Waste Glass Utilization in Cement-Based Materials for Sustainable Construction: A Review

Abstract

:1. Introduction

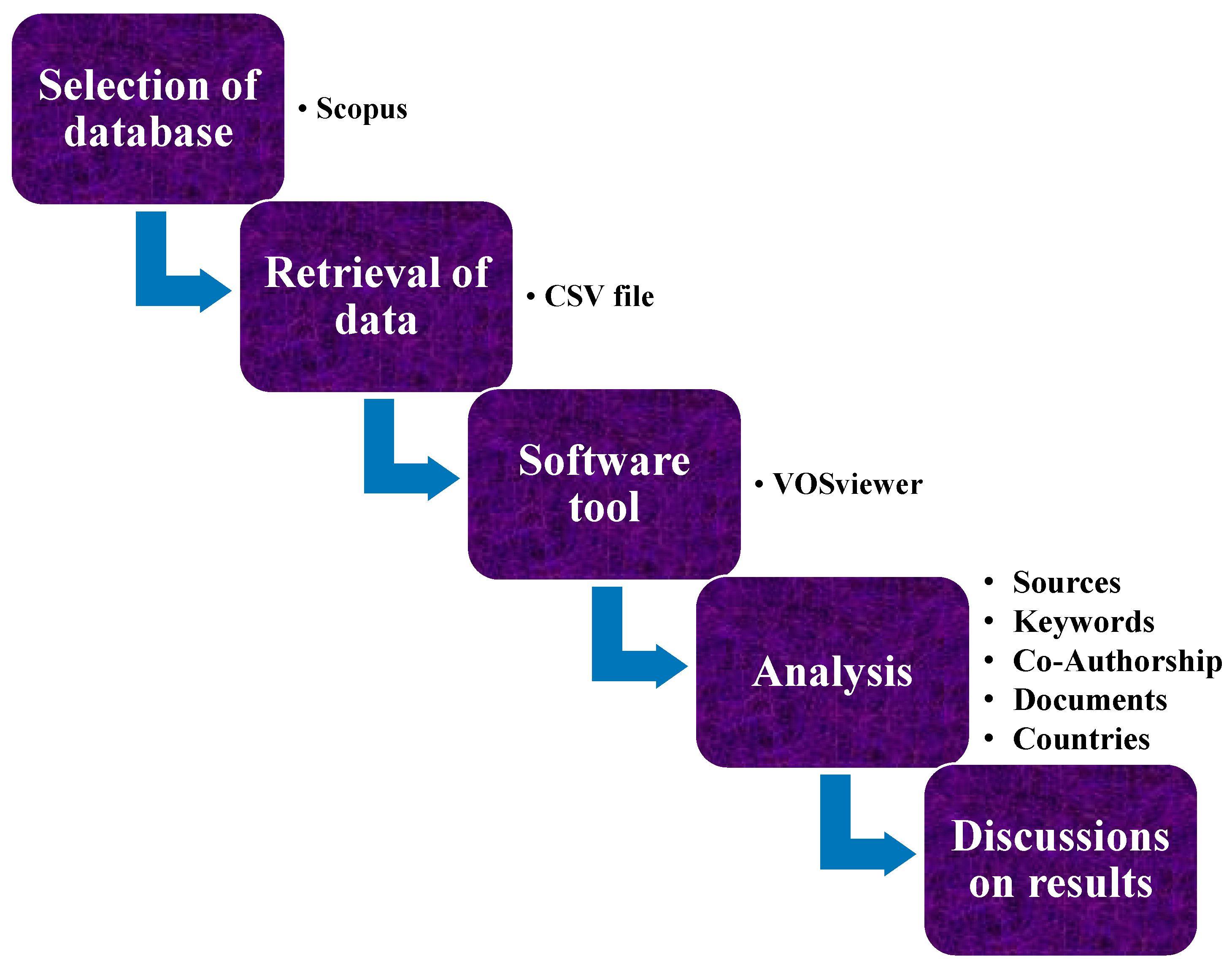

2. Research Significance

3. Methodology

4. Results and Discussion on Scientometric Analysis

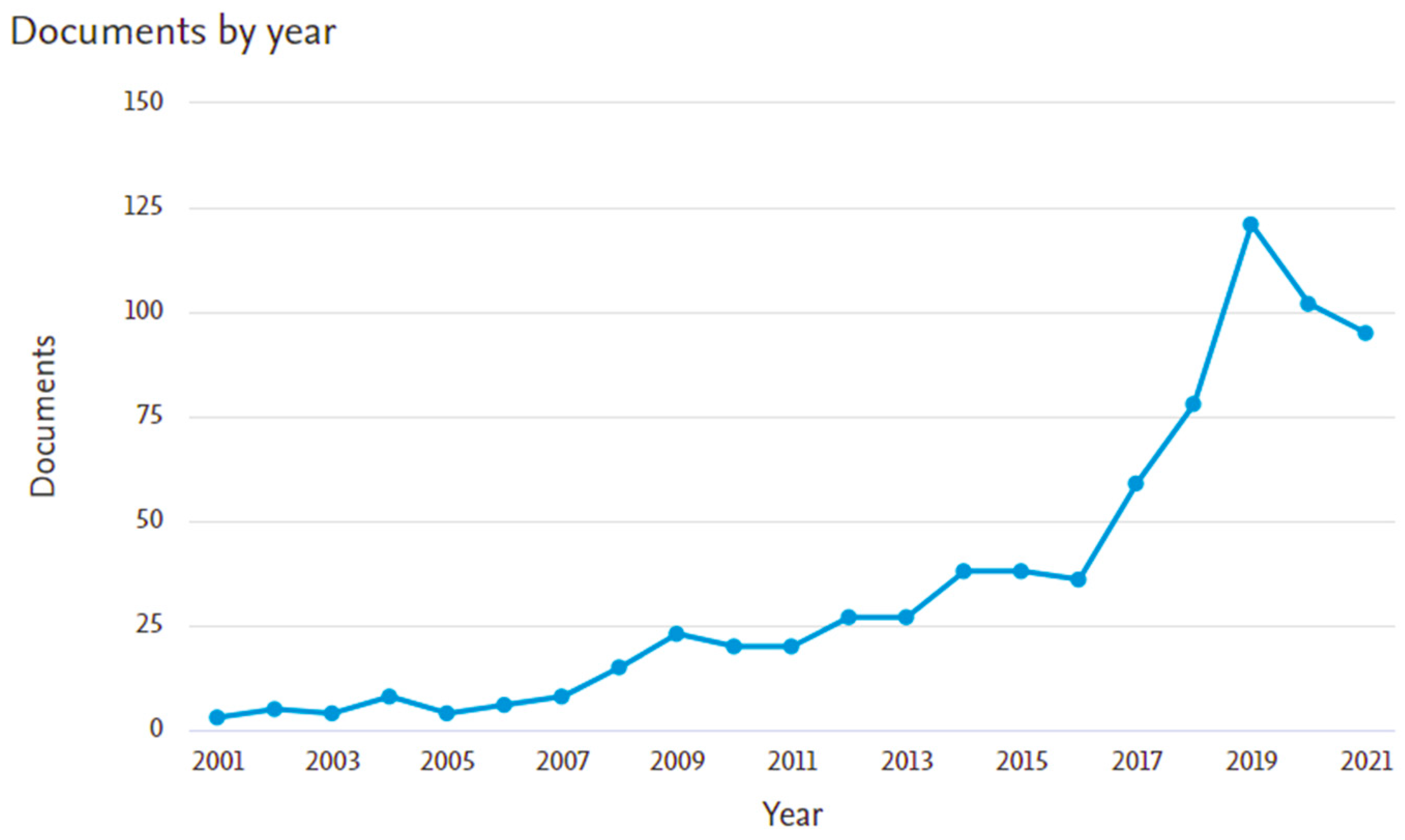

4.1. Subject Area and Annual Publication Pattern of Articles

4.2. Sources Mapping

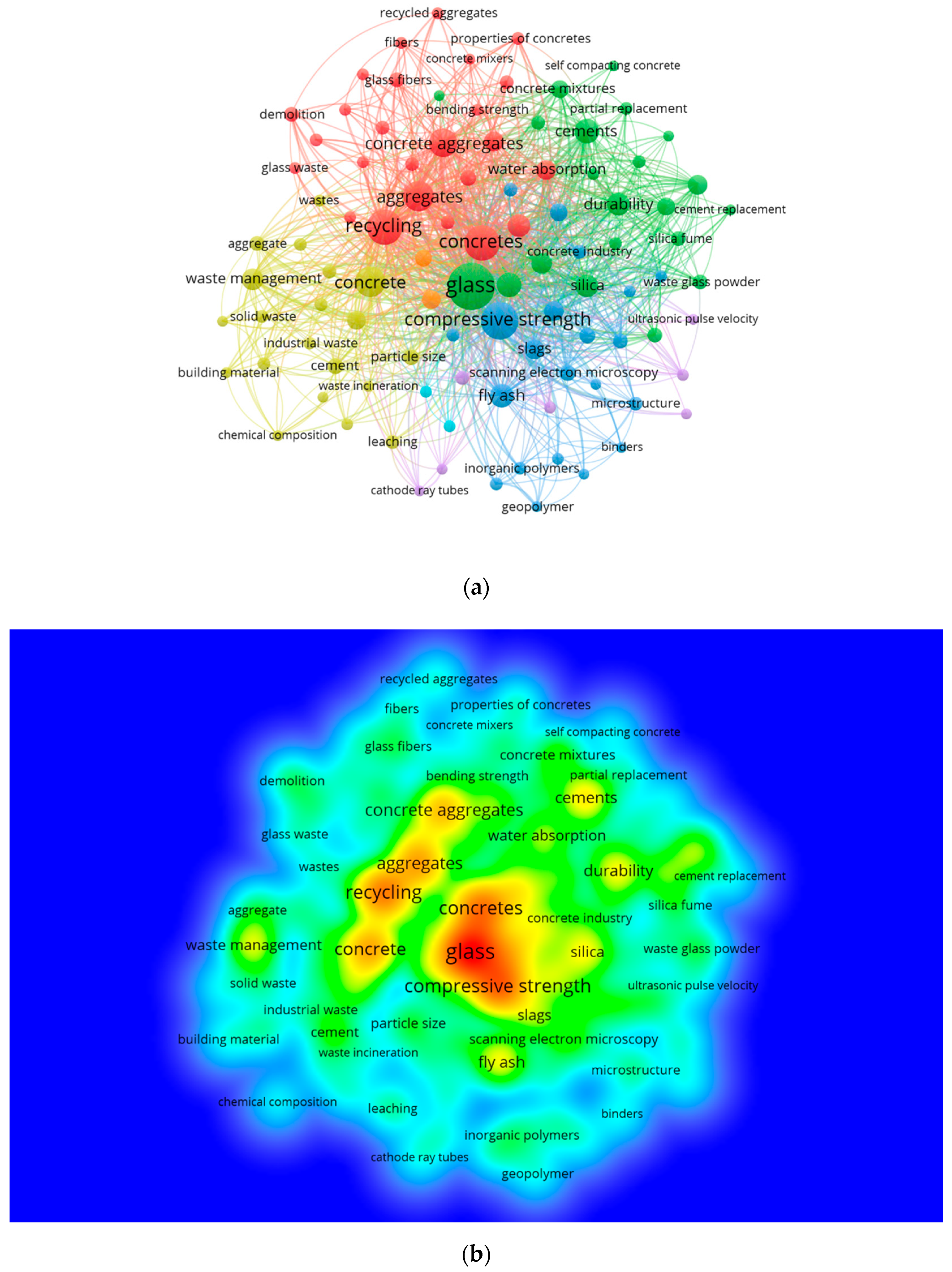

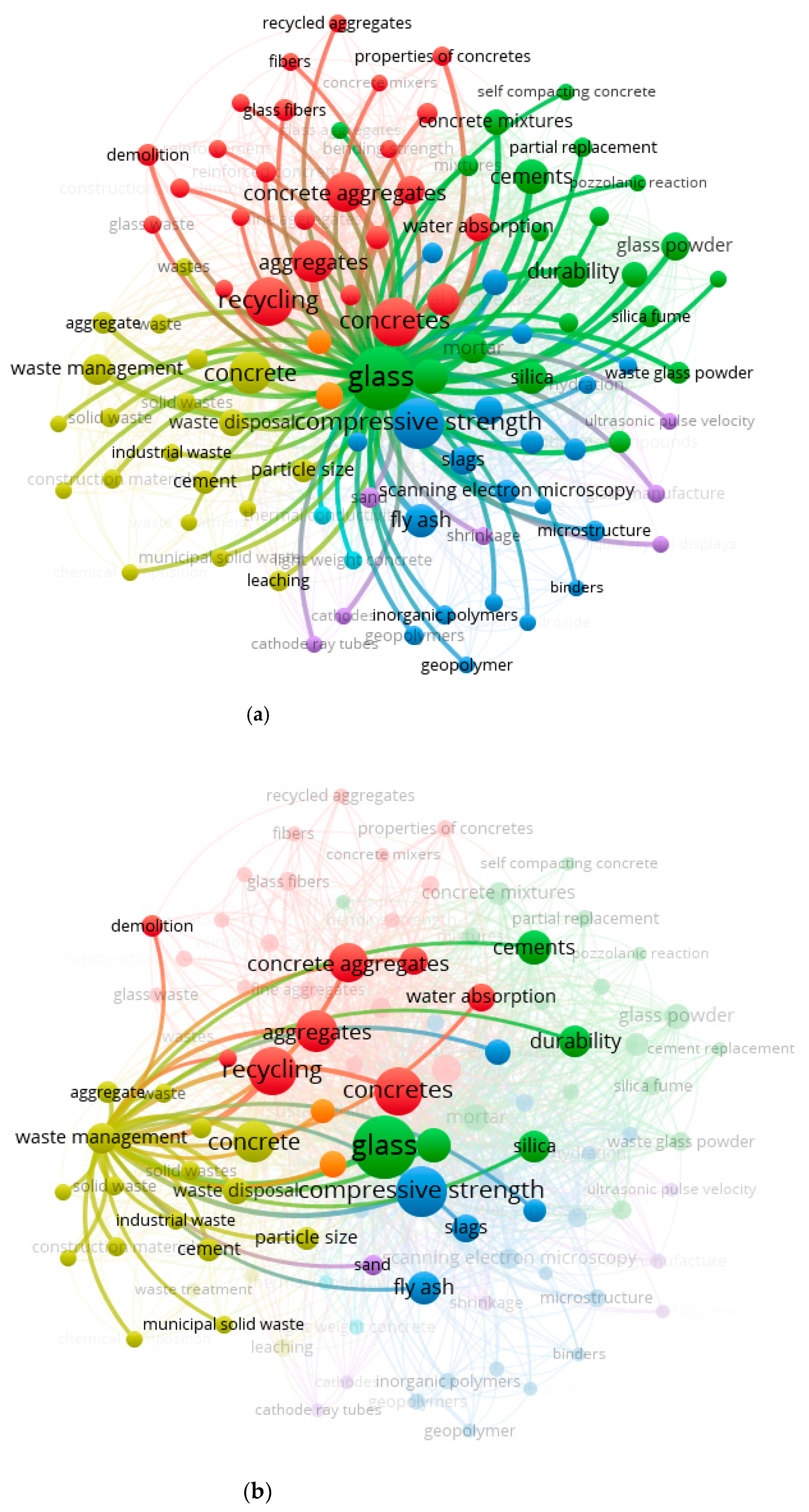

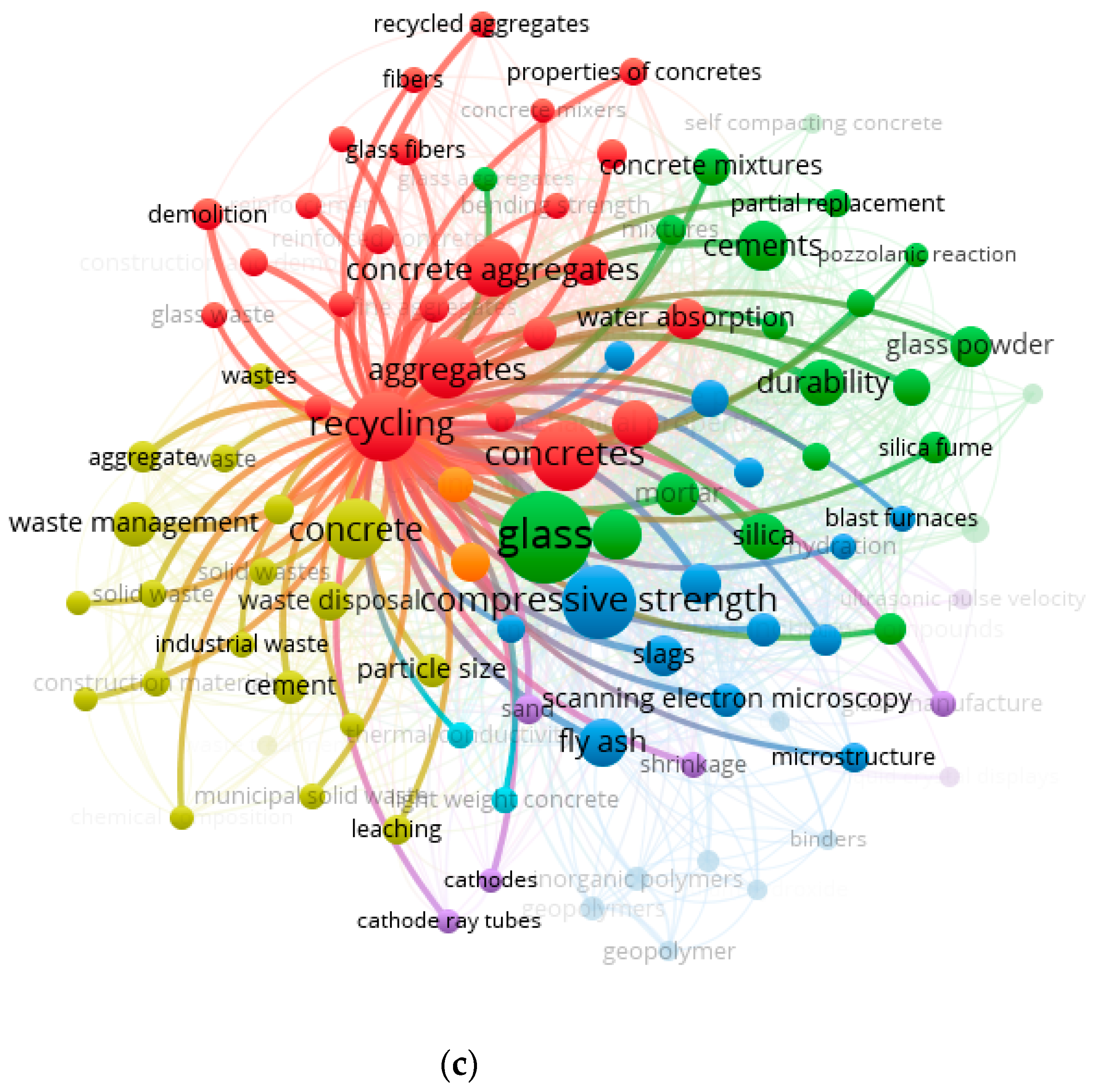

4.3. Keywords Mapping

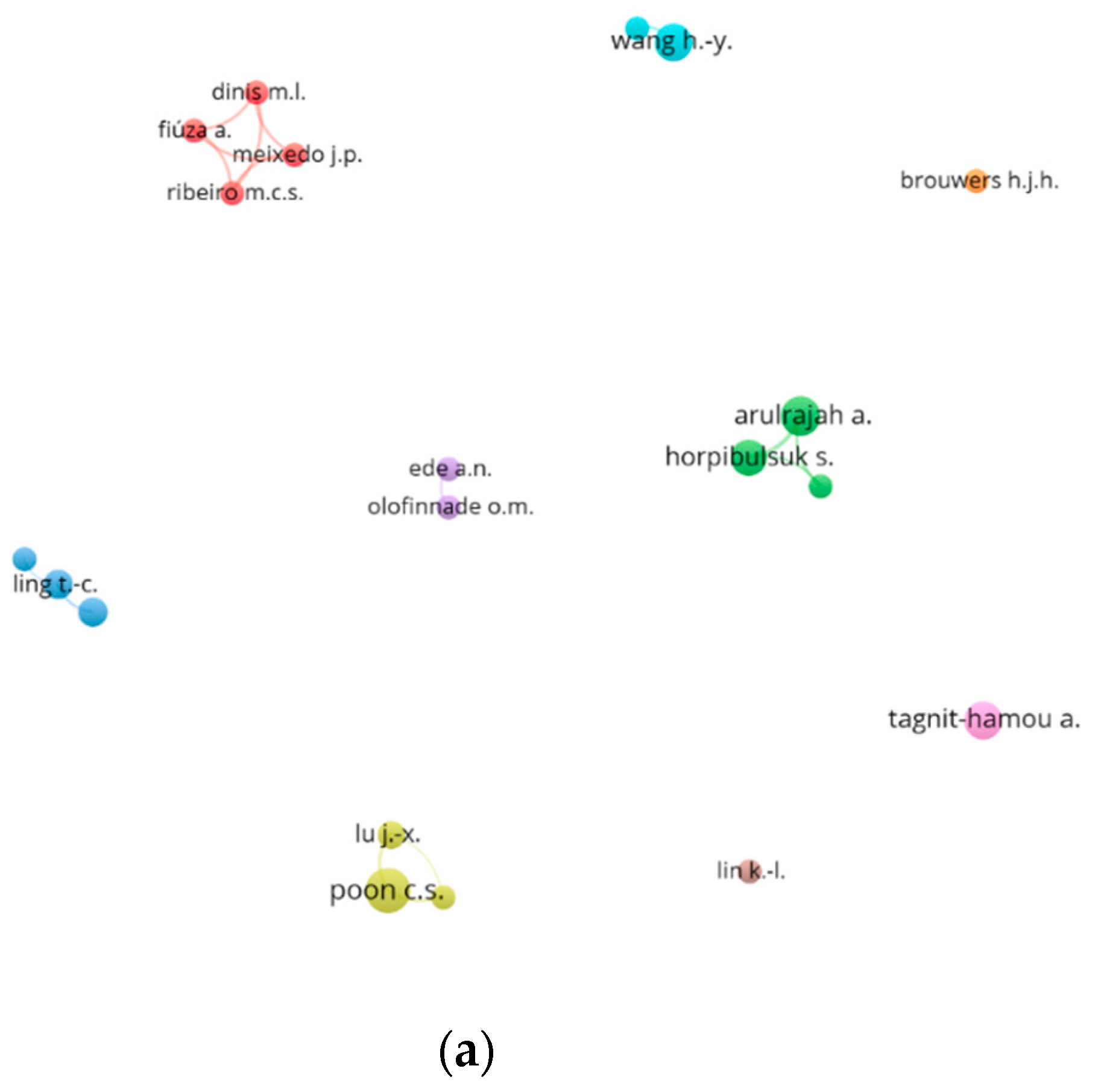

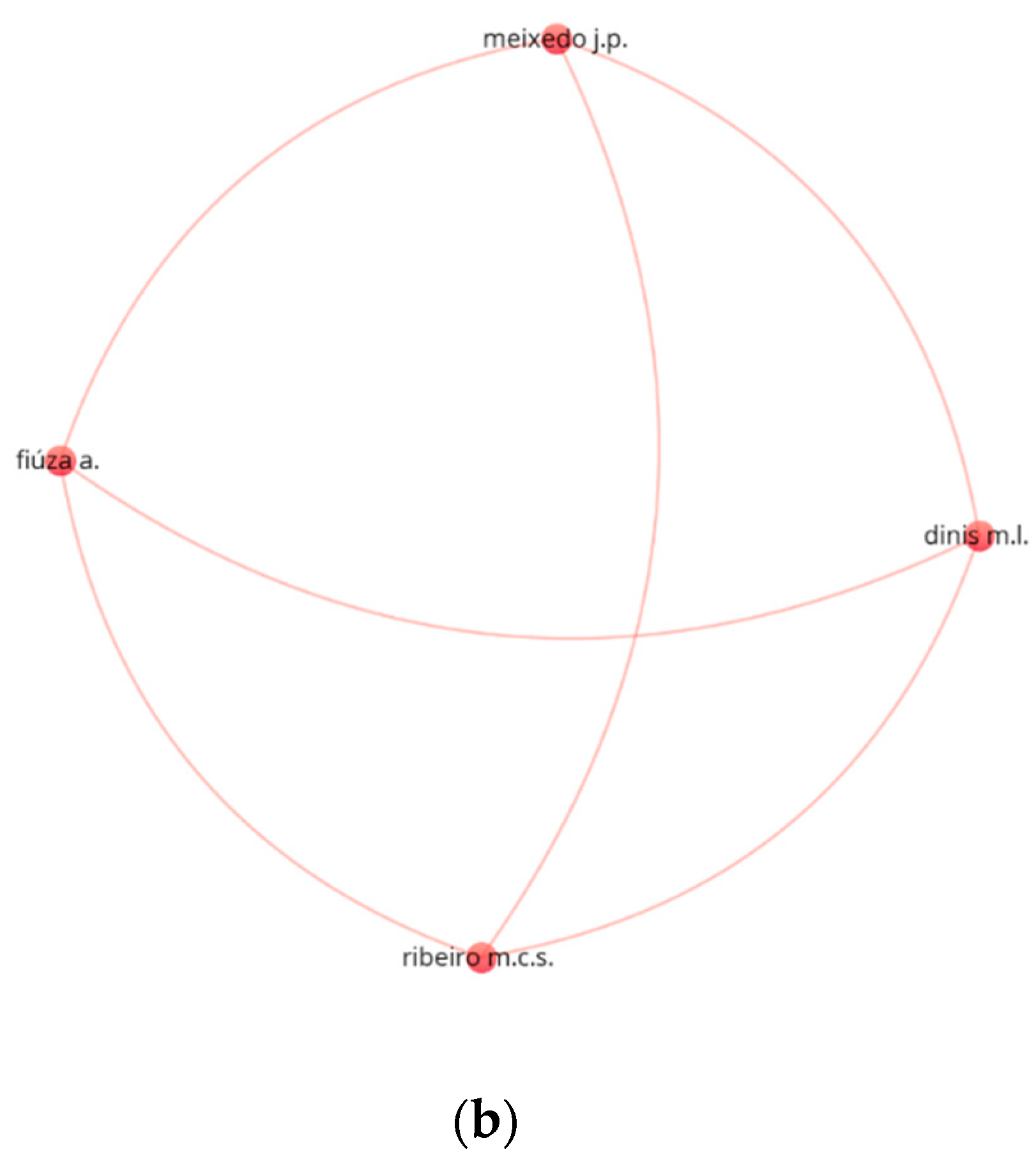

4.4. Co-Authorship Mapping

