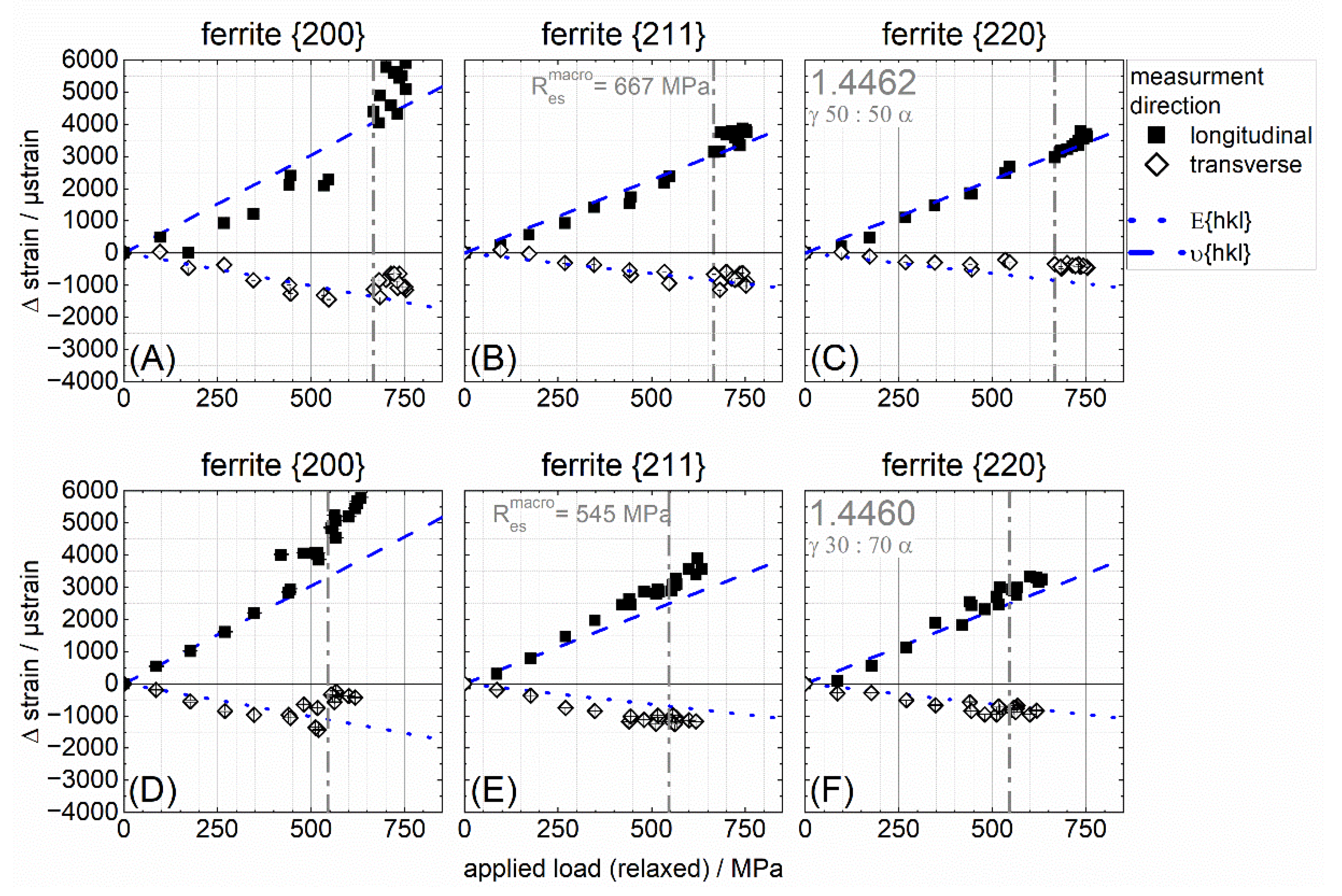

4.3. Phase-Specific Load Distribution in the Elastic Range

4.4. Phase-Specific Load Distribution in the Elasto-Plastic Range

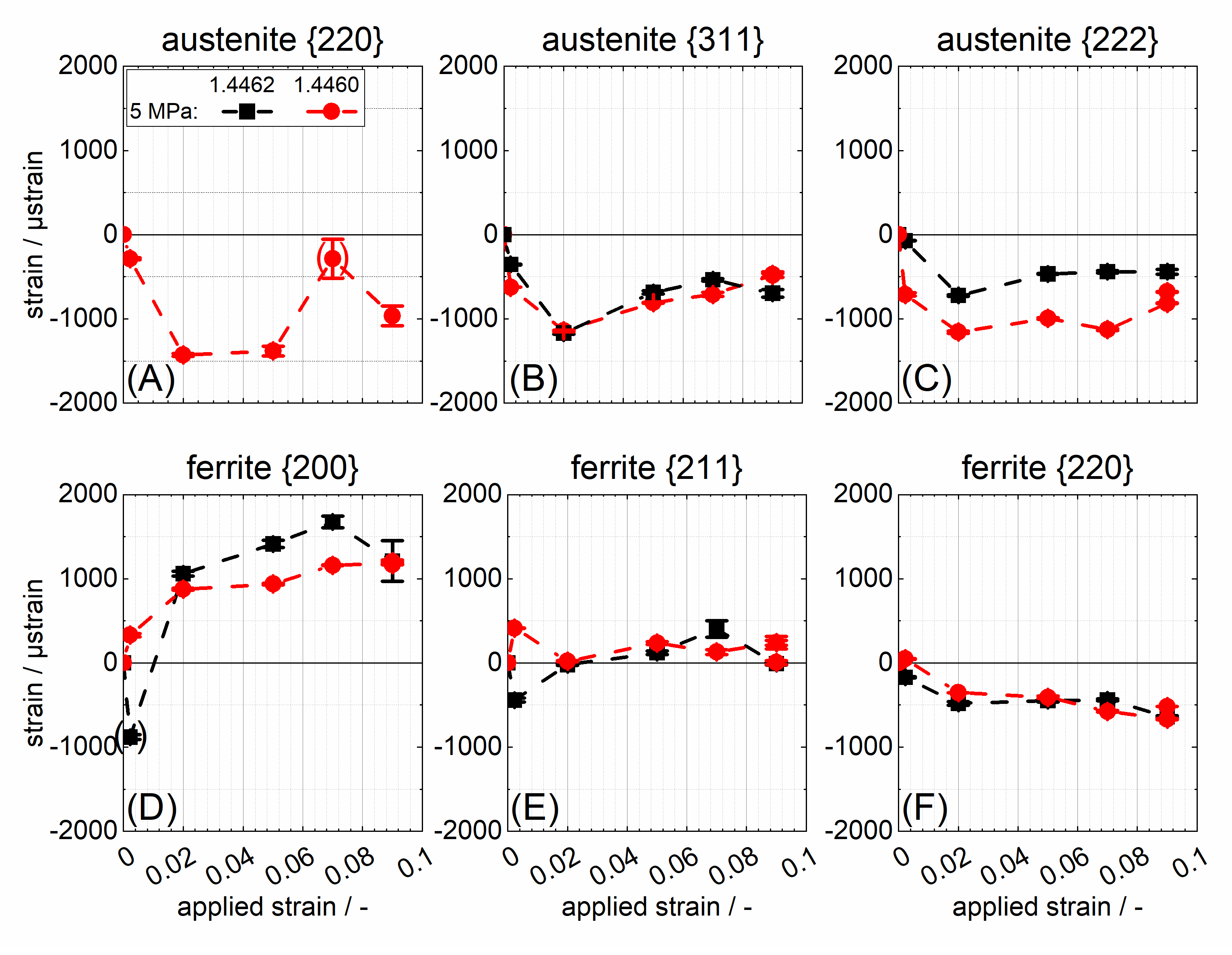

4.5. Phase-Specific (Residual) Strain Development

5. Conclusions

- The load-partitioning behaviour could be distinguished in three ranges:

- In the purely elastic case, both phases; i.e., austenite and ferrite, contributed almost equally to the load partitioning.

- After the onset of plastic deformation, which was observed for both materials in the austenite phase, the ferrite phase transmitted a higher load.

- In the further course; i.e., with increasing plastic deformation, the load partitioning changed again. However, the ferrite phase continued to transmit a higher load within the investigated range of 9% total strain.

