Study on Microstructure and Properties of 12Ag–Cu–Zn–Sn Cadmium-Free Filler Metals with Trace In Addition

Abstract

1. Introduction

2. Materials and Methods

3. Results

3.1. Melting Characteristics of 12Ag–Cu–Zn–Sn–xIn Filler Metals

3.2. Wettability of 12Ag–Cu–Zn–Sn–xIn Filler Metals

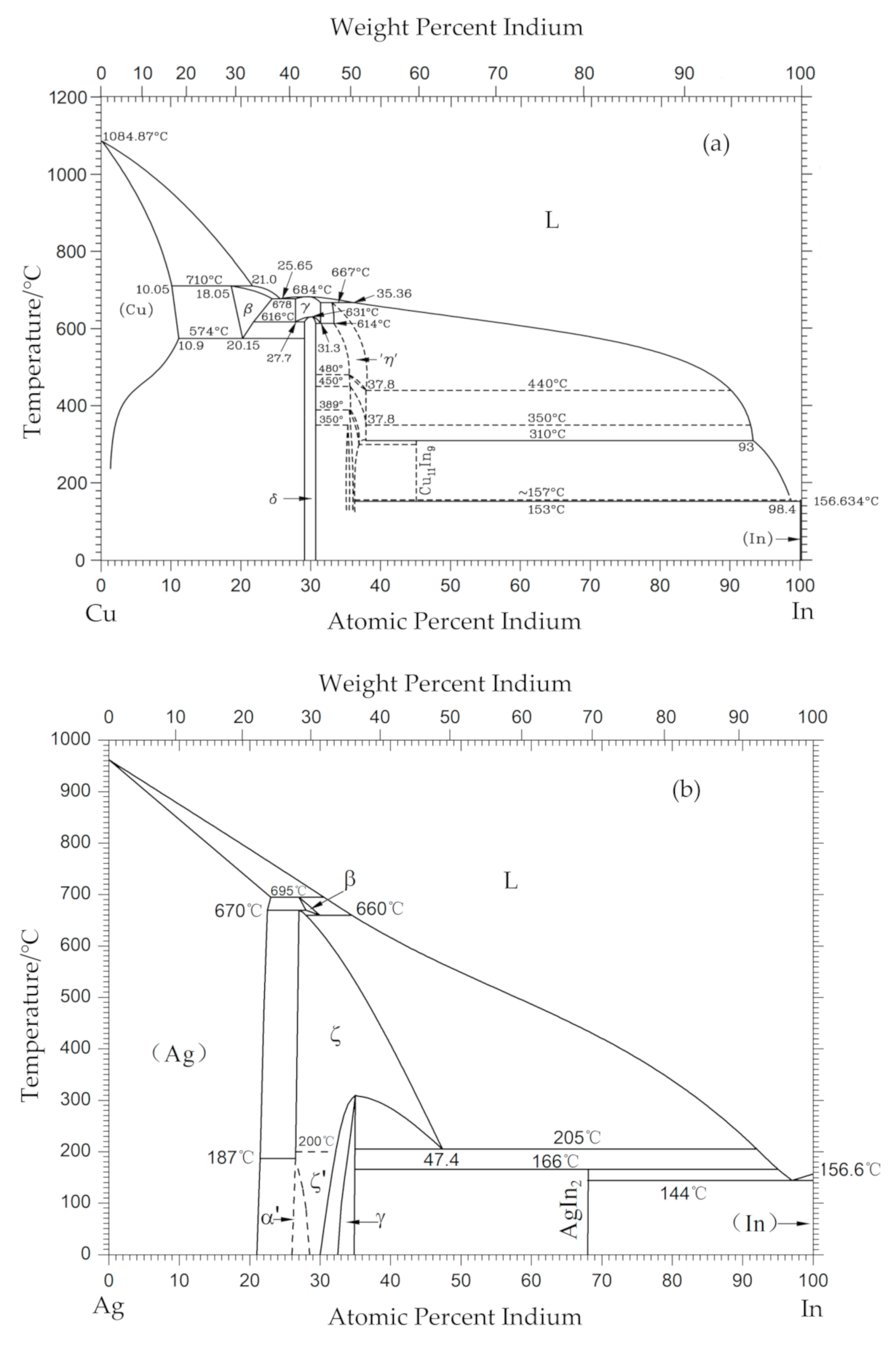

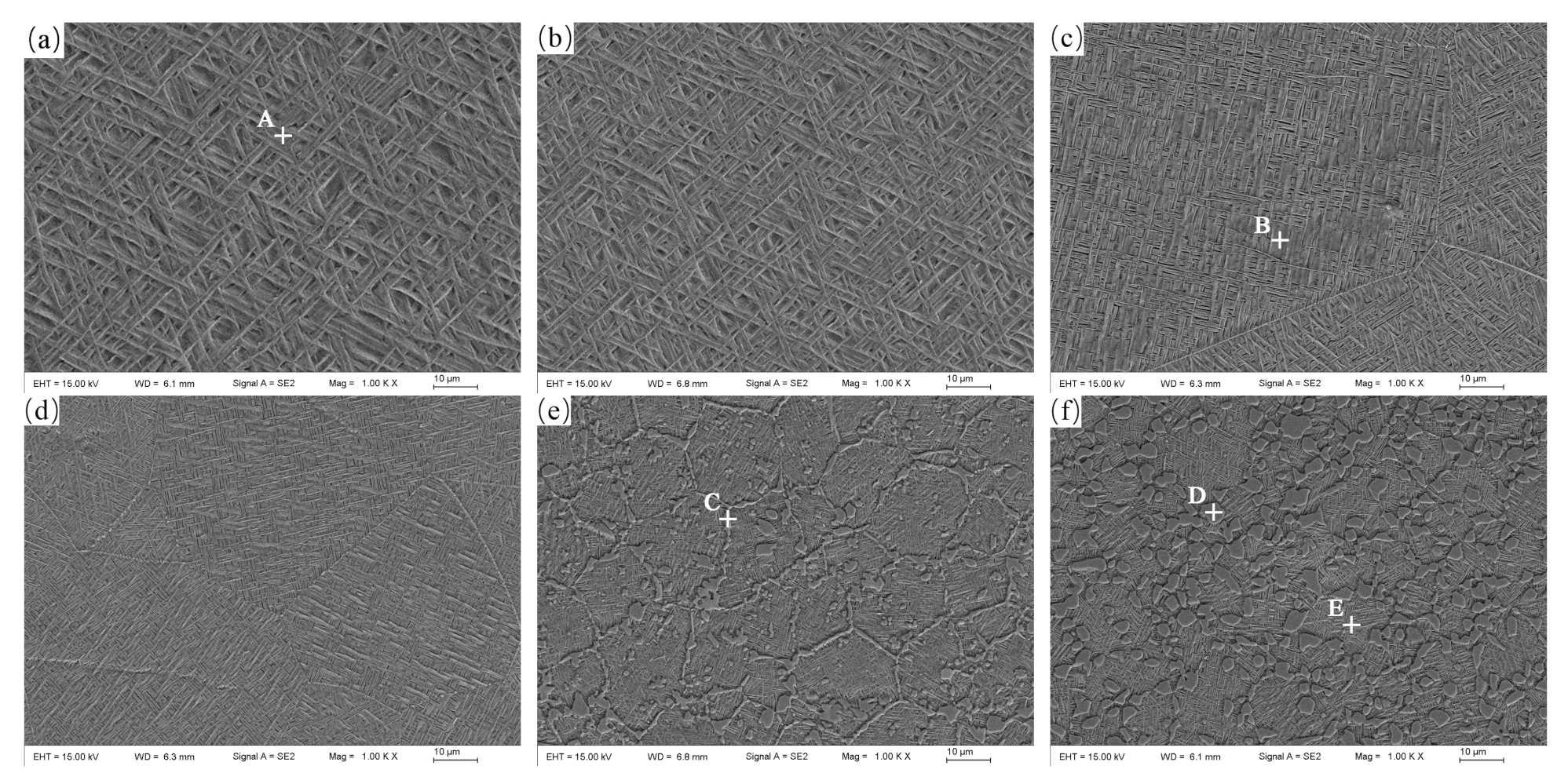

3.3. Microstructure of 12Ag–Cu–Zn–Sn–xIn Filler Metals

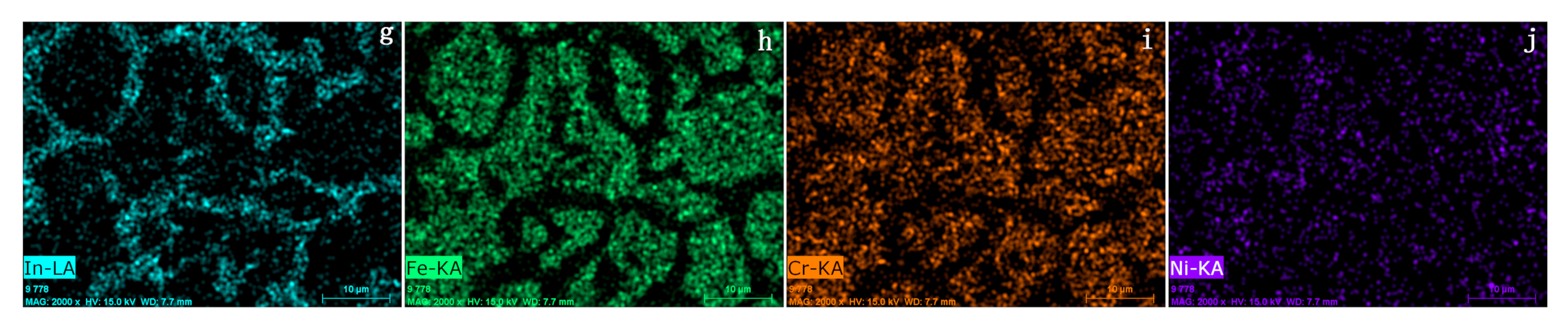

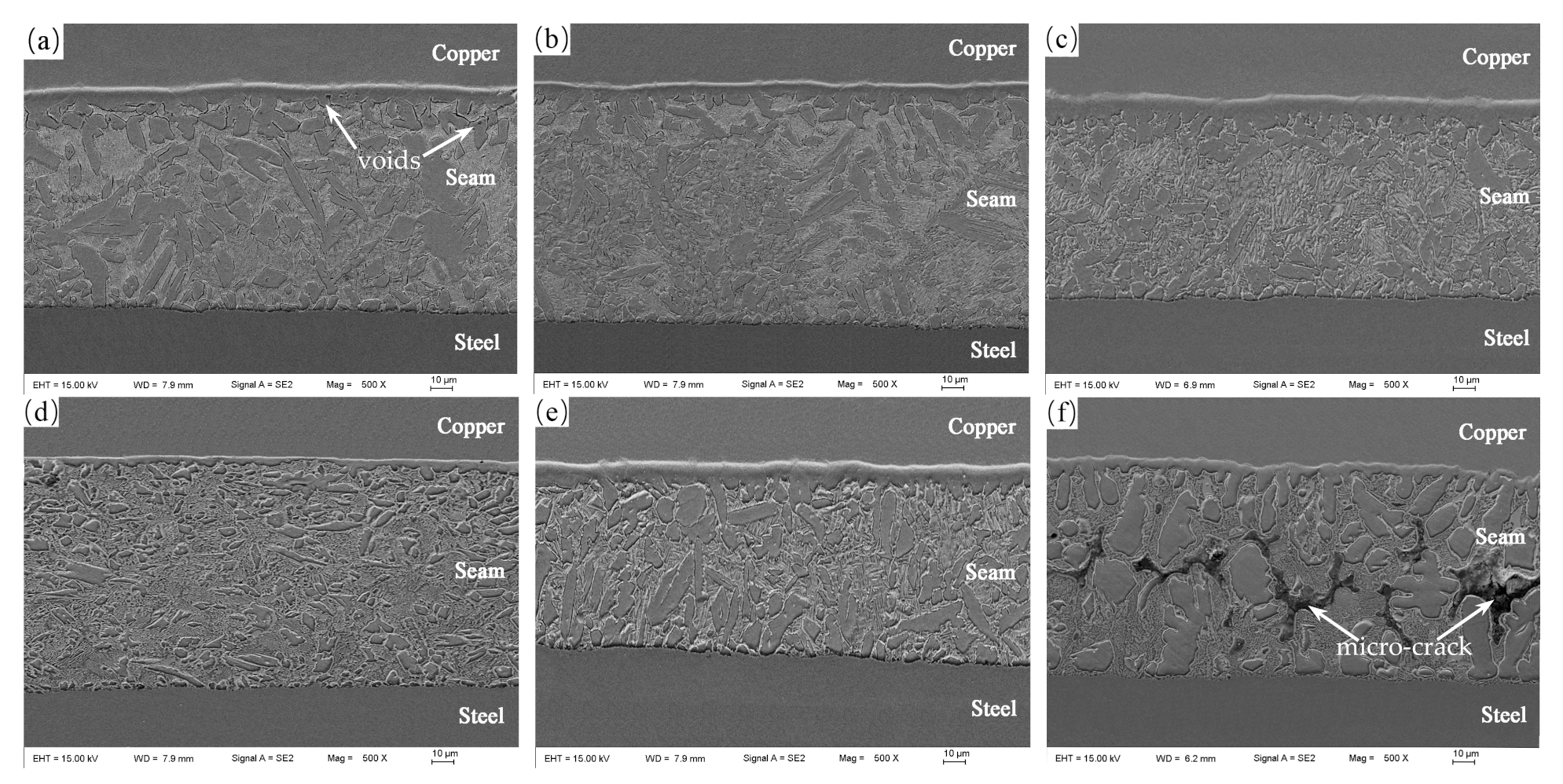

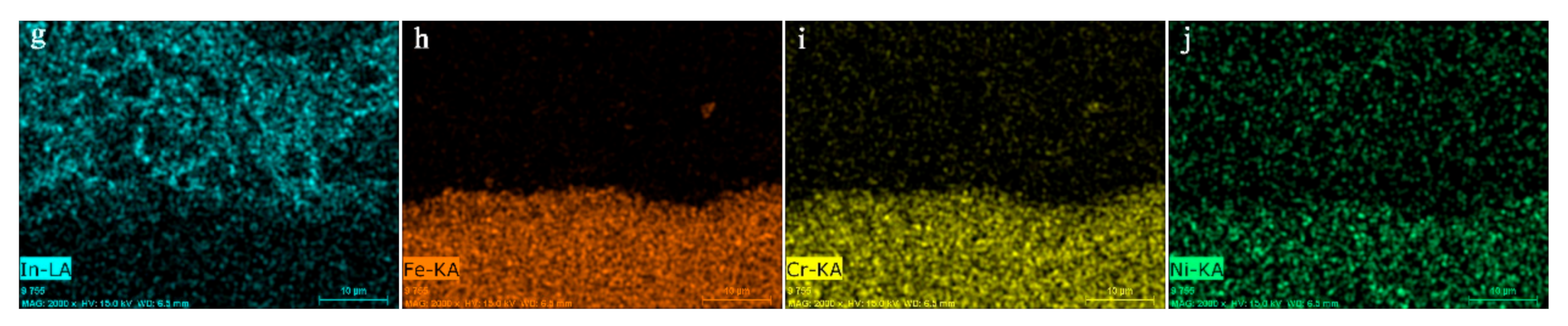