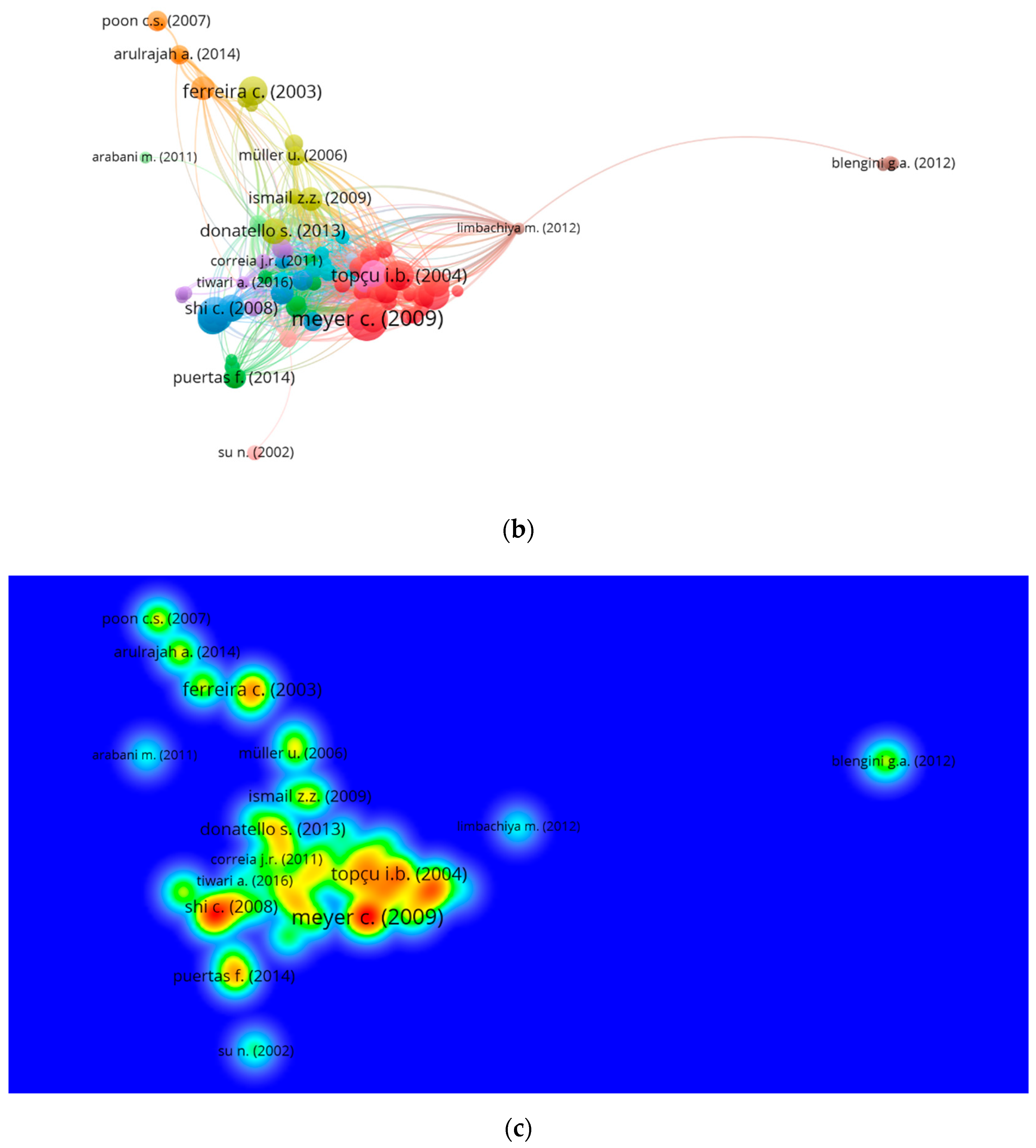

4.5. Articles Mapping

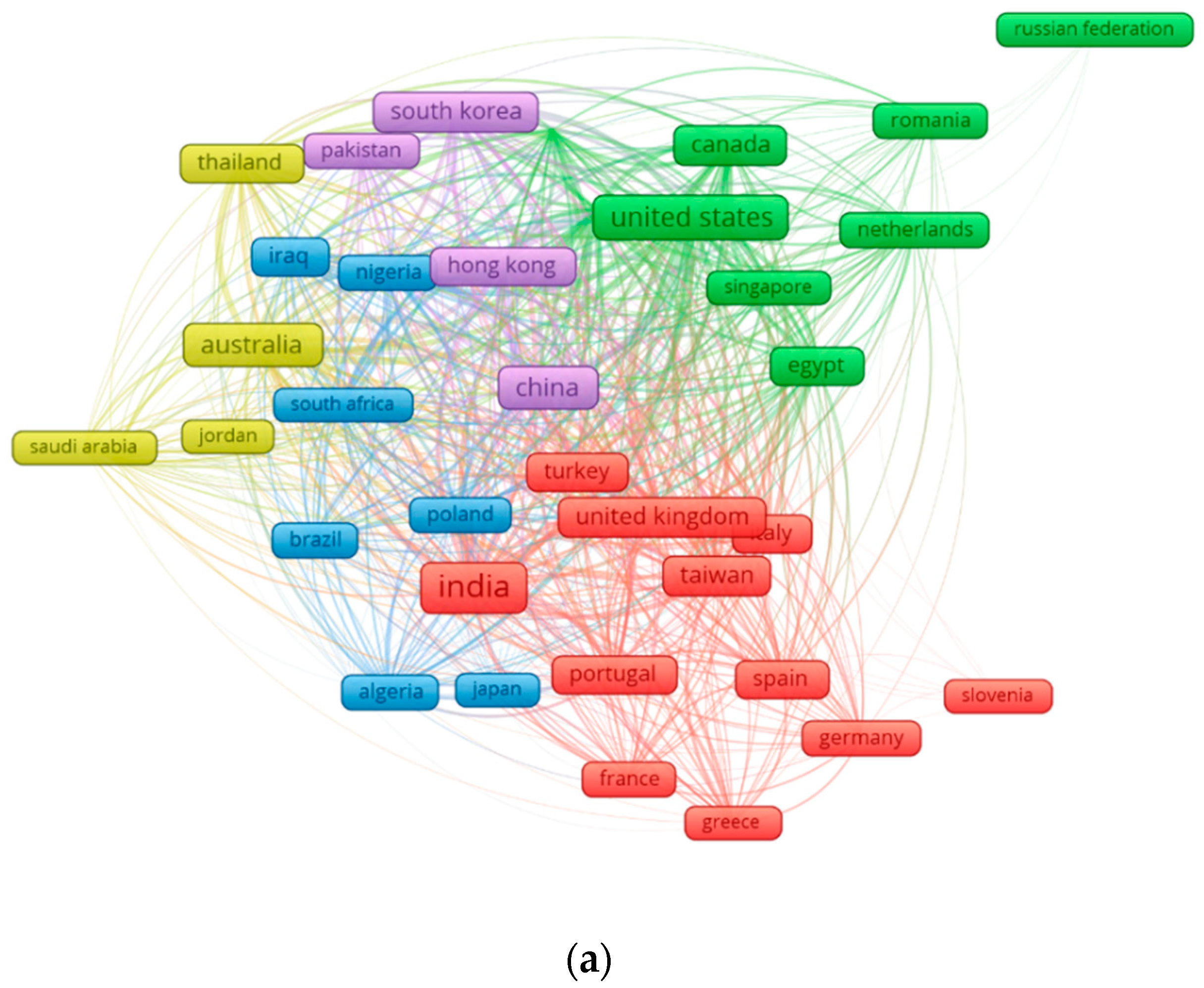

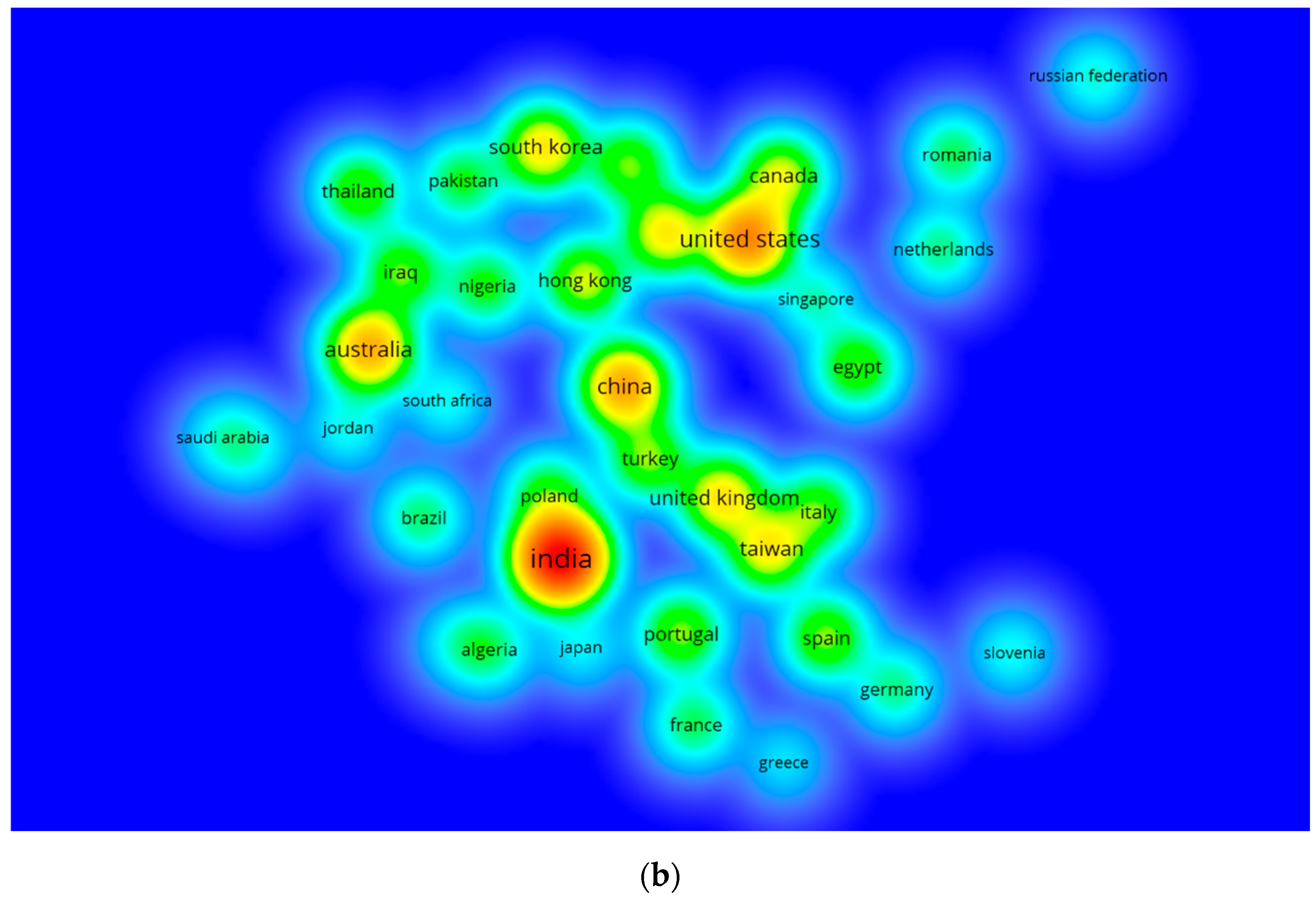

4.6. Countries Mapping

5. Types and Properties of Waste Glass

6. Waste Glass Utilization in Cement-Based Materials

6.1. Mechanical Properties of Cement-Based Materials Containing Waste Glass as Natural Aggregate Replacement

6.1.1. Workability

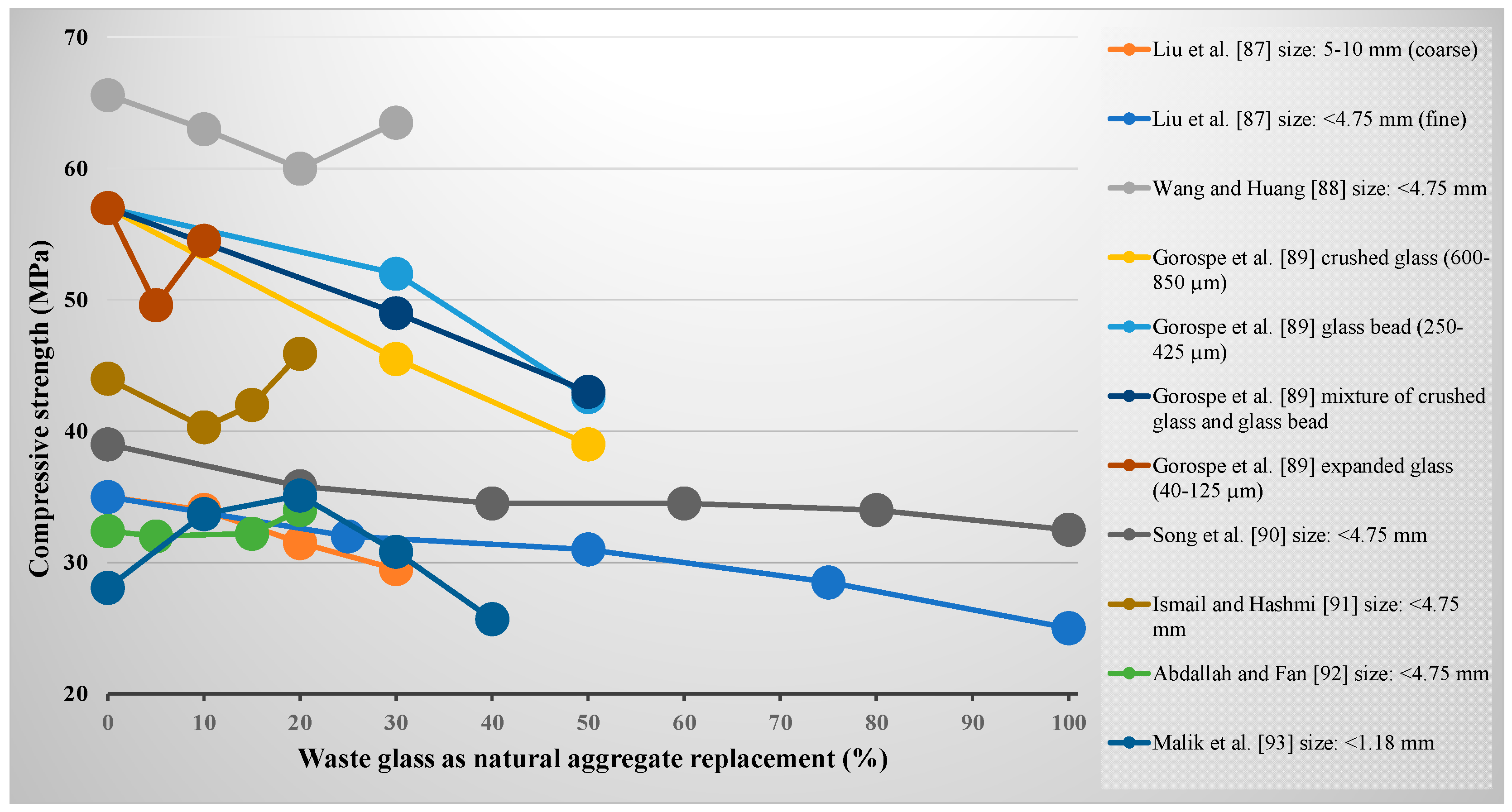

6.1.2. Compressive Strength

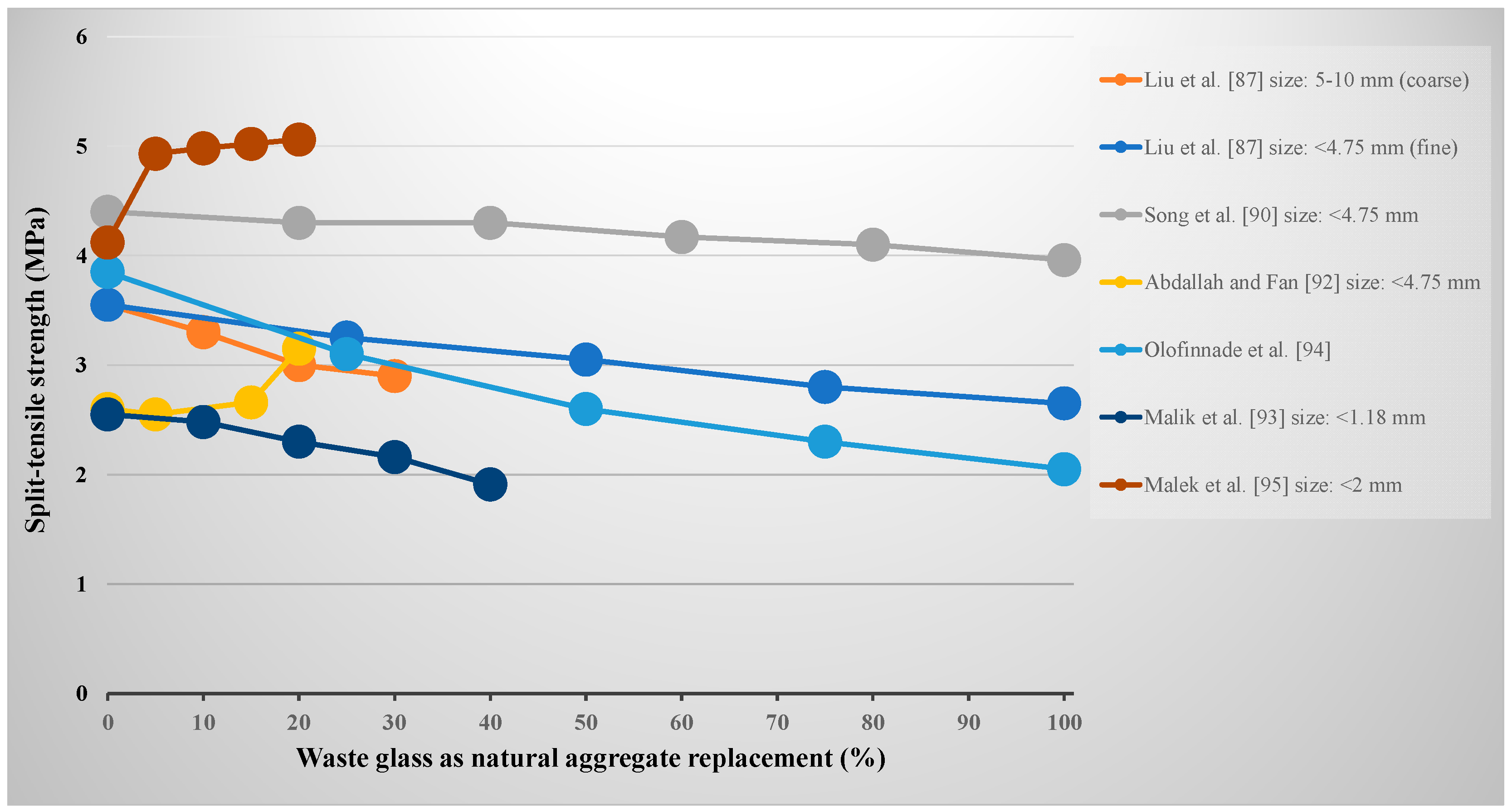

6.1.3. Split-Tensile Strength

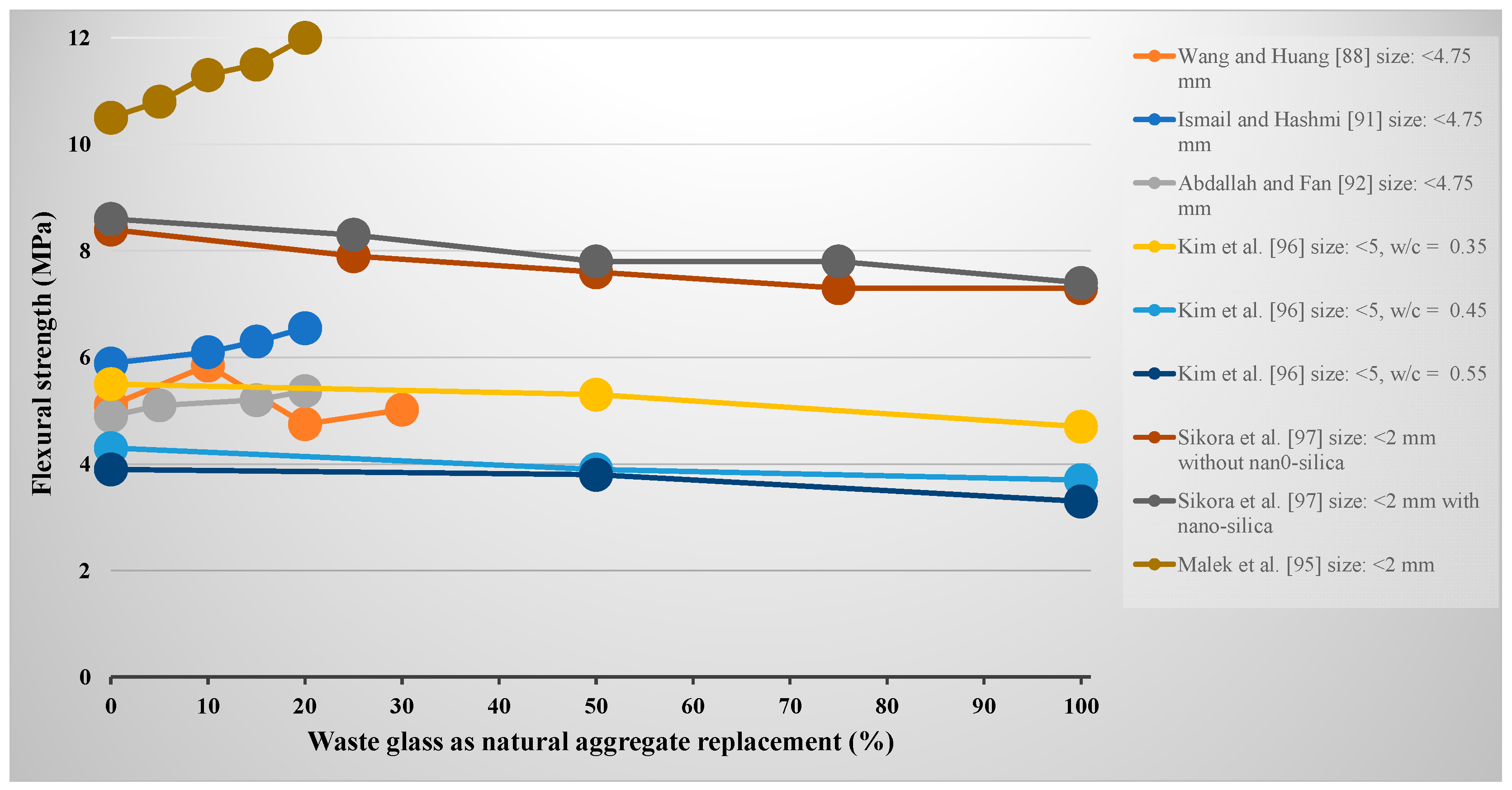

6.1.4. Flexural Strength