- For both steels, the austenite phase exhibited plastic deformation before the macroscopic yield strength was reached.

- The formation of intergranular stresses (and respective strains) with increasing plastic deformation were similar in their principal course. This was observed despite the different phase contents and phase-specific crystallographic textures.

- In the austenitic phase, only intergranular compressive strains occurred in the unloaded state for the investigated lattice planes, which clearly differed from the behaviour observed for the ferrite phase.

- For the three investigated lattice planes of the ferrite phase, the two lattice planes {211} and {220} were only weakly sensitive to plastic anisotropy effects as expected, despite clearly different and sharp crystallographic textures. In the austenite phase, the {222} lattice plane showed a correlation that could be described as almost linear.

- In both phases, no texture evolution with increasing plastic deformation was observed; i.e., no texture components appeared nor disappeared. Only a slight variation in the intensity distribution was observed.

- Quantitatively, the load partitioning depended on the respective phase content. For the 1.4460 duplex stainless steel, which had an austenite content of 70%, the drop in the load partitioning after reaching the phase-specific yield strength was more pronounced compared to the 1.4462 duplex stainless steel with an austenite content of 50%.

- Even though for both steels the austenite phases exhibited elasto-plastic behaviour before reaching the macroscopic yield strength, the phase-specific yield strength of the austenite phase was reached earlier for the 1.4460 duplex steel than for the 1.4462 steel.

- For the investigated lattice planes, the different phase contents only showed an effect on the residual intergranular strains for the austenite {222} lattice plane. Here, a higher residual strain was observed for the higher austenite content.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Moura, V.S.; Lima, L.D.; Pardal, J.M.; Kina, A.Y.; Corte, R.; Tavares, S. Influence of microstructure on the corrosion resistance of the duplex stainless steel UNS S31803. Mater. Charact. 2008, 59, 1127–1132. [Google Scholar] [CrossRef]

- Calderón-Uríszar-Aldaca, I.; Briz, E.; Matanza, A.; Martin, U.; Bastidas, D.M. Corrosion Fatigue Numerical Model for Austenitic and Lean-Duplex Stainless-Steel Rebars Exposed to Marine Environments. Metals 2020, 10, 1217. [Google Scholar] [CrossRef]

- Johansson, J. Residual Stresses and Fatigue in a Duplex Stainless Steel. PhD Thesis, Linkoeping Studies in Science and Technology, Linkopings Universitet, Linköping, Sweden, 1999. 91-7219-523-1. [Google Scholar]

- TMR Stainless. Practical Guidelines for the Fabrication of Duplex Stainless Steels, 3rd ed.; International Molybdenum: London, UK, 2014; ISBN 978-1-907470-09-7. [Google Scholar]

- Tang, J.; Yang, X.; Wang, Y.; Wang, H.; Xiao, Y.; Apreutesei, M.; Nie, Z.; Normand, B. Corrosion Behavior of 2205 Duplex Stainless Steels in HCl Solution Containing Sulfide. Metals 2019, 9, 294. [Google Scholar] [CrossRef]

- Simon, N.; Erdle, H.; Walzer, S.; Gibmeier, J.; Böhlke, T.; Liewald, M. Residual stresses in deep-drawn cups made of duplex stainless steel X2CrNiN23-4. Forsch. Ingenieurwes. 2021, 85, 795–806. [Google Scholar] [CrossRef]

- Simon, N.; Erdle, H.; Walzer, S.; Gibmeier, J.; Böhlke, T.; Liewald, M. Phase-specific residual stresses induced by deep drawing of lean duplex steel: Measurement vs. simulation. Prod. Eng. Res. Devel. 2019, 13, 227–237. [Google Scholar] [CrossRef]

- Peng, R.L.; Gibmeier, J.; Chai, G.C.; Johansson, S. Load partitioning in a duplex stainless steel with surface strength gradient and residual stresses. In Proceedings of the 57th Annual Conference on Applications of X-ray Analysis and the 8th International Conference on Residual Stresses, Advances in X-Ray Analysis, Denver, CO, USA, 4–8 August 2008; pp. 773–780. [Google Scholar]

