Effect of Full Temperature Field Environment on Bonding Strength of Aluminum Alloy

Abstract

1. Introduction

2. Material Selection and Specimen Design

2.1. Adhesive and Substrate

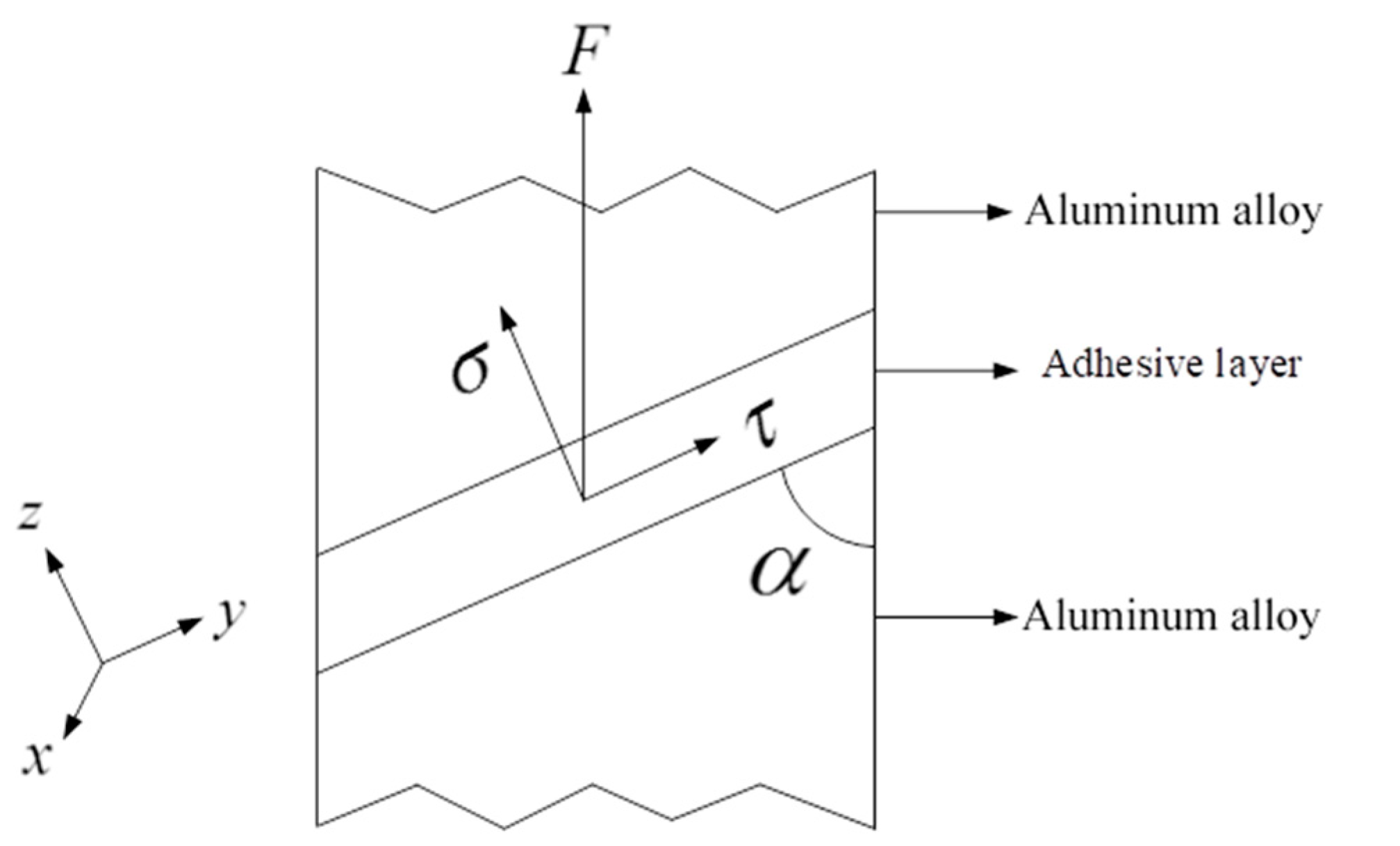

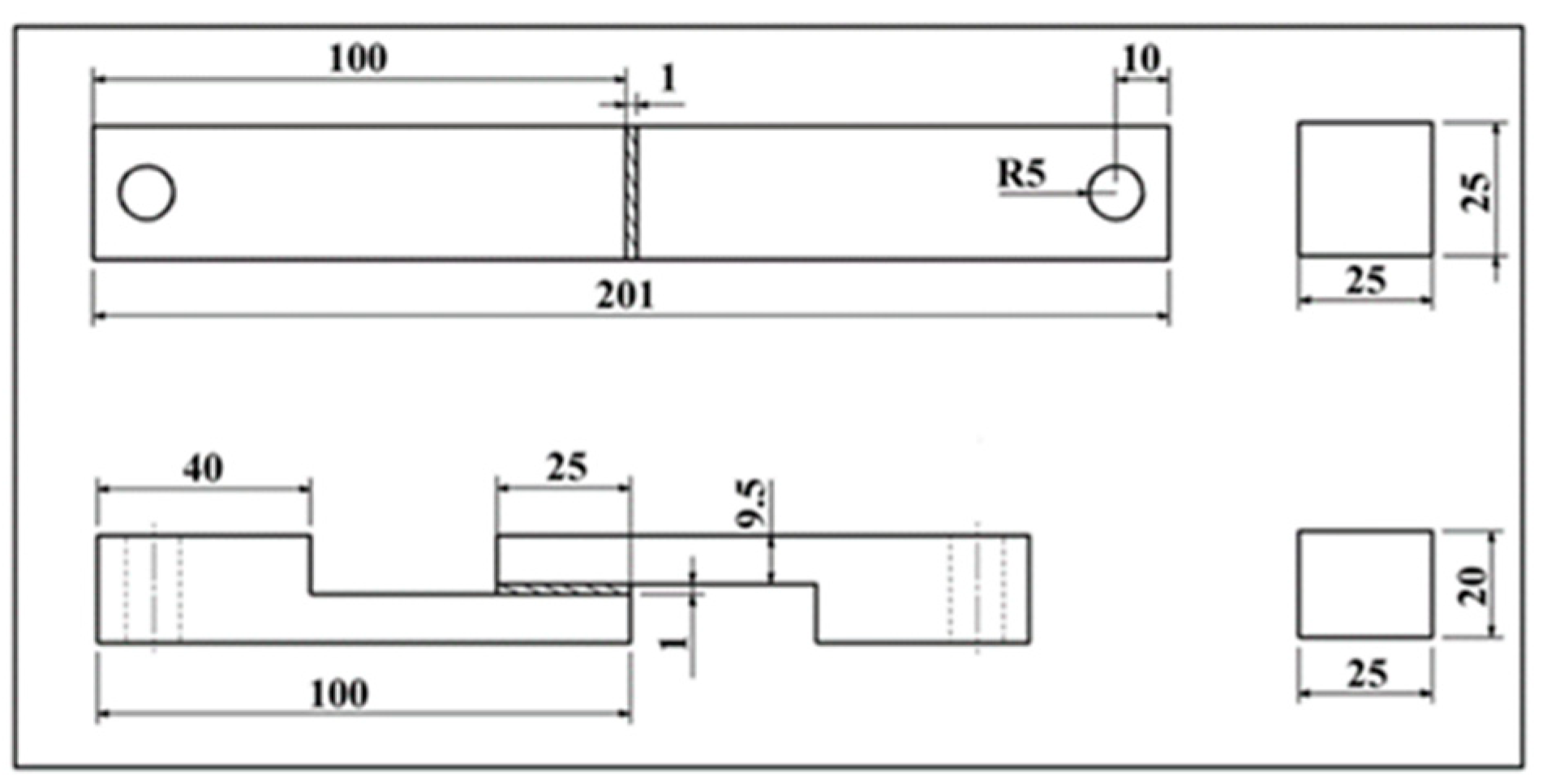

2.2. Design and Processing of Specimens

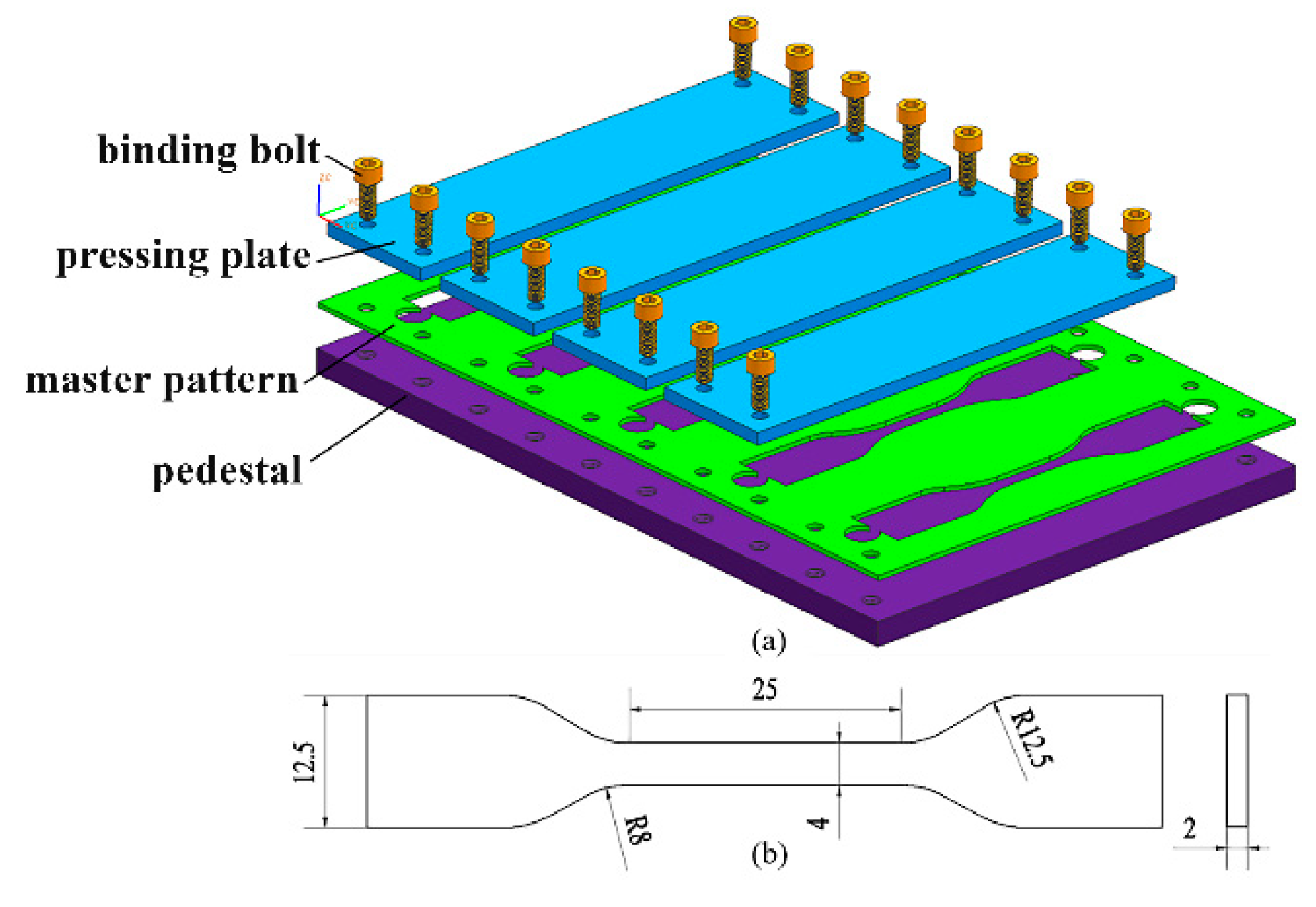

2.3. Dumbbell Sample

2.4. Design and Manufacture of Fixture

2.5. Bonding Process

- An 80 mesh sandpaper is used for the cross grind concerning the adhesive surface of aluminum alloy along the 45° direction to increase the surface roughness and facilitate the adhesive.

- Acetone is used to clean the specimen, thus removing the oil pollution and dust produced in processing. Wiping paper is dipped in acetone, and the adhesive surface is wiped in one direction until the surface of the tissue is clean. The surface is allowed to dry for 10 min.

- Surface pretreatment coating agent Primer M is used to clean the adhesive surface again. The surface is again allowed to dry for 10 min.

- As for adhesive ISR-7008, on its surface, the corresponding fixture described above is used to complete the specific adhesive work, and then it is solidified for a period of 4 weeks in the experimental environment.