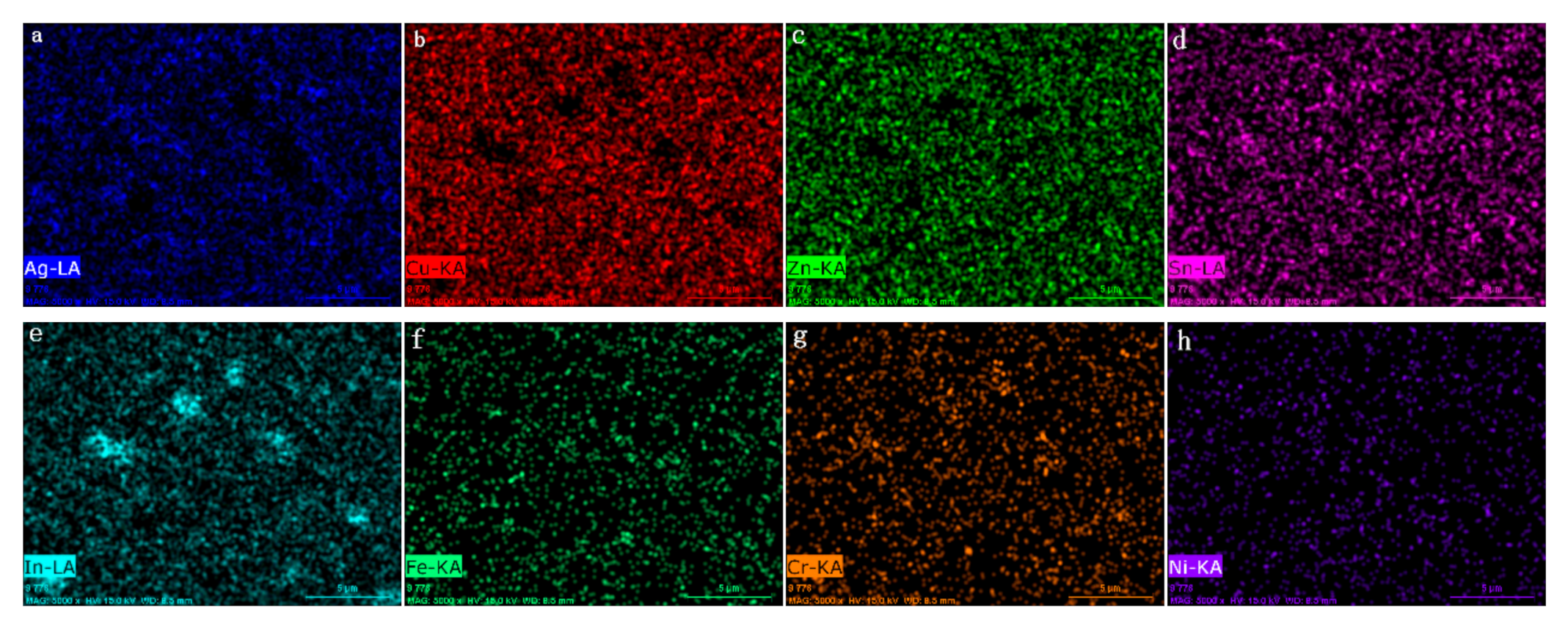

3.4. Microstructure of the Brazing Joints

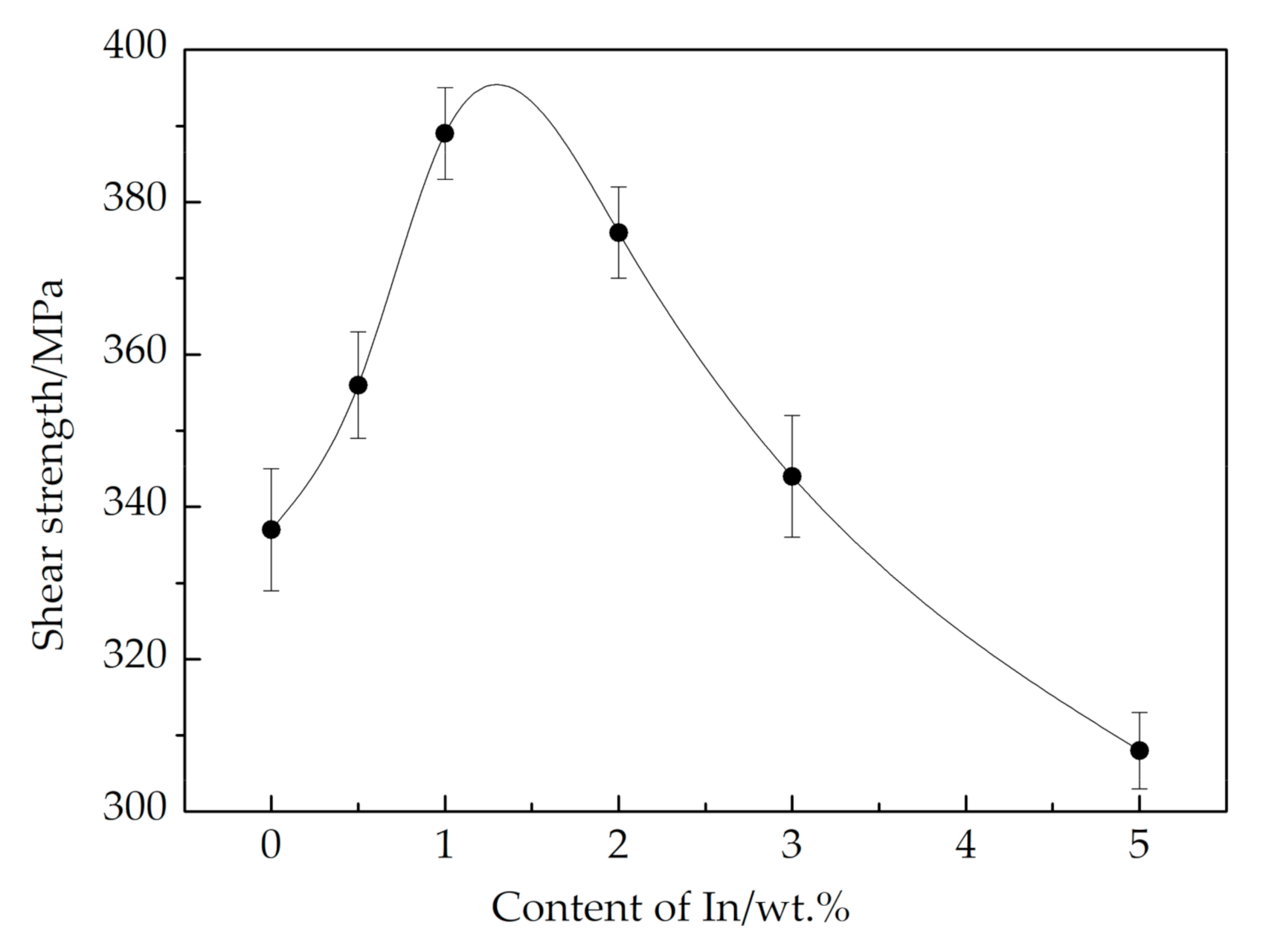

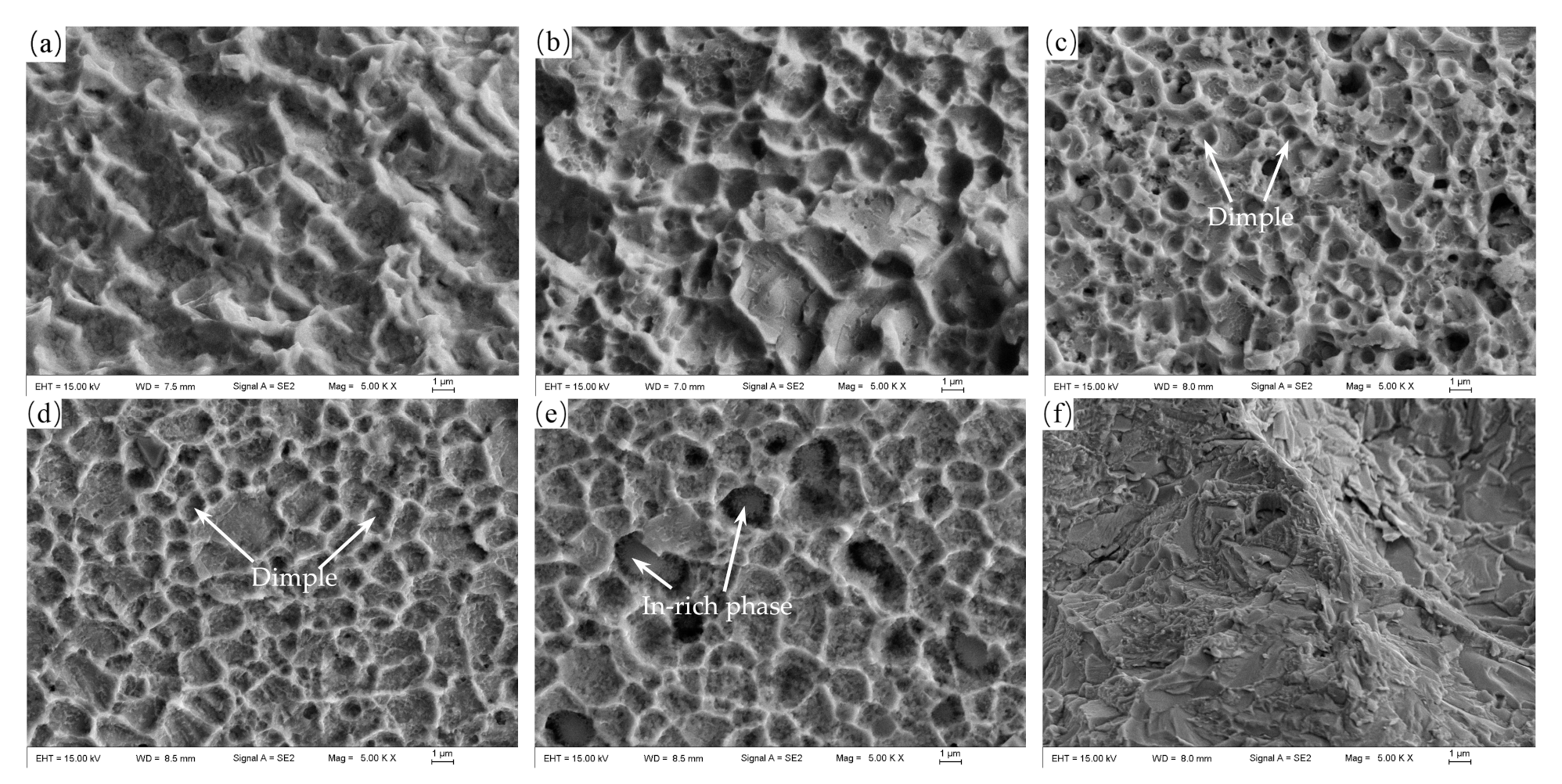

3.5. Mechanical Property of Brazed Joints

4. Conclusions

- (1)

- The melting characteristics and wettability of 12Ag–Cu–Zn–Sn–xIn filler metal were improved significantly with appropriate amount of In. Wetting ring was found on the leading edge of the molten brazing alloy on steel plates, which was mainly composed of Ag, In, and Sn.

- (2)

- The network-like structure was found in the alloys with trace In addition, the microstructure of 12Ag–Cu–Zn–Sn–2In filler metal was finer than that of Indium free one. Cu4In and Ag9In4 intermetallic compounds were formed in the matrix of brazing alloy when the content of In reaches 5 wt.%.

- (3)

- The fracture positions of copper/steel brazing joints all occurred on the copper plates. The strength of steel/steel brazing joints presented a parabolic trend with the addition of In, the peak value of 389.4 MPa was achieved using 12Ag–Cu–Zn–Sn–1In.