- Simon, N.; Krause, M.; Heinemann, P.; Erdle, H.; Böhlke, T.; Gibmeier, J. Phase-Specific Strain Hardening and Load Partitioning of Cold Rolled Duplex Stainless Steel X2CrNiN23-4. Crystals 2020, 10, 976. [Google Scholar] [CrossRef]

- Tao, P.; Gong, J.; Wang, Y.; Jiang, Y.; Li, Y.; Cen, W. Characterization on stress-strain behavior of ferrite and austenite in a 2205 duplex stainless steel based on nanoindentation and finite element method. Results Phys. 2018, 11, 377–384. [Google Scholar] [CrossRef]

- Baczmański, A. Elastoplastic properties of duplex steel determined using neutron diffraction and self-consistent model. Acta Mater. 2004, 52, 1133–1142. [Google Scholar] [CrossRef]

- Baczmański, A.; Zhao, Y.; Gadalińska, E.; Le Joncour, L.; Wroński, S.; Braham, C.; Panicaud, B.; François, M.; Buslaps, T.; Soloducha, K. Elastoplastic deformation and damage process in duplex stainless steels studied using synchrotron and neutron diffractions in comparison with a self-consistent model. Int. J. Plast. 2016, 81, 102–122. [Google Scholar] [CrossRef]

- Dakhlaoui, R.; Braham, C.; Baczmański, A. Mechanical properties of phases in austeno-ferritic duplex stainless steel—Surface stresses studied by X-ray diffraction. Mater. Sci. Eng. A 2007, 444, 6–17. [Google Scholar] [CrossRef]

- Fu, H.; Dönges, B.; Krupp, U.; Pietsch, U.; Fritzen, C.-P.; Yun, X.; Christ, H.-J. Microcrack initiation mechanism of a duplex stainless steel under very high cycle fatigue loading condition: The significance of load partitioning and micro residual stresses. Acta Mater. 2020, 199, 278–287. [Google Scholar] [CrossRef]

- Hutchings, M.T.; Withers, P.J.; Holden, T.M.; Lorentzen, T. Introduction to the Characterization of Residual Stress by Neutron Diffraction, 1st ed.; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2005; ISBN 0-415-31000-8. [Google Scholar]

- Clausen, B.; Lorentzen, T.; Bourke, M.A.; Daymond, M.R. Lattice strain evolution during uniaxial tensile loading of stainless steel. Mater. Sci. Eng. A 1999, 259, 17–24. [Google Scholar] [CrossRef]

- DIN Deutsches Institut für Normung e.V.; DIN German Institute for Standardization. Non-destructive testing—Standard test method for determining residual stresses by neutron diffraction; Beuth Verlag GmbH: Berlin, Germany, 2020; 19.100 (ISO 21432:2020). [Google Scholar]

- Pang, J.W.L.; Holden, T.M.; Mason, T.E. The development of intergranular strains in a high-strength steel. J. Strain Anal. Eng. Des. 1998, 33, 373–383. [Google Scholar] [CrossRef]

- Allen, A.J.; Bourke, M.; David, W.I.F.; Dawes, S.; Hutchings, M.T.; Krawitz, A.D.; Windsor, C.G. Effects of Elastic Anisotropy on the Lattice Strains in Polycrystalline Metals and Composites Measured by Neutron Diffraction. In International Conference on Residual Stresses: ICRS2; Beck, G., Denis, S., Simon, A., Eds.; Springer: Dordrecht, The Netherlands, 1989; pp. 78–83. ISBN 978-94-010-7007-2. [Google Scholar]

- Dakhlaoui, R.; Baczmański, A.; Braham, C.; Wroński, S.; Wierzbanowski, K.; Oliver, E.C. Neutron Diffraction Study of Duplex Stainless Steel during Loading at 200 °C. In Materials Science Forum; Trans Tech Publications, Ltd.: Wollerau, Switzerland, 2008; Volume 571–572, pp. 175–180. [Google Scholar] [CrossRef]

- Dye, D.; Stone, H.J.; Reed, R.C. Intergranular and interphase microstresses. Curr. Opin. Solid State Mater. Sci. 2001, 5, 31–37. [Google Scholar] [CrossRef]