6.2. Mechanical Properties of Cement-Based Materials Containing Waste Glass as Cement Replacement

6.2.1. Workability

6.2.2. Compressive Strength

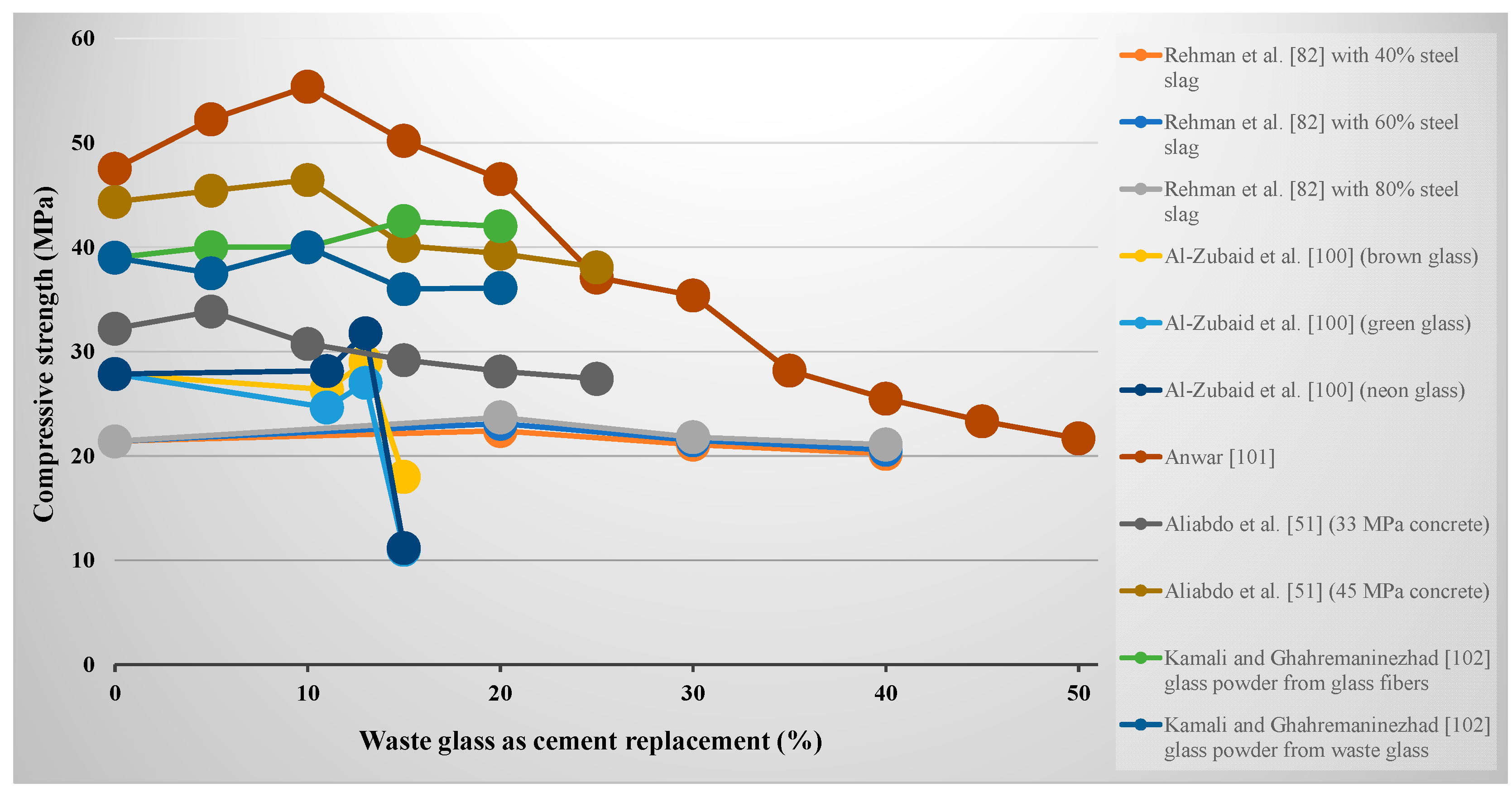

6.2.3. Split-Tensile Strength

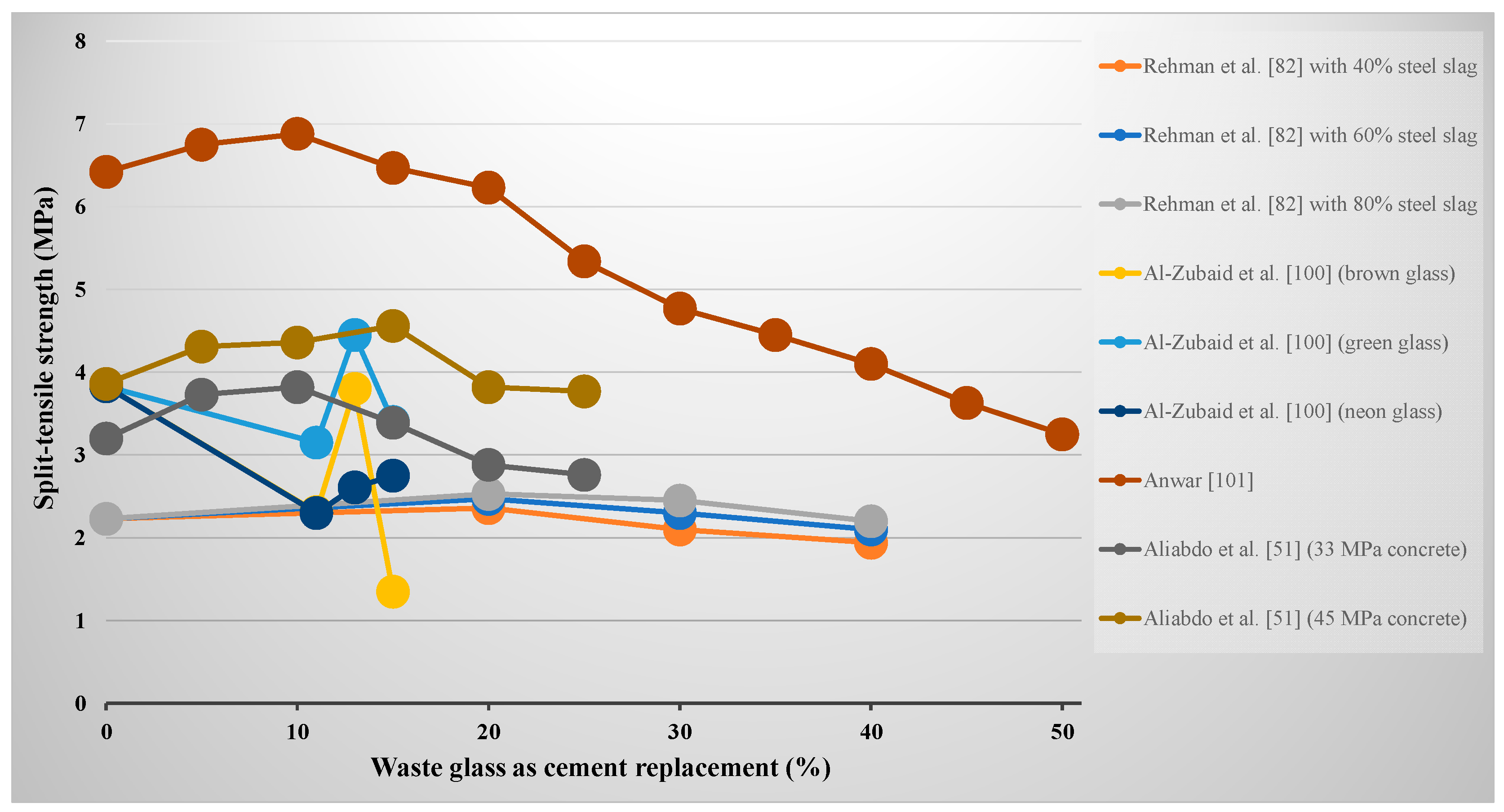

6.2.4. Flexural Strength

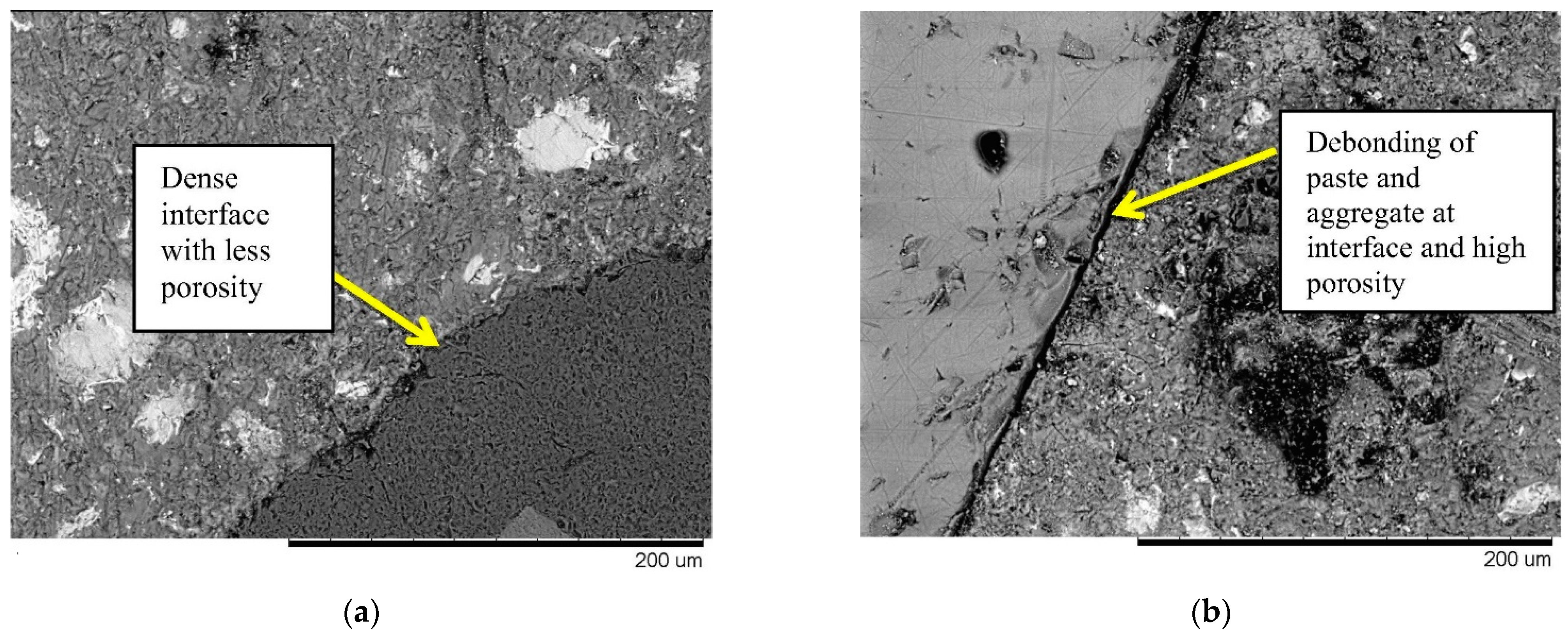

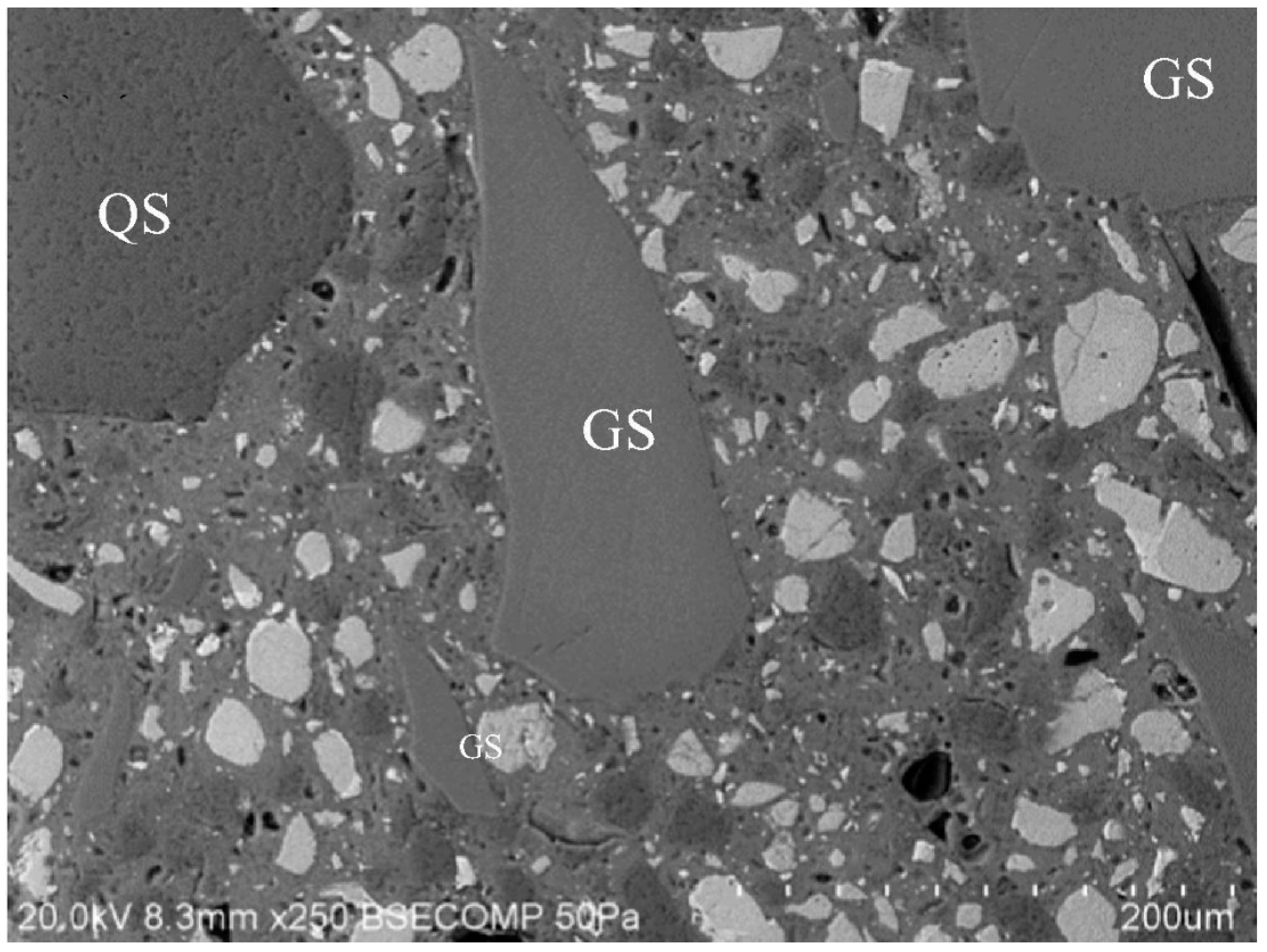

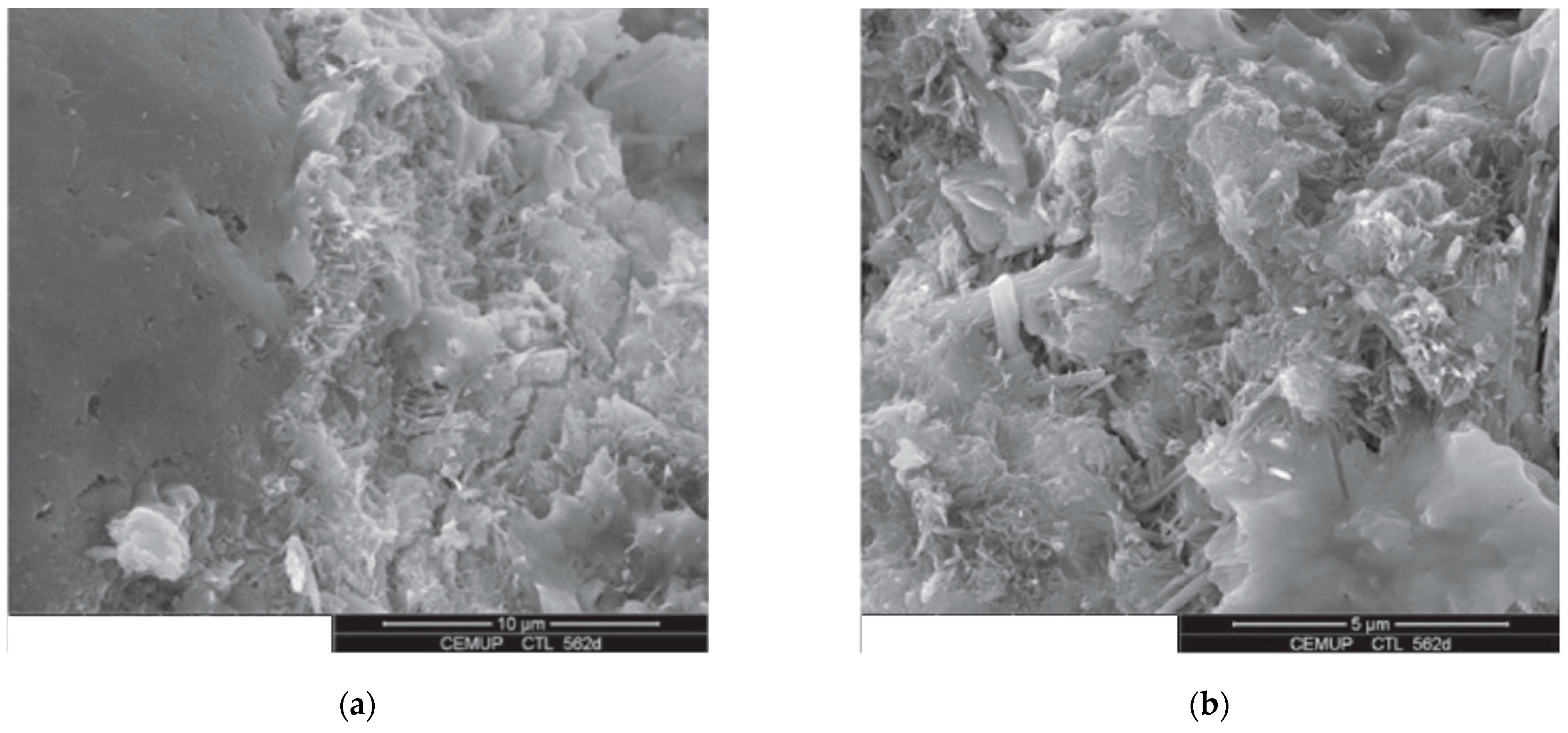

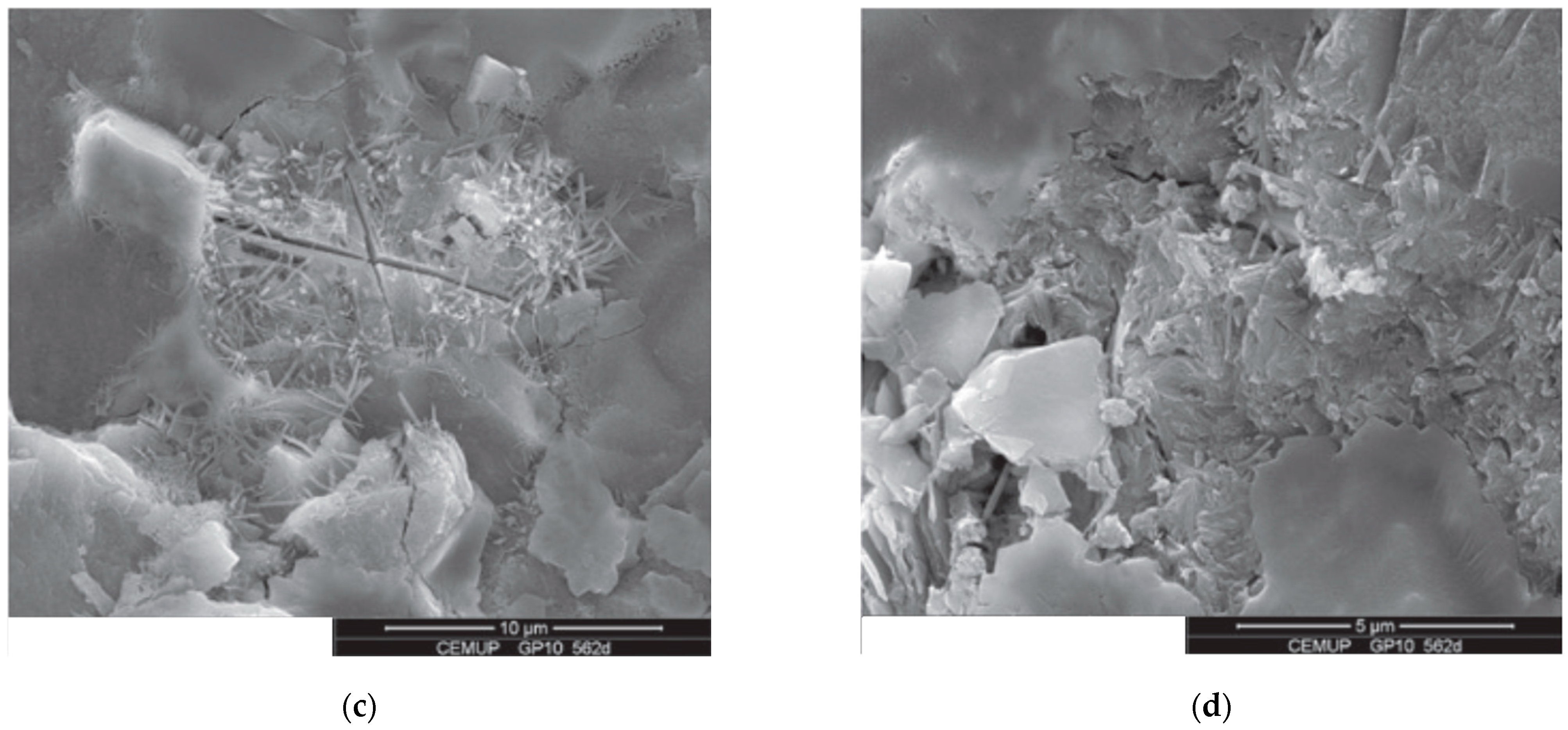

6.3. Microstructure of Cement-Based Materials Containing Waste Glass

6.4. Durability of Cement-Based Materials Containing Waste Glass

7. Utilization of Waste Glass Powder in 3D Printing and Geopolimerization

7.1. 3D Printing

7.2. Geopolimerization

8. Conclusions and Future Recommendations

8.1. Conclusions

- Scientometric analysis on the available data retrieved from the Scopus database exposed that the top four fields based on the number of documents were Engineering, Environmental Science, Materials Science, and Energy, containing 26.4%, 22.4%,11.6%, and 9.9% of the total documents, respectively. A slight increase in the number of publications on the utilization of WG in construction materials was observed up to 2015. However, a remarkable increase was observed in the last 5 years. The top 3 journals based on the number of documents were found to be the journal of cleaner production, construction and building materials, and resources, conservation, and recycling, containing 241, 202, and 79 documents, respectively, of the 2066 total documents. Sustainable development, recycling, construction industry, compressive strength, and sustainability were observed to be the top 5 most occurred keywords. Additionally, the connection network demonstrated that waste management and recycling have a strong link with sustainable development and may have a sizable impact on sustainability in construction. Furthermore, India, China, and United Kingdom contributed the most documents in the current study field.