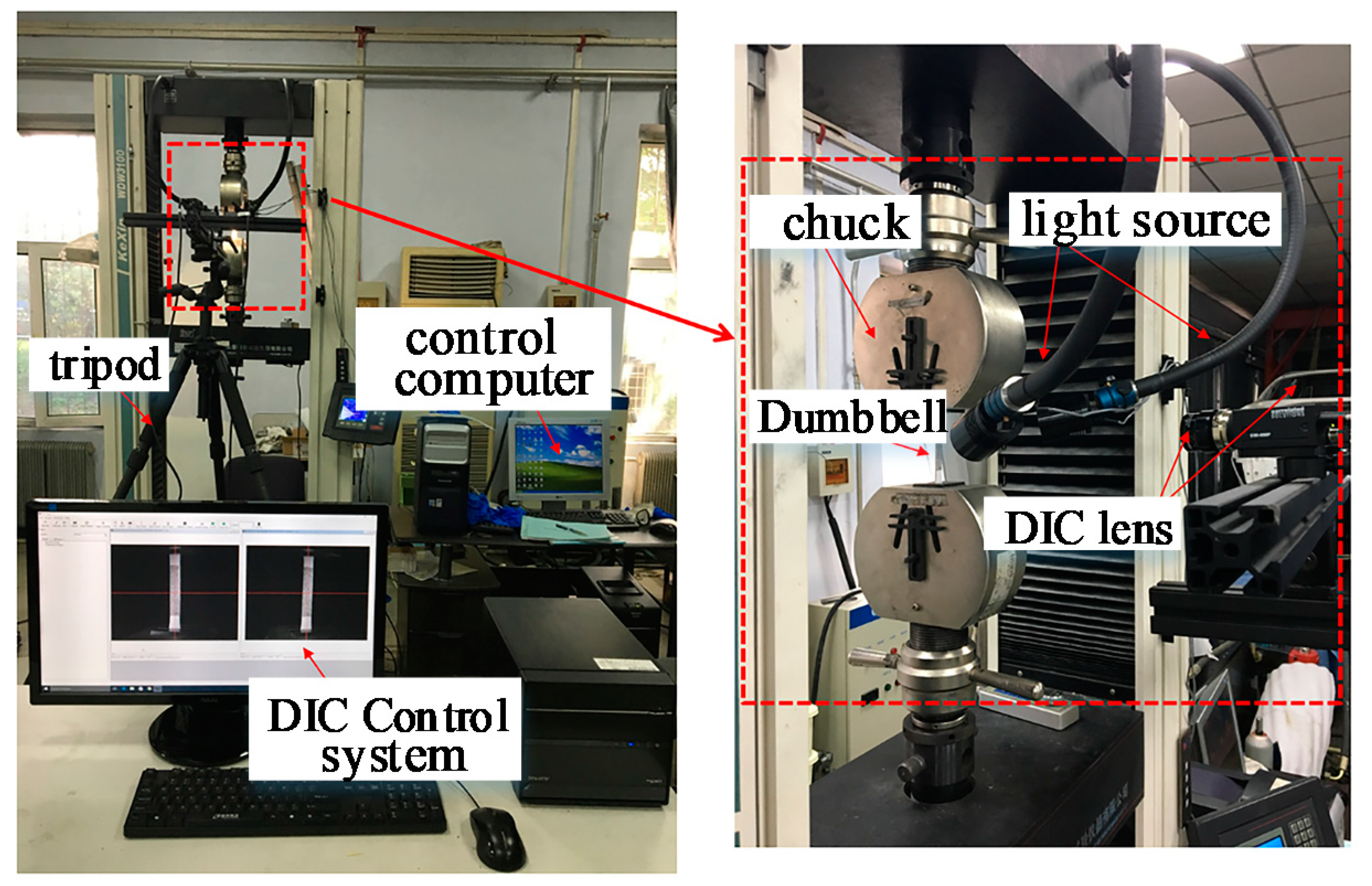

2.6. Testing of Strength under the Condition of the Full Temperature Field

3. Experimental Data Analysis

3.1. Dumbbell Sample Test

3.2. Mechanics Performance Testing

4. Analysis and Discussion of Experimental Results

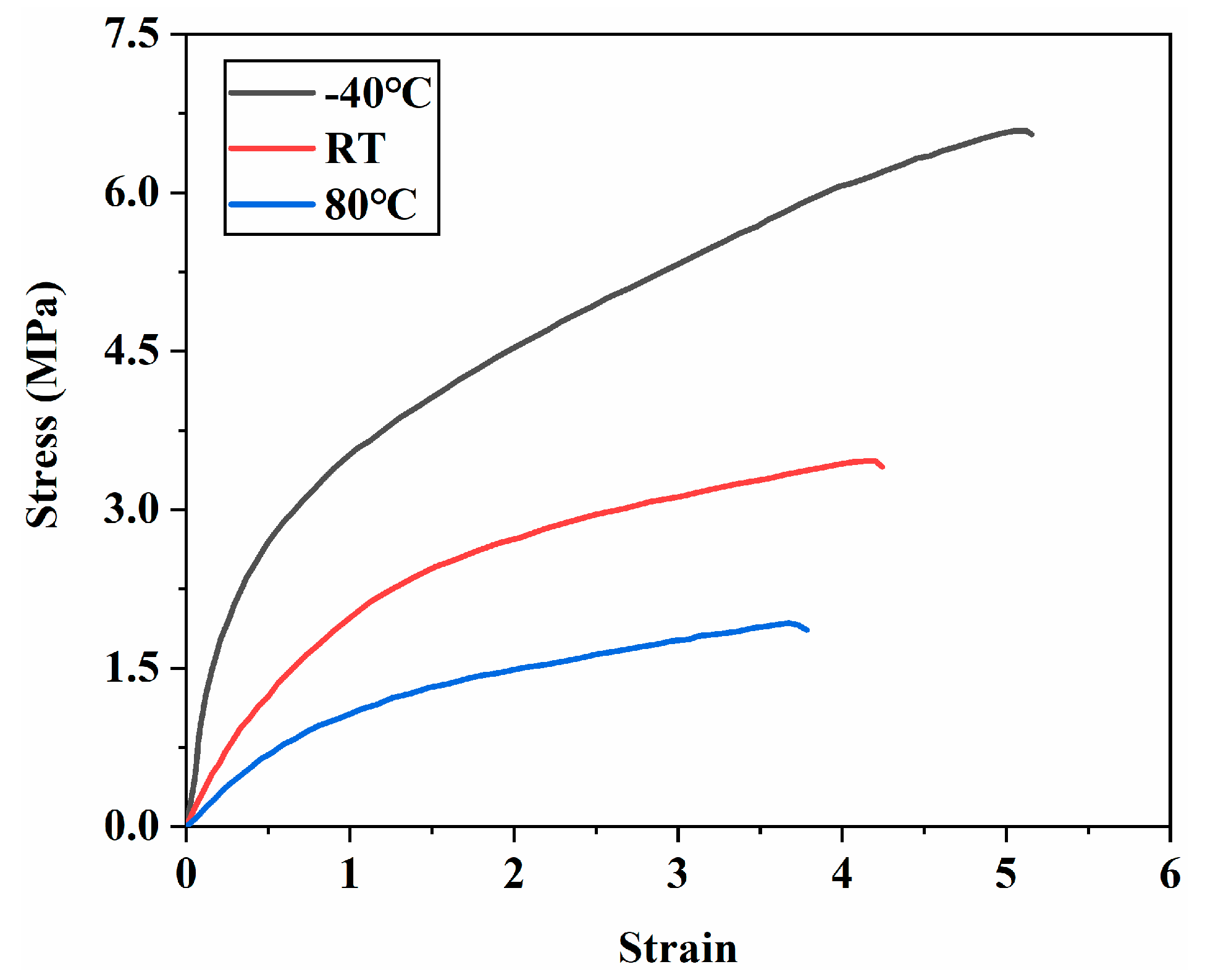

4.1. Dumbbell Sample Test

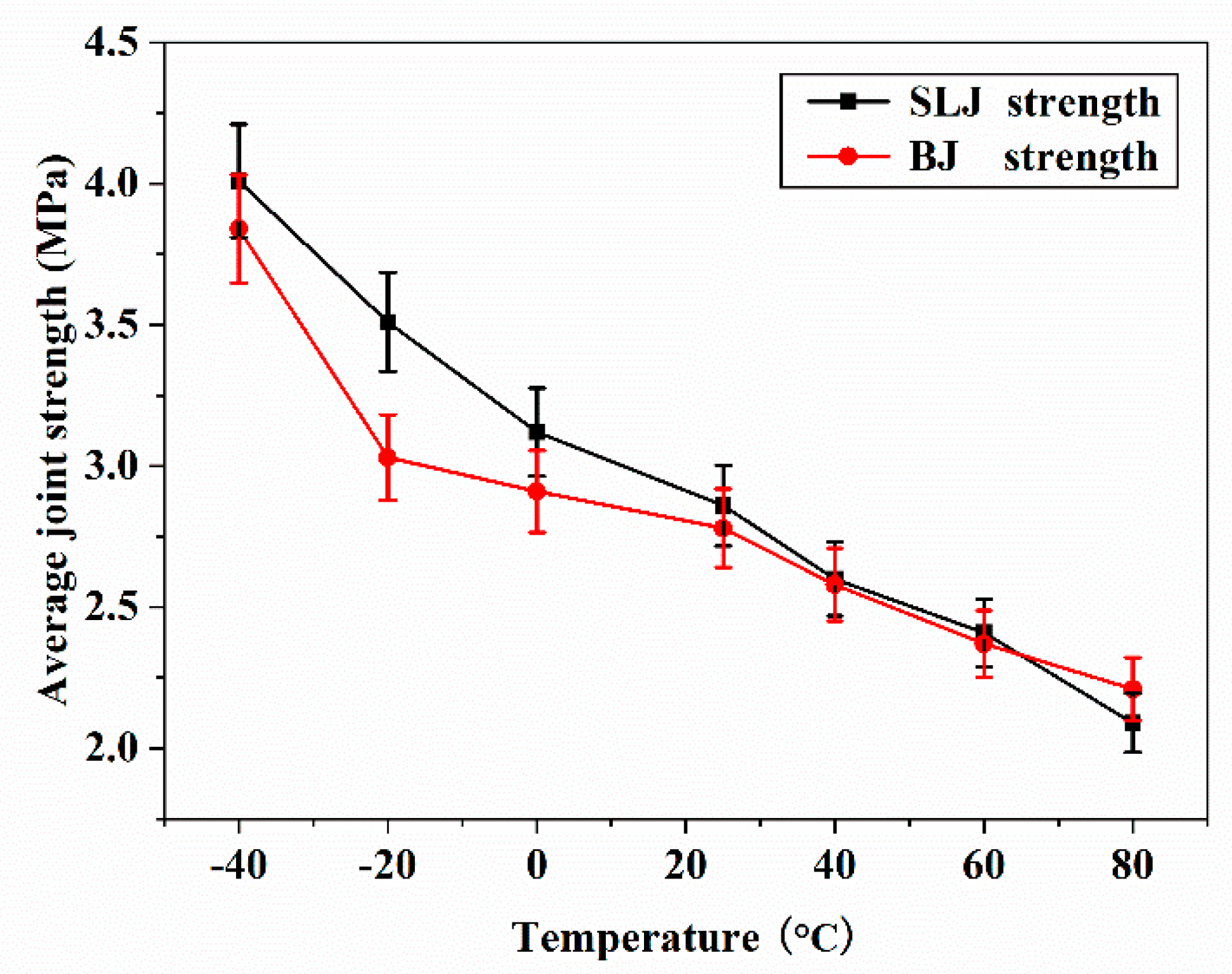

4.2. BJ and SLJ Tests

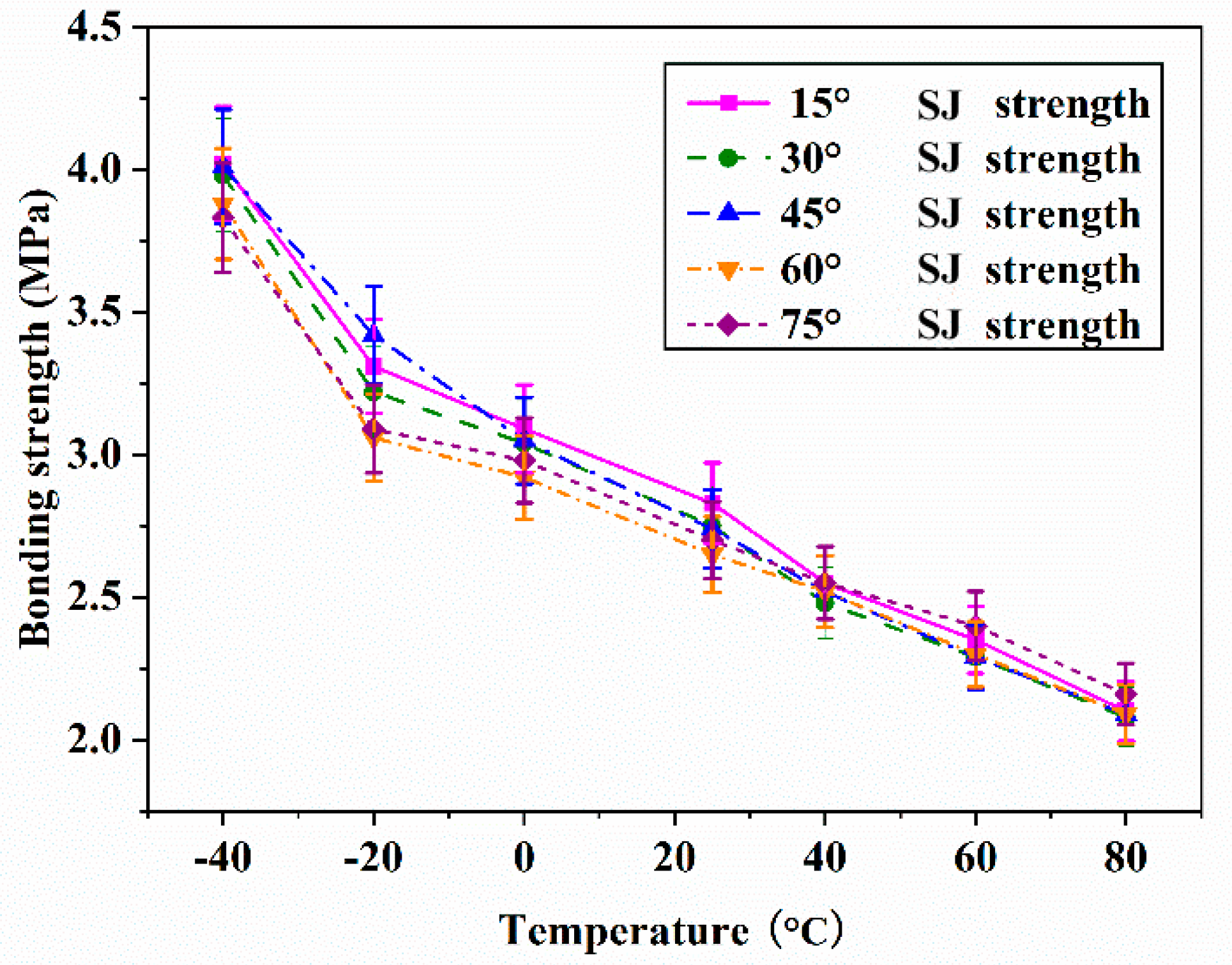

4.3. SJ Tests

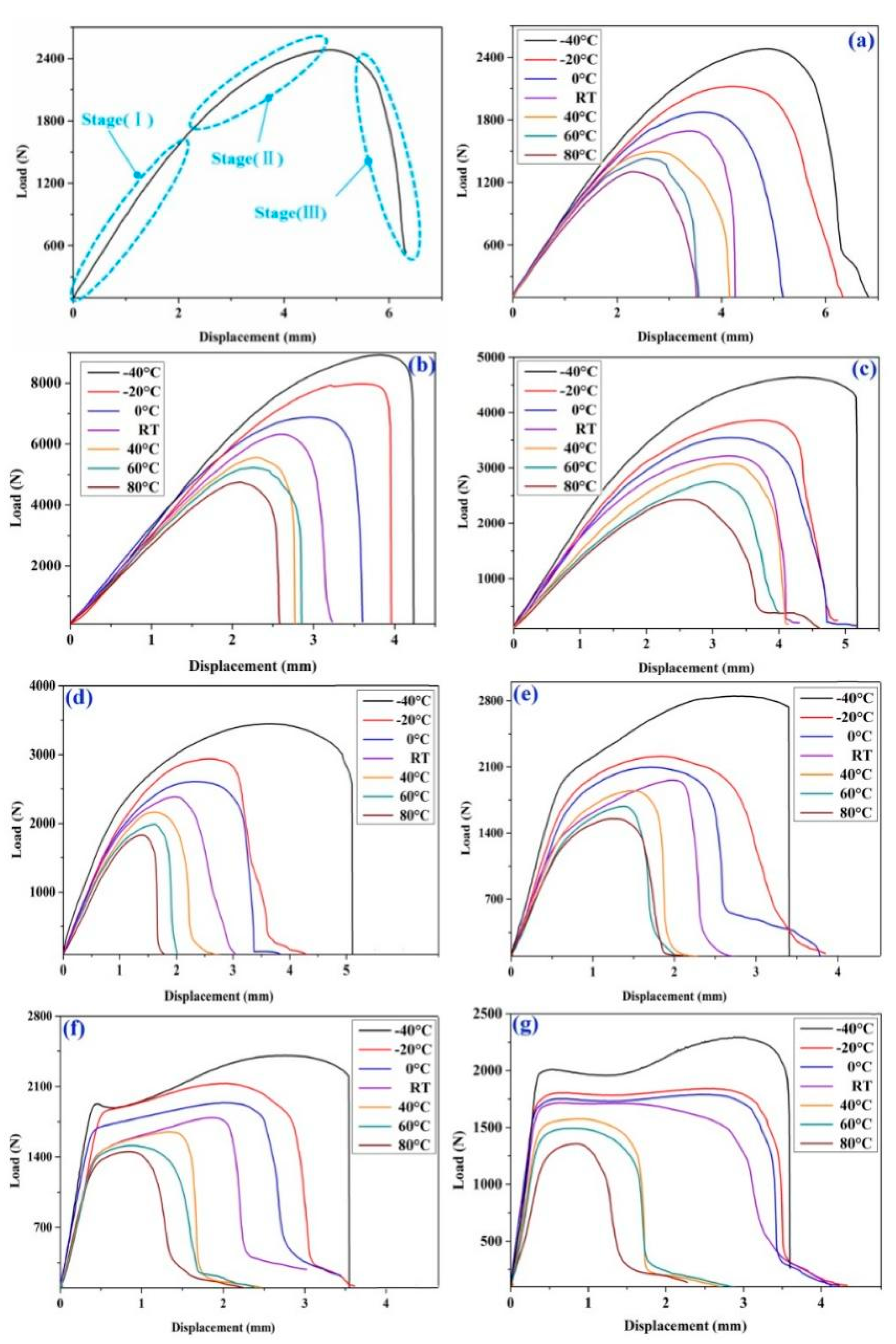

4.4. Force-Displacement Curve Comparison

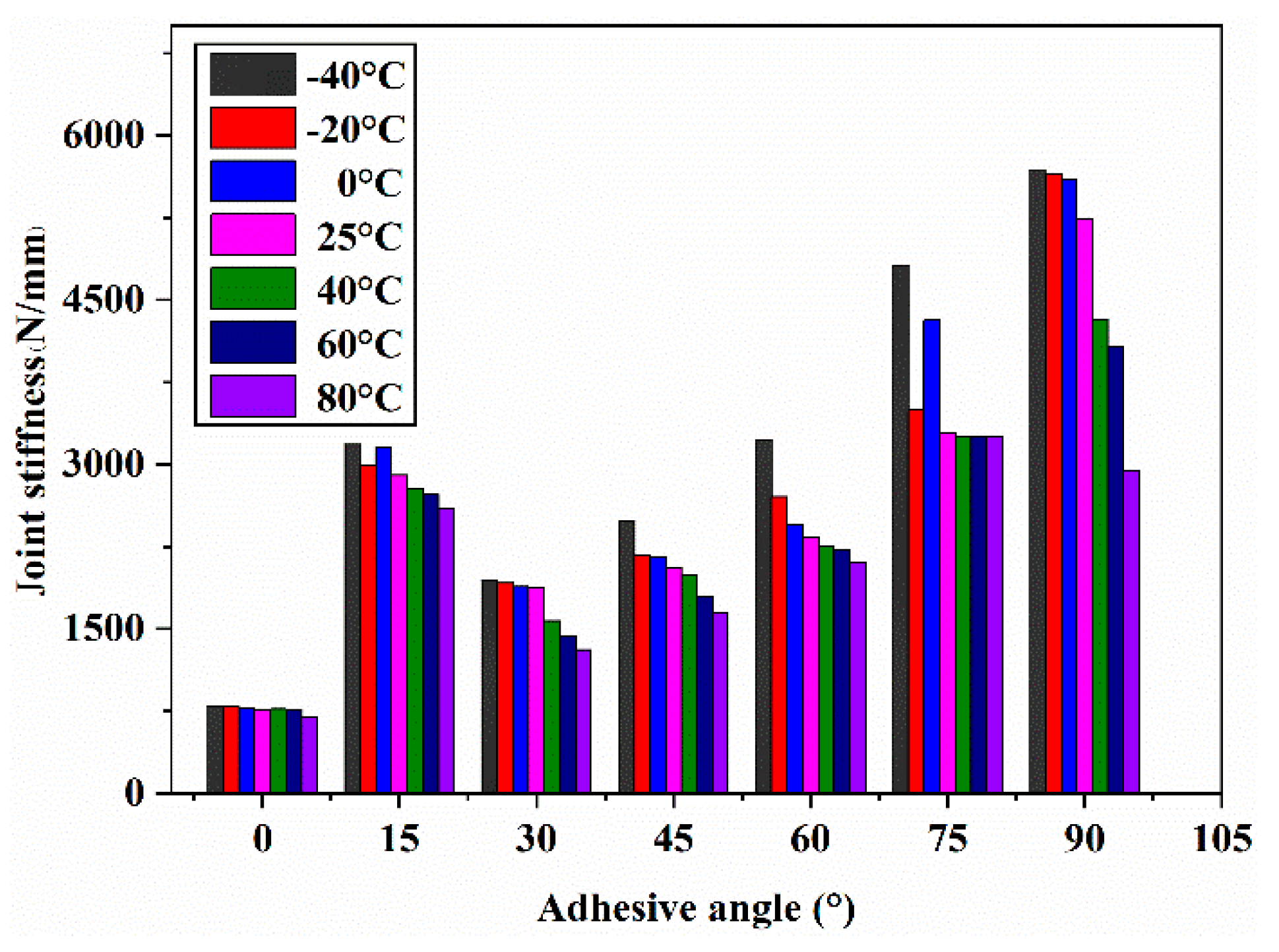

4.5. Joint Stiffness

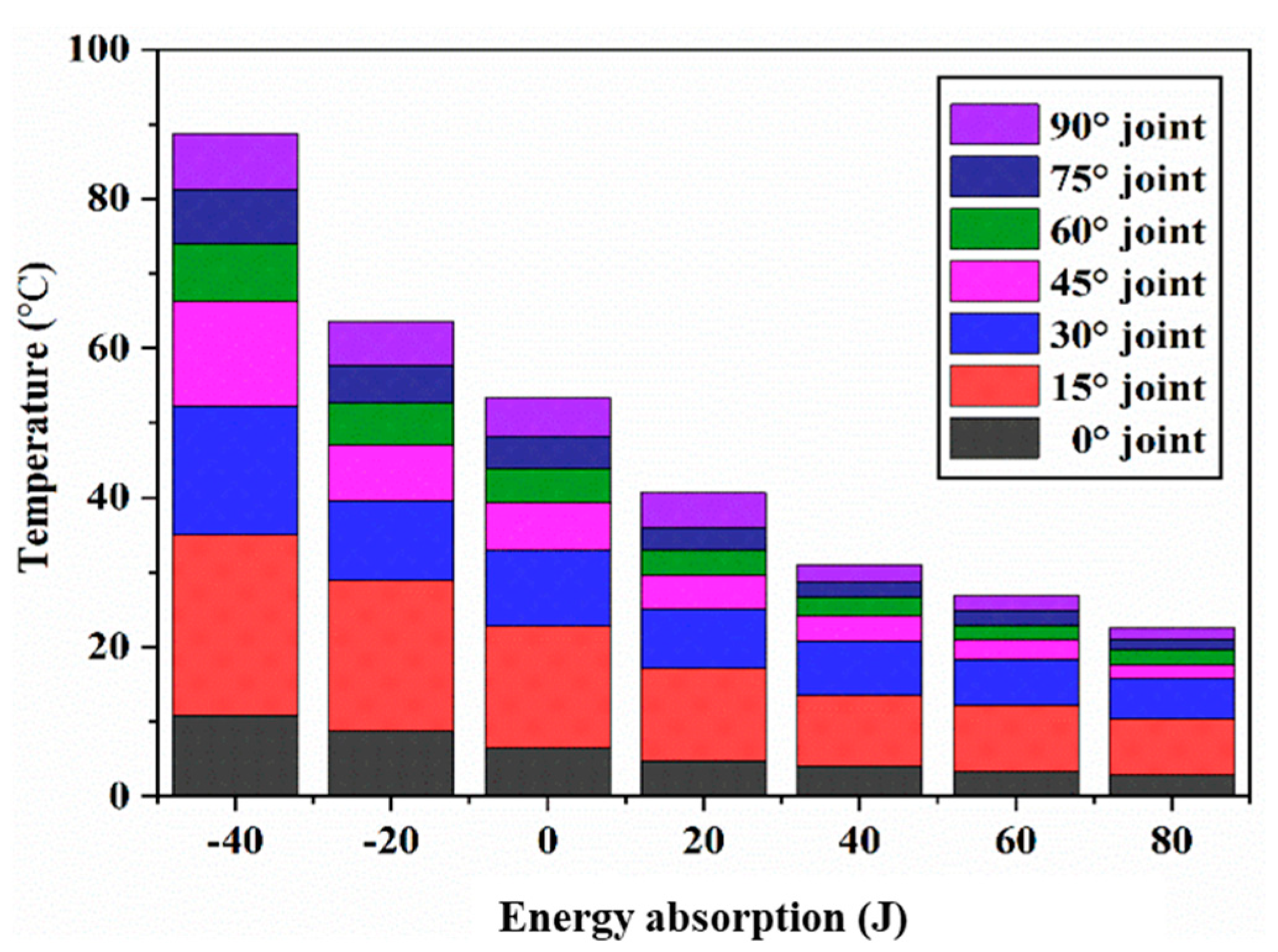

4.6. Energy Absorption

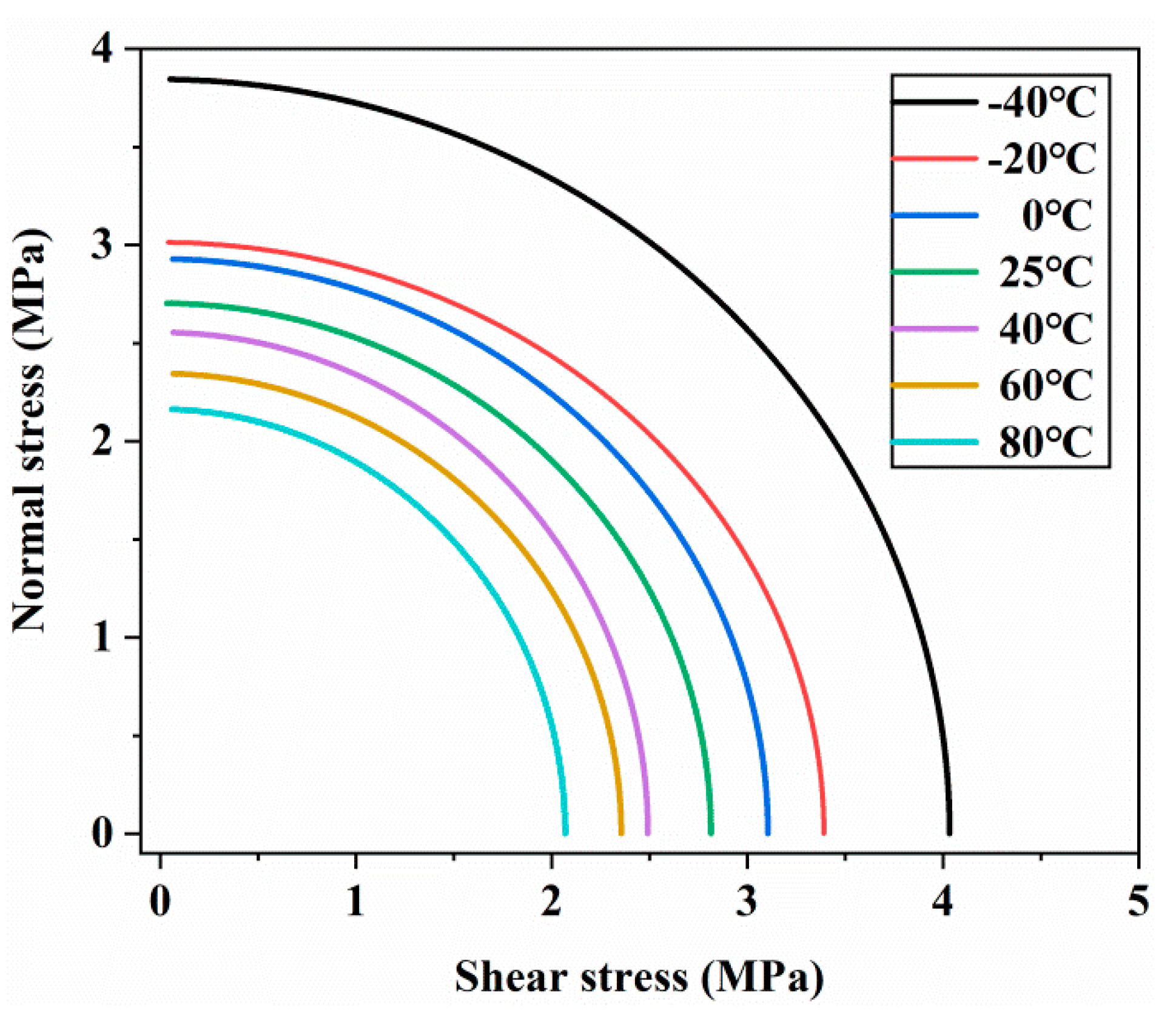

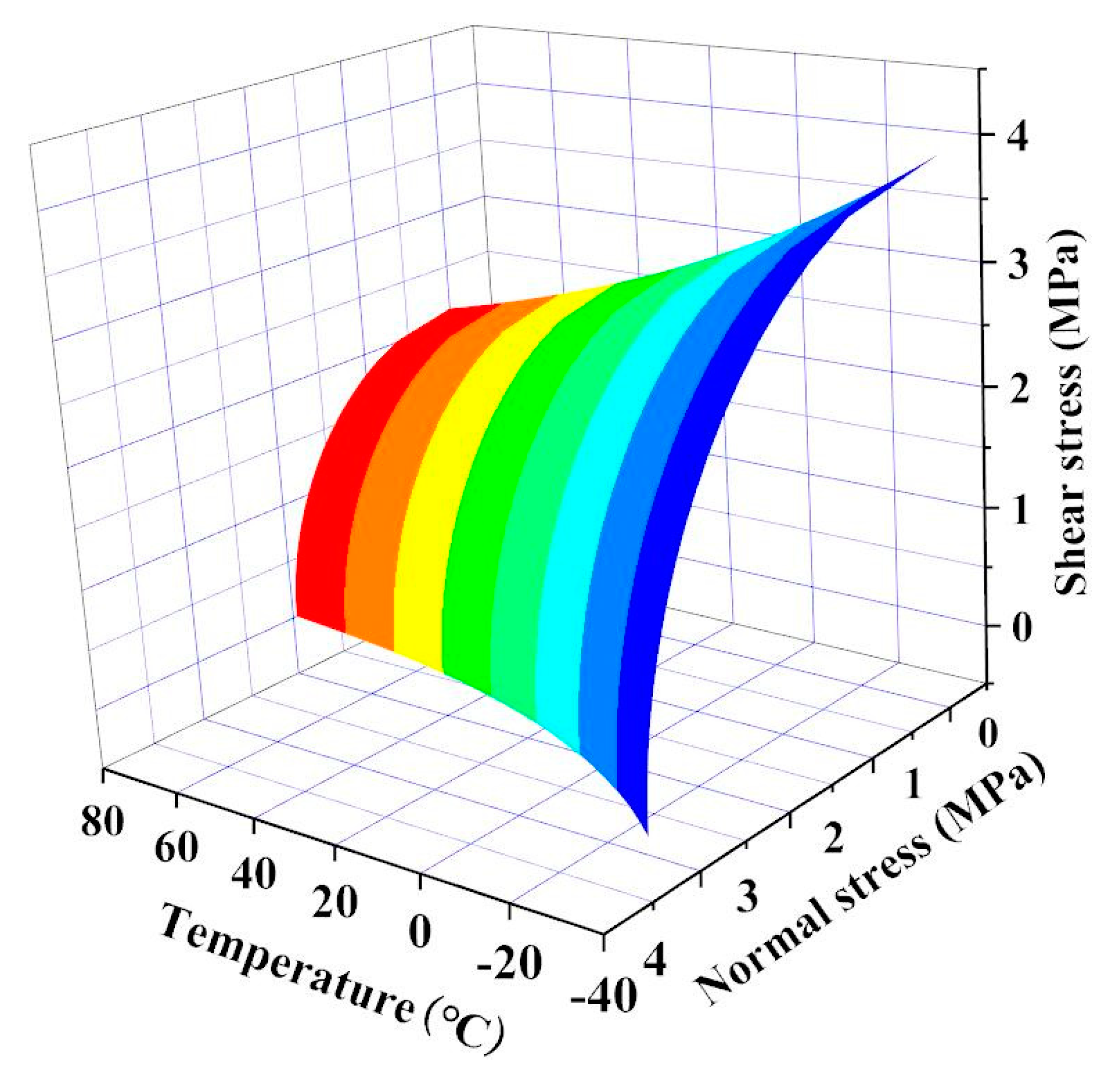

4.7. Failure Criterion Surface of Adhesive Joint

5. Conclusions

- The effect of ambient temperature on the mechanical properties of ISR-7008 adhesive was studied. The results show that the Young’s modulus, tensile strength and failure strain of the adhesive decrease with the increase in temperature.