- Withers; Preuss, P.J.M.; Steuwerb, A.; Pang, J.W.L. Methods for obtaining the strain-free lattice parameter when using diffraction to determine residual stress. Appl. Crystallogr. 2007, 40, 891–904. [Google Scholar] [CrossRef]

- Daymond, M.R.; Johnson, M.W. The determination of a stress-free lattice parameter within a stressed material using elastic anisotropy. J. Appl. Crystallogr. 2001, 34, 263–270. [Google Scholar] [CrossRef]

- Repper, J.; Hofmann, M.; Krempaszky, C.; Regener, B.; Berhuber, E.; Petry, W.; Werner, E. Effect of macroscopic relaxation on residual stress analysis by diffraction methods. J. Appl. Phys. 2012, 112, 64906. [Google Scholar] [CrossRef]

- Hofmann, M.; Gan, W.; Rebelo-Kornmeier, J. STRESS-SPEC: Materials science diffractometer. J. Larg.-Scale Res. Facil. 2015, 1, 6. [Google Scholar] [CrossRef]

- Pirling, T.; Bruno, G.; Withers, P.J. SALSA—A new instrument for strain imaging in engineering materials and components. Mater. Sci. Eng. A 2006, 437, 139–144. [Google Scholar] [CrossRef]

- Eigenmann, B.; Macherauch, E. Röntgenographische Untersuchung von Spannungszuständen in Werkstoffen: X-Ray Investigation of Stress States in Materials. Materialwiss. Werkstofftech. 1995, 26, 148–160. [Google Scholar] [CrossRef]

- Pulvermacher, S.; Bücker, T.; Šaroun, J.; Rebelo-Kornmeier, J.; Hofmann, M.; Gibmeier, J. Neutron and X-ray Diffraction Analysis of Macro and Phase-Specific Micro Residual Stresses in Deep Rolled Duplex Stainless Steels. Materials 2021, 14, 1854. [Google Scholar] [CrossRef] [PubMed]

- Knabben, H. Werkstoffblatt TK 1.4462 (X2CrNiMoN22-5-3), 45313 Essen, 2006. Available online: https://www.steelinox.nl/en/qualities/duplex-superduplex/1.4462-s31803-f51-x2crnimon22-5-3 (accessed on 13 October 2016).

- DIN EN 10088-3:2014-12, Nichtrostende Stähle_- Teil_3: Technische Lieferbedingungen für Halbzeug, Stäbe, Walzdraht, gezogenen Draht, Profile und Blankstahlerzeugnisse aus korrosionsbeständigen Stählen für allgemeine Verwendung; Deutsche Fassung; Beuth Verlag GmbH: Berlin, Germany. Available online: https://www.beuth.de/de/norm/din-en-10088-3/201983218 (accessed on 7 September 2022).

- Bachmann, F.; Hielscher, R.; Schaeben, H. Texture Analysis with MTEX—Free and Open Source Software Toolbox. In Solid State Phenomena; Trans Tech Publications Ltd.: Wollerau, Switzerland, 2010; Volume 160, pp. 63–68. [Google Scholar] [CrossRef]

- Du, C.; Maresca, F.; Geers, M.; Hoefnagels, J. Ferrite slip system activation investigated by uniaxial micro-tensile tests and simulations. Acta Mater. 2018, 146, 314–327. [Google Scholar] [CrossRef]

- Bunge, H.J. Some applications of the Taylor theory of polycrystal plasticity. Cryst. Res. Technol. 1970, 5, 145–175. [Google Scholar] [CrossRef]

- Börnstein, L. Elastische, piezoelektrische, piezooptische und elektrooptische Konstanten von Kristallen, Landolt-Börnstein: Zahlenwerte und Funktionen aus Naturwissenschaft und Technik, Neue Serie, Gruppe 3: Kristall-und Festkörperphysik; Band 1; Bechmann, R., Hearmon, R.F.S., Hellwege, K.H., Eds.; Springer: Berlin, Germany, 1966. [Google Scholar]

- Ledbetter, H.M. Predicted single-crystal elastic constants of stainless-steel 316. Br. J. Non-Destr. Test. 1981, 23, 286–287. [Google Scholar]