- WG can be used in CBMs as aggregate replacement and cement replacement. Thus, it conserves natural resources, solves waste management problems, reduces CO2 emission by decreasing cement demand, protects the environment from toxic chemicals, and produces cost-effective composites. Therefore, the utilization of WG in construction materials is a better approach for sustainability in construction.

- The influence of WG as aggregate/cement replacement in CBMs on the mechanical properties (MPs) was found to be inconsistent. Usually, finer glass particles improved, while coarser glass particles decreased the MPs of composites. In additions, its use in higher proportions has a negative influence on the MPs of composites.

- Due to the pozzolanic reaction and filler effect of WG powder, it is possible that substituting WG for up to 25% of the cement or 20% of natural aggregate enhanced the MPs. However, using an excessive amount of WG may decrease the mechanical strength because of the dilution effect. The optimum content of WG in concrete is related to the water/binder ratio (w/b), as the w/b affects the amount of Ca(OH)2 reacting with glass. By substituting coarser WG for natural aggregates, the mechanical strength may be reduced. The influence of WG depends on both particle size and the proportion of the replacement.

- The addition of WG can help improve the microstructure and reduce the permeability of CBMs, thereby increasing their resistance to sulphate attack and freeze-thaw and eventually enhancing the durability of composites. However, glass may impair the resistance to carbonation because of Ca(OH)2 consumption by glass.

8.2. Future Recommendations

- Further research is essential to clarify the impact of WG on the rheological properties of CBMs in terms of amount, type, particle size, and morphology of WG particles. This is an assumption, but it is possible that the rheology of the CBMs prior to incorporating WG particles influences the glass particle’s role.

- There is a necessity to explore potential coupling effects between the w/b of concrete, the size of the WG particles, and the percentage replacement. This is an assumption, but it is possible that the w/b of CBMs and the size of the WG particles affect the optimal content of WG, resulting in a loss of mechanical strength.

- There is a dearth of comprehensive knowledge regarding the effects of WG content and particle size on the durability of CBMs at various w/b. This is an assumption that the w/b has a considerable influence on the durability-related roles of WG content and particle size.

- Computer software tools s the machine learning approach and numerical modeling need to be applied to predict the various properties of CBMs containing WG.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alwan, Z.; Jones, P.; Holgate, P. Strategic sustainable development in the UK construction industry, through the framework for strategic sustainable development, using Building Information Modelling. J. Clean. Prod. 2017, 140, 349–358. [Google Scholar] [CrossRef]

- Doan, D.T.; Ghaffarianhoseini, A.; Naismith, N.; Zhang, T.; Ghaffarianhoseini, A.; Tookey, J. A critical comparison of green building rating systems. Build. Environ. 2017, 123, 243–260. [Google Scholar] [CrossRef]

- Hwang, B.-G.; Zhu, L.; Tan, J.S.H. Green business park project management: Barriers and solutions for sustainable development. J. Clean. Prod. 2017, 153, 209–219. [Google Scholar] [CrossRef]

- Escamilla, E.Z.; Habert, G.; Wohlmuth, E. When CO2 counts: Sustainability assessment of industrialized bamboo as an alternative for social housing programs in the Philippines. Build. Environ. 2016, 103, 44–53. [Google Scholar] [CrossRef]

- Alencar, M.H.; Priori, L., Jr.; Alencar, L.H. Structuring objectives based on value-focused thinking methodology: Creating alternatives for sustainability in the built environment. J. Clean. Prod. 2017, 156, 62–73. [Google Scholar] [CrossRef]

- Kang, S.; Zhao, Y.; Wang, W.; Zhang, T.; Chen, T.; Yi, H.; Rao, F.; Song, S. Removal of methylene blue from water with montmorillonite nanosheets/chitosan hydrogels as adsorbent. Appl. Surf. Sci. 2018, 448, 203–211. [Google Scholar] [CrossRef]

- Wang, W.; Zhao, Y.; Bai, H.; Zhang, T.; Ibarra-Galvan, V.; Song, S. Methylene blue removal from water using the hydrogel beads of poly (vinyl alcohol)-sodium alginate-chitosan-montmorillonite. Carbohydr. Polym. 2018, 198, 518–528. [Google Scholar] [CrossRef]

- Ren, B.; Zhao, Y.; Bai, H.; Kang, S.; Zhang, T.; Song, S. Eco-friendly geopolymer prepared from solid wastes: A critical review. Chemosphere 2020, 267, 128900. [Google Scholar] [CrossRef]

- Smarzewski, P. Mechanical properties of ultra-high performance concrete with partial utilization of waste foundry sand. Buildings 2020, 10, 11. [Google Scholar] [CrossRef] [Green Version]

- Smarzewski, P. Influence of basalt-polypropylene fibres on fracture properties of high performance concrete. Compos. Struct. 2019, 209, 23–33. [Google Scholar] [CrossRef]

- Smarzewski, P. Influence of silica fume on mechanical and fracture properties of high performance concrete. Procedia Struct. Integr. 2019, 17, 5–12. [Google Scholar] [CrossRef]

- Smarzewski, P. Study of Bond Strength of Steel Bars in Basalt Fibre Reinforced High Performance Concrete. Crystals 2020, 10, 436. [Google Scholar] [CrossRef]

- Smarzewski, P. Flexural toughness of high-performance concrete with basalt and polypropylene short fibres. Adv. Civ. Eng. 2018, 2018, 5024353. [Google Scholar] [CrossRef] [Green Version]

- Smarzewski, P. Comparative Fracture Properties of Four Fibre Reinforced High Performance Cementitious Composites. Materials 2020, 13, 2612. [Google Scholar] [CrossRef]

- Ahmad, W.; Farooq, S.H.; Usman, M.; Khan, M.; Ahmad, A.; Aslam, F.; Yousef, R.A.; Abduljabbar, H.A.; Sufian, M. Effect of coconut fiber length and content on properties of high strength concrete. Materials 2020, 13, 1075. [Google Scholar] [CrossRef] [Green Version]

- Smarzewski, P. Flexural toughness evaluation of basalt fibre reinforced HPC beams with and without initial notch. Compos. Struct. 2020, 235, 111769. [Google Scholar] [CrossRef]

- Colangelo, F.; Cioffi, R.; Liguori, B.; Iucolano, F. Recycled polyolefins waste as aggregates for lightweight concrete. Compos. Part B Eng. 2016, 106, 234–241. [Google Scholar] [CrossRef]

- Asutkar, P.; Shinde, S.; Patel, R. Study on the behaviour of rubber aggregates concrete beams using analytical approach. Eng. Sci. Technol. Int. J. 2017, 20, 151–159. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, L.; de Brito, J.; Saikia, N. Influence of curing conditions on the mechanical performance of concrete containing recycled plastic aggregate. Constr. Build. Mater. 2012, 36, 196–204. [Google Scholar] [CrossRef]

- Saikia, N.; Brito, J.D. Waste polyethylene terephthalate as an aggregate in concrete. Mater. Res. 2013, 16, 341–350. [Google Scholar] [CrossRef] [Green Version]

- Rashad, A.M. Recycled waste glass as fine aggregate replacement in cementitious materials based on Portland cement. Constr. Build. Mater. 2014, 72, 340–357. [Google Scholar] [CrossRef]

- Smarzewski, P.; Barnat-Hunek, D. Mechanical and durability related properties of high performance concrete made with coal cinder and waste foundry sand. Constr. Build. Mater. 2016, 121, 9–17. [Google Scholar] [CrossRef]

- Arshad, S.; Sharif, M.B.; Irfan-ul-Hassan, M.; Khan, M.; Zhang, J.-L. Efficiency of Supplementary Cementitious Materials and Natural Fiber on Mechanical Performance of Concrete. Arab. J. Sci. Eng. 2020, 45, 8577–8589. [Google Scholar] [CrossRef]

- Khan, M.; Ali, M. Effect of super plasticizer on the properties of medium strength concrete prepared with coconut fiber. Constr. Build. Mater. 2018, 182, 703–715. [Google Scholar] [CrossRef]

- Khan, M.; Rehman, A.; Ali, M. Efficiency of silica-fume content in plain and natural fiber reinforced concrete for concrete road. Constr. Build. Mater. 2020, 244, 118382. [Google Scholar] [CrossRef]

- Khan, U.A.; Jahanzaib, H.M.; Khan, M.; Ali, M. Improving the Tensile Energy Absorption of High Strength Natural Fiber Reinforced Concrete with Fly-Ash for Bridge Girders, Key Engineering Materials; Trans Tech Publications: Stafa-Zurich, Switzerland, 2018; Volume 765, pp. 335–342. [Google Scholar]

- Pelisser, F.; Montedo, O.R.K.; Gleize, P.J.P.; Roman, H.R. Mechanical properties of recycled PET fibers in concrete. Mater. Res. 2012, 15, 679–686. [Google Scholar] [CrossRef]

- Merli, R.; Preziosi, M.; Acampora, A.; Lucchetti, M.C.; Petrucci, E. Recycled fibers in reinforced concrete: A systematic literature review. J. Clean. Prod. 2020, 248, 119207. [Google Scholar] [CrossRef]

- Liu, J.; Liu, J.; Huang, Z.; Zhu, J.; Liu, W.; Zhang, W. Effect of Fly Ash as Cement Replacement on Chloride Diffusion, Chloride Binding Capacity, and Micro-Properties of Concrete in a Water Soaking Environment. Appl. Sci. 2020, 10, 6271. [Google Scholar] [CrossRef]

- Bueno, E.T.; Paris, J.M.; Clavier, K.A.; Spreadbury, C.; Ferraro, C.C.; Townsend, T.G. A review of ground waste glass as a supplementary cementitious material: A focus on alkali-silica reaction. J. Clean. Prod. 2020, 257, 120180. [Google Scholar] [CrossRef]

- Hamada, H.M.; Thomas, B.S.; Yahaya, F.M.; Muthusamy, K.; Yang, J.; Abdalla, J.A.; Hawileh, R.A. Sustainable use of palm oil fuel ash as a supplementary cementitious material: A comprehensive review. J. Build. Eng. 2021, 40, 102286. [Google Scholar] [CrossRef]

- Chore, H.S.; Joshi, M.P. Strength characterization of concrete using industrial waste as cement replacing materials for rigid pavement. Innov. Infrastruct. Solut. 2020, 5, 1–9. [Google Scholar] [CrossRef]

- Lim, N.H.A.S.; Shaari, F.H.; Shaari, E.H.; Sam, A.R.M.; Khalid, N.H.A.; Ariffin, N.F.; Muthusamy, K. Properties of Concrete Containing Bamboo Waste as Cement Replacement. J. Comput. Theor. Nanosci. 2020, 17, 1306–1310. [Google Scholar]

- Rattanachu, P.; Toolkasikorn, P.; Tangchirapat, W.; Chindaprasirt, P.; Jaturapitakkul, C. Performance of recycled aggregate concrete with rice husk ash as cement binder. Cem. Concr. Compos. 2020, 108, 103533. [Google Scholar] [CrossRef]

- Khan, M.; Ali, M. Improvement in concrete behavior with fly ash, silica-fume and coconut fibres. Constr. Build. Mater. 2019, 203, 174–187. [Google Scholar] [CrossRef]

- Saikia, N.; De Brito, J. Use of plastic waste as aggregate in cement mortar and concrete preparation: A review. Constr. Build. Mater. 2012, 34, 385–401. [Google Scholar] [CrossRef]

- Jain, K.L.; Sancheti, G.; Gupta, L.K. Durability performance of waste granite and glass powder added concrete. Constr. Build. Mater. 2020, 252, 119075. [Google Scholar] [CrossRef]

- Martínez-Barrera, G.; del Coz-Díaz, J.J.; Álvarez-Rabanal, F.P.; Gayarre, F.L.; Martínez-López, M.; Cruz-Olivares, J. Waste tire rubber particles modified by gamma radiation and their use as modifiers of concrete. Case Stud. Constr. Mater. 2020, 12, e00321. [Google Scholar] [CrossRef]

- Topcu, I.B.; Canbaz, M. Properties of concrete containing waste glass. Cem. Concr. Res. 2004, 34, 267–274. [Google Scholar] [CrossRef]

- Meena, A.; Singh, R. Comparative Study of Waste Glass Powder as Pozzolanic Material in Concrete; Department of Civil Engineering, National Institute of Technology: Rourkela, India, 2012. [Google Scholar]

- Pant, D.; Singh, P. Pollution due to hazardous glass waste. Environ. Sci. Pollut. Res. 2014, 21, 2414–2436. [Google Scholar] [CrossRef] [PubMed]

- Singh, N.; Li, J.; Zeng, X. Solutions and challenges in recycling waste cathode-ray tubes. J. Clean. Prod. 2016, 133, 188–200. [Google Scholar] [CrossRef]

- Olofinnade, O.M.; Ndambuki, J.M.; Ede, A.N.; Booth, C. Application of waste glass powder as a partial cement substitute towards more sustainable concrete production. Int. J. Eng. Res. Africa. 2017, 31, 77–93. [Google Scholar] [CrossRef]