- Quasi-static tensile tests were carried out on lap joints, scarf joints (15°, 30°, 45°, 60° and 75°) and butt joints at different temperatures. The results show that the strength of the joint decreases with the increase in temperature. Compared with lap joints and scarf joints, the strength of butt joints is the least sensitive to the change in temperature. With the increase of the adhesive angle, the stiffness of the joint increases gradually, while with the increase in temperature, the stiffness of all the tested joints decreases gradually. At the same time, with the increase in temperature, the failure displacement and energy absorbed by the joint also witness a downward trend.

- Based on the experimental data, the secondary stress failure criteria of adhesive joints at different temperatures are obtained. Considering this, the surface function of failure criteria under the full temperature field environment is proposed, which provides a reference for the failure prediction of adhesive structures under different temperatures and complex stress conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, Y. Advances in Welding and Joining Processes of Multi-material Lightweight Car Body. Chin. J. Mech. Eng. 2016, 52, 1–23. [Google Scholar] [CrossRef]

- Lai, W.-J.; Pan, J. Failure mode and fatigue behavior of weld-bonded lap-shear specimens of magnesium and steel sheets. Int. J. Fatigue 2015, 75, 184–197. [Google Scholar] [CrossRef]

- Sakundarini, N.S.; Taha, Z.; Abdul-rashid, S.H.; Ghazila, R.A. Optimal multi-material selection for lightweight design of automotive body assembly incorporating recyclability. Mater. Des. 2013, 50, 846–857. [Google Scholar] [CrossRef]

- Banea, M.; Rosioara, M.; Carbas, R.; da Silva, L. Multi-material adhesive joints for automotive industry. Compos. Part B Eng. 2018, 151, 71–77. [Google Scholar] [CrossRef]

- Sousa, J.; Correia, J.; Gonilha, J.; Cabral-Fonseca, S.; Firmo, J.; Keller, T. Durability of adhesively bonded joints between pultruded GFRP adherends under hygrothermal and natural ageing. Compos. Part B Eng. 2019, 158, 475–488. [Google Scholar] [CrossRef]

- Banea, M.D.; De Sousa, F.S.M.; Da Silva, L.; Campilho, R.D.S.G.; De Pereira, A.M.B. Effects of Temperature and Loading Rate on the Mechanical Properties of a High Temperature Epoxy Adhesive. J. Adhes. Sci. Technol. 2011, 25, 2461–2474. [Google Scholar] [CrossRef]