- Gibmeier, J.; Hofmann, M.; Pirling, T.; Pulvermacher, S.; Kornmeier, R.; Saroun, J.; Zürn, M. Residual stress analysis for multiphase materials with depth gradients of the strain free/independent lattice parameter d0 (cont.): 1-02-226/Cycle 183 (from 03/09/2018 to 28/10/2018), instrument SALSA. [CrossRef]

- Richard, D.; Ferrand, M.; Kearley, G.J. Analysis and visualisation of neutron-scattering data. J. Neutron Res. 1996, 4, 33–39. [Google Scholar] [CrossRef]

- Daymond, M.R. The determination of a continuum mechanics equivalent elastic strain from the analysis of multiple diffraction peaks. J. Appl. Phys. 2004, 96, 4263–4272. [Google Scholar] [CrossRef]

- Tanaka, K.; Akiniwa, Y.; Ito, T. Effect of secondary phase on diffraction elastic constants of polycrystalline materials. In Proceedings of the ICRS-6, Oxford, UK, 10–12 July 2000; pp. 1012–1019. [Google Scholar]

- Behnken, H.; Hauk, V. Die röntgenographischen Elastizitätskonstanten keramischer Werkstoffe zur Ermittlung der Spannungen aus Gitterdehnungsmessungen. Zeitschrift fuer Metallkunde 1990, 81, 891–895. [Google Scholar] [CrossRef]

- Fréour, S.; Gloaguen, D.; François, M.; Guillén, R. Modelling and simulation of multi-phase effects on X-ray elasticity constants. Phys. Stat. Sol. (B) 2003, 239, 297–309. [Google Scholar] [CrossRef]

- Heldmann, A.; Hoelzel, M.; Hofmann, M.; Gan, W.; Schmahl, W.W.; Griesshaber, E.; Hansen, T.; Schell, N.; Petry, W. Diffraction-based determination of single-crystal elastic constants of polycrystalline titanium alloys. J. Appl. Crystallogr. 2019, 52, 1144–1156. [Google Scholar] [CrossRef]

- Tanaka, K.; Akiniwa, Y. Effect of Secondary Phase on Elastic Constants for Stress Measurement of Multi-Phase Materials by X-Ray and Neutron Diffraction Methods. JSME Int. J. Ser. A 1998, 41, 280–286. [Google Scholar] [CrossRef]

| Mat.-No. | C | Si | Mn | P | S | Cr | Mo | Ni | N |

|---|---|---|---|---|---|---|---|---|---|

| 1.4462 | 0–0.03 | 0–1.0 | 0–2.0 | 0–0.035 | 0–0.015 | 21.0–23.0 | 2.5–3.5 | 4.5–6.5 | 0.1–0.22 |

| 1.4460 | 0–0.05 | 0–1.0 | 0–2.0 | 0–0.035 | 0–0.03 | 25.0–28.0 | 1.3–2.0 | 4.5–6.5 | 0.05–0.20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pulvermacher, S.; Pirling, T.; Cabeza, S.; Zuern, M.G.; Hofmann, M.; Gibmeier, J. Neutronographic Analysis of Load Partitioning and Micro Residual Stress Development in Duplex Stainless Steels. Crystals 2022, 12, 1378. https://doi.org/10.3390/cryst12101378

Pulvermacher S, Pirling T, Cabeza S, Zuern MG, Hofmann M, Gibmeier J. Neutronographic Analysis of Load Partitioning and Micro Residual Stress Development in Duplex Stainless Steels. Crystals. 2022; 12(10):1378. https://doi.org/10.3390/cryst12101378

Chicago/Turabian StylePulvermacher, Samuel, Thilo Pirling, Sandra Cabeza, Michael Georg Zuern, Michael Hofmann, and Jens Gibmeier. 2022. "Neutronographic Analysis of Load Partitioning and Micro Residual Stress Development in Duplex Stainless Steels" Crystals 12, no. 10: 1378. https://doi.org/10.3390/cryst12101378

APA StylePulvermacher, S., Pirling, T., Cabeza, S., Zuern, M. G., Hofmann, M., & Gibmeier, J. (2022). Neutronographic Analysis of Load Partitioning and Micro Residual Stress Development in Duplex Stainless Steels. Crystals, 12(10), 1378. https://doi.org/10.3390/cryst12101378