- Shelby, J. Introduction to Glass Science and Technology; The Royal Society of Chemistry: Cambridge, UK, 2005. [Google Scholar]

- Schmitz, A.; Kamiński, J.; Scalet, B.M.; Soria, A. Energy consumption and CO2 emissions of the European glass industry. Energy Policy 2011, 39, 142–155. [Google Scholar] [CrossRef]

- Jani, Y.; Hogland, W. Waste glass in the production of cement and concrete—A review. J. Environ. Chem. Eng. 2014, 2, 1767–1775. [Google Scholar] [CrossRef]

- Federico, L.; Chidiac, S. Waste glass as a supplementary cementitious material in concrete–critical review of treatment methods. Cem. Concr. Compos. 2009, 31, 606–610. [Google Scholar] [CrossRef]

- Mohajerani, A.; Vajna, J.; Cheung, T.H.H.; Kurmus, H.; Arulrajah, A.; Horpibulsuk, S. Practical recycling applications of crushed waste glass in construction materials: A review. Constr. Build. Mater. 2017, 156, 443–467. [Google Scholar] [CrossRef]

- Rashad, A.M. Recycled cathode ray tube and liquid crystal display glass as fine aggregate replacement in cementitious materials. Constr. Build. Mater. 2015, 93, 1236–1248. [Google Scholar] [CrossRef]

- Paul, S.C.; Šavija, B.; Babafemi, A.J. A comprehensive review on mechanical and durability properties of cement-based materials containing waste recycled glass. J. Clean. Prod. 2018, 198, 891–906. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Elmoaty, M.A.; Aboshama, A.Y. Utilization of waste glass powder in the production of cement and concrete. Constr. Build. Mater. 2016, 124, 866–877. [Google Scholar] [CrossRef]

- Xu, Y.; Zeng, J.; Chen, W.; Jin, R.; Li, B.; Pan, Z. A holistic review of cement composites reinforced with graphene oxide. Constr. Build. Mater. 2018, 171, 291–302. [Google Scholar] [CrossRef]

- Xiao, X.; Skitmore, M.; Li, H.; Xia, B. Mapping knowledge in the economic areas of green building using scientometric analysis. Energies 2019, 12, 3011. [Google Scholar] [CrossRef] [Green Version]

- Mryglod, O.; Holovatch, Y.; Kenna, R. Data mining in scientometrics: Usage analysis for academic publications. In Proceedings of the 2018 IEEE Second International Conference on Data Stream Mining & Processing (DSMP), Lviv, Ukraine, 21–25 August 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 241–246. [Google Scholar]

- Darko, A.; Chan, A.P.; Huo, X.; Owusu-Manu, D.-G. A scientometric analysis and visualization of global green building research. Build. Environ. 2019, 149, 501–511. [Google Scholar] [CrossRef]

- Song, J.; Zhang, H.; Dong, W. A review of emerging trends in global PPP research: Analysis and visualization. Scientometrics 2016, 107, 1111–1147. [Google Scholar] [CrossRef]

- Hosseini, M.R.; Martek, I.; Zavadskas, E.K.; Aibinu, A.A.; Arashpour, M.; Chileshe, N. Critical evaluation of off-site construction research: A Scientometric analysis. Autom. Constr. 2018, 87, 235–247. [Google Scholar] [CrossRef]

- Liao, H.; Tang, M.; Luo, L.; Li, C.; Chiclana, F.; Zeng, X.-J. A bibliometric analysis and visualization of medical big data research. Sustainability 2018, 10, 166. [Google Scholar] [CrossRef] [Green Version]

- Chadegani, A.A.; Salehi, H.; Yunus, M.; Farhadi, H.; Fooladi, M.; Farhadi, M.; Ebrahim, N.A. A comparison between two main academic literature collections: Web of Science and Scopus databases. Asian Soc. Sci. 2013, 9, 18–26. [Google Scholar] [CrossRef] [Green Version]

- Bergman, E.M.L. Finding citations to social work literature: The relative benefits of using Web of Science, Scopus, or Google Scholar. J. Acad. Librariansh. 2012, 38, 370–379. [Google Scholar] [CrossRef] [Green Version]

- Meho, L.I. Using Scopus’s CiteScore for assessing the quality of computer science conferences. J. Informetr. 2019, 13, 419–433. [Google Scholar] [CrossRef]

- Zuo, J.; Zhao, Z.-Y. Green building research–current status and future agenda: A review. Renew. Sustain. Energy Rev. 2014, 30, 271–281. [Google Scholar] [CrossRef]

- Darko, A.; Zhang, C.; Chan, A.P. Drivers for green building: A review of empirical studies. Habitat Int. 2017, 60, 34–49. [Google Scholar] [CrossRef]

- Ahmad, W.; Khan, M.; Smarzewski, P. Effect of Short Fiber Reinforcements on Fracture Performance of Cement-Based Materials: A Systematic Review Approach. Materials 2021, 14, 1745. [Google Scholar] [CrossRef] [PubMed]

- Markoulli, M.P.; Lee, C.I.; Byington, E.; Felps, W.A. Mapping Human Resource Management: Reviewing the field and charting future directions. Hum. Resour. Manag. Rev. 2017, 27, 367–396. [Google Scholar] [CrossRef]

- Saka, A.B.; Chan, D.W. A scientometric review and metasynthesis of building information modelling (BIM) research in Africa. Buildings 2019, 9, 85. [Google Scholar] [CrossRef] [Green Version]

- Goulden, S.; Erell, E.; Garb, Y.; Pearlmutter, D. Green building standards as socio-technical actors in municipal environmental policy. Build. Res. Inf. 2017, 45, 414–425. [Google Scholar] [CrossRef]

- Jin, R.; Gao, S.; Cheshmehzangi, A.; Aboagye-Nimo, E. A holistic review of off-site construction literature published between 2008 and 2018. J. Clean. Prod. 2018, 202, 1202–1219. [Google Scholar] [CrossRef] [Green Version]

- Park, J.Y.; Nagy, Z. Comprehensive analysis of the relationship between thermal comfort and building control research-A data-driven literature review. Renew. Sustain. Energy Rev. 2018, 82, 2664–2679. [Google Scholar] [CrossRef]

- Oraee, M.; Hosseini, M.R.; Papadonikolaki, E.; Palliyaguru, R.; Arashpour, M. Collaboration in BIM-based construction networks: A bibliometric-qualitative literature review. Int. J. Proj. Manag. 2017, 35, 1288–1301. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef] [Green Version]

- Wuni, I.Y.; Shen, G.Q.; Osei-Kyei, R. Scientometric review of global research trends on green buildings in construction journals from 1992 to 2018. Energy Build. 2019, 190, 69–85. [Google Scholar] [CrossRef]

- Su, H.-N.; Lee, P.-C. Mapping knowledge structure by keyword co-occurrence: A first look at journal papers in Technology Foresight. Scientometrics 2010, 85, 65–79. [Google Scholar] [CrossRef]

- Yu, F.; Hayes, B.E. Applying data analytics and visualization to assessing the research impact of the Cancer Cell Biology (CCB) Program at the University of North Carolina at Chapel Hill. J. Sci. Librariansh. 2018, 7, 4. [Google Scholar] [CrossRef]

- Meyer, C. The greening of the concrete industry. Cem. Concr. Compos. 2009, 31, 601–605. [Google Scholar] [CrossRef]

- Shayan, A.; Xu, A. Value-added utilisation of waste glass in concrete. Cem. Concr. Res. 2004, 34, 81–89. [Google Scholar] [CrossRef]

- Vieitez, E.R.; Eder, P.; Villanueva, A.; Saveyn, H. End-of-Waste Criteria for Glass Cullet: Technical Proposals; JRC Scientific and Technical Reports; Publications Office of the European Union: Mercier, Luxembourg, 2011. [Google Scholar]

- Jin, W.; Meyer, C.; Baxter, S. Glascrete-Concrete with glass aggregate. ACI Mater. J. 2000, 97, 208–213. [Google Scholar]

- Elaqra, H.A.; Haloub, M.A.A.; Rustom, R.N. Effect of new mixing method of glass powder as cement replacement on mechanical behavior of concrete. Constr. Build. Mater. 2019, 203, 75–82. [Google Scholar] [CrossRef]

- Chen, C.; Huang, R.; Wu, J.; Yang, C.-C. Waste E-glass particles used in cementitious mixtures. Cem. Concr. Res. 2006, 36, 449–456. [Google Scholar] [CrossRef]

- Kou, S.; Poon, C.S. Properties of self-compacting concrete prepared with recycled glass aggregate. Cem. Concr. Compos. 2009, 31, 107–113. [Google Scholar] [CrossRef]

- Rehman, S.; Iqbal, S.; Ali, A. Combined influence of glass powder and granular steel slag on fresh and mechanical properties of self-compacting concrete. Constr. Build. Mater. 2018, 178, 153–160. [Google Scholar] [CrossRef]

- Hendi, A.; Mostofinejad, D.; Sedaghatdoost, A.; Zohrabi, M.; Naeimi, N.; Tavakolinia, A. Mix design of the green self-consolidating concrete: Incorporating the waste glass powder. Constr. Build. Mater. 2019, 199, 369–384. [Google Scholar] [CrossRef]

- Wang, H.-Y.; Huang, W.-L. A study on the properties of fresh self-consolidating glass concrete (SCGC). Constr. Build. Mater. 2010, 24, 619–624. [Google Scholar] [CrossRef]

- Tuaum, A.; Shitote, S.; Oyawa, W. Experimental study of self-compacting mortar incorporating recycled glass aggregate. Buildings 2018, 8, 15. [Google Scholar] [CrossRef] [Green Version]

- Taha, B.; Nounu, G. Utilizing waste recycled glass as sand/cement replacement in concrete. J. Mater. Civ. Eng. 2009, 21, 709–721. [Google Scholar] [CrossRef]

- Liu, H.; Shi, J.; Qu, H.; Ding, D. An investigation on physical, mechanical, leaching and radiation shielding behaviors of barite concrete containing recycled cathode ray tube funnel glass aggregate. Constr. Build. Mater. 2019, 201, 818–827. [Google Scholar] [CrossRef]

- Wang, H.-Y.; Huang, W.-L. Durability of self-consolidating concrete using waste LCD glass. Constr. Build. Mater. 2010, 24, 1008–1013. [Google Scholar] [CrossRef]

- Gorospe, K.; Booya, E.; Ghaednia, H.; Das, S.J.C.; Materials, B. Effect of various glass aggregates on the shrinkage and expansion of cement mortar. Constr. Build. Mater. 2019, 210, 301–311. [Google Scholar] [CrossRef]

- Song, W.; Zou, D.; Liu, T.; Teng, J.; Li, L. Effects of recycled CRT glass fine aggregate size and content on mechanical and damping properties of concrete. Constr. Build. Mater. 2019, 202, 332–340. [Google Scholar] [CrossRef]

- Ismail, Z.Z.; Al-Hashmi, E.A. Recycling of waste glass as a partial replacement for fine aggregate in concrete. Waste Manag. 2009, 29, 655–659. [Google Scholar] [CrossRef]

- Abdallah, S.; Fan, M. Characteristics of concrete with waste glass as fine aggregate replacement. Int. J. Eng. Tech. Res. 2014, 2, 11–17. [Google Scholar]

- Malik, M.I.; Bashir, M.; Ahmad, S.; Tariq, T.; Chowdhary, U. Study of concrete involving use of waste glass as partial replacement of fine aggregates. IOSR J. Eng. 2013, 3, 8–13. [Google Scholar] [CrossRef]

- Olofinnade, O.M.; Ndambuki, J.M.; Ede, A.N.; Olukanni, D.O. Effect of substitution of crushed waste glass as partial replacement for natural fine and coarse aggregate in concrete. Mater. Sci. Forum 2016, 866, 58–62. [Google Scholar] [CrossRef]

- Małek, M.; Łasica, W.; Jackowski, M.; Kadela, M. Effect of waste glass addition as a replacement for fine aggregate on properties of mortar. Materials 2020, 13, 3189. [Google Scholar] [CrossRef]

- Kim, I.S.; Choi, S.Y.; Yang, E.I. Evaluation of durability of concrete substituted heavyweight waste glass as fine aggregate. Constr. Build. Mater. 2018, 184, 269–277. [Google Scholar] [CrossRef]

- Sikora, P.; Augustyniak, A.; Cendrowski, K.; Horszczaruk, E.; Rucinska, T.; Nawrotek, P.; Mijowska, E. Characterization of mechanical and bactericidal properties of cement mortars containing waste glass aggregate and nanomaterials. Materials 2016, 9, 701. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Islam, G.S.; Rahman, M.; Kazi, N. Waste glass powder as partial replacement of cement for sustainable concrete practice. Int. J. Sustain. Built Environ. 2017, 6, 37–44. [Google Scholar] [CrossRef] [Green Version]

- Soliman, N.; Tagnit-Hamou, A. Partial substitution of silica fume with fine glass powder in UHPC: Filling the micro gap. Constr. Build. Mater. 2017, 139, 374–383. [Google Scholar] [CrossRef]

- L-Zubaid, A.B.A.; Shabeeb, K.M.; Ali, A.I. Study the effect of recycled glass on the mechanical properties of green concrete. Energy Procedia 2017, 119, 680–692. [Google Scholar] [CrossRef]

- Anwar, A. The influence of waste glass powder as a pozzolanic material in concrete. Int. J. Civ. Eng. Technol 2016, 7, 131–148. [Google Scholar]

- Kamali, M.; Ghahremaninezhad, A. Effect of glass powders on the mechanical and durability properties of cementitious materials. Constr. Build. Mater. 2015, 98, 407–416. [Google Scholar] [CrossRef]

- Hama, S.M. Improving mechanical properties of lightweight Porcelanite aggregate concrete using different waste material. Int. J. Sustain. Built Environ. 2017, 6, 81–90. [Google Scholar] [CrossRef]

- Olutoge, F. Effect of waste glass powder (WGP) on the mechanical properties of concrete. Am. J. Eng. Res. 2016, 5, 213–220. [Google Scholar]

- Afshinnia, K.; Rangaraju, P.R. Impact of combined use of ground glass powder and crushed glass aggregate on selected properties of Portland cement concrete. Constr. Build. Mater. 2016, 117, 263–272. [Google Scholar] [CrossRef]

- Soliman, N.A.; Tagnit-Hamou, A. Using glass sand as an alternative for quartz sand in UHPC. Constr. Build. Mater. 2017, 145, 243–252. [Google Scholar] [CrossRef]