- (4)

- The fracture micrograph of the joint brazed with 12Ag–Cu–Zn–Sn–1In showed numerous small and uniform dimples, and a step-like structure was observed on the fracture surface when the 12Ag–Cu–Zn–Sn–5In was employed.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Winiowski, A.; Rózanski, M. Impact of tin and nickel on the brazing properties of silver filler metals and on the strength of brazed joints made of stainless steels. Arch. Metall. Mater. 2013, 58, 1007–1011. [Google Scholar] [CrossRef]

- Long, W.M.; Zhang, G.X.; Zhang, Q.K. In situ synthesis of high strength Ag brazing filler metals during induction brazing process. Scr. Mater. 2016, 110, 41–43. [Google Scholar] [CrossRef]

- Lu, B.; Xu, C.; Yang, J.X. WEEE flow and mitigating measures in China. Waste Manag. 2008, 28, 1589–1597. [Google Scholar]

- Wierzbicki, L.; Malec, W.; Stobrawa, J.; Cwolek, B.; Ju, B. Studies into new, environmentally friendly Ag-Cu-Zn-Sn brazing alloys of low silver content. Arch. Metall. Mater. 2011, 56, 147–158. [Google Scholar] [CrossRef]

- Ma, C.L.; Xue, S.B.; Wang, B. Study on novel Ag-Cu-Zn-Sn brazing filler metal bearing Ga. J. Alloy. Compd. 2016, 688, 854–862. [Google Scholar] [CrossRef]

- Ma, C.L.; Xue, S.B.; Wang, B.; Wang, J.X.; Hu, A.M. Effect of Ce addition on the microstructure and properties of Ag17CuZnSn filler metal. J. Mater. Eng. Perform. 2017, 26, 3180–3190. [Google Scholar] [CrossRef]

- Lai, Z.M.; Xue, S.B.; Han, X.P.; Gu, L.Y.; Gu, W.H. Study on microstructure and property of brazed joint of AgCuZn-X (Ga, Sn, In, Ni) brazing alloy. Rare Met. Mater. Eng. 2010, 39, 397–400. [Google Scholar]

- Ghosh, A.; Chattopadhyay, A.K. Interfacial reaction and wetting behavior of active Ag-Cu filler alloys on surface of cBN grits and its influence on failure patterns of brazed joint. Int. J. Refract. Met. Hard Mater. 2017, 68, 96–103. [Google Scholar] [CrossRef]

- Murray, J.L. ASM Handbook: Alloy Phase Diagrams; ASM International: Geauga County, OH, USA, 1992. [Google Scholar]

- GB/T 11364-2008. Test Method of Wettability for Brazing Filler Metals; Standardization Administration: Beijing, China, 2008. [Google Scholar]

- GB/T 11363-2008. Test Method of the Strength for Brazed and Soldered Joint; Standardization Administration: Beijing, China, 2008. [Google Scholar]

- Chiang, M.J.; Tsao, L.C.; Lin, W.H. Effects of zinc additions on the microstructure and melting temperatures of Al–Si–Cu filler metals. Mater. Charact. 2002, 48, 341–346. [Google Scholar]

- Yang, W.C.; Li, J.D.; Li, Y.; Feng, J.L.; Wu, J.W. Effect of aluminum addition on the microstructure and properties of non-eutectic Sn-20Bi solder alloys. Materials 2019, 12, 1194. [Google Scholar] [CrossRef] [PubMed]

- Zhu, W.W.; Zhang, H.; Guo, C.H.; Liu, Y.D.; Ran, X. Wetting and brazing characteristic of high nitrogen austenitic stainless steel and 316L austenitic stainless steel by Ag–Cu filler. Vacuum 2019, 166, 97–106. [Google Scholar] [CrossRef]

- Lai, Z.M. Effects of Ga/In and Rare Earth Ce on Microstructures and Properties of Brazed Joint of 30AgCuZn Filler Metal. Ph.D. Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2011. [Google Scholar]

- Kogi, S.; Kajiura, T.; Hanada, Y.; Miyazawa, Y. Wetting and spreading behavior of molten brazing filler metallic alloys on metallic substrate. Mater. Sci. Eng. 2014, 61, 1757. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, X.Y.; Huang, H.; Zhan, W. Effects of Ti on microstructure, mechanical properties and biodegradation behavior of Zn-Cu alloy. Mater. Lett. 2019, 244, 119–122. [Google Scholar] [CrossRef]

- Ma, C.L. Effect of Ga and Ce on the Microstructure and Properties of Ag17CuZnSn Filler Metals. Ph.D. Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2017. [Google Scholar]