- Kang, S.-G.; Kim, M.-G.; Kim, C.-G. Evaluation of cryogenic performance of adhesives using composite–aluminum double-lap joints. Compos. Struct. 2007, 78, 440–446. [Google Scholar] [CrossRef]

- Fan, Y.; Shangguan, L.; Zhang, M.; Peng, H.; Na, J. Effect of cyclic hygrothermal aging on mechanical behaviours of adhesive bonded aluminum joints. J. Adhes. Sci. Technol. 2021, 35, 199–219. [Google Scholar] [CrossRef]

- Banea, M.D.; Da Silva, L.; Campilho, R. Effect of Temperature on Tensile Strength and Mode I Fracture Toughness of a High Temperature Epoxy Adhesive. J. Adhes. Sci. Technol. 2012, 26, 939–953. [Google Scholar] [CrossRef]

- Viana, G.; Costa, M.; Banea, M.D.; Da Silva, L. A review on the temperature and moisture degradation of adhesive joints. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2017, 231, 488–501. [Google Scholar] [CrossRef]

- Grant, L.; Adams, R.; Da Silva, L.F. Effect of the temperature on the strength of adhesively bonded single lap and T joints for the automotive industry. Int. J. Adhes. Adhes. 2009, 29, 535–542. [Google Scholar] [CrossRef]

- Banea, M.D.; Da Silva, L.F.M. The effect of temperature on the mechanical properties of adhesives for the automotive industry. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2010, 224, 51–62. [Google Scholar] [CrossRef]

- Marques, E.; Da Silva, L.F.M.; Banea, M.D.; Carbas, R.J.C. Adhesive Joints for Low- and High-Temperature Use: An Overview. J. Adhes. 2014, 91, 556–585. [Google Scholar] [CrossRef]

- Adams, R.; Coppendale, J.; Mallick, V.; Al-Hamdan, H. The effect of temperature on the strength of adhesive joints. Int. J. Adhes. Adhes. 1992, 12, 185–190. [Google Scholar] [CrossRef]

- Na, J.; Mu, W.; Qin, G.; Tan, W.; Pu, L. Effect of temperature on the mechanical properties of adhesively bonded basalt FRP-aluminum alloy joints in the automotive industry. Int. J. Adhes. Adhes. 2018, 85, 138–148. [Google Scholar] [CrossRef]

- Tan, W.; Na, J.X.; Mu, W.L.; Shen, H.; Qin, G. Effect of service temperature on static failure of BFRP/aluminum alloy adhesive joints. J. Traffic Transp. Eng. 2020, 20, 171–180. [Google Scholar]