- Kong, Y.; Wang, P.; Liu, S.; Gao, Z.; Rao, M. Effect of microwave curing on the hydration properties of cement-based material containing glass powder. Constr. Build. Mater. 2018, 158, 563–573. [Google Scholar] [CrossRef]

- Matos, A.M.; Sousa-Coutinho, J. Durability of mortar using waste glass powder as cement replacement. Constr. Build. Mater. 2012, 36, 205–215. [Google Scholar] [CrossRef]

- Tony, S.; Ion, D.; Bob, B. Long Term Durability Properties of Field Concretes with Glass Sand and Glass Powder. In Proceedings of the Fourth International Conference on Sustainable Construction Materials and Technologies, Las Vegas, NV, USA, 7–11 August 2016. [Google Scholar]

- Du, H.; Tan, K. Durability performance of concrete with glass powder as supplementary cementitious material. ACI Mater. J. 2015, 112, 429–438. [Google Scholar]

- Mardani-Aghabaglou, A.; Tuyan, M.; Ramyar, K. Mechanical and durability performance of concrete incorporating fine recycled concrete and glass aggregates. Mater. Struct. 2015, 48, 2629–2640. [Google Scholar] [CrossRef]

- Patel, D.; Shrivastava, R.; Tiwari, R.; Yadav, R. Properties of cement mortar in substitution with waste fine glass powder and environmental impact study. J. Build. Eng. 2020, 27, 100940. [Google Scholar] [CrossRef]

- Lalitha, G.; Sasidhar, C.; Ramachandrudu, C. Durability performance of concrete (M-60) fine aggregate partially replaced with crushed waste glass. Technology 2020, 11, 1–9. [Google Scholar]

- Tan, K.H.; Du, H. Use of waste glass as sand in mortar: Part I–Fresh, mechanical and durability properties. Cem. Concr. Compos. 2013, 35, 109–117. [Google Scholar] [CrossRef]

- Patel, D.; Tiwari, R.; Shrivastava, R.; Yadav, R. Effective utilization of waste glass powder as the substitution of cement in making paste and mortar. Constr. Build. Mater. 2019, 199, 406–415. [Google Scholar] [CrossRef]

- Disfani, M.; Arulrajah, A.; Bo, M.; Sivakugan, N. Environmental risks of using recycled crushed glass in road applications. J. Clean. Prod. 2012, 20, 170–179. [Google Scholar] [CrossRef]

- Wang, H.-Y. A study of the effects of LCD glass sand on the properties of concrete. Waste Manag. 2009, 29, 335–341. [Google Scholar] [CrossRef]

- Ling, T.-C.; Poon, C.-S. Feasible use of recycled CRT funnel glass as heavyweight fine aggregate in barite concrete. J. Clean. Prod. 2012, 33, 42–49. [Google Scholar] [CrossRef]

- Soroushian, P. Strength and durability of recycled aggregate concrete containing milled glass as partial replacement for cement. Constr. Build. Mater. 2012, 29, 368–377. [Google Scholar]

- Abendeh, R.; Baker, M.B.; Salem, Z.A.; Ahmad, H. The feasibility of using milled glass wastes in concrete to resist freezing-thawing action. Int. J. Civ. Environ. Eng. 2015, 9, 1026–1029. [Google Scholar]

- Al-Akhras, N.M. Performance of glass concrete subjected to freeze-thaw cycling. Constr. Build. Technol. J. 2012, 6, 392–397. [Google Scholar] [CrossRef] [Green Version]

- Tay, Y.W.D.; Ting, G.H.A.; Qian, Y.; Panda, B.; He, L.; Tan, M.J. Time gap effect on bond strength of 3D-printed concrete. Virtual Phys. Prototyp. 2019, 14, 104–113. [Google Scholar] [CrossRef]

- Tay, Y.W.D.; Panda, B.; Paul, S.C.; Noor Mohamed, N.A.; Tan, M.J.; Leong, K.F. 3D printing trends in building and construction industry: A review. Virtual Phys. Prototyp. 2017, 12, 261–276. [Google Scholar] [CrossRef]

- Bos, F.; Wolfs, R.; Ahmed, Z.; Salet, T. Additive manufacturing of concrete in construction: Potentials and challenges of 3D concrete printing. Virtual Phys. Prototyp. 2016, 11, 209–225. [Google Scholar] [CrossRef] [Green Version]

- Gosselin, C.; Duballet, R.; Roux, P.; Gaudillière, N.; Dirrenberger, J.; Morel, P. Large-scale 3D printing of ultra-high performance concrete—A new processing route for architects and builders. Mater. Des. 2016, 100, 102–109. [Google Scholar] [CrossRef] [Green Version]

- Ting, G.H.A.; Tay, Y.W.D.; Qian, Y.; Tan, M.J. Utilization of recycled glass for 3D concrete printing: Rheological and mechanical properties. J. Mater. Cycles Waste Manag. 2019, 21, 994–1003. [Google Scholar] [CrossRef]

- Jiao, D.; Shi, C.; Yuan, Q.; An, X.; Liu, Y.; Li, H. Effect of constituents on rheological properties of fresh concrete—A review. Cem. Concr. Compos. 2017, 83, 146–159. [Google Scholar] [CrossRef]

- Cyr, M.; Idir, R.; Poinot, T. Properties of inorganic polymer (geopolymer) mortars made of glass cullet. J. Mater. Sci. 2012, 47, 2782–2797. [Google Scholar] [CrossRef]

- Novais, R.M.; Ascensão, G.; Seabra, M.; Labrincha, J. Waste glass from end-of-life fluorescent lamps as raw material in geopolymers. Waste Manag. 2016, 52, 245–255. [Google Scholar] [CrossRef]

| S/N | Source | Documents | Citations | Total Link Strength |

|---|---|---|---|---|

| 1 | Construction and building materials | 112 | 3989 | 9941 |

| 2 | Journal of cleaner production | 56 | 1878 | 5526 |

| 3 | International journal of civil engineering and technology | 25 | 70 | 437 |

| 4 | Materials | 23 | 163 | 2785 |

| 5 | Resources, conservation and recycling | 21 | 1770 | 1915 |

| 6 | Journal of building engineering | 20 | 260 | 3931 |

| 7 | Waste management | 18 | 1792 | 1290 |

| 8 | Cement and concrete composites | 13 | 1261 | 2580 |

| 9 | Applied sciences (switzerland) | 10 | 35 | 1474 |

| 10 | Cement and concrete research | 10 | 1935 | 513 |

| S/N | Keyword | Occurrences | Total Link Strength |

|---|---|---|---|

| 1 | Glass | 407 | 3435 |

| 2 | Compressive strength | 257 | 2102 |

| 3 | Concretes | 232 | 2028 |

| 4 | Recycling | 225 | 1938 |

| 5 | Concrete | 172 | 1374 |

| 6 | Aggregates | 171 | 1576 |

| 7 | Concrete aggregates | 145 | 1298 |

| 8 | Waste glass | 111 | 925 |

| 9 | Cements | 110 | 984 |

| 10 | Fly ash | 99 | 869 |

| 11 | Durability | 96 | 867 |

| 12 | Mechanical properties | 93 | 758 |

| 13 | Silica | 91 | 913 |

| 14 | Waste management | 87 | 726 |

| 15 | Mortar | 75 | 707 |

| 16 | Glass powder | 73 | 538 |

| 17 | Portland cement | 73 | 700 |

| 18 | Water absorption | 72 | 667 |

| 19 | Slags | 68 | 666 |

| 20 | Tensile strength | 67 | 638 |

| S/N | Author | Documents | Citations | Average Citations | Total Link Strength |

|---|---|---|---|---|---|

| 1 | Poon C.S. | 16 | 567 | 35 | 11 |

| 2 | Arulrajah A. | 13 | 656 | 50 | 16 |

| 3 | Wang H.-Y. | 12 | 321 | 27 | 4 |

| 4 | Tagnit-Hamou A. | 12 | 302 | 25 | 0 |

| 5 | Horpibulsuk S. | 11 | 454 | 41 | 15 |

| 6 | Poon C.-S. | 7 | 525 | 75 | 4 |

| 7 | Ling T.-C. | 7 | 378 | 54 | 5 |

| 8 | Lu J.-X. | 6 | 83 | 14 | 7 |

| 9 | Shi C. | 5 | 624 | 125 | 1 |

| 10 | Brouwers H.J.H. | 5 | 177 | 35 | 0 |

| 11 | Dinis M.L. | 5 | 150 | 30 | 15 |

| 12 | Fiúza A. | 5 | 150 | 30 | 15 |

| 13 | Meixedo J.P. | 5 | 150 | 30 | 15 |

| 14 | Ribeiro M.C.S. | 5 | 150 | 30 | 15 |

| 15 | Mohammadinia A. | 5 | 122 | 24 | 9 |

| 16 | Lin K.-L. | 5 | 108 | 22 | 0 |

| 17 | Olofinnade O.M. | 5 | 78 | 16 | 4 |

| 18 | Ede A.N. | 5 | 75 | 15 | 4 |

| 19 | Xuan D. | 5 | 69 | 14 | 6 |

| 20 | Wang C.-C. | 5 | 49 | 10 | 4 |

| S/N | Author | Title | Citations | Total Link Strength |

|---|---|---|---|---|

| 1 | Meyer C. (2009) | The greening of the concrete industry | 691 | 12 |

| 2 | Shayan A. (2004) | Value-added utilisation of waste glass in concrete | 363 | 27 |

| 3 | Topçu I.B. (2004) | Properties of concrete containing waste glass | 342 | 68 |

| 4 | Batayneh M. (2007) | Use of selected waste materials in concrete mixes | 341 | 2 |

| 5 | Park S.B. (2004) | Studies on mechanical properties of concrete containing waste glass aggregate | 264 | 0 |

| 6 | Shi C. (2007) | A review on the use of waste glasses in the production of cement and concrete | 260 | 189 |

| 7 | Shayan A. (2006) | Performance of glass powder as a pozzolanic material in concrete: A field trial on concrete slabs | 248 | 62 |

| 8 | Tam V.W.Y. (2006) | A review on the viable technology for construction waste recycling | 239 | 5 |

| 9 | Ismail Z.Z. (2009) | Recycling of waste glass as a partial replacement for fine aggregate in concrete | 211 | 108 |

| 10 | Paris J.M. (2016) | A review of waste products utilized as supplements to Portland cement in concrete | 189 | 98 |

| 11 | Nassar R.-U.-D. (2012) | Strength and durability of recycled aggregate concrete containing milled glass as partial replacement for cement | 181 | 100 |

| 12 | Taha B. (2008) | Properties of concrete contains mixed colour waste recycled glass as sand and cement replacement | 162 | 36 |

| 13 | Puertas F. (2014) | Use of glass waste as an activator in the preparation of alkali-activated slag. Mechanical strength and paste characterisation | 161 | 35 |

| 14 | Matos A.M. (2012) | Durability of mortar using waste glass powder as cement replacement | 159 | 149 |

| 15 | Federico L.M. (2009) | Waste glass as a supplementary cementitious material in concrete: Critical review of treatment methods | 149 | 165 |

| 16 | Torres-Carrasco M. (2015) | Waste glass in the geopolymer preparation. Mechanical and microstructural characterisation | 147 | 30 |

| 17 | Aly M. (2012) | Effect of colloidal nano-silica on the mechanical and physical behaviour of waste-glass cement mortar | 147 | 136 |

| 18 | Jani Y. (2014) | Waste glass in the production of cement and concrete: A review | 146 | 241 |

| 19 | Pereira-De-Oliveira L.A. (2012) | The potential pozzolanic activity of glass and red-clay ceramic waste as cement mortars components | 146 | 68 |

| 20 | Idir R. (2010) | Use of fine glass as ASR inhibitor in glass aggregate mortars | 145 | 6 |

| S/N | Country | Documents | Citations | Total Link Strength |

|---|---|---|---|---|

| 1 | India | 126 | 1581 | 15,912 |

| 2 | United States | 63 | 2778 | 19,741 |

| 3 | China | 52 | 1622 | 16,421 |

| 4 | Australia | 49 | 2098 | 17,897 |

| 5 | South Korea | 34 | 691 | 9220 |

| 6 | United Kingdom | 34 | 1857 | 9041 |

| 7 | Iran | 33 | 730 | 13,483 |

| 8 | Taiwan | 32 | 825 | 9171 |

| 9 | Canada | 28 | 1095 | 11,043 |

| 10 | Hong Kong | 26 | 1425 | 10,994 |

| 11 | Portugal | 22 | 1167 | 6173 |

| 12 | Spain | 22 | 893 | 4421 |

| 13 | Turkey | 22 | 721 | 4795 |

| 14 | Iraq | 21 | 454 | 4291 |

| 15 | Malaysia | 21 | 424 | 8844 |

| 16 | Egypt | 20 | 816 | 7705 |

| 17 | Italy | 20 | 498 | 5085 |

| 18 | Thailand | 20 | 809 | 6157 |

| 19 | Poland | 17 | 99 | 5883 |

| 20 | Nigeria | 16 | 162 | 10,632 |

| Glass Type | Chemical Compound (%) | |||||

|---|---|---|---|---|---|---|

| SiO2 | Na2O + K2O | CaO | Al2O3 | B2O3 | PbO | |

| Soda-lime | 71–75 | 12–16 | 10–15 | - | - | - |

| Lead | 54–65 | 13–15 | - | - | - | 25–30 |

| Borosilicate glass | 70–80 | 4–8 | - | 7 | 7–15 | - |

| Electric | 52–56 | 0–2 | 16–25 | 12–16 | 0–10 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, D.; Hu, Y.; Li, X. Waste Glass Utilization in Cement-Based Materials for Sustainable Construction: A Review. Crystals 2021, 11, 710. https://doi.org/10.3390/cryst11060710

Qin D, Hu Y, Li X. Waste Glass Utilization in Cement-Based Materials for Sustainable Construction: A Review. Crystals. 2021; 11(6):710. https://doi.org/10.3390/cryst11060710

Chicago/Turabian StyleQin, Di, Yidan Hu, and Xuemei Li. 2021. "Waste Glass Utilization in Cement-Based Materials for Sustainable Construction: A Review" Crystals 11, no. 6: 710. https://doi.org/10.3390/cryst11060710

APA StyleQin, D., Hu, Y., & Li, X. (2021). Waste Glass Utilization in Cement-Based Materials for Sustainable Construction: A Review. Crystals, 11(6), 710. https://doi.org/10.3390/cryst11060710