- Xue, M.; Li, L.F.; Zhang, Z.H.; Wang, H.; Wang, E.Z.; Qiu, T. Microstructure and melting properties of Ag–Cu–In intermediate temperature brazing alloys. Rare Met. 2015, 34, 324–328. [Google Scholar]

- Cao, J.; Zhang, L.X.; Wang, H.Q.; Wu, L.Z.; Feng, J.C. Effect of silver content on microstructure and properties of brass/steel induction brazing joint using Ag-Cu-Zn-Sn filler metal. J. Mater. Sci. Technol. 2011, 27, 377–381. [Google Scholar] [CrossRef]

- Zheng, Y.; Li, N.; Yan, J.Z.; Cao, Y.T. The microstructure and mechanical properties of 1Cr17Ni2/QAl7 brazed joints using Cu-Mn-Ni-Ag brazing alloy. Mater. Sci. Eng. 2016, 661, 25–31. [Google Scholar] [CrossRef]

| No. | Ag | Cu | Zn | Sn | In | |

|---|---|---|---|---|---|---|

| Nominal | Actual | |||||

| 1 | 12 | Bal. | 39.0 | 1.5 | 0 | 0 |

| 2 | 12 | Bal. | 38.7 | 1.5 | 0.5 | 0.49 |

| 3 | 12 | Bal. | 38.4 | 1.5 | 1 | 0.97 |

| 4 | 12 | Bal. | 37.9 | 1.5 | 2 | 2.03 |

| 5 | 12 | Bal. | 37.4 | 1.5 | 3 | 3.02 |

| 6 | 12 | Bal. | 36.4 | 1.5 | 5 | 4.96 |

| Points | Ag | Cu | Zn | Sn | In | Fe | Cr | Ni |

|---|---|---|---|---|---|---|---|---|

| A | 72.6 | 11.3 | 1.3 | 0.8 | 8.4 | 3.5 | 1.6 | 0.5 |

| B | 0.0 | 0.5 | 0.7 | 0.0 | 0.1 | 70.5 | 20.1 | 8.1 |

| Points | Ag | Cu | Zn | Sn | In |

|---|---|---|---|---|---|

| A | 7.3 | 53.3 | 38.4 | 1.0 | -- |

| B | 6.4 | 54.5 | 37.9 | 0.7 | 0.5 |

| C | 10.3 | 49.1 | 34.2 | 0.8 | 5.6 |

| D | 13.4 | 45.9 | 32.1 | 0.7 | 7.9 |

| E | 6.8 | 52.6 | 37.3 | 0.8 | 2.5 |

| Points | Ag | Cu | Zn | Sn | In | Fe | Cr | Ni |

|---|---|---|---|---|---|---|---|---|

| A | 4.7 | 79.3 | 15.5 | 0.3 | 0.2 | -- | -- | -- |

| B | 4.1 | 62.5 | 32.4 | 0.5 | 0.5 | -- | -- | -- |

| C | 27.3 | 44.4 | 23.3 | 1.8 | 3.2 | -- | -- | -- |

| D | 1.8 | 3.2 | 2.7 | 0.2 | 0.4 | 72.3 | 14.2 | 5.2 |

| E | 32.5 | 36.0 | 22.2 | 2.2 | 4.0 | 2.5 | 0.6 | -- |

| F | 5.1 | 58.7 | 33.5 | 0.6 | 0.6 | 0.6 | 0.4 | 0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Xue, S.; Yao, Z.; Long, W. Study on Microstructure and Properties of 12Ag–Cu–Zn–Sn Cadmium-Free Filler Metals with Trace In Addition. Crystals 2021, 11, 557. https://doi.org/10.3390/cryst11050557

Wu J, Xue S, Yao Z, Long W. Study on Microstructure and Properties of 12Ag–Cu–Zn–Sn Cadmium-Free Filler Metals with Trace In Addition. Crystals. 2021; 11(5):557. https://doi.org/10.3390/cryst11050557

Chicago/Turabian StyleWu, Jie, Songbai Xue, Zhen Yao, and Weimin Long. 2021. "Study on Microstructure and Properties of 12Ag–Cu–Zn–Sn Cadmium-Free Filler Metals with Trace In Addition" Crystals 11, no. 5: 557. https://doi.org/10.3390/cryst11050557

APA StyleWu, J., Xue, S., Yao, Z., & Long, W. (2021). Study on Microstructure and Properties of 12Ag–Cu–Zn–Sn Cadmium-Free Filler Metals with Trace In Addition. Crystals, 11(5), 557. https://doi.org/10.3390/cryst11050557