- Da Silva, L.F.; Adams, R.; Gibbs, M. Manufacture of adhesive joints and bulk specimens with high-temperature adhesives. Int. J. Adhes. Adhes. 2004, 24, 69–83. [Google Scholar] [CrossRef]

- Zhang, Y.; Vassilopoulos, A.; Keller, T. Effects of low and high temperatures on tensile behavior of adhesively-bonded GFRP joints. Compos. Struct. 2010, 92, 1631–1639. [Google Scholar] [CrossRef]

- Pascal, J.; DarqueCeretti, E.; Felder, E.; Pouchelon, A. Rubber-like adhesive in simple shear: Stress analysis and fracture mor-phology of a single lap joint. J. Adhes. Sci. Technol. 1994, 8, 553–573. [Google Scholar] [CrossRef]

- Hu, P.; Han, X.; Li, W.D. Research on the static strength performance of adhesive single lap joints subjected to extreme tem-perature environment for automotive industry. Int. J. Adhes. Adhes. 2013, 41, 119–126. [Google Scholar] [CrossRef]

- Banea, M.D.; Silva, L.F.M.D. Static and fatigue behaviour of room temperature vulcanising silicone adhesives for high tem-perature aerospace applications. Mater. Werkst. 2010, 41, 325–335. [Google Scholar] [CrossRef]

- Lubowiecka, I.; Rodríguez, M.; Rodriguez, E.; Martinez, D. Experimentation, material modelling and simulation of bonded joints with a flexible adhesive. Int. J. Adhes. Adhes. 2012, 37, 56–64. [Google Scholar] [CrossRef]

- Da Silva, L.F.; Carbas, R.; Critchlow, G.; Figueiredo, M.; Brown, K. Effect of material, geometry, surface treatment and environment on the shear strength of single lap joints. Int. J. Adhes. Adhes. 2009, 29, 621–632. [Google Scholar] [CrossRef]

- Karachalios, E.; Adams, R.; da Silva, L.F. Single lap joints loaded in tension with ductile steel adherends. Int. J. Adhes. Adhes. 2013, 43, 96–108. [Google Scholar] [CrossRef]

- Banea, M.D.; Silva, L.F.M.D. Mechanical Characterization of Flexible Adhesives. J. Adhes. 2009, 85, 261–285. [Google Scholar] [CrossRef]

- Banea, M.D.; Silva, L.F.M.D.; Campilho, R.D.S.G. The Effect of Adhesive Thickness on the Mechanical Behaviour of a Structural Polyurethane Adhesive. J. Adhes. 2015, 91, 331–346. [Google Scholar] [CrossRef]

- Loureiro, A.L.; Da Silva, L.F.M.; Sato, C.; Figueiredo, M.A.V. Comparison of the Mechanical Behaviour Between Stiff and Flexible Adhesive Joints for the Automotive Industry. J. Adhes. 2010, 86, 765–787. [Google Scholar] [CrossRef]

- Moroni, F.; Pirondi, A.; Kleiner, F. Experimental analysis and comparison of the strength of simple and hybrid structural joints. Int. J. Adhes. Adhes. 2010, 30, 367–379. [Google Scholar] [CrossRef]

| Material Attribute | ISR-7008 | 6005A Aluminum Alloy |

|---|---|---|

| Young’s modulus (MPa) | 4.3 | 71,000 |

| Poisson’s ratio | 0.44 | 0.33 |

| Density (kg/m3) | 1400 | 2730 |

| Performance | ISR-7008 |

|---|---|

| Tensile failure strength (MPa) | 2.9 |

| Shear failure strength (MPa) | 2.5 |

| Extension at break curing condition | 225% |

| Curing conditions (T/RH) | 20 °C/50%RH |

| Curing rate (mm/24 h) | 3 |

| Glass transition temperature (°C) | −59 °C |

| Temperature (°C) | Adhesive Angle (°) | Strength (MPa) | Average Strength (MPa) | ST (%) | CV (%) | Failure Mode | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| No. 1 | No. 2 | No. 3 | No. 4 | No. 5 | ||||||

| 80 | 90 | 2.27 | 2.15 | 2.19 | 2.23 | 2.21 | 2.21 | 4.47 | 2.03 | CF |

| 75 | 2.11 | 2.32 | 2.29 | 2.03 | 2.05 | 2.16 | 13.60 | 6.30 | CF | |

| 60 | 1.98 | 2.11 | 2.05 | 2.2 | 2.11 | 2.09 | 8.15 | 3.90 | CF | |

| 45 | 2.12 | 1.96 | 1.97 | 2.23 | 2.17 | 2.09 | 12.06 | 5.77 | CF | |

| 30 | 2.11 | 2.08 | 1.93 | 2.05 | 2.23 | 2.08 | 10.82 | 5.20 | CF | |

| 15 | 2.10 | 2.25 | 2.28 | 1.87 | 2.00 | 2.10 | 17.16 | 8.17 | CF | |

| 0 | 1.98 | 2.23 | 2.05 | 2.01 | 2.23 | 2.10 | 12.12 | 5.77 | CF | |

| 60 | 90 | 2.22 | 2.45 | 2.54 | 2.28 | 2.36 | 2.37 | 12.85 | 5.42 | CF |

| 75 | 2.26 | 2.50 | 2.38 | 2.49 | 2.37 | 2.40 | 9.87 | 4.11 | CF | |

| 60 | 1.98 | 2.11 | 2.05 | 2.20 | 2.11 | 2.30 | 14.02 | 6.09 | CF | |

| 45 | 2.09 | 2.35 | 2.24 | 2.37 | 2.40 | 2.29 | 12.71 | 5.55 | CF | |

| 30 | 2.11 | 2.13 | 2.32 | 2.40 | 2.49 | 2.29 | 16.66 | 7.27 | CF | |

| 15 | 2.24 | 2.31 | 2.46 | 2.50 | 2.24 | 2.35 | 12.28 | 5.23 | CF | |

| 0 | 2.48 | 2.44 | 2.31 | 2.29 | 2.53 | 2.41 | 10.56 | 4.38 | CF | |

| 40 | 90 | 2.40 | 2.57 | 2.64 | 2.73 | 2.56 | 2.58 | 12.14 | 4.70 | CF |

| 75 | 2.63 | 2.54 | 2.41 | 2.70 | 2.47 | 2.55 | 11.73 | 4.60 | CF | |

| 60 | 2.60 | 2.61 | 2.57 | 2.36 | 2.46 | 2.52 | 10.75 | 4.26 | CF | |

| 45 | 2.42 | 2.35 | 2.56 | 2.66 | 2.61 | 2.52 | 13.08 | 5.18 | CF | |

| 30 | 2.51 | 2.44 | 2.60 | 2.38 | 2.47 | 2.48 | 8.21 | 3.31 | CF | |

| 15 | 2.36 | 2.48 | 2.58 | 2.56 | 2.77 | 2.55 | 15.03 | 5.89 | CF | |

| 0 | 2.64 | 2.53 | 2.66 | 2.47 | 2.70 | 2.60 | 9.62 | 3.70 | CF | |

| RT | 90 | 2.76 | 2.61 | 2.99 | 2.93 | 2.61 | 2.78 | 17.66 | 6.35 | CF |

| 75 | 2.66 | 2.82 | 2.57 | 2.83 | 2.62 | 2.70 | 11.85 | 4.39 | CF | |

| 60 | 2.56 | 2.48 | 2.82 | 2.77 | 2.62 | 2.65 | 14.25 | 5.38 | CF | |

| 45 | 2.78 | NA | 2.64 | 2.61 | 2.93 | 2.74 | 14.67 | 5.35 | CF | |

| 30 | 2.56 | 2.62 | 2.87 | 2.91 | 2.79 | 2.75 | 15.38 | 5.59 | CF | |

| 15 | 3.01 | 2.92 | 2.69 | 2.70 | NA | 2.83 | 16.02 | 5.66 | CF | |

| 0 | 3.01 | 2.87 | 3.12 | 2.78 | 2.52 | 2.86 | 11.42 | 3.99 | CF | |

| 0 | 90 | 3.01 | 2.77 | 2.95 | 2.82 | 3.00 | 2.91 | 9.65 | 3.74 | CF |

| 60 | 3.04 | 3.13 | 2.99 | 2.75 | 2.69 | 2.92 | 14.06 | 6.52 | CF | |

| 45 | 2.90 | 2.78 | 3.12 | 3.20 | 3.25 | 3.05 | 16.79 | 6.61 | CF | |

| 30 | 2.88 | 2.98 | 2.90 | 3.17 | 3.27 | 3.04 | 11.45 | 5.66 | CF | |

| 75 | 3.01 | 3.08 | 3.13 | 2.85 | 2.83 | 2.98 | 10.57 | 4.53 | CF | |

| 15 | 3.11 | 3.03 | 3.00 | 3.06 | 3.25 | 3.09 | 4.06 | 3.18 | CF | |

| 0 | 2.81 | 3.20 | 3.03 | 3.34 | 3.22 | 3.12 | 19.78 | 6.59 | CF | |

| −20 | 90 | 3.20 | 3.11 | 3.05 | 2.78 | 3.01 | 3.03 | 15.70 | 5.18 | CF |

| 75 | 2.96 | 3.11 | 3.23 | 2.92 | 3.23 | 3.09 | 14.61 | 4.72 | CF | |

| 60 | 3.11 | 3.21 | 2.97 | 2.85 | 3.16 | 3.06 | 14.76 | 4.82 | CF | |

| 45 | 3.23 | 3.51 | 3.37 | 3.29 | 3.70 | 3.42 | 18.84 | 5.51 | CF | |

| 30 | 3.01 | 3.07 | 3.33 | 3.42 | 3.27 | 3.22 | 17.46 | 5.41 | CF | |

| 15 | 3.22 | 3.44 | 3.19 | 3.50 | 3.20 | 3.31 | 14.79 | 4.47 | CF | |

| 0 | 3.67 | 3.55 | 3.29 | 3.34 | 3.70 | 3.51 | 18.74 | 5.43 | CF | |

| −40 | 90 | 3.68 | 3.92 | 3.84 | 4.02 | 3.74 | 3.84 | 13.64 | 3.55 | CF |

| 75 | 3.82 | 3.77 | 3.90 | 3.91 | 3.75 | 3.83 | 7.31 | 1.91 | CF | |

| 60 | 4.04 | 3.90 | 3.78 | 3.82 | 3.86 | 3.88 | 10.00 | 2.58 | CF | |

| 45 | 4.32 | 4.18 | 3.99 | 3.84 | 3.72 | 4.01 | 24.41 | 6.08 | CF | |

| 30 | 3.84 | 3.99 | 3.72 | 4.13 | 4.22 | 3.98 | 20.45 | 5.14 | CF | |

| 15 | 4.12 | 4.03 | 4.21 | 3.87 | 3.87 | 4.02 | 15.09 | 3.75 | CF | |

| 0 | 3.89 | 4.16 | 4.23 | 3.87 | 3.90 | 4.01 | 17.10 | 4.26 | CF | |

| Adhesive Angle (°C) | 0 | 15 | 30 | 45 | 60 | 75 | 90 |

|---|---|---|---|---|---|---|---|

| Average failure load (N) | 2400 | 8893 | 4683 | 3445 | 2814 | 2573 | 2458 |

| Adhesive area (mm2) | 625 | 2322 | 1207 | 859 | 707 | 640 | 613 |

| Normal stress (MPa) | 0.00 | 1.04 | 1.99 | 2.83 | 3.36 | 3.70 | 3.84 |

| Shear stress (MPa) | 4.01 | 3.88 | 3.45 | 2.83 | 1.94 | 0.99 | 0.00 |

| Adhesive Angle (°C) | 0 | 15 | 30 | 45 | 60 | 75 | 90 |

|---|---|---|---|---|---|---|---|

| Average failure load (N) | 1894 | 7175 | 3693 | 2938 | 2277 | 2118 | 2152 |

| Adhesive area (mm2) | 625 | 2322 | 1207 | 859 | 707 | 640 | 613 |

| Normal stress (MPa) | 0.00 | 0.86 | 1.61 | 2.22 | 2.65 | 2.98 | 3.04 |

| Shear stress (MPa) | 3.51 | 3.20 | 2.79 | 2.22 | 1.53 | 0.80 | 0.00 |

| Adhesive Angle (°C) | 0 | 15 | 30 | 45 | 60 | 75 | 90 |

|---|---|---|---|---|---|---|---|

| Average failure load (N) | 1819 | 6920 | 3524 | 2620 | 2149 | 1978 | 1913 |

| Adhesive area (mm2) | 625 | 2322 | 1207 | 859 | 707 | 640 | 613 |

| Normal stress (MPa) | 0.00 | 0.80 | 1.52 | 2.16 | 2.53 | 2.88 | 2.91 |

| Shear stress (MPa) | 3.12 | 2.98 | 2.63 | 2.16 | 1.46 | 0.77 | 0.00 |

| Adhesive Angle (°C) | 0 | 15 | 30 | 45 | 60 | 75 | 90 |

|---|---|---|---|---|---|---|---|

| Average failure load (N) | 1738 | 6269 | 3199 | 2354 | 1944 | 1811 | 1753 |

| Adhesive area (mm2) | 625 | 2322 | 1207 | 859 | 707 | 640 | 613 |

| Normal stress (MPa) | 0.00 | 0.73 | 1.37 | 1.94 | 2.29 | 2.61 | 2.78 |

| Shear stress (MPa) | 2.86 | 2.73 | 2.38 | 1.94 | 1.33 | 0.70 | 0.00 |

| Adhesive Angle (°C) | 0 | 15 | 30 | 45 | 60 | 75 | 90 |

|---|---|---|---|---|---|---|---|

| Average failure load (N) | 1613 | 5921 | 3042 | 2165 | 1753 | 1632 | 1594 |

| Adhesive area (mm2) | 625 | 2322 | 1207 | 859 | 707 | 640 | 613 |

| Normal stress (MPa) | 0.00 | 0.66 | 1.24 | 1.78 | 2.18 | 2.46 | 2.58 |

| Shear stress (MPa) | 2.50 | 2.43 | 2.15 | 1.78 | 1.26 | 0.66 | 0.00 |

| Adhesive Angle (°C) | 0 | 15 | 30 | 45 | 60 | 75 | 90 |

|---|---|---|---|---|---|---|---|

| Average failure load (N) | 1481 | 5573 | 2776 | 1967 | 1619 | 1504 | 1477 |

| Adhesive area (mm2) | 625 | 2322 | 1207 | 859 | 707 | 640 | 613 |

| Normal stress (MPa) | 0.00 | 0.61 | 1.15 | 1.62 | 1.99 | 2.32 | 2.37 |

| Shear stress (MPa) | 2.45 | 2.27 | 1.98 | 1.62 | 1.15 | 0.62 | 0.00 |

| Adhesive Angle (°C) | 0 | 15 | 30 | 45 | 60 | 75 | 90 |

|---|---|---|---|---|---|---|---|

| Average failure load (N) | 1381 | 5016 | 2523 | 1795 | 1471 | 1344 | 1287 |

| Adhesive area (mm2) | 625 | 2322 | 1207 | 859 | 707 | 640 | 613 |

| Normal stress (MPa) | 0.00 | 0.54 | 1.03 | 1.48 | 1.80 | 2.09 | 2.21 |

| Shear stress (MPa) | 2.09 | 2.03 | 1.80 | 1.48 | 1.04 | 0.56 | 0.00 |

| Temperature (°C) | Young’s Modulus (MPa) | Tensile Strength (MPa) | Failure Strain |

|---|---|---|---|

| −40 | 11.8 ± 1.61 | 6.5 ± 0.19 | 5.2 ± 0.23 |

| RT | 5.0 ± 0.27 | 3.4 ± 0.13 | 4.2 ± 0.18 |

| 80 | 2.9 ± 0.24 | 2.07 ± 0.10 | 3.72 ± 0.11 |

| Temperature (°C) | N | S | R2 |

|---|---|---|---|

| −40 | 3.8443 | 4.0337 | 0.9948 |

| −20 | 3.0142 | 3.3914 | 0.9838 |

| 0 | 2.9296 | 3.1055 | 0.9903 |

| 25 | 2.7042 | 2.8139 | 0.9819 |

| 40 | 2.5549 | 2.4921 | 0.9919 |

| 60 | 2.3459 | 2.3558 | 0.9709 |

| 80 | 2.1639 | 2.0695 | 0.9791 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Fan, Y.; Peng, H. Effect of Full Temperature Field Environment on Bonding Strength of Aluminum Alloy. Crystals 2021, 11, 657. https://doi.org/10.3390/cryst11060657

Liu H, Fan Y, Peng H. Effect of Full Temperature Field Environment on Bonding Strength of Aluminum Alloy. Crystals. 2021; 11(6):657. https://doi.org/10.3390/cryst11060657

Chicago/Turabian StyleLiu, Haichao, Yisa Fan, and Han Peng. 2021. "Effect of Full Temperature Field Environment on Bonding Strength of Aluminum Alloy" Crystals 11, no. 6: 657. https://doi.org/10.3390/cryst11060657

APA StyleLiu, H., Fan, Y., & Peng, H. (2021). Effect of Full Temperature Field Environment on Bonding Strength of Aluminum Alloy. Crystals, 11(6), 657. https://doi.org/10.3390/cryst11060657